Page 1

Fieldpiece

MIN

MIN

MIN

MICRONS OF MERCURY

VACUUM

GAUGE

MIN

ALARM

MIN

MICRONS OF MERCURY

SVG3

VACUUM

GAUGE

MIN

ALARM

ENTER

GAUGE

MIN

Easy View

Vacuum Gauge

OPERATOR'S MANUAL

Model SVG3

Quick Start

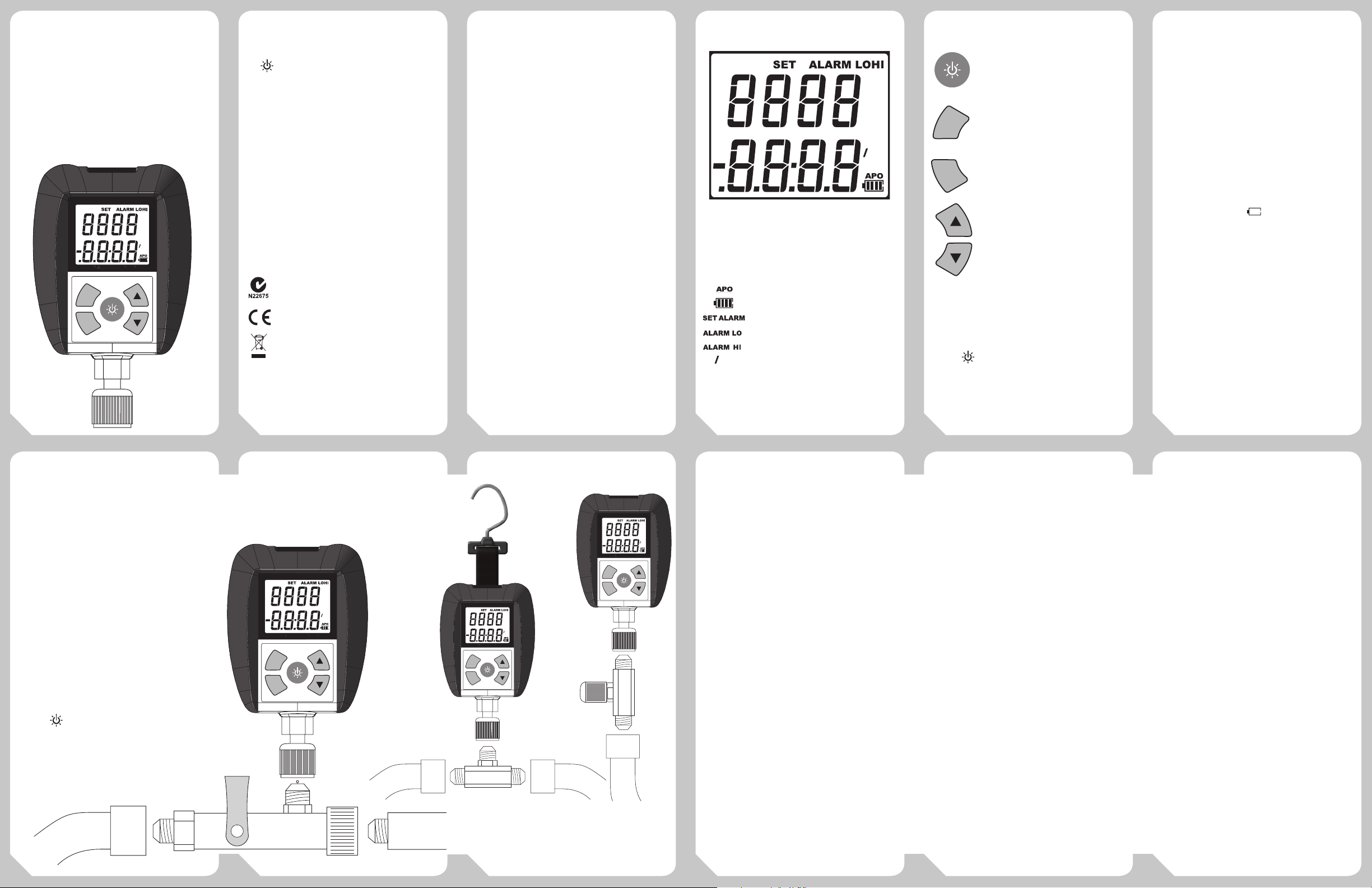

1. Power on your SVG3 by holding the

button for 1 second.

2. Connect to system directly to an

unused service port, a Schrader core

removal tool (SCRT), or via hoses.

