Page 1

80

80

80

80

80

80

80

Fieldpiece

80

80

80

80

80

80

80

80

80

PRESS FOR

1 SECOND

PRESS FOR

1 SECOND

ON/OFF

AUTO-OFF

PRESS FOR

1 SECOND

ON/OFF

UNITS

RECORD MODE

PRESS FOR

1 SECOND

DUCT

ON/OFF

ENTER

HOLD

AVERAG E

AUTO-OFF

PRESS FOR

1 SECOND

ON/OFF

UNITS

PRESS FOR

1 SECOND

DUCT

ON/OFF

UNITS

RECORD MODE

PRESS FOR

1 SECOND

DUCT

ON/OFF

ENTER

HOLD

AVERAG E

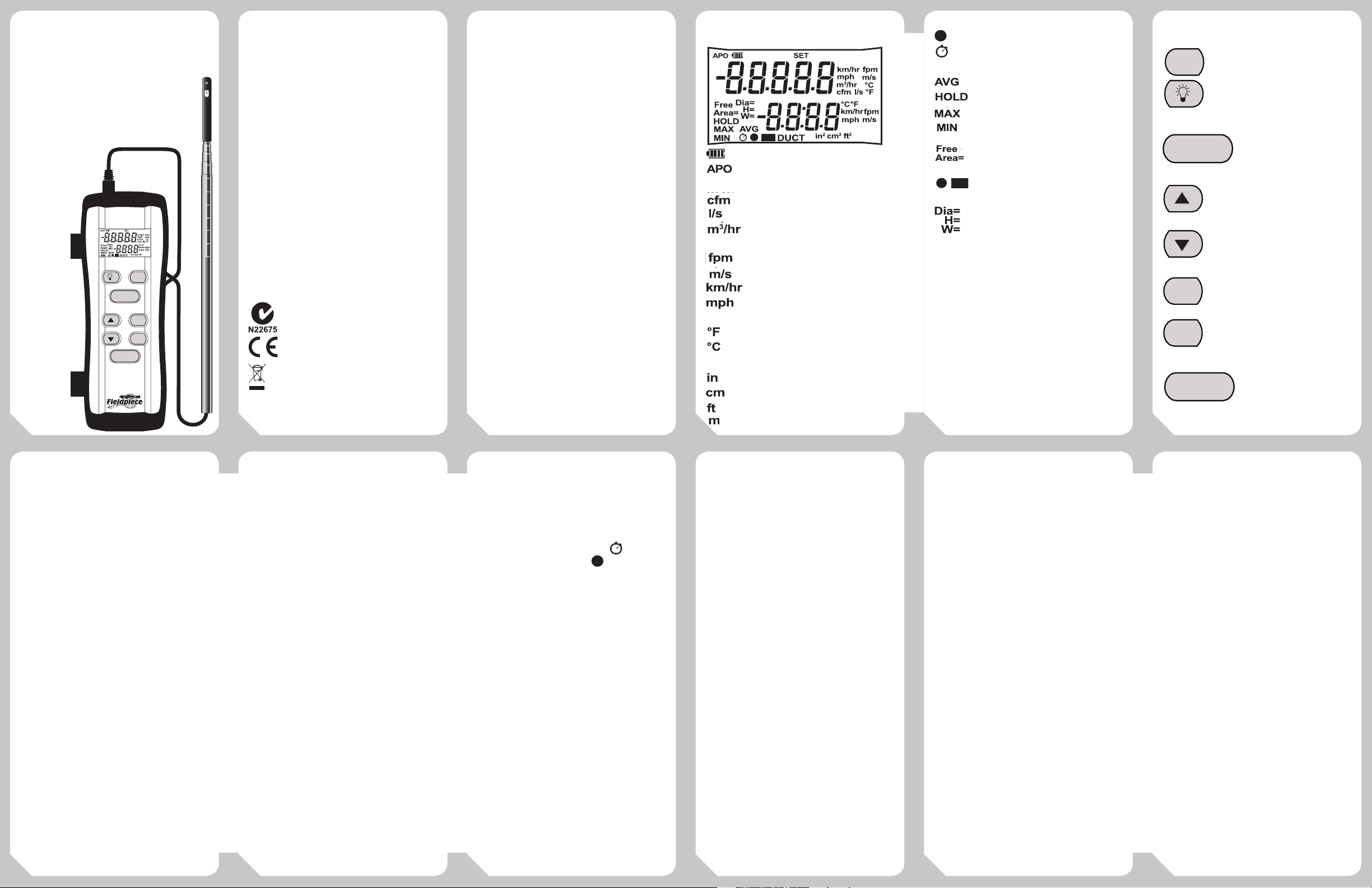

In- Duct Hot Wire

Anemometer

OPERATOR'S

MANUAL

Model STA2

PRESS FOR

AUTO-OFF

1 SECOND

ON/OFF

RECORD MODE

HOLD

AVERAGE

CLEAR DATA

MAX/MIN

In-Duct

Hot Wire

Anemometer

DUCT

ENTER

UNITS

Quick Start

1. Power on your STA2 by holding the

ON/OFF button for 1 second. There is

a 5 second count down as the meter

warms up.

2. Use the arrow buttons to cycle the

display between air velocity, volumetric ow (CFM) and temperature.

3. Press the DUCT button to enter a

duct size.

4. Press and hold the HOLD (Average)

button to enter "Record Mode."

Record ow, velocity and tempera-

ture values, over time or at specic

80

points. Then average the recorded

values.

Certifications

C-Tick (N22675)

CE

WEEE

Description

Your STA2 is a portable, hand held,

hot wire anemometer, designed for

the HVAC/R technician.

The compact probe tip makes

directly measuring air velocity a

breeze. The 38"(96cm) telescoping

probe with laser etched ruling and

attened edges allows you to locate

proper measurement points within a

duct and ensures that your probe is

properly aligned.

The STA2 calculates air flow

(CFM) based o your inputs of duct

