Page 1

Driver Version:

1.02

A Sierra Monitor Company

Driver Manual

(Supplement to the FieldServer Instruction Manual)

FS-8700-19 Metasys N2

APPLICABILITY & EFFECTIVITY

Effective for all systems manufactured after May 1, 2001

Document Revision: 22

Page 2

FS-8700-19_Metasys_N2 Driver Manual Table of Contents

TABLE OF CONTENTS

1.

Metasys N2 Description ................................................................................................. 3

2.

Driver Scope of Supply .................................................................................................. 4

2.1.

Supplied by FieldServer Technologies for this driver.................................................. 4

2.2.

Provided by the Supplier of 3rd Party Equipment ........................................................ 4

2.2.1. Hardware................................................................................................................ 4

2.2.2. Required 3rd Party Software.................................................................................... 4

2.2.3. Required 3rd Party Configuration............................................................................. 4

3.

Hardware Connections .................................................................................................. 5

3.1.

Hardware Connection Tips / Hints.............................................................................. 5

4.

Configuring the FieldServer as a Metasys N2 Client ................................................... 6

4.1.

Data Arrays/Descriptors............................................................................................. 6

4.2.

Client Side Connection Descriptions .......................................................................... 7

4.3.

Client Side Node Descriptors ..................................................................................... 8

4.4.

Client Side Map Descriptors....................................................................................... 8

4.4.1. FieldServer Related Map Descriptor Parameters.................................................... 8

4.4.2. Driver Related Map Descriptor Parameters............................................................. 9

4.4.3. Timing Parameters ................................................................................................13

4.4.4. Map Descriptor Example 1 – N2Open....................................................................14

4.4.5. Map Descriptor Example 2 - VMA..........................................................................14

4.4.6. Map Descriptor Example 3 - DX9100.....................................................................15

5.

Configuring the FieldServer as a Metasys N2 Server .................................................16

5.1.

Server Side Connection Descriptors .........................................................................16

5.2.

Server Side Node Descriptors...................................................................................17

5.3.

Server Side Map Descriptors ....................................................................................18

5.3.1. FieldServer Specific Map Descriptor Parameters...................................................18

5.3.2. Driver Specific Map Descriptor Parameters ...........................................................18

5.3.3. Map Descriptor Example........................................................................................19

Appendix A. Advanced Topics...........................................................................................20

Appendix A.1. Writing to DX9100 Binary Outputs................................................................20

Appendix A.2. Managing Analog Inputs and Outputs for DX9100. ......................................21

Appendix B. Troubleshooting tips.....................................................................................22

Appendix B.1. Connection Tips & Hints...............................................................................22

Appendix B.2. Offline Behavior ...........................................................................................22

Appendix B.3. Tip on Overrides ..........................................................................................22

Appendix C. Setting up FS-B20 for RS-485.......................................................................23

Appendix C.1. Jumper Settings:..........................................................................................23

Appendix C.2. Hardware connections .................................................................................25

Appendix C.3. Configuration Settings..................................................................................25

Appendix D. Memory Maps ................................................................................................26

Appendix D.1. Metasys DX9100 Memory Map....................................................................26

Appendix D.2. Metasys DC9100 Memory Map....................................................................33

Appendix D.3. Metasys TC9100 Memory Map ....................................................................40

Appendix E. Error Messages .............................................................................................50

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 3

FS-8700-19_Metasys_N2 Driver Manual Page 3 of 51

1. Metasys N2 Description

The Metasys N2 network supports communications with a diverse range of devices. Many N2

compatible devices use their own version of the protocol and care must be taken to ensure that

the device of interest is covered by the FieldServer implementation.

At present the FieldServer N2 driver will support communications with the following devices or

device classes when acting as a Client:

1. N2Open-compliant devices. N2Open is a published N2-compatible protocol enabling 3rd

party device vendors to integrate with N2.

2. VMA 1400 series (with restrictions, as described in this document)

3. DX9100 and XT9100

When acting as a Server, the FieldServer N2 driver can emulate an N2Open device only.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 4

FS-8700-19_Metasys_N2 Driver Manual Page 4 of 51

2. Driver Scope of Supply

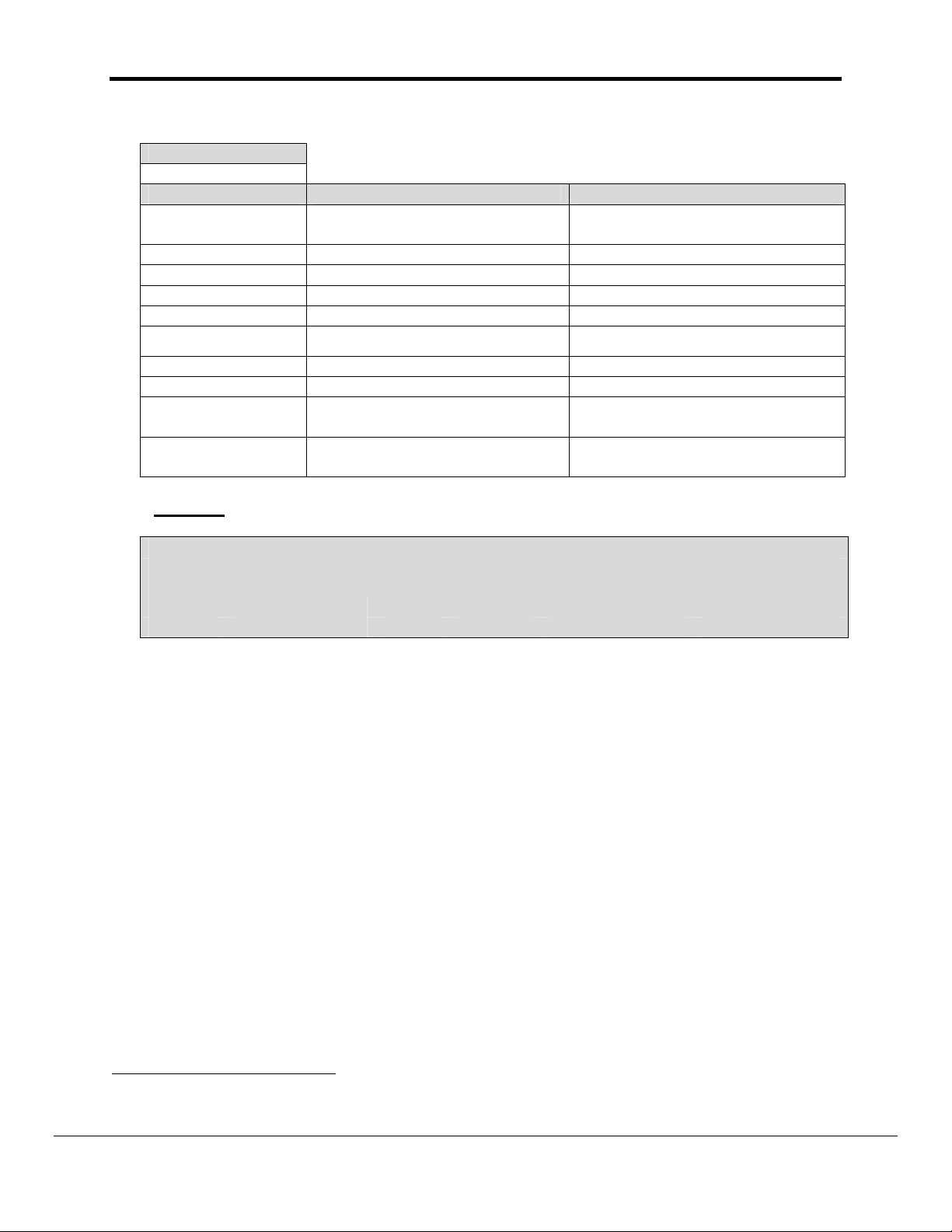

2.1. Supplied by FieldServer Technologies for this driver

FieldServer Technologies

PART #

FS-8915-10 UTP cable (7 foot) for Ethernet connection

FS-8915-10 UTP cable (7 foot) for RS-232 use

FS-8917-02 RJ45 to DB9F connector adapter

FS-8917-01 RJ45 to DB25M connection adapter

SPA59132 RS-485 connection adapter

FS-8700-19 Driver Manual.

