Page 1

FIRERAY 2000 EExd

Hazardous Area Smoke Detector

Installation Guide

KEY FEATURES

Flameproof Receiver and Transmitter

Standard Fireray Controller Unit

High Coverage - up to 15002m per system

Low Cost

Beam Range 10 metres to 100 metres

12 Volts dc to 24 Volts dc operation

Selectable Alarm Thresholds

Low Current Consumption

Manual or Automatic Fire Alarm Reset

Automatic Fault Alarm Reset

Ground Level Electronics

Extremely Rugged

Easy installation

Low maintenance

DESCRIPTION

The FIRERAY 2000 EExd SMOKE DETECTOR SYSTEM is designed primarily to protect EExd, IIB

hazardous areas.

It consists of a standard Fireray 2000 Controller/Analyser, combined with highly rugged flameproof

Transmitter and Receiver heads.

The Transmitter and Receiver Heads are designed to be mounted within the protected hazardous area,

whilst the Analyser is housed outside it. Using the Standard Analyser unit in this way allows a

significant cost reduction when compared to a system utilising flameproof enclosures for all component

parts. The maximum lateral beam coverage is 15m per Fireray System installed.

Once installed, the Transmitter Head projects a modulated Infra-Red Beam across the protected area, to

the Receiver head mounted opposite. The received signal strength is monitored and analysed in the

Ground Level Controller. Should the beam strength fall below the preset threshold for more than 8 -10

seconds, a Fire Alarm is signalled to the Control Equipment. The analyser also incorporates monitoring

for cable breaks or loss of function at the Transmitter or Receiver. If the signal strength is reduced

suddenly (<5 seconds) by greater than 93% a Fault Alarm is indicated to the Control equipment. The

Fire and Fault Alarm outputs are provided via two sets of Voltage-Free change-over relay contacts.

The Fire Alarm Relay may be set for latched or auto-reset operation as desired. The Fault Alarm is

designed to auto-reset once the signal is returned to serviceable limits.

The system may be used with ‘intelligent’ or ‘non-intelligent’ systems. Due to the very low current

consumption, back-up battery life is extended and the system may be powered from alarm loop supplies

in most cases.

PARTS LIST

1 x Transmitter Head (With Clear Lens)

1 x Receiver Head (With Dark Lens)

1 x Controller/Analyser Unit

1 x Adjustable Head Mounting Bracket

1 x Bag of Bracket Fixings

Page 1 of 12

APPLICATIONS

Ex II 2 G Environments

Refineries

Mills

Munitions Factories

Munitions Stores

Flammable Liquid Stores

Flammable Gas Stores

Flammable Powder Stores

Industrial Plants

Power Stations

Warehouses

Applications requiring highly rugged

detector heads

1 x Test Filter

1 x Installation Guide (This document)

2 x Allen keys (5mm & 10mm)

Page 2

STATEMENT OF INTENDED USE

This system is intended for use as a Smoke Detector only, in EExd IIB, or lower grade areas. It must

not be used in areas with a greater hazard rating. It must be installed and tested by approved, competent

personnel, in accordance with all regulatory and local codes of practise. No liability shall be accepted

for installations not conforming to this requirement.

The equipment is covered by certificate number Sira03ATEX1504, and the following instructions

apply.

1. The equipment may be used with flammable gases and vapours with apparatus group II and with

temperature class T6. in the ambient temperature range -20°C to +55°C.

2. The equipment is only certified for use in ambient temperatures in the range -20°C to +55°C and

should not be used outside this range.

3. Installation should be carried out by suitably trained personnel in accordance with the applicable

code of practice e.g. EN 60079-14:1997.

4. Inspection of this equipment shall be carried out by suitably trained personnel in accordance with

the applicable code of practice e.g. EN 60079-17.

5. The equipment does not have any user-serviceable parts and must be returned to the manufacturer

for servicing or repair.

6. This Installation Guide contains the system Principle of Operation; system Specification;

Installation Precautions; Installation Setting Up and Testing; Installation diagrams.

7. On the Transmitter and Receiver, the allowable gap is 0.2mm maximum between the Housing and

the Cover,

8. The certification of this equipment relies upon SM87 Enclosure Component (typically Aluminium

Alloy or Stainless Steel) Certificate No. Baseefa03ATEX0345U/1 from MEDC Ltd.

9. If the equipment is likely to come into contact with aggressive substances, then it is the

responsibility of the user to take suitable precautions that prevent it from being adversely affected,

thus ensuring that the type of protection provided by the equipment is not compromised.

Aggressive substances : e.g. acidic liquids or gases that may attack metals, or

solvents that may affect polymeric materials.

Suitable precautions : e.g. regular checks as part of routine inspections, or

establishing from the material’s data sheets that it is

resistant to specific chemicals.

NOTE : If in doubt, contact the supplier.