3. View vacuum in microns of mercury

on the top line and rate of change

(±microns per minute) on the bottom line.

Description

Proper evacuation of any system

exposed to atmosphere is critical to

ensure efficient operation and the

SVG3 is the right tool to help HVACR

professionals verify they reach proper

vacuum levels. See your vacuum

measurement clearly and easily with

the newly designed easy-view hook

and backlight. SVG3 is built for eld

use with its ruggedized rubber case.

Reducing connections minimizes leaks, so the SVG3 has

a female 1/4" flare fitting with

MIN

MICRONS OF MERCURY

VACUUM

ALARM

GAUGE

Certifications

C-Tick (N22675)

schrader depressor so you can

connect it directly to a service port or

your valve core removal tool.

Be alerted when you've reached

your desired vacuum levels with built

ENTER

CE

SVG3

WEEE

in Hi and Lo Alarm functions. Check for

leaks with rate indication in microns

per minute. The HVACR professional

can do more with condence that he

RoHS Compliant

01 03 0602 0504

is doing the job right the rst time.

Display

MIN

Top Line: Live Vacuum Measurement

in Microns of Mercury (Hg)

Bottom Line: Rate of Micron Change

or Alarm Stopwatch

Auto Power O Enabled

Battery Life

Alarm Set Mode

Low Alarm Mode

High Alarm Mode

Rate of Micron Change

(±Microns Per Minute)

Controls

Hold 1 second to power SVG3 on/ o. Press

<1 second to toggle backlight.

Press to activate Alarm Lo, Alarm Hi, and

return to real time mode. Hold 1 second to

enter or exit Alarm Set mode.

Lock in selected digit and move to next in

Alarm Set Mode.

Increase or decrease blinking digit in

Alarm Set Mode. Toggle to display

stopwatch or rate of change when an

alarm is activated in real time mode.

BACKLIGHT NOTE: The backlight timer is automatically

extended for 1 min when any button is pressed. A short

press of

toggles backlight on and o.

Specifications

General

Operating temperature: 32°F (0°C) to 122°F (50°C) at

<75%RH

Storage temperature: -4°F to 140°F (-20°C to 60°C), 0

to 80% RH (with battery removed)

Temperature coecient: 0.1 x (specied accuracy)/°C

(<18°C or >28°C)

Over range: "OL" is displayed

Power: 4 x AAA batteries, NEDA 24A, JIS UM4, IEC R03

Auto power o: after 15 minutes of readings more

than 10,000 microns if APO is active.

Battery life: 40 hours standard use (alkaline) without

backlight use.

Low battery indication: is displayed when the

battery voltage drops below the operating level.

Vacuum Pressure

Units of measure: microns (µm) of mercury

Connector type: Standard 1/4" female are tting. "T"

tting included ( 3 male are ports)

Range: 0 to 9999 microns of mercury

Accuracy: ±(5% of reading + 5 microns), 50 to 1000

microns

Resolution: 1 micron (50 to 2000 microns), 250

microns (2001 to 5000 microns), 500 microns (5001

to 8000 microns), 1000 microns (8001 to 9999

microns)

Rate: Microns per minute

Refresh rate: 0.5 seconds

Atmospheric pressure: "OL" will be displayed

Maximum overload pressure: 500 psig

How to Use

Normal Mode

Measure deep vacuums to

monitor your system evacuations. Deep vacuums help remove

non-condensable gases that can

cause problems in a system.

There are many ways to connect to

the system, Fieldpiece recommends

using a SCRT and the shortest vacuum

rated hoses possible. Fewer connections reduce the potential for leaks.

1. Connect to system. Techs typically prefer connect-

ing to the Schrader Core Removal Tool (SCRT) or an

unused service port.

2. Hold for 1 second to power ON the SVG3.

3. The top display shows the vacuum in microns of

mercury.

4. The bottom display shows how fast the measure-

ment is increasing or decreasing (± microns of

mercury per minute).

07 09 1208 1110

Hose

To

Pump

Recommended

Setup

MIN

MICRONS OF MERCURY

VACUUM

GAUGE

ALARM

ENTER

SVG3

Schrader Core

Removal Tool

(tool not included)

To

Pump

Directly to

Service Port

MICRONS OF MERCURY

VACUUM

GAUGE

ALARM

ENTER

MIN

SVG3

Other Common

Setups

To

Service

Port

MICRONS OF MERCURY

VACUUM

GAUGE

ALARM

ENTER

SVG3

Hose to

Removal

Tool

MIN

Low and High Alarms

Be alerted when you've reached your

desired vacuum levels. Work on other

tasks at the jobsite and let SVG3 alert

you when the system is ready.

