Page 1

-

A Sierra Monitor Company

Driver Manual

(Supplement to the FieldServer Instruction Manual)

FS-8700-101

Setra Digital Pressure Gage Model 370

APPLICABILITY & EFFECTIVITY

Effective for all systems manufactured after May 1, 2001

Driver Version: 1.00

Document Revision: 7

Page 2

FS-8700-101 Setra Model 370 Digital Pressure Gage Manual Table of Contents

TABLE OF CONTENTS

1. SETRA MODEL 370 DIGITAL PRESSURE GAGE DESCRIPTION.................................3

2. DRIVER SCOPE OF SUPPLY...........................................................................................4

2.1. Supplied by FieldServer Technologies for this driver ...................................................4

2.2. Provided by the Supplier of 3rd Party Equipment.......................................................... 4

2.2.1. Required 3rd Party Hardware.....................................................................................4

2.2.2. Required 3rd Party Configuration...............................................................................4

3. HARDWARE CONNECTIONS ..........................................................................................5

3.1. Hardware Connection Tips / Hints................................................................................6

4. CONFIGURING THE FIELDSERVER AS A SETRA MODEL 370 DIGITAL PRESSURE

GAGE CLIENT .............................................................................................................................7

4.1. Data Arrays/Descriptors ...............................................................................................7

4.2. Client Side Connection Descriptors.............................................................................. 8

4.3. Client Side Node Descriptors .......................................................................................8

4.4. Client Side Map Descriptors .........................................................................................9

4.4.1. FieldServer Related Map Descriptor Parameters......................................................9

4.4.2. Driver Related Map Descriptor Parameters ..............................................................9

4.4.3. Timing Parameters....................................................................................................9

4.4.4. Map Descriptor Example #1 – Read Pressure........................................................10

4.4.5. Map Descriptor Example #2 – Read Status............................................................11

4.4.6. Map Descriptor Example #3 - Verify........................................................................12

5. CONFIGURING THE FIELDSERVER AS A SETRA MODEL 370 DIGITAL PRESSURE

GAGE SERVER..........................................................................................................................13

5.1. Server Side Connection Descriptors...........................................................................13

5.2. Server Side Node Descriptors ....................................................................................14

5.3. Server Side Map Descriptors...................................................................................... 15

5.3.1. FieldServer Specific Map Descriptor Parameters ...................................................15

5.3.2. Driver Specific Map Descriptor Parameters............................................................15

5.3.3. Server Map Descriptor Example. ............................................................................16

APPENDIX A. ADVANCED TOPICS ......................................................................................17

Appendix A.1. How Data Gets Stored ..................................................................................17

Appendix A.1.1. Pressure Data.........................................................................................17

Appendix A.1.2. Status Data.............................................................................................17

Appendix A.2. Gage Pressure Units ..................................................................................... 18

Appendix A.3. Driver Limitations & Exclusions ..................................................................... 18

APPENDIX B. TROUBLESHOOTING TIPS............................................................................19

Appendix B.1. Connection Tips & Hints................................................................................19

APPENDIX C. DRIVER ERROR MESSAGES........................................................................20

Appendix C.1. Exposing Driver Diagnostic Statistics............................................................21

Appendix C.2. Standard Driver Stats....................................................................................22

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 3

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 3 of 23

1. Setra Model 370 Digital Pressure Gage Description

The ‘Setra Model 370 Digital Pressure Gage’ driver allows the FieldServer to transfer data to

and from devices over either RS-232 or RS-485 using the ‘Setra Model 370 Digital Pressure

Gage’ protocol. The FieldServer can emulate either a Server or Client.

The driver implements a subset of the commands and responses that an actual Setra Model

370 Digital Pressure Gage is capable of. Thus the driver permits the transfer of current pressure

information, Gage status information and the processing of Gage verification information.

The driver is capable of providing active Client and passive Server support. An active Client

polls for data and processes responses, it is not capable of processing unsolicited messages

from the remote device. A passive Server can respond to polls but is not capable of sending

unsolicited messages reporting change of state or other information.

When configured as a Client it is important the digital Gage is configured correctly and that it is

left in an operational mode where it can respond easily to the commands sent to it. If a user,

were to operate the Gage from its front panel and leave it in a configuration state, awaiting input

from a user, then the Gage would be incapable of responding to commands from the

FieldServer. The driver cannot write to the digital Gage. Thus alarm set points and other

configuration tasks cannot be performed using a FieldServer.