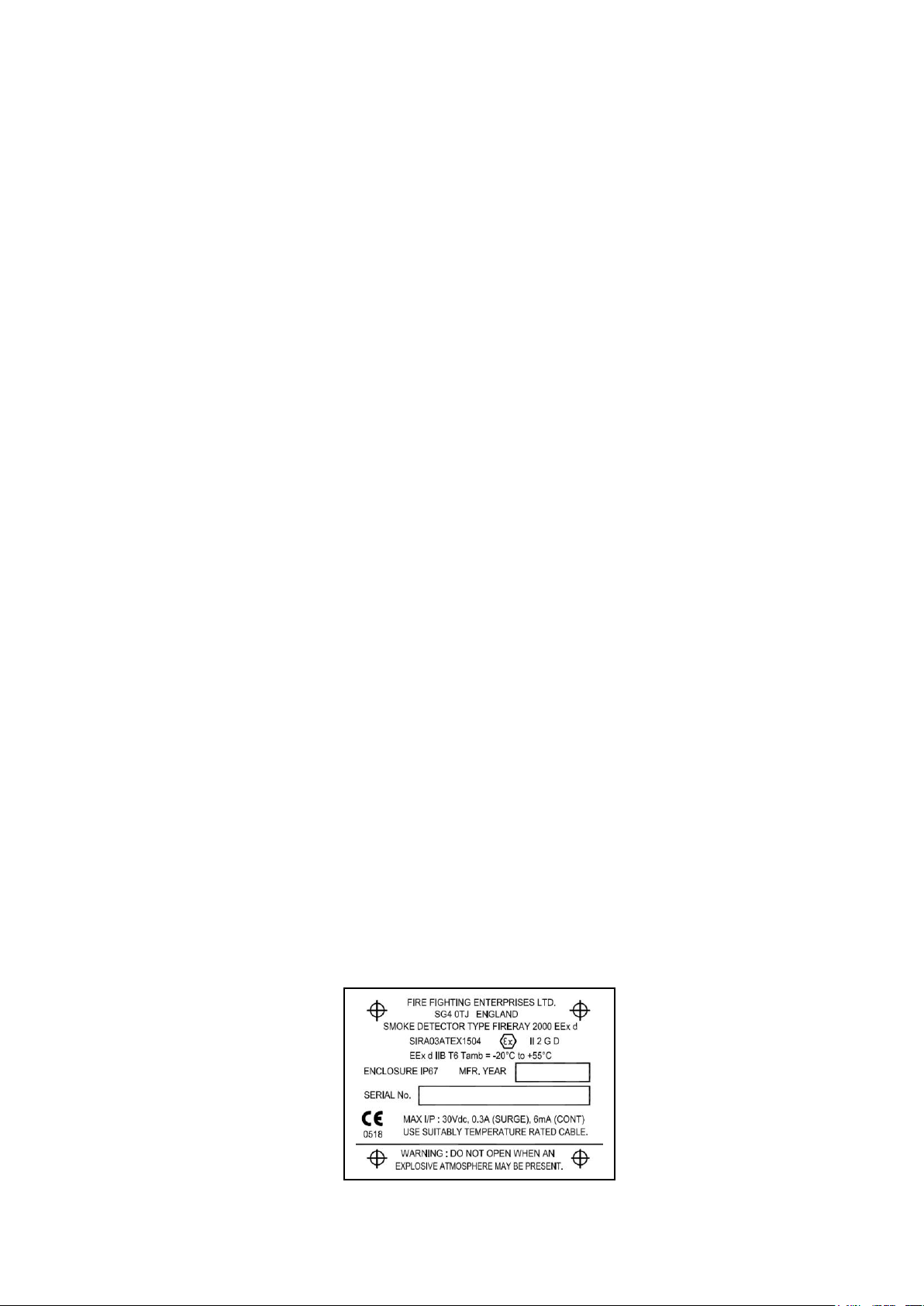

10. Label details :

Page 2 of 12

Page 3

WARNING

The area into which the Fireray parts are to be fitted must be made safe before attempting any work

on the system. It must also be checked thoroughly prior/during/after commissioning, to ensure it

cannot compromise the safety of the area in which it is fitted. Note that only the Transmitter and

Receiver parts may be installed in the hazardous area, NOT the Controller Unit.

If the flamepath of the enclosure is damaged in any way, the unit must be returned to the

manufacturer and a new unit purchased.

PRINCIPLE OF OPERATION

General

The Fireray system operates by passing an infra-red beam between a Transmitter and Receiver, through

the protected area. The received signal strength will be attenuated if smoke is present in the beam. The

beam strength is measured continuously and, should any attenuation be present which exceeds presets

thresholds, fire or fault alarms are generated as appropriate. Each installed Fireray can cover an area 7.5

metres either side of the beam, giving a maximum coverage of up to 15002m with a 100m beam path

length.

Transmitter and Receiver Units

A modulated Infra-Red light beam is projected from the Tx (Transmitter ) via it’s optical system. The

projected beam has a circular footprint, with a useable spread of approx 3m @ 100m range. The Rx

(Receiver) has a corresponding filtered optical system which collects and focuses the beam onto a

photo-detector. During installation, the Rx has a maximum beam acceptance angle of up to 5

(dependant on gain and threshold settings). The wide Tx beam, in conjunction with the large Rx

acceptance angle simplifies alignment and gives good tolerance to beam mis-alignments after

installation.

Controller Unit And Alarm Thresholds

The signal received at the Rx is amplified and filtered to reject sunlight and other unwanted optical

noise such as may be caused by ambient lighting,. The signal is then passed to the Controller Unit,

where it undergoes further filtering and validity checking, before finally being analysed for signal

strength. The signal is then compared to a reference level (determined by the user’s threshold setting),

and should the signal be reduced below the set threshold, the FIRE ALARM relay will be activated

within approx 12 seconds. Three user selectable threshold setting are available **. Note that only one

threshold switch must be closed to select the required threshold. A red lamp on the Controller Unit

front panel also indicates a FIRE ALARM condition.

