Page 1

%

%

CO

2

EA

MAX

SET

ON/OFF

°C

°F

HOLD

APO

%

MAX MIN

%

CO

2

EA

MAX

SET

PRESS FOR

1 SECOND

ON/OFF

°C

°F

HOLD

%

MAX MIN

%

CO

2

EA

MAX

SET

Fieldpiece

PRESS FOR

1 SECOND

ON/OFF

%

%

CO

2

EA

MAX

SET

Press for 1 Sec to Exit

PRESS FOR

1 SECOND

FUEL

ON/OFF

MAX/MIN

AUTO-OFF

°F

MEASURE/HOLD

°C

°F

HOLD

APO

%

MAX MIN

%

CO

2

EA

MAX

SET

PRESS FOR

1 SECOND

FUEL

ON/OFF

%

%

CO

2

EA

MAX

SET

!

Quick Start

Description

The SOX3 is a portable hand

Combustion Check

with AutoPump

OPERATOR'S

MANUAL

Model

SOX3

APO MAXMIN HOLD SET

Natural

Oil#2PropaneCustom

Gas

AUTO-OFF

MEASURE/HOLD

°F

°C

Combustion

Check

Excess Air,

and %O

%CO

2

TEMP CAL

SOX3

°F %

°C

ON/OFF

ENTER

SET CUSTOM

MAX/MIN

2

EXHAUST

%

CO

2

MAX

EA

PRESS FOR

1 SECOND

FUEL

CLEAR

1. Press ON/OFF to power on the SOX3.

2. A 30 second warm up ensues.

3. Press FUEL to cycle through fuel

types.

4. Insert the barrel of the SOX3 into

ue.

5. Press MEASURE/HOLD to begin taking measurements.

6. Use the up arrow button to toggle

the upper display between %O2 and

%CO2.

7. Use the down arrow button to

toggle the lower (right) display

between %EA and % (Eciency of

condensing or non-condensing).

8. Make sure all holes in the ue are

sealed after testing is nished.

held automated combustion check

designed for the HVACR technician.

The SOX3 provides all the essential

measurements for checking and

tuning combustion equipment.

Measure ue temperature and %O2

directly to view the calculated %CO2,

%Excess Air (%EA) and %Eciency (%)

for condensing or non-condensing

equipment.

The ergonomic handle and 8ft hose

make for easy ue gas measurements.

Use the magnetic strap and the barrel

lock to go entirely hands free.

With three common fuel types as

well as a custom fuel input the SOX3

allows you to check %O2, %CO2, %EA

and % (eciency) on any combustion

equipment you may encounter.

Keep your SOX3 up and running

longer with the field calibratable

thermocouple and replaceable

oxygen sensor.

