Fire Fighting Enterprises FireRay 100R, FireRay 50 User Manual

TITLE SLIDE

®

FIRERAY50/100R

OPTICAL BEAM SMOKE DETECTOR

Doc. No: 32-0008-01

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

OPTICAL BEAM SMOKE DETECTORS

This training material provides information to assist the Fire System

Designer and Installer in achieving a successful Optical Beam Smoke

Detector installation.

The appropriate local installation standards and legislation in effect

at the time of installation must be adhered to and take precedence

over any statements made or implied by this training material.

Fire Fighting Enterprises cannot take responsibility for the

installation (beam positioning and mounting), commissioning or

maintenance of products.

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

AGENDA

AGENDA

•WHAT IS FIRERAY50/100R?

• INSTALLING FIRERAY50/100R

• COMMISSIONING FIRERAY50/100R

•USING FIRERAY50/100R

• MAINTAINING FIRERAY50/100R

• TECHNICAL SPECIFICATIONS OF FIRERAY50/100R

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

OVERVIEW

Optical Beam Smoke Detector (Reflective)

TECHMAINTAIN

USECOMMISSIONINSTALLWHAT

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

Fireray 50/100R is a reflective type beam detector comprising a transmitter and

receiver contained within one enclosure.

It transmits an Infrared beam that is reflected from a retro reflector on the opposite

wall, back to the internal receiver for analysis.

Fireray50/100R reports its status back to the alarm/fire panel or monitoring device.

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

VERSIONS OF FIRERAY50/100R

There are three different types Fireray50/100R:

•Conventional

• Analogue Addressable

• Zone Powered

All of these types are available in either:

• (5 to 50m) or (50 to 100m) versions

TECHMAINTAIN

USECOMMISSIONINSTALLWHAT

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

The FIRERAY50/100 comes in two ranges - 5m to 50m and 50m to 100m.

There are a number of variants available in these two ranges.

Conventional:

50RV / 100RV – Standard conventional beam with EN54-12 and CPD approval.

Typically used in Europe.

50RU / 100RU – Standard conventional beam with UL and ULC approval. Typically

used in United States and other countries requiring UL approval.

We also do Analogue Addressable and Zone Powered versions for various

customers.

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

WHY USE THE FIRERAY50/100R?

• 3 year warranty

• Designed, fully assembled and tested at FFE factory

• International Approvals including EN54:12 and UL

• Minimal reflective prisms versus range

Note: If more flexibility is required consider the FIRERAY5000

TECHMAINTAIN

USECOMMISSIONINSTALLWHAT

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

Any FIRERAY50/100 returned under warranty is replaced with new product without

question, provided the fault is due to a manufacturing fault. We conduct full tests to

establish and resolve causes of failures, improving product quality.

FFE have full control over product quality and minimising customer lead times.

Fully approved by all the internationally recognised authorities including LPCB, UL,

VdS, VNIIPO (Russia)

Needs only 1 reflective prism for 5 to 50m and only 4 prisms for 50 to 100m.

Adjustable brackets, brackets to hold reflective prisms (surface mount or

adjustable).

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

OUT OF THE BOX

BREAKDOWN OF PARTS

Detector

Reflector

(Fly lead

connected to

Test Filter

detector)

User Guide

TECHMAINTAIN

USECOMMISSIONINSTALLWHAT

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

The FIRERAY50/100 can be broken down into 2 key elements.

The Detector

Transmits and receives the infrared and then communicates the status to the

alarm/fire panel or device monitor.

The Reflector

Reflects the infrared from the transmitter lens along the same path back onto the

receiver lens.

The number of Reflectors required depends on the operating distance.

5 to 50m = 1 Reflector

50 to 100m = 4 Reflectors.

Note the additional 3 reflectors required for 50 to 100m operation must be

purchased separately as the Long Range Kit.

Additional components

In the box one will also find the User Guide, test filter and the fly lead for the

detector. No End-Of-Line components or Fire resistors are provided as these

components are fire panel specific and as such are normally provided by the fire

panel manufacture.

