FineTek PT-8320 Series Operating Manual

CODE

:

G

:

Q

:

B

:

L

:

V

:

H

:

R

:

C

:

M

:

W

:

O

:

E

:

Y

:

T

:

J

:

A

:

K

:

U

:

F

:

P

:

Z

:

I

:

S

:

N

:

D

:

X

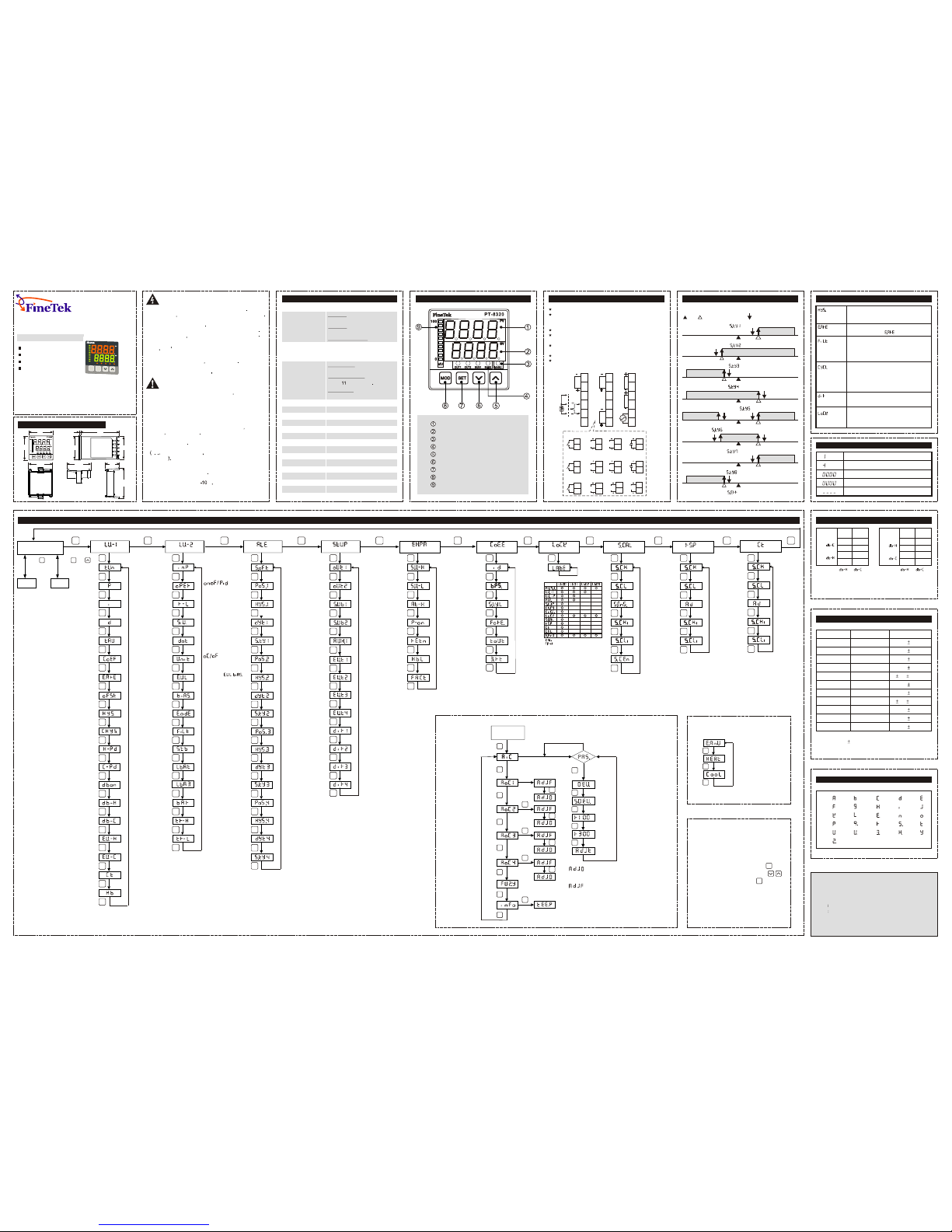

SPECIFICATIONS

Power Supply: 85~265VAC 50/60Hz

Display: Upper row: (red)

