Page 1

A Sierra Monitor Company

Driver Manual

(Supplement to the FieldServer Instruction Manual)

FS-8700-31 Siemens TIWAY I

APPLICABILITY & EFFECTIVITY

Effective for all systems manufactured after May 1, 2001

Driver Version 1.01b

Document revision Rev 1

Page 2

FS-8700-31 Siemens TIWAY I Index

TABLE OF CONTENTS

1. Siemens TIWAY I Driver Description............................................................................... 1

2. Driver Scope of Supply..................................................................................................... 2

2.1. Supplied by FieldServer Technologies for this driver ...................................................2

2.2. Provided by the Supplier of 3rd Party Equipment..........................................................2

2.2.1. Hardware...................................................................................................................2

2.2.2. Required 3rd Party Software ...................................................................................... 2

2.2.3. Required 3rd Party Configuration ...............................................................................2

2.2.4. Optional Items ........................................................................................................... 2

3. Hardware Connections .....................................................................................................3

3.1. Hardware Connection Tips / Hints................................................................................ 3

4. Configuring the FieldServer as a TIWAY Client .............................................................3

4.1. Data Arrays/Descriptors ...............................................................................................3

4.2. Client Side Connection Descriptions ............................................................................4

4.3. Client Side Node Descriptors .......................................................................................5

4.4. Client Side Map Descriptors .........................................................................................5

4.4.1. FieldServer Related Map Descriptor Parameters...................................................... 5

4.4.2. Driver Related Map Descriptor Parameters ..............................................................6

4.4.3. Timing Parameters ....................................................................................................7

4.4.4. Reading TIWAY data map descriptor examples .......................................................8

4.4.4.1. Reading data from contiguous PLC data memory locations............................... 8

4.4.4.2. Reading data from random PLC data memory locations .................................... 8

4.4.4.3. Reading Drum_Count_Preset data from contiguous PLC data memory

locations 8

4.4.4.4. Reading Drum_Count_Preset data from random PLC data memory locations .. 9

4.4.4.5. Reading secondary PLC status ..........................................................................9

4.4.5. Writing TIWAY data map descriptor examples........................................................ 10

4.4.5.1. Writing data to contiguous PLC data memory locations ...................................10

4.4.5.2. Writing data to random PLC data memory locations ........................................10

4.4.5.3. Writing the same value to a block of contiguous PLC data memory locations .11

4.4.5.4. Writing Drum_Count_Preset data to contiguous PLC data memory locations .11

4.4.5.5. Writing Drum_Count_Preset data to random PLC data memory locations.......11

4.4.6. TIWAY host adapter command map descriptor examples ......................................12

4.4.6.1. Read Secondary Log ........................................................................................12

4.4.6.2. Report HIU Configuration .................................................................................12

4.4.6.3. Report Adapter Configuration ...........................................................................13

4.4.6.4. Report Network Manager Configuration ...........................................................13

4.4.6.5. Soft Reset .........................................................................................................14

4.4.6.6. Reset Adapter...................................................................................................15

4.4.6.7. Disconnect Secondaries ...................................................................................15

4.4.6.8. Connect Secondaries .......................................................................................15

5. Configuring the FieldServer as a TIWAY Server ..........................................................17

5.1. Server Side Connection Descriptors...........................................................................17

5.2. Server Side Node Descriptors ....................................................................................18

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 3

FS-8700-31 Siemens TIWAY I Index

5.3.

Server Side Map Descriptors...................................................................................... 19

5.3.1. FieldServer Specific Map Descriptor Parameters ...................................................19

5.3.2. Driver Specific Map Descriptor Parameters ............................................................19

5.3.3. Serving TIWAY data map descriptor example ........................................................21

5.3.4. Serving Drum_Count_Preset TIWAY data map descriptor example....................... 21

5.3.5. Serving PLC status data map descriptor example .................................................. 21

6. Advanced Topics ............................................................................................................22

7. Driver Notes.....................................................................................................................22

8. Troubleshooting tips ......................................................................................................22

8.1. Connection Tips & Hints .............................................................................................22

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 4

FS-8700-31 Siemens TIWAY I Page 1 of 23

1. Siemens TIWAY I Driver Description

The Siemens TIWAY I driver allows the FieldServer to transfer data to and from devices

over RS-

emulate either a Server or Client.

