Page 1

Fieldpiece

T1 T2

Atmospheric

Pressure

Superheat

Subcooling

T1 T2 Direct Saturation

Target

Superheat

CAL CAL

CAL CAL

Test

Pressure

AUTO

OFF

Refrigerant

ON/OFF

Enter

Units

Alarm

Digital Manifold + Vacuum Gauge

SMAN3

LOW HIGH

Digital Manifold &

Vacuum Gauge

OPERATOR'S MANUAL

Models SMAN2 SMAN3

SMAN3

T1 T2

CAL CAL

01

Digital Manifold + Vacuum Gauge

AUTO

OFF

Superheat

Subcooling

Alarm

T1 T2 Direct Saturation

CAL CAL

Atmospheric

Pressure

Refrigerant

Target

Superheat

Pressure

ON/OFF

Enter

Units

Test

Quick Start

1 Power on your SMAN by holding the ON/OFF

button for 1 second.

2 Select desired units (English or Metric) by

pressing the UNITS button (SMAN3) or hold-

ing the ENTER button for 1 second (SMAN2).

3 Connect hoses and pipe clamps to the system.

4 Press the circular button to select between

Actual Superheat and Subcooling, Target

Superheat, Direct Temperature Display (T1 T2

Direct) or Saturation Temperature Display.

Certifications

C-Tick (N22675)

CE

RoHS Compliant

02

Description

Your SMAN is the portable digital refrigerant

manifold and vacuum gauge (SMAN3) for A/C

and refrigeration professionals. Your SMAN

combines high pressure manifold gauges, a

superheat/subcooling calculator, micron gauge

for vacuum (SMAN3), and dual temperature

measurements into one easy-to-use instrument.

Your SMAN calculates and displays target

superheat and actual superheat to ensure

proper charging of a unit. Your SMAN can

also display the liquid and vapor saturation

temperatures in Saturation mode to help you

trouble shoot your system.

Your SMAN is designed to meet the demands

of the HVAC/R professional with a ruggedized

rubber boot for durability, a strong metal

hanger for easy storage and a high quality,

water resistant nylon pouch. A bright blue

backlight and very large, easily viewable display

lets you see your measurements in any work

environment. SMAN has a very intuitive user

interface and extremely long battery life.

Your SMAN comes pre-programmed with

the most accurate P-T charts for 44 of the most

common refrigerants in the field so you are

always prepared for any job.