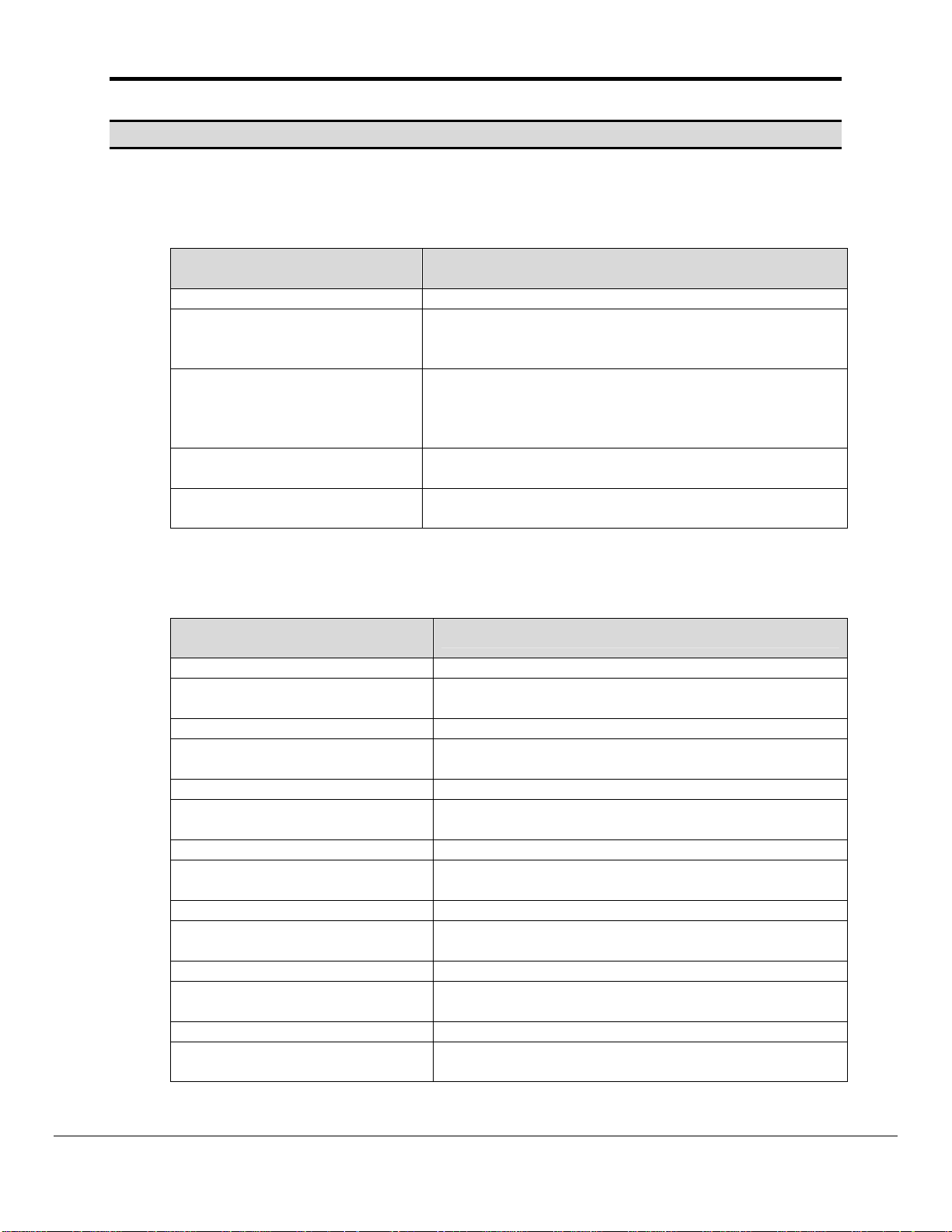

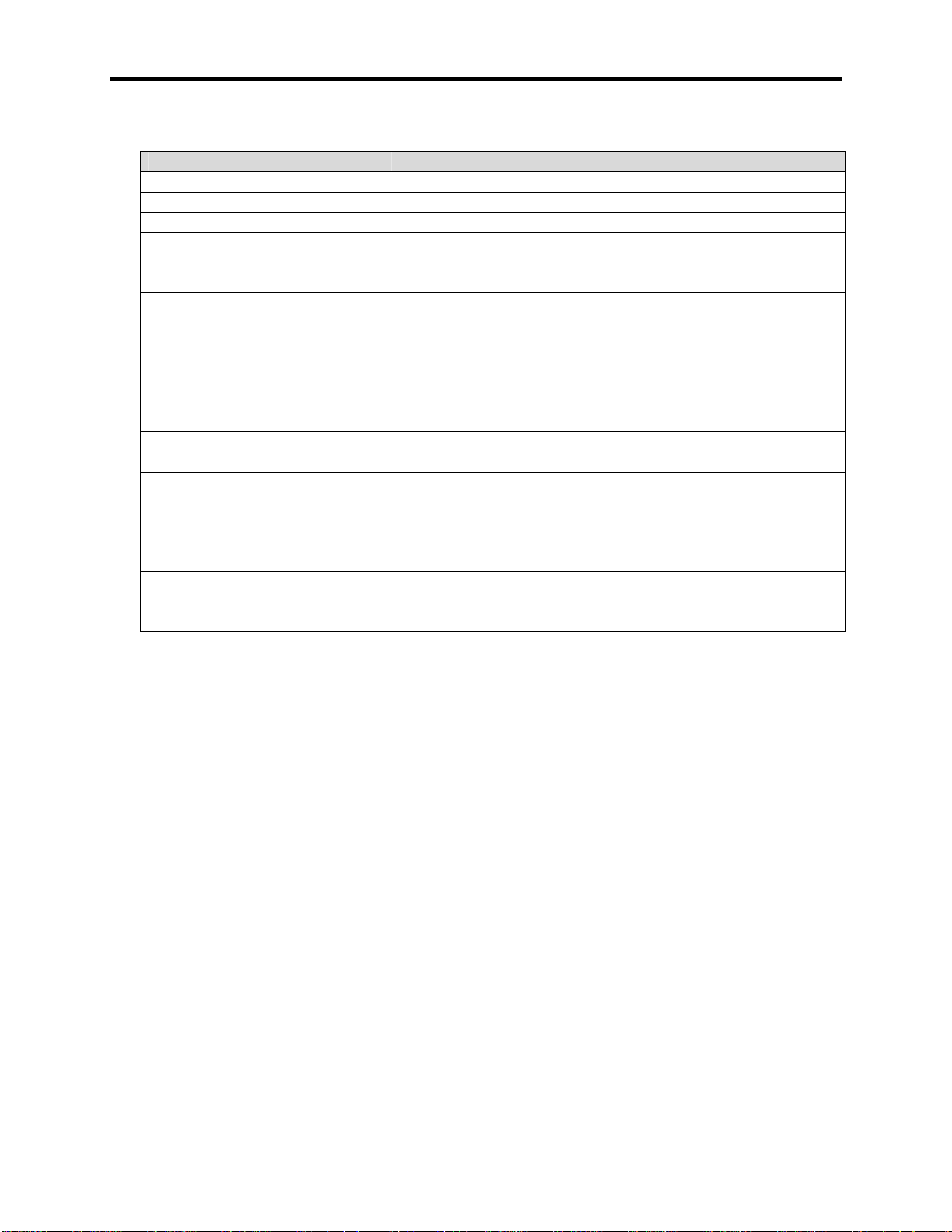

Max Nodes Supported

FieldServer

Mode

Client 1

Nodes Comments

This is a nodeless protocol. Only one Server per FieldServer

port.

Server 1 This is a nodeless protocol. Only one Client per FieldServer port.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 4

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 4 of 23

2. Driver Scope of Supply

2.1. Supplied by FieldServer Technologies for this driver

FieldServer Technologies

PART #

Description

FS-8917-01 Connector, 25 pin male: Connects to DCE, RTS/CTS loop

FS-8700-101 Driver Manual.

2.2. Provided by the Supplier of 3rd Party Equipment

2.2.1. Required 3rd Party Hardware

Part # Description

M370 SETRA DIGITAL PRESSURE GAGE

2.2.2. Required 3rd Party Configuration

The M370 Gage must be configured using the operator’s manual and the front panel

push buttons so that its serial port settings match the FieldServer settings.

The following notes have been extracted from the operator’s manual.

The Setra Digital Pressure Gage is capable of interfacing with a wide variety of computers or

other devices through the RS-232 serial communications port. Devices which are connected this

way must be set up to communicate at the same rate of speed. To change the baud rate of the

gage (the rate at which the gage sends information out through the port) so it agrees with that of

the device connected to it, use the following procedure.

1. Press CONV until the gage is displaying pressure units (make sure it is not displaying in "ft" or

"meters").

2. Press the "-" key.

3. Enter "5555". This is the baud rate access code.

4. Press SETUP. The display will read "CAL br".

5. Enter the baud rate. Choose either 300, 600, 1200, 1800, 2400, 3600, 4800or 9600.

6. Press SETUP.

The baud rate is factory set to 2400. If you change the baud rate and wish the gage to retain the

new rate after power is removed and restored, repeat steps 2-6 a second time.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 5