Max Nodes Supported

Client 1 Only 1 client node allowed

Server 254 Up to 254 secondary PLCs

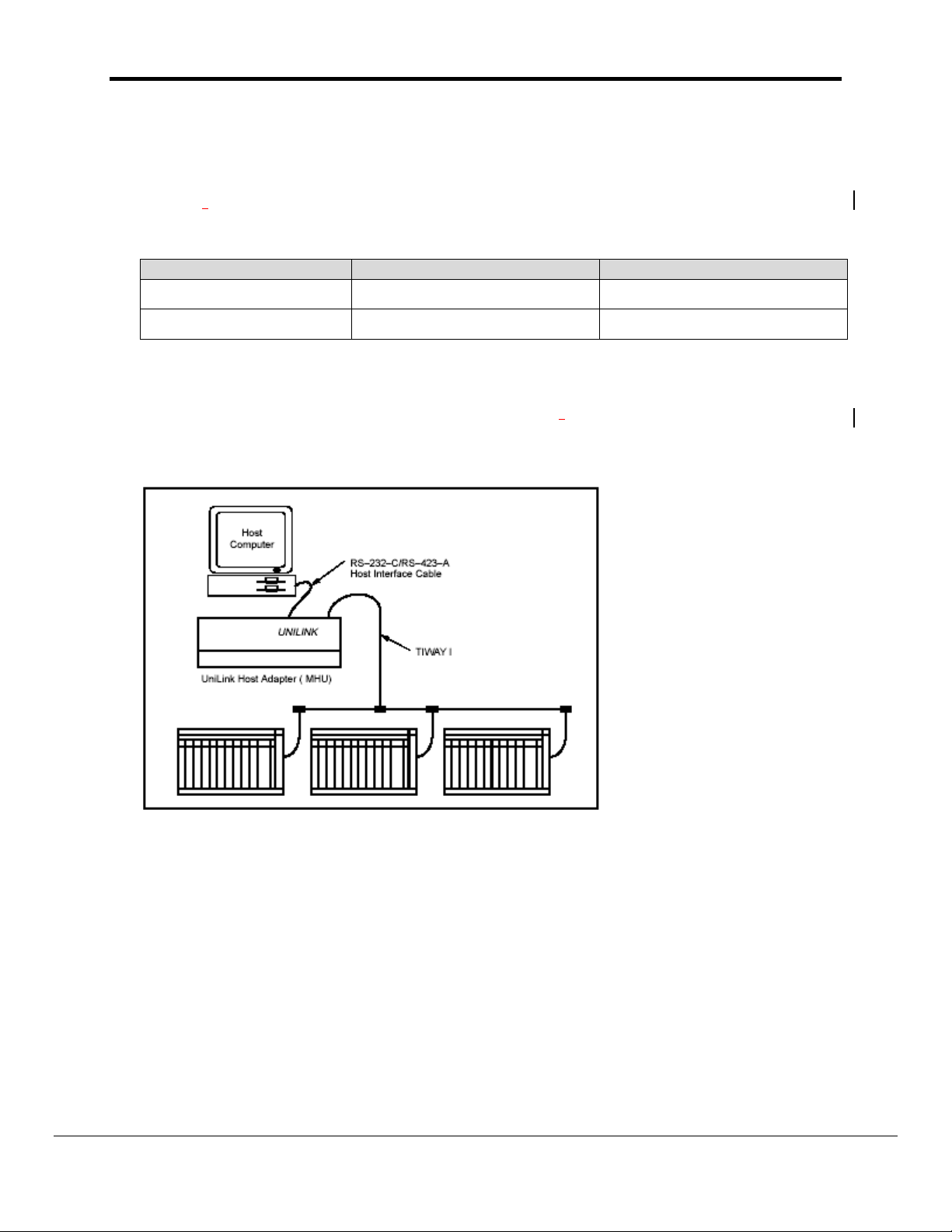

The FieldServer Siemens TIWAY I driver, hereafter simply referred to as the TIWAY driver,

can be used to emulate the host side of a Siemens Unilink Host Adaptor (UHA) using BDLC

“Host Command Protocol”. The original Siemens UHA device was used to interface other

host devices to a TIWAY I network as shown below:

232C using TIWAY BDLC “Host Adapter Command” protocol. The FieldServer can

FieldServer Mode Nodes Comments

The original Siemens UHA is really a protocol bridge in itself. It speaks “Host Command

Protocol” on the host interface which may contain embedded TIWAY primitives (commands)

and speaks Siemens TIWAY I protocol on its secondary interface. The FieldServer TIWAY I

driver emulates the UHA’s host interface when used in the server mode, however the

FieldServer does not speak Siemens TIWAY protocol and therefore cannot be used to

connect to legacy TIWAY devices directly. The driver’s use is primarily as a server to allow

legacy SCADA systems speaking “Host Command Protocol” containing TIWAY primitives to

communicate with modern PLCs speaking Modbus or other industrial protocols. The

accompanying FieldServer client driver in a configuration setup will typically be Modbus or

some other industrial protocol. The TIWAY driver’s use as a client is limited to emulating a

host to a UHA or for testing purposes.

The TIWAY driver operates in the Master Host Interface Unit ( MHIU ) mode and only

supports a limited selected set of Host Adapter commands and TIWAY primitives which are

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 5

FS-8700-31 Siemens TIWAY I Page 2 of 23

listed under the Supported Host Adaptor Commands and Primitives section of the driver

factsheet.

2. Driver Scope of Supply

2.1. Supplied by FieldServer Technologies for this driver

FieldServer Technologies

PART #

Description

FS-8915-10 UTP cable (7 foot) for Ethernet connection

FS-8915-10 UTP cable (7 foot) for RS232 use

FS-8917-02 RJ45 to DB9F connector adapter

FS-8917-01 RJ45 to DB25M connection adapter

- Driver Manual.

2.2. Provided by the Supplier of 3rd Party Equipment

2.2.1. Hardware

Part # Description

2.2.2. Required 3rd Party Software

SCADA TIWAY Unilink adapter client software such as Intellution’s FIX

driver.

2.2.3. Required 3rd Party Configuration

The BDLC protocol has to be selected on any 3rd party client.

