Page 1

-

A Sierra Monitor Company

Driver Manual

(Supplement to the FieldServer Instruction Manual)

FS-8700-103 ATMI-TGM Serial Driver

APPLICABILITY & EFFECTIVITY

Effective for all systems manufactured after May 1, 2001

Driver Version: 1.00

Document Revision: 2

Page 2

FS-8700-103_ATMI_TGM_Serial Manual Table of Contents

TABLE OF CONTENTS

1. ATMI TGM SERIAL DRIVER DESCRIPTION...................................................................3

2. DRIVER SCOPE OF SUPPLY...........................................................................................4

2.1. Supplied by FieldServer Technologies for this driver ...................................................4

2.2. Provided by the Supplier of 3rd Party Equipment..........................................................4

2.2.1. Required 3rd Party Hardware.....................................................................................4

2.2.2. Required 3rd Party Configuration...............................................................................4

3. HARDWARE CONNECTIONS ..........................................................................................5

3.1. Hardware Connection Tips / Hints................................................................................6

4. CONFIGURING THE FIELDSERVER AS A ATMI TGM SERIAL CLIENT.......................7

4.1. Data Arrays/Descriptors ...............................................................................................7

4.2. Client Side Connection Descriptions ............................................................................8

4.3. Client Side Node Descriptors .......................................................................................8

4.4. Client Side Map Descriptors .........................................................................................9

4.4.1. FieldServer Related Map Descriptor Parameters......................................................9

4.4.2. Driver Related Map Descriptor Parameters ..............................................................9

4.4.3. Timing Parameters....................................................................................................9

4.4.4. Map Descriptor Example #1 – CALR Report...........................................................10

4.4.5. Map Descriptor Example #2 – QLA Report.............................................................11

4.5. Map Descriptor Example #3 – QIR Report – Malfunctions ......................................... 12

APPENDIX A. TGM TABLES..................................................................................................13

Appendix A.1. Hard Coded Gas Name Table.......................................................................13

Appendix A.2. Malfunction Table .......................................................................................... 14

Appendix A.3. Gas Concentration Engineering Units ........................................................... 15

APPENDIX B. ADVANCED TOPICS ......................................................................................16

Appendix B.1. How Malfunctions are determined and stored...............................................16

Appendix B.2. How Gas Data is Stored................................................................................17

Appendix B.3. Adding/Modifying Gas Concentration Value Engineering Units ....................18

Appendix B.4. Adding / Modifying Hard Coded Gas Names ................................................18

Appendix B.5. Adding / Modifying Malfunction Strings .........................................................19

Appendix B.6. Adding / Modifying ‘Return to Normal’ Strings...............................................20

Appendix B.7. Using the TGM’s Config.dat file to customize malfunctions ..........................20

Appendix B.8. Synchronizing Malfunctions...........................................................................21

APPENDIX C. DRIVER ERROR MESSAGES........................................................................22

Appendix C.1. Exposing Driver Operating Statistics.............................................................25

APPENDIX D. TROUBLESHOOTING TIPS............................................................................27

Appendix D.1. Connection Tips & Hints................................................................................27

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 3

FS-8700-103_ATMI_TGM_Serial Manual Page 3 of 28

1. ATMI TGM Serial Driver Description

The ATMI-TGM driver allows the FieldServer to transfer data to and from devices over RS-232

using the ATMI-TGM printer port protocol.

This driver connects to an ATMI TGM device using a serial connection. One device may be

connected per FieldServer port. (This limitation exists because the protocol is node-less; that is,

messages do not contain information about the node and thus messages from different TGM

devices could not be distinguished if they were connected on the same port.)

The driver reports Gas and sensor readings and Gas alarm / warning status. The driver reports

TGM module malfunctions.

The driver is a client only driver.

When reporting port and sensor data, the driver reports the gas name by setting a gas name

index value. The index value is obtained from a list of gas names / index values hard coded into

the driver. The list may be extended and/or modified using the configuration by using

appropriate entries in the configuration CSV file. The driver reports a second gas name index

value based on reading the TGM calibration report. When the report is read each gas is

allocated an identifier value based on the gas’s position in the configuration report.

The driver does not provide emulation of a TGM device and thus may not be used as a server.

It is not possible to use this driver to write to the TGM device.

Max Nodes Supported

FieldServer Mode Nodes Comments

CLIENT 1 ONLY 1 SERVER NODE ALLOWED PER PORT.

SERVER 1 Server capability not provided.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 4

FS-8700-103_ATMI_TGM_Serial Manual Page 4 of 28

2. Driver Scope of Supply

2.1. Supplied by FieldServer Technologies for this driver

FieldServer Technologies

PART #

FS-8917-12

Description

Connector, 9-pin female: connects to DTE, DSR/DTR

loop

FS-8700-103 Driver Manual.

2.2. Provided by the Supplier of 3rd Party Equipment

2.2.1. Required 3rd Party Hardware

Part # Description

No specific Hardware requirements other than TGM unit.

2.2.2. Required 3rd Party Configuration

The FieldServer’s serial port must be configured to be used as a ‘Console Port’ on the

TGM device. The ‘Console Port’ is configurable. At least one of the two serial ports on

the TGM device must be configured to enable the ‘Console Port’. This is not always the

case when the TGM is shipped. Notes in Appendix D provide additional information.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 5

