Page 1

F300-24-00 1 I56-1971-00R

Fire•Lite, One Fire•Lite Place, Northford, CT 06472, (203) 484-7161

SD355, SD355T and AD355 Addressable Photoelectric Smoke Sensors

Installation and Maintenance Instructions

This sensor must be installed in compliance with the control panel system installation manual. The installation must meet the requirements of the Authority Having

Jurisdiction (AHJ). Sensors offer maximum performance when installed in compliance with the National Fire Protection Association (NFPA); see NFPA 72.

GENERAL DESCRIPTION

Model SD355, SD355T and AD355 are addressable sensors that combine a state-of-the-art photoelectronic sensing chamber with communications. The sensors transmit an analog representation of smoke density over a communication line to a control panel. Rotary decade switches are provided for setting the sensor’s address.

Two LEDs on the sensor are controlled by the panel to indicate sensor status. An output is provided for connection to an optional remote LED annunciator (P/N

RA400Z). Models AD355 and SD355T combine a photoelectronic sensing chamber and 135°F (57.2°C) fixed temperature heat detector.

SPECIFICATIONS

Operating Voltage Range: 15 to 32 VDC

Standby Current: 300µA@ 24 VDC (one communication every

5 seconds with LED blink enabled)

Max. Alarm Current (LED on): 6.5 mA @ 24 VDC

Operating Humidity Range: 10% to 93% Relative Humidity, noncondensing

Operating Temperature Range: 0° to 49°C (32° to 120°F); SD355

Operating Temperature Range: 0° to 38°C (32° to 100°F); SD355T and AD355

Height: 2.1 inches (51 mm) installed in B350LP Base

Diameter: 6.2 inches (155 mm) installed in B350LP Base

Weight: 5.2 oz. (147 g)

SPACING

Fire•Lite recommends spacing sensors in compliance with NFPA72. In low air flow

applications with smooth ceilings, space sensors 30 feet apart. For specific information regarding sensor spacing, placement, and special applications, refer to NFPA72

or the System Smoke Detector Application Guide available from Fire•Lite.

WIRING INSTRUCTIONS

All wiring must be installed in compliance with the National Electrical Code, applicable local codes, and any

special requirements of the Authority Having Jurisdiction. Proper wire gauges should be used. The installation

wires should be color-coded to limit wiring mistakes and ease system troubleshooting. Improper connections

will prevent a system from responding properly in the event of a fire.

Remove power from the communication line before installing sensors.