01 03 0602 0504

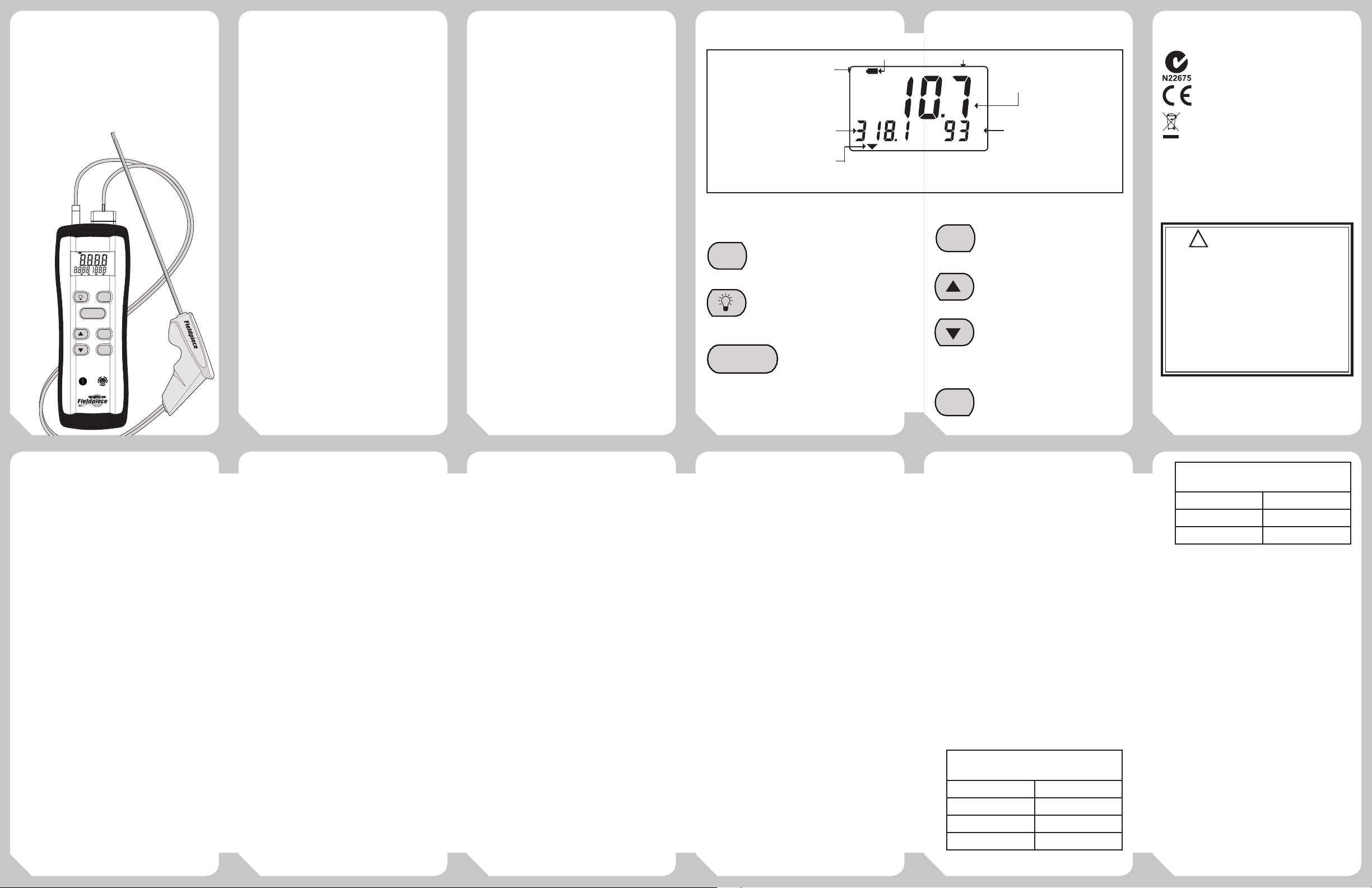

Display

Auto Power Off

Temperature or Combustion Type

(Condensing ‘cond’ vs

Non-condensing ‘nonc’)

Fuel Type

Controls

ON/OFF

MEASURE/HOLD

Hold for one second to toggle power.

Toggle backlight on display.

(Hold while powering on the SOX3 to

disable the meter's APO.)

Toggle between MEASURE

mode (pump on, live readings)

and HOLD mode (pump o,

frozen readings).

Battery Life

APO

Natural

Gas

MAX MIN

HOLD

°F

Oil

Propane Custom

#2

Custom Fuel Setup

SET

%

%CO2 or %O2

CO

2

MAX

%

% Excess Air or % (Efficiency)

EA

Cycle through fuel types. Fuel indication

FUEL

arrow moves along lower display. (Hold

for one second to enter Custom Fuel

setup.)

(UP)Toggle between %O2 and %CO2.

(Down) Toggle between %EA and %.

Use during Custom Fuel setup to adjust

max %CO2. (Hold respective arrow button

while powering on to change

temperature units to °F or °C.)

Press to cycle through maximum,

MAX/MIN

minimum, and real-time measurements.

(Hold for one second to clear saved values

and continue measuring.)

Certifications

C-Tick (N22675)

CE

WEEE

RoHS Compliant

WARNINGS

Combustion equipment is

extremely hot. Never touch the

SOX3 without knowing it is cool

to the touch.

Exhaust may be hot. Do not

put your skin directly in front of

exhaust port.

How to Use

Pre-Testing

1. Power on the SOX3 and allow the

unit to warm up for 30 seconds.

2. Calibrate temperature if needed (see

Field Temp Calibration).

3. Check that SOX3 water and particle

lters are dry and properly sealed.

4. Thoroughly inspect combustion

equipment for damage.

