Page 1

A Sierra Monitor Company

Driver Manual

(Supplement to the FieldServer Instruction Manual)

FS-8700-17 Optomux

APPLICABILITY & EFFECTIVITY

Effective for all systems manufactured after January 1, 199 9

Instruction Manual Part Number FS-8700-01

2/18/2004

Rev: 1.2

Page 2

FS-8700-17 Optomux Driver Manual

TABLE OF CONTENTS

1 Optomux Driver Description...................................................................................................................1

1.1 Operating Methods.........................................................................................................................1

1.2 Statistics and Command Reponses ...............................................................................................1

2 Driver Scope of Supply..........................................................................................................................2

2.1 Supplied by FieldServer Technologies for this driver.....................................................................2

2.2 Provided by user.............................................................................................................................2

3 Hardware Connections ..........................................................................................................................3

4 Configuring the FieldServer as a Optomux Driver Client......................................................................4

4.1 Data Arrays.....................................................................................................................................4

4.2 Client Side Connections.................................................................................................................5

4.3 Client Side Nodes...........................................................................................................................5

4.4 Client Side Map Descriptors...........................................................................................................6

4.4.1 FieldServer Related Map Descriptor Parameters ...................................................................6

4.4.2 Driver Related Map Descriptor Parameters............................................................................7

4.4.3 Timing Parameters..................................................................................................................9

4.4.4 Map Descriptor Example 1 – Read on/off Status..................................................................10

4.4.5 Map Descriptor Example 2 – Read On/Off Status (Data stored differently) .........................11

4.4.6 Map Descriptor Example 3 – Command Response/Completion Status ...............................12

4.4.7 Map Descriptor Example 4 – Triggered Action .....................................................................13

4.4.8 Map Descriptor Example 5 – Using Address and Length to tell the FieldServer which module

positions to access...............................................................................................................................14

4.4.9 Map Descriptor Example 6 – Using a Mask to Address specific module positions .............15

4.4.10 Map Descriptor Example 7 – Specifying Module Positions Dynamically..............................16

5 Configuring the FieldServer as a Optomux Server.............................................................................17

6 Driver Notes.........................................................................................................................................18

6.1 Data_Array_Name, DA_Bit_Name, DA_Byte_Name...................................................................18

6.2 Module Positions ..........................................................................................................................18

6.3 Command Response Status.........................................................................................................18

6.4 Optomux Commands....................................................................................................................19

6.5 Driver Stats...................................................................................................................................25

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page Index

Page 3

FS-8700-17 Optomux Driver Manual

1 Optomux Driver Description

The Optomux Driver allows the FieldServer to transfer data to and from devices over either

RS-232 or RS-485 using the Optomux Driver protocol.

The Optomux driver is a client only driver. This means that the driver can poll an

Optomux protocol compliant device but cannot emulate one.

The Optomux protocol provides a large command set. Many of the commands are used for

OPTO22 device configuration. This driver supports the full command set and thus the

driver may be used to configure as well as to poll OPTO22 devices.

1.1 Operating Methods

The Optomux driver provides three methods of operation. Users may use any

combination of methods.

Static Operation

If the hardware configuration is fixed and known then this is a suitable method. The

devices to be polled / commanded are configured using the FieldServer CSV file.

Dynamic Operation

If the hardware configuration may change or if hardware settings may change

dynamically or (more realistically) if you wish to change some aspect of the hardware

configuration such as a delay time or reset a latch without changing the CSV file and

resetting the FieldServer then this operating method is suitable. The commands set can

be configured by changing the values in the FieldServer’s data arrays. This operating

mode may be considered a data driven one.

Triggered Operation

This operating mode allows commands to be triggered by changing the value in the

FieldServer’s data arrays. This operating mode is useful if requiring an action triggered

by a remote device.

1.2 Statistics and Command Reponses

All FieldServer drivers report communication statistics that allow the operation of the

driver to be monitored.

In addition to the standard statistics, this driver exposes the communication statistics for

each port by presenting them in a user specified data array where they can be monitored

by a remote device or HMI system.

The Optomux driver also exposes the response status to each poll and command (if

required) by writing the response statuses to a user specified data array. This useful

feature allows remote devices to check whether a command has been completed

successfully.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 1

Page 4

FS-8700-17 Optomux Driver Manual

2 Driver Scope of Supply

2.1 Supplied by FieldServer Technologies for this driver

Driver Manual.