FS-8700-103_ATMI_TGM_Serial Manual Page 5 of 28

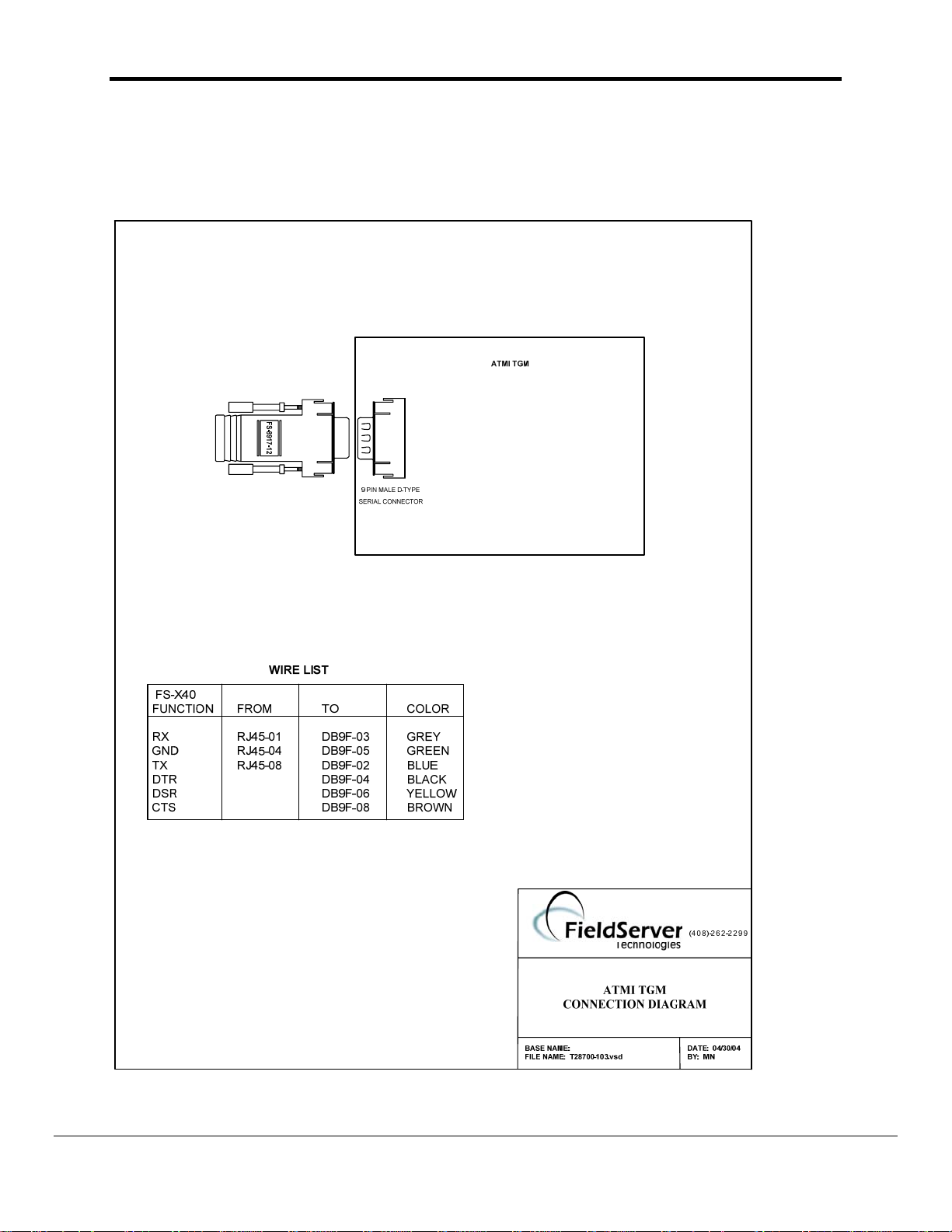

3. Hardware Connections

The FieldServer is connected to the TGM device’s printer port as shown in connection drawing.

Configure the TGM device according to manufacturer’s instructions

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 6

FS-8700-103_ATMI_TGM_Serial Manual Page 6 of 28

3.1. Hardware Connection Tips / Hints

The following notes are provided from a TGM manual:

The TGM code constantly checks the status of the DSR input of its serial ports connected to

the DTR output of the remote serial ports. If the TGM DSR is NOT ASSERTED (FALSE),

then the TGM software will suspend serial data output out of TGM Tx, and start a timeout

timer (the default timeout time = 30 seconds as set in CONFIG.DAT). During this timeout, if

the DSR is ASSERTED (TRUE), then the TGM software will begin transmitting data. If the

DSR hold exceeds the (configurable) 30 second timeout, the TGM will report a malfunction:

MALFUN PRINTER OFF LINE hh:mm dd mmm yy

MALFUN REMOTE OFF LINE hh:mm dd mmm yy

depending upon which port has timed out. Restoration of the DSR status as ASSERTED or

TRUE will clear the above malfunction(s). The above malfunctions will occur if the active

TGM serial ports (printer or remote) are not connected upon bootup with the proper null

modem cables to active serial ports with DTR (connected to theTGM DSR)

ASSERTED/TRUE. The TGM can have the hardware control defeated by jumpering CTS to

DTR to DSR on the TGM side of the connector.

The driver does not provide the hardware handshaking required and assumes the hardware

control has been defeated with jumpers.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 7

FS-8700-103_ATMI_TGM_Serial Manual Page 7 of 28

4. Configuring the FieldServer as a ATMI TGM Serial Client

For a detailed discussion on FieldServer configuration, please refer to the FieldServer

Configuration Manual. The information that follows describes how to expand upon the factory

defaults provided in the configuration files included with the FieldServer (See “.csv” sample files

provided with the FieldServer).

This section documents and describes the parameters necessary for configuring the FieldServer

to communicate with a TGM device.

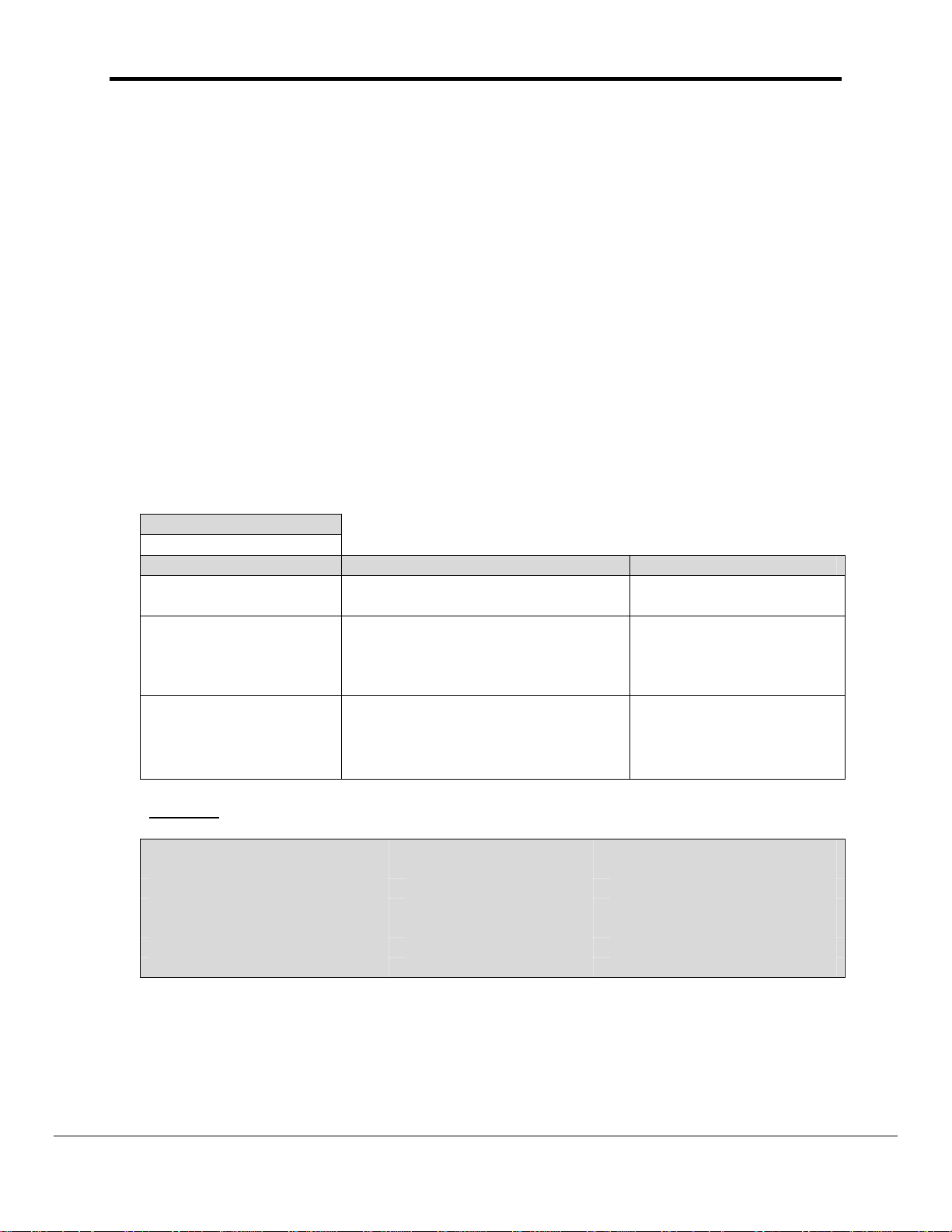

4.1. Data Arrays/Descriptors

The configuration file tells the FieldServer about its interfaces, and the routing of data

required. In order to enable the FieldServer for ATMI TGM Serial communications, the driver

independent FieldServer buffers need to be declared in the “Data Arrays” section, the

destination device addresses need to be declared in the “Client Side Nodes” section, and

the data required from the servers needs to be mapped in the “Client Side Map Descriptors”

section. Details on how to do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value being the

default.