03

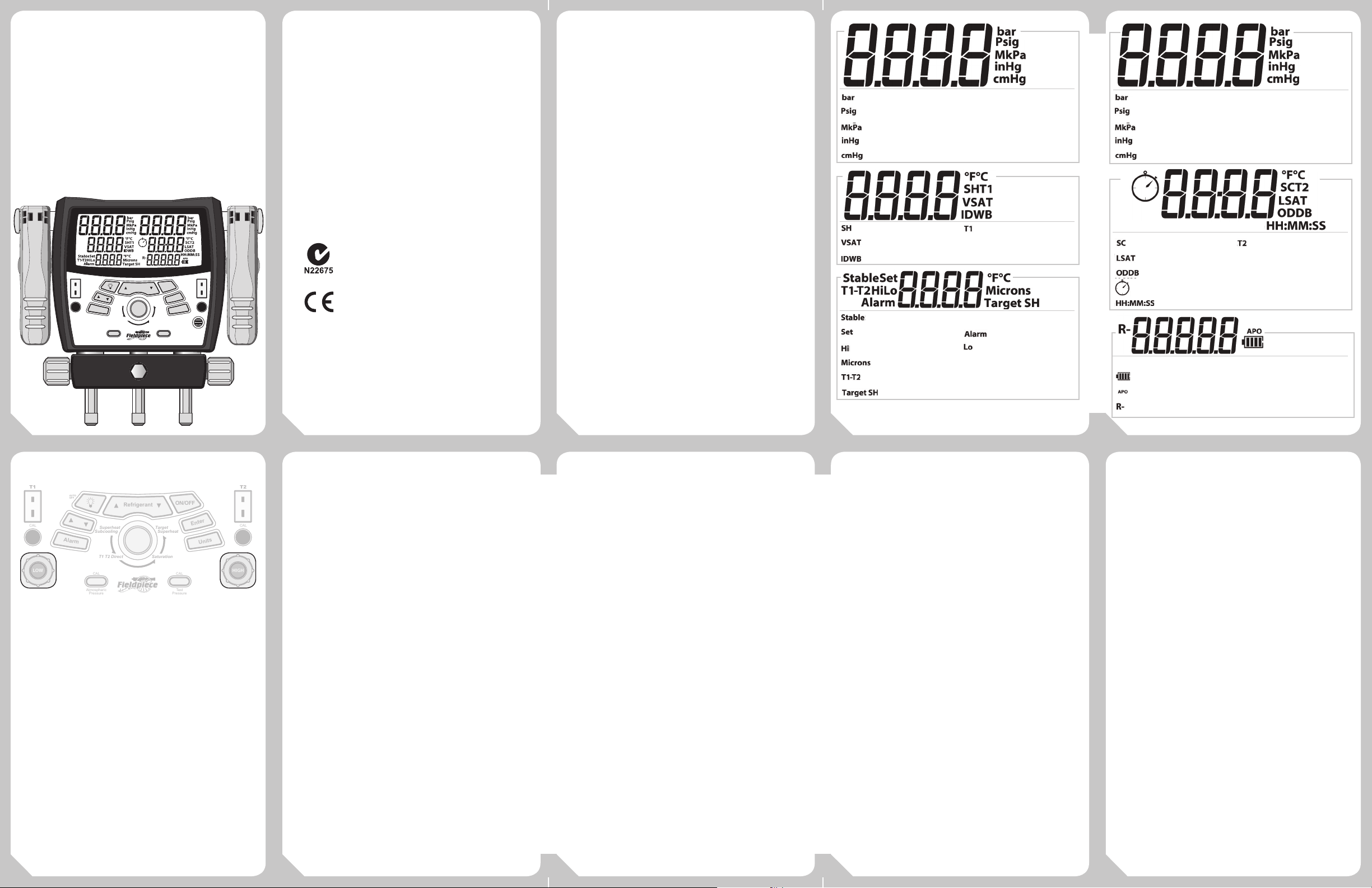

Pressure (bar)

Pressure (pounds/in2)

Pressure (kilopascals or Megapascals)

Negative Pressure (inches of mercury)

Negative Pressure (cm of mercury)

Superheat T1 Direct

Vapor Saturation Temperature

Indoor Wet Bulb

Micron Reading Has Stabilized

Set Mode Alarm Mode

High Alarm Low Alarm

Vacuum (Microns of Mercury)

T1 thermocouple - T2 thermocouple

Target Superheat

04

Pressure (bar)

Pressure (pounds/in2)

Pressure (kilopascals or Megapascals)

Negative Pressure (inches of mercury)

Negative Pressure (cm of mercury)

Subcooling T2 Direct

Liquid Saturation Temperature

Outdoor Dry Bulb

Vacuum Stopwatch

Hours:Minutes or Minutes:Seconds

Battery Life

Auto Power O Enabled

Selected Refrigerant of System

05

Controls

5

8

2

13

6

10

3

11

7

9

12

14

4

1 Insert K-type thermocouple plugs here.

2 Temperature calibration pots.

3 Press to zero atmospheric pressure.

4 Press to linear adjust pressure curve. (See

Advanced Pressure Calibration section.)

5 Press to engage backlight. Hold when

powering on to toggle Auto Power O.

6 Press/hold to cycle through refrigerants.

7 Hold 1 second to toggle power on/o.

8 Press up or down arrow to adjust values.

9 Press to confirm selection. For the

SMAN2, hold 1 second to adjust units.

10 Press to turn on/o the Hi/Lo vacuum alarms

11 Press to toggle through temperature tests.

12 Press to adjust units. (SMAN3)

13 Turn clockwise to close Low side port.

14 Turn clockwise to close High side port.

06

and hold to change alarm settings.

Functions

11

2

Standard Pressure

1 Connect your SMAN to the system using EPA approved 1/4in

refrigerant hoses.

2 Read pressures directly from the upper display.

Superheat and Subcooling

1 Press circular button to cycle through temperature modes until SH

and SC are shown. The SMAN can show superheat and subcooling

simultaneously.