2.2 Provided by user

Optomux System

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 2

Page 5

FS-8700-17 Optomux Driver Manual

A

A

A

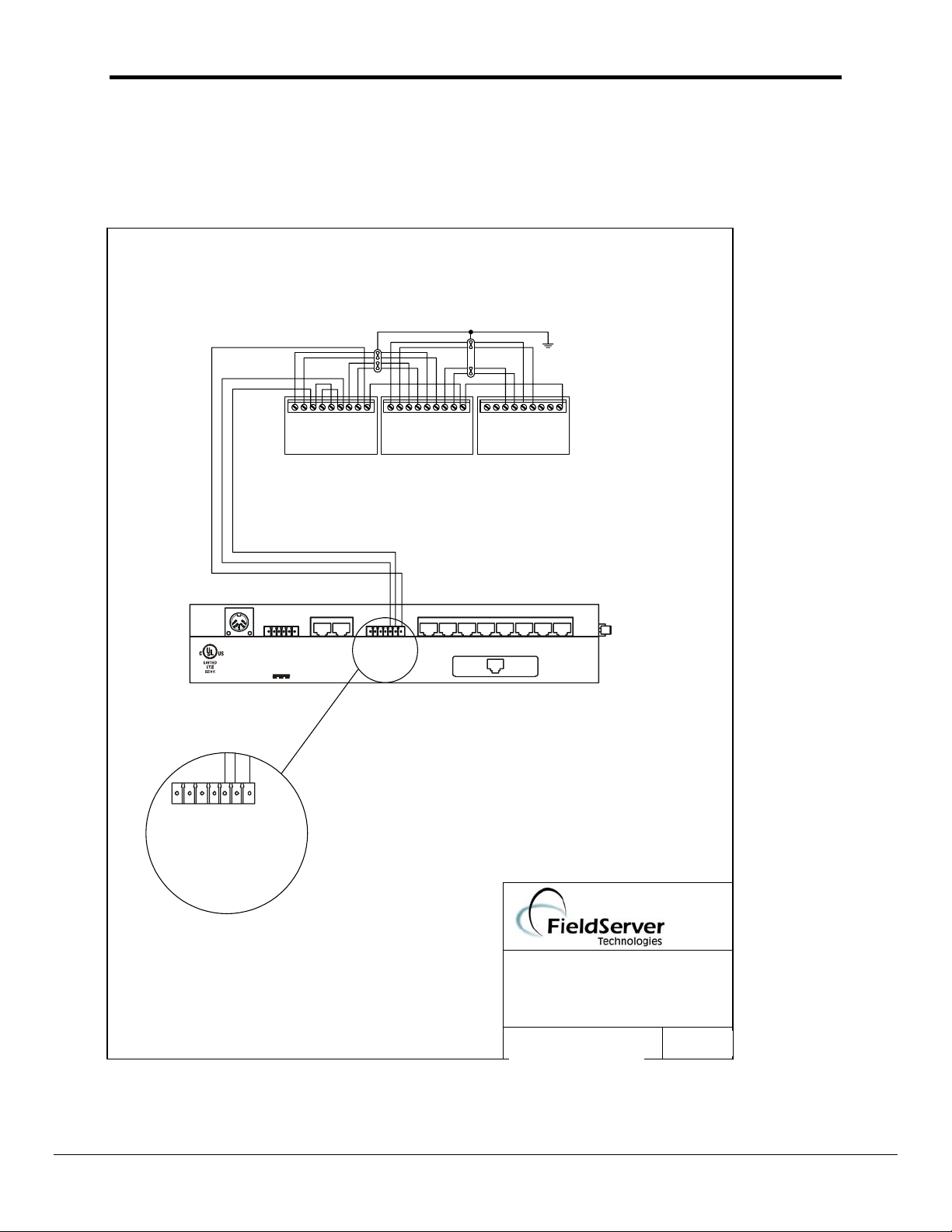

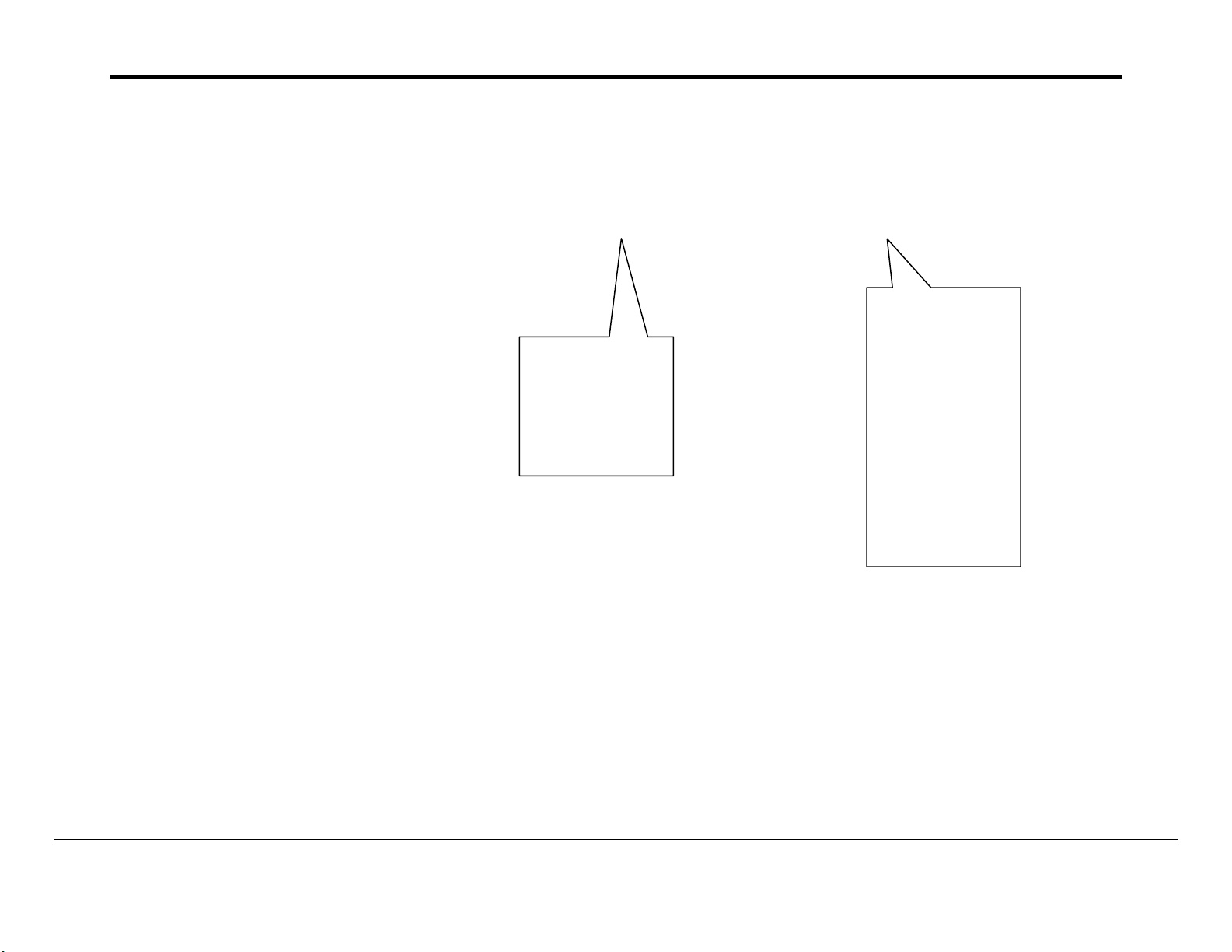

3 Hardware Connections

The FieldServer is connected to the OPTO22 device as shown below.

Configure the OPTO22 device according to manufacturer’s instructions.

FS-X40

GndFG_

+

R2 R1

RS 485

(Opt o - Isolat ed)

B1 OR B2

Net 1

Et he rn et

10 Base T

COM

- + - + - + - +

FO FH TH TO

GndFG_

+

R2 R1

RS 48 5

(Opto - Isolated)

Gnd_+

- + - + - + - +

FO FH TH TO * *

PREVIOUS OPTOMUX *

* B2 COMMUNICATION CONNECTIONS ARE MADE TO THE RACK (PB4AH, PA8AH OR

PB16AH), NOT TO THE BRAIN BOARD.

** DO NOT CONNECT ANY "COM" POINT TO EARTH GROUND.

_

_

+

+12V 500m

Power

+

12V 500m

Net 2

5V 500m

5V 1.5A

0V

FG

DC AUX Power

Gnd

_

COM

- + - + - + - +

FO FH TH TO

GRO U ND 5

DTR 6

RTS 7

Tx 8

NEXT OPTOMUX *

B1 OR B2

RS 23 2

1 Rx

18

2 CTS

3 DSR

4 GROUND

AC30A/B

P8 P7 P 6 P5 P4 P3 P2 P1

COM

(408)-262-2299

FIELDSERVER - OPTO22

CONNECTION DIAGRAM

BASE NAME:

FILE NAME: T28700-17.VSD

DATE: 6/27/01

BY: MN

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 3

Page 6

FS-8700-17 Optomux Driver Manual

4 Configuring the FieldServer as a Optomux Driver Client

For a detailed discussion on FieldServer configuration, please refer to the FieldServer

Configuration Manual. The information that follows describes how to expand upon the

factory defaults provided in the configuration files included with the FieldServer (See “.csv”

files on the driver diskette).

This section documents and describes the parameters necessary for configuring the

FieldServer to communicate with an Optomux Device.

The configuration file tells the FieldServer about its interfaces, and the routing of data

required. In order to enable the FieldServer for Optomux Driver communications, the driver

independent FieldServer buffers need to be declared in the “Data Arrays” section, the

destination device addresses need to be declared in the “Client Side Nodes” section, and

the data required from the servers needs to be mapped in the “Client Side Map

Descriptors” section. Details on how to do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value being

the default.