Controller Unit -Fault Thresholds

If the signal is reduced suddenly by more than 93% in 8 to 10 seconds, perhaps due to total beam

blockage, a cable break, or the Tx or Rx becoming unserviceable, the controller interprets this as a fault

situation. Loss of power to any of the system parts will also cause a fault signal to be generated. In any

of these events, the controller will activate the FAULT ALARM relay continuously. The system will

return to normal operation immediately, once the correct signals are restored, except in the event of a

power loss to the controller, in which case normal operation is resumed after 50 seconds from

restoration of power. A yellow lamp (LED4) in the Controller Unit also indicates when the system is in

a FAULT or RESET condition.

Controller Unit - Compensation (AGC) Operation And Action At Compensation Limit

The Controller Unit also incorporates an AGC (Automatic Gain Control) system , which monitors very

slow changes in the received signal due to contamination of the optical system (EG: build up of dust on

the lenses) and any changes due to system ageing. If the signal is reduced by more than approx 11%, the

AGC system is activated. Then if the signal is still low after 1.5 hours, a 7% increase is made to the

system gain, to bring the signal strength back into the nominal range. Additionally, should the signal

strength increase, perhaps due to improved alignment following building movement, the system can

reduce its gain in 7% steps. From an initial nominal setting, up to 11 increasing and 3 decreasing

correction steps are possible.

Page 3 of 12

Page 4

Two possible actions are selectable, once the system has exhausted all compensation steps, as follows:-

Leave the COMP switch in the Controller unit OPEN for BS5839 installations (UK). This

setting allows generation of a FIRE ALARM after reaching the compensation limit, even

though a FAULT ALARM will be active. This is the only time Fire and Fault indications can

occur together.

Close the COMP switch if it is required that FIRE ALARM generation is inhibited once a

FAULT ALARM has occurred, due to reaching compensation limit.

Controller Unit - Relay Outputs

The Controller Unit has two sets of outputs for Fire and Fault indication, in the form of voltage free

single pole changeover relay contacts. The FIRE relay may be set to give either latching or non-latching

operation, determined by a switch (ALARM LATCH) on the Controller pcb. With the switch closed,

latching operation is selected.

Controller Unit - Signal Strength Metering

A ‘Metering ‘ output is also provided, to assist with installation. This gives a dc voltage which is

proportional to the received signal strength and can be monitored using a voltmeter.

Controller Unit - System Resetting

The system can be reset in any of three ways, as follows :-

Using the RESET switch in the Controller Unit (Normally only used during installation).

By taking the External Reset input low (to system 0V) for at least 5mS.

By de-powering the system for 1 second, then re-powering.

Following a reset the system takes 50 seconds to self-calibrate. During this time the Fireray adjusts it’s

100% signal reference level and so must have a clear unobstructed beam. No tests should be carried out

until this initialisation period has elapsed.

Notes On Resetting Using The Internal RESET Switch

Note that for correct operation, the internal RESET switch must not be set to OFF whilst either of

the HIGH or LOW signal lamps in the Controller Unit are illuminated. The gain must be set

correctly to extinguish both lamps first. If this is not done the system AGC is locked and will not

operate. (This does not apply to the other two reset methods).

SUMMARY OF SYSTEM CONDITIONS :-

Possible Causes of FAULT Alarms

Controller Unit RESET switch in ON position.

Controller Unit EXTERNAL RESET input active ( at 0V)

No power to Controller unit

No Power to Tx unit

Beam obscuration >93% for >5 seconds (for whatever reason)

Tx or Controller power cable break.

Receiver Signal cable break.

AGC at limit of compensation.

Rx/Tx Mis-alignment causing low signal strength

System unable to initialise following reset, due to inability to calibrate correctly (perhaps caused by

interference or testing of the beam before expiry of the 50 second calibration period.

High or Low signal when Controller Unit’s RESET switch set to OFF (AGC locked out).

Possible Causes Of FIRE Alarms

In normal use, beam strength reduced by more than the set threshold (Smoke in beam).

Page 4 of 12

Page 5

During installation, no threshold switch set at the Controller Unit (One switch only must be set).

Possible Causes Of FIRE And FAULT Alarms Together

AGC at limit of compensation, COMP switch OPEN (UK installations only) and beam strength

reduced by more than the set threshold.

PRECAUTIONS WHEN INSTALLING THE SYSTEM

Always ensure that the hazardous area into which the system will be installed is safe to work in, and that

neither you nor the installation will compromise the safety of that area.

Ensure that all mandatory and local regulations, regarding both fire alarm systems and EExd, IIB

applications, are adhered to.

Choose solid, stable surfaces on which to mount the Receiver and Transmitter.

If one of the mounting surfaces for the Transmitter or Receiver is likely to be susceptible to movement,

always mount the Transmitter on the more stable surface. The Receiver is less affected by misalignments.

The beam should be positioned approx 30cm to 60cm below the ceiling, to avoid smoke layering or

masking effects.

Take precautions to position the beam such that it cannot be blocked during the normal course of

operations in the building.

Avoid mounting near or over heaters systems etc. Heat haze may cause obscuration and high levels of

beam ‘noise’.