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 5 of 23

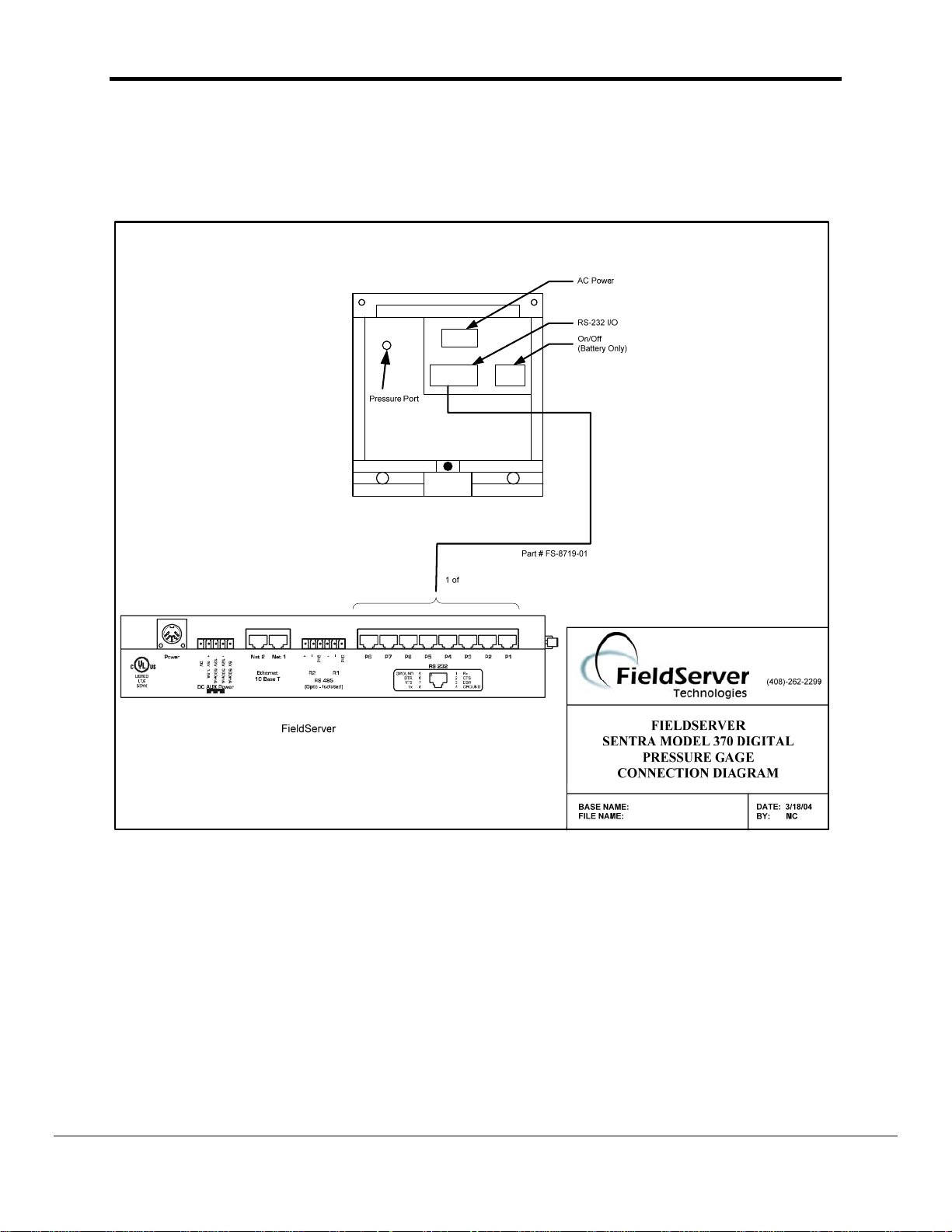

3. Hardware Connections

The FieldServer is connected to the rear side of the Model 370 Digital Pressure Gage as shown

in the following connection drawing.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 6

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 6 of 23

3.1. Hardware Connection Tips / Hints

The following notes are extracted from the Setra 370 Operator Manual.

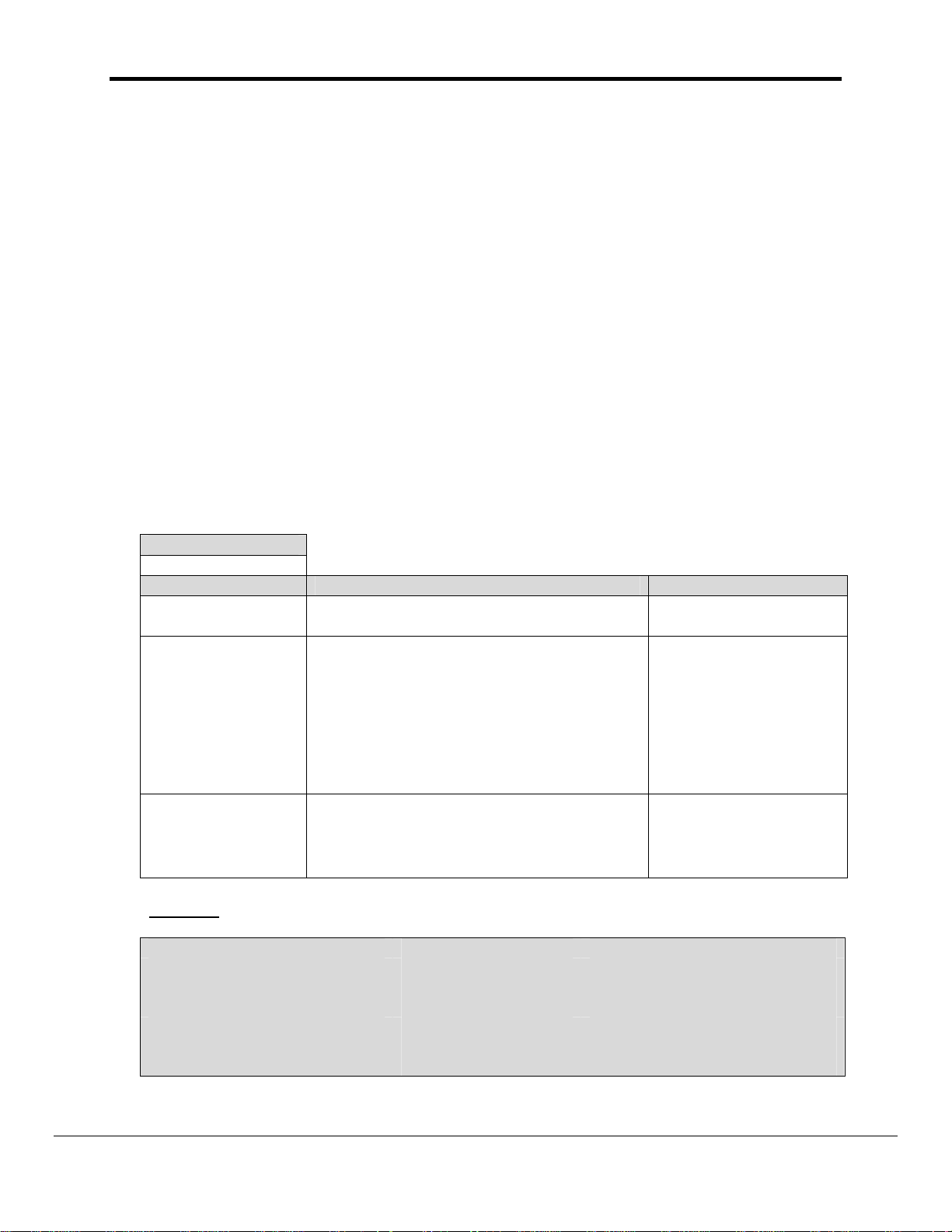

The Setra Digital Pressure Gage implements the majority of the RS-232 communications standard,

but does not provide handshaking lines (such as busy, DSR, or DTR). The four lines which must be

connected are diagrammed below, along with the pin layout of the female connector on the back of

the gage.

13 7 3 2 1

O O O O O O O O O O O O O

O O O O O O O O O O O O

25 14

Pin Desc.

1 Protective ground

2 Input to gage (RXD)

3 Output from gage (TXD)

7 Signal ground

The Model 370 serial interface is a DCE (Data Communications Equipment) type, with a standard

female DB25S pin connector. This means that it receives data on pin 2 and sends data on pin 3. This

is in contrast to DTE (Data Transmission Equipment) which receives data on pin 3 and sends data on

pin 2. The RS-232 standard describes communications between DTE and DCE devices.

Since many computers have serial ports configured as DTE, the Model 370 conveniently plugs

directly into the standard serial port on most computers, using a standard RS-232 "straight-through"

cable available from SETRA, or from any computer hardware vendor. Some devices, including some

printers and computers, will be equipped with DCE interfaces like that in the Model 370. To connect

the Model 370 to these devices, a "null modem" cable is required. This is simply a cable which

connects pin 2 and 3 of the Model 370 to pin 3 and 2 of the other device respectively by crossing

them in the cable. This kind of cable is also available from SETRA, or from any computer hardware

vendor.