Section Title

Data_Arrays

Column Title Function Legal Values

Data_Array_Name Provide name for Data Array

Data_Array_Format

Data_Array_Length

Example

// Data Arrays

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length

DA_AI_01, UInt16, 200

DA_AO_01, UInt16, 200

DA_DI_01, Bit, 200

DA_DO_01, Bit, 200

Provide data format. Each Data

Array can only take on one format.

Number of Data Objects. Must be

larger than the data storage area

required by the Map Descriptors for

the data being placed in this array.

Up to 15 alphanumeric

characters

Float, Bit, UInt16, SInt16,

Packed_Bit, Byte,

Packed_Byte,

Swapped_Byte

1-10,000

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 8

FS-8700-103_ATMI_TGM_Serial Manual Page 8 of 28

4.2. Client Side Connection Descriptions

Section Title

Connections

Column Title Function Legal Values

Port

Protocol Specify protocol used TGM-Serial, ATMI-TGM-Serial

Baud* Specify baud rate

Parity* Specify parity None (Vendor limitation)

Data_Bits* Specify data bits 8 (Vendor limitation)

Stop_Bits* Specify stop bits

Handshaking* Specify hardware handshaking

Poll _Delay* Time between internal polls 0-32000 seconds, 1 second

Example

// Client Side Connections

Connections

Port, Protocol, Baud, Parity, Handshaking, Poll_Delay

P8, TGM-Serial, 9600, None, None, 0.100s

Specify which port the device is

connected to the FieldServer

P1-P8, R1-R21

110 – 19200, standard baud

rates only (Vendor limitation)

1

None

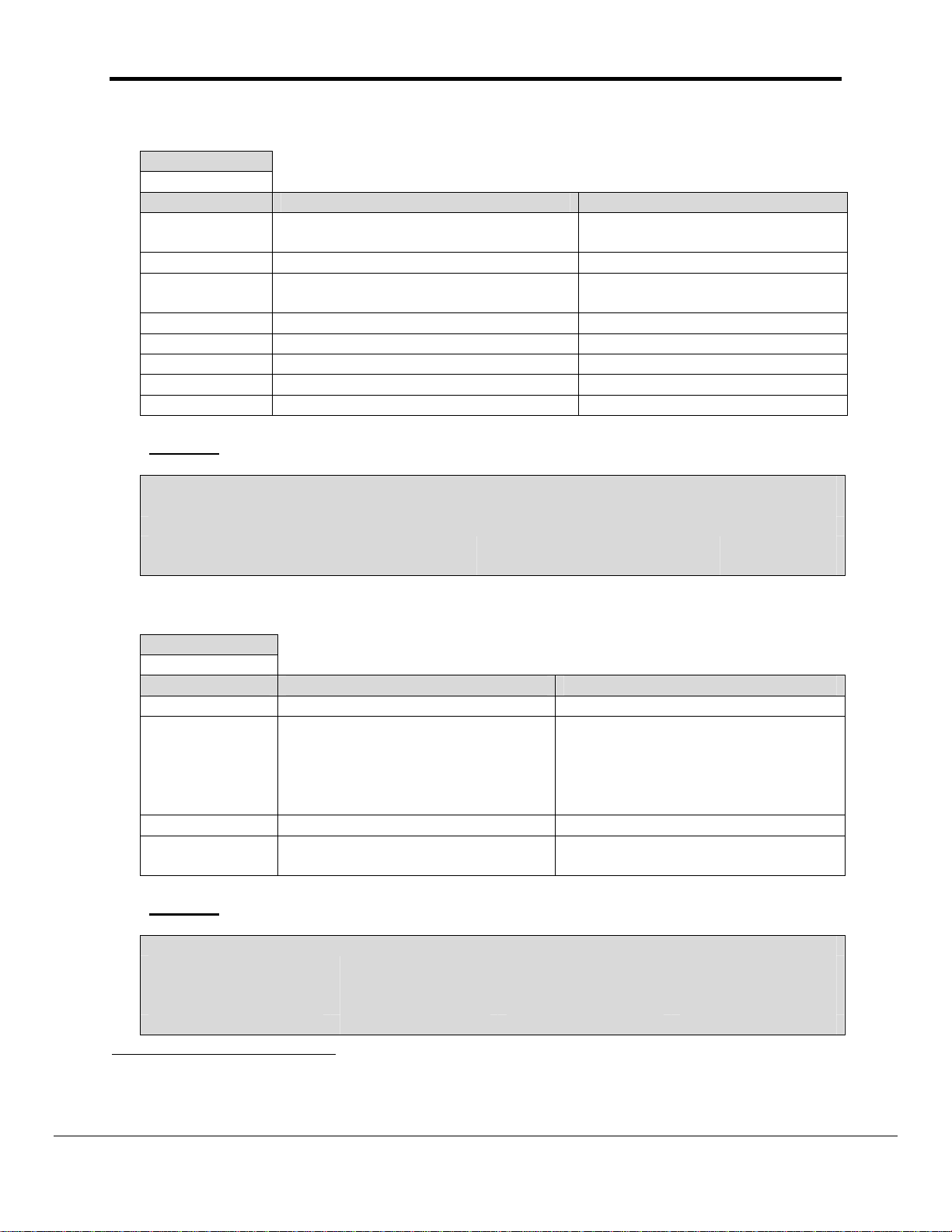

4.3. Client Side Node Descriptors

Section Title

Nodes

Column Title Function Legal Values

Node_Name Provide name for node Up to 32 alphanumeric characters

This parameter is not required for

the TGM driver. However, if you

Node_ID

Protocol Specify protocol used TGM-Serial, ATMI-TGM-Serial

Connection

Example

// Client Side Nodes

Nodes

Node_Name, Node_ID, Protocol, Connection

PLC 1, 1, TGM-Serial, P8

1

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction

manual for details of the ports available on specific hardware.

intend to use the Node_Status

function with a Data Array then

the Node_ID must be specified.

Specify which port the device is

connected to the FieldServer

1-255

P1-P8, R1-R21

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 9

FS-8700-103_ATMI_TGM_Serial Manual Page 9 of 28

4.4. Client Side Map Descriptors

4.4.1. FieldServer Related Map Descriptor Parameters

Column Title Function Legal Values

Map_Descriptor_Name Name of this Map Descriptor

Name of Data Array where

Data_Array_Name

Data_Array_Offset Starting location in Data Array

Function

data is to be stored in the

FieldServer

Function of Client Map

Descriptor. The driver cannot

write to the TGM device.