4 digits 7 segment

Lower row: (green)

4 digits 7 segment

10 segment bar graph

Input Signal: Thermocouple: J, K, B, N, R, S, T, E

DC Voltage: 0~230mV

Control Output: Output Relay 1: (resistive load)

SPST-NO, 5A/250VAC

Voltage pulse output: (for SSR drive)

NPN, > VDC with max 20mA

Analog Output: 4~20mA, 2~10VDC

(Allowable load resistive: Max. 600W)

Alarm Relay: SPST-NO, 3A/250VAC (resistive load)

Dwell Timer: 00~99s

Hysteresis: 0~999.9C ( F)

Communication: RS485 (MODBUS)

Operating Conditions: 0~50 (20~85%RH)

Control Output Cycle: 0~50s

Decimal Point: 0~3 digits

Digital Filter: 1~100

Control method: ON/OFF or PID+Fuzzy (Auto Tuning)

Input Offset: -199.9~999.9

Fraction Value: 0.0~999.9

Settings Range: -1999~9999

Accuracy: 0.3%FS 1 digit

Sampling Time: 400ms

Memory: EEPROM

RTD: PT100, JPT100

A

BB

BC

All can with Hysteresis and de-energized function for

ON/OFF control

: Alarm Setting Value

ALARM MODE SETTING

: Hysteresis Setting Value

: SV

DESCRIPTION OF PARAMETERS

Control output

hysteresis

Manual reset

PV input filter

Control output

cycle time

Function list

lock

You can set a hysteresis around the set

point to prevent chattering

In PID control, I=0, PV=SV, reset the

control output to " " value

This function should be used the PV

display value may fluctuate greatly, for

example, when the measured input signal

contains noise. If a larger time constant is

set, the filter can remove more noise.

The cycle time is the period of on/off

repetitions of a relay or voltage pulse

output in time proportional PID control.

The ratio of the ON time to the cycle time

is proportional to the control output value.

If output for the relay, setting more than 10.

Direction of relay

You can set the mode of function lists

which can be displayed and edited.

TROUBLESHOOTING

Display over scale

Display under scale

PV over scale

PV under scale

Sensor break

1. Assure the end terminal screw is tightlyscrewed If the

screw fell off it may cause fire or mechanical breakdown

2. Please do not apply this product inflammable application

to avoid possibleexplosion

3. Life-span of the relay is relative to how the user uses it

When using relay itmust follow specified load and life

span of the electronics as labeled. If the use of relay

overloads contactsmay melt or it may cause fire.

4. Dont disassemble, repair or modify the products without

factory consultation. Such change may cause circuit

shortage of theelectronics breakage or fire

5. Do not drop metal chipsor wire chips inside the product to

avoid possible circuitshortage breakage or fire.

WARNING!

Please strictly follow the instructionsbelow it can guarantee

the safeoperation of the controller:

CAUTION!

* Use the product within the ratings specified for submerging

in water and exposure to oil.

* Do not use the product in locations subject to vibrations or

shocks. Using the product in such locations over a long

period may result in damage due to stress.

* Do not use the product in applications with dust corrosive

gasses ordirect sunlight

* Separate the power cable and signal cable to avoid static

signal interference

* Keep the product awayfrom the source of static electricity

e g Forming compounds pipes that transport liquid

materials

* Organic solvents (such as pain thinner), as well as strong

acidic or alkalinesolutions might damage the outer casing

of the Temperaturecontroller

* Store at specified temperature. If the Temperature

controller is storedunder BC please allow the

temperature controller to stand at room temperature for at

least 3 hours before use.

* Allow 30 minutes of warm-up for best performance.