dimensions or free area, making

for quick and accurate readings, no

matter the duct size or shape.

Use either of the averaging methods

in Record Mode to counter turbulent

spikes in air velocity.

The dual display with a bright

backlight, and rugged rubber boot

with probe clips, make sure the STA2

is ready for any job.

STA2

01 03 0602 0504

RoHS Compliant

Display

Battery Life

Auto Power O Enabled

Volumetric Flow (cubic feet/minute)

Volumetric Flow (liters/second)

Volumetric Flow (cubic meters/hour)

Velocity (feet/minute)

Velocity (meters/second)

Velocity (kilometers/hour)

Velocity (miles/hour)

Temperature (Fahrenheit)

Temperature (Celsius)

Length (inches)

Length (centimeters)

Length (feet)

80 Length (meters)

Point Recording

Time Recording

Average Display

Hold Display

Maximum Display

Minimum Display

Free Area Input

Duct Shapes

Dimension Input

(diameter, height, width)

Controls

ON/OFF

Scroll up or down. Cycles displayed

DUCT

ENTER

Hold 1 second to toggle power on/o.

Toggle Backlight. (Hold while powering

your STA2 on to disable APO.)

RECORD MODE

HOLD

AVERAG E

measurement parameters (CFM, Velocity,

and Temp.)

UNITS

CLEAR DATA

MAX/MIN

Toggle display Hold (displays

average of recorded values

while in record mode).

Hold for 2 seconds or longer

to enter/exit record mode.

Press for duct setup.

Hold for 2 seconds for Units setup.

Conrm Selection.

Displays Maximum or Minimum

values. Hold for 1 second to exit

and clear stored values.

Functions

Backlight

1. Press the backlight button to toggle the backlight

on/o at any time during the STA2's use.