2.2.4. Optional Items

PART # Vendor/Manufacturer Description

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 6

FS-8700-31 Siemens TIWAY I Page 3 of 23

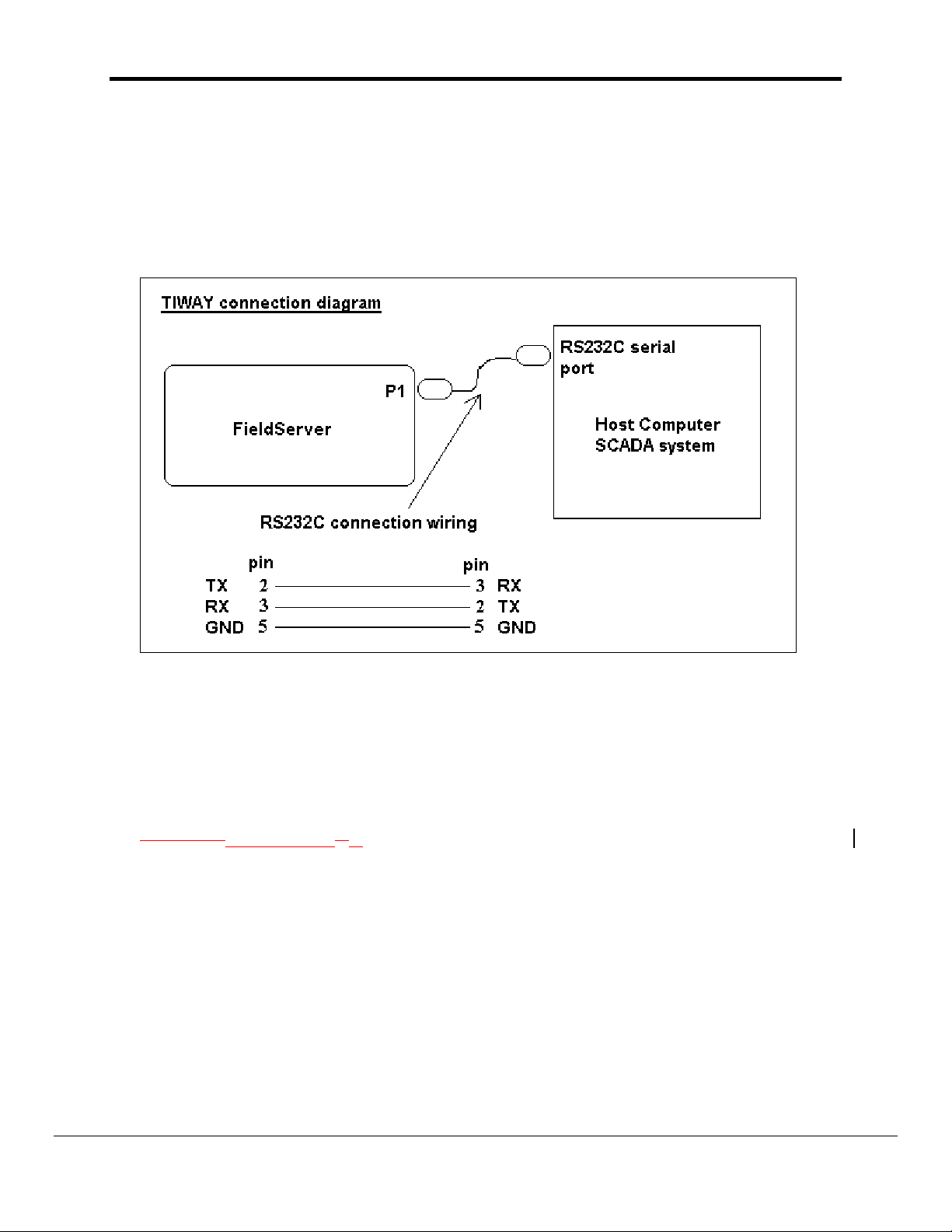

3. Hardware Connections

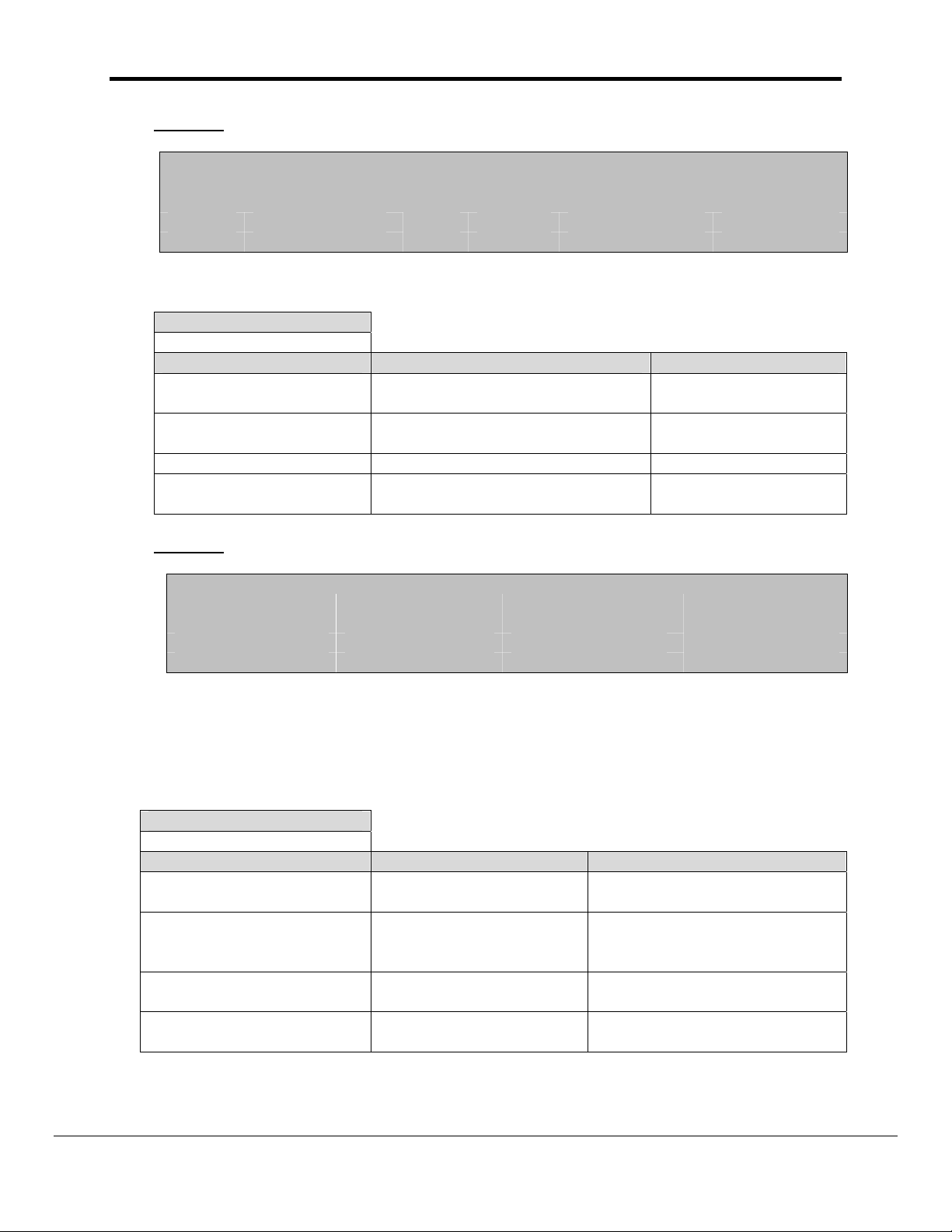

The FieldServer is connected to the SCADA system as shown below.

Configure the SCADA system according to manufacturer’s instructions.

3.1. Hardware Connection Tips / Hints

To be updated from testing feedback.

4. Configuring the FieldServer as a TIWAY Client

For a detailed discussion on FieldServer configuration, please refer to the FieldServer

instruction

upon the factory defaults provided in the configuration files included with the FieldServer

(See “.csv” sample files provided with the FS).

This section documents and describes the parameters necessary for configuring the

FieldServer to communicate with a TIWAY Server. The driver is normally used in the server