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

INSTALLATION & WIRING

FOR 50/100RV & RU

• FIRERAY50/100R to the Fire System

•Cables

• Typical Single Zone Wiring

• Multiple Detectors On Single Zone Wiring

• Mounting of the Detector

TECHMAINTAIN

USECOMMISSIONINSTALLWHAT

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

INSTALLING THE FIRERAY50/100R TO

THE FIRE SYSTEM

Detector mounted

at high level

Reflector

Fly Lead

Junction Box for fly

lead to fire proof

Protected Area

cable connection

Dedicated fireproof

Fire Panel

screened cable

(1 to 100m)

TECHMAINTAIN

USECOMMISSIONINSTALLWHAT

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

The Detector and Reflector must to be mounted to a secure structure.

The fly lead that is supplied with the detector should not be extended, but rather

wired into a termination box where it is interfaced to the fire proof cable that goes

back to the fire panel.

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

CABLES

• It is always advisable to have a dedicated, screened (shielded),

fireproof cable for both power and signal lines

• Don’t leave the shield of the cable unconnected, always connect it

to the earth of the system

• Always mount power and signal cables away from any switching

machinery or HV (High Voltage) lines

• Ensure that any connections are made properly. Intermittent

connections are very difficult to trace and cause problems that

are not easy to diagnose.

TECHMAINTAIN

USECOMMISSIONINSTALLWHAT

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

Wiring up other equipment with the same cable that is used to monitor or power

the detector can lead to unexpected behavior. It is always best to have a dedicated,

screened cable for the power and the zone wiring. Also avoid the temptation to

place the wiring in the same conduit that may be carrying cables that are used for

large switching machinery or high voltage cables. These can sometimes cause

problems due to mutual induction.

Although it is possible to have a long power cable or zone cable, it is always worth

remembering that that shorter the cable the less the risk of there being any

interference on the cable.