Note: The backlight will automatically shut o after 1

minute to conserve battery life.

Hold

1. The HOLD button toggles the Hold Function on/o.

The Hold function will pause the measured values

on the upper and lower displays until cancelled.

2. Pressing the HOLD button for longer than 2 seconds

will take the STA2 into "Record Mode." (Please see

the Record Mode section for more information.)

Maximum/Minimum

1. Pressing the MAX/MIN button activates the Max-

2. Once the Max-Min function has been enabled,

Clear Data

1. Press and hold the MAX/MIN button for 2 seconds

07 09 1208 1110

Min function, holding the maximum and minimum

values measured until cleared.

pressing MAX/MIN cycles between displaying

maximum (MAX), minimum (MIN) and real time

values (MAX MIN).

to CLEAR DATA, this erases all stored data points

and resets the Record Mode counter to zero.

Display Scrolling

1. At any point during operation the arrow keys

may be used to change the display(s) on your

STA2 to show velocity, ow and temperature

measurements.

Duct Setup

1. Enables the STA2 to calculate volumetric ow

based on user entered information specic to the

equipment being worked on. Pressing the DUCT

button will lead you through the duct setup. (See

the "Set up your STA2" section for detailed use of

this function.)

Units Setup

1. To enter the Units setup mode hold down the DUCT

button for 2 seconds.

2. Use the Arrow and ENTER buttons to select air

velocity, ow, temperature and length units.

Note: Length units will also be used as area units for

Free Area inputs during Duct setup.

3. Once all units are selected you will be returned to

the main display screen.

Record Mode

Record Mode allows you to nd the Average,

Maximum and Minimum of recorded

measurements taken over a length of time, or in

dierent positions.

1. Enter the Record Mode and select either time

or point recording. Time recording 80 will be

continuous, a point recording 80 will only record

at entered points. Use the Arrow buttons to choose

between time and point recording and press ENTER

to lock in your selection.

2. a.)Time Recording: Use the ENTER button to start

and pause recording. The lower display shows the

total time recorded.

b.) Point Recording: Press the ENTER button to

take a measurement at a specic point. The lower

display shows the total number of measurements

recorded.

3. Press the AVERAGE button to display the

average of recorded values. Press the MAX/MIN

button to display the maximum and minimum

measurements taken. These functions can be used

while still recording.

Note: Average replaces Hold while in Record Mode.

What is Free Area?

How Do I Get It?

Free Area is the total area through

which air can ow on either a supply

outlet or a return grille. Free area

is also sometimes referred to as

"eective area" or "see through area."

If there is no grille or restriction on

the area through which air is owing

then the free area is equal to the actual

area. This would be the case if you

were measuring air ow in the middle

of a duct, or if you were to remove the

grille from a supply or return.

If you are measuring airow where

there is a restriction present, then the

free area is the total area minus the

area covered by the ns or grating.

Free Area is published by grille

manufacturers and is the most

accurate representation of the Free

Area of a duct. Use manufacturer's

data whenever available.

How to Measure

Accurate Airflow

Find a Suitable Location

for a Traverse

1. The cross sectional area at, before, and after the

traverse location should be either rectangular

or round.

2. Make sure you have sucient access around

the traverse location so that the duct may be

traversed at multiple angles.

3. The traverse location should be chosen so as to

minimize the eects of leaks in the portion of

the system between the fan and the traverse

location.

4. The traverse location should be located far

enough downstream of the fan to allow the

airow to come to a uniform distribution.

To determine an eective length, assume a

minimum of 2.5 duct diameters for 2500ft/

min or less and add 1 duct diameter for each

additional 1000ft/min measured. (For a

rectangular duct the equivalent diameter can

be calculated as D=√(4hw/π) where “h” is the

height of the duct and “w” is the width.)

5. Locations directly downstream from

obstructions, bends or sudden changes in the

duct are not good locations for a traverse.