mode, but may be configured as a client for testing purposes.

Configuration mManual. The information that follows describes how to expand

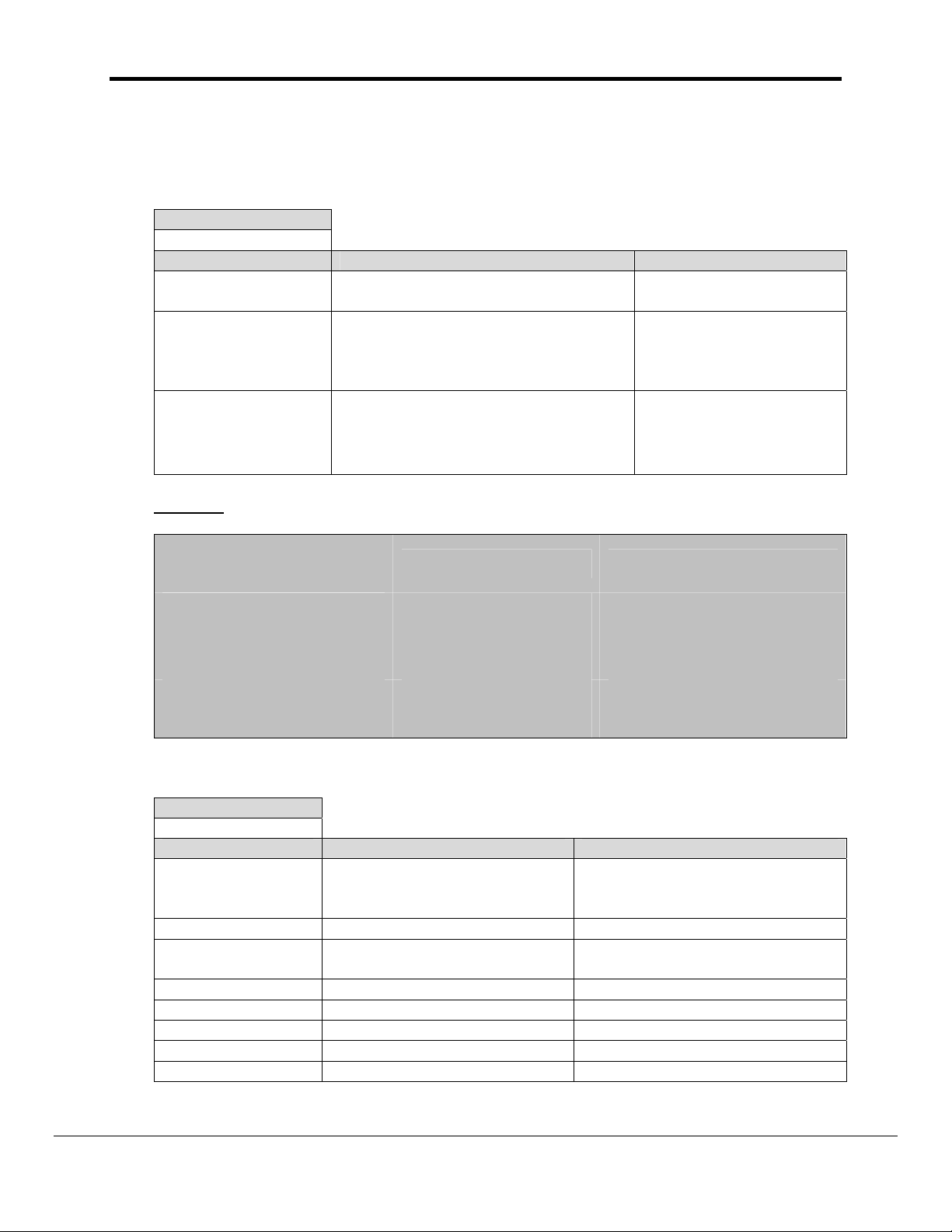

4.1. Data Arrays/Descriptors

The configuration file tells the FieldServer about its interfaces, and the routing of data

required. In order to enable the FieldServer for TIWAY communications, the driver

independent FieldServer buffers need to be declared in the “Data Arrays” section, the

destination device addresses need to be declared in the “Client Side Nodes” section, and

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 7

FS-8700-31 Siemens TIWAY I Page 4 of 23

the data required from the servers needs to be mapped in the “Client Side Map Descriptors”

section. Details on how to do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value being the

default.