Up to 32 alphanumeric

characters

One of the Data Array

names from “Data Array”

section above

0 to maximum specified in

“Data Array” section above

RDBC, ARS

4.4.2. Driver Related Map Descriptor Parameters

Column

Title

Node_Name Name of Node to fetch data from

Data_Type This commonly used driver parameter is not used by the driver.

Length of Map Descriptor

The parameter is not used by

Length

Address This commonly used parameter is ignored by the driver.

the driver but is used by the

FieldServer Kernel to reserve

space in the Data Array.

Set the Length according to the

function.

Function Legal Values

One of the node names specified in

“Client Node Descriptor” above

QIR Report: Length = 100

CALR Report: Variable. Depends on

number of gases reported in CALR

report. Start with a length of 100 and

increase if necessary.

QLA Report:

If the config has no sensors and port

x is the max port number, then make

the array (x+1) * 10 elements long

If the config has any sensors and

sensor x is the max sensor number

then make the array 200 + (x+1) *

10 elements long

4.4.3. Timing Parameters

Column Title Function

Rate at which data is polled

For CALR report use a long interval (600s) as the TGM

Scan_Interval

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

configuration seldom changes.

Set the Scan_Interval for the QLA and QIR reports to zero

to have the driver poll for this data as often as possible.

Legal

Values

≥0.001s

Page 10

FS-8700-103_ATMI_TGM_Serial Manual Page 10 of 28

4.4.4. Map Descriptor Example #1 – CALR Report.

To be useful to the upstream device the driver reports gas concentration values and gas names from the QLA report. In reporting the

gas names it is most useful when a driver stores an index value which is used to imply the gas names. The reason this is most useful

is that it is typically easier for automation devices to work with numbers and not text.

When the driver reads the Calibration report, it does two things.

1) It stores a string of gas names vs. index values in the Data Array. This string can be viewed using the Ruinet Utility and may be of

help in interpreting the gas name index values stored by the QLA report.

2) The data is stored internally by the driver and when a QLA report is parsed the driver looks the gas names up in the CALR report

data and uses the lookup to determine what gas name index value to store.

// Client Side Map Descriptors

Map Descriptors

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Address Length, Scan_Interval, TGM_Funtion

RD_CALR, DA_CALR, 0, RDBC, Node_A, 0, 100, 600s, CALR

Although not

mandatory it is

recommended

that each MD is

given a unique

name.

A list of gas names vs. index values is

stored in the Data Array specified here.

In this particular example, the list is

stored as an ASCII string and hence it

makes most sense to ensure that the

Data Array’s format is BYTE so that it

can be viewed as a string when using

Ruinet.

Data storage

starts at this

location in the

Data Array.

Tells the driver to repeat this

read task continuously. The

polling interval is set by the

Scan_Interval parameter.

For the CALR report is may

also make sense to use the

‘ARS’ function which gets the

driver to read this data once

each time the driver restarts.

The node name connects the Map Descriptor to a

Node definition which in turn is connected to a port.

That is how the driver knows which port to use to

poll for this data.

Reserve enough

space in the Data

Array to store the

gas/index string.

Tells the driver

to read the

Calibration

report.

No need to

read this report

too often.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 11

FS-8700-103_ATMI_TGM_Serial Manual Page 11 of 28

y

4.4.5. Map Descriptor Example #2 – QLA Report.

In this example, a Map Descriptor is created to read the Latest Area Report (QLA). This report contains gas concentration and status

for each port and sensor. Ten Data array elements are required for each port / sensor that is reported. The poistion in the array is

dependent on the port/sensor number. Appendix B provides additional information. By specifying the extra arrays (DA_Bit_Name and

DA_Byte_Name) the driver stores additional information.

// Client Side Map descriptors

Map Descriptors

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name Address Length Scan_Interval DA_Byte_Name DA_Bit_Name TGM_Funtion

RD_QLA, DA_CALR, 0, RDBC, Node_A, 0, 300, 1.0s DA_GAS_UNITS DA_QLA_GAS QLA

Gas concentration

value, status,

engineering units index

values, gas name index

values are stored in this

Data Arra

This parameter may be omitted. If specified

then the Data Array will be used to store

the gas concentration value engineering

units in ASCII. Storage position is

dependent on the port/ sensor number.

This parameter may be omitted. If

specified then the Data Array will

be used to store the gas name in

ASCII. Storage position is

dependent on the port/ sensor

number.

Tells the driver

to read the QLA

report.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 12

FS-8700-103_ATMI_TGM_Serial Manual Page 12 of 28

4.5. Map Descriptor Example #3 – QIR Report – Malfunctions

In this example the Map Descriptor is configured to read the incident report. The driver parses the report looking for malfunctions and

reports that show a malfunction has been cleared. Other incidents / events are ignored except for events #19 and #37 which cause

all malfunctions to be cleared. The Driver updates the array setting values to 1 (malfunction) or zero when a malfunction has been

cleared. The position indicates the malfunction number. The driver has a list of malfunctions and index numbers stored internally.

Refer to Appendix A.2 for this list. The list can be modified in the configuration CSV file.

CAUTION: When the QIR report is polled it responds with the latest incidents only. This means that care should be taken to

synchronize the FieldServer and the TGM. Read more about this in Appendix B.8

// Client Side Map Descriptors

Map Descriptors

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name Address Length Scan_Interval TGM_Funtion

RD_QIR, DA_MALFUNC, 0, RDBC, Node_A, 0, 100, 2.0s QIR

Driver sets the Data Array elements to 1 when there is

malfunction and sets the value to zero when the malfunction is

cleared.

Position in the array indicates the malfunction number.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Tells the driver

to read the

incident report

.

Page 13

FS-8700-103_ATMI_TGM_Serial Manual Page 13 of 28

Appendix A. TGM Tables

Appendix A.1. Hard Coded Gas Name Table

This table is used by the driver when storing data from the QLA report. The driver looks the

reported gas name up in this table. If a match is found then the driver stores the

corresponding index value in the Data Array. If no match is found the the driver stores a

value of –1.

The table may be extended/modified using the configuration file. Refer to Appendix B.4

Gas Name Index Value

Error / Unknown -1

NONE 1

ASH3 3

B2H6 6

CH4 9

CH4AC 12

CL2 15

DET 18

F123 21

GEH4 24

H2 27

H2AC 30

H2S 33

H2SE 36

HCL 39

HF 42

N2O 45

NF3 48

NH3 51

O2 54

O3 57

PH3 60

POCL 63

POCL3 66

SIHX 69

SIHx 70

TMBP 75

WF6 78

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 14

FS-8700-103_ATMI_TGM_Serial Manual Page 14 of 28

Appendix A.2. Malfunction Table

When an event is reported in the Incident Report (QIR) then the driver compares the event

description to text in the table below. If the text matches an an entry in the ‘Malfunction’

column (and is preceeded by the string MALFUNC) then the Data Array element at the

specified offset is set to 1. If the text matches the ‘Return to Normal’ text then the

malfunction is considered as cleared and the Data Array element is set to zero.