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

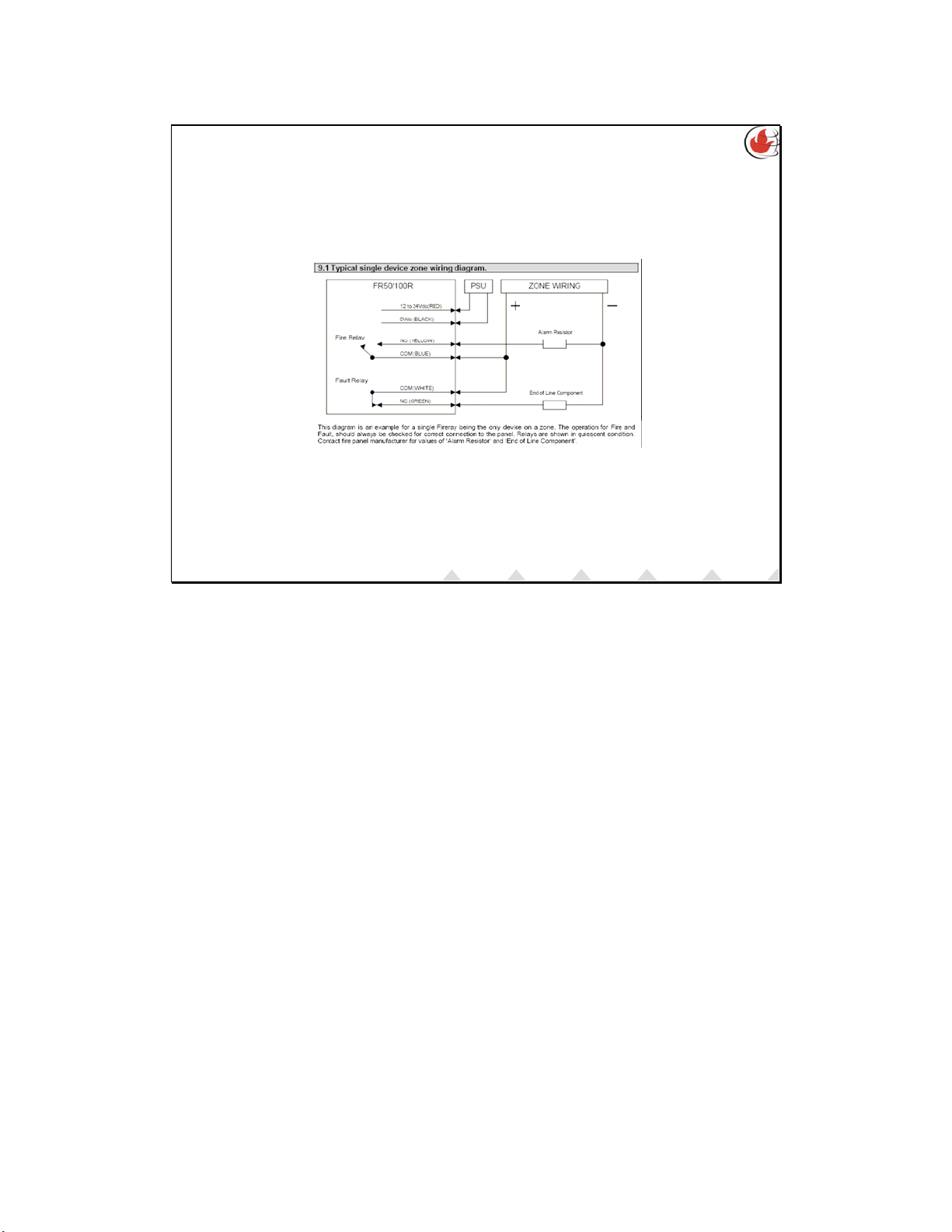

TYPICAL SINGLE ZONE WIRING

TECHMAINTAIN

USECOMMISSIONINSTALLWHAT

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

The diagram can be found in the installation guide for the FIRERAY50/100.

Zone wiring – sometimes called a ‘Conventional’ system.

Note: External PSU, end-of-line device (EOL device), and fire resistor are not

supplied by Fire Fighting Enterprises. The EOL and fire resistor are specified by the

fire panel manufacturer.

The power supply should be able to supply a minimal current of 20mA (between

10.2 to 30v DC to power 1 FIRERAY50/100).

Power should not be applied until all wiring has been completed.

EOL Device and fire resistor are either supplied or specified by the switch monitor

manufacturer.

A complete fire and fault test of the FIRERAY50/100 should be conducted to ensure

correct wiring to the fire panel.

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

MULTIPLE DETECTORS ON SINGLE ZONE

WIRING

TECHMAINTAIN

USECOMMISSIONINSTALLWHAT

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

In the event that more than one detector is connected to a “Zone” it is important

to ensure that the fire panel or device monitor is capable of checking for “Detector

out faults”. It is also crucial that the schottky diode is inserted, failing to do so will

not allow a detector further down the zone wiring to report a fire condition if a

detector preceding it goes into a fault condition, as it will break the line to remove

the EOL component from the zone.

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

MOUNTING OF THE DETECTOR

Do

• Do… Mount onto a secure

structure.

• Do… Fasten all mounting

points before aligning.

• Do… Mount where both

thumb screws and mode switch

are accessible.

• Do… Use the correct number

of reflectors for the required

distance.

• Don’t… Mount onto the skin

of a building.

• Don’t… Remove the detector

from the mounting to switch

the mode switch.

• Don’t… Use a single piece of

uni-strut to mount the

detector from the main

structure.

• Don’t… Mount anywhere near

open louvres that could allow

condensation to build up.

• Don’t… Mount where there

will be direct sunlight on the

detector, consider the path of

the sun all year round.

Do Not

USECOMMISSIONINSTALLWHAT

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

TECHMAINTAIN

It is not always obvious to installers but one of the crucial elements of a beam type

detector is its mounting!

The detector is designed to compensate for a certain amount of building movement,

it is not designed for poor installation. One of the most useful pieces of kit a

installer can have on his possession is a laser pointer. By mounting this onto the

mounting where the beam is going to go will give you a great deal of information

about the sturdiness of the mounting setup.

If one considers that the beam has a angle of misalignment of 0.8 Degrees then there

is not much required to move the beam off alignment. This is why it is crucial that

the beam in not mounted on plaster board, single pieces of hanging uni-strut… etc...