Section Title

Data_Arrays

Column Title Function Legal Values

Data_Array_Name Provide name for Data Array

Up to 15 alphanumeric

characters

Float, Bit, UInt16, SInt16,

Data_Array_Format

Provide data format. Each Data Array

can only take on one format.

Packed_Bit, Byte,

Packed_Byte,

Swapped_Byte

Number of Data Objects. Must be

Data_Array_Length

larger than the data storage area

required by the map descriptors for

1-10,000

the data being placed in this array.

Example

// Data Arrays

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length,

RAW16_Data, UInt16, 20

RAW8_Data, Byte, 20

Float_Data, Float, 20

4.2. Client Side Connection Descriptions

Section Title

Connections

Column Title Function Legal Values

Specify which port the device

Port

Protocol Specify protocol used TIWAY, TIWAY_BDLC

Baud* Specify baud rate

Parity* Specify parity Even, Odd, None, Mark, Space

Data_Bits* Specify data bits 7, 8

Stop_Bits* Specify stop bits

Handshaking* Specify hardware handshaking RTS, RTS/CTS, None

Poll _Delay* Time between internal polls 0-32000 seconds, 1 second

is connected to the

FieldServer

P1-P8

110 – 115200, standard

baudrates only

1

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 8

FS-8700-31 Siemens TIWAY I Page 5 of 23

Example

// Client Side Connections

Connections

Port, Protocol, Baud, Parity, Handshaking, Poll_Delay

P1, TIWAY_BDLC, 9600, None, None, 0.100s

4.3. Client Side Node Descriptors

Section Title

Nodes

Column Title Function Legal Values

Node_Name Provide name for node

Node_ID

Protocol Specify protocol used TIWAY, TIWAY_BDLC

Connection

Example

// Client Side Nodes

Nodes

Node_Name, Node_ID, Protocol, Port

PLC_01, 01, TIWAY_BDLC, P1

Secondary PLC station address to

communicate with

Specify which port the device is

connected to the FieldServer

Up to 32 alphanumeric

characters

1-254

P1-P8

4.4. Client Side Map Descriptors

4.4.1. FieldServer Related Map Descriptor Parameters

Section Title

Map Descriptors

Column Title Function Legal Values

Map_Descriptor_Name

Data_Array_Name

Data_Array_Offset

Function

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Name of this Map

Descriptor

Name of Data Array

where data is to be stored

in the FieldServer

Starting location in Data

Array

Function of Client Map

Descriptor

Up to 32 alphanumeric

characters

One of the Data Array names

from “Data Array” section

above

0 to maximum specified in

“Data Array” section above

RDBC, WRBC, WRBX, AWT

Page 9

FS-8700-31 Siemens TIWAY I Page 6 of 23

4.4.2. Driver Related Map Descriptor Parameters

Section Title

Map Descriptors

Column Title Function Legal Values

One of the node names

specified in “Client Node

Descriptor” above

16-bit word datatypes

IE_Ladder

Variable

Constant

Word_Input

Word_Output

Timer_Cnt_Preset

Timer_Cnt_Current

Drum_Count_Preset

Loop_Status

Status_Primitive

8-bit byte datatypes

Discrete_Input

Discrete_Output

Control_Register

Discrete_Force

Control_Register_Force

Drum_Step_Preset

Drum_Step_Current

32-bit float datatypes

Loop_Gain

Loop_Reset

Loop_Rate

Loop_High_Alarm

Loop_Low_Alarm

Loop_Process_Variable

Loop_High_Process_Variable

Loop_Low_Process_Variable

Loop_Orange_Deviation

Loop_Yellow_Deviation

Loop_Sample_Rate

Loop_Set_Point

Node_Name

TIWAY_Data_Type

Name of Node to fetch

data from

Specifies fundamental

datatype to address in

PLC

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 10

FS-8700-31 Siemens TIWAY I Page 7 of 23

Loop_Output

24-bit datatypes

Word_Force

Packed-bit datatypes

Discrete_Input_Packed

Discrete_Output_Packed

Control_Register_Packed

Read_Secondary_Log

Report_HIU_Config

Report_Adapter_Config

TIWAY_Host_Adapter_Cmd

TIWAY_Address_List

Preset_Step_List

Secondaries_List A list of secondary PLC

Address

Length Length of Map Descriptor 1-65535

Specifies a host adapter

command to execute

A list of PLC memory

addresses that may be

used for random read

and writes

A list of preset step

values to be used with

the Drum_Count_Preset

datatype. Each value is

tied to an address.

addresses to be used

with the Connect_ and

Disconnect_Secondaries

host adapter commands.

Starting address of read

or write block

Report_NM_Config

Soft_Reset

Reset_Adapter

Disconnect_Secondaries

Connect_Secondaries

0-65535

0-255 for loop datatypes and

Drum_Count_Preset

Maximum of 80 space

seperated values allowed.

0-255

Maximum of 80 space

seperated values allowed.

1-255

255 indicates all secondaries

from 1 to 254

0-65535

0-255 for loop datatypes and

Drum_Count_Preset

4.4.3. Timing Parameters

Section Title

Map Descriptors

Column Title Function Legal Values

Scan_Interval Rate at which data is polled ≥0.001s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 11

FS-8700-31 Siemens TIWAY I Page 8 of 23

4.4.4. Reading TIWAY data map descriptor examples

4.4.4.1. Reading data from contiguous PLC data memory locations

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, Address, Length,

C01_RAW16_PLC01, RAW16_Data, 0, RDBC, PLC_01, IE_Ladder, 0, 10,

Scan_Interval

0s

The above map descriptor will continuously read 10 data elements starting from address 0 of type “IE_Ladder” from

PLC_01. The data will be stored in the data array called “RAW16_Data” from an offset of 0.

