Page 1

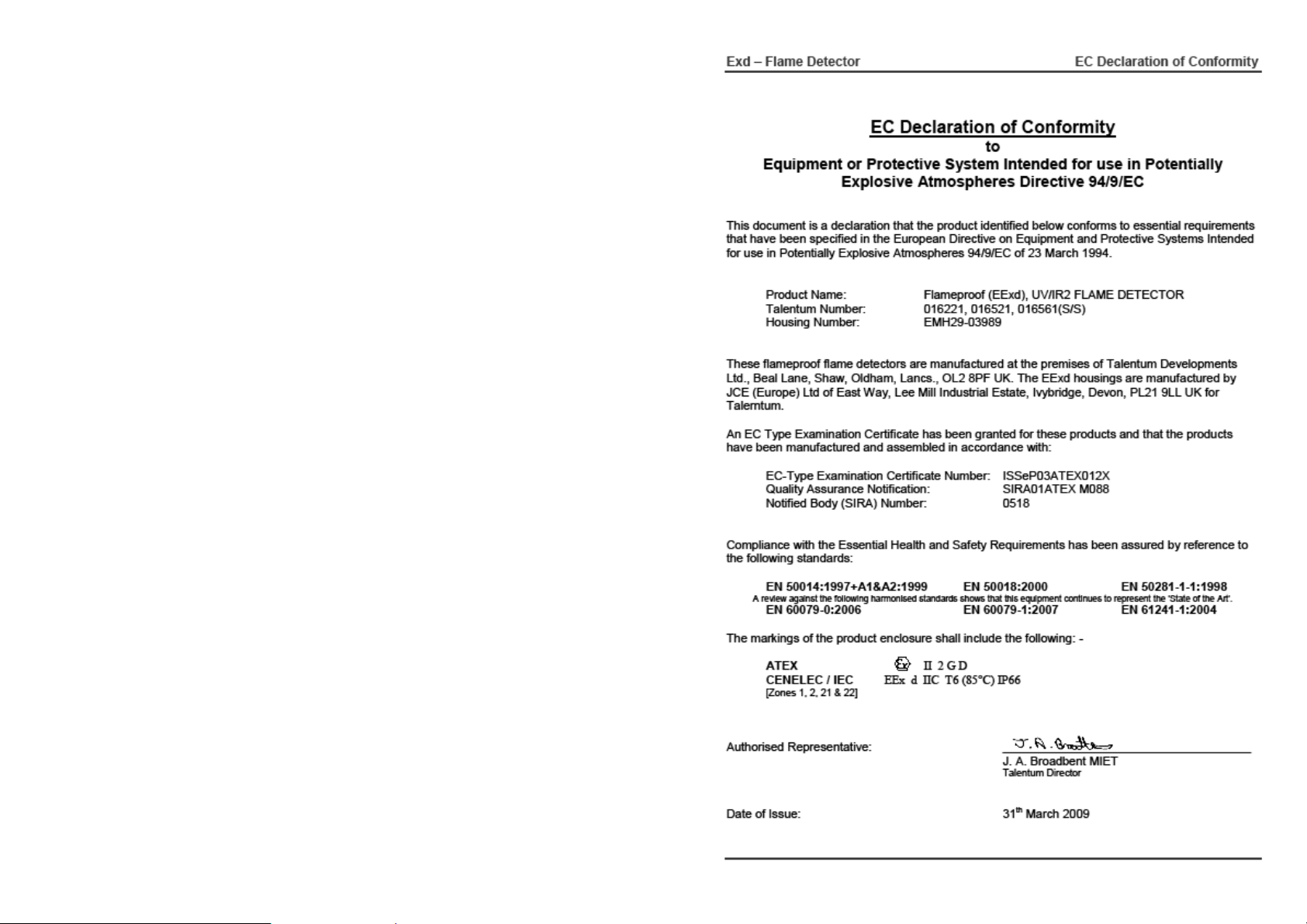

This document is the EExd Flame Detector Installation Guide/2013/Issue 2

Flameproof – (EExd)

UV/ IR² Flame Detector

Installation Guide

General

This Installation Guide gives information on the Flameproof (EExd) version of the flame

detectors that have been approved by ISSeP (Institut Scientifique de Service Public; notified

body number:492). The requirements of the European Community Directive 94/9/EC, the

ATmosphere EXplosives ATEX Directive have been met. The approval has been accessed by

reference to the following standards, EN50014:1997+A1 and A2:1999, EN 50018:2000 and pr

AA EN 50018 plus a review against EN60079-1:2004 which showed that there were no

changes which materially affected the “state of technological progress” with respect to the

product. EN50281-1-1:1998

The detector enclosures are certified category II 2 G D, EExd IIC T6 IP66.