5. Identify the fuel being combusted

and use the FUEL button on the

SOX3 to select that fuel. For fuel

other than Natural Gas, Oil #2, or

Propane see Custom Fuel setup.

6. Identify the ue and locate service

port for taking ue measurements

or, if necessary, drill a hole using a

1/2" bit (12.7mm) within 18" of the

breech.

7. Once your combustion equipment

has passed all of your preliminary

and visual inspections, turn on the

equipment to be tested.

Testing

1. Identify manufacturer's specications for % eciency, %EA (% Excess

Air), %CO2 , or %O2 in the ue. If

manufacturer’s specs are not available see Table 2 (on back).

2. Once combustion equipment has

stabilized, insert rie into ue gas

at service port or drilled hole.

Note: Combustion samples should

be taken before dilution air enters

the system, before components like

draft hoods and barometric dampers. Testing at least 6" upstream of

the breach is the typical location for

most equipment. As a general rule,

the sample hole should be more

than twice the ue diameter away

from any elbows.

3. Press MEASURE/HOLD to start the

internal pump and begin taking fuel

measurements.

4. Toggle between %CO2 and %O2

with the up arrow button. Toggle

between %EA and eciency with

the down arrow button.

Note: Eciency calculations displayed

toggle through % efficiency of

condensing "cond" and noncondensing "nonc" equipment. The

condensing % eciency uses the

high heating value (HHV) and the

non-condensing % eciency uses

the low heating value (LHV) of the

fuel type selected. Identify what

equipment you are working on to

decide which % eciency calculation to use.

Note: The correct fuel type must be

selected to properly display calculated values. Eeciency will not be

calculated when using the custom

fuel setting.

5. Wait for readings to stabilize, this

can take a couple minutes.

6. Press the MAX/MIN button to cycle

through maximum, minimum, and

real-time values. (Hold MAX/MIN to

clear saved values.)

7. Once stabilized, press MEASURE/

HOLD to hold measurements and

stop the pump.

8. Make necessary adjustments to

bring the equipment within manufacturer's specications.

9. Retest.

Post-Testing

1. Remove the rie from the ue and

allow time for the barrel to cool.

2. Plug any holes you may have put into

the ue, with heat resistant silicone

or comparable plug.

3. Power the meter o. The internal

pump will run for a short time to

purge the meter before completely

shutting o.

4. Open and empty water trap before

storing SOX3 in its case.

Custom Fuel Setup

The SOX3 can be setup to work with

various fuel types. In order to enter a

custom fuel, follow the steps below.

1. Hold the FUEL button, for one second until “SET” starts blinking in the

upper right corner of the display and

the units read “% CO2 MAX”

2. Use the Arrow buttons to select the

appropriate CO2 MAX for the fuel

you are working with.

Note: CO2 Max is the theoretical maxi-

mum percentage of CO2 produced

when a fuel goes through complete

combustion. Table 1 shows CO2 max

values for some more common fuel

types.

3. Once you have selected the appropriate CO2 max press the MEASURE/

HOLD button to lock in this value

and return the Hold display.

4. The fuel indication arrow on the

display will automatically be moved

to your newly entered custom fuel.

%CO2 Max values

Fuel Oil #5 16.3

Kerosene 15.12

Bagasse 20.3

Dry Wood 20

%CO2 Max values

Coal Anthracite 19.9

Coal Bituminous 18.5

Wood Pellets 20.1

Table 1

Field Temp Calibration

To calibrate the temperature

sensor, turn the Temp-Cal pot while

measuring a known temperature. Ice

water is very close to 32°F (0°C) and is

readily available.

1. Stabilize a large cup of ice water.

2. Dissconnect water trap in order to cut o suction to

the barrel. This will prevent sucking up water.

3. Plug in the k-type thermocouple and then immerse

the barrel tip of the SOX3 into the ice water.

4. Press the Measure/Hold button and read

temperature on the lower left display.

5. For optimum accuracy, adjust the calibration pot to

read 32°F or 0°C, depending on the scale selected.

