Page 1

Fieldpiece

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

80

808080

80

80

80

80

80

80

80

Displa

y

!

!

!

!

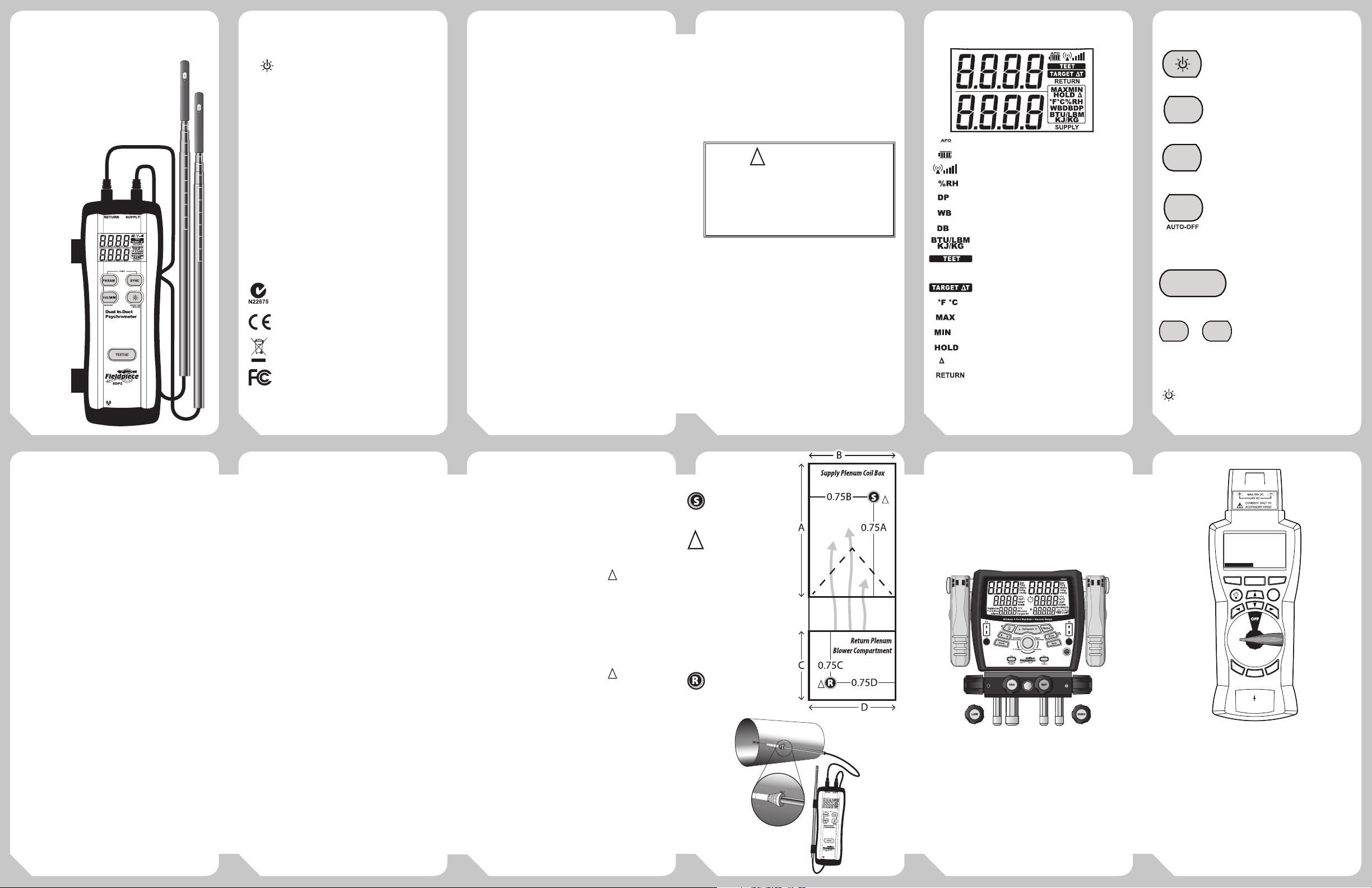

Dual In-Duct

Psychrometer

OPERATOR'S

MANUAL

Model SDP2

Quick Start

1. Power on your SDP2 by holding the

button for 1 second.