Description

2.2. Provided by the Supplier of 3rd Party Equipment

2.2.1. Hardware

PART # DESCRIPTION

Metasys NCU or other device

2.2.2. Required 3rd Party Software

Depending on application, JCI software may be necessary

2.2.3. Required 3rd Party Configuration

Depending on application, third party devices may need configuration

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 5

FS-8700-19_Metasys_N2 Driver Manual Page 5 of 51

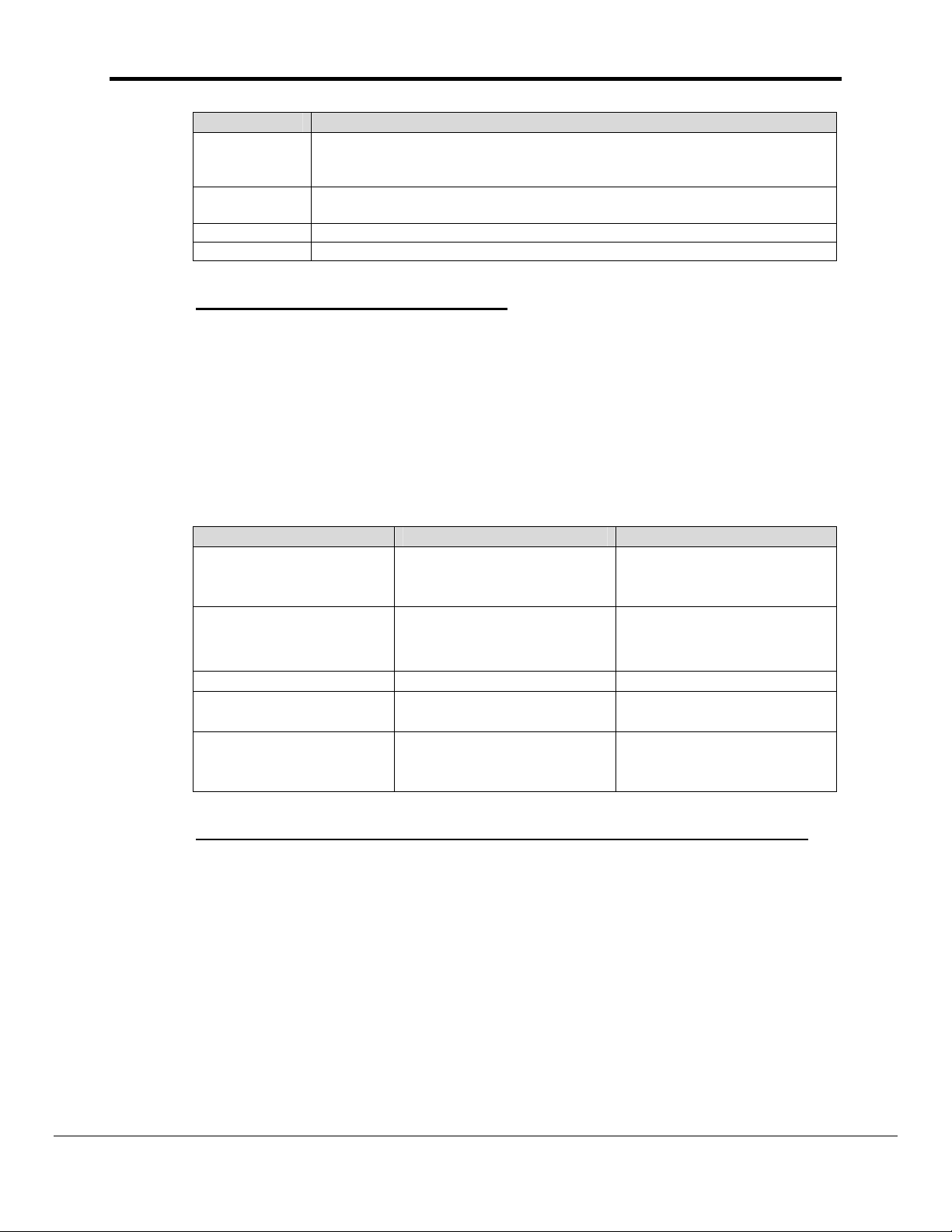

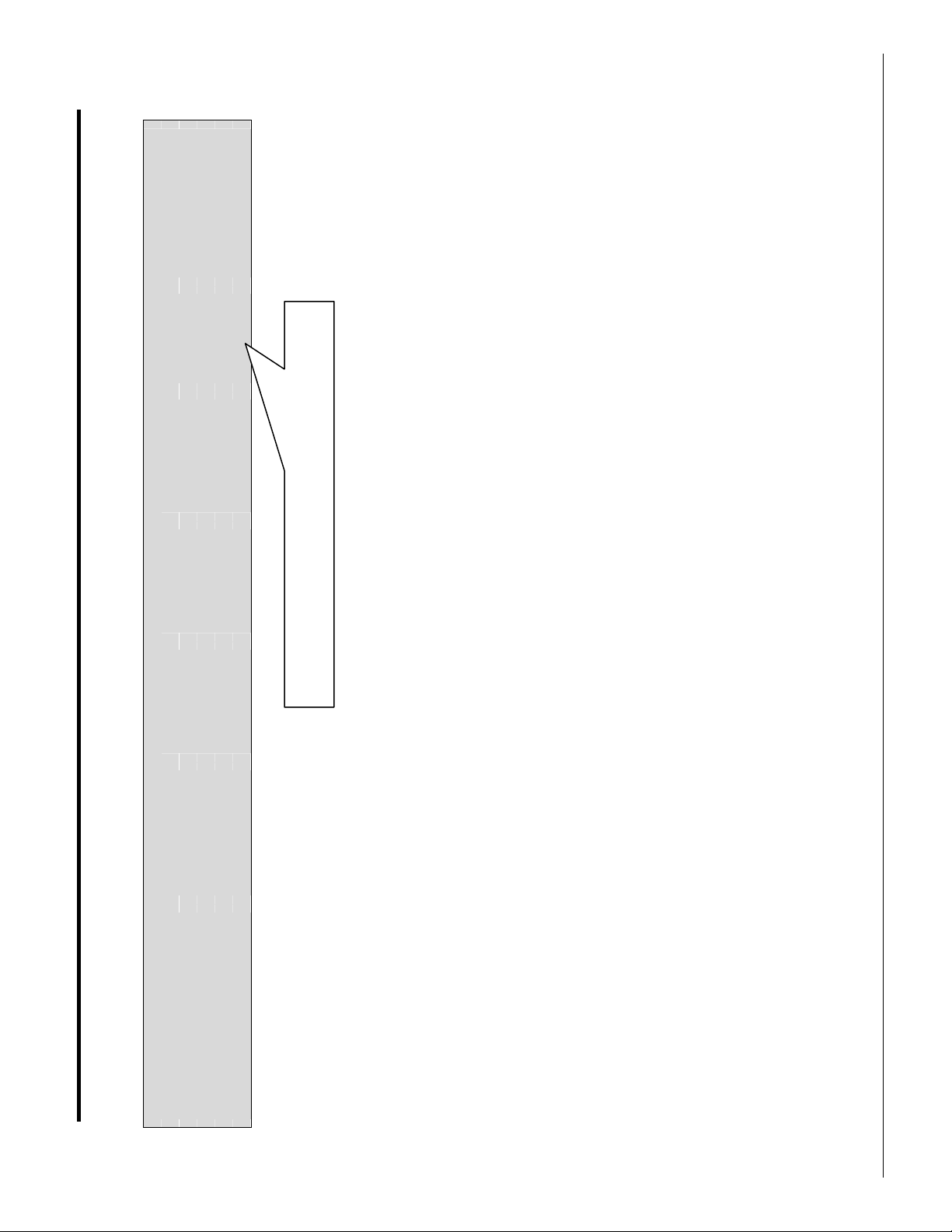

06

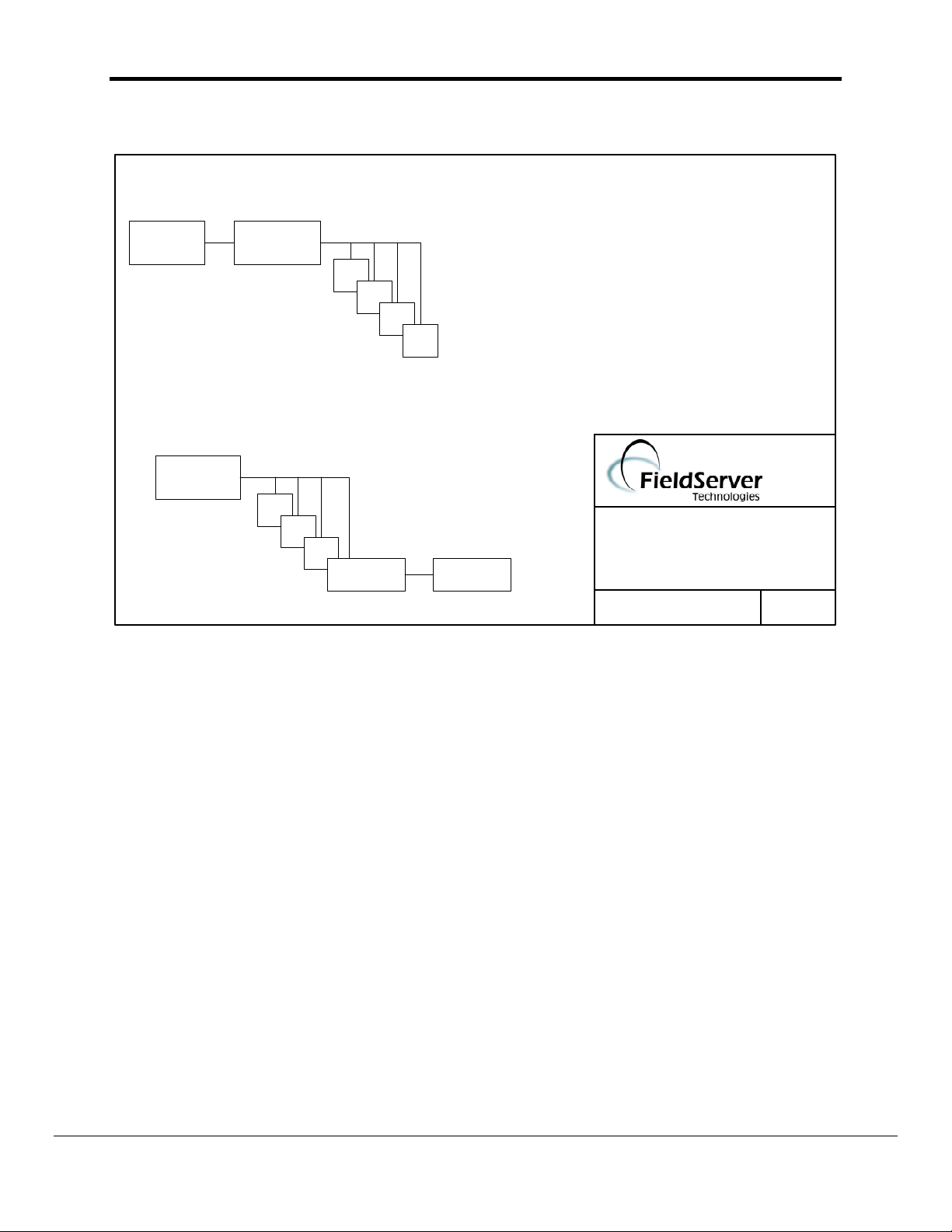

3. Hardware Connections

FieldServer as a Client

3rd Party

System

FieldServer

N2 bus

N2 devices

FieldServer as a Server

NCM, N30 or

other N2 client

N2 bus

N2 devices

FieldServer

3rd Party

System

3.1. Hardware Connection Tips / Hints

MetasysN2

CONNECTION DIAGRAM

BASE NAME:

FILE NAME: FS-8700-19

(408)-262-2299

DATE: 05/31/

BY: MC

When using the FS-X40 ensure that the FieldServer is connected to the network using one

or both of the RS-485 ports marked R1 and R2. If more ports are required, P1-P8 may be

used in conjunction with an RS-232-to-RS-485 converter.

When using the FS-X20, ensure that the serial port is configured as an RS-485 port. Refer

to Appendix B.3 for more information.

Only one N2 Client may be connected to a N2 network. If the FieldServer is to act as a

Client, ensure that no other Clients are connected to the same N2 network.

Note: Interceptor mode is no longer supported for this driver.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 6

FS-8700-19_Metasys_N2 Driver Manual Page 6 of 51

4. Configuring the FieldServer as a Metasys N2 Client

For a detailed discussion on FieldServer configuration, please refer to the FieldServer

Configuration manual. The information that follows describes how to expand upon the factory

defaults provided in the configuration files included with the FieldServer (See “.csv” sample files

provided with the FieldServer).

This section documents and describes the parameters necessary for configuring the FieldServer

to communicate with a Metasys N2 Server.

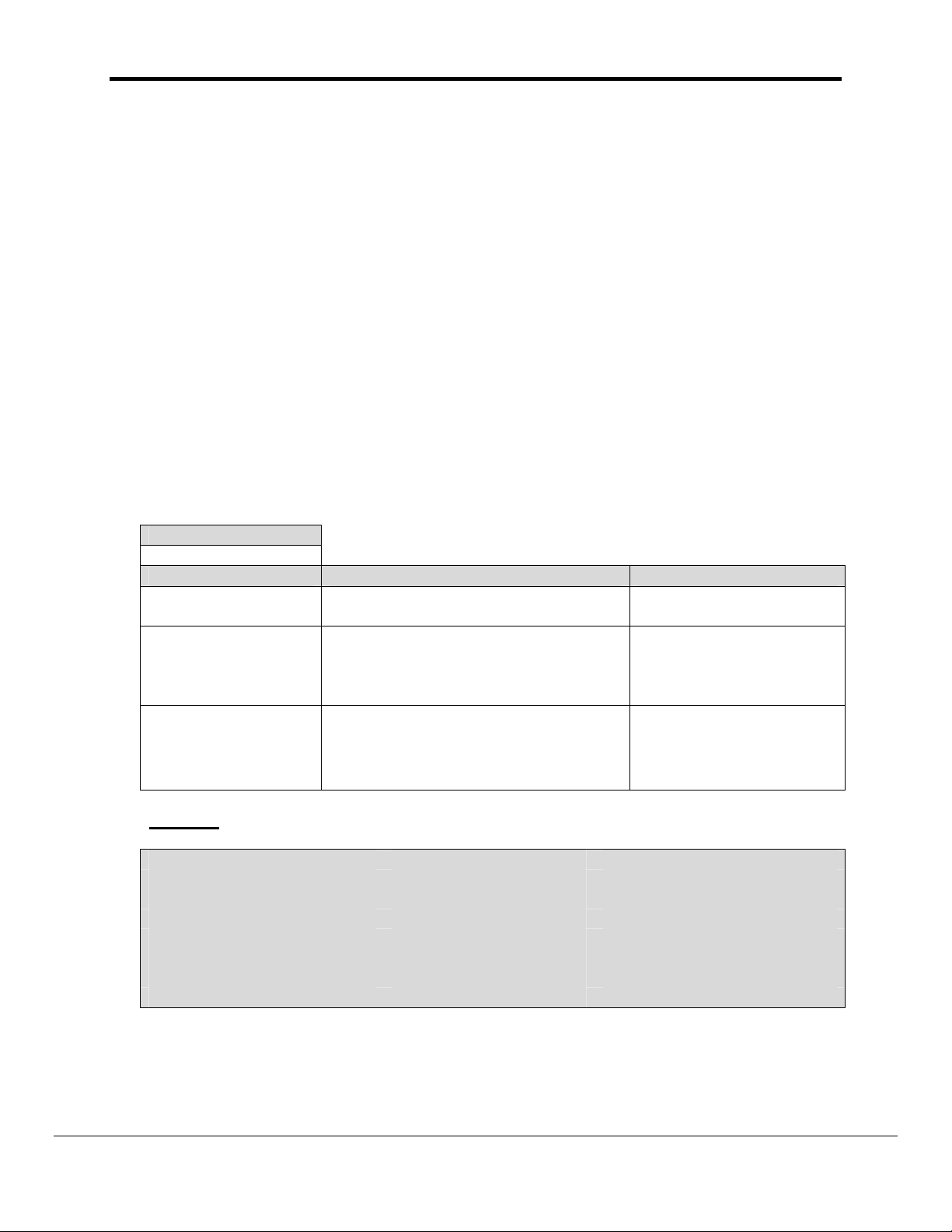

4.1. Data Arrays/Descriptors

The configuration file defines the FieldServer interfaces, and the data routing required. In

order to enable the FieldServer for Metasys N2 communications, the driver independent

FieldServer buffers need to be declared in the “Data Arrays” section, the destination device

addresses need to be declared in the “Client Side Nodes” section, and the data required

from the Servers needs to be mapped in the “Client Side Map Descriptors” section.

Note that in the tables, * indicates an optional parameter, with the bold legal value being the

default value. Where only one legal value is given, no other values for that parameter are

allowed.

Section Title

Data_Arrays

Column Title Function Legal Values

Data_Array_Name Provide name for Data Array

Data_Array_Format

Provide data format. Each Data Array

can only take on one format.

Number of Data Objects. Must be

Data_Array_Length

larger than the data storage area

required by the Map Descriptors for

the data being placed in this array.