The Data Array elements are all set to zero when

Event 19 reports ” ALARM RESET “ or Event 37 reports “ALL MALFUNCTIONS CLEAR”

The Malunction text strings generated by the TGM unit are not the same for all units. They

can be customized in theTGM’s config.dat file. For this reason, this driver allows the strings

in the table below to be customized too – see Appendix B.5. In addition to allowing this

table to be customised in the configuration file, the driver can use a config.dat file to directly

customise the table – see Appendix B.7

Offset Malfunction Return to Normal

20 BASELINE OUT OF RANGE BASELINE BACK TO NORMAL

22 IGNITER SWITCH IS ON IGNITER SWITCH IS OFF

24 FLAME IGNITION DISABLED FLAME IGNITION ENABLED

26 LOW VACUUM VACUUM BACK TO NORMAL

28 FLAMEOUT RESTART FLAMEOUT BACK TO NORMAL

30 LINE LEAK TEST MALFUN LINE LEAK BACK TO NORMAL

32 POWER FAILURE POWER RESTORED

38 FAILED TO LOAD PROGRAM

39 DPM TIMEOUT DPM BACK TO NORMAL

41 RELAY FILE ERROR OPERATIONS CHECK DONE

45 CHECK I/O AND FUSES I/O AND FUSES OK NOW

47 TGM IN DEBUG MODE

48 DISK NEARLY FULL ADEQUATE DISK STORAGE NOW

50 FLAMEOUT CONDITION RETURN FROM FLAMEOUT

52 FAILED FLAME TEST FLAME TEST OK NOW

54 FAILED RESPONSE TEST RESPONSE TEST OK NOW

56 FAILED BLOCK LEAK CHECK BLOCK LEAK CHECK OK NOW

58 ANALOG SUBSYSTEM FAILURE ANALOG SUBSYSTEM NORMAL

60 ANALOG CHANNEL FAILURE ANALOG CHANNEL NORMAL

62 PRINTER OFF LINE PRINTER BACK TO NORMAL

64 REMOTE OFF LINE REMOTE BACK TO NORMAL

66 DISK READ/WRITE ERR DISK BACK TO NORMAL

68 LAN READ/WRITE ERROR LAN BACK TO NORMAL

70 DISK FULL - DATA LOST DISK NO LONGER FULL

75 HIGH SAMPLE VARIANCE SAMPLE VARIANCE OK NOW

80 COUS SENSOR TIMEOUT COUS TIMEOUT CORRECTED

82 COUS GETTER INOPERATIVE COUS GETTER OK NOW

84 ACOUSTIC SENSOR FAILURE ACOUSTIC SENSOR RECOVERD

86 GETTER TEMPERATURE LOW GETTER TEMPERATUR OK NOW

88 LOW SAMPLE FLOW SAMPLE FLOW OK NOW

90 TGM HYDROGEN LEAK HYDROGEN LEAK REPAIRED

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 15

FS-8700-103_ATMI_TGM_Serial Manual Page 15 of 28

Appendix A.3. Gas Concentration Engineering Units

This table is used by the driver when storing data from the QLA report. The driver looks the

reported engineering units up in this table. If an matching entry is found then the driver

stores the index value. If a matching entry cannot be found then the driver stores a value of

–1. (Note that when –1 is stored in a BYTE or UINT16 formatted Data Aray it will appear as

a positive number such as 255 (Byte Array) or 65535 (uint16 Array).

The table may be extended/modified using the configuration file. Refer to Appendix B.1

Engineering Units Index Value

Error / Unknown -1

ARU 1

PPM 2

PPB 3

LEL 4

% 5

PCT 6

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 16

FS-8700-103_ATMI_TGM_Serial Manual Page 16 of 28

Appendix B. Advanced Topics

Appendix B.1. How Malfunctions are determined and stored

• The notes below describe how the driver parses incident reports obtained by the QIR

poll.

• The driver starts at the end of the report and works its way to the top, line by line.

• Each line is inspected to see if it contains either of the following strings

“ALARM RESET"

"ALL MALFUNCTIONS CLEAR”

• If either is reported then the driver sets all the array elements to zero except those

corresponding to lines of the report appearing after (and hence later in time) one of the

above lines that indicates that malfunctions be set, in which case those particular

malfunctions will be reported as 1’s in the Data Array.

• When either one of these two events is found the driver stops parsing the report as all

prior lines predate the clear event.

• Each line is inspected for the string “MALFUN”. If it is found then ‘Event’ field in the

report is inspected and the description is extracted and compared to the malfunction list

provided in Appendix A.2. If a match is found the driver uses the offset value and sets

the corresponding element in the Data Array to 1.

• If the string “MAFUN” is not found then the description found in the ‘Event’ field of the

report is used to look up a ‘Return to Normal’ event in the table provided in Appendix

A.2. If a match is found then the corresponding offset in the Data Array is set to zero.

• If the description is not recognized then it it is ignored.

Example

Only the Malfunction ‘COUS SENSOR TIMEOUT’ would have its Data Array element set to

1. All others will be set to zero. The reason is that all events above the ‘ALARM RESET’ line

are considered to be prior to the reset and are thus cleared when the driver sets all the Data

Array elements to zero. The timeout event occurs later and hence its malfunction is set.

When the driver uses the lookup table to see if it recognizes the event description then it

compares the strings looking for an exact match. If no exact match is made then the driver

uses a so-called ‘soundex’ function to see if the strings are very similar, if they are then they

are considered to be matched. If a similar match is made the driver reports this in the error

log.