2 Choose the appropriate refrigerant using the REFRIGERANT

button.

3 Connect the K-type thermocouple and EPA approved refrigerant

hoses to your SMAN.

4 Connect your SMAN to the system:

Superheat: Hand tighten low side hose to suction line service

port. Place the thermocouple on the suction line between the

evaporator and compressor, no closer than 6 inches to compressor.

Subcooling: Hand tighten high side hose to liquid line service

port. Attach the thermocouple on the liquid line between the

condenser and expansion valve (TXV), as close to the service port

as possible.

5 After turning the system on or making any adjustments to

the system wait 15 minutes before charging by superheat or

subcooling to ensure that the system is stable and running

normally. Add or remove refrigerant using the low and high side

valves as needed. Let system stabilize again for 15 minutes.

Saturation

Shows vapor (VSAT) and liquid (LSAT) saturation temperatures

calculated from the pressures measured and the refrigerant selected.

T1 T2 Direct

1 Press circular button until T1 and T2 are shown.

2 Plug in any K-type thermocouple into T1 and/or T2.

3 Read the temperature directly from the display.

4 T1-T2 is displayed in the lower left corner of the display.

Target Superheat

Target Superheat is only used for charging xed orice air

conditioning systems. Your SMAN allows you to input indoor

wet bulb (IDWB) and outdoor dry bulb (ODDB) temperatures

manually, in real-time using K-type thermocouples, or a

combination of both to calculate the Target Superheat. Your SMAN

will detect if a thermocouple is plugged in or not. Unplugging the

thermocouple lead(s), at any time, sends the SMAN into manual

input mode and plugging them in, at any time, automatically

sends the SMAN to input directly from the thermocouples.

Input temperatures with K-type thermocouples

1 Press circular button until Target SH is shown in the bottom,

center of display.

2 Plug ATWB1 Wet bulb K-type thermocouple into T1 and ATA1 Dry

bulb K-type thermocouple into T2.

3 Press ENTER. The IDWB will display the real-time temperature

measured from T1. Use the ARROW button to select the

temperature you want to input rst, either IDWB or ODDB.

4 For IDWB input, wet the sock of the ATWB1. Clip it to the return

of the evaporator between the lter and coil. When the wet bulb

temperature reaches its lowest point and stabilizes, press ENTER

to lock the reading. If the inputted temperature is below the wet

bulb range, “-OL” will blink. If the inputted temperature is above

the wet bulb range, “OL” will blink. Retake the measurement if

“OL” or “-OL” is displayed.

07

08

5 For ODDB input, clip the ATA1 thermocouple to the side of the

condenser. Once reading is stable, press ENTER. If the inputted

temperature is below the dry bulb range, “-OL” will blink. If the

inputted temperature is above the dry bulb range, “OL” will blink.

Re-take the measurement if “OL” or “-OL” is displayed. For accurate

results, keep the ATA1 shaded from direct sunlight.

6 Once both IDWB and ODDB are locked in, the Target Superheat

will show in the lower left corner of the display. If the Target

Superheat calculated from the IDWB and ODDB temperatures is

outside the range in which air conditioning is recommended then

“OL” is displayed. Usually, raising the indoor temperature will

bring the conditions within manufacturer’s recommendations.

If your target superheat is out of the recommended range, press

ENTER to re-take both your measurements.

7 To re-take either IDWB or ODDB, press the ARROW button until

the label (IDWB or ODDB) you wish to re-take is blinking. Press

ENTER. Re-do the measurement and press ENTER to lock it in. The

newly calculated target superheat will be displayed.

8 To clear both IDWB and ODDB simultaneously, press ENTER.

Input temperatures manually

1 Press circular button until Target SH is shown at the bottom,

center of display. Unplug thermocouples from T1 and/or T2.

2 Press ARROW button to select a blinking IDWB or ODDB. Press

ENTER to make a selection. Use the ARROW button to change

blinking digit and press ENTER to lock in each digit. Once the

last digit for ODDB or IDWB is locked in, the calculated target

superheat will show in the lower left corner of the display.