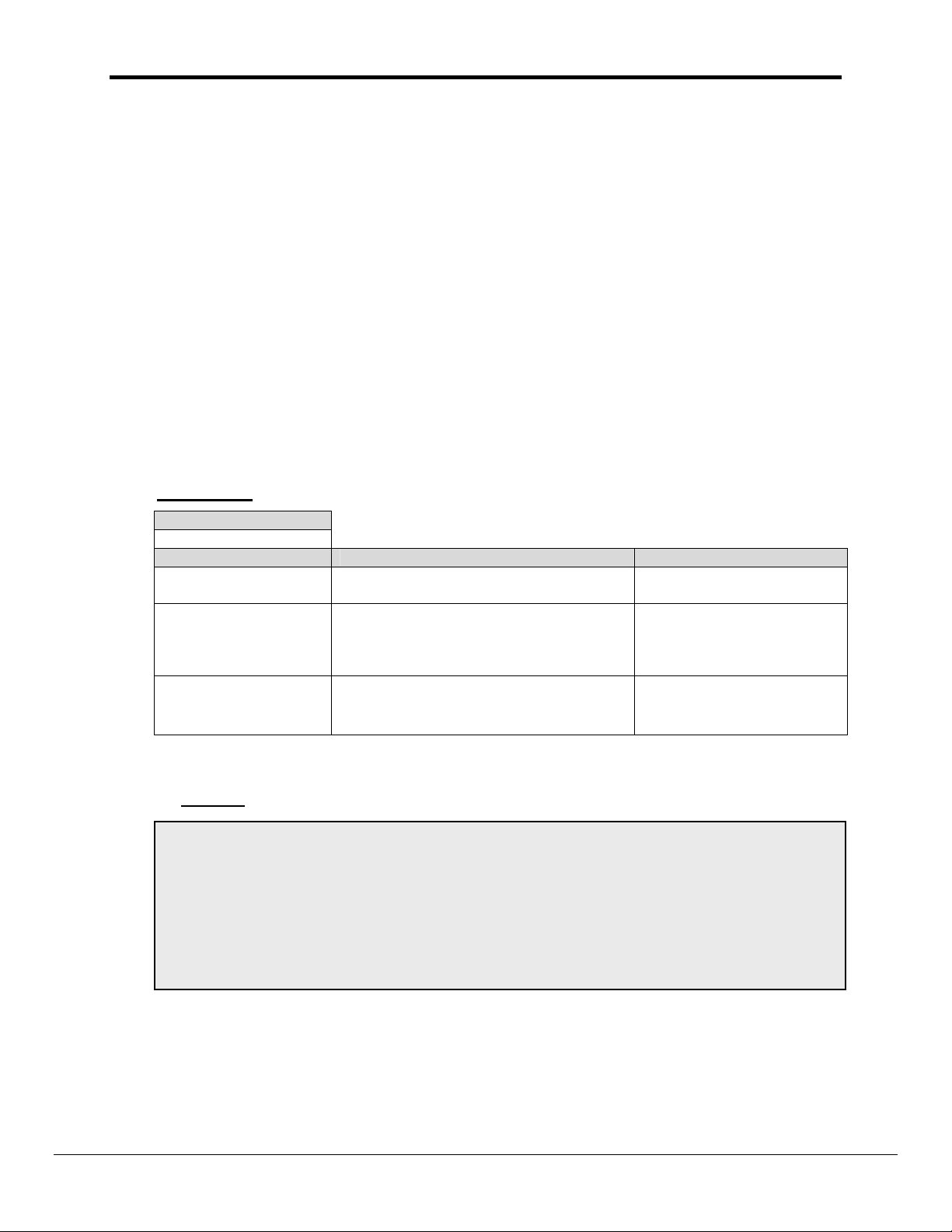

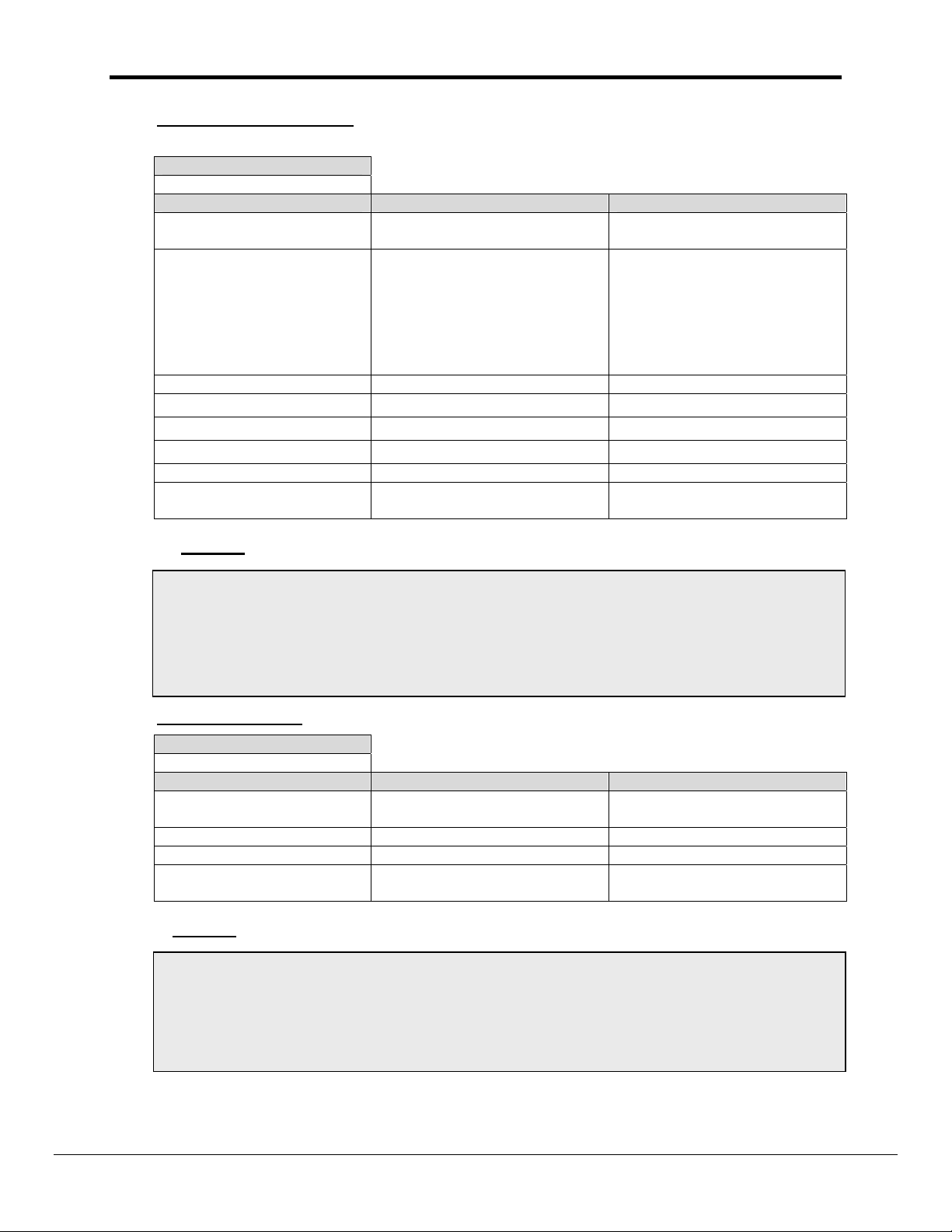

4.1 Data Arrays

Section Title

Data_Arrays

Column Title Function Legal Values

Data_Array_Name Provide name for Data Array Up to 15 alphanumeric

Data_Format Provide data format. Each data array can

Data_Array_Length Number of Data Objects. Must be larger

Example

// Data Arrays

//

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length

DA_AI_01, UInt16, 200

DA_AO_01, UInt16, 200

DA_DI_01, Bit, 200

DA_DO_01, Bit, 200

characters

FLOAT, BIT, UInt16, SInt16,

only take on one format.

than the data storage area required for

the data being placed in this array.

Packed_Bit, Byte,

Packed_Byte,

Swapped_Byte

1-10,000

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 4

Page 7

FS-8700-17 Optomux Driver Manual

4.2 Client Side Connections

Section Title

Connections

Column Title Function Legal Values

Port Specify which port the device is

connected to the FieldServer

Baud* Specify baud rate

Parity* Specify parity Even, Odd, None, Mark, Space

Data_Bits* Specify data bits 7, 8

Stop_Bits* Specify stop bits

Protocol Specify protocol used Optomux

Handshaking* Specify hardware handshaking RTS, RTS/CTS, None

Poll Delay* Time between internal polls 0-32000 seconds

Example

// Client Side Connections

Connections

Port, Baud, Parity, Protocol, Handshaking, Poll_Delay

R1, 9600, None, Opto22 , None , 0.100s

R1-R2, (FS-X40 Series)

R1 (FS-X20 Series)

110 – 115200, standard baud

rates only

At the time of publication of this

manual the OPTO22 device’s

support standard baud Rates in

the range 300-38400.

1

default 1 second

4.3 Client Side Nodes

Section Title

Nodes

Column Title Function Legal Values

Node_Name Provide name for node Up to 32 alphanumeric

characters

Node_ID OPTO22 device address. 0-255

Protocol Specify protocol used Optomux

Port Specify which port the device is

connected to the FieldServer

Example

// Client Side Nodes

Nodes

Node_Name, Node_ID, Protocol, Port

Optomux1 , 1 , Optomux , R1

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 5

R1-R2, (P1-P8 with a

converter)