MALFUN POWER FAILURE 00:00 00 00

POWER RESTORED 10:29 16 FEB 04

MALFUN TGM IN DEBUG MODE 10:29 16 FEB 04

MALFUN FAILED FLAME TEST 10:29 16 FEB 04

ALARM RESET 10:29 16 FEB 04

MALFUN COUS SENSOR TIMEOUT 10:29 16 FEB 04

16 T02> TGM:#21 FYI. Malfunction. Dont recognize <POWER FAILED>

17 T02> But sounds like <POWER FAILURE>.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 17

FS-8700-103_ATMI_TGM_Serial Manual Page 17 of 28

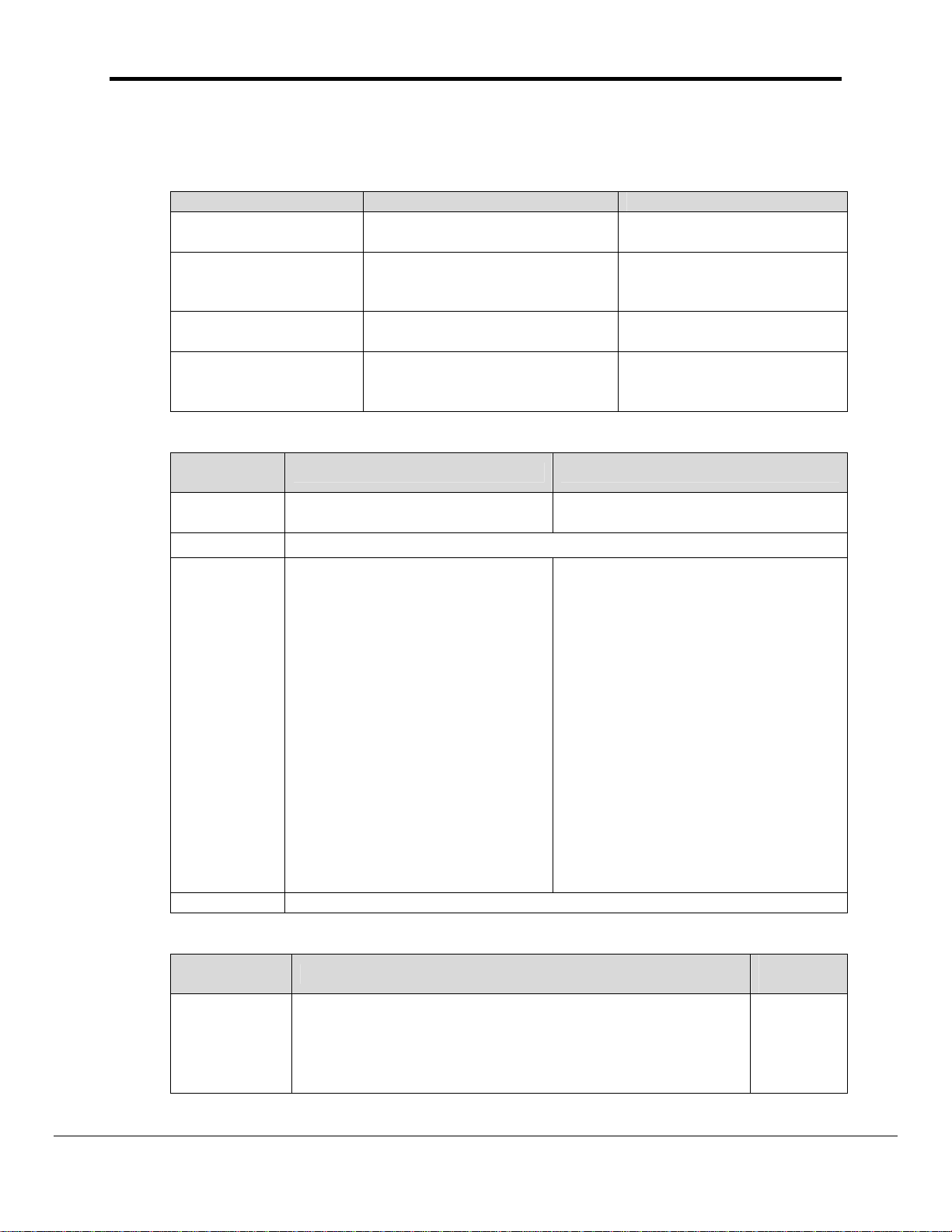

Appendix B.2. How Gas Data is Stored

• The QLA reports provides Gas Concentration values for each configured port/sensor

connected to the TGM.

• The driver stores the data using the “Data_Array_Name” and “Data_Array_Offset”

parameters specified on the Map Descriptor. Two additional Data Array’s can be

specified to tell the driver where to store the gas names and egineering units.

• The position at which data is stored in the array is deprendent on the TGM port/sensor

number. Use the following formula to determine the position.

For Port x : Relative Offset = Port_Number * 10

For Sensor x : Relative Offset = 200 + ( Sensor_Number * 10 )

• Thus enough room is provided to store data from 20 ports and provided the Array is long

enough, there is no limit to the maxium sensor number.

• The offset’s described here are relative to the offset provided in the Map Descriptor,

which should be added to the offsets specified here

Relative

Offset

In the Data Array specified by the “Data_Array_Name”

0 Port Number

1 Set to 'P' for a port. Set to 'S' for a sensor

Gas concentration Value. Can be scaled by applying Map Desc scaling using

2

the parameters Data_Array_Low_Scale, Data_Array_High_Scale,

Node_Low_Scale, Node_High_Scale

3

4

Gas Conc. Engineering Units as an index value. Stores –1 if units are not

recognized. Index value is based on lookup table - Appendix A.3

Gas Status.

0=Normal; 1=Warn; 2=Alarm; 4=Error

Gas Name index (based on CALR report)

A list of gas names and index values is built when the CALR report is parsed. It

is not possible to provide a list of index values vs gas names in advance

5

because this is dependent on the TGM configuration.

To facilitate debugging your application the driver stores the list it builds in a

Data Array which can be read by an upstream device or which can be seen by

uisng the Ruinet Utility.

If the gas name is not recognized then the driver stores a value of –1.

Gas Name index based on looking up the gas name in the table provided in

6

Appendix A.1

If the gas name is not recognized by the lookup then a value of –1 is stored.

In the Data Array specified by the “DA_Bit_Name”

Gas Name is stored character for character to a max of 9 characters.

0

The name of the Map Desc parameter is confusing. The Data Array specified

with this parameter can have any format - ‘BYTE’ format is reccomended.

In the Data Array specified by the “DA_Byte_Name”

Gas Concentration Engineering Units are stored character for character to a

max of 9 characters.

0

The name of the Map Desc parameter is confusing. The Data Array specified

with this parameter can have any format and in fact the ‘BYTE’ format is

reccomended.

Contents

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 18

FS-8700-103_ATMI_TGM_Serial Manual Page 18 of 28

Appendix B.3. Adding/Modifying Gas Concentration Value Engineering Units

The configuration CSV file can be used to modify the table of engineering units that is hard

coded into the driver. This table is presented in Appendix A.3

Add a section to the configuration file which is similar to the following example.

In the example below the Units specified is ‘PPM’, an entry from the existing list. When the

driver finds the lines below, it will update the index value to 20.

// Change index value of existing unit to 20.

Driver_Table

TGM_Units_Name, TGM_Units_Index_Value, Protocol

PPM, 20, TGM

In the example below the units specified are ‘gpl’ and they have been assigned an index

value of 7.

// Add a new engineering unit

Driver_Table

TGM_Units_Name, TGM_Units_Index_Value, Protocol

gpl 7, TGM

Appendix B.4. Adding / Modifying Hard Coded Gas Names

When a gas concentration is reported, the driver reports the gas name by looking up the gas

name in a list of hard coded gas names. When a match is found the driver stores the

associated index value. The table may be modified/extended in the configuration CSV file.

The table of names and index values is provided in Appendix A.1

Add a section to the configuration file which is similar to the text found in the examples

below.

In the example below the gas name specified is ‘H2’, an entry from the existing list. When

the driver finds the lines below, it will update the index value to 20.

// Change index value of existing gas to 20.

Driver_Table

TGM_Gas_Name, TGM_Gas_Index_Value, Protocol

H2, 20, TGM

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 19

FS-8700-103_ATMI_TGM_Serial Manual Page 19 of 28

In the example below the gas name specified is ‘C2H5OH’ and it has been assigned an

index value of 7. It will be added to the table.

// Add a new gas name

Driver_Table

TGM_Gas_Name, TGM_Gas_Index_Value, Protocol

C2H5OH, 7, TGM

Appendix B.5. Adding / Modifying Malfunction Strings

When an event is reported, the driver compares the “MAFLUN” events to those in the table

provided in Appendix A.2. The table can be modified or extended.

Add a section to the configuration file which is similar to the text found in the examples

below.

In the example below the gas name specified is ‘DISK NEARLY FULL’, an entry from the

existing list. When the driver finds the lines below, it will update the index value to 20.

Ensure the index value is less than 100.

// Change index value of existing malfunction.

Driver_Table

TGM_Malfunction_Name, TGM_Malfunction_Index, Protocol

DISK NEARLY FULL, 20, TGM

In the example below the gas name specified is ‘DISK IS FULL’ and it has been assigned

an index value of 20. It will be added to the table.