07 09 1208 1110

Page 2

COM

CAT III

600V

Fieldpiece

Select

M/m

SC260

TRUE RMS

V

AC

NCV

A

AC

°F°C

V

DC

MFD

TEMP

AUTO OFF

TYPE K

30V

MAX

TRUE RMS AUTO OFF

TYPE K 30V MAX

T1

L1

L2

L3

T2

Sync

OFF

VAC

VAC

%

NCV

V

DC

ADC

µADC

MFD

RECV

H

Z

AAC

50

HZ

AAC

400

°F°C

T1-T2

L1L2

L1L3

Test

H

Z

Range

Select

m/M/H

SC660

ZERO A

DC

°F °C

COM

INRUSH

Typical Recommended

SC440

Fieldpiece

TRUE RMS

V

AC

NCV

MFD

H

Z

A

AC

°F°C

Select

RangeHold

%

V

DC

µA

DC

H

Z

TEMP

AUTO OFF

COM

TYPE K

30V

MAX

CAT III

600V

Flue Gas Measurements

Atmospheric Fan Assisted Natural Gas or LPG

Oxygen (

Stack Temperature 325 to 500°F

Condensing Natural Gas or LPG

Oxygen (

Stack Temperature 90 to 140°F

Natural Gas/LPG Power Burners

Oxygen (

Stack Temperature 275 to 500°F

Fuel Oil Flame Retention Power Burners

Oxygen (

Stack Temperature 325 to 500°F

Fuel Oil Non-Flame Retention Power Burners

Oxygen (

Stack Temperature 400 to 600°F

Condensing Oil

Oxygen (

Stack Temperature 90 to 140°F

Table 2.

) 6 to 9%

O

2

) 6 to 9%

O

2

) 3 to 6%

O

2

) 3 to 7%

O

2

) 6 to 9%

O

2

) 3 to 7%

O

2

Specifications

Sensor Type: Highly accurate oxygen sensor.

Operating environment: 32 to 122°F (0 to 50°C) at

<75% R.H.

Storage environment: -4 to 140°F (-20 to 60°C) at

<80% R.H. with battery removed from meter.

Temperature Coecient: 0.1 times the applicable

accuracy per ° from 32°F to 64°F and 82°F to 122°F

(0 to 18°C and 28 to 50°C)

Battery: 9V.

Battery Life: 28 hours typical alkaline.

Auto Power o: After 15 minutes.

Accuracy: Stated accuracy at 23°C±5°C, <75% R.H.

Dimensions: 45.0mm(H) x 69.8mm(W) x

211.7mm(D).

Weight: approx. 579.7g with battery.

Display: 4 digit liquid crystal display(LCD) with

maximum reading of 9999.

Low battery indication: The is displayed

when the voltage drops below the operating level.

TEMPERATURE

Range: -58°F to 1000°F (-50°C to 538°C)

Resolution: 0.1°

Accuracy: ±[0.6%+3°F(1.7°C)]after eld calibration.

Sensor Type: Rod K-type thermocouple.

Range: -50°F to 900°F (continuous operation range)

up to 1000°F (single exposure use)

Accuracy: (±4°F) on -50°F to 545°F (±0.75%) on

545°F to 1000°F

Oxygen

Oxygen Range: 0 to 25%

Accuracy: ±0.3%O2(Calibrated at 72°F, 20.9%O2)

Max Overload: 30% Oxygen

Operational temp range: -4°F to 122°F

Response time: Under 2 minutes.

Maintenance

Clean the exterior with a dry cloth.

Do not use liquid.

Check lter before each use. If the

lter looks dirty, wet or has not been

changed for an extended period of

use, replace with new lter.

It is good practice to empty the

water trap after every use. This helps

prevent water build up that may

damage the sensor or freeze within

the hose during storage.

Battery Replacement

When the meter displays the

battery should be replaced. Turn your

SOX3 o and replace with 9V battery.

O2 Sensor Replacement

The SOX3 uses an oxygen smart

sensor. The sensor should be replaced

when incorrect oxygen levels in

ambient air are displayed.

1. Remove sensor cap by twisting CCW

slightly and then pulling.

2. Pull out old sensor.

3. Align plug of new sensor and care-

fully press into place. Display will

show "Err1" if sensor is not installed

properly or damaged.

To obtain an SOX3 replacement

oxygen sensor (model# RS02) contact

your local distributor.