Example

// Data Arrays

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length

DA_AI_01, UInt16, 200

DA_AO_01, UInt16, 200

DA_DI_01, Bit, 200

DA_DO_01, Bit, 200

Up to 15 alphanumeric

characters

Float, Bit, UInt16, SInt16,

Packed_Bit, Byte,

Packed_Byte,

Swapped_Byte

1-10,000

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 7

FS-8700-19_Metasys_N2 Driver Manual Page 7 of 51

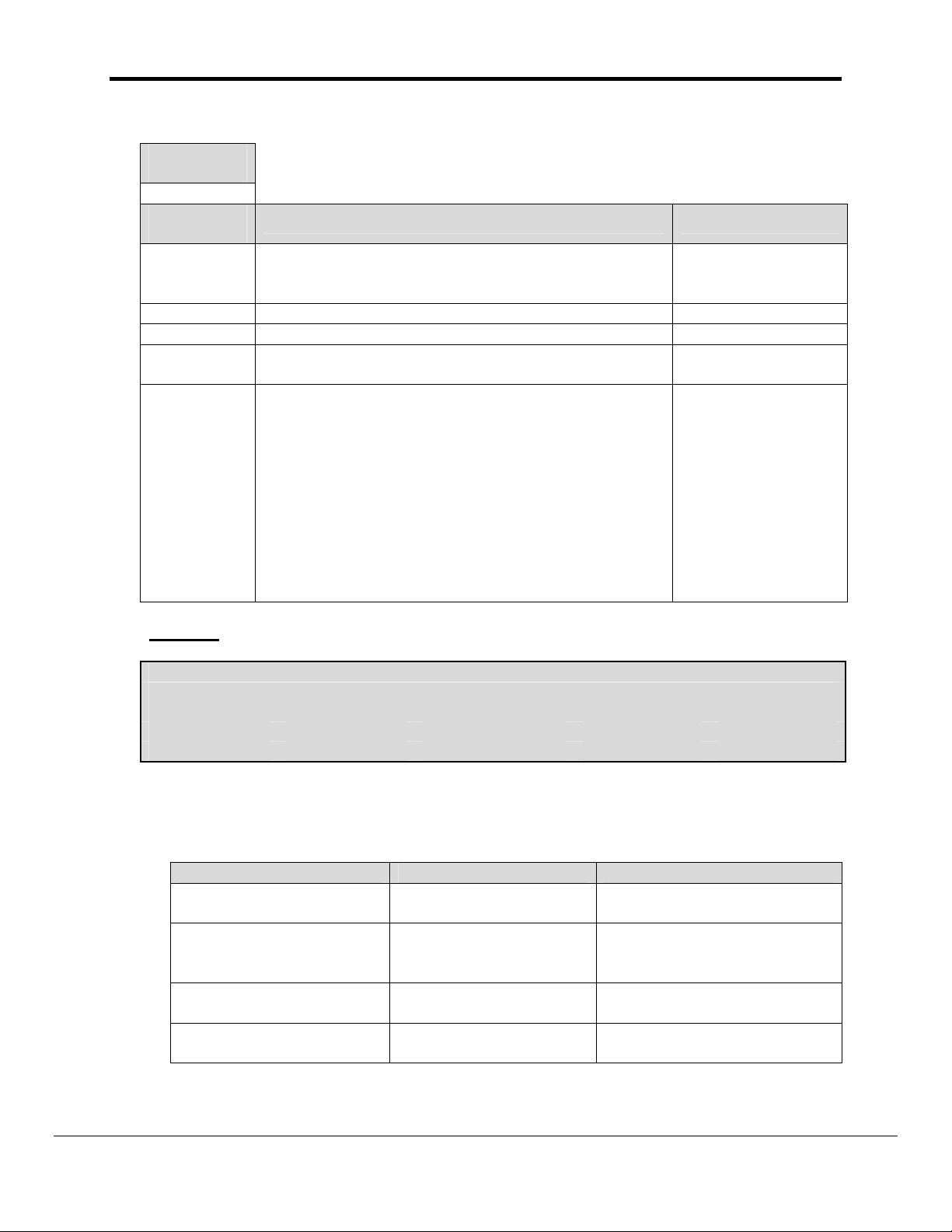

4.2. Client Side Connection Descriptions

Section Title

Connections

Column Title Function Legal Values

Port

Protocol Specify protocol used Metasys_N2

Baud* Specify baud rate

Parity* Specify parity

Data_Bits* Specify data bits

Stop_Bits* Specify stop bits

Handshaking* Specify hardware handshaking

Poll _Delay* Time between internal polls

Line_Drive_On*

Line_Drive_Off*

Example

// Client Side Connections

Connections

Port, Protocol

R1, Metasys_N2

Specify which port the device is

connected to the FieldServer

Duration of RTS assert before

start of transmission

Duration of RTS assert after

end of transmission

P1-P8, R1-R21

9600

None

8

1

None

0

0.001s

0.000s

1

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction

manual for details of the ports available on specific hardware.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 8

FS-8700-19_Metasys_N2 Driver Manual Page 8 of 51

4.3. Client Side Node Descriptors

Section

Title

Nodes

Column

Title

Node_Name Provide name for node

Node_ID Station address of physical Server node 1-255

Protocol Specify protocol used Metasys_N2

Connection

Specify which port the device is connected to the

FieldServer

Identify type of device

If this parameter is omitted the driver treats the

configuration as a N2Open configuration and marks

the Node_Type as N2OpenClient when using Ruinet

Node_Type

to check the Node parameters.

If the Node_Type is specified as N2Open then the

driver still acts as N2 Open configuration but some

legacy port expander functionality used in some

legacy advanced configuration is enabled.

Example

// Client Side Nodes

Nodes

Node_Name, Node_ID, Protocol, Connection, Node_Type

PLC 1, 1, Metasys_N2, P8, VMA

Function Legal Values

Up to 32

alphanumeric

characters

P1-P8, R1-R2

1

N2OpenClient,

DX9100, VMA,

N2Open

4.4. Client Side Map Descriptors

4.4.1. FieldServer Related Map Descriptor Parameters

Column Title Function Legal Values

Map_Descriptor_Name

Name of this Map

Descriptor

Name of Data Array

Data_Array_Name

where data is to be

stored in the FieldServer

Data_Array_Offset

Function

Starting location in Data

Array

Function of Client Map

Descriptor

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Up to 32 alphanumeric

characters

One of the Data Array names

from “Data Array” section

above

0 to maximum specified in

“Data Array” section above

RDBC, WRBC, WRBX

Page 9

FS-8700-19_Metasys_N2 Driver Manual Page 9 of 51

4.4.2. Driver Related Map Descriptor Parameters

4.4.2.1. N2Open Map Descriptor Parameters

Column Title Function Legal Values

One of the node names

Node_Name Name of Node to fetch data from

Data_Type Data type

Length Length of Map Descriptor 1

Address Starting address of read block 1-256

Used to specify an N2-specific

MN2_Function*

function, e.g. COS. See

description below.

Used to specify the attribute if an

MN2_Attribute*

attribute other than Current Value

is to be accessed. See attribute

table below

specified in “Client Node

Descriptor” above

If the vendor device lists a

point as BD then use

Data_Type=Byte.

If the vendor device lists a

point as ADI then use

Data_Type=Integer.

If the vendor device lists a

point as ADF then use

Data_Type=Float_Reg.