Activate the low alarm (default 500

microns) to alert when the vacuum has

dropped to your desired micron level.

Activate the high alarm (default 1000

microns) to see how long it takes the

system to stabilize after the vacuum

pump has been isolated. If the system

does not stabilize over time, you may

have a leak in the system or your connections.

The stopwatch will start when an

alarm is activated. It will restart when

the low alarm has been reached to show

how long you've pulled a vacuum after

reaching your desired micron level. The

stopwatch will stop when the high alarm

has been reached to show how long it

took to rise to your high alarm value.

When an alarm is activated the UP or

DOWN ARROW toggles the stopwatch

and rate of change (± microns per minute) display.

How to Activate the Alarms

1. Press ALARM to activate low alarm.

2. Press ALARM again to deactivate low alarm and

activate high alarm.

3. Press ALARM again to deactivate high alarm and

return to real time mode.

How to Set the Alarms

The default low (500 microns) and

high (1000 microns) alarm values can

easily be set to whatever you want.

1. Hold ALARM for 1 second to enter Alarm Set Mode.

The rst digit of LO alarm will blink.

2. Use ARROWS to change the blinking number. Press

ENTER to lock in a digit and move to the next digit.

Repeat for all LO alarm digits.

3. When LO alarm is complete, the rst digit of HI alarm

will blink. Use ARROWS to change the blinking

number. Press ENTER to lock in a digit and move to

the next digit. Repeat for all HI alarm digits.

4. When all digits of HI alarm are locked in you will

automatically exit Alarm Set Mode and your

customized alarm values will be saved.

Note: Anytime while in Alarm Set Mode, you can press

ALARM to toggle between alarm HI set and alarm

LO set. Hold ALARM to exit Alarm Set Mode and

save at any time.

Note: "Err" will show if you try to set the HI alarm

lower than the LO alarm, or the LO alarm higher

than the HI alarm.

Vacuum Tips

Follow all manufacturer's evacuation procedures over those in this

manual in regards to specications on

how to evacuate systems. To achieve

a deep vacuum eciently Fieldpiece

recommends the following practices.

1. Remove Schrader cores and core depressors from

the service ports using a valve core removal tool

(purchased separately).

2. Use the shortest vacuum rated hoses with the

largest diameter available.

3. Inspect rubber seals at both ends of your hoses for

damage that may result in leakage.

4. Avoid using hoses with low loss ttings when

evacuating a system.

5. Avoid over-tightening the female are tting of

the SVG3. Over-tightening may cause the rubber

gasket to wear more quickly and create leaks. It is

not necessary to over tighten SVG3 to the extreme

to create a good seal.