// Add a new malfunction

Driver_Table

TGM_Malfunction_Name, TGM_Malfunction_Index, Protocol

DISK IS FULL, 20, TGM

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 20

FS-8700-103_ATMI_TGM_Serial Manual Page 20 of 28

Appendix B.6. Adding / Modifying ‘Return to Normal’ Strings

When an event is reported, the driver compares the description to those in “Return to

Normal” column of the table provided in Appendix A.2. The table can be modified or

extended.

Add a section to the configuration file which is similar to the text found in the examples

below.

The index value allocated should match the malfunction index for the driver to clear the

malfunction when the return to normal event is found.

In the example below the gas name specified is ‘DISK NO LONGER FULL, an entry from

the existing list. When the driver finds the lines below, it will update the index value to 20.

Ensure the index value is less than 100.

// Change index value of existing Return to Normal Event.

Driver_Table

TGM_Event_Normal_Name, TGM_Event_Normal_Index, Protocol

DISK NO LONGER FULL, 20, TGM

In the example below the gas name specified is ‘DISK NOT FULL’ and it has been assigned

an index value of 20. It will be added to the table.

// Add a new Return to Normal Event

Driver_Table

TGM_Event_Normal_Name, TGM_Event_Normal_Index, Protocol

DISK NOT FULL, 20, TGM

Appendix B.7. Using the TGM’s Config.dat file to customize malfunctions

Copy the TGM’s config.dat file to the FieldServer as a file called atmitgm.ini. When the driver

starts it looks for this file and updates the malfunction table based on the malfunction strings

found inside the config file. The Ruinet utility is required

Ruinet –i1.2.3.4 –u0 –lc:\…\config.dat –fatmitgm.ini

Where

1.2.3.4 is the IP address of the FieldServer

c:\….\config.dat is the path of the file to be downloaded from your C driver.

To stop the driver using the ini file remove it from the FieldServer by deleting it.

Ruinet –i1.2.3.4 –zatmitgm.ini

When the driver inspects the configuration file it searches for the string “malfunStat” and

uses the table that follows to update the malfunction table. Note that the config file only

contains malfunction strings and does not provide the ‘Return to Normal’ strings. Thus, if

the config file contains a malfunction for which the driver does not have a matching return to

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 21

FS-8700-103_ATMI_TGM_Serial Manual Page 21 of 28

normal string then you will need to add the matching ‘Return to Normal’ string. This process

is described in Appendix B.6

Appendix B.8. Synchronizing Malfunctions

THE Incident Report (QIR) only reports events which occurred since the previous poll.

The following procedure is recommended for synchronizing the FieldServer and the TGM

1. Turn off the FieldServer. Clear all events on the TGM and then restart the FieldServer.

Or

2. With the FieldServer online, cause the TGM to send an RESET ALARMS message to

the FieldServer.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 22

FS-8700-103_ATMI_TGM_Serial Manual Page 22 of 28

Appendix C. Driver Error Messages

Message

TGM:#1 Err. Diagnostic #1.

TGM:#2 Err. TGM_Function not

specified.

TGM:#3 FYI. Use an Array

called <%s> to expose

diagnostics.

Notes and Corrective Action∼

If this message is printed an internal diagnostic has been

generated. Contact FieldServer tech support for help.

Each Map Descriptor must have the parameter called

“TGM_Function” set. See section 4.4.2

This message may be ignored. For more information read

Appendix C.1

4a: The text string “CUR=” could not be found in the QLA

report.

4b: The text string “GAS=” could not be found in the QLA

report.

4c: The text string “STATUS=” could not be found in the

TGM: #4c Err. Bad format in

latest area report. Discarding

data.

QLA report.

If the error is printed rarely and data is being stored

correctly then the error probably arises from a corrupted

message. If the error occurs frequently then it is possible

that the report format has changed and the driver firmware

may require an update. To facilitate the evaluation of the

problem, take a serial communications log, ensuring at least

one of the errors occurs during the log, and then contact

Tech Support.

This message is printed to alert you to the fact that the

TGM: #5 FYI. atmitgm.ini being

used for malfunctions

malfunction list is being based on the contents of a TGM

config file. Refer to Appendix B.7. If you expect the driver to

be using this list, ignore the message.

TGM: #6 FYI. You could have

used a TGM config file to define

malfunctions. Working with hard

coded list.

TGM: #7 Err. Driver cannot

write. MD=%s

TGM: #8 Err. Array=%s too

short. Act/Rqd=%d/%d

TGM: #9 FYI. Duplicate Gas

Name=<%s>.

Value has been updated

from=%d to=%d

This message is printed to alert you to the possibility that

the TGM config file can be used with this driver. Refer to

Appendix B.7.

The Map Descriptor function has been set so that the driver

will attempt to write to the TGM. Writing is not possible.

Change the function to a read.

This error is printed when the driver attempts to store data

from the QLA report. Modify the length of the Data Array as

discussed in section 4.1.

This message may be safely ignored. It is printed to alert

you to the fact that the driver has updated the Gas Name

table so that default values have been modified.

2

2

2

2

Modify the configuration CSV file. Download the modified file to the FieldServer and Reset the

FieldServer for the changes to take effect.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 23

FS-8700-103_ATMI_TGM_Serial Manual Page 23 of 28

Message

TGM: #10 Err. No space. Reject

Gas Name=<%s> Index

Value=%d

Notes and Corrective Action∼

An attempt has been made to extend the gas name table.

There is insufficient space to add more names. Remove this

entry from the configuration CSV file

3

.

This message may be ignored. It is printed to alert you to

TGM: #11 FYI. User added Gas

Name=<%s> Index Value=%d

the fact that the driver has updated the Gas Name table by

adding a new gas name and index value. Ensure that index

values are unique.

TGM: #12 FYI. Duplicate Gas

Units=<%s>. Value has been

updated from=%d to=%d

TGM: #13 Err. No space. Reject

Gas Units=<%s> Index

Value=%d

This message may be ignored. It is printed to alert you to

the fact that the driver has updated the Gas Engineering

Unit table so that default values have been modified.

An attempt has been made to extend the Fas Engineering

Units table. There is insufficient space to add more names.

Remove this entry from the configuration CSV file.

3

This message may be ignored. It is printed to alert you to

TGM: #14 FYI. User added Gas

Units=<%s> Index Value=%d

the fact that the driver has updated the Gas Engineering

Units Table by adding a new gas name and index value.

Ensure that index values are unique.

TGM: #15 FYI. Duplicate

Malfunction=<%s>. Index Val

has been updated from=%d

to=%d

TGM: #16 Err. No space. Reject

Malfunction=<%s> Index

Val=%d

TGM: #17 FYI. User added

Malfunction=<%s> Index

Val=%d

TGM: #18 FYI. Duplicate

Normal Event=<%s>.

Index Val has been updated

from=%d to=%d

TGM: #19 Err. No space. Reject

Normal Event=<%s> Index

Val=%d

This message may be ignored. It is printed to alert you to

the fact that the driver has updated the Malfunction Table so

that default values have been modified. Ensure that the

index value is less than 100.

An attempt has been made to extend the Malfunction Table.

There is insufficient space to add more names. Remove this

entry from the configuration CSV file.