Page 8

FS-8700-17 Optomux Driver Manual

4.4 Client Side Map Descriptors

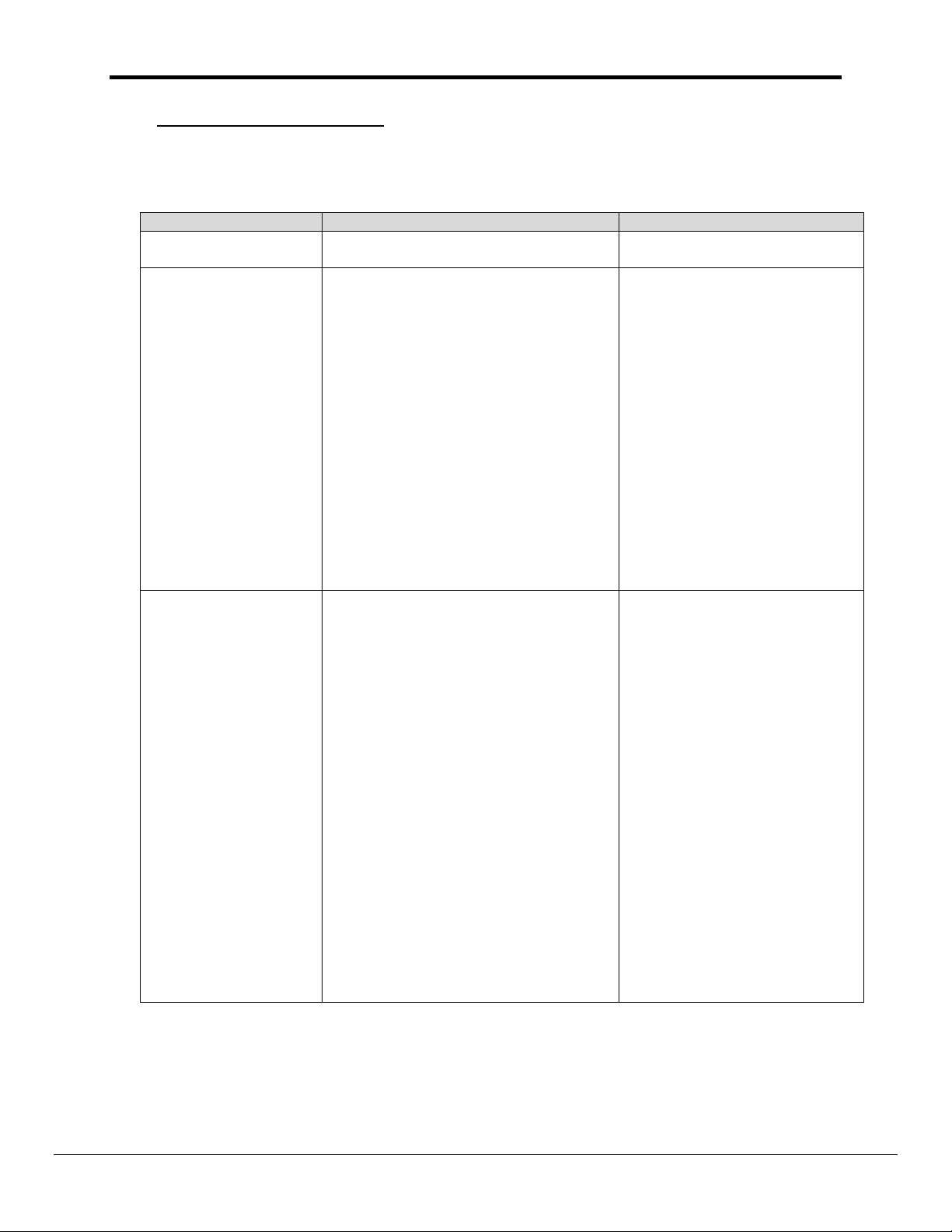

4.4.1 FieldServer Related Map Descriptor Parameters

Column Title Function Legal Values

Map_Descriptor_Name Name of this Map Descriptor Up to 32 alphanumeric

characters

Data_Array_Name Name of Data Array where data is to be

stored / retrieved in the FieldServer.

The use of this array is dependent on

the Optomux command used in the map

descriptor.

For example some commands use one

data value for all module positions to be

affected by the command (Driver will

only use one data array element). Other

commands may use one data element

per module position specified. In this

case the FieldServer may use up to 16

data array elements.

To fully understand this, read the notes

in chapter 6.

Da_Bit_Name* This parameter is only required for

dynamic module position specification.

Ie. You intend using a data array to tell

the driver which module positions to

affect by a command. In this case use

this parameter. Up to 16 elements will

be inspected. The first element will

always be used for the first module

position , the 2

nd

element for the 2nd

module position ….

Module positions are specified by setting

the corresponding array element to a

non-zero value. Module positions are left

unspecified by setting the module array

position to zero.

The first element of this array that is

used is determined by the

Data_Array_Offset parameter.

Additional information is provided in

chapter 6.

One of the Data Array names

from “Data Array” section above

One of the Data Array names

from “Data Array” section above

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 6

Page 9

FS-8700-17 Optomux Driver Manual

Da_Byte_Name* Names a data array that the driver will

use to store poll/query response status

One of the Data Array names

from “Data Array” section above

data.

One data element is used per map

descriptor. The element is determined

by the Data_Array_Offset parameter.

Data_Array_Offset Starting location in Data Array 0 to maximum specified in “Data

Array” section above

Function Function of Client Map Descriptor RDBC, WRBC, WRBX

4.4.2 Driver Related Map Descriptor Parameters

Column Title Function Legal Values

Node_Name Name of Node to fetch data

from

Address* This field is only required if the

address/length method of

module position specification is

used.

Length Length of Map Descriptor

Only some commands / queries

use the value of this map

descriptor parameter. This is

indicated in a table provide in

chapter 6.

For those commands and

queries that do use the Length

parameter the driver never uses

more than 16 elements of data

even if the length is set to a

larger number.

Although this driver does not

use the length parameter for

some commands the

FieldServer kernel does use

this parameter to ensure that no

more than one client map

descriptor has control of a

range of array data elements.

For this reason it is best to

always specify the length – in

these cases set it to 1.

One of the node names

specified in “Client Node

Descriptor” above

1..16

Indicating 1

st

to 16th module

position.

1 - 1000

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 7

Page 10

FS-8700-17 Optomux Driver Manual

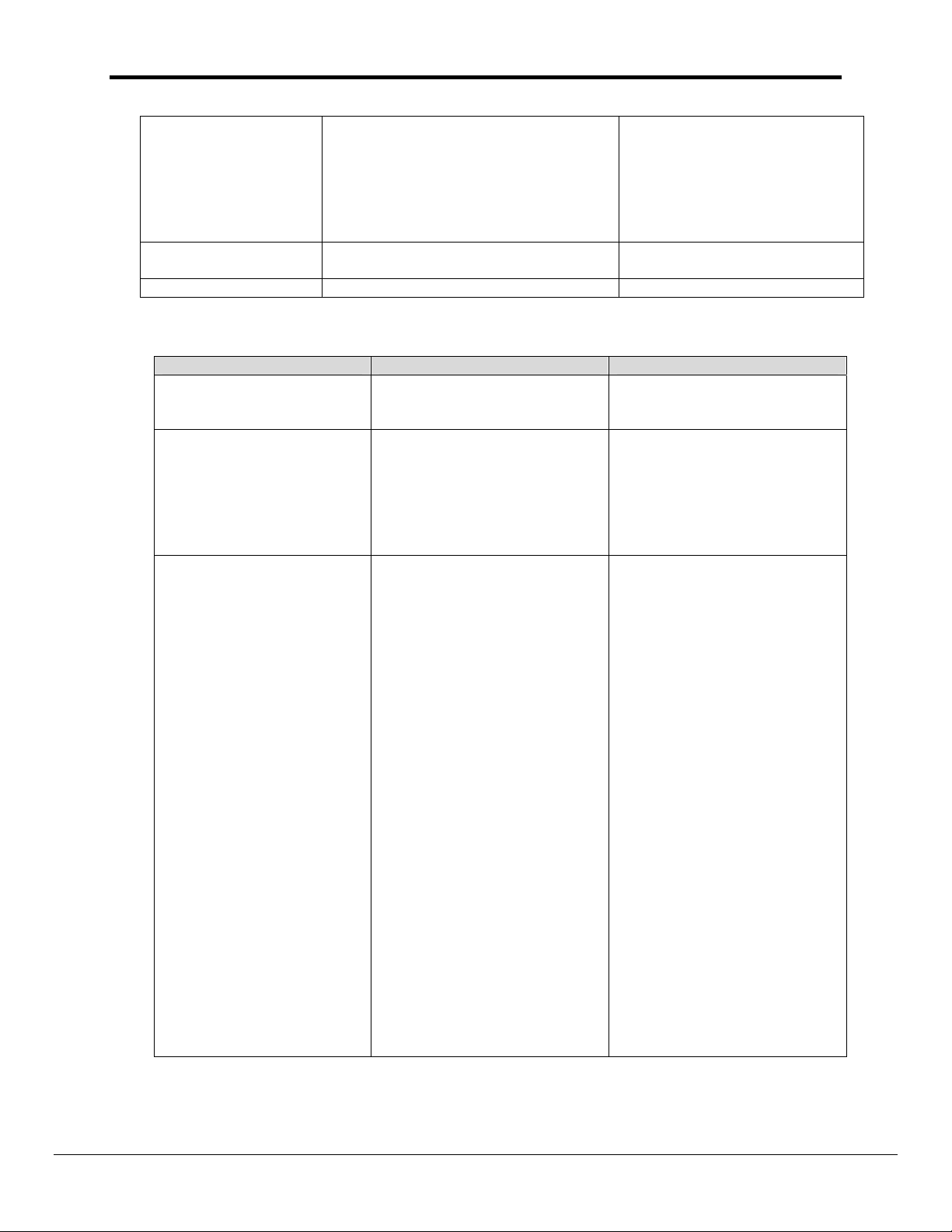

Opto22_trigger* An optional parameter. If used then set the

No, Yes

value of this parameter to yes or no and

the da_byte_name parameter must be

specified too.

When this parameter is set to yes then the

Optomux driver processes this map

descriptor differently from a normal wrbc or

rdbc function.

The driver processes the map descriptor at

the scan interval specified. Each time that

it is processed the driver checks the

element of the da_byte_name data array

specified. If the value of the 1

st

element of

array located at data_array_offset is 1 then

the driver executes the command. If the

value is not equal to one then the driver

ignores the map descriptor.

If the map descriptor is triggered then the

driver will write a response status to the

same data element on completion of the

poll. Thus the value of 1 will be set to zero

for success or some other value indicating

an error.

More information is provided in chapter 6.

Opto22_format* This parameter only has meaning when

the function is a read of digital data.

Bit, Packed

By default the OPTO22 devices returns 16

position states when digital data is read (

eg. READ STATUS). The Optomux driver

writes the data as one 16 bit unsigned

integer to one data element of the data

array specified. (That is, the data is written

to the data array in packed bit format.)

For example, if the 1

st

and 5th inputs were

on and all others were off the driver would

write the value 17 to the first element of the

data array.

The driver can be instructed to unpack this

data into separate bit states, writing each

module position’s state to a consecutive

data array element.

When the Bit keyword is used the driver

sets the states of consecutive data array

elements starting at Data_Array_Offset.

The number of elements that are written is

determined by length and a maximum of

16 elements will be written.