2. Select mode with the TEET/ΔT

button: Target Evaporator Exit

Temperature, Target Temp Split, or

Normal (real-time return and supply.)

3. Press the PARAM button to cycle

between dry bulb, relative humidity,

wet bulb, dew point, and enthalpy.

4. Insert sensing probes into duct or

plenum for in-duct measurements.

80

80

5. Hold SYNC to pair and send all

measurements to Fieldpiece model

HG3 or SMAN4 Analyzers.

Description

The two probes each simultaneously measure temperature and

RH%. One goes before the evaporator (RETURN) and one goes after

the evaporator (SUPPLY). These four

measurements can be displayed or

used in calculations to display the

actual temperature split (delta T), the

target temperature split, the actual

exit evaporator temperature, or the

target exit evaporator temperature

(TEET), plus the dierence between

the actual and target. Enthalpy (BTU/

LBM) and Dew Point can also be displayed.

Certifications

C-Tick (N22675)

The TEET takes into consideration

the latent heat used to condense

water from the air, while a simple 20°

CE

temperature split ignores latent heat.

TEET, developed by Fieldpiece, is an

WEEE

intuitive test allowing you to aim for

a target value rather than a target

FCC

RoHS Compliant

01 03 0602 0504

dierence between two values.

The 38"(96cm) telescoping probe

with laser etched ruling and attened

edges allows you to locate proper

measurement points within a duct

and ensures that your probe is properly aligned. The dual display, bright

backlight, and rugged rubber boot

with probe clips make sure the SDP2

is ready for any job.

WARNING

Do not retract the sensor probe by pulling on the

cord. Doing so may sever the cord from the sensors.

Do not punch or drill holes into an evaporator

without making sure there is not critical system parts

behind the hole location.

Maintenance

Clean the exterior with a dry cloth.

Do not use liquid.

Battery Replacement

Turn your SDP2 off, remove rubber boot, unscrew battery cover, and

replace 9V battery.

Display

Auto Power O Enabled

Battery Life

Wireless Signal Strength

Relative Humidity

Dew Point

Wet Bulb

Dry Bulb

Enthalpy

Target Evaporator Exit

Temperature

Target Dry Bulb Temp Split

Temperature

Maximum Display

Minimum Display

Hold Display

Δ Display (Return-Supply)

Top Display Shows Return

Bottom Display Shows Supply

or the dierence between actual and target

values for TEET and ΔT.

Controls

Hold 1 second to toggle power on/o.

Press to toggle backlight.

Cycle through dry bulb, wet bulb, dew

PAR A M

point, relative humidity, and Enthalpy.

Hold for 1 second to search for a model

HG3 or SMAN4 and send real-time

SYNC

measurements.

Cycles through Hold, Dierence (Δ),

Maximum, Minimum, and Real-time.

H/Δ/M/M

Hold for 1 second to exit and clear stored

values. Hold while turning ON to toggle

Auto-O (APO).

Press to cycle between Target

Evaporator Exit Temp,

TE E T/ΔT

Target Delta T and Normal

modes.

Press both to toggle between

PAR AM

for 3 min when any button is pressed. A quick press of

SYNC

Fahrenheit or Celsius and BTU/

+

LBM or KJ/KG.

BACKLIGHT NOTE: The timer is automatically reset

toggles backlight.

How to Use

Normal Mode

Measure real-time dry bulb, relative humidity, wet bulb, dew point, or

BTU/LBM for each probe.

1. Remove vinyl protective sleeves if covering sensors.

2. Press the PARAM button to cycle dry bulb

temperature, relative humidity, wet bulb, dew

point, or BTU/LBM.

3. The top display shows Return probe and the

bottom display shows Supply probe. The probes are

interchangeable.

TEET (Target Evaporator

Exit Temperature) Mode

Target Evaporator Exit Temperature,

is similar to temperature drop or ΔT.

TEET is better than a simple temp-split

because it uses a wet and dry bulb

temperature on the evaporator coil

to determine the coil load and then

calculates a corresponding correct

exit dry bulb temperature.

Insert the Return probe to nd the

TEET. Insert the Supply probe to moni-

07 09 1208 1110

tor how close the target temperature

is to the actual temperature.