Page 2

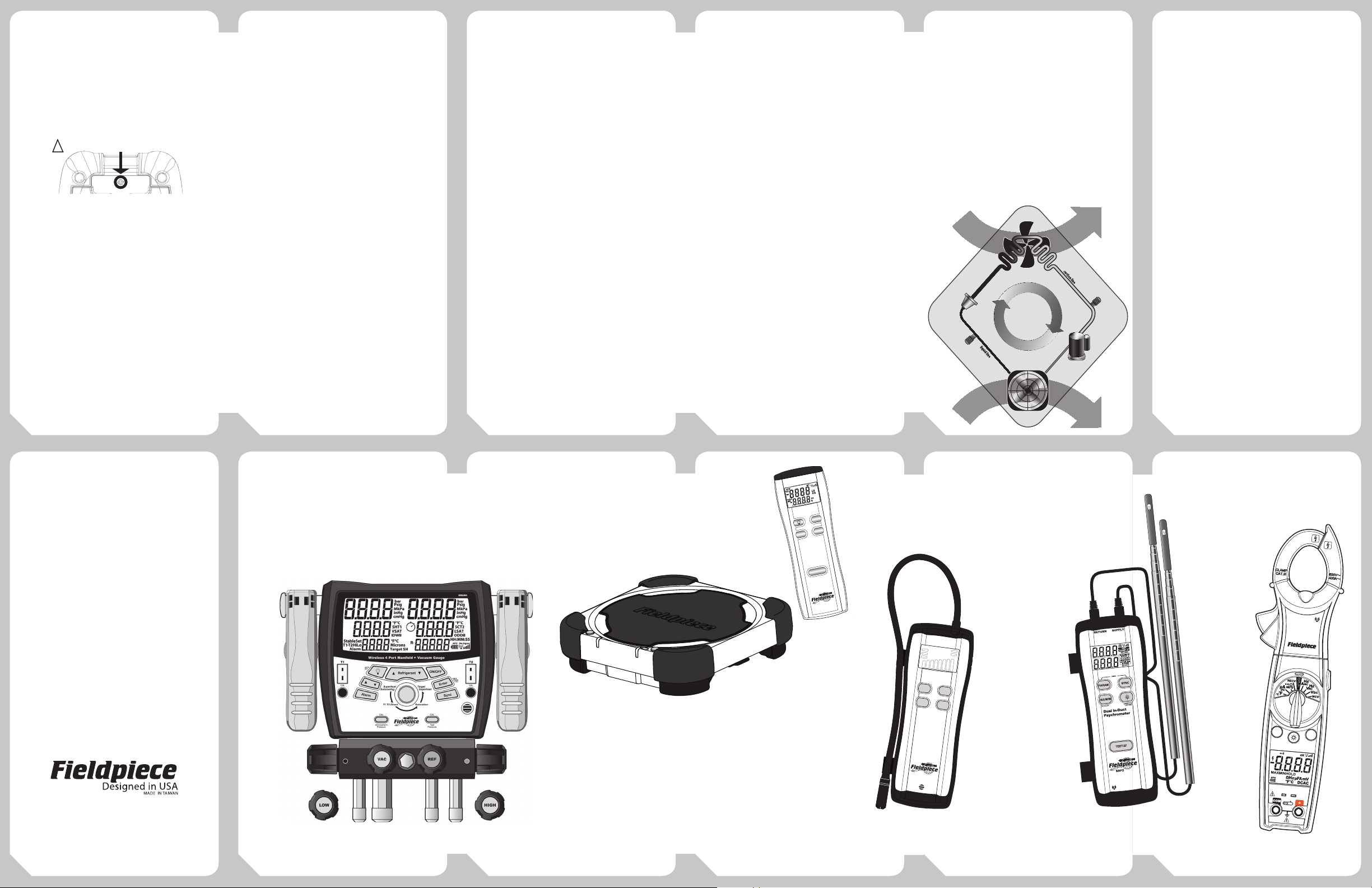

Maintenance

Battery Cover Screw

PRESS FOR 1 SECOND

AUTO-OFF

SRS2

Wireless

Refrigerant

Scale

ZERO

SYNC

UNITS

ON/OFF

PRESS FOR

1 SECOND

SC57

AUTO OFFTRUE RMS

CAT III

600V

TEMP

K-TYPE

30V

MAX

SC57

O

F

F

WIRELESS ENABLED

SEL

HOLD

HOLD

MAX

MIN

SYNC

SYNC

MAX

MIN

SENSITIVITY

H

M

L

AUTO-ZERO

LOW-BATT

SRL8

ON/OFFMUTE

ZEROL/M/H

Heated Diode

Refrigerant

Leak Detector

PRESS FOR

1 SECOND

BATTERY

CHECK

80

80

Clean the exterior with a dry cloth.

Do not use liquid.

Battery Replacement

Power off SVG3. Unscrew battery

cover, and replace the 4 AAA batteries.

!

Cleaning the Sensor

1. Turn o your SVG3.

2. Remove the core valve depressor and rubber gasket.

A small pair of needle nose plyers can easily pull

out the depressor and the gasket at the same time.

Be careful to not puncture or tear the gasket.

3. Fill the cavity halfway with isopropyl (rubbing)

alcohol.

4. Use your index nger to cover female are tting

and gently swirl and shake the alcohol within the

cavity for about 15 to 30 seconds.

5. Pour out the alcohol and let the vacuum sensor dry

with the are tting facing down.

6. Re-insert core depressor and rubber gasket. Screw in

T-tting (included) to lock in the rubber gasket.

Note: Do not use an object such as a cotton swab to

clean the sensor. This may damage the sensor.

Replacement Parts

Rubber gasket and Schrader depressor are user-replaceable. Worn

out gaskets and depressors can lead

to a bad seal. Over-tightening of the

SVG3 female are tting may cause

the rubber gasket to wear more

quickly. Replace if the rubber gasket

becomes worn or the Shrader depressor is not in the center. Both these

parts can easily be found at your local

HVACR distributor.