Set Up Your STA2

Press the DUCT button to enter Duct setup mode and

choose to input either duct dimensions or Free Area.

1. Duct dimensions: Use this option if measuring

in a duct or at an obstruction-free Supply/Return.

2. Use the arrow and ENTER buttons to select the

Duct dimensions icon.

3. Use the arrow and ENTER buttons to select the

shape of the Duct.

4. Use the arrow and ENTER buttons to enter either

the Height (H=) and Width (W=) of the duct

(for rectangular ducts) or the Diameter (D=) (for

round ducts).

1. Free Area: Use this option if measuring at a

Supply/Return with an obstruction such as a

grille and the free area is known.

2. Use the arrow and ENTER buttons to select the

Free Area icon.

3. Use the arrow and ENTER buttons to enter the

manufacturer specied Free Area.

After the appropriate information is input you will be

returned to the main display screen.

When you are ready to execute the traverse you will

want to put the STA2 into RECORD mode and select

time recording. Use the ENTER button to start and stop

recording at each of the points along your traverse. How

long you record at each point depends on how much

variance you see while measuring.

Continued on reverse...

Page 2

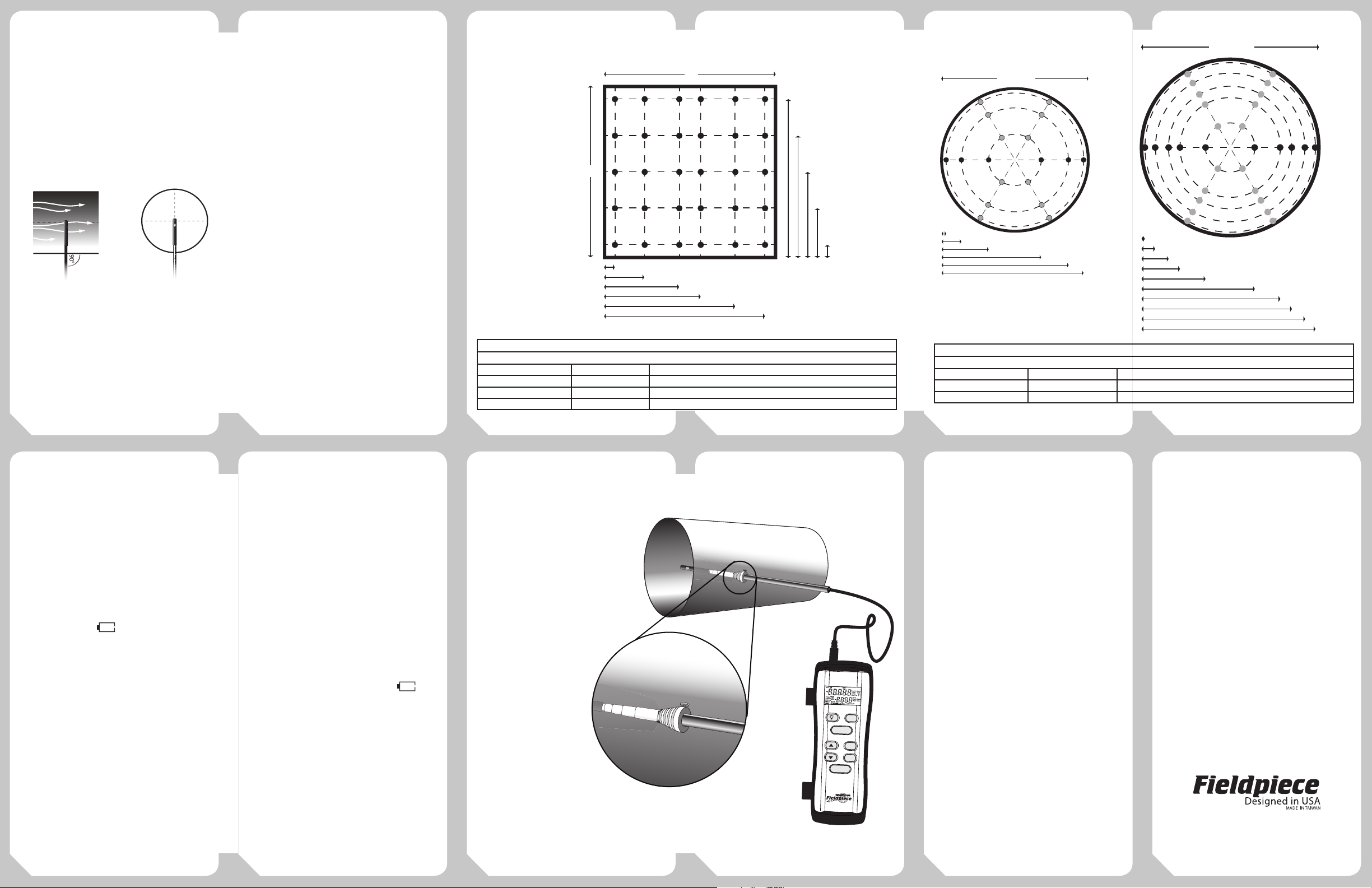

90°

90°

90°

D (<10”)

D (>10”)

0.032D

0.135D

0.321D

0.679D

0.865D

0.968D

0.019D

0.077D

0.153D

0.217D

0.361D

0.639D

0.783D

0.847D

0.923D

0.981D

90°

D (<10”)

D (>10”)

0.032D

0.135D

0.321D

0.679D

0.865D

0.968D

0.019D

0.077D

0.153D

0.217D

0.361D

0.639D

0.783D

0.847D

0.923D

0.981D

D

(<10”)

0.032D

0.135D

0.321D

0.679D

0.865D

0.968D

Execute the Traverse

1. Determine the appropriate measurement

points by measuring either the diameter of

the duct or the width and height. Then use the

appropriate table (See table 1 and 2) to calculate

the insertion depth where each of the point

measurements should be recorded.

2. Insert the probe of the STA2 into the duct and