1. Insert the RETURN probe into the return plenum.

See Figure 1 for recommended return plenum

placement of probe. Drill or punch a 3/8" hole into

the return plenum if needed.

2. Press the TEET/ΔT button until TEET is displayed on

the top line.

3. Insert the SUPPLY probe into the supply plenum

to see how close the target temperature is to the

actual temperature. See Figure 1 for recommended

supply plenum placement of probe. Drill or punch a

3/8" hole into the supply plenum if needed.

4. (Actual evaporator temp - target evaporator

temp) will be shown on the bottom "SUPPLY"

line. A negative number means the actual exit

temperature and airow are both too low. You

want to be within ± 3°F (± 1.7°C) of the target for

good evaporator performance.

5. Seal any holes before leaving the jobsite.

Target ΔT (Target TempSplit) Mode

Temperature split is simple. It is the

return temperature minus the supply

temperature. Target ΔT uses RETURN

wet bulb and dry bulb to measure

heat load and automatically calculate

what the ΔT should be.

Insert the RETURN probe to find

the Target ΔT. Switch over to Normal

mode, and use both probes to then

see what your dry bulb Δ actually is.

1. Insert the RETURN probe into the return plenum.

See Figure 1 for recommended return plenum

placement of probe. Drill or punch ! a 3/8" hole

into the return plenum if needed.

2. Press the TEET/ΔT button until TARGET ΔT is

displayed on the top line.

3. Switch to Normal Mode to nd the actual ΔT so you

can compare the two values.

4. Insert the SUPPLY probe into the supply plenum.

See Figure 1 for recommended supply plenum

placement of probe. Drill or punch ! a 3/8" hole

into the supply plenum if needed.

5. Press PARAM until DB is shown. Press H/Δ/M/M

until Δ is shown.

6. Seal any holes before leaving the jobsite.

RCONE1 Probe Lock

Figure 2. Screw a threaded RCONE1

into the duct or plenum wall to secure

a sensing probe. Use the RCONE1s

and the magnet on the SDP2 for

hands-free in-duct testing.

Figure 1

Recommended hole

placem ent for SUPPLY

measurement.

Look be hind the

panel be fore drilling

and make su re you

do NOT dril l a hole

throug h any critical

components.

Recommended hole

placem ent for RETURN

measurement.

Figure 2

Use the RCONE1 for

hands-free in-duct

measuremesnts.

Wireless Sync

The SDP2 can wirelessly send all of

its measurements to a wireless Fieldpiece model that accepts them. As of

this printing, models HG3 and SMAN4

both can receive measurements.

4-Port Wireless Manifold

Model SMAN4

1. Enter Target Superheat mode.

2. Use arrow keys to select IDWB. (IDWB will blink)

3. Press SYNC on SMAN4 for 1 second.

4. Press SYNC on SDP2 for 1 second to connect and

sync real-time indoor wet bulb.

5. Use a temperature accessory head and ET2W wire-

less transmitter to sync ODDB and view real-time

target superheat while you charge outside.

INPUT FORM

SET 01

Set ID:Indoor Temp

Measurement: 72.8

SET 02

SET ID:Comp Amps

Measurement: 23.6

CustomerID: __JONES123

Input

Evaporator

Exit Temp

Data

Logger

Service

Light

Clear

Target

Sync

CFM

SETUP

SubcoolingCombustion

Recall

HVAC Guide

Fieldpiece HG3

Enter

CheckMe!

Display

Superheat

Save

Output

HVAC Guide® System Analyzer

Model HG3

1. Select test.

2. Use arrow keys to select a measurement line.

3. Press SYNC on HG3 for 1 second.

4. Press SYNC on SDP2 for 1 second to connect and

sync ALL lines of the test that it can ll.

5. Values will be held if OUTPUT is pressed. Going back

to INPUT will show the held values. Press SYNC on

the HG3 to return to real-time values.