Note: When pressing ENTER to lock in the last digit for IDWB or

ODDB, if the inputted temperature is below the wet bulb or dry

bulb range, “-OL” will ash once. If the inputted temperature is

above the wet bulb or dry bulb range, “OL” will ash once. In both

instances you must re-input the measurement.

3 See steps 6-8 above.

09

Pulling a Vacuum (model SMAN3)

Follow all manufacturers’ evacuation procedures over those in

this manual.

Note: larger systems may take much longer to reach a deep vacuum

and a dierent evacuation method or equipment might be preferred.

1 Connect your SMAN3 in between your vacuum pump and the

system, then power on your SMAN3.

2 Draw a vacuum on the system. The SMAN will automatically

sense the negative pressure and display the vacuum in microns.

3 Press Alarm button to toggle between the High (Hi) alarm, the

Low (Lo) alarm and no alarm. No Display of Lo or Hi means alarm

is o. Note: The stopwatch will start when an alarm is selected.

Pressing Alarm will reset the stopwatch.

4 When the rate of change in pressure is less than 1 micron per 10

seconds, Stable will appear in the lower left corner of the display.

Additional Tips:

To achieve a deep vacuum as quickly as possible:

1 Use the shortest hoses with the largest diameter available.

2 Remove Schrader cores and core depressors. Core removal tools

like the "MegaFlow Valve Core Removal Tool" can be purchased to

help with this process.

3 Inspect the rubber seals at both ends of your hoses for damage

that may result in leakage.

4 Do not use hoses with low loss ttings when evacuating or

pulling a vacuum on a system.

Set Vacuum Alarms (SMAN3)

1 Hold the ALARM button for one second to enter Alarm Set mode.

2 Press the ALARM button to toggle between Alarm Hi and Lo.

3 Use ARROW button to select the value and press ENTER to lock in

each digit. Once last digit in Alarm Lo is locked, your SMAN will

automatically revert to normal testing mode.