The maximum recommended cable length is 15 meters.

The RS-232 data format used by the Model 370 is:

8 bits, 1 start bit, 1 stop bit, no parity.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 7

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 7 of 23

4. Configuring the FieldServer as a Setra Model 370 Digital Pressure Gage

Client

For a detailed discussion on FieldServer configuration, please refer to the FieldServer

Configuration Manual. The information that follows describes how to expand upon the factory

defaults provided in the configuration files included with the FieldServer (See “.csv” sample files

provided with the FieldServer).

This section documents and describes the parameters necessary for configuring the FieldServer

to communicate with a Setra Model 370 Digital Pressure Gage.

4.1. Data Arrays/Descriptors

The configuration file tells the FieldServer about its interfaces, and the routing of data

required. In order to enable the FieldServer for Setra Model 370 Digital Pressure Gage

communications, the driver independent FieldServer buffers need to be declared in the

“Data Arrays” section, the destination device addresses need to be declared in the “Client

Side Nodes” section, and the data required from the Servers needs to be mapped in the

“Client Side Map Descriptors” section. Details on how to do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value being the

default.

Section Title

Data_Arrays

Column Title Function Legal Values

Data_Array_Name Provide name for Data Array

Provide data format. Each Data Array can

only take on one format.

For this driver, FieldServer recommends

Data_Array_Format

Data_Array_Length

Example

// Data Arrays

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length,

DA_PRESSURE, FLOAT, 200

DA_STATUS, FLOAT, 200

DA_DI_01, Bit, 200

DA_DO_01, Bit, 200

the use of a FLOAT Data Array. This is

because the pressure and status settings

are reported as real signed numbers with

some significant digits after the decimal

point.

Number of Data Objects. Must be larger

than the data storage area required by the

Map Descriptors for the data being placed

in this array.

Up to 15 alphanumeric

characters

Float, Bit, UInt16,

SInt16, Packed_Bit,

Byte, Packed_Byte,

Swapped_Byte

1-10,000

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 8

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 8 of 23

4.2. Client Side Connection Descriptors

Section Title

Connections

Column Title Function Legal Values

Port

Protocol Specify protocol used Setra370

Baud* Specify baud rate

Parity* Specify parity Even, Odd, None, Mark, Space

Data_Bits* Specify data bits 7, 8

Stop_Bits* Specify stop bits

Handshaking*

Poll _Delay* Time between internal polls 0-32000 seconds, 1 second

Example

// Client Side Connections

Connections

Port, Protocol, Baud, Parity, Handshaking, Poll_Delay

P8, Setra370, 2400, None, None, 0.100s

Specify which port the device is

connected to the FieldServer

Specify hardware handshaking

The Setra Model 370 does not support

handshaking.

P1-P8, R1-R21

110 – 115200, standard baud

rates only, 2400.

1

RTS, RTS/CTS, None

4.3. Client Side Node Descriptors

Section Title

Nodes

Column Title Function Legal Values

Node_Name Provide name for node

Node_ID

This commonly used parameter has no meaning for this driver and may be

omitted.

Protocol Specify protocol used Setra370.

Connection

Specify which port the device is connected

to the FieldServer

Example

// Client Side Nodes

Nodes

Node_Name, Protocol, Connection

Gage1, Setra370, P8

1

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction

manual for details of the ports available on specific hardware.

Up to 32 alphanumeric

characters

P1-P8, R1-R21

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 9

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 9 of 23

4.4. Client Side Map Descriptors

4.4.1. FieldServer Related Map Descriptor Parameters

Column Title Function Legal Values

Map_Descriptor_Name Name of this Map Descriptor

Name of Data Array where

Data_Array_Name

Data_Array_Offset

Function

data is to be stored in the

FieldServer

Starting location in Data

Array

Function of Client Map

Descriptor

Up to 32 alphanumeric

characters

One of the Data Array names

from “Data Array” section

above

0 to maximum specified in

“Data Array” section above

RDBC

4.4.2. Driver Related Map Descriptor Parameters

Column Title Function Legal Values

Node_Name

Data_Type

Length Length of Map Descriptor

Address

Gage_Function*

Name of Node to fetch data

from

This commonly used

parameter has no special

meaning to this driver and

may be omitted.

This commonly used parameter has no special meaning to this

driver and may be omitted.

Specifies what data should

be read and stored.

If you omit this parameter

then the driver assumes

you are reading pressure.

One of the node names specified in

“Client Node Descriptor” above

Register, Coil, AI, DI

The driver knows the correct length

for the various Map Descriptors and

will prompt you accordingly if an

invalid length is specified.

Pressure : Set Length 5

Status: Set Length 14

Verification Info: Set length 100.