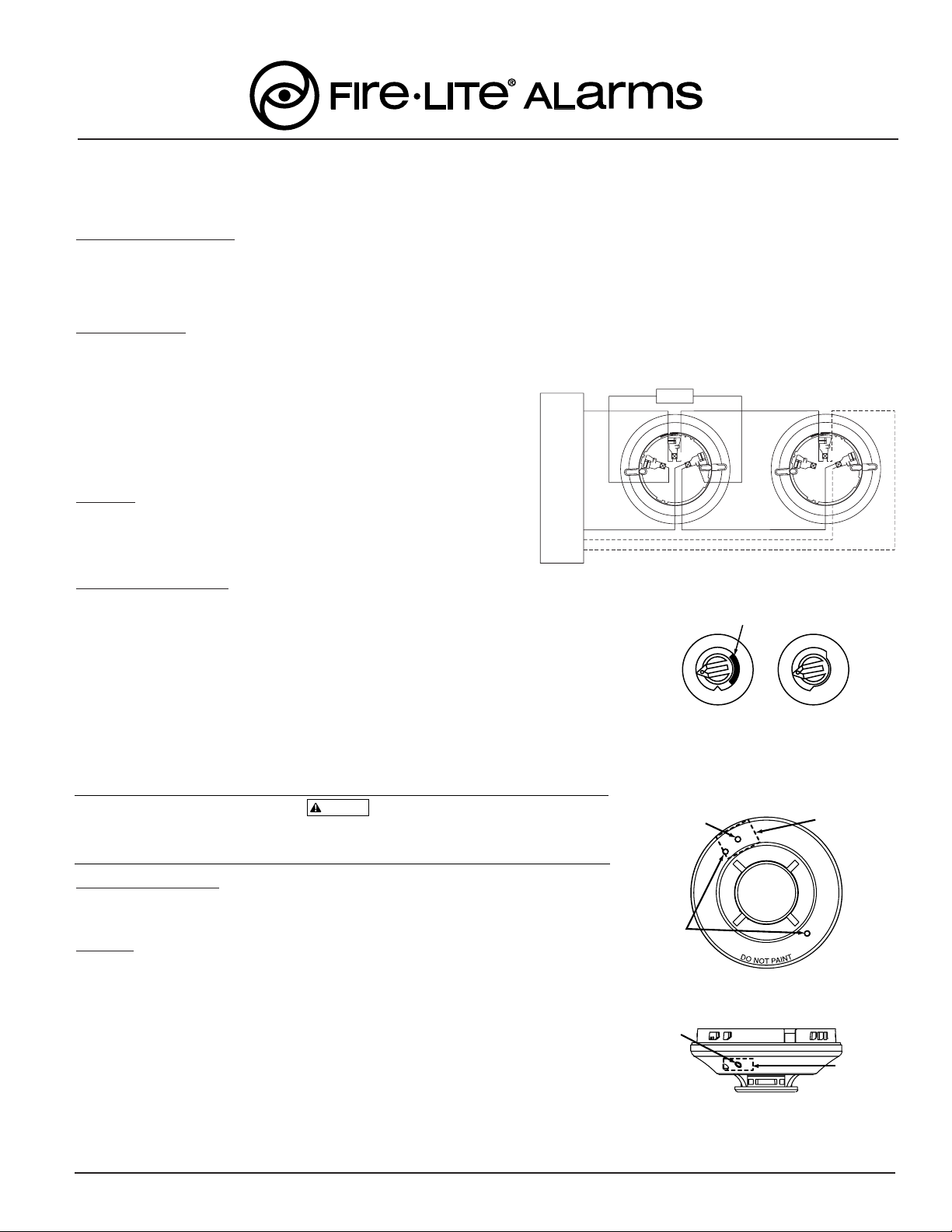

1. Wire the sensor base (supplied separately) per the wiring diagram, see Figure 1.

2. Set the desired address on the sensor address switches, see Figure 2.

NOTE: Some panels support extended addressing. In order to set the sensor above address 99 on compatible systems, carefully remove the stop on the upper rotary switch with thumb or as shown in Figure 2.

3. Install the sensor into the sensor base. Push the sensor into the base while turning it clockwise to secure it

in place.

4. After all sensors have been installed, apply power to the control unit and activate the communication line.

5. Test the sensor(s) as described in the TESTING section of this manual.

Dust covers provide limited protection against airborne dust particles during shipping. Dust

covers must be removed before the sensors can sense smoke. Remove sensors prior to heavy

remodeling or construction.

TAMPER-RESISTANCE

Models SD355, SD355T and AD355 include a tamper-resistant capability that prevents its removal

from the bracket without the use of a tool. Refer to the base manual for details on making use of this

capability.

TESTING

Before testing, notify the proper authorities that the system is undergoing maintenance, and will temporarily be out of service. Disable the system to prevent unwanted alarms.

All sensors must be tested after installation and periodically thereafter. Testing methods must satisfy

the Authority Having Jurisdiction (AHJ). Sensors offer maximum performance when tested and maintained in compliance with NFPA72. The sensor can be tested in the following ways:

A. Functional: Magnet Test (P/N M02-04-01 or M02-09-00)

This sensor can be functionally tested with a test magnet. The test magnet electronically simulates

smoke in the sensing chamber, testing the sensor electronics and connections to the control panel.

1. Hold the test magnet in the magnet test area as shown.

2. The sensor should alarm the panel.

Two LEDs on the sensor are controlled by the panel to indicate sensor status. Coded signals,

transmitted from the panel, can cause the LEDs to blink, latch on, or latch off. Refer to the control

panel technical documentation for sensor LED operation and expected delay to alarm.

A78-2461-00

Figure 1. Wiring Diagram

Figure 2. Rotary Address Switches

CAUTION: Do not loop wire under

terminals 1 or 2. Break

wire run to provide

supervision of connections.

A78-2733-00

A78-2745-00

CAUTION

Figure 3.

REMOTE ANNUNCIATOR

+

CONTROL PANEL

-

UL LISTED COMPATIBLE

+

+-

3

2

1

OPTIONAL RETURN LOOP

Breakaway Stop

7

8

9

6

5

10

1

0

TENS

11

12

13

14

15

4

3

2

2

3

1

7

8

6

9

5

4

3

2

1

0

ONES

Magnet T est

Marker

Test Magnet

Position

LED Status

Indicators

Magnet T est

Marker

Test Magnet

Position

Page 2

F300-24-00 2 I56-1971-00R

©2002 Fire•Lite

B. Smoke Entry: Aerosol Generator (Gemini 501)

The GEMINI model 501 aerosol generator can be used for smoke entry testing. Set the generator to represent 4%/ft to 5%/ft obscuration as described in the

GEMINI 501 manual. Using the bowl shaped applicator, apply aerosol until the panel alarms.

For AD355, smoke entry testing should be performed immediately following the magnet test. Magnet test initiates an approximately 10 minute period when

the detector’s signal processing software routines are not active. Failure to first perform the magnet test will introduce a time delay before the detector alarms.

C. Direct Heat Method (Hair dryer of 1000-1500 watts). SD355T and AD355 only.

A hair dryer of 1000-1500 watts should be used to test the thermistors. Direct the heat toward either of the two thermistors, holding the heat source approximately 12 inches from the detector in order to avoid damaging the plastic housing. The detector will reset only after it has sufficient time to cool. Make sure

both thermistors are tested individually.

A sensor that fails any of these tests should be cleaned as described under CLEANING, and retested. If the sensor fails after cleaning, it must be replaced and

returned for repair.

When testing is complete, restore the system to normal operation and notify the proper authorities that the system is back in operation.