The range comprises dual infra-red (IR²), triple infra-red (IR³) and UV/IR² flame detectors. The

detector housings are available in copper free aluminium alloy (LM25) and stainless steel

(316).

The guide also provides information on Flameproof (type‘d’) enclosures, the application,

maintenance, installation and adjustments of the detectors. Reference to other individual

detector publications can be made for more information on none Flameproof issues. These

publications are available on request.

Information in this guide is given in good faith, but the manufacturer cannot be held responsible

for any omissions or errors. The company reserves the right to change the specifications of

products at any time and without prior notice.

12

1

Page 2

Introduction to Flameproof Enclosures

There are many places where an explosive mixture of air and gas or vapour is or may be

present, intermittently or as a result of an accident. These are defined as hazardous areas by

EN 60079-0 (formally EN 50014), Electrical apparatus for explosive gas atmospheres –

General requirements.

Hazardous areas are common in petroleum and chemical engineering plants and in factories

processing and storing gases, solvents, paints and other volatile substances.

Electrical equipment for use in these areas needs to be designed so that it cannot ignite an

explosive mixture, not only in normal operation but also in fault conditions. There are a number

of methods available to achieve this – oil immersion, pressurised apparatus and powder filling,

for example, but the two most common used are intrinsic safety and flameproof enclosures.

Flameproof equipment is contained in a box so strong that an internal explosion will neither

damage the box nor be transmitted outside the box. The surface must remain cool enough not

to ignite the explosive mixture.

When flameproof equipment is interconnected, flameproof wiring must be used. This method is

helpful for installations in areas were explosive gas/air mixture are not present continuously or

not present for long periods.

Classification of Hazardous Areas

EN 60079-0 (formally EN50014) states that electrical apparatus for potentially explosive

atmospheres is divided into:

• Group I: Electrical apparatus for mines susceptible to fire damp;

• Group II: Electrical apparatus for places with a potentially explosive atmosphere,

other than mines susceptible to fire damp.

These flame detectors are designed to meet the requirements of Group II apparatus. For the

type of protection “d” Flameproof, Group II is subdivided into Equipment Categories, Type of

Explosive Atmosphere (Table 1), Type of Protection Code (Table 2), Temperature Class (Table

3) and Gas Group (Table 4).

2

11

Page 3

EExd System Drawing

Hazardous Area Safe Area

Flame Detector

1

+

2

-

Flame Detector

Flame Detector

Fire

Relay

Fault

Relay

Fire

Relay

Fault

Relay

1

+

2

-

5

6

7

8

1

+

2

-

5

6

7

8

EOL

Refer to note 6

Safe Area Apparatus

Unspecified except that it

must not be supplied from

nor contain under normal or

abnormal conditions a source

of potential exceeding 250V

RMS or 250V DC with

respect to earth.

+

No

i

Barrier

Required

- -

+

No

-

Barriers

+

Required

-

NOTE 1

WARNING – Ensure ALL power is OFF before/during

installation/maintenance.

NOTE 2

Ensure the details on the enclosure label comply with

the hazardous area specified.

NOTE 3

The installation must comply with national installation

requirements (for example to EN 60079-14)

NOTE 4

If required a loading resistor or end of line device (EOL)

can be connected between the detector terminals of any

circuit. The total power dissipation and temperature

classes within the enclosure must not be exceeded,

30W – T6.

24V DC Normal

+

(Break supply to reset

if detector set to latch)

i = See detector data

sheet for details

24V DC Normal

+

(Break supply to reset

if detector set to latch)

-

+

Zone

-

Equipment Markings

ATEX

CE Marking

EU Explosive

Atmosphere

Symbol

Equipment

Definition

Category

1 - very high level of protection

in which explosive atmosphere mixtures of air gases,

vapours or mist are present continuously, for long

periods

2 - high level of protection

in which explosive atmosphere mixture of air and gases,

vapours or mist are likely to occur

3 - normal level of protection

in which explosive atmosphere mixtures of air and

gases, vapours or mist are unlikely to occur and if it

occurs it will exist only for a short period

These Flame Detectors are suitable for equipment categories 2 and 3, G or D.