If possible, avoid areas subject to thermal ‘shock’, such as near external loading bay doors etc. If

condensation forms on the lenses, this will be seen as an obscuration.

Avoid high intensity lighting near the receiver lens and avoid angling the Receiver directly at the sun.

The system incorporates circuitry to minimise effects due to high levels of ambient light (>15000 Lux),

but over heating of internal parts may occur with very strong sources, due to the focused beam within

the Receiver.

If possible, avoid bunching the system cables with factory power or other cabling.

To achieve maximum EMI rejection, use screened cables for the system wiring, properly terminated at

metal glands (Do not use screen pigtails). MICC cable is recommended.

Use the correct EExd approved cable gland types for all system parts in the hazardous area.

Cables must be suitable for a minimum temperature of 101°C.

SETTING UP AND ALIGNING

The Transmitter and Receiver heads must be positioned on stable, solid facing surfaces, such as

parallel walls, approx 0.3m to 0.6m below the area ceiling (See application notes near the end of this

guide). The surfaces must be parallel, vertically and horizontally within approx 20 degrees, although a

greater positioning range is possible (up to 40 degrees off line-of-sight) if the Receiver is also fitted it

with an Adjustable Mounting Bracket. This is available as an optional extra. If only small adjustments

are required, the Receiver line-of-sight may be adjusted by fitting spacer washers to its wall fixing

Page 5 of 12

Page 6

screws, between the Receiver Case and the mounting surface. (Some applications may require

fabrication of angled mounting brackets etc, in order to cope with awkward wall positions etc. These

are not supplied).

Install all required cabling to the defined positions for each system part. (See wiring diagram on

following page, for a typical installation). Ensure compliance with all regulatory and local requirements

for Hazardous Areas and Fire Alarm Systems. Approved screened cables and approved EExd glands

and termination methods must be used. Glands at the Controller, Rx and Tx must be metal EExd types.

The Cable screens or jackets must be terminated properly at the glands, with a 360 termination. Screen

Pigtails must not be used.

Mount the Receiver first, such that it faces, and has un-obstructed line of sight with the expected final

Transmitter position. Remove the Receiver housing top (using 5mm Allen key provided). Connect the

system cabling to the 3 way terminal block on the internal pcb. It is recommended that the External

Earth point be used on the Tx and Rx housings, to minimise wiring lengths. This must be taken to the

nearest suitable building Earth point. Alternatively, the housing’s Internal Earth stud may be connected,

via an additional cable core and connected back at the Control Unit Earth. (see wiring diagram on the

following page for connections and earthing regimes). Check the connections and tighten the cable

glands, then refit the housing top, taking care to position the ‘O’ ring seal correctly, just below the

flange. Tighten the 4 securing screws firmly. For safety reasons, and to give the best EMI rejection,

do not omit any of the Earth connections.

Fit the Transmitter head in a position which aligns as closely as possible with the Receiver line of sight,

making use of the adjustment bracket provided. A 12mm AF spanner/wrench is required for the

adjustment bolts. Remove the Transmitter housing top (using 5mm Allen key provided) and set the

Range Switch to the correct or next higher setting, to match the expected operating range. Use a biro tip

to set the switches. The switches are ‘ON’ when moved outward, and ‘OFF’ when moved inward,

toward the housing centre. Note that only one setting must be selected ‘ON’. Connect the system

cabling to the 3 way terminal block on the internal pcb and Earth the unit housing in the same manner

as used for the Rx (see wiring diagram on the following page for connections and earthing regimes).

Check the connections and tighten the cable glands, then refit the housing top, taking care to position

the ‘O’ ring seal correctly, just below the flange. Tighten the 4 securing screws firmly. For safety

reasons, and to give the best EMI rejection, do not omit any of the Earth connections.

Install and wire the Controller unit in it’s defined position, outside the hazardous area. Set the unit’s

Alarm threshold to 25%, 35% or 50%. Only close one switch position, for the desired threshold. Set

the ‘ALARM LATCH’ switch as required. Switch Closed = latching Fire Alarm operation. For UK

installations, leave the ‘COMP’ switch open (Sets AGC operation at compensation limit - See

functional descriptions on page 2).

Check all wiring then apply power to all parts of the system.

At the Controller Unit, Set the Reset Switch to ‘ON’, and the Gain Control knob to approx midway.

Connect a length of two core bell wire or similar to the Metering terminals in the Control Unit. Run this

temporarily to the Transmitter position and connect a dc voltmeter to the ends. Set the voltmeter to

read up to 10Vdc or ‘autorange’.

Whilst observing the meter reading, adjust the Transmitter-to-Receiver alignment to achieve the highest

reading possible. A reading of at least 4.1Vdc is required for correct function (Note : <=2.7Vdc = no

signal). On completion, lock the transmitter adjustment bracket and all mountings securely, checking

the alignment on the meter whilst doing so. Remove the temporary meter wiring on completion.

Return to the Controller Unit and observe the Green lamps either side of the Gain Control. Adjust the

Gain Control such that the two lamps both extinguish completely.

Set the Controller unit’s Reset Switch to ‘OFF’, observe that the yellow FAULT lamp extinguishes,

then wait at least 50 seconds while the system calibrates. After 50 seconds, check that the FAULT lamp

is still extinguished. The system is now armed and active.