10

Page 2

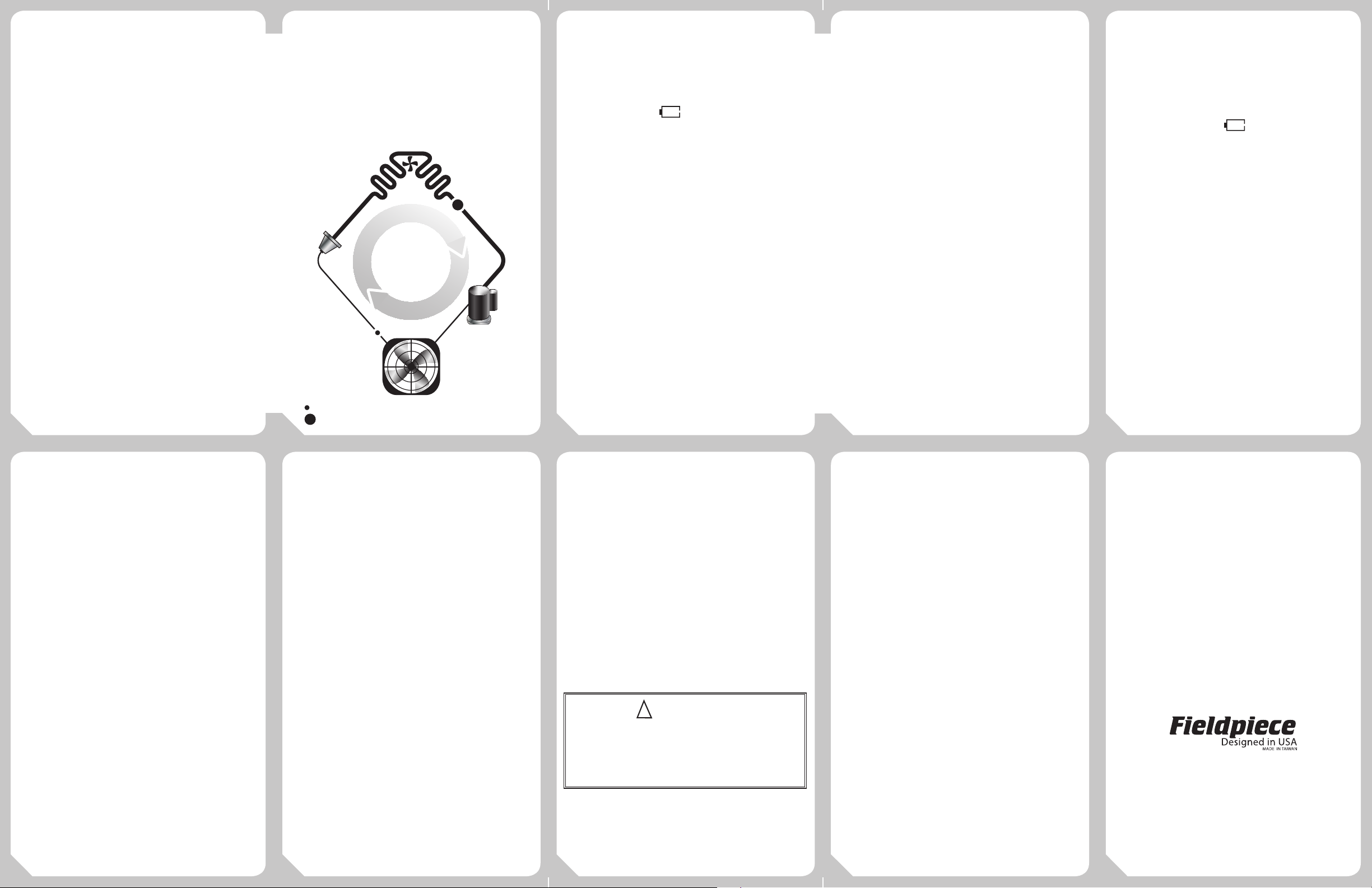

What is Superheat and Subcooling?

!

Why Do I Need to Measure It?

Superheat is the difference between the

actual temperature of the refrigerant (gas) as

it leaves the evaporator and the boiling point

of the refrigerant. After boiling, the refrigerant

continues to heat up. The number of degrees it

“heats up” after boiling is called the superheat.

Under worst case conditions (low load for xed

orice systems), the refrigerant in the evaporator

boils o near the end of the evaporator coil. To

make sure liquid doesn’t enter the compressor

under the worst case condition (low load),

the refrigerator or A/C manufacturers publish

charts indicating what the superheat should be

at a given indoor wet bulb measurement and

outdoor air temperature.

Measuring superheat is your best indication

on a fixed orifice system of the proper

refrigerant charge and operating conditions.

If everything else is working properly and the

actual superheat is too high, add refrigerant. If

it’s too low, evacuate refrigerant.

Subcooling is the dierence between the

boiling point of the refrigerant in the condenser

and the actual temperature of the refrigerant

11

as it leaves the condenser. The degrees that the

refrigerant “cools down” below the boiling point

is the subcooling. Under worst case scenario

(low load for TXV) the subcooling will continue

to rise. If the subcooling rises too high, liquid

may be backed into the compressor causing

damage and catastrophic failure. See www.

eldpiece.com for more technical articles.

Evaporator

Low Side

TXV

High Side

Condenser

Location of Subcooling Test

Location of Superheat Test

12

Direction of

Refrigerant

Flow

Compressor

Specifications

Display size: 5 inches (diagonal)

Backlight: Blue (On for 1 minute unless turned o manually)

Battery: 6 x AA (Battery life below based on alkaline type)

Battery life (SMAN2): Approx. 500 hours (without backlight)

Battery life (SMAN3): Approx. 135 hours (without backlight)

Low battery indication: is displayed when the battery

voltage drops below the operating level

Auto Shut o: 30 minutes of inactivity when APO is activated

Operating environment: 32°F to 122°F (0°C to 50°C) at <75%

relative humidity

Storage temperature: -4°F to 140°F (-20°C to 60°C), 0 to 80% RH

(with battery removed)

Temperature coecient: 0.1 x (specied accuracy) per °C (0°C to

18°C, 28°C to 50°C), per 0.6°F (32°F to 64°F, 82°F to 122°F)

Over range: "OL" or "-OL" is displayed

Weight: 3.05 lbs (1.38 kg)

Pressure

Connector Type: Standard 1/4 NPT male are tting

Range: 29” HgV to 580 Psig (English), 74 cmHgV to 0 to 4000KPa

(Metric)