Note: The detectors are not certified for category 1 areas, see ‘IS’ products.

Table 1 Equipment Categories and Type of Explosive Atmosphere (Group II)

(EU Directive 94/9/EC)

II 2 G D

Type of Explosive

Atmosphere

G D - dust

Group II

Group II

gas vapour mist

Zone

0

1

2

10

3

Page 4

CENELEC / IEC

Conformity with

European Standards.

IEC marking omits

this character

E Ex d IIC T6

Explosion Protection

symbol

Code

These Flame Detectors are approved ‘d’.

Table 2 Type of Protection Codes Table 3 Temperature Classification

Type of

Protection Code

ia Intrinsic safety 1

ib Intrinsic safety 2

d Flameproof 2

Equipment

Category

Gas Group Representative Gas Other Gases, Liquids, Vapours

IIC

IIB

IIA

These Flame Detectors are approved IIC for listed gases in EN 50014.

Table 4 Subdivisions of Group II Gases

Hydrogen Acetylene, Carbon Disulphide

Ethylene Diethyl ether, Tetrafluoroethylene

Methane Butane, Methanol, Petroleum, Propane, Styrene

Temperature

Class

Referred to

ambient of

-20°C to +40°C

T6 85°C

T5 100°C

T4 135°C

T3 200°C

T2 300°C

T1 450°C

Detectors approved to T6.

Maximum

Surface

Temperature

Health and Safety at Work Act

In the UK all equipment must be installed and disposed of (as required) within the legislative

requirements of the Health & Safety at Work Act 1974.

Installation

No modification should be made to the enclosure without reference to the manufacturer as

unauthorised modification to an approved enclosure will invalidate the certificate/approval.

1. The enclosures are supplied with drilled and tapped entries. See enclosure drawing

2. The surface of the machined/threaded flamepaths between cover and body must be

3. Before the cover is refitted, the flamepath/threaded joint between cover and body must

4. Threaded covers must be screwed on to a minimum of 5 full threads of engagement and

5. All tapped entries must be fitted with an approved flameproof (EExd) device which is

6. The enclosure should be mounted using the two rear M6 tapped holes.

7. Do not scratch the glass.

8. Glanding of cables should be as in Selection of Cable Gland section.

protected from scratches or damage during installation. Any such damage can destroy

the validity of the enclosure.

be thoroughly wiped clean of dirt, grit or other foreign substances, and then a thin

coating of an approved form of non-setting grease applied to joint/threads. Ensure the

gasket o-ring is free from damage.

then locked in position with the locking screw provided.

equivalent or superior to the gas group of the enclosure.

Enclosure with Front Cover Removed

1 2 3 4 5 6 7 8

JCE EExd HOUSING EMH29

WITH FRONT REMOVED.

FLAME SENSOR

ELECTRONIC MODULE.

FLAME SENSOR

CONNECTION TERMINALS.

4

9

Page 5

.

A1A1A2 A3A

Selection of Cable Glands

Application of barrier glands certified and approved to meet EN 60079-14 for Thermo Plastic,

Thermosetting and Elastomeric Cables.

Hazardous Area Type Gland Method

Zone 1, 2 21 & 22 Hazardous areas requiring IIC

1)

apparatus

Zone 2 & 22 Hazardous areas requiring IIA & IIB

2)

EExd Barrier Glands

mandatory

Any EExd Gland permitted

apparatus.

Table 5 Examples of barrier glands

Enclosure Details

UNITS: mm.

86

150

146

Entry Thread Type – A1, 2 & 3

3 off – M20 x 1.5

B

100

150

B

27

110

2 & 3

Fixing Holes – B

2 off – M6 (8mm deep)

Flameproof Products

Flameproof Flame Detector

(Alloy Housing)

Fig. 1

The flame detectors respond to light emitted

from flames during combustion.