Page 6 of 12

Page 7

TESTING THE SYSTEM

Following installation, test the system as follows :-

First ensure that the system is running and has been allowed time to calibrate (50 seconds after powerup or reset).

Fire Alarm

Place the striped end of the test filter over the Receiver lens.

A Fire Alarm shall be indicated in approx 10 to 12 seconds.

Fault Alarm

Place a complete blockage (example: a hand) over the Receiver lens. Ensure that the lens is

fully covered.

A Fault Alarm shall be indicated in approx 4 to 6 seconds.

Page 7 of 12

Page 8

Rx

HIGH

LOW

RELAY WIRING,

CONNECT AS REQUIRED

TO INDICATING

EQUIPMENT

TEST/RESET

SW5

+V Rx

SIGNAL Rx

0V Rx

TEST

EXTERNAL

RESET

-

+

0V

+VE

OPTIONAL

TRANSMITTER P.S.U

(OR USE CONTROLLER

AND RECEIVER P.S.U)

12Vdc TO 24Vdc

-

N/O

100MA (T)

0V

+VE

CONTROLLER AND

RECEIVER P.S.U

ALARM

N/C

CO

N/O

N/C

CO

F

A

U

L

A

L

A

R

SIGNAL LEVEL

+

COMP

25%

35%

50%

EExd

GLAND

EExd

GLAND

METAL

GLAND

METAL

GLAND

METAL

GLAND

METAL

GLAND

OPTIONAL REMOTE

RESET WIRING

(SEE TEXT)

CLOSE TO

RESET

HAZARDOUS

AREA

NON-HAZARDOUS

AREA

METAL EExd

GLAND

Tx

METAL EExd

GLAND

Rx EXTERNAL CASE

EARTH (SEE TEXT)

Tx EXTERNAL

CASE EARTH (SEE

SUPPLY

12Vdc

TO

FAULT

LED1

LED2

LED4

FUSE

CONTROLLER UNIT/PCB

Typical installation shown (See text).

Do not omit any Earth connections.

MICC cable recommended for all cabling.

Approved, EExd glands must be used at the Rx

and Tx, and at the interface partitioning the

hazardous and non-hazardous areas.