Resolution: 0.1 psi/inHg; 1 kPa/cmHg

Accuracy: 29” HgV to 0” HgV: ±0.2” HgV

74 cmHgV to 0 cmHgV: ±1 cmHgV

0 to 200 Psig: ±1 Psi; 0 to 1378 KPa: ±7 KPa; 0 to 1.378MPa:

±0.007MPa; 0 to 13.78 bar ±0.07 bar

200 to 580 Psig: ±0.3%+1 Psi; 1378 to 4000KPa: ±0.3%+7 Kpa;

1.378 to 4.000MPa: ±0.3%+0.007MPa; 13.78 to 40.00bar:

±0.3%+0.07bar

Maximum overload pressure: 800 psig

Units: Psig, kPa, MPa, bar, inHg, and cmHg

13

Microns for Vacuum (SMAN3 only)

Connector Type: Standard 1/4 NPT male are tting

Range: 50 to 9999 microns of mercury

Resolution: 1 micron (50 to 2000 microns), 250 microns (2001 to

5000 microns), 500 microns (5001 to 8000 microns), 1000 microns

(8001 to 9999 microns)

Accuracy: ±10% or ±10 microns, whichever is greater (50 to 1000

microns)

Maximum Overload pressure: 500 psig

Units: Microns of mercury

Temperature

Sensor type: K-Type thermocouple

Range: -95°F to 999.9°F (-70°C to 537.0°C)

Resolution: 0.1°F/°C

Accuracy: ±(1.0°F) -95°F to 199.9°F; ±(0.5°C) -70°C to 93°C

±(2.0°F) 200°F to 999.9°F; ±(1.0°C) 93°C to 537.0°C

Note: All accuracies are after a eld calibration.

Refrigerants

The P-T charts of the following refrigerants come pre-programmed

into your SMAN. In your SMAN the refrigerants are listed in order of

most commonly used. Here, they are listed in numerical order for easy

reference.

R11, R113, R114, R12, R123, R1234YF, R124, R125, R13, R134A, R22,

R23, R401A(MP39), R401B, R402A, R402B, R404A, R406A, R407A,

R407C, R407F, R408A, R409A, R410A, R414B (Hotshot), R416A, R417A,

R417C (HOT SHOT 2), R420A, R421A, R421B, R422A, R422B(NU22B),

R422C(Oneshot), R422D, R424A, R427A, R434A(RS-45), R438A(MO99),

R500, R502, R503, R507A, R508B (Suva95)

14

Maintenance

Clean the exterior with a dry cloth. Do not

use liquid.

Battery Replacement

The battery must be replaced when the

battery life indicator is empty. Turn your

SMAN o and replace with 6 AA batteries.

Cleaning the Sensors (SMAN3)

Over time, the vacuum sensor of the SMAN3

may become contaminated with dirt, oil, and

other contaminents introduced from pulling

vacuums.

1 Never use an object such as a cotton swab to clean the sensor,

you may cause damage to the sensor.

2 Open all knobs/valves, and cap all the ports except for the center

port.

3 Drop enough Isopropyl (rubbing) alcohol into the uncapped

port using an eye dropper or funnel so that it can ush out

contaminents.

4 Cap central port and gently shake your SMAN upside down to

clean sensor.

5 Turn right side up. Open a port to pour out the rubbing alcohol

and open all ports to allow sensors to dry out; usually an hour or

so.

15

Calibration

Temperature

To calibrate your SMAN temperature

thermocouples, adjust the pot on the front of

the meter labeled T1 Cal or T2 Cal. The best way

to calibrate is to match to a known temperature.

Ice water is very close to 32°F and is readily

available. Accuracies of one degree or better

are easily obtained.

1 Stabilize a large cup of ice water by stirring. Pure, distilled water

will be the most accurate.

2 Press the circular button until your SMAN enters Direct

Temperature (T1 T2) mode.

3 Immerse the temp probe in ice water from T1 and adjust the

T1 Cal pot with a athead screwdriver and let it stabilize, keep

stirring.

4 Repeat Step 3 for temp probe in T2.

Pressure Zeroing

To calibrate your SMAN pressure sensors to

atmospheric pressure, ensure that your SMAN

is disconnected from any pressure source and

at equilibrium with the ambient pressure.