AI, AO, DI, DO,

Float_Reg, Integer, Byte

COS, Override, Release

See

N2Open Attribute Table

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 10

FS-8700-19_Metasys_N2 Driver Manual Page 10 of 51

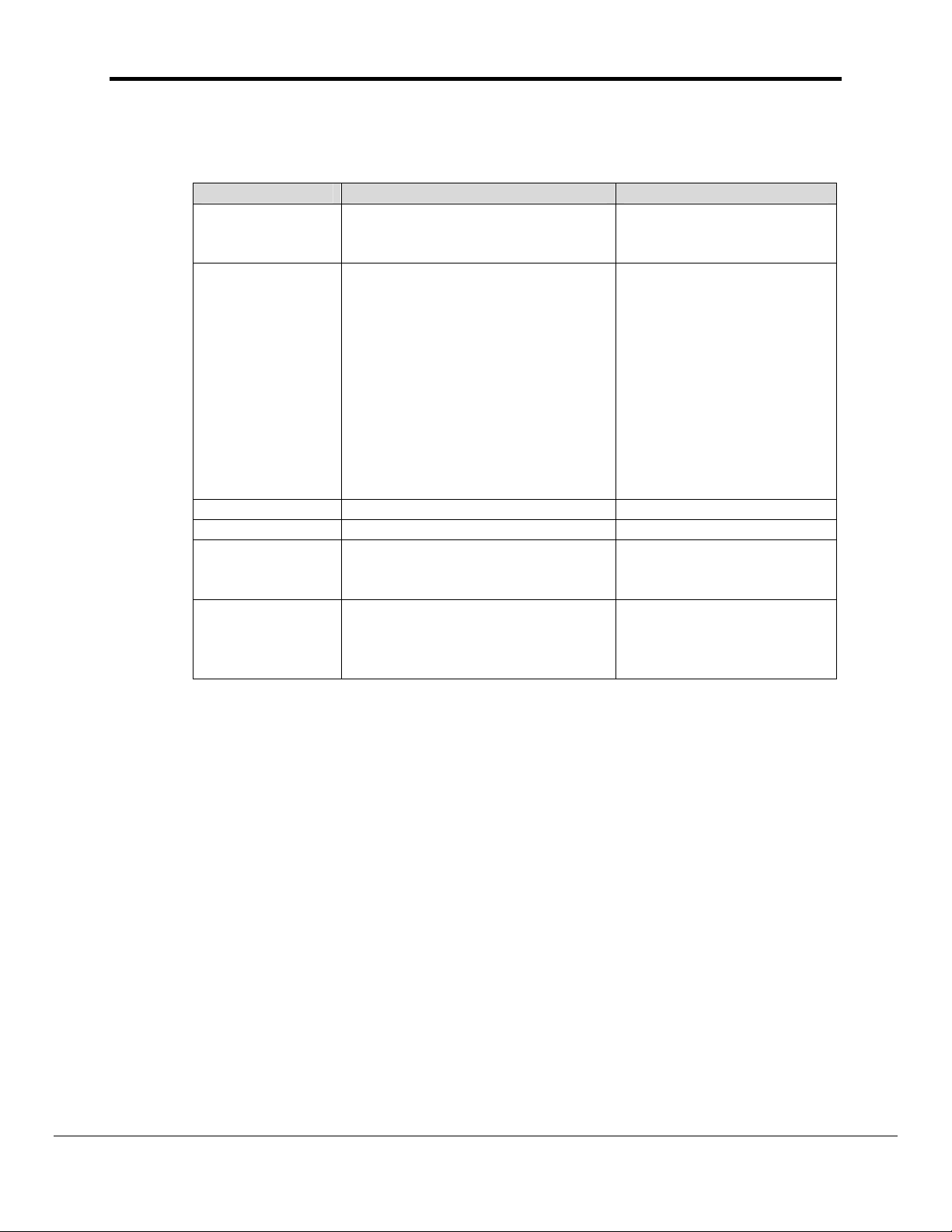

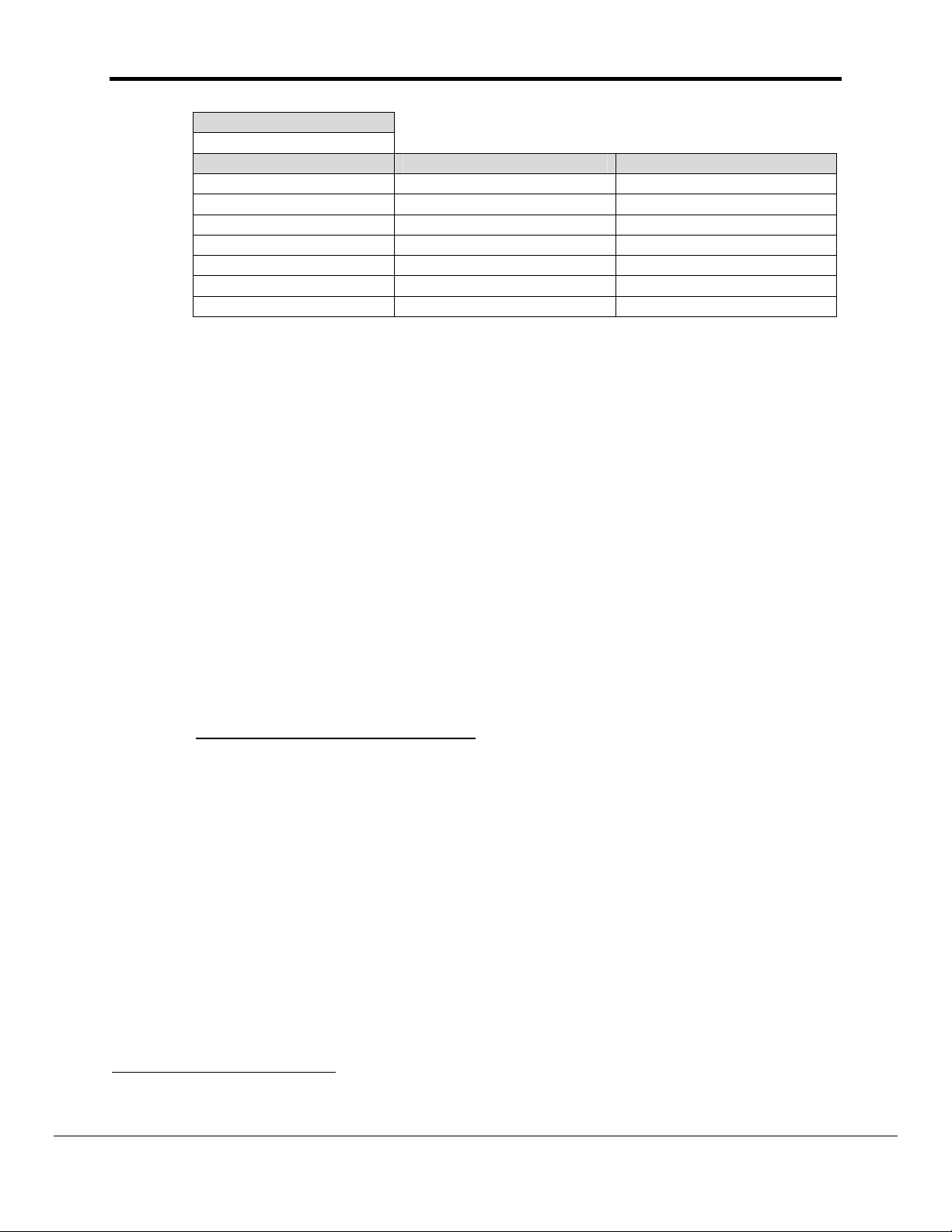

N2Open Attribute Table

Data Type Attribute No. Attribute

Analog Input

Binary Input

Analog Output

Binary Output

Internal Float

Internal Integer

Internal Byte

1

2

3

4

5

6

7

8

1

2

1

2

3

1

2

3

4

5

1

2

1

2

1

2

Object Configuration

Object Status

Analog Input Value

Low Alarm Limit

High Alarm Limit

Low Warn Limit

High Warn Limit

Differential

Object Configuration

Object Status

Object Configuration

Object Status

Current Value

Object Configuration

Object Status

Minimum On-Time

Minimum Off-Time

Maximum Cycles/Hour

Object Status

Current Value

Object Status

Current Value

Object Status

Current Value

Using Change of State (COS) – N2Open

If a large number of points are to be monitored, optimal efficiency is achieved by

using the COS mechanism instead of reading each individual point directly. A

N2Open device responds to a COS poll with a change record if a change has taken

place. On startup the device will report the state of all its points when it receives a

COS poll.

Two kinds of Map Descriptors are required for every node that is to be monitored

using COS:

A COS polling Map Descriptor with Function set to COS_Poll.

A COS_Read (i.e. Function set to COS_Read) Map Descriptor for every point

on that node that is to be monitored. Any COS records received will be stored to

the matching Map Descriptor data location.

Note that the COS_Read Map Descriptor has an optional scan_interval. If a value is

set the Map Descriptor will poll at that rate in addition to receiving COS data. This

can be used if the values are to be refreshed continually even if they don’t change. If

the scan_interval is not configured (through omitting the column, or by setting the

value to ‘-‘) the COS_Read Map Descriptor will not cause active polls once the value

has been initialized. See 4.4.4 for example.

Important Note on COS Operation in N2Open

Please be aware that N2Open devices will only report value changes under the

following conditions:

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 11

FS-8700-19_Metasys_N2 Driver Manual Page 11 of 51

Point Type Conditions that will trigger a COS report

point status change (e.g. override)

AI

AO

BI, BO

ADI, ADF, BD

change in alarm or warning status

NB: no value changes within the normal band are reported by COS!

point status change (e.g. override)

NB: no value changes within the normal band are reported by COS!

point status change (e.g. override); includes current value (On/Off)

none; COS cannot be used with internal data types.

Using Override and Release – N2Open

It is not normally necessary to use the Override command explicitly as the

FieldServer automatically uses this command when the Current Value attribute of a

point is written. For any other attribute it uses the Write command. It will sometimes

be necessary to send a Release command to an overridden point, however. To do

this, a Map Descriptor must be configured with Function set to wrbx and

MN2_Function set to Release. Then, when any value is stored to the Map

Descriptor data location, the Release command will be sent to the N2Open point

specified by the Map Descriptor.

4.4.2.2. VMA Map Descriptor Parameters

Column Title Function Legal Values

One of the node names

specified in “Client Node

Descriptor” above

Node_Name

Name of Node to fetch

data from

AI, AO, DI, DO, Driver

Data_Type Data type

(used for ADF, ADI and

BD)

Length Length of Map Descriptor 1

Address

Starting address of read

block

1-256

Data type specifier to be

MN2_Type

set when Data_Type has

5-7

been set to Driver

ADI, ADF and BD types: using the “Driver” Data_Type and MN2_Type fields

The VMA protocol uses a byte value to specify the data types. The standard types

AI, AO, DI and DO correspond to a byte value of 1 through 4 respectively. The types

ADF, ADI and BD are believed to correspond to a byte value of 5 through 7

respectively. If the user wishes to use any other type value based on knowledge of a

particular VMA configuration, then that value may also be specified here. Refer to

Section 4.4.5 for a specific example.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 12

FS-8700-19_Metasys_N2 Driver Manual Page 12 of 51

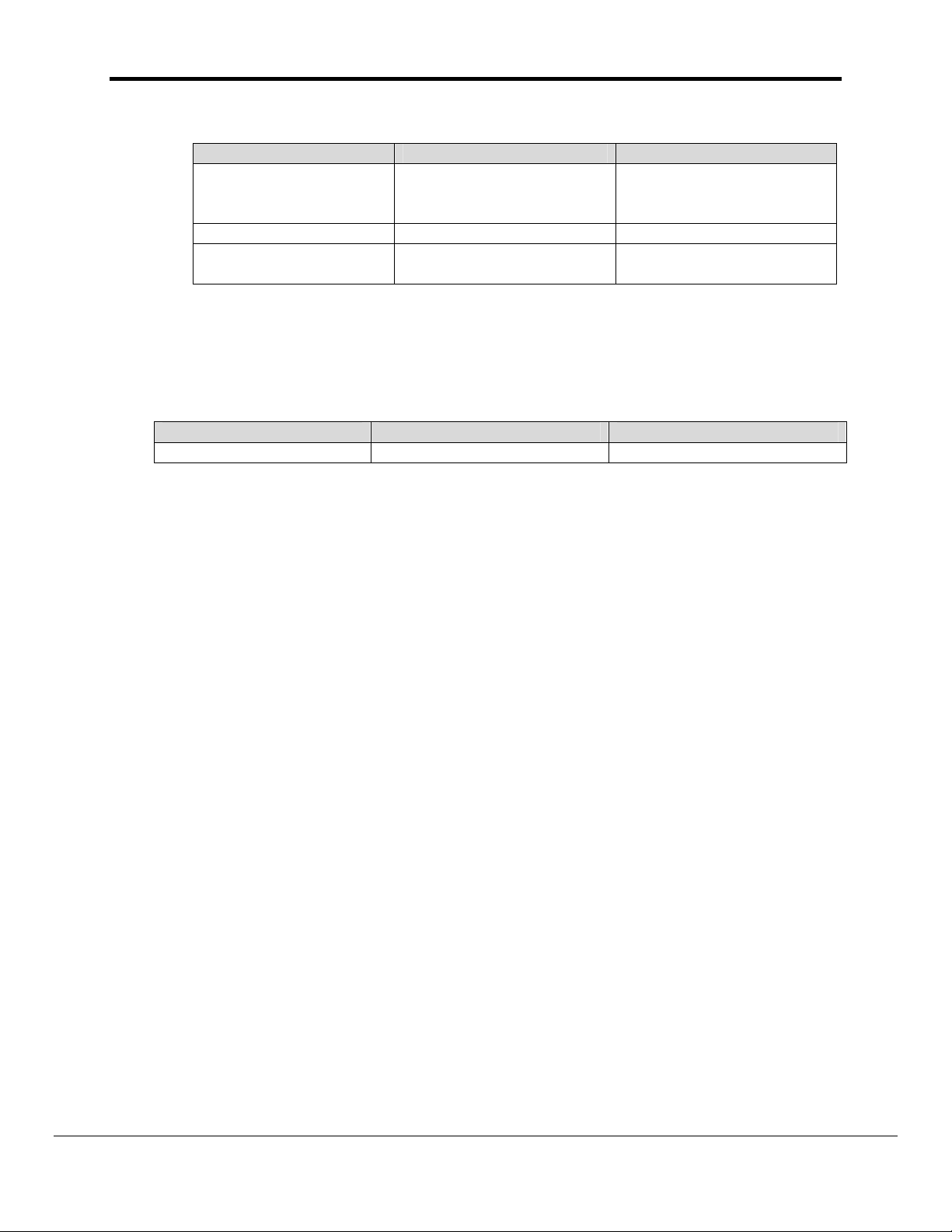

Driver Data_Type

MN2_Type values

Point Type Known Value

2

Suggested Value

3

AI 1

AO 2

BI 3

BO 4

ADF 5

ADI 6

BD 7

If a large number of points are to be monitored, optimal efficiency is achieved by

using the COS mechanism instead of reading each individual point directly. An

N2Open device responds to a COS poll with a change record if a change has taken

place. On startup the device will report the state of all its points when it receives a

COS poll.

Three kinds of Map Descriptors are required for every node that is to be monitored

using COS:

• A COS initialization Map Descriptor with Function set to ARS and

MN2_Function set to COS_Enable. This Map Descriptor enables COS polling

of those points on the VMA for which Passive Map Descriptors exist.

• A COS polling Map Descriptor with Function set to rdbc and MN2_Function set

to COS.

• A Passive (i.e. Function set to Passive) Map Descriptor for every point on that

node that is to be monitored. Any COS records received will be stored to the

matching Map Descriptor data location.

See example in Section 4.4.5

Using Override and Release - VMA

It is normally not necessary to use the Override command explicitly as the

FieldServer automatically uses this command when the Current Value attribute of a

point is written. For any other attribute it uses the Write command. It will sometimes

be necessary to send a Release command to an overridden point, however. To do

this, a Map Descriptor must be configured with Function set to wrbx and

MN2_Function set to Release. Then, when any value is stored to the Map

Descriptor data location, the Release command will be sent to the VMA point

specified by the Map Descriptor.

Note: The VMA Release function only works for analog and binary inputs (AI and

BI). Outputs may be restored to their original value using an explicit write command.

2

For information only. Do not use Driver type for these, but specify AI, AO, BI or BO directly in the Data_Type field.

3

These values are believed to be correct for the corresponding point types, but no guarantee can be given at this time.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 13

FS-8700-19_Metasys_N2 Driver Manual Page 13 of 51

4.4.2.3. DX9100 Map Descriptor Parameters

Column Title Function Legal Values

One of the node names

specified in “Client Node

Descriptor” above

Node_Name

Name of Node to fetch

data from

Length Length of Map Descriptor 1

Address

Starting address of read

block

0 - 2397

For DX9100 addresses please refer to the DX9100 user documentation. This lists

the name, function (read/write) and data format of all available points. Alternatively,

obtain assistance from FieldServer Technical Support.

4.4.3. Timing Parameters

Column Title Function Legal Values

Scan_Interval Rate at which data is polled ≥0.001s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 14

Release function used in conjunction with

wrbx. If the Data Array value specified in this

Map Descriptor is changed, then a Release

command is sent to the specified point.

Node_name Address Data_Type Scan_Interval

MN2_Function

,

COS_Read Map

Descriptor sets point type

the same as normal read

Map Descriptor. Optional

scan_interval.

COS_Poller Map

Descriptor. This only

specifies the

Function, Node and

Scan_Interval.

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

4.4.4. Map Descriptor Example 1 – N2Open

Normal read Map Descriptor.

Note RDBC function,

Data_Type and Address

specification.

FS-8700-19_Metasys_N2 Driver Manual Page 14 of 51

// Client Side Map Descriptors

Map_Descriptors

Map_Descriptor_Name, DA_Name, DA_Offset, Function,

COS_POLLER, DA_COS, 0, COS_Poller, -, Node_A, -, -, 30s

AI_READ, DA_AI3, 0, RDBC, -, Node_A, 1, Ana_Input 5s

BI_BY_COS, DA_BI, 3, COS_Read, -, Node_A, 2, Dig_Input, 10

AI_BY_COS, DA_AI3, 1, COS_Read, -, Node_A, 1, Ana_Input, -

AI_1_Release, DA_Release, 0, WRBX, Release, Node_A, 1, Ana_Input, -

Note:

To get change of state (COS) reports from an analog port, the warning/alarm levels need to be configured. If the alarm/warning

values are not known, then it would be better to configure an RDBC Map Descriptor which reads the analog input directly. Limits will

then not be required.