Pressure, Status, Verify

4.4.3. Timing Parameters

Column Title Function Legal Values

Scan_Interval Rate at which data is polled ≥0.001s

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 10

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 10 of 23

t

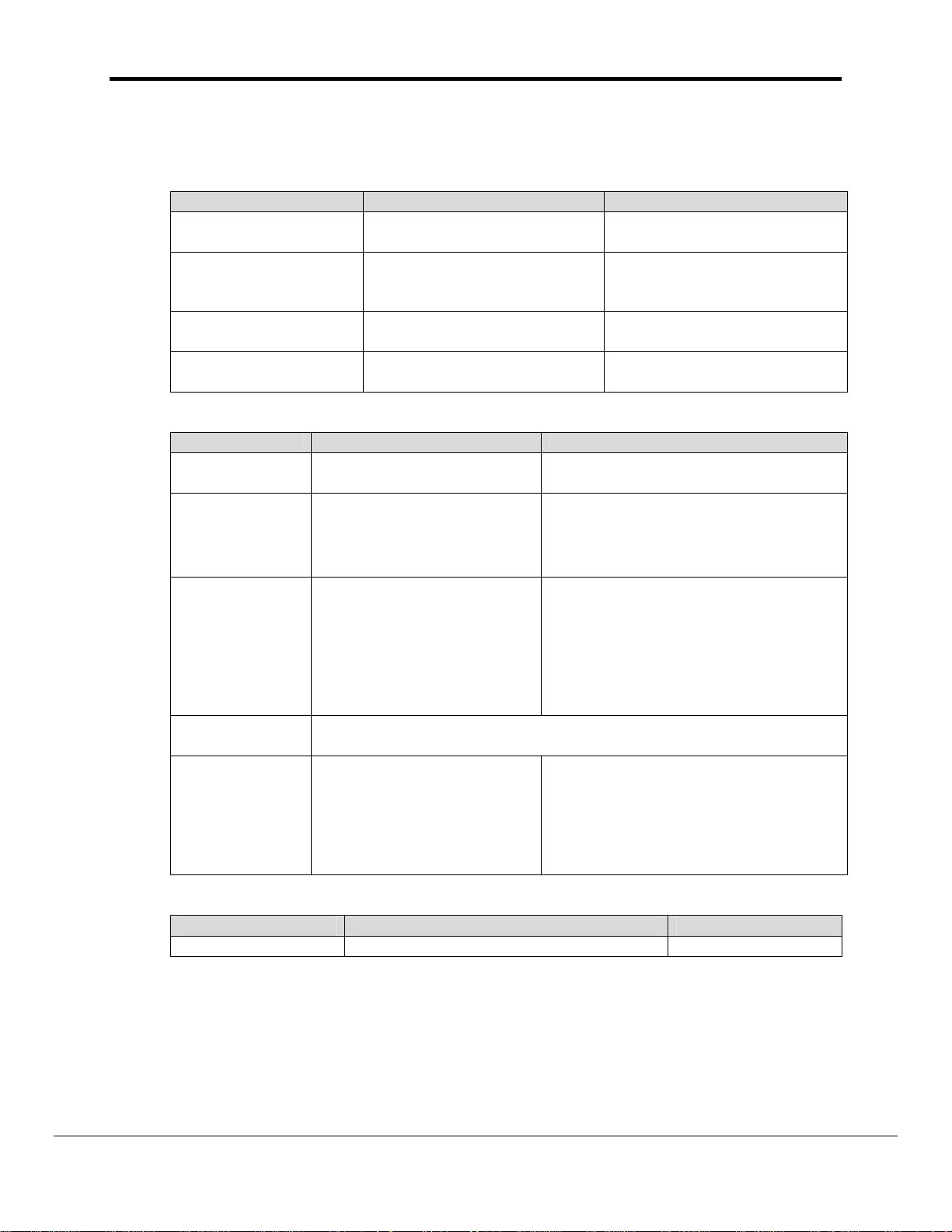

4.4.4. Map Descriptor Example #1 – Read Pressure.

In this example a Map Descriptor is defined which controls the task of reading pressure data from the Setra Model 370 Digital

Pressure Gage. The task gets performed every 5.0 seconds. When a response is received the data is stored in the Data Array

called DA_PRESSURE stating at element zero (the offset). Each pressure reading requires the driver store 5 parameters and hence

the length of the Map Descriptor is 5. Refer to Appendix A for further information.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Gage_Function, Length, Scan_Interval

Read_Press, DA_PRESSURE, 0, RDBC, Gage1, Pressure, 5, 5.0s

Unique names

assist config file

validation

debugging but

are not

necessary.

The name of a

Data Array in

which the

response data

will be stored

s

The 1

in the Data

Array which will

be used for

.

storage.

location

The name of a Node

defined in the CSV file.

The node name connect

the MD to a node which

in turn points to a

connection Thus the

driver knows what port

and port settings to use

to send the poll..

Tells the driver

to read the

current

pressure

measurement

from the Gage

Reserves 5

elements of the

Data Array to

store response

data.

Tells the driver

to schedule this

MD no more

often than 5

seconds.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 11

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 11 of 23

t

4.4.5. Map Descriptor Example #2 – Read Status

In this example a Map Descriptor is defined which controls the task of reading status data from the Setra Model 370 Digital Pressure

Gage. The task gets performed every 5.0 seconds. When a response is received the data is stored in the Data Array called

DA_STATUS stating at element zero (the offset). Each pressure status reading requires the driver store 20 parameters and hence

the length of the Map Descriptor is 20. Refer to Appendix A for further information.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Gage_Function, Length, Scan_Interval

Read_Status, DA_STATUS, 0, RDBC, Gage1, Status , 20, 5.0s

Unique names

assist config file

validation

debugging but

are not

necessary

.

The name of a

Data Array in

which the

response data

will be stored.

s

The 1

in the Data

Array which will

be used for

storage.

location

The name of a Node defined in

the CSV file. The node name

connect the MD to a node which

in turn points to a connection

Thus the driver knows what port

and port settings to use to send

the poll..

Tells the driver

to read the

current status

from the Gage

Reserves 20

elements of the

Data Array to

store response

data.

Tells the driver

to schedule this

MD no more

often than 5

seconds.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 12

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 12 of 23

t

4.4.6. Map Descriptor Example #3 - Verify.

The verification string contains revision and model information about the Gage. In this example a Map Descriptor is defined which

controls the task of reading verification data from the Setra Model 370 Digital Pressure Gage. The task gets performed every 5.0

seconds. When a response is received the data is stored in the Data Array called DA_VERIFY stating at element zero (the offset).

Each Gage verification reading requires the driver store a string containing two lines of data. The actual length is unknown in

advance and it is recommended that 100 Data Array elements be reserved to store the verification sting. The verification string is

stored by writing each consecutive letter in consecutive Data Array elements. It is recommended that the Data_Array_Format is set

to BYTE in this case. This will enable the use of the “String” display to read the verification string in RuiNet.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_Name, Gage_Function, Length, Scan_Interval

Read_Verify, DA_VERIFY, 0, RDBC, Gage1, Verify, 100, 5.0s

Unique names

assist config file

validation

debugging but

are not

The name of a

Data Array in

which the

response data

will be stored.

s

The 1

in the Data

Array which will

be used for

storage.

location

The name of a Node defined in

the CSV file. The node name

connect the MD to a node

which in turn points to a

connection Thus the driver

knows what port and port

settings to use to send the

poll..

Tells the driver

to read the

verification

string

measurement

from the Gage

Tells the driver

to schedule this

MD no more

often than 5

seconds.

Reserves 100

elements of the

Data Array to

store response

data.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 13

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 13 of 23

5. Configuring the FieldServer as a Setra Model 370 Digital Pressure Gage

Server

For a detailed discussion on FieldServer configuration, please refer to the FieldServer

Configuration Manual. The information that follows describes how to expand upon the factory

defaults provided in the configuration files included with the FieldServer.

This section documents and describes the parameters necessary for configuring the FieldServer

to communicate with a Setra Model 370 Digital Pressure Gage Client

The configuration file tells the FieldServer about its interfaces, and the routing of data required.

In order to enable the FieldServer for Setra Model 370 Digital Pressure Gage communications,

the driver independent FieldServer buffers need to be declared in the “Data Arrays” section, the

FieldServer virtual node(s) needs to be declared in the “Server Side Nodes” section, and the

data to be provided to the Clients needs to be mapped in the “Server Side Map Descriptors”

section. Details on how to do this can be found below.

Note that in the tables, * indicates an optional parameter, with the bold legal value being the

default.

5.1. Server Side Connection Descriptors

Section Title

Connections

Column Title Function Legal Values

Port

Protocol

Specify which port the device is

connected to the FieldServer

Specify protocol used Setra370

Baud* Specify baud rate

Parity* Specify parity

Data_Bits*

Stop_Bits*

Specify data bits 7, 8

Specify stop bits

P1-P8, R1-R2

110 – 115200, standard

baud rates only

Even, Odd, None, Mark,

Space

1

2

Handshaking* Specify hardware handshaking RTS, RTS/CTS, None

Specifies time FieldServer will

reserve Server side connection

Server_Hold_Timeout*

while waiting for the Client side to

>1.0s

update data in Data_Array (if

necessary)

Example

// Server Side Connections

Connections

Port, Protocol, Baud, Parity, Handshaking,

P8, Setra370, 9600, None, None,

2

Not all ports shown are necessarily supported by the hardware. Consult the appropriate Instruction

manual for details of the ports available on specific hardware.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 14

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 14 of 23

5.2. Server Side Node Descriptors

Section Title

Nodes

Column Title Function Legal Values

Node_Name Provide name for node

Node_ID

This commonly used parameter is not used by this driver and

maybe omitted.

Protocol Specify protocol used Setra370

Specifies time FieldServer will

reserve Server side connection

Server_Hold_Timeout*

while waiting for the Client side

to update data in Data_Array (if

necessary)

Example

// Server Side Nodes

Nodes

Node_Name, Protocol

∗

PLC 1, Setra370

Up to 32 alphanumeric

characters

>1.0s

∗

Note that no connection information is necessary on Server side.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 15

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 15 of 23

5.3. Server Side Map Descriptors

5.3.1. FieldServer Specific Map Descriptor Parameters

Column Title Function Legal Values

Map_Descriptor_Name

Data_Array_Name

Data_Array_Offset

Function

Server_Hold_Timeout*

Name of this Map

Descriptor

Name of Data Array where

data is to be stored in the

FieldServer

Starting location in Data

Array

Function of Server Map

Descriptor

Specifies time FieldServer

will reserve Server side

connection while waiting for

the Client side to update

data in Data_Array (if

necessary)

Up to 32 alphanumeric

characters

One of the Data Array

names from “Data Array”

section above

0 to maximum specified in

“Data Array” section above

Server

>1.0s

5.3.2. Driver Specific Map Descriptor Parameters

Column Title Function Legal Values

Node_Name

Data_Type

Length Length of Map Descriptor 1 - 1000

Address

Name of Node to fetch data

from

This commonly used

parameter has no special

meaning to this driver and

may be omitted.