Opto22_function This parameter is specified by using one of See Table 6.1

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 8

Page 11

FS-8700-17 Optomux Driver Manual

the functions provided in table 6.1.

The parameter must be spelled and

spaced exactly as provided in the table.

Leading and trailing spaces are not

important but inter-word spaces are very

important. Take care not to use tabs.

Opto22_modifier1* A few Opto22_Functions require one ore

See Chapter 6.

more additional arguments.

SET TIME DELAY

GENERATE N PULSES

READ AND AVERAGE INPUTS

Additional information in chapter 6 will

indicate the types of values that may be

assigned to this parameter.

Opto22_modifier2* See Opto_modifier1

Opto22_mask* The mask specifies the positions (1-16) of

a module that will be affected by a

command.

The positions can be specified dynamically

0-65535

or

0x0000 – 0xffff

using a data array or statically by using this

parameter.

When this parameter is used and its value

is non zero then the driver does not

consider the data contained in the position

defining array even if it is also defined.

The value of the mask may be specified in

hexadecimal or in decimal.

To specify a number in hexadecimal the

number must be prefixed with 0x and have

a maximum of 4 digits.

Examples.

Decimal: 257 -> Indicates the 1

st

and 9th

positions.

Hexadecimal: 0x0101 -> indicates the 1

th

and 9

positions.

st

4.4.3 Timing Parameters

Column Title Function Legal Values

Scan_Interval Rate at which data is polled >0.1s

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 9

Page 12

FS-8700-17 Optomux Driver Manual

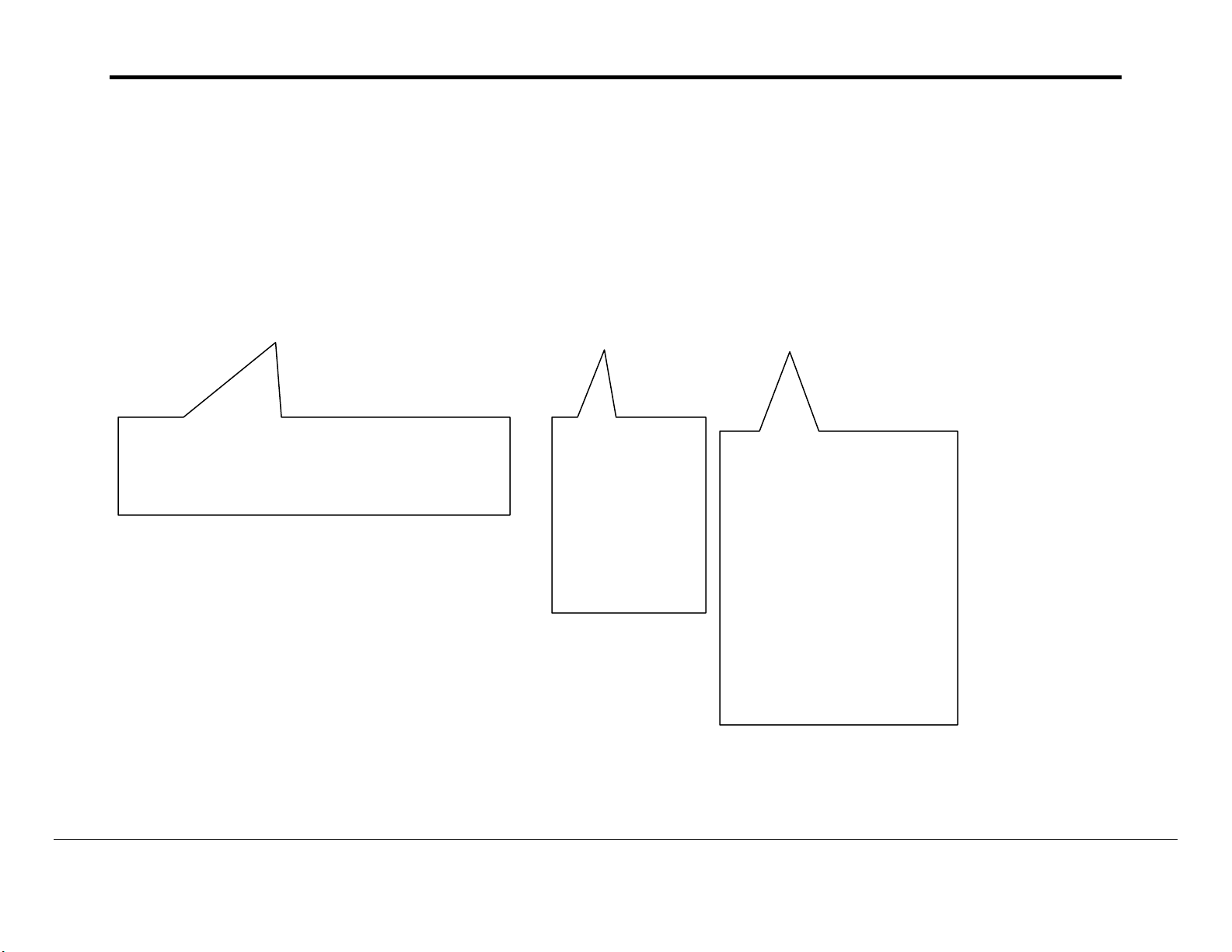

4.4.4 Map Descriptor Example 1 – Read on/off Status

In this example the on/off status of all module positions of the Optomux device are read and stored. They are read continuously (rdbc) every 5 seconds

(Scan_Interval). The Read Status command returns one packed 16 bit value. There is one bit per module position, thus, if the returned value was 2 then this would

indicate that the 2nd position is on and all other positions are off.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, node_name, Length, Scan_Interval, opto22_function ,

DEVICE77_STAT , DISC_INPUTS , 0 , rdbc , DEV77 , 1 , 5.0s , READ STATUS ,

Map descriptor

names are often

used in error

messages so it may

be helpful to have

unique names.

Dashes, spaces,

upper and lowercase

characters may be

used.

This is the name of

the data array in

which the data will

be stored.

Ensure that the

Data_Format of the

array is suitable for

storing the data

returned by the

device.

Chapter 6 provides

details of the type of

data returned by

each command.

The device will

be read

continuously.

The data will be

stored at offset

zero (First

element) of the

data array.

This is the name

of the node. The

node must have

previously been

defined in the

Nodes section

of the CSV file.

Its Node_ID

should be set to

77 to reference

the device

addressed as 77.

Only one

element of the

data array is

reserved for this

map descriptor.

This is the name

of the Optomux

command /

query that must

be performed.

It must be

spelled and

spaced exactly

as in table 6.1

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 10

Page 13

FS-8700-17 Optomux Driver Manual

4.4.5 Map Descriptor Example 2 – Read On/Off Status (Data stored differently)

This example reads the same data as the previous example. The difference is that the data is stored differently. In this example the data is

unpacked and stored in 16 consecutive data array elements – one element per m odule position.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, node_name, Length, Scan_Interval, opto22_function , opto22_format

DEVICE77_STAT , DISC_INPUTS , 0 , rdbc , DEV77 , 16 , 5.0s , READ STATUS , Bit

This is how the

driver is instructed

The length has

changed to 16 to

reserve 16 data array

elements for this

map descriptor.