1

2

Limited Warranty

This meter is warranted against

defects in material or workmanship

for one year from date of purchase.

Fieldpiece will replace or repair the

defective unit, at its option, subject

to verication of the defect.

This warranty does not apply

to defects resulting from abuse,

neglect, accident, unauthorized

repair, alteration, or unreasonable use

of the instrument.

Any implied warranties arising

from the sale of a Fieldpiece product,

including but not limited to implied

warranties of merchantability and

tness for a particular purpose, are

limited to the above. Fieldpiece shall

not be liable for loss of use of the

instrument or other incidental or

consequential damages, expenses, or

economic loss, or for any claim of such

damage, expenses, or economic loss.

State laws vary. The above

limitations or exclusions may not

apply to you.

13 15 1814 1716

Combustion Basics

Combustion is the rapid oxidation

of fuel. Oxygen from air (20.9%

oxygen & 79.1% nitrogen) is used to

burn fuel which produces heat. The

appliances installed and serviced by

technicians rely on clean efficient

ames to produce the energy needed

to heat homes, water, etc. Combustion

testing is necessary to maximize

the efficiency of the combustion

systems and to minimize the harmful

emissions produced such as carbon

monoxide and carbon dioxide. Proper

tuning of the combustion process

by combustion testing reduces

the production of harmful carbon

monoxide and decreases the amount

of fuel burned due to increase in

eciency.

Combustion eciency can typically

be increased by creating a more

balanced air to fuel ratio. The ratio of

air to fuel determines how much CO2

is produced and how efficient the

ame is.

19 21 2420 2322

Tuning the O2, CO2 excess air, stack

temperature, and temperature rise to

match the appliance manufacturers

specifications will increase the

eciency and help to maximize the

performance and life expectancy of

the equipment.

A properly tuned natural gas

appliance will have between 6-9 O2%

in the ue while an oil appliance will

have 3-7 O2%.

Adjustments to the combustion

process ensures that the highest

combustion efficiency is safely

achieved, thereby reducing the overall

amount of fuel used in producing the

energy needed. It is still necessary to

test and adjust the appliance to the

manufacturers’ specication for airow

in the duct system, temperature

rise across the heat exchanger and

anything else that may need testing.

Testing and balancing appliances to

meet manufacturers’ specifications

helps to ensure maximum system

eciency and equipment longevity.

Combustion testing does not take

into account start up losses, standby

losses, cabinet/boiler body losses, or

distribution losses in ducts or piping.