This commonly used parameter has no special meaning to

this driver and may be omitted.

One of the node names

specified in “Client Node

Descriptor” above

Register, Coil, AI, DI

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 16

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 16 of 23

p

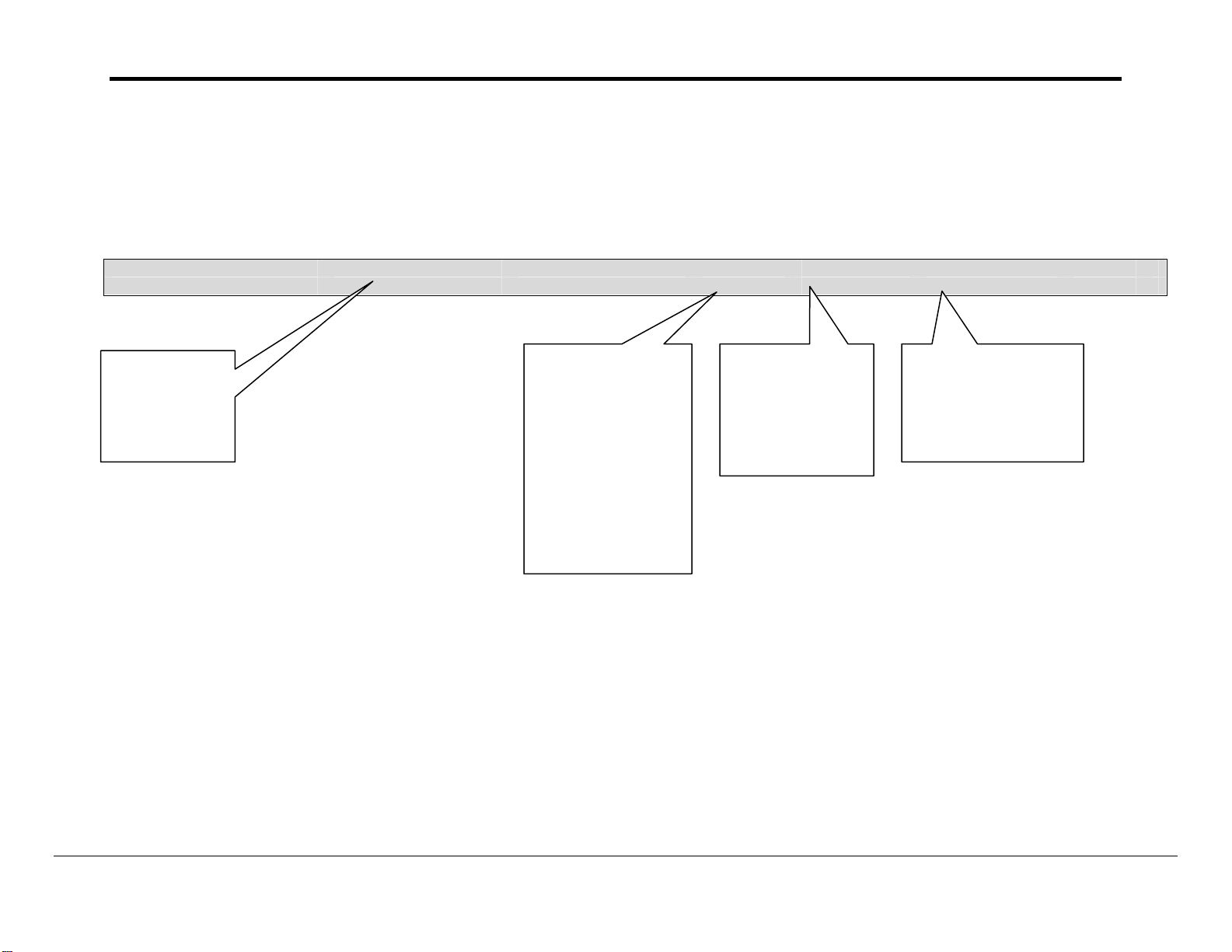

5.3.3. Server Map Descriptor Example.

This Map Descriptor defines a capability of the FieldServer to respond to a poll for an immediate Pressure Print (Command Code =

‘P’). When the poll is received, the driver inspects 5 consecutive array elements starting at offset 0 in the Data Array named

DA_PRESSURE. The contents of the 5 elements are defined in Appendix A.1.1. The 2

pressure indicating letter. Both of these elements must be set to non-zero values.

Map_Descriptor_Name, Data_Array_Name, Data_Array_Offset, Function, Node_name Gage_Functon Length

SRV_Pressure, DA_PRESSURE 0, Server Gage1 Pressure, 5

nd

element is the units index, the 3rd is the

Data for the

response to a

‘P’ poll is

extracted from

this Data Array.

This function defines

a capability of the

FieldServer to

respond to an

incoming poll.

The Map Descriptor

is passive. It does

not generate

messages but is

used to respond.

The Node Name

must be the same

as one of the

nodes defined in

the ‘nodes’ section

of the CSV file.

Defines the capability

of this Map Descriptor.

This Map Descriptor

can only be used to

form responses to a

‘P’