TEMPERATURE RANGE

Type R and S 9BC for 0 to 500BC

Type B accuracy is not guaranteed for 0 to 400BC

K TYPE

J TYPE

R TYPE

S TYPE

B TYPE

E TYPE

N TYPE

T TYPE

PT100

DC

JPT100

0.3% 1digit

0.3% 1digit

0.3% 1digit

0.3% 1digit

0.3% 1digit

0.3% 1digit

0.3% 1digit

0.3% 1digit

0.3% 1digit

8BC 1digit

2BC 1digit

INPUT TYPE ACCURACYRANGE

-200~1370BC

-210~1200BC

-50~1760BC

-50~1760BC

250~1820BC

-200~1000BC

-200~1300BC

-200~400BC

-200~850BC

-200~850BC

0~350mV

FINETEK CO., LTD.

No.16, Tzuchiang Street, Tucheng Industrial Park,

Taipei Hsien, Taiwan

TEL 886-2-22696789

FAX 886-2-22686682

E-mail: info@fine-tek.com

http://www.fine-tek.com/

Made in Taiwan

Disable : Inhibit output

Enable : Enable control output to follow PID / ON-OFF

control algorithm

Disable

Heater Cooler

Enable

Disable

Disable

Enable

Disable

Disable

Disable

SV

SV+

SV+

>0<0,

Disable

Heater Cooler

Enable

Enable

Disable

SV

SV+

SV+

Enable

EnableEnable

Enable

<0>0,

PARAMETERS OF HYSTERESIS LIST

Cooler's output

energy Display

CT current display

Heater Break

Alarm setting

Auto-tuning

Main Menu

Display PV,SV

Calibration

mode

Manual

mode

Press five

seconds enter

into Calibrating

mode

Press and

five seconds enter

into Manual mode

PID setting

Proportional Gain

Differentiation

Unit:second

Integration

Unit:second

Fuzzy parameter

Cooling

parameter

Manual reset

SV Offset during

Auto-tuning

Hysteresis for

Heater output

(ON / OFF )control

Hysteresis for

Cooler output

(ON / OFF )control

Control Cycle time

for Heater output

Control Cycle time

for Cooler output

Enable / Disable of

Dead Band control

Dead Band

interval for Heater

Dead Band interval

for Cooler

Heater's output

energy Display

Advance Setting

Select Input Signal

Set value

SV Enable / Disable

Remote

Decimal point setting

Bias of PV input

Heater major /

Cooler major

Digital filter

Startup delay time

(min)

LBA detection time

(sec)

LBA temperature

differentiation

Bar graph display

setting

High Limit for

Retransfer SV.

Low Limit for

Retransfer SV.

Alarm setting

Alarm set point 1

Alarm delay time

Adjustment 1

(second)

Alarm hysteresis

Adjustment 1

Alarm mode 1

Alarm soft activation

Frame setting

Auxiliary output

Control / Alarm 1

Auxiliary signal

input 1

Auxiliary

command input 1

Output direction (Hi or Lo) 1

Output Control /

Alarm 1

Expand setting

Auto-tuning

hysteresis

Operation at

Power-ON

Automatic return

SV / PV screen

(second)

HBA alarm Latch

Restore Factory

default setting

High Limit for SV

Low Limit for SV

Communication setting

Transmission

type

Transmission

mode

Time-out

setting

Allow communication

writing

Device ID

identification

Baud rate

Security selection

Menu locking

Advanced setting for PV

Maximum

Voltage input

Minimum

Voltage input

Input A / D switch

High Limit for

PV display

Low Limit for

PV display

Display voltage

from Sensor AD

converter

Advanced setting for SV

Span Voltage

setting

Zero Voltage

setting

High Limit for

SV (RSP)

Low Limit for

SV (RSP)

Display Voltage

of AD converter

CT input setting

Setting Span

Voltage

Setting Zero

Voltage

High Limit

display for

CT current

Low Limit

display for

CT current

Select

control mode

PV Multiplier

PV=PV*

+

:Calibration menu

:Manual control menu

Temperature

Unit

Manual mode:

Percentage of Heater

Control Output

Percentage of Cooling

Control Output

Display PV value

Input Correct Password

for following menu

: Full (0~10V)

(4~20mA)

Calibrating Output

Current

:Calibrating Zero Output(0~10V)

Current(4~20mA)

Display PV,SV

Password error, resetting Input

Calibrating for

Sensor Input

st

1 Calibrating

for Analog Output

nd

2 Calibrating

for Analog Output

rd

3 Calibrating

for Analog Output

th

4 Calibrating

for Analog Output

Fuzzy Switch

Display the

temperature of

cold junction

Quick setting for SV:

Calibration mode:

*Calibrating 100 W, 300 W,

please use 3 wire input

Calibrating OmV Input

Calibrating 50mV Input

Password

correct

Calibrating for cold

junction compensation

Calibrating 300 W Input

Alarm set point 2

Alarm set point 3

Alarm set point 4

Alarm hysteresis

Adjustment 2

Alarm hysteresis

Adjustment 3

Alarm hysteresis

Adjustment 4

Alarm delay time

Adjustment 2

(second)

Alarm delay time

Adjustment 3

(second)

Alarm delay time

Adjustment 4

(second)

Alarm mode 2

Alarm mode 3

Alarm mode 4

Output Control /

Alarm 2

Auxiliary output

Control / Alarm 2

Output direction (Hi or Lo) 2

Output direction (Hi or Lo) 3

Output direction (Hi or Lo) 4

Calibrating 100 W Input

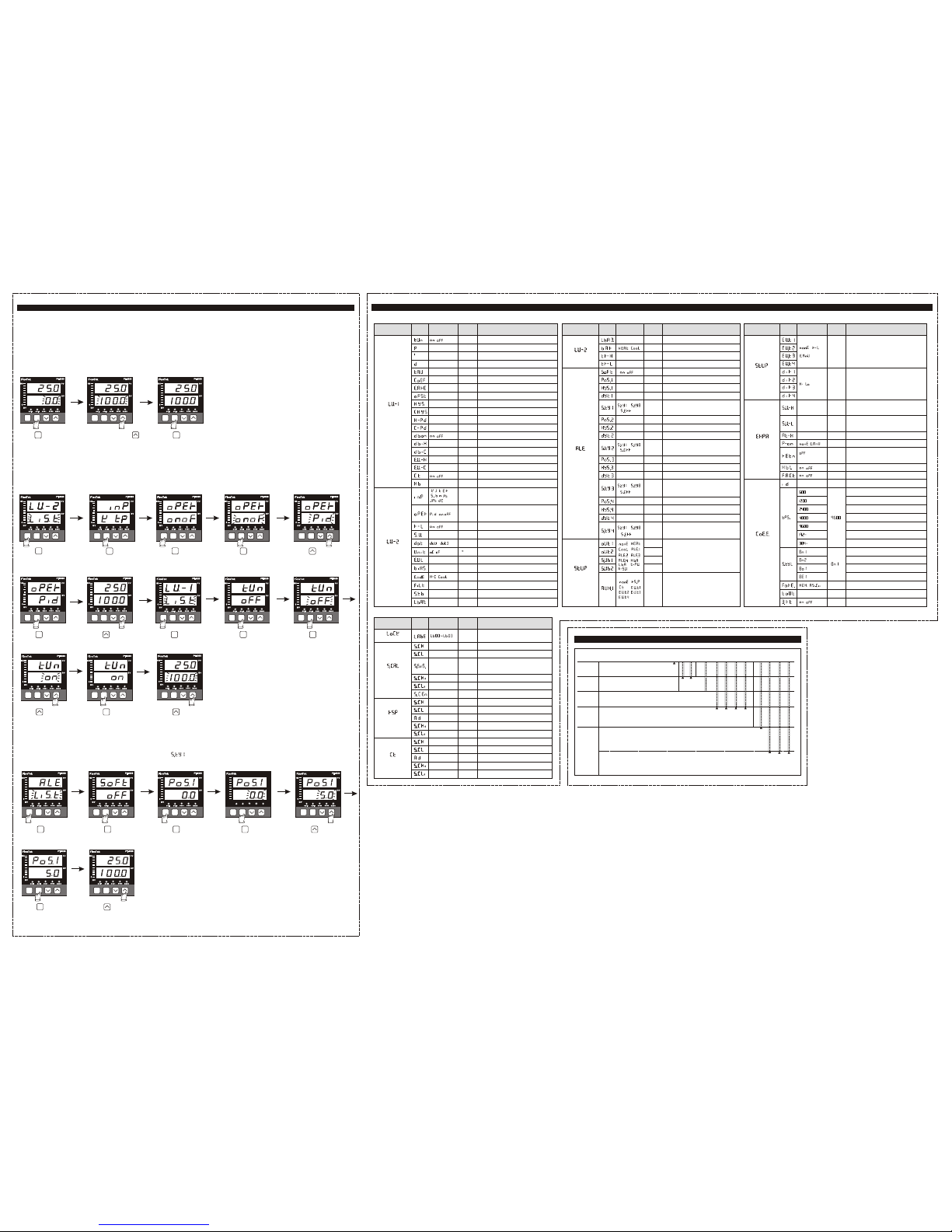

PROGRAM SETTING FLOWCHART

Auxiliary

command input 2

Auxiliary

command input 3

Auxiliary

command input 4

MOD MOD

MOD

SET

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD MOD MOD MOD MOD MOD MOD MOD MOD MOD

SET

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

SET

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

SET

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

SET

MOD

MOD

MOD

MOD

MOD

MOD

MOD

SET

MOD

MOD

MOD

MOD

MOD

MOD

SET SET

MOD

MOD

MOD

MOD

MOD

MOD

SET

MOD

MOD

MOD

MOD

MOD

SET

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