1

0

0

m

m

a

x

Page 8 of 12

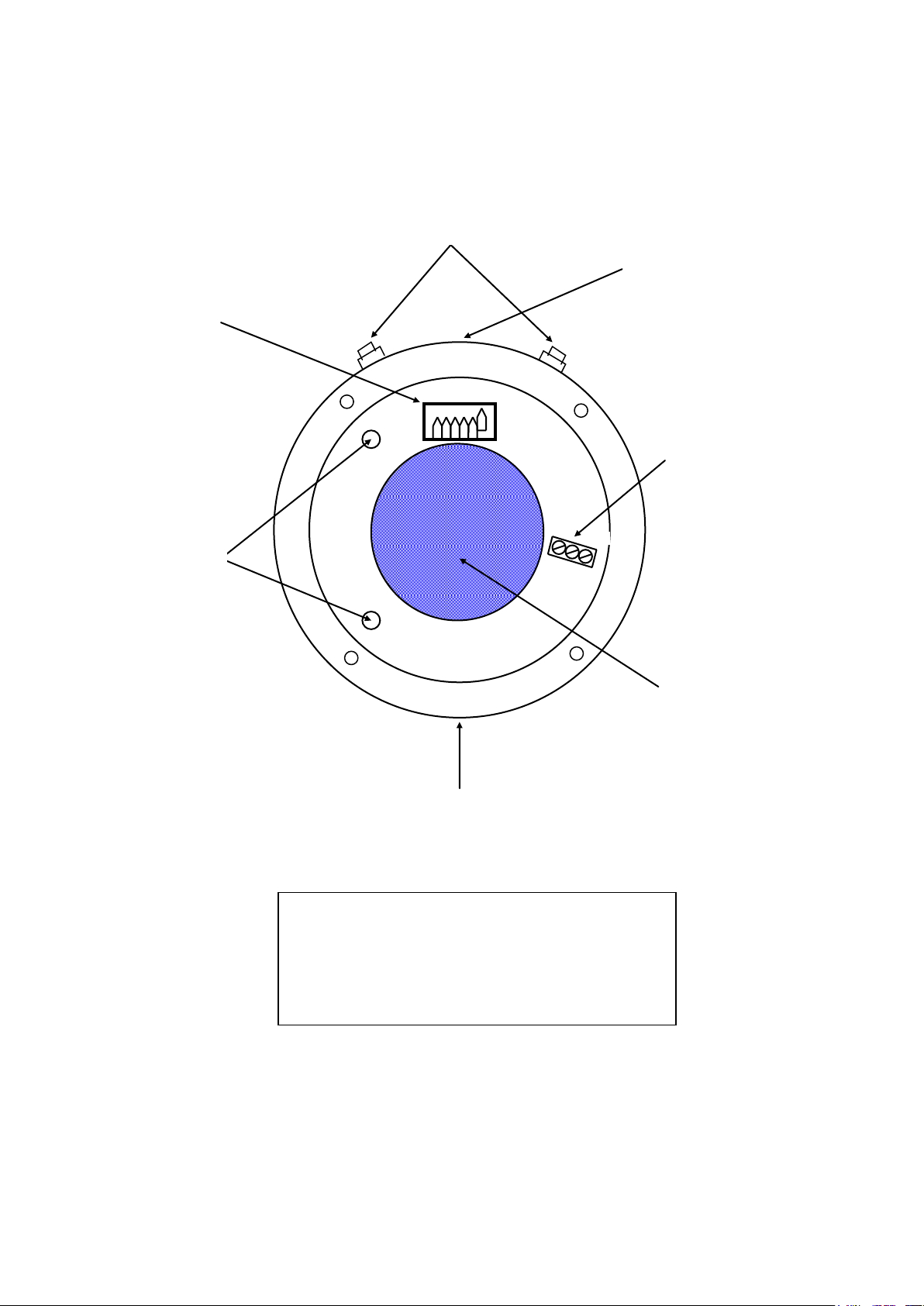

Page 9

1020406080

100

TRANSMITTER REQUIRES 2 CORE SCREENED WIRING

TO SUITABLE POWER SUPPLY, PLUS ENCLOSURE

EARTH BONDING.

THE ENCLOSURE EARTH BOND MAY BE CONNECTED

TO THE INTERNAL OR EXTERNAL EARTH TERMINALS

AND MUST NOT BE OMITTED.

-VE

+VE

Do not route wiring within the

50mm circular central area, to avoid

obscuring optical components

Internal Earth stud

will be found in one

of these two positions

External Earth terminal will be

found in one of these two positions

User wiring terminals.

Wire only to the -VE and +VE

terminals. (Middle ‘SIG’ terminal

not used on Transmitter units)

Field wiring must be correctly

terminated with insulation stripped

no more than 1mm from connector

terminal.

User wiring to enter here, via suitable

EExd IIB or IIC approved gland.

VIEW INSIDE TRANSMITTER UNIT WITH TOP WINDOW SECTION REMOVED

SHOWING TERMINALS AND SETTINGS ETC

note: some components not shown for clarity

REF:

Range switch shown set to 100m.

Only one switch position to be

ON at a time

Do not use this hole for cable entry

(EExd blanking plug fitted at factory)