1 SMAN must be in Superheat/Subcooling, Saturation, or T1 T2

Direct mode.

2 Press the CAL Atmospheric Pressure button and your SMAN will

set the zero point of pressure to the ambient pressure.

16

Advanced Pressure Calibration

Your SMAN has the ability to perform a linear

adjustment of the pressure sensors based on

refrigerant type, temperature, and pressure.

Calibration setup: For best results, perform both the Temperature

and Pressure Zeroing procedures. See Calibration section for

details. This will ensure pressure readings are zeroed and

thermocouple is properly calibrated to the T1 port of the SMAN.

Calibration to T2 port is not necessary for this calibration.

The refrigerant cylinder should be stored in a stable ambient

environment for at least 24 hours before calibration.

1 Press circular button until your SMAN enters T1 T2 Direct mode.

2 Plug in a K-type thermocouple into T1. (A bead type

thermocouple, like the ATB1, is recommended.)

3 Connect the SMAN to a refrigerant cylinder of a known, single

refrigerant using an EPA approved service hose. Be sure to open

both HIGH and LOW side valves on your manifold and cap the

unused ports. (If caps are not available you can connect both ends

of a refrigerant hose to the two unused caps. Note you will lose

some refrigerant into the hose using this method.)

4 Press the REFRIGERANT button to match the refrigerant of the

cylinder you are using.

5 Attach bead-type thermocouple to the side of the cylinder using

tape. It is recommended to attach in the middle of the cylinder.

Important: Let the temperature of the thermocouple stabilize to

the refrigerant temperature for 1 to 2 minutes or until stable.

6 Open the refrigerant cylinder. The pressure inside cylinder should

now be displayed on both HIGH and LOW side pressure sensors.

7 Press the CAL Test Pressure button. If successful, "Good" will

display for 3 seconds. If failed, "Err" will display for same time.

17

Your SMAN checks with its built-in P-T charts to compare the

temperature of the refrigerant in the tank to the vapor saturation

temperature based on the refrigerant you selected. If the measured

pressures on your SMAN are within ±3psi of the P-T chart pressure

corresponding to the vapor saturation temperature, the SMAN will

adjust the pressure sensor linearity to match the P-T chart.

Possible causes of failed "Err" pressure calibration:

1. Refrigerant tank was not stored in stable ambient conditions for at

least 24 hours.

2. Thermocouple attached to refrigerant tank was not properly

calibrated to T1 port of SMAN.

3. Thermocouple was plugged into wrong port T2 instead of T1.

4. Incorrect refrigerant was selected on the SMAN.

WARNINGS

DO NOT APPLY MORE THAN 800 PSI TO ANY PORT ON THE MANIFOLD.

FOLLOW ALL EQUIPMENT MANUFACTURER'S TESTING PROCEDURES

ABOVE THOSE IN THIS MANUAL IN REGARDS TO PROPERLY

SERVICING THEIR EQUIPMENT.

18

Limited Warranty

This meter is warranted against defects in

material or workmanship for one year from

date of purchase. Fieldpiece will replace or

repair the defective unit, at its option, subject

to verication of the defect.

This warranty does not apply to defects

resulting from abuse, neglect, accident,

unauthorized repair, alteration, or unreasonable

use of the instrument.

Any implied warranties arising from the sale of

a Fieldpiece product, including but not limited

to implied warranties of merchantability and

tness for a particular purpose, are limited to

the above. Fieldpiece shall not be liable for loss

of use of the instrument or other incidental or

consequential damages, expenses, or economic

loss, or for any claim of such damage, expenses,

or economic loss.

State laws vary. The above limitations or

exclusions may not apply to you.

19

Obtaining Service

Call Fieldpiece Instruments for current costs

on our fixed price warranty service. Send

check or money order for the amount quoted.

Send your digital manifold, freight prepaid, to

Fieldpiece Instruments. Send proof of date and

location of purchase for in-warranty service.

The meter will be repaired or replaced, at the

option of Fieldpiece, and returned via least cost

transportation.

For international customers, warranty for

products purchased outside of the U.S. should

be handled through local distributors.

www.fieldpiece.com

© Fieldpiece Instruments, Inc 2013; v32

20

Loading...

Loading...