to unpack the digital

data.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 11

Page 14

FS-8700-17 Optomux Driver Manual

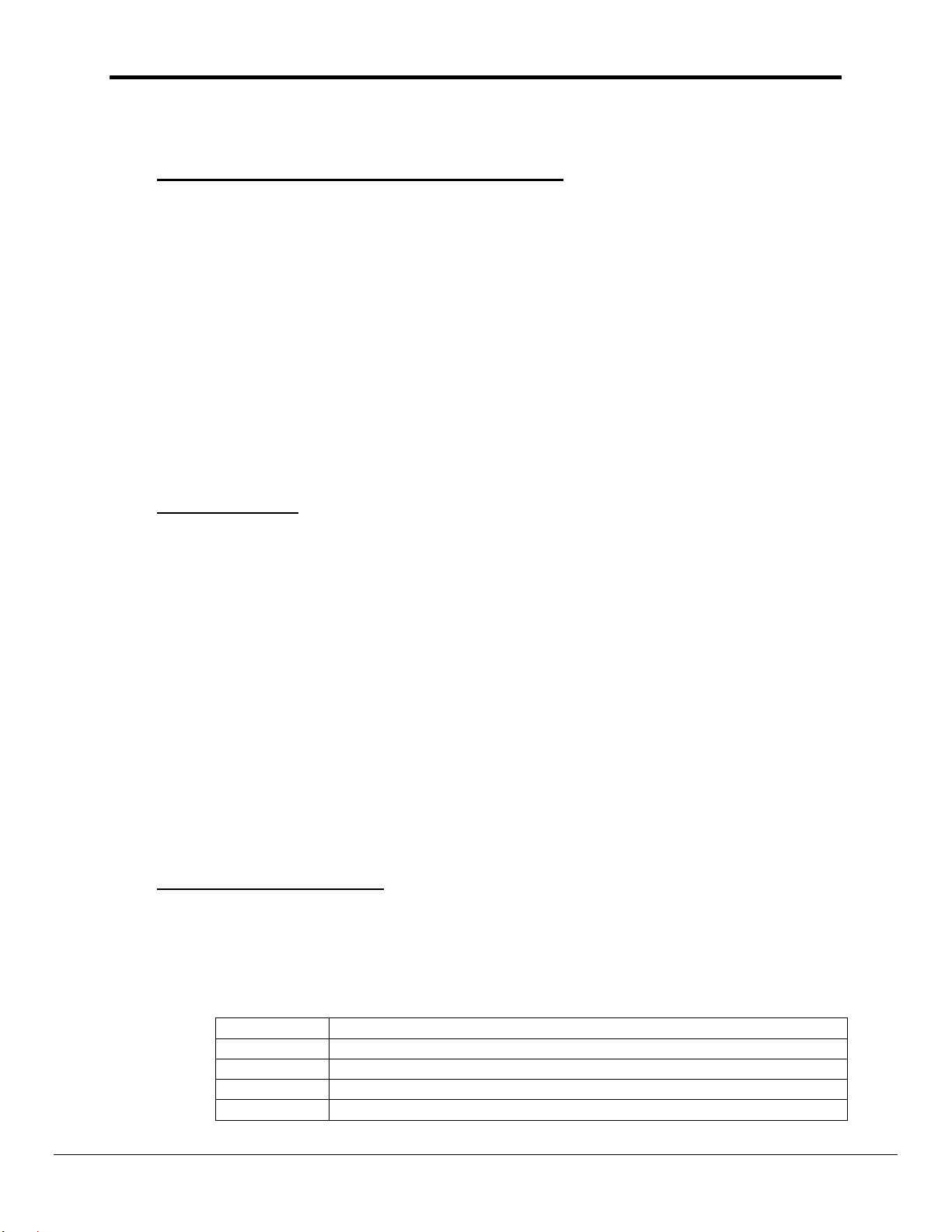

4.4.6 Map Descriptor Example 3 – Command Response/Completion Status

We use example 1 to show how it can be modified to get the driver to expose the response / status generated whe n the command was executed.

The response / status values indicate the success / failure of the command based either on the driver’s ability to complete the command OR on

the ack/nack returned by the device.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, node_name, Length, Scan_Interval, opto22_function , DA_Byte_Name

DEVICE77_STAT , DISC_INPUTS , 0 , rdbc , DEV77 , 1 , 5.0s , READ STATUS, RESPONSE_ARR

By virtue of defining the DA_Byte_Name parameter the

driver will now store a response status each time the poll is

executed.

The response / status code will be stored in the data array

called REPONSE_ARR. One element of the array located

at Data_Array_Offset will be used. The data array’s data

format should at least be able to store a byte of data as

response/status codes range from 0-255.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 12

Page 15

FS-8700-17 Optomux Driver Manual

4.4.7 Map Descriptor Example 4 – Triggered Action

This example shows the elements necessary to generate a triggered poll. Even though this map descriptor appears to write to the device

continuously the driver recognizes the opto22_trigge r parameter and based on its value will only send the poll when the trigger value is set.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Length, Scan_Interval, opto22_function , opto22_trigger, DA_Byte_Name

DEVICE77_STAT , CNTR_POSNS , 0 , wrbc , DEV77 , 16 , 0.2s , CLEAR COUNTERS , Yes , COMMAND_ARRAY

This map descriptor

is processed as a

write command and

will be processed

continuously.

The Driver will process this

map descriptor every 0.2

seconds.

In this example, this does not

mean that the command will

be sent to the device every

0.2 seconds. It does mean

that the driver will check to

see if a trigger has been set

every 0.2 seconds.

This keyword value for the

opto22_trigger parameter

tells the driver only to send

this Optomux command if it

has been triggered.

When this parameter is used

the DA_Byte_Name

parameter must also be used.

This is the name of a data array

whose contents will be used to

trigger the command.

The driver looks at the element

found at the Data_Array_Offset

and if that value=1 then the

command is sent. On

completion/error the driver will

change this value to some other

number.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 13

Page 16

FS-8700-17 Optomux Driver Manual

4.4.8 Map Descriptor Example 5 – Using Address and Length to tell the FieldServer which module positions to access.

This example shows a map descriptor which reads analog inputs from an Optomux Device. The address and length tell the driver which inputs to

read. Take care to ensure that the data array used for storage has a data format suitable for storing the data type returned by the command. In

this case an unsigned integer at least 16 bits long ( eg UINT16 or FLOAT). Also take care to ensure that you understand the scaling of the data

returned by the Optomux device. There are parameters that you can add to a map descripto r to have the d river scale the value. This is discussed

in the FieldServer Configuration Manual.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Address, Length, Scan_Interval, opto22_function

DEVICE77_STAT , ANA_DATA , 0 , rdbc , DEV77 , 2 , 15 , 1.0s , READ ANALOG INPUTS

Data read from the

Optomux Device is

placed in this array.

Starting at this array

position.

The first module

position that is read

is position 2.

Module positions

are numbered 1 to

16.

Data from 15

module positions

must be read. Thus

starting at 2, the last

module position

read is 16.

This is the Optomux

Driver function that

must be performed.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 14

Page 17

FS-8700-17 Optomux Driver Manual

4.4.9 Map Descriptor Example 6 – Using a Mask to Address specific module positions

There may be occasions when it is not suitable to use address and length. For example if you are attempting to address non-consecutive

Optomux module positions OR when you wish to use a command that affects all module positions. The driver provides an alternate method for

module position specification by allowing you to specify a mask as a parameter in the CSV file. The mask may be specified in decimal or

hexadecimal format.

In this example, module positions 1 and 5 are pulsed.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Length, Scan_Interval, opto22_mask, opto22_function

PULSE77 , TIME_DATA , 0 , wrbc , DEV77 , 1 , 10.0s , 0x0011 , START ON PULSE

This function turned

on the specified

Module positions are specified in hexadecimal

in this example.

0x0001 = Module Position 1

0x0002 = Module Position 2

0x0003 = Module Positions 1 & 2

…..

module positions for

a specified period.

Un specified

positions (mask bit

positions equal zero)

are non affected by

the command.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 15

Page 18

FS-8700-17 Optomux Driver Manual

4.4.10 Map Descriptor Example 7 – Specifying Module Positions Dynamically

Previous examples addressed module positions statically. This example illustrates how you can use a data array’s value to specify the module position’s to be

affected by a command. As data arrays can have their values chan ged by remote devices, the module position specification may be changed dynamically. The

CSV file does not require editing. This method can be used all the time or only if you wish to use one of those commands which would typically require dynamic

addressing.

In this example, module positions 1 and 5 are pulsed.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Length, Scan_Interval, DA_Bit_Name , opto22_function

CLRLOW77 , LOW_ARRAY , 0 , wrbc , DEV77 , 16 , 10.0s , POS_ARR , READ AND CLEAR LOWEST VALUES

In this example, the driver will store 16 lowest values in an array

called LOW_ARR starting at position Data_Array_Offset.

Any number 1 to 16.

The driver stops at

16, ignoring larger

values.

This data array will be used by

the driver to determine the

module positions to be affected

by the command.

The driver uses the length

(max=16) and the

Data_Array_Offset. The first

specified element corresponds to

module position 1. If its value is

non-zero then the position is

specified by the driver.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-22 99 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 16

Page 19

5 Configuring the FieldServer as a Optomux Server

The FieldServer does not support the emulation of an Optomux server at present.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-2299 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 17

Page 20

FS-8700-17 Optomux Driver Manual

6 Driver Notes

6.1 Data_Array_Name, DA_Bit_Name, DA_Byte_Name

These parameters are used to specify data array names. Despite their

names a data array of any Data_Format can be used for any of these

parameters.

This driver uses DA_Byte_Name exclusively as a location for the commands

to trigger map descriptors and in which to store poll response status.

The use of DA_Bit_Name is command sensitive and is used to allow the

values in a data array to determine the module positions to be affected by a

command.

The use of the Data_Array_Name Parameter is typical i.e. Used to store

data that is read or used as a source for data that is written.

6.2 Module Positions

Specify module positions Statically by

• Using Address and Length or

• Using the opto22_mask parameter or

Specify module positions dynamically by

• Using the values of a data array (da_bit_array)

What happens if more than one method is used for module position specification ?

The driver evaluates the specification in the order listed above. Thus if address &

length are specified as well as the opto22_mask, the driver will use the address

and length.

6.3 Command Response Status

If a data array is specified using the DA_Byte_Array parameter then the driver

will store a response status code in the array, updating the value each time a

command is executed.