Page 9 of 12

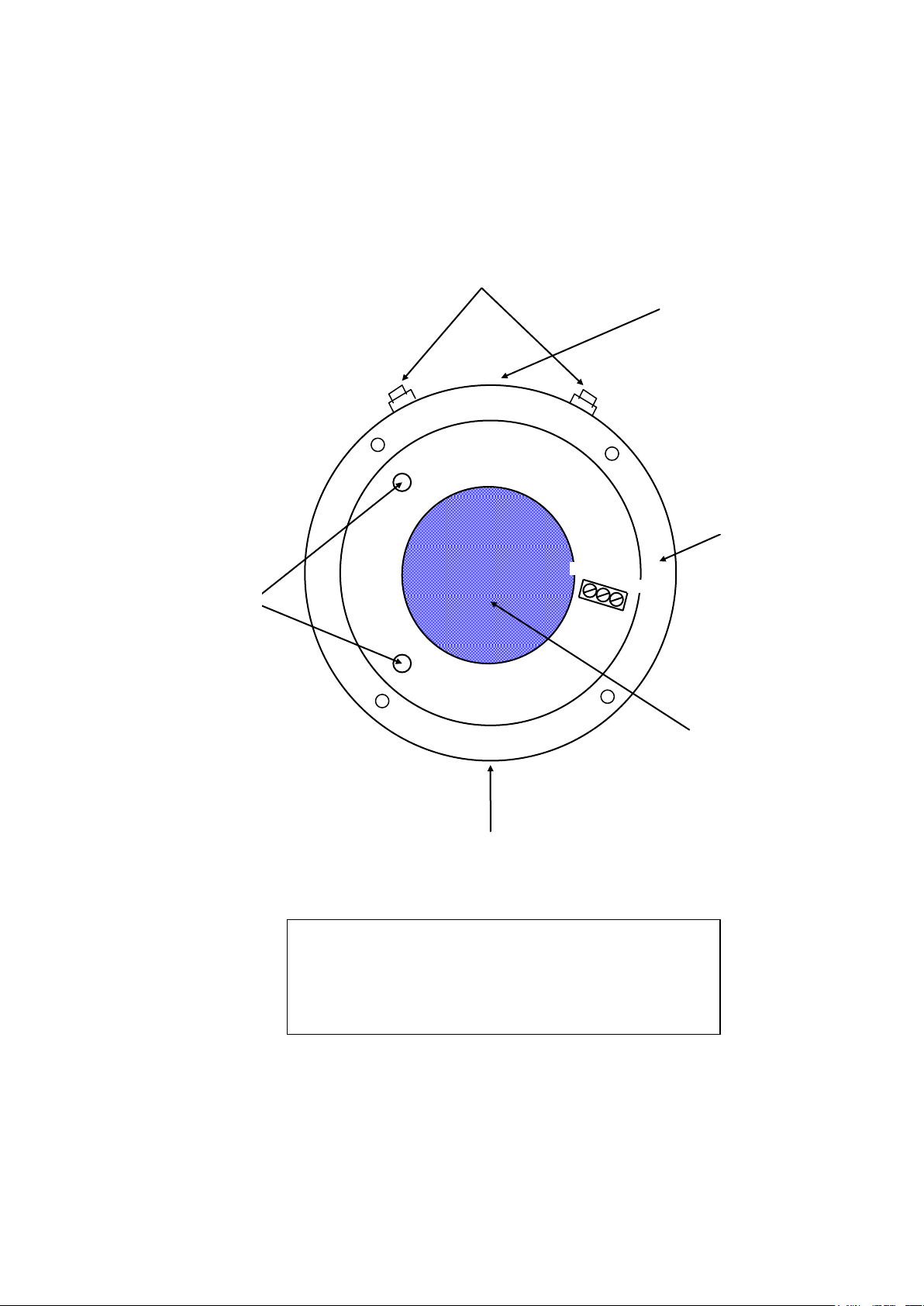

Page 10

-VE

+VE

Do not route wiring within the

50mm circular central area, to avoid

obscuring optical components

Internal Earth stud

will be found in one

of these two positions

External Earth terminal will be

found in one of these two positions

User wiring to enter here, via suitable

EExd IIB or IIC approved gland.

VIEW INSIDE RECEIVER UNIT WITH TOP WINDOW SECTION REMOVED

SHOWING TERMINALS AND SETTINGS ETC

note: some components not shown for clarity

SIG

RECEIVER REQUIRES 3 CORE SCREENED WIRING TO

CONTROLLER UNIT, PLUS ENCLOSURE EARTH BONDING.

THE ENCLOSURE EARTH BOND MAY BE CONNECTED TO

THE INTERNAL OR EXTERNAL EARTH TERMINALS

AND MUST NOT BE OMITTED.

User wiring terminals.

Connect back to Controller

Unit via suitable EExd

cabling. Field wiring must

be correctly terminated with

insulation stripped no more

than 1mm from connector

terminal.

Do not use this hole for cable entry

(EExd blanking plug fitted at

factory)

Page 10 of 12

Page 11

This page left intentionally blank

Page 11 of 12

Page 12

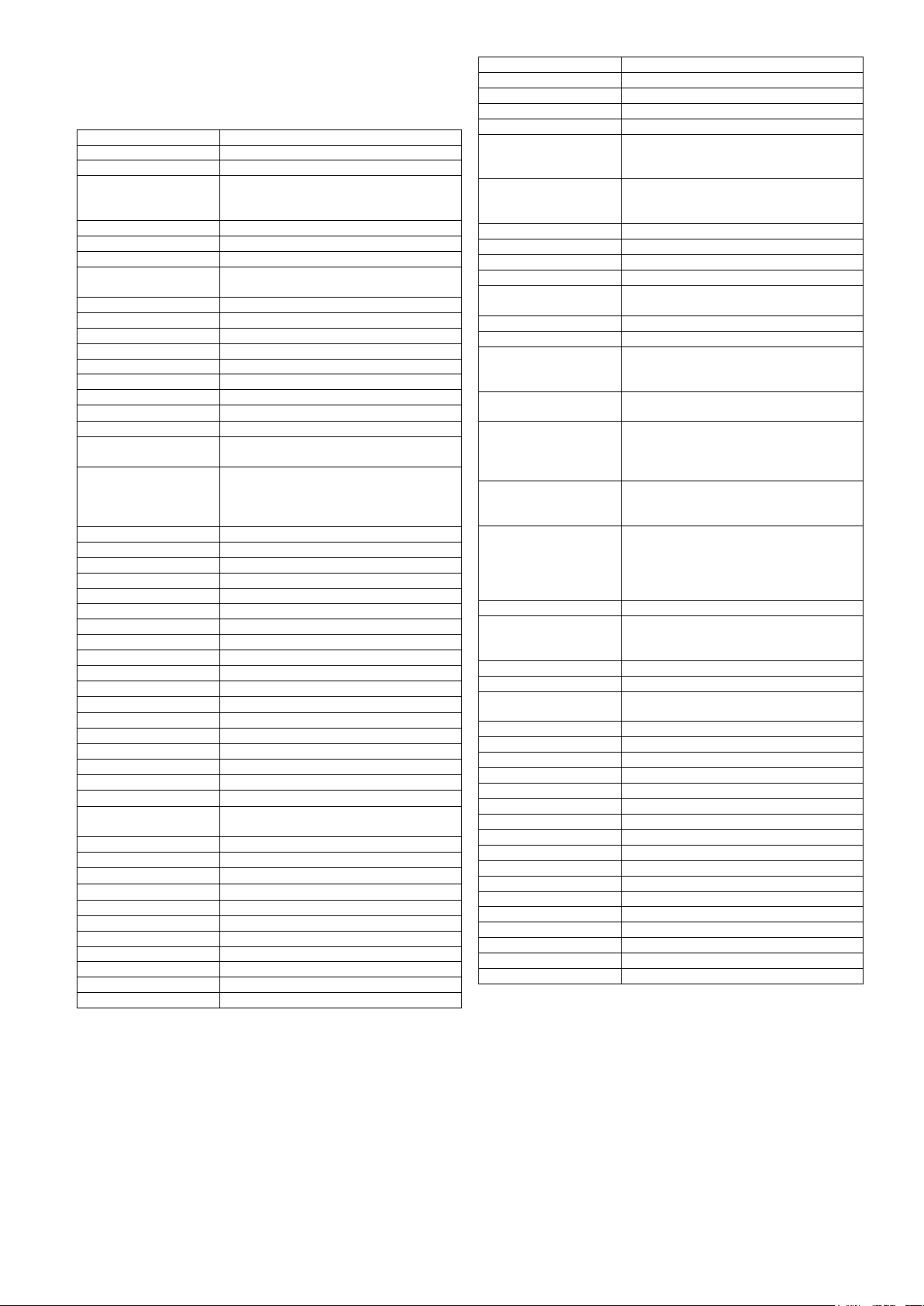

FIRERAY 2000 EExd - SYSTEM

SYSTEM TYPE

Transmitter (TX)