The detectors discriminate between flames

and other light sources by responding only to

low frequency flickering produced by flames

(typically 1 to 15Hz). The detectors ignore

fixed light sources and rapidly flickering

illumination predominantly produced by

lighting.

The flame flicker techniques have the

advantage of still allowing the detection of

flames through a thin layer of oil, water

vapour, ice or dust. This makes these

detectors particularly useful in industrial

applications.

Full details of the principles of operation,

electrical description, and other detailed

technical data are published in the products

individual data sheet.

Technical Data

Mechanical

Housing Material:

See figure 1

Housing Colour: Red

Housing

Dimension:

(Excluding Mount)

Cable Gland

Entries:

Electrical

Supply In:

Voltage

Current

Polarity sensitive

Optional Input:

Voltage

Current

Polarity sensitive

Power Up Time: 2 seconds

Relays

Contact Ratings:

Voltage

Current

Power

Resistive Loads Only

Environmental

Operating Ambient

Temperature:

ATEX

Approval Category

CENELEC / IEC

Marking

Apparatus

Certificate Number ISSeP 03ATEX012

IP Rating IP66

Copper Free

Aluminium Alloy

LM25

Height = 150mm

Width = 146mm

Depth = 137mm

3 X 20mm

Terminals 1(+) & 2(-)

14 to 30Vdc

2 to 28mA

Terminals 3(+) & 4(-)

See data

sheet for detail

14 to 30Vdc

typ. @ 24V IN

40µA

Terminals 5 to 8

30Vdc. Max.

1 Amp. Max.

30W Max.

Check detector data

sheet.

II 2 G D

EEx d IIC T6

Zone 1, 21, 2 & 22

8

5

Page 6

Flameproof Flame Detector

(Stainless Steel Housing)

Fig. 2

Technical Data

Mechanical

Housing Material:

See figure 2

Housing Colour: Natural

Housing

Dimension:

(Excluding Mounts)

Cable Gland

Entries:

Electrical

Supply In:

Voltage

Current

Polarity sensitive

Optional Input:

Voltage

Current

Polarity sensitive

Power Up Time: 2 seconds

Relays

Contact Ratings:

Voltage

Current

Power

Resistive Loads Only

Environmental

Operating Ambient

Temperature:

ATEX

Approval Category

CENELEC / IEC

Marking

Apparatus

Certificate Number ISSeP 03ATEX012

IP Rating IP66

6

316 Stainless Steel

Height = 150mm

Width = 146mm

Depth = 137mm

3 X 20mm - typical

Terminals 1(+) & 2(-)

14 to 30Vdc

2 to 28mA

Terminals 3(+) & 4(-)

14 to 30Vdc

typ. @ 24V IN

40µA

Terminals 5 to 8

30Vdc. Max.

1 Amp. Max.

30W Max.

Check detector data

sheet.

II 2 G D

EEx d IIC T6

Zone 1, 21, 2 & 22

See data

sheet for detail

System Design

Engineers familiar with codes of practice for

hazardous area systems should only

undertake the design of an flameproof fire

detection system. In Europe the standard is

EN 60079-0 (formally EN 50014), Electrical

apparatus for potentially explosive

atmospheres – General requirements.

The fire detector performance is the same as

the standard none flameproof counterparts.

Performance information given in standard

product guides is therefore applicable to the

flameproof range.

The ISSeP certification of the flameproof

device enclosure covers their characteristics

as components of a flameproof system. This

indicates that the flame detectors can be

used with a margin of safety in such

systems.

Service & Repairs

1. Frequent inspection should be made. A schedule for the maintenance check should be

determined by the environment and frequency of use but should be regular enough to

ensure the detector continues to operate in the designed manner. It is recommended that

Servicing of the fire protection system should be carried out as recommended by the local regulation

in force.

it should be at least once a year.

2. External surfaces of the enclosure should be periodically cleaned to ensure dust deposits

are not allowed to accumulate.

3. Check flamepath/threads on enclosure body and lid for signs of corrosion. If badly pitted,

replace component.

4. All components that are replaced must be in accordance with the manufactures

specification. Failure to use such components may invalidate the certication/approval on

the enclosure and may make the enclosure dangerous.

5. After inspection and maintenance have been carried out, items 3 & 4 of the installation

instructions should be adhered to when resealing the enclosure.

7

Loading...

Loading...