SET

SET

SET

SET

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

MOD

Under PV / SV main screen, press button

one second enter SV setting mode,

please adjust SV value, press button for

saving setting value

SET

SET

FRONT PANEL

Measured Value (PV) display

Set Value (SV) display

Indicator for Manual Operation

Indicator for Output

"UP" key

"DOWN" key

Set key

MOD key

Bargraph indicator

PT-8320 SERIES

Content of the packaging

Thank you for please read the User's manual first

before buying Fine-Tek products and using And is

familiar with product performance and every function,

please keep the user's manual so that consult in future.

Modbus communication can be downloaded from

http: //www.fine-tek.com

TEMPERATURE CONTROLLER

OPERATION MANUAL

1

0

01

0

0

0

0

O

U

T1

O

U

T1

O

UT

2

O

UT

2

S

UB

1

S

UB

1

SUB2

SUB2

M

AN

U

M

AN

U

MV

MV

P

T

-

83

2

0

P

T

-

83

2

0

M

O

D

M

O

D

SE

T

SE

T

Noumenon

Washer

User's manual

Bracket

unit:(mm)

DIMENSION/PANEL CUTOUT

FK-PT-A0-E-M,11/08/2007

28.8

63

48.2 48.2

48

48

75

3

44.5

44.3

4~20mA

0~10V

12DC

4~20mA

0~10V

12DC

RS485

RSP

0~10V

4~20mA

RSP

AUX1

OUT1/2

SUB1/2

TERMINAL ASSIGNMENT

12

9

11

7

8

10

2

3

4

5

1

AC85

~265V

RTD

TC/mV

A

B

b

14

13

16

15

17

18

OUT1

AUX1

OUT2

SUB1

SUB2

Please use proper terminal.

If Electro-magnetic interference exists, please separate wire

cable between sensor and power line or shield sensor's wire

to ground.

Please use filter when there is power interference.

Stay away from Hi - frequency signal while using the

equipment.

It is recommended to install power switch or circuit breaker

near the equipment to control power of controller.

Fuse can be applied to prevent over-current.

Please use proper temperature compensation lead wire for

termocouple transmission.