Value Description

0 Command completed successfully.

1 Used to trigger a command.

All other values indicate error conditions. For Responses 128 to

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-2299 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 18

Page 21

FS-8700-17 Optomux Driver Manual

255 the Optomux literature should be read for additional

information as these are codes returned by the Optomux device.

128 Nak from Optomux Device. Power Up Clear Expected. Command

Ignored.

129 Nak from Optomux Device. Undefined Command

130 Nak from Optomux Device. Checksum Error

131 Nak from Optomux Device. Input Buffer Overun

132 Nak from Optomux Device. Non Printable Ascii character received

133 Nak from Optomux Device. Data Field Error

134 Nak from Optomux Device. Communication watchdog timeout

135 Nak from Optomux Device. Specified limits invalid.

The following codes are generated by the driver. They all indicate

errors.

250 An ack with no data was expected. Ack with Data was received.

251 The driver Complete function returned an error, could be

checksum, bad 1st char ... ie. The message was badly formatted.

252 Driver Timeout

253 An ack was received but it was badly formatted

254 A nak was received but was badly formatted

255 Message was not acknowledged correctly.

6.4 Optomux Commands

The following provides a list of commands supported by the driver. The Command

Name’s provided in the table must be used in providing values for the opto22_function

parameter. The notes provided only apply when module positions are specified

dynamically.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-2299 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 19

Page 22

FS-8700-17 Optomux Driver Manual

Read/

Write/

Both

w

w

w

w

w

w

r

w

w

w

w

w

w

w

r

w

w

w

r

w

COMMAND NAME OPTO22_FORMAT

OPTION

POWER UP CLEAR 4

RESET 4

SET TURN-AROUND DELAY 4

SET WATCHDOG DELAY 4

SET WATCHDOG DELAY (Analog) 3

SET PROTOCOL 4

IDENTIFY Optomux TYPE 4

SET ENHANCED DIGITAL WATCHDOG 3

SET ENHANCED ANALOG WATCHDOG 1

SET TIMER RESOLUTION

SET TEMPERATURE PROBE TYPE 3

CONFIGURE POSITIONS 3

CONFIGURE AS INPUTS 3

CONFIGURE AS OUTPUTS 3

READ MODULE CONFIGURATION 4

WRITE OUTPUTS 1

ACTIVATE OUTPUTS 3

DEACTIVATE OUTPUTS 3

READ STATUS 1 2

SET LATCH EDGES 3

MASTER LENGTH

CONSIDERED (See

Notes)

Uses 1 element of data array. Legal

values are 0,1,2,3

Uses 1 element of data array. Legal

values are 0 to 7

Uses the 1st element of data array for

the timer value.

Uses 1 element of data array. Legal

values are 0,1

Polled data is stored in the 1st

element of the data array.

Delay is found in data array.

Uses up to Length (max=16) array

elements. Module positions specified

get setup for fail values by using the

corresponding positions in data array.

Uses 1 element of data array.

Temp probe type is found in first

element of data array

Non-zero module positions get set to

outputs. Zero module positions get

set to inputs

Only module positions specified get

affected by command.

Only module positions specified get

affected by command.

Uses up to Length (max=16) array

elements. Non-zero elements get

turned on, zero value elements get

turned off.

Only module positions specified get

affected by command.

Only module positions specified get

affected by command.

If format=Bit then length is considered

during storage as bits are unpacked

into data array. If format is non equal

to bit then result is written as a single

value into one array element.

Retrieved data is stored in data array.

Always affects all module positions.

Cannot be limited by length. Length is

only used when determining which

module positions are specified as

non-zero. Non-zero (Specified)

elements get set on->off, Zero (Non-

NOTES

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-2299 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 20

Page 23

FS-8700-17 Optomux Driver Manual

Read/

Write/

Both

w

w

r

b

w

w

w

w

r

b

w

w

w

w

w

w

COMMAND NAME OPTO22_FORMAT

OPTION

SET LATCH OFF TO ON 3

SET LATCH ON TO OFF 3

READ LATCHES 1 2

READ AND CLEAR LATCHES 1 3,2

CLEAR LATCHES 3

START/STOP COUNTERS 3

START COUNTERS 3

STOP COUNTERS 3

READ COUNTERS 1

READ AND CLEAR COUNTERS 1

CLEAR COUNTERS 3

SET TIME DELAY 3

INITIATE SQUARE WAVE 3

HIGH RESOLUTION SQUARE WAVE 3

RETRIGGER TIME DELAY 3

GENERATE N PULSES 3

MASTER LENGTH

CONSIDERED (See

Notes)

NOTES

Specified) module positions get set

off->on

Only module positions specified get

affected by command.

Only module positions specified get

affected by command.

If format=Bit then length is considered

during storage as bits are unpacked

into data array. If format is non equal

to bit then result is written as a single

value into one array element.

Non-zero (Specified) module

positions get affected (cleared) by

command. But all positions get read.

Read data get stored in data array.

During storage opto22_format is

considered. If format=bit then data is

unpacked and stored otherwise the

result for all 16 positions is stored as

one data element.

Only module positions specified get

affected by command.

All positions are affected by

command. Non-zero (specified)

module positions start counting, zero

(unspecified) module positions stop

counting

Only module positions specified get

affected by command.

Only module positions specified get

affected by command.

Data that is read is put into the

corresponding array elements of the

data array based on which module

positions are read.

Data that is read is put into the

corresponding array elements of the

data array based on which module

positions are read.

Only module positions specified get

affected by command.

The Modifier is specified in the CSV

file with the opto22_modifier1

parameter. The data (timeout) is

retrieved from the first element of the

data array.

Only module positions specified get

affected by command.

Only specified module positions get

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-2299 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 21

Page 24

FS-8700-17 Optomux Driver Manual

Read/

Write/

Both

w

w

w

w

w

r

r

b

w

w

r

w

r

COMMAND NAME OPTO22_FORMAT

START ON PULSE 3

START OFF PULSE 3

SET TRIGGER POLARITY 3

TRIGGER ON POSITIVE 3

TRIGGER ON NEGATIVE 3

READ PULSE COMPLETE BITS 1 2

READ DURATION COUNTERS 3

READ AND CLEAR DURATION

COUNTERS

CLEAR DURATION COUNTERS 3

WRITE ANALOG OUTPUTS 3

READ ANALOG OUTPUTS 3

UPDATE ANALOG OUTPUTS 3

READ ANALOG INPUTS 3

OPTION

3

MASTER LENGTH

CONSIDERED (See

Notes)

NOTES

affected. The Modifier (byte 1&2) are

specified in the CSV file with the

opto22_modifier1/2 parameters. The

data (number of pulses) is retrieved

from the 1st element of the data

array.

Only specified module positions get

affected. The data (period of pulses)

is retrieved from the 1st element of

the data array.

Only specified module positions get

affected. The data (period of pulses)

is retrieved from the first element of

the data array.

All Module positions are affected by

this command. Non-zero (Specified)

module positions triggered by on,

zero module positions (un-specified)

elements get triggered by off.

Only module positions specified get

affected by command.

Only module positions specified get

affected by command.

If format=Bit then length is considered

during storage as bits are unpacked

into data array. If format is non equal

to bit then result is written as a single

value into one array element.

Retrieved data is stored in standard

data array.

Only specified module positions get

read. Data read gets put in

corresponding positions of data array.

Only specified module positions get

read. Data read gets put in

corresponding positions of data array.

Only module positions specified get

affected by command.

Only specified module positions get

written. Data written gets extracted

from corresponding positions of data

array.

Only specified module positions get

read. Data read gets put in

corresponding positions of data array.

Only specified module positions get

written. Data written gets extracted

from corresponding positions of data

array.

Only specified module positions get

read. Data read gets put in

corresponding positions of data array.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-2299 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 22

Page 25

FS-8700-17 Optomux Driver Manual

Read/

Write/

Both

r

w

r

r

r

r

w

r

b

w

r

w

b

r

w

COMMAND NAME OPTO22_FORMAT

OPTION

READ AND AVERAGE INPUT 4

START INPUT AVERAGING 3

READ AVERAGE COMPLETE BITS 1 2

READ INPUT AVERAGE DATA 3

READ TEMPERATURE INPUTS 3

READ AVERAGE TEMPERATURE INPUTS 3

SET INPUT RANGE 3

READ OUT-OF-RANGE LATCHES 4

READ AND CLEAR RANGE LATCHES 3

CLEAR OUT-OF-RANGE LATCHES 4

READ LOWEST VALUES 3

CLEAR LOWEST VALUES 3

READ AND CLEAR LOWEST VALUES 3

READ PEAK VALUES 3

CLEAR PEAK VALUES 3

MASTER LENGTH

CONSIDERED (See

Notes)

NOTES

Only one module position may be

specified. This position is averaged

and the result is put in the first

element of the data array The number

of samples is specified in modifier1 in

the csv file.