Rugged for EExd IIB areas - IP67

Receiver (RX)

Rugged for EExd IIB areas - IP67

Controller (CU)

Designed to be sited outside the hazardous

area. Rugged for light industrial and

domestic use - IP50

CERTIFICATION

SIRA03ATEX1504

CONFORMS WITH

EExd General

requirements)

BS EN 50014 : 1998

EExd enclosures

BS EN 50018 : 2000

Fire Alarm Systems

BS 5839 : Pt 5 : 1988

Emc Immunity

BS EN 61000-6-2:1999

Emc Emissions

BS EN 61000-6-4:2001

Alarm Systems - EMC

BS EN 50130-4 1996

ATEX Directive

94/9/EC

TEMPERATURE

Range

-20C to +55C

THRESHOLDS

Alarm

25%, 35% or 50%**, switch selectable

(1.25db, 1.87db or 3.01db**)

** For full compliance with BS5839 Pt.5,

use 25% and 35% thresholds. 50%

threshold is normally recommended for retro

mode.

Fault

>=93% (11.55db), fixed

DETECTION TIMES

Fire

10 seconds (min)

Fault

5 seconds (min)

SYSTEM RANGE

Minimum

10m

Maximum

100m

TRANSMITTER

Type

Pulsed, Focused Infra-Red beam

Beam Half-Angle

1 approx

Spectrum

Nominally 880Nm (Near Infra-Red)

Max IR O/P (mean)

6.4mW/Sr at IR LED

Max IR O/P (peak)

800mW/Sr at IR LED

Misalignment angle

@25% and (@ 50%) threshold settings

During installation

+/-1 (+/-1) for a measurable signal

After installation

+/-0.5 (+/-0.75) (After perfect alignment)

Connections

2 wire, power only required - no connection

to other system parts necessary

RECEIVER

Misalignment angle

@25% and (@ 50%) threshold settings

During installation

+/-4 (+/-5) for a measurable signal

After installation

+/-3 (+/-4) (After perfect alignment)

Connections

3 wire, connected to Controller Unit only

SUPPLY VOLTAGES

(At each detector component)

Tx (nominal)

+12Vdc to +24Vdc

Tx (min/max)

+11.5Vdc to +28Vdc

Control/Rx (nominal)

+12Vdc to +24Vdc

Control/Rx (min/max)

+11.5Vdc to +28Vdc

Rx

N/A, Supplied from Control Unit

SUPPLY CURRENT

Control/Rx (Normal)

7.5mA @ all ranges

Control/Rx (Alarm)

13.5mA @ all ranges

Tx

1.6mA @10m to 5.6mA max @100m

SUPPLY RIPPLE

Tx

0.5V p-p min, sine, 50-100Hz @11.5Vdc

Immunity increases with higher supply

voltage

Control/Rx

0.5V p-p min, sine, 50-100Hz @11.5Vdc

Immunity increases with higher supply

voltage

SYSTEM RESET

Internal

Via slider switch in controller unit

External (1)

Remote Reset input - Ground for >5mS

External (2)

Power break for 1 second then re-power

INITIALISATION

TIME

Following reset

50 seconds

SYSTEM OUTPUTS

Fire Alarm

Voltage-Free SPCO contacts, switch

selectable for latching or auto-reset

operation.

Fault Alarm

Voltage-Free SPCO contacts, auto-resetting

operation

Contact ratings

1.0A @ 24Vdc (resistive)

0.3A @ 24Vdc (Inductive)

0.5A @ 120Vac (resistive)

0.2A @ 120Vac(inductive)

Meter Output

DC output proportional to signal strength,

for alignment and maintenance check

purposes

Meter Range

No signal

Low signal

Normal signal

High signal

2.7Vdc to 6Vdc approx

2.7Vdc

>2.7Vdc to <4.1Vdc

4.25Vdc +/-0.15Vdc

> 4.4Vdc

COMPENSATION

(AGC)

Function

Detects and corrects for Rx/Tx lens

contamination, or minor gain errors after

installation or reset.

Update Period

Every 1.5 hours

Correction step

Approx 7% per step

Correction Range

Approx -28% to +77% (% with respect to

initial setting)

SYSTEM CABLING

Max Cable Run

100m to any system part

Cable Type

Screened (MICC recommended)

Max Capacitance

100pF/m

SIZES

Controller

215mm x 265mm x 88mm

Heads

120mm x 125mm x 125mm

Brackets

172mm x 124mm x 56mm

WEIGHTS

Controller

1060 grammes

Tx

2140 grammes

Rx

2165 grammes

Brackets

1530 grammes

FINISH

Controller

White Powder Coat, to RAL 9010

Heads

Red Powder Coat to RAL 2002

Brackets

Red Powder Coat to RAL 2002

SPECIFICATION

Document Number: 23989.00.01

Page 12 of 12

Loading...

Loading...