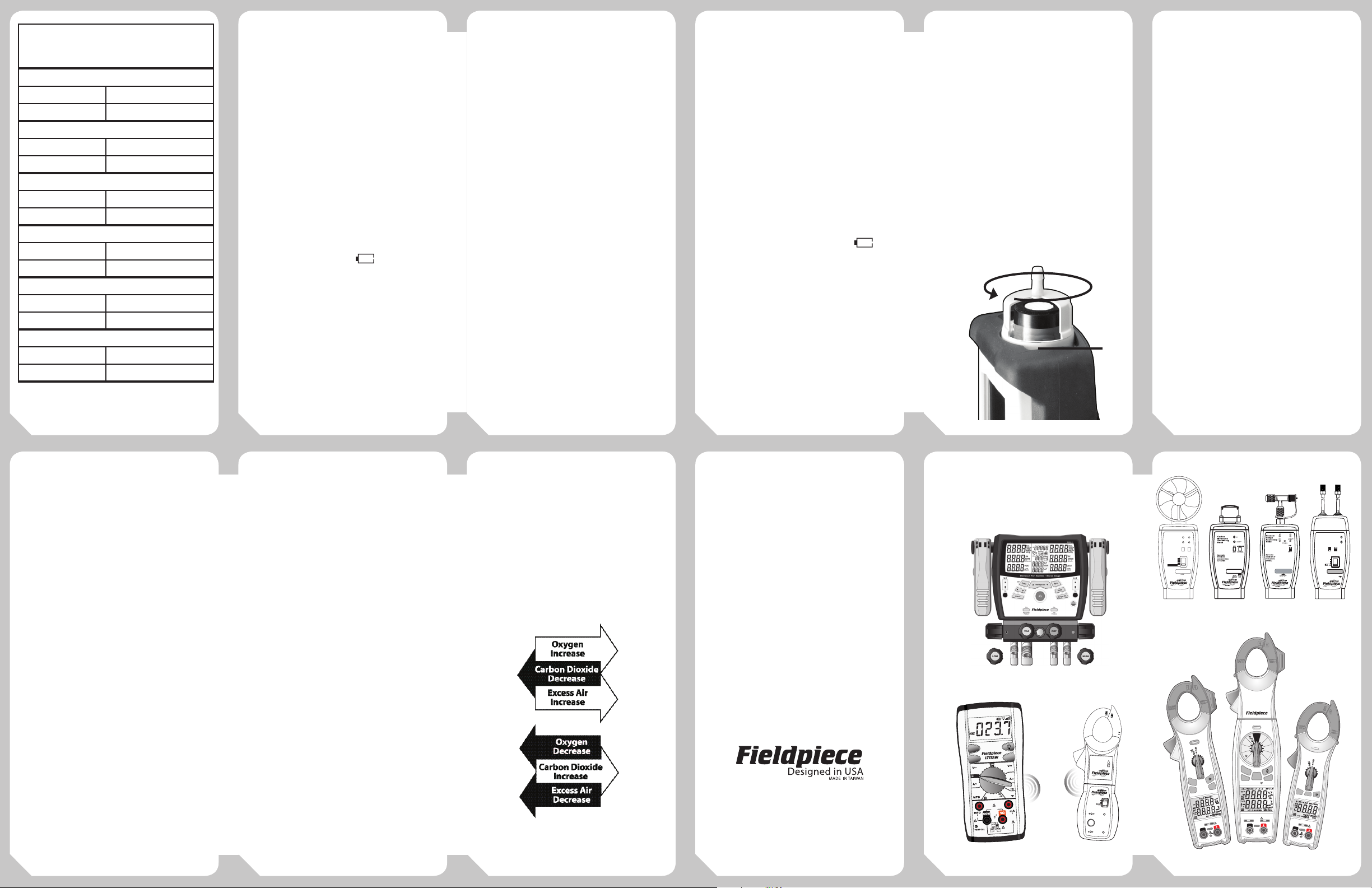

The diagram below is a simplied

representation of the relationship

between the various combustion

measurables, and how a change in

one parameter aects the others.

Courtesy of Erik Rasmussen ESCO Press 2007.

For Service

Call Fieldpiece Instruments for

current costs on our fixed price

warranty service. Send check or

money order for the amount quoted.

Send your digital manifold, freight

prepaid, to Fieldpiece Instruments.

Send proof of date and location of

purchase for in-warranty service. The

meter will be repaired or replaced, at

the option of Fieldpiece, and returned

via least cost transportation.

For international customers,

warranty for products purchased

outside of the U.S. should be handled

through local distributors.

www.eldpiece.com

©Fieldpiece Instruments, Inc 2015; v16

More Instruments

from Fieldpiece

Digital Refrigerant Manifolds

CLAMP

300V

CAT.III

RECEIVE

SEND

SYNC

AC Current

Clamp

1AAC / 1mVAC

400AAC MAX

ACH4

ET2W

Wireless

Transmitter

400A

!

AC

DC

ON

LO BATT

AUTO-OFF

WIRELESS

ENABLED

MAX/MIN

SYNC HOLD

600600

500

50

500

50

5000m

5000m

500m

500m

RECV

500µ

50m

200m

500µ

50m

200m

500

750

K

2

500

200

1400

20

M

20

K

2

200

K

200

V

m

500

15 SEC FOR

RANGE

CAT.III

MAX

FUSED

600V

A

FUSED

m

200

MAX

30V

MAX

Wireless Measurements Clamp Meters

AirVelocity

&Temperature

Head

English Metric

Ft/min M/s

KM/hrMPH

ºF ºC

OFF

AAV3

P1 P2

LCDX

100

ON

READLOBATT

Average

English

(16sec)

Real

Metric

time

AUTO-

OFF

Dual-Port

Manometer

Accessory

Head

Resolution

ON

Lo Batt

0.1

ENGLISH

0.01

METRIC

(LCD/10)

P1-P2

P2

P1

AUTO

ZERO

OFF

ADMN2

Accessory Heads

Loading...

Loading...