Only specified module positions get

affected by command. First element

in data array is sent as the number of

sample to average over.

If format=Bit then length is considered

during storage as bits are unpacked

into data array. If format is non equal

to bit then result is written as a single

value into one array element.

Retrieved data is stored in standard

data array.

Only specified module positions get

read. Data read gets put in

corresponding positions of data array.

Only specified module positions get

read. Data read gets put in

corresponding positions of data array.

Only specified module positions get

read. Data read gets put in

corresponding positions of data array.

Only specified module positions have

their range set to the 2 values found

in the data array. 1st is high limit,

second is lo limit.

High limit latches are placed in first

element of data array. Low limit

latches are placed in 2nd element of

data array.

Only specified module positions get

read and cleared. Data read gets put

in corresponding positions of data

array.

Only specified module positions get

read. Data read gets put in

corresponding positions of data array.

Only module positions specified get

affected by command.

Only specified module positions get

read and cleared. Data read gets put

in corresponding positions of data

array.

Only specified module positions get

read. Data read gets put in

corresponding positions of data array.

Only module positions specified get

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-2299 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 23

Page 26

FS-8700-17 Optomux Driver Manual

Read/

Write/

Both

b

r

w

r

r

w

r

w

w

COMMAND NAME OPTO22_FORMAT

OPTION

READ AND CLEAR PEAK 3

CALCULATE OFFSETS 1

SET OFFSETS 1

CALCULATE AND SET OFFSETS 1

CALCULATE GAIN COEFFICIENTS 1

SET GAIN COEFFICIENTS 1

CALCULATE AND SET GAIN 1

SET OUTPUT WAVEFORM R 4

IMPROVED OUTPUT WAVEFORMS 4

MASTER LENGTH

CONSIDERED (See

Notes)

Notes on how the Length parameter is used in the CSV file.

1. The length parameter is always considered.

2. The length parameter is only considered when the keyword Bit is used in the

opto22_format parameter.

3. The length is only used using the address/length method to specify module

positions or when the dynamic method is used to specify module positions.

4. The length is never considered.

NOTES

affected by command.

Only specified module positions get

read and cleared. Data read gets put

in corresponding positions of data

array.

Only specified module positions get

calculated and read. Data read gets

put in corresponding positions of data

array.

Only specified module positions get

written. Data written gets extracted

from corresponding positions of data

array.

Only specified module positions get

calculated and read. Data read gets

put in corresponding positions of data

array.

Only specified module positions get

calculated and read. Data read gets

put in corresponding positions of data

array.

Only specified module positions get

written. Data written gets extracted

from corresponding positions of data

array.

Only specified module positions get

calculated and read. Data read gets

put in corresponding positions of data

array.

Uses opto22_modifier1/2 from the

CSV file set waveform rates and

types. Only specified positions get

affected. 2 elements of data array

are used.

Uses opto22_modifier1/2 from the

CSV file set waveform rates and

types. Only specified positions get

affected. 3 elements of data array

are used.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-2299 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 24

Page 27

FS-8700-17 Optomux Driver Manual

6.5 Driver Stats

In addition to the standard FieldServer communication statistics described in the FieldServer

User’s Manual the Optomux Driver can also

a data array. A special map descriptor is required. The driver recognizes the map

descriptor by its name which must be "opto22-stats" .

The following example shows how this special map descriptor can be configured.

Nodes

Node_name, Node_ID, Protocol

null_node, 0 , Optomux

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length

OPTO22_STATS , UINT32 , 300

Map_Descriptors

Map_descriptor_Name, Data_Array_Name, Node_name, length

Opto22-stats , OPTO22_STATS , null_node , 300

When the driver sees this map descriptor it uses the data array SK_STATS (in this

example) to store driver specific statistics. Only one of these map descriptors may be

specified per FieldServer.

The driver stores the following data.

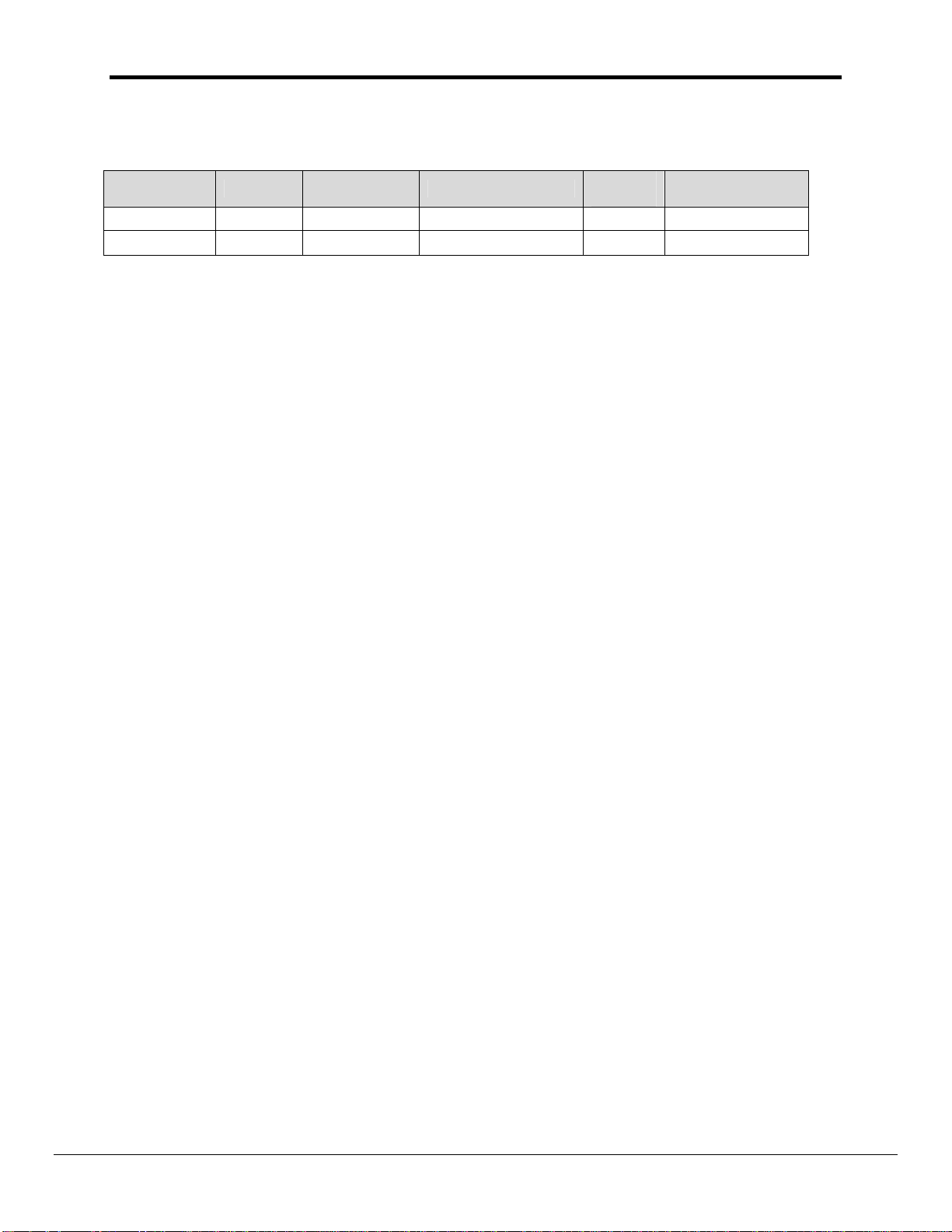

Array Element Contents

0

1 OPTO_STAT_DYNAMIC_MASK Mask cannot be specified in a

2 OPTO_STAT_TIMEOUT

3 OPTO_STAT_STREAMING

4 OPTO_STAT_NAK

5 OPTO_STAT_PROTOCOL

6 OPTO_STAT_IC_TIMEOUT

7 OPTO_STAT_DEVICE_MSG_RECD

8 OPTO_STAT_DEVICE_BYTES_RECD

9 OPTO_STAT_DEVICE_FUNCTION

10 OPTO_STAT_NO_START

11 OPTO_STAT_MSG_IGNORED

12 OPTO_STAT_POLL_MSG_SENT

12 OPTO_STAT_POLL_BYTES_SENT

expose some driver statistics by writing data to

OPTO_STAT_BAD_FUNCTION

The Opto22_Function has a

bad value.

CSV file with a zero value.

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-2299 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 25

Page 28

FS-8700-17 Optomux Driver Manual

7 Revision History

Date Resp Format Driver Ver.

2/18/04 JD MF 0 1 Releasing

Doc.

Rev.

Comment

FieldServer Technologies 1991 Tarob Court, Milpitas, California 95035 (408) 262-2299 fax: (408) 262-9042

Visit our website: www.fieldserver.com E-mail: support@fieldserver.com

Page 26

Loading...

Loading...