4.4.5. Map Descriptor Example 2 - VMA

// Client Side Map Descriptors

Map_Descriptors

Map_Descriptor_Name, DA_Name, DA_Offset, Function, MN2_Function, Node_name, Address, Data_Type, MN2_Type, Scan_Interval

AI_READ, DA_AI3, 0, RDBC, -, Node_VMA, 1, Ana_Input -, 5s

Special_type, DA_DRV, 10, RDBC, -, Node_VMA, 23, Driver, 5, 10s

AO_WRITE, DA_AO, 0, WRBX, -, Node_VMA, 3, Ana_Output, -, 30s

AO_Release, DA_AO, 0, WRBX, Release, Node_VMA, 3, Ana_Output, -, -

Override release function configured as wrbx. Driver type 5 (ADF) configured here.

Page 15

The address alone is sufficient to specify DX9100

point. The Data Type is determined by the device.

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

4.4.6. Map Descriptor Example 3 - DX9100

FS-8700-19_Metasys_N2 Driver Manual Page 15 of 51

// Client side Map Descriptors

Map_Descriptors

Map_Descriptor_Name, DA_Name, DA_Offset, Function, Node_name, Address, Scan_Interval

D191_ZN1-T, DA_AI3, 0, RDBC, Node_DX, 1223, 5s

D191_ZN1-S, DA_AO3, 0, WRBX, Node_DX, 1225, -

Page 16

FS-8700-19_Metasys_N2 Driver Manual Page 16 of 51

5. Configuring the FieldServer as a Metasys N2 Server

For a detailed discussion on FieldServer configuration, please refer to the FieldServer

Configuration Manual. The information that follows describes how to expand upon the factory

defaults provided in the configuration files included with the FieldServer (See “.csv” files on the

driver diskette).

This section documents and describes the parameters necessary for configuring the FieldServer

to communicate with a Metasys N2Open Client. Note that only the N2Open variation of the

N2 protocol may be used when configuring the FieldServer as a Server.

The configuration file tells the FieldServer about its interfaces, and the routing of data required.

In order to enable the FieldServer for Metasys N2 communications, the driver independent

FieldServer buffers need to be declared in the “Data Arrays” section, the FieldServer virtual

node(s) needs to be declared in the “Server Side Nodes” section, and the data to be provided to

the Clients needs to be mapped in the “Server Side Map Descriptors” section. Details on how to

do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value being the

default.

5.1. Server Side Connection Descriptors

Section Title

Connections

Column Title Function Legal Values

Port

Specify which port the device is

connected to the FieldServer

P1-P8, R1-R24

Protocol Specify protocol used Metasys_N2

Baud* Specify baud rate

Parity* Specify parity

Data_Bits* Specify data bits

Stop_Bits* Specify stop bits

Handshaking* Specify hardware handshaking

Poll _Delay* Time between internal polls

Line_Drive_On*

Line_Drive_Off*

Duration of RTS assert before

start of transmission

Duration of RTS assert after

end of transmission

9600

None

8

1

None

0

0.001s

0.000s

Example

// Server Side Connections

Connections

Port, Protocol

P8, Metasys_N2

4

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction

manual for details of the ports available on specific hardware.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 17

FS-8700-19_Metasys_N2 Driver Manual Page 17 of 51

5.2. Server Side Node Descriptors

Section Title

Nodes

Column Title Function Legal Values

Up to 32

Node_Name Provide name for node

Node_ID

MetasysN2 station address of physical

Server node

Protocol Specify protocol used Metasys_N2

Specifies time FieldServer will reserve

Server_Hold_Timeout*

Server side connection while waiting for the

Client side to update data in Data_Array

Identify type of device

This parameter need not be specified. The

Node_Type*

Server side of the driver can only operate

as an N2 Server and the option for setting it

to N2Open is purely for backward

compatibility.

Example

// Server Side Nodes

Nodes

Node_Name, Node_ID, Protocol

PLC 1, 1, Metasys_N2

alphanumeric

characters

1-255

< 0.175s5

N2OpenServer,

N2Open

5

Can be set to >0.175s if the Client has bee set to timeout after >200ms. Refer to Appendix E for more

information.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 18

FS-8700-19_Metasys_N2 Driver Manual Page 18 of 51

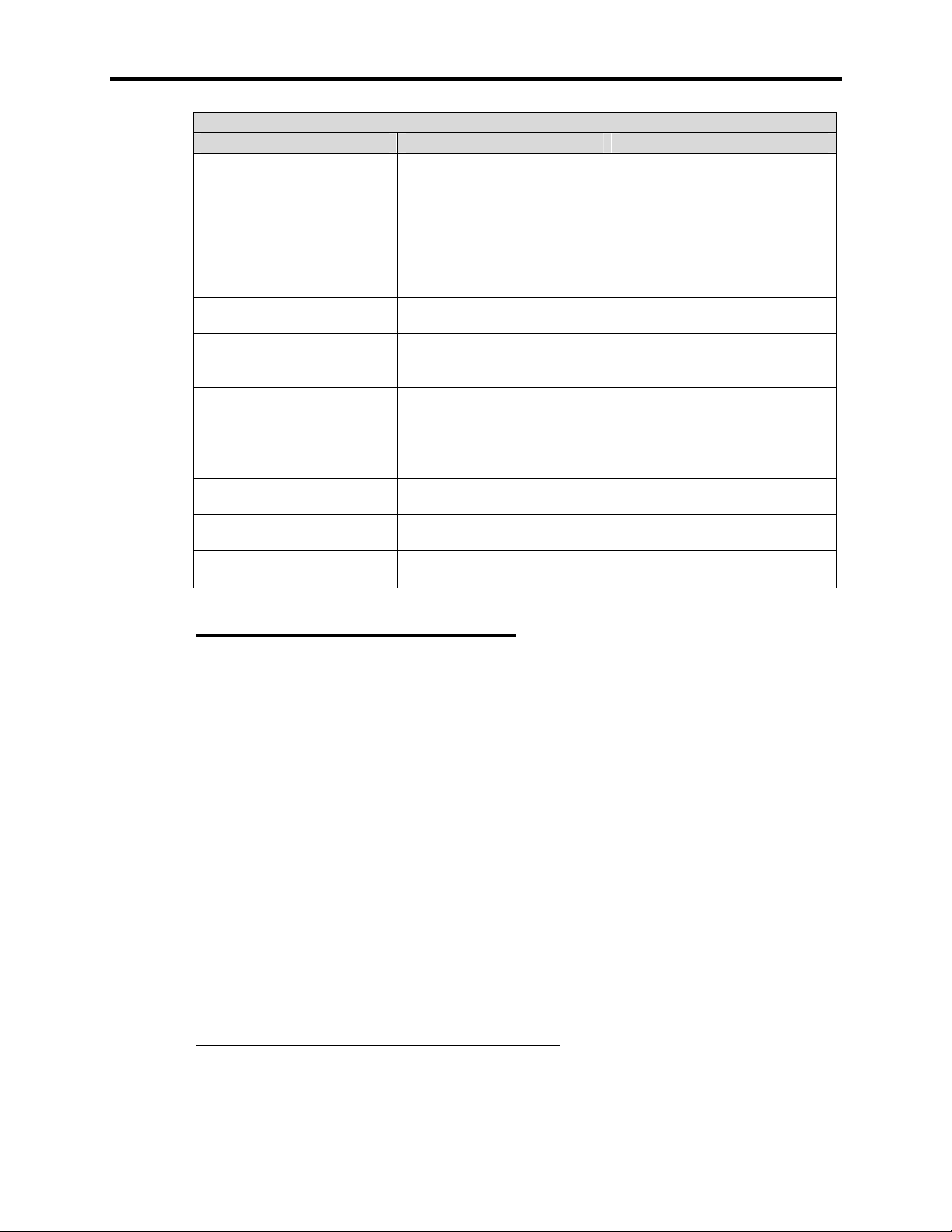

5.3. Server Side Map Descriptors

5.3.1. FieldServer Specific Map Descriptor Parameters

Column Title Function Legal Values

Map_Descriptor_Name

Data_Array_Name

Data_Array_Offset

Function

Name of this Map

Descriptor

Name of Data Array where

data is to be stored in the

FieldServer

Starting location in Data

Array

Function of Server Map

Descriptor

Up to 32 alphanumeric

characters

One of the Data Array

names from “Data Array”

section above

0 to maximum specified in

“Data Array” section above

Server

5.3.2. Driver Specific Map Descriptor Parameters

Column

Title

Node_Name

Data_Type Data type

Length

Address

Function Legal Values

Name of Node to

fetch data from

Length of Map

Descriptor

Starting address of

read block

One of the node names specified in “Client

Node Descriptor” above

If the vendor device lists a point as BD then

use Data_Type=Byte.

If the vendor device lists a point as ADI then

use Data_Type=Integer.

If the vendor device lists a point as ADF then

use Data_Type=Float_Reg.

AI, AO, DI, DO, Float_Reg, Integer, Byte

1 - 256

1 - 256

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 19

Note that a single Server Map

Descriptor of length 256 can

represent all possible points of

one type (e.g. AI).

The Server function tells the

FieldServer that this Map

Descriptor makes data

available to a Client sending

polls to the FieldServer.

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

The Data_Array_Offset sets

the start of the data range

covered by the Server Map

Descriptor. The number of

points included is determined

by the Length field.

5.3.3. Map Descriptor Example.

FS-8700-19_Metasys_N2 Driver Manual Page 19 of 51

// Server Side Map Descriptors

Map_Descriptors

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Data_Type, Function, Node_name, Address, Length

A1, DA_AI3, 10, Ana_Input, Server, Node_A, 1, 256

Page 20

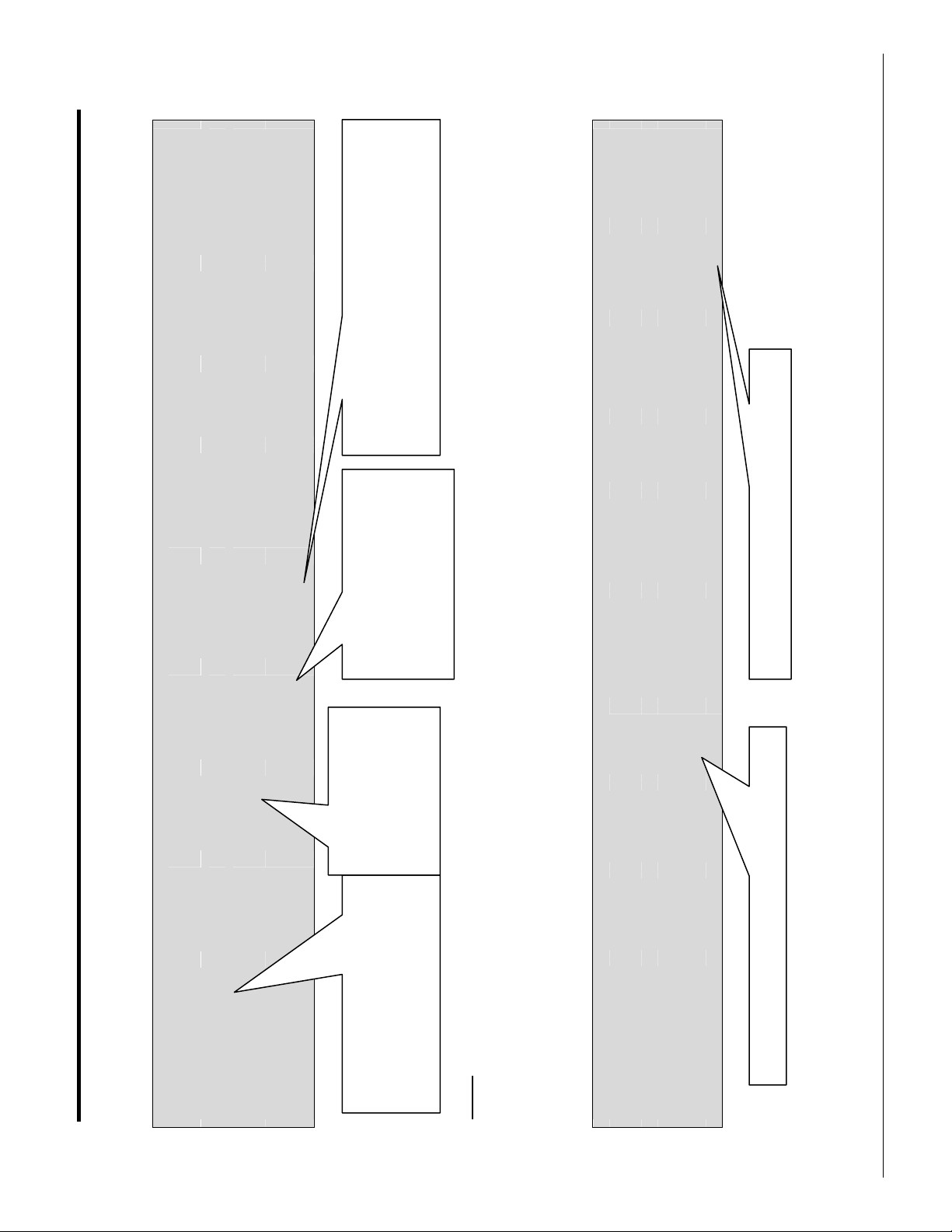

6

Low byte of

High byte of

Address 1

Address 5

Address 1

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

The status bit will indicate the actual status of the output in the field. This bit cannot be

modified by the FieldServer as it is read only, and is meant for actual status display.