3

This message may be ignored. It is printed to alert you to

the fact that the driver has updated the Malfunction Table by

adding a new gas name and index value. Ensure that index

values are unique and that the index value is less than 100.

This message may be ignored. It is printed to alert you to

the fact that the driver has updated the ‘Return to Normal’

Table so that default values have been modified. Ensure

that the index value is less than 100.

An attempt has been made to extend the ‘Return to Normal’

Table. There is insufficient space to add more names.

Remove this entry from the configuration CSV file.

3

This message may be ignored. It is printed to alert you to

TGM: #20 FYI. User added

Normal Event=<%s> Index

Val=%d

the fact that the driver has updated the ‘Return to Normal’

Table by adding a new gas name and index value. Ensure

that index values are unique and that the index value is less

than 100.

3

Modify the configuration CSV file. Download the modified file to the FieldServer and Reset the

FieldServer for the changes to take effect.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 24

FS-8700-103_ATMI_TGM_Serial Manual Page 24 of 28

Message

Notes and Corrective Action∼

The driver has found a malfunction but could not match it

exactly to a malfunction in the Malfunction Table. The

TGM: #21 FYI. Malfunction.

Don’t recognize <%s> But

sounds like <%s>.

driver used a soundex function which looks for matches

based on a ‘sounds like’ evaluation. As the match is not

exact the driver provides the alert.

To suppress this message in the future, note the message

and add it to the Malfunction Table. Notes in Appendix B.5

provide information on how to do this.

The driver has found an event description that is being

evaluated as a potential ‘Return to Normal’ message, but

could not match it exactly to a ‘Return to Normal’ in the

TGM: #22 FYI. Return to

Normal. Don’t recognize

<%s>But sounds like <%s>.

Malfunction Table. The driver used a soundex function

which looks fro matches based on a ‘sounds like’

evaluation. As the match is not exact the driver provides the

alert.

To suppress this message in the future, note the message

and add it to the ‘Return to Normal' Table. Notes in

Appendix B.6 provide information on how to do this.

TGM: #23 FYI. Duplicate

Malfunction Number=<%d>.Text

has been updated from=<%s>

to=<%s>

TGM: #24 Err. No space. Reject

Malfunction=<%s> Index

Val=%d

If these messages are produced then the driver processes

the TGM config file. Read Appendix B.7 for more

information.

TGM: #25 FYI. User added

Malfunction=<%s> Index

Val=%d

TGM: #26a Err. Malfunction=%s

Index value=%d > 99.

The maximum malfunction index value is 99. Use the

procedure in Appendix B.5 to modify the malfunction index

4

value.

It is almost impossible for the driver to distinguish between

‘Return to Normal’ events and those events not associated

with a malfunction. When a non-malfunction event is found

that doesn’t match the entries in the Return to Normal Table

TGM: #27 Err. Event=%s is

Unknown. Read manual.

then this message is printed. It is printed 20 times and then

suppressed.

Ignore the messages if they clearly are not ‘Return to

Normal’ events that correspond to Malfunctions. If, however,

they are obviously associated with Malfunctions then add

the description to the ‘Return to Normal’ Table. Notes in

Appendix B.6 provide information on how to do this.

TGM: #28 Err

TGM_Function=%s invalid.

This message is printed during Map Descriptor Validation.

The function is not recognized. Correct the configuration

using information found in section 4.4.2

4

4

Modify the configuration CSV file. Download the modified file to the FieldServer and Reset the

FieldServer for the changes to take effect.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 25

FS-8700-103_ATMI_TGM_Serial Manual Page 25 of 28

Appendix C.1. Exposing Driver Operating Statistics

In addition to the standard FieldServer operating statistics the driver exposes certain key

stats in a Data Array if required. These stats can then be monitored by an upstream device.

Add the following to your configuration file to activate these stats

Expose Driver Operating Stats.

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length

ATMI-TGM-stats, UINT16, 1000

To calculate the actual offset multiply the port number by 100 and add the relative offset.

Items marked * do not consider the port number in calculating the actual offset.

Stat Relative

Offset

1 Increments each time client sends a poll.

2 Total of all the bytes sent to the TGM device

3

4 Increments each time the client receives a CR-lf pair in a response

5 Count of all the bytes received by the client in response to TGM polling

6 Count of all the messages that were sent to the parse function.

8 Count of all the message that were parsed successfully

9 Increments by 1 each time a poll times out

10

11

12

13

14

15 When set to 1 the driver does not use the soundex function.

16

17

To execute a table dump do the following

• Connect to the FieldServer using RUINET

• Browse to the Array called “ATMI-TGM-stats”

• Modify the value found at offset by typing M x 1 <Enter>

Where x = 10 or 11 or 12 or 13 or 14

A typical dump is shown below

Notes

Increments each time the client receives a complete response as

indicated by the prompt character

*When set to 1 the driver dumps the contents of its gas name lookup table

to the error log. Driver resets to zero after dump.

*When set to 1 the driver dumps the contents of its gas engineering units

lookup table to the error log. Driver resets to zero after dump.

*When set to 1 the driver dumps the contents of its CALR gas lookup

table to the error log. Driver resets to zero after dump.

*When set to 1 the driver dumps the contents of its Malfunction Lookup

table to the error log. Driver resets to zero after dump.

*When set to 1 the driver dumps the contents of its 'Return to Normal'

Lookup table to the error log. Driver resets to zero after dump.

Increments by 1 each time a response line is too large to fit the

connection in buffer

Increments by 1 each time a response is too large to fit the in the report

buffer

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 26

FS-8700-103_ATMI_TGM_Serial Manual Page 26 of 28

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 27

FS-8700-103_ATMI_TGM_Serial Manual Page 27 of 28

Appendix D. Troubleshooting tips

Appendix D.1. Connection Tips & Hints

The ATMI-TGM’s serial ports are configured using the TGM’s configuration file – typically

named config.dat

Search for the following section. The port you wish to connect to must be set as a “Remote

Console”.

/* the channel utilization array specifies how a parallel (or serial) */

/* channel is to be utilized. The possible entries are: */

/* 0 = this channel is forced out of service (not implemented, etc)*/

/* 1 = this channel is a printer device */

/* 2 = this channel is a remote console */

/* There can be more than one printer device (max = all 3 channels), */

/* but there can be only one remote console (COM1: or COM2 :). */

/* Leave the Acoustic Sensor entry = 0 (controlled by bvCous) */ /* PMC */

BYTE chanUtil[] = {

0, // [0] = local (parallel) printer

0, // [1] = COM1: serial channel

2, // [2] = COM2: serial channel

0, // [3] = Acoustic Sensor serial channel

};

/* the baudRate table specifies the baud rate for the serial channels */

/* can be one of: 110, 300, 600, 1200, 2400, 4800, 9600, 19200, 38400 */

/* an entry of 0 in chanUtil[] overrides the entry here */ /* PMC, too slow and wont finish printing in time

*/

WORD baudRate[] = {

XX, // [0]

9600, // [1] // COM1:

9600, // [2] // COM2:

9600, // [3] // cous chan

};

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Page 28

FS-8700-103_ATMI_TGM_Serial Manual Page 28 of 28

THIS PAGE INTENTIONALLY LEFT BLANK

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldserver.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldserver.com

Loading...

Loading...