1. Remove both the Schrader depressor and rubber

gasket from the are tting. Dispose of worn

rubber gasket. A small pair of needle nose plyers

can easily pull out the depressor and the gasket at

the same time. Be careful not damage the Schrader

depressor.

2. Re-insert and center the Schraeder depressor into

the are tting. If the depressor does not stay

centered, replace with a new one.

3. Drop in and position of the new rubber gasket

(standard 1/4" rubber gasket replacement part)

around the Schraeder depressor. Push in with your

nger.

4. Lock O-ring into place by screwing in the included

brass T-tting. Do not over-tighten.

A/C Basics

The Evaporator, Condenser, Restrictor (Throttling valve) and Compressor

are the four basic components of an

air conditioner. Following one pound

of refrigerant through the system

shows the function of each component.

Subcooled liquid refrigerant at high

pressure enters the restrictor and is

throttled to saturated refrigerant at a

lower pressure. The restrictor can be

either a xed or TXV/EXV type. The

xed type must be charged to a target

superheat that varies with indoor and

outdoor conditions. TXV/EXV systems

must be charged to subcooling.

The evaporator capacity varies

with the indoor heat load on a xed

restrictor. The TXV/EXV regulates the

size of the restriction to maintain a

constant superheat. This essentially

adjusts the capacity of the evaporator

responding to the indoor heat load.

After the restrictor, refrigerant

enters the evaporator at a low temperature and pressure, and boils

13 15 1814 1716

(evaporates) into a gas by absorbing

heat from the indoor air. The refrigerant stays at the same temperature

and pressure until all the refrigerant

evaporates into a gas. After the refrigerant becomes a gas, it will continue to

absorb heat and become superheated

at which point its temperature will

change. The Superheat measurement

is the best indication of refrigerant

charge level in a xed restrictor system. A TXV/EXV system will keep the

superheat constant. There must be

superheat present to ensure liquid

does not ood the compressor.

Superheat measurements are

taken on the suction line between

the evaporator and compressor.

The compressor takes this low

temperature, low pressure, slightly superheated refrigerant and compresses

it to a much higher temperature and

pressure.

The highly superheated gas enters

the condenser and rejects heat into

the outside air. The refrigerant condenses back into a liquid. Once all of

the gas is condensed into a liquid,

additional removal of heat causes

a temperature drop that is known

as subcooling. TXV/EXV systems are

charged to subcooling since superheat is controlled by the throttle

valve. Subcooling measurements are

taken on the liquid line between the

condenser and TXV/EXV. Finally, the

subcooled liquid enters the restrictor

and the cycle starts again.

EVAPORATOR

RETURN AIR SUPPLY AIR

w

o

L

P

r

e

s

s

u

r

e

REFRIGERANT

FLOW

s

u

r

e

e

d

i

S

CONDENSER

S

i

d

e

COMPRESSOR

THROTTLE

VALVE

H

i

g

h

P

r

e

s

OUTDOOR AIR HOT AIR

Limited Warranty

This meter is warranted against

defects in material or workmanship

for one year from date of purchase.

Fieldpiece will replace or repair the

defective unit, at its option, subject

to verication of the defect.

This warranty does not apply to

defects resulting from abuse, neglect, accident, unauthorized repair,

alteration, or unreasonable use of the

instrument.

Any implied warranties arising

from the sale of a Fieldpiece product,

including but not limited to implied

warranties of merchantability and

fitness for a particular purpose, are

limited to the above. Fieldpiece shall

not be liable for loss of use of the

instrument or other incidental or

consequential damages, expenses, or

economic loss, or for any claim of such

damage, expenses, or economic loss.

State laws vary. The above limitations or exclusions may not apply to

you.

For Service

More Great Tools

In the USA, call Fieldpiece Instru-

ments for one-price-x-all out of war-

from Fieldpiece

ranty service pricing. Send check or

money order for the amount quoted.

Send the meter freight prepaid to

Fieldpiece Instruments. Send proof

of date and location of purchase for

in-warranty service. The meter will be

repaired or replaced, at the option of

Fieldpiece, and returned via least cost

transportation.

For international customers, warranty for products purchased outside

of the U.S. should be handled through

local distributors.

19 21 2420 2322

www.fieldpiece.com

© Fieldpiece Instruments, Inc 2013; v22

Wireless Refrigerant Scale

Model SRS2C

Wireless 4-Port Manifold

Model SMAN4

Heated Diode Refrigerant Leak Dectector

Model SRL8

Dual In-Duct Psychrometer

Model SDP2

Wireless Clamp Meter

Model SC57

Loading...

Loading...