CLEANING

Before removing the detector, notify the proper authorities that the smoke detector system is

undergoing maintenance and will be temporarily out of service. Disable the zone or system

undergoing maintenance to prevent unwanted alarms.

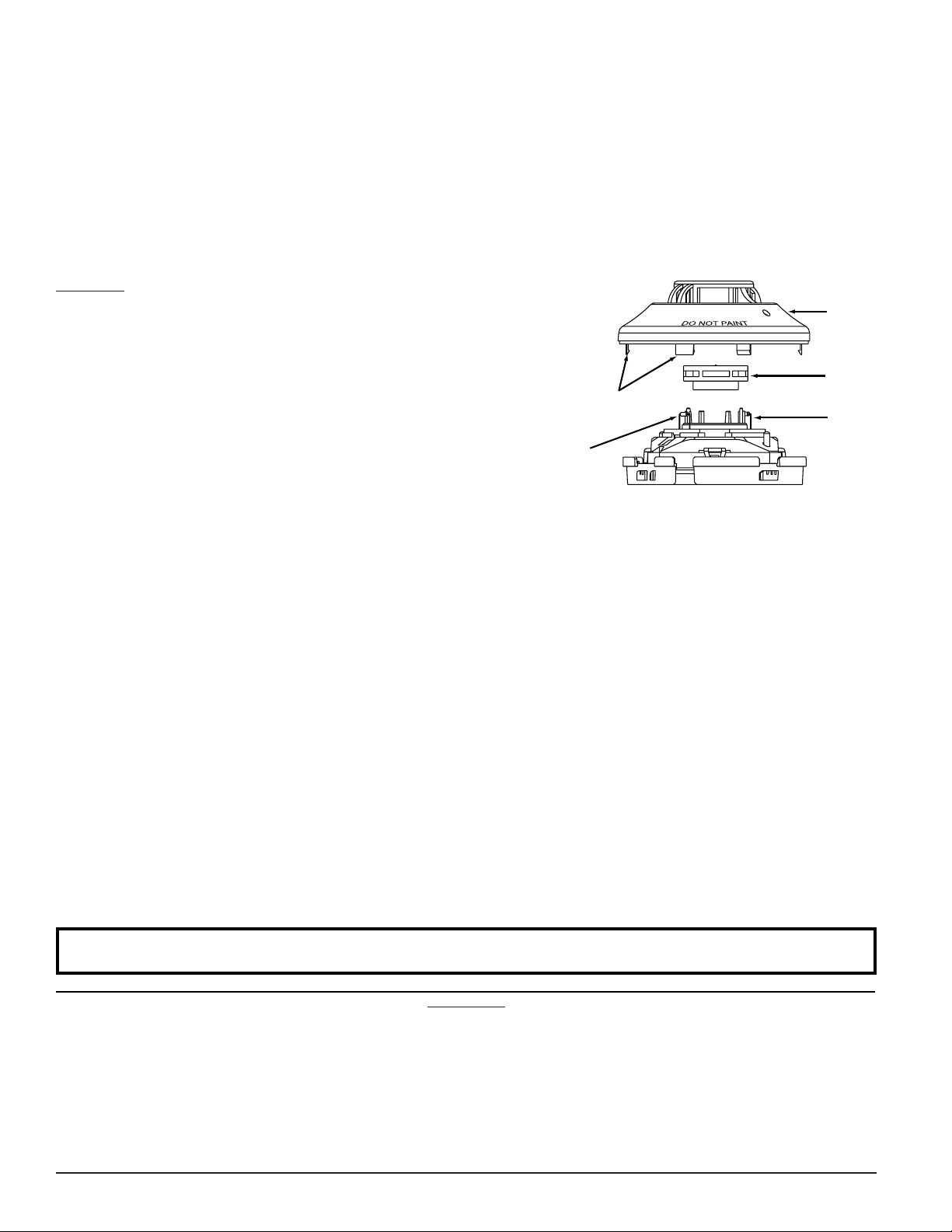

1. Remove the sensor to be cleaned from the system.

2. Remove the sensor cover by pressing firmly on each of the four removal tabs that hold the

cover in place.

3. Vacuum the screen carefully without removing it. If further cleaning is required continue with

Step 4,

otherwise skip to Step 7.

4. Remove the chamber cover/screen assembly by pulling it straight out.

5. Use a vacuum cleaner or compressed air to remove dust and debris from the sensing

chamber.

6. Reinstall the chamber cover/screen assembly by sliding the edge over the sensing chamber. Turn until it is firmly in place.

7. Replace the cover using the LEDs to align the cover and then gently pushing it until it locks

into place. Make sure that the thermistors do not become bent under the cover on SD355T

and AD355 models.

8. Reinstall the detector.

9. Test the detector as described in TESTING.

10. Reconnect disabled circuits.

11. Notify the proper authorities that the system is back on line.

FCC Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

Please refer to insert for the Limitations of Fire Alarm Systems

A78-2734-03

Figure 4.

Optional

Thermistors

(SD355T and

AD355)

Cover

Removal

Tabs

Sensor

Cover

Sensing

Chamber

Cover and

Screen

Sensing

Chamber

Loading...

Loading...