Page 2

Specifications

80

STA2

UNITS

CLEAR DATA

RECORD MODE

PRESS FOR

1 SECOND

In-Duct

Hot Wire

Anemometer

DUCT

ON/OFF

ENTER

HOLD

AVERAGE

MAX/MIN

AUTO-OFF

APO MAXMIN HOLD SET

CO

2

EA

MAX

°F %

%

°C

ENTER

AUTO-OFF

°F

°C

TEMP CAL

PRESS FOR

1 SECOND

SOX3

Combustion

Check

Excess Air,

%CO

2

and %O

2

Natural

Gas

Oil#2PropaneCustom

EXHAUST

CLEAR

SET CUSTOM

ON/OFF

FUEL

MAX/MIN

MEASURE/HOLD

SC54

AUTO OFFTRUE RMS

CAT III

600V

TEMP

K-TYPE

30V

MAX

O

F

F

SEL

HOLD

HOLD

MAX

MIN

MAX

MIN

SYNC

MAX

MIN

Ω

VDC

VAC

µADC

HZ

MFD

400m

400

Auto

4000m

1000

400

°C

°F

NCV

MAX

MIN

TRUE RMS

BACKLIGHT

NON-CONTACT VOLTAGE

HS36

AC

80

AAT3

In-Duct

Psychrometer

& Air Velocity

Head

ON

LO BATTAVG

ENGLISH

ENGLISH METRIC

RH%

Ft/min

°F

RH%

M/s

°C

METRIC

DRY BULB

WET BULB

DEW POINT

AVG

NORMAL

AUTO OFF

Telescoping probe length: Up to 38 inches (97cm)

Probe tip diameter: 0.35 inch (9mm)

Storage temperature: -4°F to 140°F (-20°C to 60°C), 0

to 80% RH (with battery removed)

Temperature coecient: 0.1 x (specied accuracy)/°C

(<18°C or >28°C)

Over range: "OL" or "-OL" is displayed

Power: Single standard 9-volt battery, NEDA 1604, JIS

006P, IEC 6F22

Auto power o: after 30 minutes of inactivity if APO

is active.

Battery life: Approx. 120 hours standard use (alkaline)

Low battery indication: is displayed when the

battery voltage drops below the operating level.

Dimensions: 7.9 in (H) x 2.6 in (W) x 1.4 in (D),

[200mm (H) x 66mm (W) x 36mm (D)]

Weight: Approx. 570g, including battery

Temperature:

Sensor type: Precision thermistor

Operating environment: -4°F to 140°F (-20°C to 60°C)

Range: -4°F to 140°F (-20°C to 60°C)

Resolution: 0.1°F / 0.1°C

Accuracy: ±(1°F) 32°F to 113°F

±(2°F) -4°F to 32°F, 113°F to 140°F

±(0.5°C) 0°C to 45°C

±(1°C) -20°C to 0°C, 45°C to 60°C

Relative Humidity:

Sensor type: Capacitance polymer lm

Operating environment: 32°F to 131°F (0°C to 55°C)

Range: 0% to 100%RH

Accuracy: ±(2.5%) 10% to 90%RH

±(5%) <10%RH and >90%RH

Note: Above accuracies stated at 73.4°F (23°C).

Sensor response time: 60 seconds typical for 90% of

total range.

Sensor hysteresis: ±1%RH typical (Excursion of 10% to

90% to 10%RH)

Wireless:

Frequency range: 910MHz ~ 920MHz

FCC ID: VEARF915

Range: 100 feet

Minimum Wireless Range: 1 foot (30cm)

Error Codes

You may see an error code in TEET

or Target Delta T mode. Usually it

means probes are swapped or a bad

sensor (model RSDP2).

Err 01: Return wet bulb is higher than dry bulb.

Err 02: Return wet bulb is extremely low.

Err 03: Supply dry bulb is higher than return dry bulb.

Err 04: Return values are outside calculating range.

Err 05: Supply values are outside calculating range.

Err 06: Both the return and supply values are outside

Sensor Care

When not in use, protect the sen-

sors with the black vinyl slip covers.

Extreme conditions or exposure to

solvent vapors may oset the relative

humidity sensor. If this happens, place

the exposed sensor in a controlled

environment of 75%RH and between

68°F - 86°F for a period of 24 hours.

To create a 75%RH environment

moisten a small amount of table salt,

in an open container such as a clean

2 liter bottle cap.

Place the container with the salt

solution and the SDP2 probe in a sealable plastic bag, and leave the bag in

a room temperature location where

it will not be disturbed for 24 hours.

Note: It is important that the salt

solution does not come in direct

contact with the sensor, as this may

permanently damage the sensor.

calculating range.