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

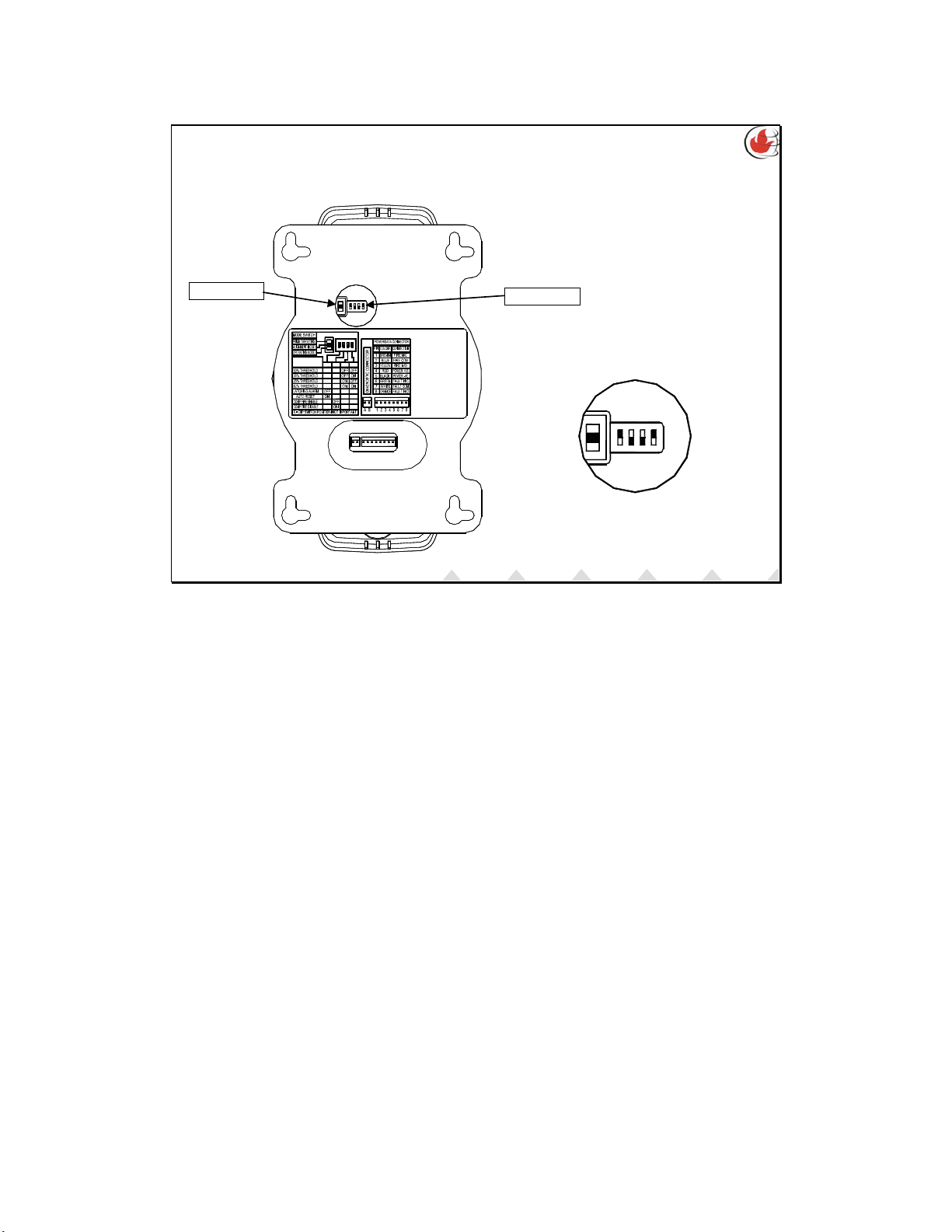

BEAM SETTINGS PRIOR TO ALIGNMENT

Mode Switch

DIP SWITCH

SETTINGS

ON

1234

1

X2X

XX

X

X

X

X

X

XXX

XXXX

X

ON

4321

3X4

X

X

DIP Switches

ON

321

4

Shows defaults

INSTALL

USECOMMISSIONINSTALLWHAT

TECHMAINTAIN

Prior to alignment, the user should select the alarm threshold to suit the

environment using the switches shown. See next slide.

Alarm thresholds of 12, 25,35 and 50% can be selected. The Default setting is 35%.

The alarm relay can be set in one of two modes – Auto reset or alarm latching using

switch 1. Auto reset is the factory default setting.

Auto reset mode will reset the alarm relay and alarm LED 5 seconds after received

signal has recovered to a level above the alarm threshold.

Latching mode holds the alarm relay and alarm LED active indefinitely, until cleared

by either:

placing the beam into prism targeting or alignment mode and then going back to run

mode, or

Removing the power to the beam for 10 seconds before powering back up

Copyright © 2008-2010 Fire Fighting Enterprises Ltd.

Loading...

Loading...