The control bit will allow the FieldServer to write a command to the DX9100 for the associated

output. This command will only execute if the override is enabled by the override bit.

The override bit must be set to enable an output to be written to by the FieldServer. If this is

not set, then the control bit will be ignored.

When writing to DX9100 Binary Outputs, it is important to understand that each binary output has three bits associated with it as

described in the table below:

Bit Description Address

Output

status bit

Output

control bit

Override bit

Example

The example below better illustrates the mapping that is typically needed to deal with DX9100 Binary Outputs. Note that since all

6 outputs are packed into word format when transmitted, a Packed_Bit Array is typically required to access the bits individually.

Appendix A.1. Writing to DX9100 Binary Outputs

FS-8700-19_Metasys_N2 Driver Manual Page 20 of 51

Appendix A. Advanced Topics

In this Example, the status for BO3-BO8 can be found in offsets 0-5 of DA_PO1_02, the control bits can be found in offsets 0-5 of

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length

DA_PO1_01 , Packed_Bit , 100

DA_PO1_02 , Packed_Bit , 100

Map_Descriptors

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Address, Scan_Interval

CMD_DO1_05 , DA_PO1_01 , 0 , Rdbc , Dev_30 , 0001 , 1.0s // DO3 -

DA_PO1_01, and the override bits can be found in offsets 8-13 of DA_PO1_01.

CMD_DO1_06 , DA_PO1_02 , 0 , Rdbc , Dev_30 , 0005 , 1.0s // DO3 - DO8 Status

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Binary Outputs start at address 3, so the first bit of each of these addresses will represent B03

6

Page 21

FS-8700-19_Metasys_N2 Driver Manual Page 21 of 51

Appendix A.2. Managing Analog Inputs and Outputs for DX9100.

Relative offset for viewing an AI is 7

Relative offset for viewing and forcing an AO is 6

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 22

FS-8700-19_Metasys_N2 Driver Manual Page 22 of 51

Appendix B. Troubleshooting tips

Appendix B.1. Connection Tips & Hints

When using the FieldServer as an N2 Client, make very sure that it is the only Client /

master on the N2 network. If there is another Client on the network there will be

communication conflicts. These will be reflected on the FieldServer as protocol errors.

Appendix B.2. Offline Behavior

When the Client node on the FieldServer goes offline, the corresponding data objects on the

FieldServer are also marked offline. If a client polls a virtual FieldServer node for this

particular data, therefore, an offline response will be returned by the FieldServer. A request

from an master device for a FieldServer to identify itself would be met by a valid response,

however. This could lead to confusion and status toggling. This can be addressed using

Responsible Map Descriptors and by configuring the virtual FieldServer using the

Offline_Method option. Please refer to the Configuration Manual for further information.

Appendix B.3. Tip on Overrides

It is important that there be only one device (including the slave device itself) updating a

point which is in overridden mode. The reason for this is that the value of the point could be

changed by an update from a non-Metasys Server before the override is released by the

Metasys Master. In this case, the FieldServer would respond to a poll from the Master with

this changed data.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 23

FS-8700-19_Metasys_N2 Driver Manual Page 23 of 51

Jmpr 17 in 485 position.

Jmpr 16 in 485 position.

Jmpr 18 in 485 position.

Appendix C. Setting up FS-B20 for RS-485

Appendix C.1. Jumper Settings:

Jumpers jp16, jp17, and jp18 need to be transferred from pins 1-2 to pins 2-3 in order to

enable RS-485. These jumpers can be found just behind the RJ45 ports inside the box

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 24

FS-8700-19_Metasys_N2 Driver Manual Page 24 of 51

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 25

FS-8700-19_Metasys_N2 Driver Manual Page 25 of 51

Appendix C.2. Hardware connections

The FS-8917-16 pigtail cable is typically used for this port arrangement. Connection is

depicted in the following diagram.

SERIAL

FS-X20

RJ45 Male Modular

Jack

ORANGE/WHITE

(RJ45-08)

BROWN

(RJ45-01)

+

-

G

RJ45 M ale M odular Jack

Appendix C.3. Configuration Settings

BLUE/WHITE

(RJ45-04)

12345678

FS-8917-16

12345678

RJ45 Female M o dular J ack

• The Port address in the Configuration needs to be set to R1 instead of P1.

• Line_Drive_On and Line_Drive_Off need to be defined in the connections section of the

configuration file. These need to be set to at least 0.001s. Refer to Sections 4.2 and 5.1

for more information.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 26

FS-8700-19_Metasys_N2 Driver Manual Page 26 of 51

Appendix D. Memory Maps

Appendix D.1. Metasys DX9100 Memory Map

Module 1 64 0040H

Module 2 160 00A0H

Module 3 256 0100H

Module 4 352 0160H

Module 5 448 01C0H

Module 6 544 0220H

Module 7 640 0280H

Module 8 736 02E0H

Module 9 832 0340H

Module 10 928 03A0H

Module 11 1024 0400H

Module 12 1120 0460H

Module 1 1216 04C0H

Module 2 1232 04D0H

Module 3 1248 04E0H

Module 4 1264 04F0H

Module 5 1280 0500H

Module 6 1296 0510H

Module 7 1312 0520H

Module 8 1328 0530H

Module 1 1344 0540H

Module 2 1360 0550H

Version 2 or later (new for version 6.0):