use the at edges of the probe to position the

probe tip so air ows directly past the sensor.

Check that the direction of airow is at 90° to the

probe by making sure that the wand itself is at a

right angle to the side of the duct.

3. Use the laser etched ruler on the side of the

probe to measure the insertion depth and nd

the locations you determined in step 1.

4. Press the ENTER button to record a point

measurement at each of the locations

determined in step 1.

5. Press the Average button to display the

calculated average of all recorded points. Then

use the arrow buttons to cycle display between,

average temperature, velocity and airow.

6. If the above steps were followed, the average

ow number on your STA2 will be an accurate

representation of the airow through the

traverse location you selected.

7. (Optional) More is better. If the traverse location

you have selected is not ideal for any of the

reasons listed above, it may be benecial to

conduct multiple traverses at dierent locations.

Proper Measurement

Points for Rectangular/

Square Ducts

H

Traverse locations using log-Tchebyche rule in a rectangular duct

Length of Side # of Traverse Lines Distance from Inner Wall in % of Length of Side

< 30 in (76 cm) 5 7.4%, 28.8%, 50%, 71.2%, 92.6%

30-63in (76-160cm) 6 6.1%, 23.5%, 43.7%, 56.3%, 76.5%, 93.9%

>63in (160cm) 7 5.3%, 20.3%, 36.6%, 50%, 63.4%, 79.9%, 94.7%

0.061W

0.235W

W

0.437W

TABLE 1

Proper Measurement

Points for Round Ducts

0.926H

0.712H

0.500H

0.288H

0.074H

0.563W

0.765W

0.939W

TABLE 2

Log linear rule for traverse points on two diameter for a round duct

Diameter # of points per diameter Distance from inner wall in % of diameter

<10in (25.4cm) 6 3.2%, 13.5%, 32.1%, 67.9%, 86.5%, 96.8%

≥ 10in (25.4cm) 10 1.9%, 7.7%, 15.3%, 21.7%, 36.1%, 63.9%

13 15 1814 1716

Specifications

Accuracy: Stated accuracy @ 73°F±9°F (23°C±5°C),

<90%RH

Temperature coecient: 0.1 x (specied accuracy)

per °C for 0°C to 18°C, 28°C to 50°C (32°F to 64°F,

82°F to 122°F)