4.4.4.2. Reading data from random PLC data memory locations

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, TIWAY_Address_List, Length,

C02_RAW16_PLC01, RAW16_Data, 10, RDBC, PLC_01, Variable, 5 9, 2,

Scan_Interval

0s

The above map descriptor will continuously read 2 data elements from address 5 and 9 of type “Variable” from

PLC_01. The data will be stored in the data array called “RAW16_Data” from an offset of 10. The data will be

stored at offsets 10 and 11.

4.4.4.3. Reading Drum_Count_Preset data from contiguous PLC data memory locations

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, Address, Length,

C08_RAW16_PLC01, RAW16_Data, 70, RDBC, PLC_01, Drum_Count_Preset, 0, 5,

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 12

FS-8700-31 Siemens TIWAY I Page 9 of 23

Preset_Step_List, Scan_Interval

5 8 9 33 49, 0s

The above map descriptor will continuously read 5 data elements from addresses 0-4 of type

“Drum_Count_Preset” from PLC_01. The Preset Steps associated with addresses are (address 0):5, (address 1):8,

(address 2):9, (address 3):33, and (address 4):49. The data will be stored contiguously in the data array from offset

70.

4.4.4.4. Reading Drum_Count_Preset data from random PLC data memory locations

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, TIWAY_Address_List,

C08_RAW16_PLC01, RAW16_Data, 75, RDBC, PLC_01, Drum_Count_Preset, 5 9,

Length, Preset_Step_List, Scan_Interval

2, 42 22, 0s

The above map descriptor will continuously read 2 data elements from addresses 5 and 9 of type

“Drum_Count_Preset” from PLC_01. The Preset Steps associated with addresses are (address 5):42 and (address

9):22. The data will be stored in the data array at offset 75 and 76.

4.4.4.5. Reading secondary PLC status

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, Length, Scan_Interval

C36_STATUS_PRIM, Status, 0, RDBC, PLC_01, Status_Primitive, 3, 0s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 13

FS-8700-31 Siemens TIWAY I Page 10 of 23

The above map descriptor will continuously read the three status values from PLC_01. The status values are

defined as follows and will be stored in the data array contiguously from an offset of zero:

Status element 1 (DD) : Operational Status

Status element 2 (EE) : Auxiliary power source status

Status element 3 (FF) : NIM Operational Status

Please refer to the TIWAY systems manual for operational values and their meanings.

4.4.5. Writing TIWAY data map descriptor examples

4.4.5.1. Writing data to contiguous PLC data memory locations

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, Address, Length,

C12_RAW8_PLC07, RAW8_Data, 20, WRBC, PLC_07, Control_Register, 0, 10,

Scan_Interval

0s

The above map descriptor will continuously write data of type “Control_Register” to 10 PLC data memory

addresses. The data to write will be collected from the data array “RAW8_Data” from an offset of 20.

4.4.5.2. Writing data to random PLC data memory locations

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, TIWAY_Address_List, Length,

C17_FLOAT_PLC254, FLOAT_Data, 0, WRBC, PLC_254, Loop_Gain, 5 9, 2,

Scan_Interval

0s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 14

FS-8700-31 Siemens TIWAY I Page 11 of 23

The above map descriptor will continuously write data of type “Loop_Gain” to 2 PLC data memory addresses of 5

and 9. The data to write will be collected from the data array “FLOAT_Data” from offsets 0 and 1.

4.4.5.3. Writing the same value to a block of contiguous PLC data memory locations

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, Address, Length,

C18_FLOAT_PLC254, FLOAT_Data, 10, WRBC, PLC_254, Loop_Reset, 0, 3,

TIWAY_Fill_Block_Value, Scan_Interval

50.5, 0s

The above map descriptor will continuously write a value of 50.5 of type “Loop_Reset” to 3 contiguous PLC data

memory addresses starting from 0.

4.4.5.4. Writing Drum_Count_Preset data to contiguous PLC data memory locations

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, Address, Length,

C08_RAW16_PLC01, RAW16_Data, 70, WRBC, PLC_01, Drum_Count_Preset, 0, 5,

Preset_Step_List, Scan_Interval

5 8 9 33 49, 0s

The above map descriptor will continuously write data of type “Drum_Count_Preset” to 5 PLC data memory

addresses. The data to write will be collected from the data array “RAW16_Data” from an offset of 70. The Preset

Steps associated with the addresses are (address 0):5, (address 1):8, (address 2):9, (address 3):33, and (address

4):49.

4.4.5.5. Writing Drum_Count_Preset data to random PLC data memory locations

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, TIWAY_Address_List,

C08_RAW16_PLC01, RAW16_Data, 70, WRBC, PLC_01, Drum_Count_Preset, 5 9,

Length, Preset_Step_List, Scan_Interval

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 15

FS-8700-31 Siemens TIWAY I Page 12 of 23

2, 33 49, 0s

The above map descriptor will continuously write data of type “Drum_Count_Preset” to 2 PLC data memory

addresses. The data to write will be collected from the data array “RAW16_Data” from an offset of 70 and 71. The

Preset Steps associated with the addresses are (address 5):33 and (address 9):49.

4.4.6. TIWAY host adapter command map descriptor examples

A number of map descriptors that send specific host adapter commands are available mainly for testing purposes

and should not be used under normal circumstances.