Module 9 2304 0900H

Module 10 2320 0910H

Module 11 2336 0920H

Module 12 2352 0930H

Module 13 2368 0940H

Module 14 2384 0950H

Module 3 1376 0560H

Module 4 1392 0570H

Module 5 1408 0580H

Module 6 1424 0590H

Module 7 1440 05A0H

Module 8 1456 05B0H

Module 1 1472 05C0H

Module 2 1552 0610H

Module 3 1632 0660H

Module 4 1712 06B0H

Module 5 1792 0700H

Module 6 1872 0750H

Module 7 1952 07A0H

Module 8 2032 07F0H

Module 1 2112 0840H

Module 2 2128 0850H

Module 3 2144 0860H

Module 4 2160 0870H

Module 5 2176 0880H

Module 6 2192 0890H

Module 7 2208 08A0H

Module 8 2224 08B0H

Module 1 2240 08C0H

Module 2 2272 08E0H

Programmable modules

Analog input modules

Analog output modules

Digital output modules

Extension modules

Time schedule modules

Optimal start / stop module

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 27

FS-8700-19_Metasys_N2 Driver Manual Page 27 of 51

General control module

Relative Item Signal Condition Read/Write Johnson Tag Description

0 Byte Read UNIT Device model. For DX-9100 always 5

1 Word Write SUP Supervisory central control

2 Byte Read MNT Maintenance control

3 Word Read DIAG Diagnistics

4 Byte Read DICT Digital input counters

5 Byte Read TOS Triac output status

6 Byte Read DIS Digital input status

7 Word Read AIS Analog input status

8 Word Read LRST1 Logic results 37637

9 Word Read LRST2 Logic results 17-32

10 Word Write LCOS1 Logic constants 37637

11 Word Write LCOS2 Logic constants 17-32

12 - - - Spare

13 LONG Write CNTR1 DI1 pulse count

14 LONG Write CNTR2 DI2 pulse count

15 LONG Write CNTR3 DI3 pulse count

16 LONG Write CNTR4 DI4 pulse count

17 LONG Write CNTR5 DI5 pulse count

18 LONG Write CNTR6 DI6 pulse count

19 LONG Write CNTR7 DI7 pulse count

20 LONG Write CNTR8 DI8 pulse count

21 Word Write PASS Password code

22 Byte Write PC1 Prescaler DI1 counter

23 Byte Write PC2 Prescaler DI2 counter

24 Byte Write PC3 Prescaler DI3 counter

25 Byte Write PC4 Prescaler DI4 counter

26 Byte Write PC5 Prescaler DI5 counter

27 Byte Write PC6 Prescaler DI6 counter

28 Byte Write PC7 Prescaler DI7 counter

29 Byte Write PC8 Prescaler DI8 counter

30 Byte Write UIA User interface address

31 Word Write ALD@ Alarm disable condition source

32 Byte Write DXS1 DX-9100 type settings

33 Word Write ALG Standard algorithm type

34 FP Write ACO1 Analog constant 1

35 FP Write ACO2 Analog constant 2

36 FP Write ACO3 Analog constant 3

37 FP Write ACO4 Analog constant 4

38 FP Write ACO5 Analog constant 5

39 FP Write ACO6 Analog constant 6

40 FP Write ACO7 Analog constant 7

41 FP Write ACO8 Analog constant 8

42 Byte Write PLCNT PLC control and status

43 Word Read PLCPC PLC program counter

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 28

FS-8700-19_Metasys_N2 Driver Manual Page 28 of 51

Programmable Module Type

Relative Item Signal Condition Read/Write Johnson Tag Description

0 Byte Write PMTYP Programmable module type

1 Word Write PMOPT Programmable module options

2 Byte Write PMF1 Function channel number 1 - F1

3 Byte Write PMF2 Function channel number 2 - F2

4 Byte Write PMF3 Function channel number 3 - F3

5 Byte Write PMF4 Function channel number 4 - F4

6 Byte Write PMF5 Function channel number 5 - F5

7 Byte Write PMF6 Function channel number 6 - F6

8 Byte Write PMF7 Function channel number 7 - F7

9 Byte Write PMF8 Function channel number 8 - F8

10 Word Write PMI1@ Input connection - I1@

11 Word Write PMI2@ Input connection - I2@

12 Word Write PMI3@ Input connection - I3@

13 Word Write PMI4@ Input connection - I4@

14 Word Write PMI5@ Input connection - I5@

15 Word Write PMI6@ Input connection - I6@

16 Word Write PMI7@ Input connection - I7@

17 Word Write PMI8@ Input connection - I8@

18 Word Write PMI9@ Input connection - I9@

19 Word Write PMI10@ Input connection - I10@

20 Word Write PMI11@ Input connection - I11@

21 Word Write PMI12@ Input connection - I12@

22 Word Write PMI13@ Input connection - I13@

23 Word Write PMI14@ Input connection - I14@

24 Word Write PMI15@ Input connection - I15@

25 Word Write PMI16@ Input connection - I16@

26 FP Write PMK01 Module constant - K1

27 FP Write PMK02 Module constant - K2

28 FP Write PMK03 Module constant - K3

29 FP Write PMK04 Module constant - K4

30 FP Write PMK05 Module constant - K5

31 FP Write PMK06 Module constant - K6

32 FP Write PMK07 Module constant - K7

33 FP Write PMK08 Module constant - K8

34 FP Write PMK09 Module constant - K9

35 FP Write PMK10 Module constant - K10

36 FP Write PMK11 Module constant - K11

37 FP Write PMK12 Module constant - K12

38 FP Write PMK13 Module constant - K13

39 FP Write PMK14 Module constant - K14

40 FP Write PMK15 Module constant - K15

41 FP Write PMK16 Module constant - K16

42 FP Write PMK17 Module constant - K17

43 FP Write PMK18 Module constant - K18

44 FP Write PMK19 Module constant - K19

45 FP Write PMK20 Module constant - K20

46 FP Write PMK21 Module constant - K21

47 FP Write PMK22 Module constant - K22

48 FP Write PMK23 Module constant - K23

49 FP Write PMK24 Module constant - K24

50 FP Write PMK25 Module constant - K25

51 FP Write PMK26 Module constant - K26

52 FP Write PMK27 Module constant - K27

53 FP Write PMK28 Module constant - K28

54 FP Write PMK29 Module constant - K29

55 FP Write PMK30 Module constant - K30

56 FP Write PMK31 Module constant - K31

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 29

FS-8700-19_Metasys_N2 Driver Manual Page 29 of 51

Programmable Module Type

Relative Item Signal Condition Read/Write Johnson Tag Description

57 FP Write PMK32 Module constant - K32

58 FP Write PMK33 Module constant - K33

59 FP Write PMK34 Module constant - K34

60 FP Write PMOU1 Output channel 1

61 FP Write PMOU2 Output channel 2

62 FP Write PMOU3 Output channel 3

63 FP Write PMOU4 Output channel 4

64 FP Write PMOU5 Output channel 5

65 FP Write PMOU6 Output channel 6

66 FP Write PMOU7 Output channel 7

67 FP Write PMOU8 Output channel 8

68 FP Write PMAX1 Auxiliary output 1

69 FP Write PMAX2 Auxiliary output 2

70 Byte Write PMHDC Hold mode control/status

71 Byte Write PMDO Logic output control and status

72 Word Read PMST Programmable module status

73 LONG Write PMAC1 Accumulator channel 1

74 LONG Write PMAC2 Accumulator channel 2

75 LONG Write PMAC3 Accumulator channel 3

76 LONG Write PMAC4 Accumulator channel 4

77 LONG Write PMAC5 Accumulator channel 5

78 LONG Write PMAC6 Accumulator channel 6

79 LONG Write PMAC7 Accumulator channel 7

80 LONG Write PMAC8 Accumulator channel 8

Analog Input Modules

Relative Item Signal Condition Read/Write Johnson Tag Description

0 Word Write AIT Analog inout type

1 FP Write HR High range input

2 FP Write LR Low range input

3 FP Write HIA High alarm limit

4 FP Write LOA Low alarm limit

5 FP Write FTC Filter constant

6 FP Write ADF Differential on alarm limit (units)

7 FP Read AI Analog input value

8 FP Read AI% Analog input %

9 FP Read ADC Analog input in counts

10 Byte Read AIST Analog input status

Analog Output Modules

Relative Item Signal Condition Read/Write Johnson Tag Description

0 Byte Write AOT Analog output type

1 Word Write AO@ Source of analog output module

2 Word Write AOF@ Output forcing logic connection

3 FP Write HRO Output high range

4 FP Write LRO Output low range

5 FP Write OFL Output % value in forcing mode

6 FP Write OUT Output module output value %

7 Byte Write AOC Analog output control and status

8 FP Write HLO Output high limit

9 FP Write LLO Output low limit

10 Word Write INC@ DDC increase logic connection

11 Word Write DEC@ DDC decrease logic connection

12 Word Write ENL@ Limit function enable logic connection

Digital Output Modules

Relative Item Signal Condition Read/Write Johnson Tag Description

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 30

FS-8700-19_Metasys_N2 Driver Manual Page 30 of 51

Digital Output Modules

Relative Item Signal Condition Read/Write Johnson Tag Description

0 Byte Write DOT Digital output options

1 Word Write DO@ Source of digital output module

2 Word Write FB@ Source of feedback signal

3 Word Write DOF@ Output forcing logic connection

4 FP Write HRO Output high range

5 FP Write LRO Output low range

6 FP Write FST PAT output full stroke time/DAT cycle

7 FP Write DB PAT deadband

8 FP Write HLO Output high limit

9 FP Write LLO Output low limit

10 FP Write OFL Output % value in forcing mode

11 FP Write OUT Output module output value %

12 Byte Write DOC Logic output control and status

13 Word Write INC@ DDC increase logic connection

14 Word Write DEC@ DDC decrease logic connection

15 Word Write ENL@ Limit function enable logic connection

Extension Modules

Relative Item Signal Condition Read/Write Johnson Tag Description

0 Word Write XTIOMAP Extension module I/O map

1 Word Write XTIOTYP Extension module I/O type

2 Word Write XTIOMOD Extension module I/O mode

3 Byte Write XTADX Extension module address 0-255

4 Word Write XTI1@ Point connection - I1

5 Word Write XTI2@ Point connection - I2

6 Word Write XTI3@ Point connection - I3

7 Word Write XTI4@ Point connection - I4

8 Word Write XTI5@ Point connection - I5

9 Word Write XTI6@ Point connection - I6

10 Word Write XTI7@ Point connection - I7

11 Word Write XTI8@ Point connection - I8

12 FP Write XTHR01 High output range point 1

13 FP Write XTLR01 Low output range point 1

14 FP Write XTHR02 High output range point 2

15 FP Write XTLR02 Low output range point 2

16 FP Write XTHR03 High output range point 3

17 FP Write XTLR03 Low output range point 3

18 FP Write XTHR04 High output range point 4

19 FP Write XTLR04 Low output range point 4

20 FP Write XTHR05 High output range point 5

21 FP Write XTLR05 Low output range point 5

22 FP Write XTHR06 High output range point 6

23 FP Write XTLR06 Low output range point 6

24 FP Write XTHR07 High output range point 7

25 FP Write XTLR07 Low output range point 7

26 FP Write XTHR08 High output range point 8

27 FP Write XTLR08 Low output range point 8

28 FP Write XTHIA1 High alarm limit point 1

29 FP Write XTLOA1 Low alarm limit point 1

30 FP Write XTHIA2 High alarm limit point 2

31 FP Write XTLOA2 Low alarm limit point 2

32 FP Write XTHIA3 High alarm limit point 3

33 FP Write XTLOA3 Low alarm limit point 3

34 FP Write XTHIA4 High alarm limit point 4

35 FP Write XTLOA4 Low alarm limit point 4

36 FP Write XTHIA5 High alarm limit point 5

37 FP Write XTLOA5 Low alarm limit point 5

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 31

FS-8700-19_Metasys_N2 Driver Manual Page 31 of 51

Extension Modules

Relative Item Signal Condition Read/Write Johnson Tag Description

38 FP Write XTHIA6 High alarm limit point 6

39 FP Write XTLOA6 Low alarm limit point 6

40 FP Write XTHIA7 High alarm limit point 7

41 FP Write XTLOA7 Low alarm limit point 7

42 FP Write XTHIA8 High alarm limit point 8

43 FP Write XTLOA8 Low alarm limit point 8

44 Word Read XTAIS Extension module alarms

45 FP Read XTAI1 Analog input value 1

46 FP Read XTAI2 Analog input value 2

47 FP Read XTAI3 Analog input value 3

48 FP Read XTAI4 Analog input value 4

49 FP Read XTAI5 Analog input value 5

50 FP Read XTAI6 Analog input value 6

51 FP Read XTAI7 Analog input value 7

52 FP Read XTAI8 Analog input value 8

53 FP Write XTAO1 Analog output value 1

54 FP Write XTAO2 Analog output value 2

55 FP Write XTAO3 Analog output value 3

56 FP Write XTAO4 Analog output value 4

57 FP Write XTAO5 Analog output value 5

58 FP Write XTAO6 Analog output value 6

59 FP Write XTAO7 Analog output value 7

60 FP Write XTAO8 Analog output value 8

61 LONG Write XTDIC1 Digital input 1 pulse count

62 LONG Write XTDIC2 Digital input 2 pulse count

63 LONG Write XTDIC3 Digital input 3 pulse count

64 LONG Write XTDIC4 Digital input 4 pulse count

65 LONG Write XTDIC5 Digital input 5 pulse count

66 LONG Write XTDIC6 Digital input 6 pulse count

67 LONG Write XTDIC7 Digital input 7 pulse count

68 LONG Write XTDIC8 Digital input 8 pulse count

69 Byte Write XTCNT Extension module hold control

70 Byte Write XTDO Logic outputs control and status

71 Byte Read XTDI Logic inputs status

72 Byte Read XTSTC Extension module local status

Time schedule modules

Relative Item Signal Condition Read/Write Johnson Tag Description

0 Word Write TSOPT Time schedule options LSB

1 Word Write TSEX@ External extension logical connection

2 Word Write TSON@ On forcing logical connection

3 Word Write TSOF@ Off forcing logical connection

4 FP Write TSXTM Extension time (min)

5 FP Write TSTIM Time to next event (min)

6 Byte Write TSSTA Time schedule status

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 32

FS-8700-19_Metasys_N2 Driver Manual Page 32 of 51

Programmable modules

Module 1 64 0040H

Module 2 160 00A0H

Module 3 256 0100H

Module 4 352 0160H

Module 5 448 01C0H

Module 6 544 0220H

Module 7 640 0280H

Module 8 736 02E0H

Module 9 832 0340H

Module 10 928 03A0H

Module 11 1024 0400H

Module 12 1120 0460H

Analog input modules

Module 1 1216 04C0H

Module 2 1232 04D0H

Module 3 1248 04E0H

Module 4 1264 04F0H

Module 5 1280 0500H

Module 6 1296 0510H

Module 7 1312 0520H

Module 8 1328 0530H

Analog output modules

Module 1 1344 0540H

Module 2 1360 0550H

Version 2 or later (new for version 6.0):

Module 9 2304 0900H

Module 10 2320 0910H

Module 11 2336 0920H

Module 12 2352 0930H

Module 13 2368 0940H

Module 14 2384 0950H

Digital output modules

Module 3 1376 0560H

Module 4 1392 0570H

Module 5 1408 0580H

Module 6 1424 0590H

Module 7 1440 05A0H

Module 8 1456 05B0H

Extension modules

Module 1 1472 05C0H

Module 2 1552 0610H

Module 3 1632 0660H

Module 4 1712 06B0H

Module 5 1792 0700H

Module 6 1872 0750H

Module 7 1952 07A0H

Module 8 2032 07F0H

Time schedule modules

Module 1 2112 0840H

Module 2 2128 0850H

Module 3 2144 0860H

Module 4 2160 0870H

Module 5 2176 0880H

Module 6 2192 0890H

Module 7 2208 08A0H

Module 8 2224 08B0H

Optimal start / stop module

Module 1 2240 08C0H

Module 2 2272 08E0H

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 33

FS-8700-19_Metasys_N2 Driver Manual Page 33 of 51

Write

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Appendix D.2. Metasys DC9100 Memory Map

Note: The DC9100 is not currently supported by the FieldServer MetasysN2 Driver.

The information below is for interest and future use only.