Operating environment: -4°F to 122°F (-20°C to

50°C) at <75%RH

Storage temperature: -4°F to 140°F (-20°C to 60°C),

0 to 80% RH (with battery removed)

Battery: 9V

Battery life: 20-35 hours approx. (alkaline)

Battery indication: is displayed when the

battery voltage drops below the operating level.

Auto Power o: after 15 minutes of inactivity if APO

is active.

Over range: "OL" or "-OL" is displayed

Dimensions: 7.2 in (H) x 2.5 in (W) x 1.3 in (D)

[185mm (H) x 65mm (W) x 35mm (D)]

Weight: 12 oz. (340g) including battery

Temperature

Sensor type: Thermistor

Range: -4°F to 140°F (-20°C to 60°C)

Resolution: 0.1°C, 0.1°F

Accuracy:

±1.0°F for 32°F to 113°F

±2.0°F for -4°F to 32°F, 113°F to 140°F

±0.5°C for 0°C to 45°C

±1.0°C for -20°C to 0°C, 45°C to 60°C

Maintenance

Clean the exterior with a dry cloth.

Do not use liquid.

Battery Replacement

When the meter displays the

battery should be replaced. Turn your

STA2 o and replace with 9V battery.

Optional Accessory

RCONE1 being used

to hold the STA2

probe in place in

round duct.

Velocity

Sensor type: Micro-glass bead thermistor.

Resolution: 1 fpm (0.01 m/s)

Range: 40-3960 fpm (0.20-20.00 m/s)

Accuracy: ± (5%+1 dgt) reading or ± (1%+1dgt)

Units: fpm, m/s, km/hr, mph

19 21 2420 2322

full scale

Protecting the Sensor

The STA2 uses a delicate glass bead

thermistor sensor. When not in use it

is best to protect this sensor with the

vinyl slip cover included with the STA2

and keep it stored in the provided

blow molded case.

Limited Warranty

This meter is warranted against

defects in material or workmanship

for one year from date of purchase.

Fieldpiece will replace or repair the

defective unit, at its option, subject to

verication of the defect.

This warranty does not apply

to defects resulting from abuse,

neglect, accident, unauthorized repair,

alteration, or unreasonable use of the

instrument.

Any implied warranties arising

from the sale of a Fieldpiece product,

including but not limited to implied

AUTO-OFF

RECORD MODE

HOLD

AVERAGE

CLEAR DATA

MAX/MIN

In-Duct

Hot Wire

Anemometer

STA2

PRESS FOR

1 SECOND

ON/OFF

UNITS

DUCT

ENTER

warranties of merchantability and

tness for a particular purpose, are

limited to the above. Fieldpiece shall

not be liable for loss of use of the

instrument or other incidental or

consequential damages, expenses, or

economic loss, or for any claim of such

damage, expenses, or economic loss.

State laws vary. The above limitations

or exclusions may not apply to you.

For Service

In the USA, call Fieldpiece

Instruments for one-price-x-all out of

warranty service pricing. Send check or

money order for the amount quoted.

Send the meter freight prepaid to

Fieldpiece Instruments. Send proof

of date and location of purchase for

in-warranty service. The meter will be

repaired or replaced, at the option of

Fieldpiece, and returned via least cost

transportation. Outside of the USA,

please visit www.eldpiece.com for

service contact information.

www.eldpiece.com

©Fieldpiece Instruments, Inc 2011;v19

Loading...

Loading...