(Err 04, 05, 06 supersedes Err 01, 02, 03)

13 15 1814 1716

A/C Basics

The Evaporator, Condenser, Restrictor (Throttling valve) and Compressor

are the four basic components of an air

conditioner. Following one pound of

refrigerant through the system shows

the function of each component.

Subcooled liquid refrigerant at high

pressure enters the restrictor and is

throttled to saturated refrigerant at a

lower pressure. The restrictor can be

of either a xed or TXV/EXV type. The

xed type must be charged to a target

superheat that varies with indoor and

outdoor conditions. TXV/EXV systems

must be charged to subcooling.

The evaporator capacity varies with

the indoor heat load on a xed restrictor. The TXV/EXV regulates the size of

the restriction to maintain a constant

superheat. This essentially adjusts the

capacity of the evaporator responding

to the indoor heat load.

After the restrictor, refrigerant enters

the evaporator at a low temperature

and pressure, and boils (evaporates)

into a gas by absorbing heat from the

indoor air. The refrigerant stays at the

same temperature and pressure until

all the refrigerant evaporates into a

gas. After the refrigerant becomes a

gas, it will continue to absorb heat

and become superheated at which

point its temperature will change. The

Superheat measurement is the best

indication of refrigerant charge level

in a fixed restrictor system. A TXV/

EXV system will keep the superheat

constant. There must be superheat

present to ensure liquid does not

ood the compressor.

Superheat measurements are

taken on the suction line between

the evaporator and compressor.

The compressor takes this low temperature, low pressure, slightly superheated refrigerant and compresses it

to a much higher temperature and

pressure.

The highly superheated gas enters

the condenser and rejects heat into

the outside air. The refrigerant condenses back into a liquid. Once all

of the gas is condensed into a liquid,

additional removal of heat causes

a temperature drop that is known

as subcooling. TXV/EXV systems are

charged to subcooling since superheat is controlled by the throttle

valve. Subcooling measurements are

taken on the liquid line between the

condenser and TXV/EXV. Finally, the

subcooled liquid enters the restrictor

and the cycle starts again.

EVAPORATOR

RETURN AIR SUPPLY AIR

w

o

L

P

r

e

s

s

u

r

e

r

FLOW

e

S

i

d

e

e

d

i

S

THROTTLE

VALVE

REFRIGERANT

H

i

g

h

P

r

e

s

s

u

OUTDOOR AIR HOT AIR

CONDENSER

COMPRESSOR

Limited Warranty

This meter is warranted against

defects in material or workmanship

for one year from date of purchase.

Fieldpiece will replace or repair the

defective unit, at its option, subject

to verication of the defect.

This warranty does not apply to

defects resulting from abuse, neglect, accident, unauthorized repair,

alteration, or unreasonable use of the

instrument.

Any implied warranties arising

from the sale of a Fieldpiece product,

For Service

In the USA, call Fieldpiece Instruments for one-price-x-all out of warranty service pricing. Send check or

money order for the amount quoted.

Send the meter freight prepaid to

Fieldpiece Instruments. Send proof

of date and location of purchase for

in-warranty service. The meter will be

repaired or replaced, at the option of

Fieldpiece, and returned via least cost

transportation. Outside of the USA,

please visit www.fieldpiece.com for

service contact information.

More Great

Products from

Fieldpiece

including but not limited to implied

warranties of merchantability and

fitness for a particular purpose, are

limited to the above. Fieldpiece shall

not be liable for loss of use of the

instrument or other incidental or

consequential damages, expenses, or

economic loss, or for any claim of such

damage, expenses, or economic loss.

tions or exclusions may not apply to

you.

19 21 2420 2322

State laws vary. The above limita-

www.fieldpiece.com

© Fieldpiece Instruments, Inc 2013; v12

Wireless 4-Port Manifold

Model SMAN4

In-Duct Hot-Wire

Anemometer

Model STA2

Vacuum Gauge

Accessory Head

Model AVG2

In-Duct

Psychrometer

and Air Velocity

Accessory Head

Model AAT3

Swivel Clamp Meter

Model SC54

Combustion Check with AutoPump

Model SOX3

True RMS Stick Meter

Model HS36

Loading...

Loading...