ONOFF

( )

Deviation high alarm

ONOFF

( )

Deviation high alarm

ON OFF

Deviation low alarm

( )

ON OFF

( )

Deviation low alarm

ON ONOFF

Deviation high/low alarm ( )

OFF

OFF

ON

Band alarm

( )

ONOFF

Process high alarm

( )

( )

ON OFF

Process low alarm

Sensor error alarm ( )

Set alarm while sensor break or out of measuring range.

Display

Voltage of AD

converter

SETTING MODE

Press one second

and enter into SV setting

Press and holding

for accumulating

continue till 100.0

Press for setting

finish

1.Quick setting, For examples; Set SV=100

Parameters programming as following:

Press twice to

display LV-2

Press for display

control mode

Press enter into

LV-2 Sub item

Press enter into

edit mode

Press in order to

choose PID mode

Press for setting

finish

Press twice to

come back Main menu

Press one time

to display LV-1

Press enter into

LV-1 Sub item

Press enter into

edit mode

Press in order to

choose on

Press for setting

finish

S VS V

Press twice to

come back Main menu

*SV flash for operating Auto Tune

2.Auto Tuning

Press three times

to display ALM

Press enter into

ALM Sub item

PT-8320PT-8320

Press to display

alarm position setting

S U B 2S U B 2

S U B 1S U B 1

M A N UM A N U

O U T1O U T1

O U T 2O U T 2

PT-8320PT-8320

P VP V

S VS V

M VM V

00

100100

Press enter into

edit mode

Press and holding

for accumulating continue

up to 5.0

Press for setting

finish

Press twice to

come back Main menu

3.

Set alarm for pre-set deviation High-Alarm mode for

Alarm starting when PV more than SV+5

*Totally nine alarm mode, please refer to introduction of Alarm mode

FUNCTION LIST

Sty1

Heat

Cool

ALM1

ALM2

None

HEAT

1.0

100.0

0

Sty1

OFF

0.0

0.0

0

0.0

0.0

0

Sty1

0.0

0.0

0

Sty1

0.0

0.0

0

,

,

,

,

,

,

,

,

,

~

0~9999

-1999~9999

-1999~9999

-1999~9999

0000~9999

-1999~9999

0~99

0000~9999

0~99

-1999~9999

0000~9999

0~99

-1999~9999

0000~9999

/

/

0~99

~

~

~

Output Control / Alarm

Auxiliary signal input

Temperature differentiation

High Limit for Retransfer SV.

Bar graph display setting

Alarm set point 1

Low Limit for Retransfer SV.

Alarm soft activation

Alarm hysteresis Adjustment 1

Alarm delay time Adjustment 1(second)

Alarm mode 1

Alarm mode 2

Alarm set point 2

Alarm set point 3

Alarm set point 4

Alarm hysteresis Adjustment 2

Alarm hysteresis Adjustment 3

Alarm hysteresis Adjustment 4

Alarm delay time Adjustment 2(second)

Alarm delay time Adjustment 3(second)

Alarm delay time Adjustment 4(second)

Alarm mode 3

Alarm mode 4

Advance Setting

Alarm setting

Description

Main Item

Sub

Item

Data Range

Default

Value

Advance Setting

Setting

PID

Auto-tuning

Proportional Gain

SV Offset during Auto-tuning

Integration(unit:second)

Differentiation(unit:second)

Fuzzy parameter

Cooling parameter

Manual reset

Hysteresis for Heater output

Hysteresis for Cooler output

Control Cycle time for Heater output

Control Cycle time for Cooler output

Enable / Disable of Dead Band control

Dead Band interval for Heater

Dead Band interval for Cooler

Heater's output energy Display

Cooler's output energy Display

CT current display

Select Input Signal

Heater Break Alarm setting

Decimal point setting

Select control mode

SV Enable / Disable Remote

Set value

Temperature Unit

PV Multiplier

Bias of PV input

Heater major / Cooler major

Digital filter

Startup delay time(min)