4.4.6.1. Read Secondary Log

Returns a list of secondary PLC stations addresses that are connected.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Host_Adapter_Cmd, Length,

C37_READ_SEC_LOG, Secondary_Log, 0, RDBC, PLC_01, Read_Secondary_Log, 254,

Scan_Interval

0s

The above map descriptor will continuously execute the indicated host adapter command and will store the list of

connected secondary PLCs in the data array “Secondary Log” from an offset of 0. Offset 0 will correspond to

secondary address 1, offset 1 to secondary 2 up to offset 253 corresponding to secondary address 254.

4.4.6.2. Report HIU Configuration

Reports the HIU Configuration option values that was used to configure the HIU.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Host_Adapter_Cmd, Length,

C38_REP_HIU_CONFIG, HIU_Config, 0, RDBC, PLC_01, Report_HIU_Config, 5,

Scan_Interval

0s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 16

FS-8700-31 Siemens TIWAY I Page 13 of 23

The above map descriptor will continuously execute the indicated host adapter command and will store the

following parameter values in the data array “HIU_Config”:

Offset Parameter

0 Dipswitch 1 and 2 settings

1 Config flag ( 0 = HIU not configured, 1 = HIU configured )

2 Option 01 configuration value

3 Option 02 configuration value

4 Option 03 configuration value

4.4.6.3. Report Adapter Configuration

Reports the Adapter Configuration option values that was used to configure the adapter.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Host_Adapter_Cmd, Length,

C39_REP_ADAP_CONFIG, Adapter_Config, 0, RDBC, PLC_01, Report_Adapter_Config, 6,

Scan_Interval

0s

The above map descriptor will continuously execute the indicated host adapter command and will store the

following parameter values in the data array “Adapter_Config”:

Offset Parameter

0 Dipswitch 1 and 2 settings

1 Config flag ( 0 = Adapter not configured, 1 = Adapter configured )

2 Option 01 configuration value

3 Option 02 configuration value

4 Option 03 configuration value

5 Option 04 configuration value

4.4.6.4. Report Network Manager Configuration

Reports the Network Manager option values that was used to configure the network manager.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Host_Adapter_Cmd, Length,

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 17

FS-8700-31 Siemens TIWAY I Page 14 of 23

C40_REP_NM_CONFIG, Nm_Config, 0, RDBC, PLC_01, Report_NM_Config, 16,

Scan_Interval

0s

The above map descriptor will continuously execute the indicated host adapter command and will store the

following parameter values in the data array “Nm_Config”:

Offset Parameter

0 Dipswitch 1 and 2 settings

1 Config flag ( 0 = Network Manager not configured, 1 = Network Manager configured )

2 Option 01 configuration value

3 Option 02 configuration value

4 Option 03 configuration value

5 Option 04 configuration value

6 Option 05 configuration value

7 Option 06 configuration value

8 Option 07 configuration value

9 Option 08 configuration value

10 Option 09 configuration value

11 Option 0A configuration value

12 Option 0B configuration value

13 Option 0C configuration value

14 Option 0D configuration value

15 Option 0E configuration value

4.4.6.5. Soft Reset

Forces the UNILINK Host Adapter to do a software reset.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Host_Adapter_Cmd, Length

C41_SOFT_RESET, Cmd_Triggers, 0, AWT, PLC_01, Soft_Reset, 1

The above map descriptor will execute the indicated host adapter command once every time a value is written to

the data array “Cmd_Triggers” at offset 0.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 18

FS-8700-31 Siemens TIWAY I Page 15 of 23

4.4.6.6. Reset Adapter

Forces the UNILINK Host Adapter to do a hardware reset.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Host_Adapter_Cmd, Length

C42_RESET_ADAPTER, Cmd_Triggers, 1, AWT, PLC_01, Reset_Adapter, 1

The above map descriptor will execute the indicated host adapter command once every time a value is written to

the data array “Cmd_Triggers” at offset 1.

4.4.6.7. Disconnect Secondaries

Disconnect Secondary PLCs from the network.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Host_Adapter_Cmd, Length,

C43_DISC_SECDS, Cmd_Triggers, 2, AWT, PLC_01, Disconnect_Secondaries, 1,

Secondaries_List

1 9 147 254

The above map descriptor will execute the indicated host adapter command once every time a value is written to

the data array “Cmd_Triggers” at offset 2. Secondaries 1 9 147 and 254 will be disconnected from the network.

To disconnect all secondaries, use only one value of 255 in the Secondaries_List field.

4.4.6.8. Connect Secondaries

Disconnect Secondary PLCs from the network.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Host_Adapter_Cmd, Length,

C45_CONNECT_SECDS, Cmd_Triggers, 4, AWT, PLC_01, Connect_Secondaries, 1,

Secondaries_List

1 9 147 254

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 19

FS-8700-31 Siemens TIWAY I Page 16 of 23

The above map descriptor will execute the indicated host adapter command once every time a value is written to

the data array “Cmd_Triggers” at offset 4. Secondaries 1 9 147 and 254 will be connected to the network.

To connect all secondaries, use only one value of 255 in the Secondaries_List field.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 20

FS-8700-931 Siemens TIWAY I Page 17 of 23

5. Configuring the FieldServer as a TIWAY Server

For a detailed discussion on FieldServer configuration, please refer to the FieldServer

instruction

to expand upon the factory defaults provided in the configuration files included with the

FieldServer (See “.csv” files on the driver diskette).

This section documents and describes the parameters necessary for configuring the

FieldServer to communicate with a TIWAY Client.

The configuration file tells the FieldServer about its interfaces, and the routing of data

required. In order to enable the FieldServer for TIWAY communications, the driver

independent FieldServer buffers need to be declared in the “Data Arrays” section, the

FieldServer virtual node(s) needs to be declared in the “Server Side Nodes” section, and the

data to be provided to the clients needs to be mapped in the “Server Side Map Descriptors”

section. Details on how to do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value being the

default.