oll.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 17

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 17 of 23

Appendix A. Advanced Topics

Appendix A.1. How Data Gets Stored

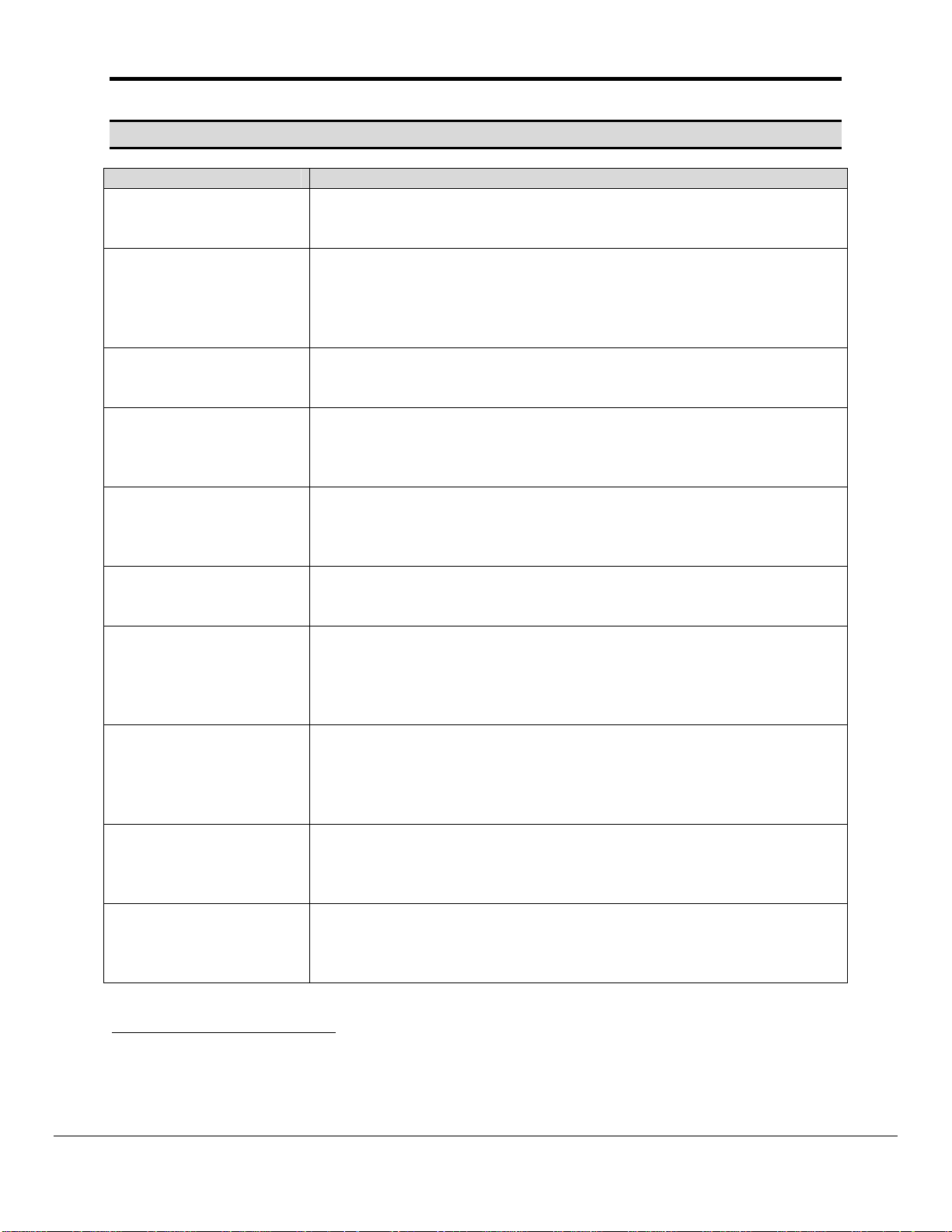

Appendix A.1.1. Pressure Data

Offset (where x is the offset

specified in the MD)

X + 0 Gage Pressure. A signed real number.

X + 1

X + 2

X + 3

X + 4

Notes

Gage Pressure Units. A whole number which is used

as a lookup into the table provide in section

“Appendix A.2 Gage Pressure Units”

Gage Pressure Indicating Letter

‘A’ = 65

‘G’ = 71

‘T’ = 84

Set to 1 If the pressure reading reports the status as

‘OK’

Set to 1 If the pressure reading reports the pressure

as a ‘SEA LEVEL’ reading

Appendix A.1.2. Status Data

If any fields are absent in the response to a poll for status data then the values are set to

zero for that field.

Offset (where x is the offset

specified in the MD)

X + 0 ‘ELEV:’ measurement. A signed real number.

X + 1

X + 2 ‘MAX:’ measurement. A signed real number.

X + 3

X + 4 ‘MIN:’ measurement. A signed real number.

X + 5

X + 6 ‘HI ALARM:’ measurement. A signed real number.

X + 7

X + 8 ‘LO ALARM:’ measurement. A signed real number.

X + 9

X + 10 ‘ZERO:’ measurement. A signed real number.

X + 11

X + 12 ‘UNIT:’ measurement. A signed real number.

X + 13

Notes

‘ELEV:’ engineering units index. See table

“Appendix A.2 Gage Pressure Units”

‘MAX:’ engineering units index. See table “Appendix

A.2 Gage Pressure Units”

‘MIN:’ engineering units index. See table “Appendix

A.2 Gage Pressure Units”

‘HI ALARM:’ engineering units index. See table

“Appendix A.2 Gage Pressure Units”

‘LO ALARM:’ engineering units index. See table

“Appendix A.2 Gage Pressure Units”

‘ZERO:’ engineering units index. See table

“Appendix A.2 Gage Pressure Units”

‘UNIT:’ engineering units index. See table “Appendix

A.2 Gage Pressure Units”

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 18

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 18 of 23

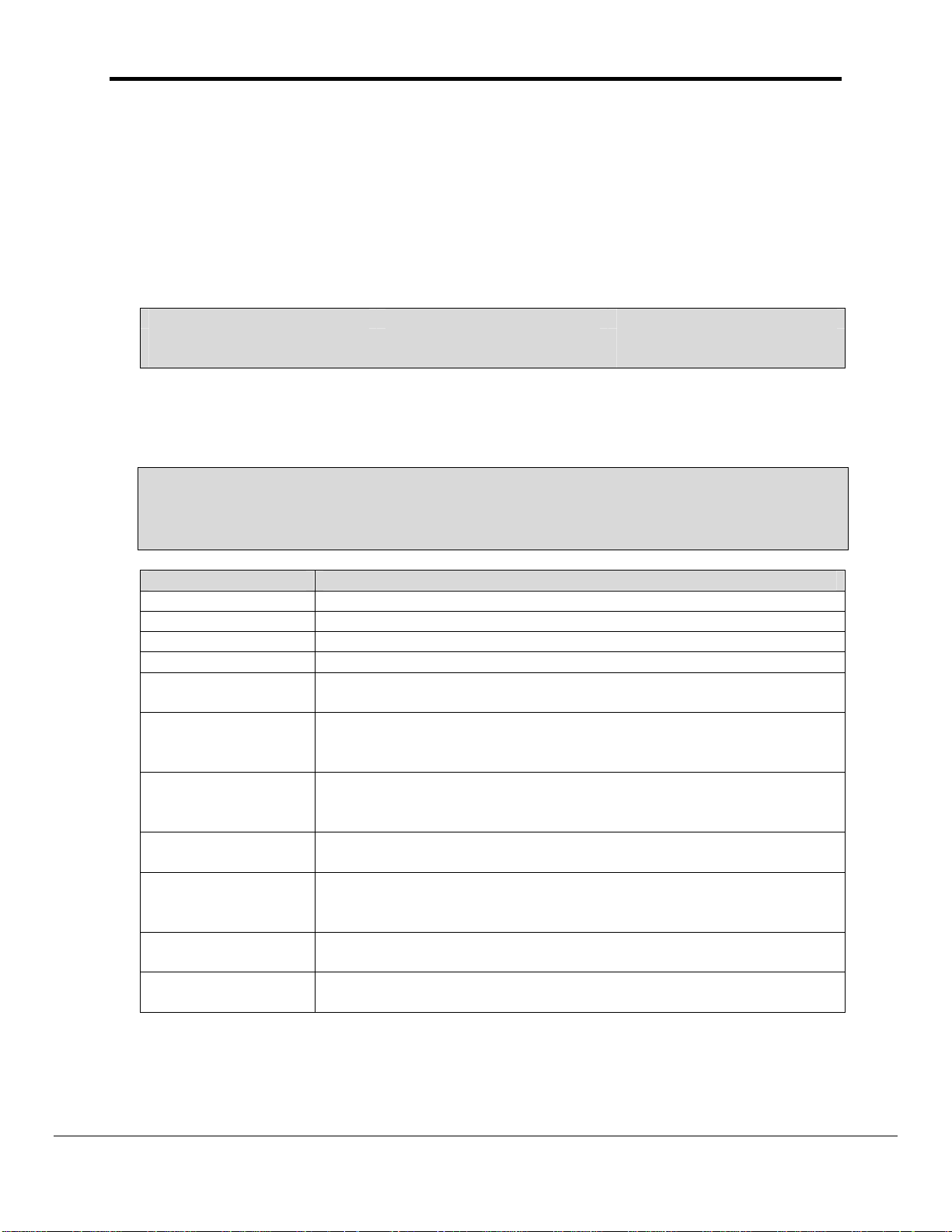

Appendix A.2. Gage Pressure Units

The driver does not report status and pressure reading units as text strings. Rather, the

driver reports and index number. Use the index number and the table below to determine

the units being reported.