PAGE 0

Item

DEC

0

1

2

3

4

5

6

7

8

9

Item

HEX

Signal Condition Read/

Byte Read MODL

FP Read INP1 Analog input 1

FP Read INP2 Analog input 2

FP Read INP3 Analog input 3

FP Read INP4 Analog input 4

FP Read INP5 Analog input 5

FP Read INP6 Analog input 6

FP Read INP7 Analog input 7

FP Read INP8 Analog input 8

FP Read NCM1 Numeric calculation modul result

Johnson

Tag

Description

Device model. Value always either 2 or

12

10 A FP Read NCM2 Numeric calculation modul result

11 B FP Read NCM3 Numeric calculation modul result

12 C FP Read NMC4 Numeric calculation modul result

13 D FP Write REC1 Remote constant 1

14 E FP Write REC2 Remote constant 2

15 F FP Write REC3 Remote constant 3

16

17

18

19

20

21

22

23

24

25

FP Write REC4 Remote constant 4

FP Write OUT1 Control output 1

FP Write OUT2 Control output 2

FP Write OUT3 Control output 3

FP Write OUT4 Control output 4

FP Write OUT5 Control output 5

FP Write OUT6 Control output 6

FP Write OUT7 Control output 7

FP Write OUT8 Control output 8

FP Write WSP1 Working setpoint 1

26 1A FP Write WSP2 Working setpoint 2

27 1B FP Write WSP3 Working setpoint 3

28 1C FP Write WSP4 Working setpoint 4

29 1D FP Write WSP5 Working setpoint 5

30 1E FP Write WSP6 Working setpoint 6

31 1F FP Write WSP7 Working setpoint 7

32

33

34

35

36

37

38

39

40

41

FP Write WSP8 Working setpoint 8

Word Read STW1 Status word 1

Word Read STW2 Status word 2

Word Read STW3 Status word 3

Word Read STW4 Status word 4

Word Read STW5 Status word 5

Word Read STW6 Status word 6

Word Read STW7 Status word 7

Word Read STW8 Status word 8

Word Write DOUT Logic output DDC control

42 2A Byte Write CHLD Hold mode control

43 2B Byte Write COMP Supervisory mode control

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 34

FS-8700-19_Metasys_N2 Driver Manual Page 34 of 51

Write

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

PAGE 0

Item

DEC

Item

HEX

Signal Condition Read/

Johnson

Tag

Description

44 2C - - Spare

45 2D - - Spare

46 2E Byte Write PV1@ Process variable connection

47 2F Byte Write RS1@ Remote setpoint connection

48

49

50

51

52

53

54

55

56

57

Byte Write RV1@ Reference variable connection

Byte Write PB1@ Proportional band connection

Byte Write OF1@ OFF mode logic control connection

Byte Write SB1@

STAND-BY mode logic control

connection

Byte Write RA1@ Reverse action logic control connection

Byte Write EF1@

External forcing logic control

connection

Byte Write TYPE1 Controller type

FP Write LS1 Local setpoint

FP Write PB1 Proportional band

FP Write TI1 Reset action

58 3A FP Write TD1 Rate action

59 3B FP Write HL1 Upper limit of the control output

60 3C FP Write LL1 Lower limit of the control output

61 3D FP Write BS1 Change of setpoint during STAND-BY

62 3E FP Write BO1 Change of setpoint during OFF

63 3F FP Write AD1 Deviation alarm

64

65

66

67

68

69

70

71

72

73

Byte Write PV2@ Process variable connection

Byte Write RS2@ Remote setpoint connection

Byte Write RV2@ Reference variable connection

Byte Write PB2@ Proportional band connection

Byte Write OF2@ OFF mode logic control connection

Byte Write SB2@

STAND-BY mode logic control

connection

Byte Write RA2@ Reverse action logic control connection

Byte Write EF2@

External forcing logic control

connection

Byte Write TYPE2 Controller type

FP Write LS2 Local setpoint

74 4A FP Write PB2 Proportional band

75 4B FP Write TI2 Reset action

76 4C FP Write TD2 Rate action

77 4D FP Write HL2 Upper limit of the control output

78 4E FP Write LL2 Lower limit of the control output

78 4E FP Write LL2 Lower limit of the control output

79 4F FP Write BS2 Change of setpoint during STAND-BY

80

81

82

83

84

85

86

87

88

FP Write BO2 Change of setpoint during OFF

FP Write AD2 Deviation alarm

Byte Write PV3@ Process variable connection

Byte Write RS3@ Remote setpoint connection

Byte Write RV3@ Reference variable connection

Byte Write PB3@ Proportional band connection

Byte Write OF3@ OFF mode logic control connection

Byte Write SB3@

STAND-BY mode logic control

connection

Byte Write RA3@ Reverse action logic control connection

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 35

FS-8700-19_Metasys_N2 Driver Manual Page 35 of 51

Write

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

PAGE 0

Item

DEC

89

Item

HEX

Signal Condition Read/

Byte Write EF3@

Johnson

Tag

Description

External forcing logic control

connection

90 5A Byte Write TYPE3 Controller type

91 5B FP Write LS3 Local setpoint

92 5C FP Write PB3 Proportional band

93 5D FP Write TI3 Reset action

94 5E FP Write TD3 Rate action

95 5F FP Write HL3 Upper limit of the control output

96

97

98

99

100

101

102

103

104

105

FP Write LL3 Lower limit of the control output

FP Write BS3 Change of setpoint during STAND-BY

FP Write BO3 Change of setpoint during OFF

FP Write AD3 Deviation alarm

Byte Write PV4@ Process variable connection

Byte Write RS4@ Remote setpoint connection

Byte Write RV4@ Reference variable connection

Byte Write PB4@ Proportional band connection

Byte Write OF4@ OFF mode logic control connection

Byte Write SB4@

STAND-BY mode logic control

connection

106 6A Byte Write RA4@ Reverse action logic control connection

107 6B Byte Write EF4@

External forcing logic control

connection

108 6C Byte Write TYPE4 Controller type

109 6D FP Write LS4 Local setpoint

110 6E FP Write PB4 Proportional band

111 6F FP Write TI4 Reset action

112

113

114

115

116

117

118

119

120

121

FP Write TD4 Rate action

FP Write HL4 Upper limit of the control output

FP Write LL4 Lower limit of the control output

FP Write BS4 Change of setpoint during STAND-BY

FP Write BO4 Change of setpoint during OFF

FP Write AD4 Deviation alarm

Byte Write PV5@ Process variable connection

Byte Write RS5@ Remote setpoint connection

Byte Write RV5@ Reference variable connection

Byte Write PB5@ Proportional band connection

122 7A Byte Write OF5@ OFF mode logic control connection

123 7B Byte Write SB5@

STAND-BY mode logic control

connection

124 7C Byte Write RA5@ Reverse action logic control connection

125 7D Byte Write EF5@

External forcing logic control

connection

126 7E Byte Write TYPE5 Controller type

127 7F FP Write LS5 Local setpoint

128

129

130

131

132

133

134

FP Write PB5 Proportional band

FP Write TI5 Reset action

FP Write TD5 Rate action

FP Write HL5 Upper limit of the control output

FP Write LL5 Lower limit of the control output

FP Write BS5 Change of setpoint during STAND-BY

FP Write BO5 Change of setpoint during OFF

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 36

FS-8700-19_Metasys_N2 Driver Manual Page 36 of 51

Write

87

88

89

90

91

92

93

94

95

96

97

98

99

PAGE 0

Item

DEC

135

136

137

Item

HEX

Signal Condition Read/

FP Write AD5 Deviation alarm

Byte Write PV6@ Process variable connection

Byte Write RS6@ Remote setpoint connection

Johnson

Tag

Description

138 8A Byte Write RV6@ Reference variable connection

139 8B Byte Write PB6@ Proportional band connection

140 8C Byte Write OF6@ OFF mode logic control connection

141 8D Byte Write SB6@

STAND-BY mode logic control

connection

142 8E Byte Write RA6@ Reverse action logic control connection

143 8F Byte Write EF6@

144

145

146

147

148

149

150

151

152

153

Byte Write TYPE6 Controller type

FP Write LS6 Local setpoint

FP Write PB6 Proportional band

FP Write TI6 Reset action

FP Write TD6 Rate action

FP Write HL6 Upper limit of the control output

FP Write LL6 Lower limit of the control output

FP Write BS6 Change of setpoint during STAND-BY

FP Write BO6 Change of setpoint during OFF

FP Write AD6 Deviation alarm

External forcing logic control

connection

154 9A Byte Write PV7@ Process variable connection

155 9B Byte Write RS7@ Remote setpoint connection

156 9C Byte Write RV7@ Reference variable connection

157 9D Byte Write PB7@ Proportional band connection

158 9E Byte Write OF7@ OFF mode logic control connection

159 9F Byte Write SB7@

STAND-BY mode logic control

connection

160 A0 Byte Write RA7@ Reverse action logic control connection

161 A1 Byte Write EF7@

External forcing logic control

connection

162 A2 Byte Write TYPE7 Controller type

163 A3 FP Write LS7 Local setpoint

164 A4 FP Write PB7 Proportional band

165 A5 FP Write TI7 Reset action

166 A6 FP Write TD7 Rate action

167 A7 FP Write HL7 Upper limit of the control output

168 A8 FP Write LL7 Lower limit of the control output

169 A9 FP Write BS7 Change of setpoint during STAND-BY

170 AA FP Write BO7 Change of setpoint during OFF

171 AB FP Write AD7 Deviation alarm

172 AC Byte Write PV8@ Process variable connection

173 AD Byte Write RS8@ Remote setpoint connection

174 AE Byte Write RV8@ Reference variable connection

175 AF Byte Write PB8@ Proportional band connection

176 B0 Byte Write OF8@ OFF mode logic control connection

177 B1 Byte Write SB8@

STAND-BY mode logic control

connection

178 B2 Byte Write RA8@ Reverse action logic control connection

179 B3 Byte Write EF8@

External forcing logic control

connection

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 37

FS-8700-19_Metasys_N2 Driver Manual Page 37 of 51

Write

PAGE 0

Item

DEC

Item

HEX

Signal Condition Read/

Johnson

Tag

Description

180 B4 Byte Write TYPE8 Controller type

181 B5 FP Write LS8 Local setpoint

182 B6 FP Write PB8 Proportional band

183 B7 FP Write TI8 Reset action

184 B8 FP Write TD8 Rate action

185 B9 FP Write HL8 Upper limit of the control output

186 BA FP Write LL8 Lower limit of the control output

187 BB FP Write BS8 Change of setpoint during STAND-BY

188 BC FP Write BO8 Change of setpoint during OFF

189 BD FP Write AD8 Deviation alarm

190 BE Byte Write IR1 Range analog input 1

191 BF FP Write HA1 High alarm input 1

192 C0 FP Write LA1 Low alarm input 1

193 C1 FP Write FI1 Filter time input 1

194 C2 Byte Write IR2 Range analog input 2

195 C3 FP Write HA2 High alarm input 2

196 C4 FP Write LA2 Low alarm input 2

197 C5 FP Write FI2 Filter time input 2

198 C6 Byte Write IR3 Range analog input 3

199 C7 FP Write HA3 High alarm input 3

200 C8 FP Write LA3 Low alarm input 3

201 C9 FP Write FI3 Filter time input 3

202 CA Byte Write IR4 Range analog input 4

203 CB FP Write HA4 High alarm input 4

204 CC FP Write LA4 Low alarm input 4

205 CD FP Write FI4 Filter time input 4

206 CE Byte Write IR5 Range analog input 5

207 CF FP Write HA5 High alarm input 5

208 D0 FP Write LA5 Low alarm input 5

209 D1 FP Write FI5 Filter time input 5

210 D2 Byte Write IR6 Range analog input 6

211 D3 FP Write HA6 High alarm input 6

212 D4 FP Write LA6 Low alarm input 6

213 D5 FP Write FI6 Filter time input 6

214 D6 Byte Write IR7 Range analog input 7

215 D7 FP Write HA7 High alarm input 7

216 D8 FP Write LA7 Low alarm input 7

217 D9 FP Write FI7 Filter time input 7

218 DA Byte Write IR8 Range analog input 8

219 DB FP Write HA8 High alarm input 8

220 DC FP Write LA8 Low alarm input 8

221 DD FP Write FI8 Filter time input 8

222 DE FP Write OH1 Output 1 high range

223 DF FP Write OL1 Output1 low range

224 E0 Byte Write OMS1 Source of analog output module 1

225 E1 FP Write OH2 Output 2 high range

226 E2 FP Write OL2 Output 2 low range

227 E3 Byte Write OMS2 Source of analog output module 2

228 E4 FP Write OH3 Output OUTA1 high range

229 E5 FP Write OL3 Output OUTA1 low range

230 E6 Byte Write OMS3 Source of logic output module OUTA

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 38

FS-8700-19_Metasys_N2 Driver Manual Page 38 of 51

Write

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

PAGE 0

Item

DEC

Item

HEX

Signal Condition Read/

Johnson

Tag

Description

231 E7 Byte Write OMS4 Source of logic output module OUTB

232 E8 Byte Write OMTY1 Output module type

233 E9 FP Write FST1 PAT/DAT output 1 timing

234 EA FP Write DB1 Dead band PAT output 1

235 EB FP Write OH5 Output OUTA2 high range

236 EC FP Write OL5 Output OUTA2 low range

237 ED Byte Write OMS5 Source of logic output module OUTA

238 EE Byte Write OMS6 Source of logic output module OUTB

239 EF Byte Write OMTY2 Output module type

240 F0 FP Write FST2 PAT/DAT output 2 timing

241 F1 FP Write DB2 Dead band PAT output 2

242 F2 FP Write OH7 Output OUTA3 high range

243 F3 FP Write OL7 Output OUTA3 low range

244 F4 Byte Write OMS7 Source of logic output module OUTA

245 F5 Byte Write OMS8 Source of logic output module OUTB

246 F6 Byte Write OMty3 Output module type

247 F7 FP Write FST3 PAT/DAT output 3 timing

248 F8 FP Write DB3 Dead band PAT output 3

249 F9 FP Write SB1 Symmetry band controller module 5

250 FA FP Write SB2 Symmetry band controller module 6

251 FB Byte Write ALDIS Alarm disable condition source

252 FC Byte Write RCTY1 DC type settings

253 FD Byte Write ALGT Standard algorithm type

254 FE FP Write COS1 Spare constant

255 FF FP Write COS2 Spare constant

PAGE 1

Relative Item Signal Condition Read/Write Johnson Tag Description Relative Item

0

1

2

3

4

5

6

7

8

9

10 A FP Write HR6 High range analog input 6

11 B FP Write LR6 Low range analog input 6

12 C FP Write HR7 High range analog input 7

13 D FP Write LR7 Low range analog input 7

14 E FP Write HR8 High range analog input 8

15 F FP Write LR8 Low range analog input 8

16

17

18

19

20

21

22

23

FP Write HR1 High range analog input 1

FP Write LR1 Low range analog input 1

FP Write HR2 High range analog input 2

FP Write LR2 Low range analog input 2

FP Write HR3 High range analog input 3

FP Write LR3 Low range analog input 3

FP Write HR4 High range analog input 4

FP Write LR4 Low range analog input 4

FP Write HR5 High range analog input 5

FP Write LR5 Low range analog input 5

FP Write OM%1 Output % Output module 1

FP Write OM%2 Output % Output module 2

FP Write OM%3 Output % Output module 3

FP Write OM%4 Output % Output module 4

FP Write OM%5 Output % Output module 5

FP Write OM%6 Output % Output module 6

FP Write OM%7 Output % Output module 7

FP Write OM%8 Output % Output module 8

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-2296 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 39

FS-8700-19_Metasys_N2 Driver Manual Page 39 of 51

Optimal start / stop module

Relative Item Signal Condition Read/Write Johnson Tag Description

0 Byte Write OSOPT Module options

1 Word Write OSZT@ Zone temperature connection

2 Word Write OSOT@ Outdoor temperature connection

3 Word Write OSSP@ Zone temperature setpoint connection

4 Word Write OSOB@ Off setpoint bias connection

5 Word Write OSDI@ Disable module connection

6 Word Write OSDA@ Disable adaptive action connection

7 Word Write OSTS@ Connection at time schedule output

8 Word Write OSNX@ Connection at next output

9 Word Write OSTIM@ Connection at time to next output

10 FP Write OSPURGE Minimum cool / heat time (min)

11 FP Write OSMAXST Maximum start up time (min)

12 FP Write OSMAXSO Maximum shut down time (min)

13 FP Write OSBHK Start mode building heating factor

14 FP Write OSBCK Start mode building cooling factor

15 FP Write OSSBHK Stop mode building heating factor