Configuration mManual (Virtual PLC). The information that follows describes how

5.1. Server Side Connection Descriptors

Section Title

Connections

Column Title Function Legal Values

Port

Protocol

Baud* Specify baud rate

Parity* Specify parity

Data_Bits*

Stop_Bits*

Handshaking* Specify hardware handshaking RTS, RTS/CTS, None

Server_Hold_Timeout*

Specify which port the device is

connected to the FieldServer

Specify protocol used TIWAY, TIWAY_BDLC

Specify data bits 7, 8

Specify stop bits

Specifies time FieldServer will

reserve server side connection

while waiting for the Client side

to update data in Data_Array (if

necessary)

P1-P8

110 – 115200, standard

baud rates only

Even, Odd, None, Mark,

Space

1

>1.0s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 21

FS-8700-931 Siemens TIWAY I Page 18 of 23

Example

// Server Side Connections

Connections

Port, Protocol, Baud, Parity, Handshaking,

P1, TIWAY_BDLC, 9600, None, None,

5.2. Server Side Node Descriptors

Section Title

Nodes

Column Title Function Legal Values

Node_Name Provide name for node

Node_ID

Secondary PLC station address

of physical server node

Protocol Specify protocol used TIWAY, TIWAY_BDLC

Specifies time FieldServer will

reserve server side connection

Server_Hold_Timeout*

while waiting for the Client side

to update data in Data_Array (if

necessary)

Example

// Server Side Nodes

Nodes

Node_Name, Node_ID, Protocol

PLC_01, 01, TIWAY_BDLC

* Note that no connection information such as the Port is necessary on Server side.

Up to 32 alphanumeric

characters

1-254

>1.0s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 22

FS-8700-931 Siemens TIWAY I Page 19 of 23

5.3. Server Side Map Descriptors

5.3.1. FieldServer Specific Map Descriptor Parameters

Section Title

Map Descriptors

Column Title Function Legal Values

Map_Descriptor_Name Name of this Map Descriptor

Name of Data Array where

Data_Array_Name

Data_Array_Offset

Function

Server_Hold_Timeout*

data is to be stored in the

FieldServer

Starting location in Data

Array

Function of Server Map

Descriptor

Specifies time FieldServer

will reserve server side

connection while waiting for

the Client side to update

data in Data_Array (if

necessary)

Up to 32 alphanumeric

characters

One of the Data Array

names from “Data Array”

section above

0 to maximum specified in

“Data Array” section above

Server

>1.0s

5.3.2. Driver Specific Map Descriptor Parameters

Section Title

Map Descriptors

Column Title Function Legal Values

One of the node names

specified in “Client Node

Descriptor” above

16-bit word datatypes

IE_Ladder

Variable

Constant

Word_Input

Word_Output

Timer_Cnt_Preset

Timer_Cnt_Current

Drum_Count_Preset

Loop_Status

Status_Primitive

8-bit byte datatypes

Discrete_Input

Discrete_Output

Node_Name

TIWAY_Data_Type

Name of Node to fetch data

from

Specifies fundamental

datatype represented by

the PLC

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 23

FS-8700-931 Siemens TIWAY I Page 20 of 23

Control_Register

Discrete_Force

Control_Register_Force

Drum_Step_Preset

Drum_Step_Current

32-bit float datatypes

Loop_Gain

Loop_Reset

Loop_Rate

Loop_High_Alarm

Loop_Low_Alarm

Loop_Process_Variable

Loop_High_Process_Variable

Loop_Low_Process_Variable

Loop_Orange_Deviation

Loop_Yellow_Deviation

Loop_Sample_Rate

Loop_Set_Point

Loop_Output

24-bit datatypes

Word_Force

Packed-bit datatypes

Discrete_Input_Packed

Discrete_Output_Packed

Control_Register_Packed

A list of preset step values

0-255

Maximum of 80 space

seperated values allowed.

Preset_Step_List

to be used with the

Drum_Count_Preset

datatype. Each value is tied

to an address.

0-65535

0-255 for loop datatypes and

Drum_Count_Preset

Address

Starting address of read or

write block

Length Length of Map Descriptor 1 - 65535

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 24

FS-8700-31 Siemens TIWAY I Page 21 of 23

5.3.3. Serving TIWAY data map descriptor example

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, Address, Length

S01_RAW16_PLC0, RAW16_Data, 0, Server, PLC_01, IE_Ladder, 0, 10

The above map descriptor serves 10 data elements starting from address 0 of type “IE_Ladder” for PLC_01.

5.3.4. Serving Drum_Count_Preset TIWAY data map descriptor example

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, Address, Length,

S10_RAW16_PLC01, RAW16_Data, 71, Server, PLC_01, Drum_Count_Preset, 0, 4,

Preset_Step_List

3 5 9 167

The above map descriptor serves 4 data elements starting from address 0 of type “Drum_Count_Preset” for

PLC_01. Each address location is contiguously associated with a preset step value from the Preset_Step_List field.

5.3.5. Serving PLC status data map descriptor example

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name, TIWAY_Data_Type, Length

S36_PRIM_STATUS, Status, 0, Server, PLC_01, Status_Primitive, 3

The above map descriptor serves 3 status data elements for PLC_01 in the data array “Status” starting from offset

0.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 25

FS-8700-31 Siemens TIWAY I Page 22 of 23

6. Advanced Topics

None.

7. Driver Notes

None.

8. Troubleshooting tips

8.1. Connection Tips & Hints

None.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 26

FS-8700-31 Siemens TIWAY I Page 23 of 23

Revision History

Date

Driver

Version

04/24/03 1.00a 0 DR Created

8/13/03 1.00a 1 JD Format Changes

11/20/03 1.00a 2 JD Formatting Changes

Document

Revision

Resp

Comment

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Loading...

Loading...