Index # Meaning

0 The Units field could not be interpreted correctly / there were no units reported

/ the units reported were not part of the following list. This may be the case if

the Gage is reporting some custom units that the driver does not recognize.

1 HPA

2 PSI, psi

3 mbar, MBAR

4 MmHG, mmHg,

5 MmH20

6 InH20

7 ft, FT

8 m. M

9 Units

10 inHG, In HG, IN HG

Appendix A.3. Driver Limitations & Exclusions

This driver implements a subset of the commands defined by the protocol. The commands

that have been implemented have been selected to provide relevant real time data transfer

and have omitted configuration/setup functions.

The following table lists the commands that have been implemented.

Command Code Implemented

Immediate Print of Pressure Reading P Yes

Status Print SP Yes

Verification String V Yes

All others No

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 19

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 19 of 23

Appendix B. Troubleshooting tips

Appendix B.1. Connection Tips & Hints

The digital pressure Gage must be left in an operational state, in which it is able to respond

to the commands (polls) sent by the FieldServer. It is possible to enter a configuration mode

using the buttons on the front panel of the Gage and then fail to complete the configuration

sequence. In such cases, the Gage will not be able to respond to polls from the

FieldServer. This problem can be eliminated by ensuring that, after operating the Gage

from the front panel, that it is left in a mode where it is displaying the current measured

pressure.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 20

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 20 of 23

Appendix C. Driver Error Messages

Message Notes and Corrective Action

Set370:#1 FYI. Use an

Array called <%s> to

expose diagnostic info.

Set370:#2a. FYI. MD

Length=%d assigned by

driver.

Set370:#3 Err. No Write

MD's allowed.

Set370:#4 FYI. MD

param=Address has no

meaning. Ignoring.

Set370:#5 Err.

Diagnostic x

Set370:#6 Err. Array too

short. DA=%s MD=%s

Set370:#7 Err. Pressure

message can’t be

parsed. Abandoned!

Set370:#8* Err. Status

message can’t be

parsed. Abandoned!

Set370:#9 FYI. Default

to reading pressure.

Set370:#10 Err. DA=%s

too short. Act=%d

Rqd=%d MD=%s

This message is provided for information and may be ignored. Read

Appendix C.1 for more information.

This message is provided for information and may be ignored. The

message is printed when the Map Descriptor length in the

configuration file has not been specified. The driver makes the

correction by itself. To stop this message being printed, modify the

configuration file to match the length reported in the message.

This Driver cannot be used to write to the Setra device. Remove

any Map Descriptors whose function requires the FieldServer to

write to the Setra device.

3

This message is provided for information and may be ignored. The

address parameter is ignored by the driver. To stop this message

being printed, remove the address parameter from the configuration

file.

There are a few variations of this message. Note the variation and

report the error to FieldServer tech support. You cannot resolve this

error yourself. The error is printed when the driver executes a

diagnostic function used for QA testing.

The Data Array associated with the reported MD is too short to store

all the data returned by the Setra Gage. Increase the length of the

Data Array and of the Map Descriptor.

3

The response to a pressure reading request cannot be parsed by the

driver. Use the connection view to check the number of protocol

errors. If they keep rising, then take a log and report the error to

FieldServer Tech Support. If the protocol errors are occasional then

ignore them.

4

The response to a status reading request cannot be parsed by the

driver. Use the connection view to check the number of protocol

errors. If they keep rising, then take a log and report the error to

FieldServer Tech Support. If the protocol errors are occasional then

ignore them.

A Map Descriptor is found which does not have the ‘Gage_Function”

specified. The driver assumes your intention was to read the Gage’s

pressure. If you wish stop this message being printed then modify

the configuration file and specify the ‘Gage_Function’ = ‘Pressure’.

3

This message is printed when the driver is configured as a Server.

The Data Array associated with the reported MD is too short to store

the message. Modify the MD length and the DA length and try

again.

3

3

Modify the configuration CSV file. Download the modified file to the FieldServer and reset the

FieldServer for the changes to take effect

4

Message is printed once and then suppressed. This is to prevent the error log filling with redundant

repetition and thus obscuring other important information

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

.

.

Page 21

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 21 of 23

Appendix C.1. Exposing Driver Diagnostic Statistics

In addition to the standard FieldServer communication statistics described in Appendix C.2

and in the FieldServer Instruction Manual, this driver can also expose some driver statistics

by writing data to a data array. A special Data Array name is required. The driver

recognizes the Data Array by its name which must be "Setra370-Stats"

The following example shows how this Data Array can be configured. You can copy this

section of text directly into your CSV file.

Data_Arrays

Data_Array_Name, Data_Format, Data_Array_Length

setra370-stats, UINT32, 1000

The driver stores the following data. The location in the data array is obtained by

multiplying the port number by 100 and then using the location offset indicated in the table

below.

Offset + x

Where x = port_number*100

Physical Port 1 = Port Number 2

Physical Port 2 = Port number 1

Data Array Offset Contents

0 For FieldServer use only.

1 For FieldServer use only.

2 For FieldServer use only.

3 Increments by 1 each time a Client poll message is sent to a Gage.

4

5

6

7

8

9

10

Increments each time a Client poll message is sent to a Gage.

Increases by the number of bytes in the message.

Increments by 1 each time the Gage sends a response which is

completely unsuitable for data storage. Includes messages which

report the Gage is in a setup mode and is unable.

Increases each time the Gage receives a response which has some

hope of containing data. Increased by the number of bytes in that

message.

Increases each time the Gage receives a response which has some

hope of containing data. Increased by 1 each time.

Increments by one each time a status response contains a line

which appears not to be a heading but which does no appear to be

suitable for data extraction.

Increments by 1 each time a status response contains no data

which could be stored.

Increments by 1 each time a pressure reading response is not

suitable for data extraction and storage.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 22

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 22 of 23

Appendix C.2. Standard Driver Stats

Driver Statistics Recorded Explanation

PLC Read Messages sent Number of message sent to the Gage

PLC Write Messages sent Should be zero

PLC Bytes sent Total number of bytes sent by the Client side driver

Total number of messages of all types received (ACK,

PLC Message received

PLC Bytes received

Protocol

IC_Timeout

Timeout

Streaming

Exception

NAK, error response, normal response) on the Client side

driver.

Total number of bytes received by all message types on

the Client side driver.

Protocol errors are incremented when the Client side

cannot correctly parse a response message from the

Gage. This includes responses that are formatted

differently from what the driver expects, or messages that

report the Gage is ‘unable’ or in setup mode.

Incoming message buffer experiences an excessive

delay between incoming bytes

Client side messages that were not responded to by a

Server. Possibly a communications error or a command

was made to a unit that does not exist.

Message size was too large for the input buffer. This

should never occur.

Increments when a ‘status’ response contains a line with

insufficient information for storage but which may be a

heading.

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Page 23

FS-8700-101_Setra Model 370 Digital Pressure Gage Manual Page 23 of 23

THIS PAGE INTENTIONALLY LEFT BLANK

FieldServer Technologies 1991 Tarob Court Milpitas, California 95035 USA Web:www.fieldServer.com

Tel: (408) 262-2299 Fax: (408) 262-9042 Toll_Free: 888-509-1970 email: support@fieldServer.com

Loading...

Loading...