Detection time(sec)

OFF

10

0

100

2.0

0

0.060

1.00

0

0

5.0

5.0

0

0

0

-1

0

0

K tp

onoF

oFF

1.000

dot1

0.0

C

0.0

5

H-C

0

0

, , ,

,

,

,

,

,

,

/

/

/

/

/

~

0~999.9

-1999~9999

0~9999

0~9999

0.001~9.999

0.01~99.99

0.0~100.0

0~9999

0~9999

0.1~50.0

0.1~50.0

-1999~9999

-1999~9999

0.0~100.0

0.0~100.0

0~55.0

-1999~9999

-1.999~9.999

-1999~9999

1~100

0~9999

0~9999

/

/

OFF

/

/

/

,10,20,30

40,50,60

/

,

-1999~9999

-1999~9999

0.0~100.0

1~255

/

100~999

0.5

9999

-1999

OFF

OFF

1

None

Hi

None

OFF

ON

100

Hex

ORDERING INFORMATION

OUT/SUB

select

0---None

1---5A RELAY

2---4~20mA DC

Optional

Dimension

20---48x48

30---96x48

3---0~10VDC Output

4---Voltage pulse output (12Vdc)

5---0~5VDC

31---48x96

40---72x72

50---96x96

Input

Signal

0---T/C & PT & 0~230mV

1---4~20mA

2---0~10VDC

6---0~20mA DC

OUT1OUT2 SUB1 SUB2

AUX1

AUX2 AUX3 AUX4

48*48 is available for AUX 1 only

( 9 PT-89 9 9 -S 9 - 9 9 9 9 - 9 9 9 )

Operating

mode

3:Standard mode

8:8 pattern Ramp Soak

Device ID identification

Auxiliary command input

Output direction ( Hi or Lo )

Auto-tuning hysteresis

Automatic return PV / SV screen

HBA alarm Latch

Restore Factory default setting

High Limit for SV

SV-H>SV-L

Low Limit for SV

SV-L<SV-H

Operation at Power-ON

8 Bytes size, No Parity, 1 stop Bits

Transmission mode

Time-out setting

Allow communication writing

Baud rate:600

Baud rate:1200

Baud rate:2400

Baud rate:4800

Baud rate:9600

Baud rate:19200

Baud rate:38400

8 Bytes size, No Parity, 2 stop Bits

8 Bytes, Odd Parity, 1 stop Bits

8 Bytes, Even Parity, 1 stop Bits

Description

Main Item

Sub

Item

Data Range

Default

Value

Description

Main Item

Sub

Item

Data Range

Default

Value

Menu locking

Maximum Voltage input

Minimum Voltage input

Input A/D switch

High Limit for PV display

Low Limit for PV display

Display voltage from Sensor

AD converter

Span Voltage setting

Zero Voltage setting

High Limit for SV (RSP)

Low Limit for SV (RSP)

Display Voltage of AD converter

-1999~9999

-1999~9999

10.0

-1.999~9.999

-1.999~9.999

-1999~9999

-1999~9999

-1.999~9.999

-1.999~9.999

100.0

0.0

0.25

0.1

0.0

2.264

0.072

LB00

Span Voltage setting

Zero Voltage setting

High Limit display for CT current

Display Voltage of AD converter

Low Limit display for CT current

-1.999~9.999

-1999~9999

-1999~9999

-1.999~9.999

35.0

2.5

0.1

0.0

Advanced

setting for PV

CT input setting

Advanced

setting for SV

Description

Main Item

Sub

Item

Data Range

Default

Value

0---RS485

1---CT

2---RSP(0~10V)

3---RSP(0~20mA)

4---Event

1---CT

2---RSP(0~10V)

3---RSP(0~20mA)

4---Event

Frame setting

Frame setting

Expand setting

Communication

setting

SET

MOD MOD

SET

SET

MOD

SET SET

SET

MOD

SET

MOD

SET

SET

SET SET

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

SET

MOD

Security selection

Loading...

Loading...