Page 1

Fieldpiece

!

!

Carbon Monoxide

Accessory Head

OPERATOR'S

MANUAL

Model

ACM4

ACM4

Quick Start

1. Install 9V battery (included).

2. Connect ACM4 to Fieldpiece Meter.

3. Select the mVDC range on DMM.

4. Slide the power switch to ON and

allow the warmup to complete.

Note: Green and red LEDs will light

solidly for 10 seconds.

5. If necessary, ZERO the ACM4 to

atmosphere with no carbon monoxide (CO).

6. Carbon monoxide (CO) above nominal levels will be displayed in parts

per million (ppm).

7. Power ACM4 o by sliding the power

switch to the OFF position.

Certifications

C-Tick (N22675)

CE

WEEE

RoHS Compliant

Description

The ACM4 carbon monoxide

accessory head measures carbon

monoxide in parts per million (ppm).

It is intended to measure levels

of CO in still, ambient air. The most

practical application of the ACM4 is

to determine if the indoor CO levels

are higher than outdoor levels and to

determine the source. In many cases,

it can help locate a source of CO.

The ACM4 uses a fast reacting,

electrochemical sensor that does not

consume chemicals and can easily be

replaced in the eld if needed. Sensor

Life is primarily determined by the

type of exposure.

Precautions

1. Do not measure gas engine

exhaust or other high CO or highly

contaminated gases. High levels of

CO and other contaminants can ruin

the sensor and be a health hazard.

2. Do not take readings directly in

stream of air at register or in a ue.

3. Allow enough time for ACM4 to

reach ambient temperature and

%RH.

4. The sensor has built-in permanent

non-replaceable filter to filter

out trace concentrations of SO2,

NO2, and most hydrocarbons. If

exposed to high concentrations of

harmful chemicals such as methanol,

ethanol, or dirt, the filter can

deteriorate and/or impede diusion

of CO to the sensor.

WARNING

Extended exposure to even relatively low carbon monoxide concentrations can be hazardous to human health.

Evacuate areas of signicant CO concentration immediately. See the CO Exposure Eects section of this manual.

CAUTION

Do not take measurements directly at a tailpipe, or at a ue. See "Precautions."

Do not rely solely on a carbon monoxide measurement to determine if a heat exchanger is bad. See “CO

Detectors and Cracked Heat Exchangers" section.

The majority of toxic gas sensors contain sulphuric acid electrolyte and the chemical hazard is mainly related

to the corrosive nature of this compound. These sensors also contain platinum, ruthenium, gold, silver, carbon

some of which are toxic.

Any skin or eye contact with the contents of these sensors should be washed immediately with copious amount

of water. Obtain medical advice.

Electrochemical gas sensors are sealed units containing an aqueous electrolyte and a combination of other

substances as detailed above. Provided these sensors are used only for their intended application they do not

represent a chemical hazard.

The sensors must not be exposed to temperatures outside the range -50°C to 60°C. Toxic gas sensors should

not be exposed to organic vapours which may cause physical damage to the body of the sensor, for example 1,

2 dichloroethane.

Should any sensor be so severely damaged that leakage of the contents occurs then the following procedures

should be adopted.

a. Avoid skin contact with any liquid or internal component through use of protective gloves.

b. Disconnect sensor if it is attached to any equipment.

c. Use copious amounts of clean water to wash away any spilt liquid. This is particularly important in

equipment where the sensor involved contains sulphuric acid or phosphoric acid because of the corrosive

nature of these electrolytes.

01 03 0602 0504

How to Use

1. Connect COM and Volts jacks using

Fieldpiece deluxe test leads. For

Fieldpiece "stick" meter, slide the

head directly over the meter.

2. Select the mVDC range.

3. Power ACM4 on by sliding the power

switch to the ON position and allow

warmup to complete.

4. Take the instrument outside and

adjust it to zero. Then bring inside

to take measurements.

5. Expose sensor to a still, stable air

sample (see precautions). The display reacts to the presence of CO

in seconds. Take nal reading when

reading stabilizes.

6. For initial tests, walk around the

building, watch for the readings

to go up to determine where

maximum concentrations of CO

are present. To measure air from

register, use a pump or measure

out of the air stream. Hot blowing

air can adversely aect the reading.

The temperature of the sample must

be near ambient.

07 09 1208 1110

Zero Adjust

As needed, set the reading to zero in

a known zero CO atmosphere and in a

temperature similar to the sample air

to be tested. Zero only when ambient

air is within specications and probe

is in equilibrium (temperature and

relative humidity) with ambient.

To zero, removing the protective

rubber cover to access the calibration

screw. Using the calibration Tool

provided, turn the calibration screw

until the display reads ZERO. (Note:

For safety reasons the ACM4 will not

zero if reading is above 5ppm.)

"Walk Around" Test

The ACM4 responds almost

instantly to changes in CO levels in

the air. If you see a difference in CO

levels from outside to inside, you

need to find the source of the CO.

Walk around and watch the display.

By constantly going towards the

area of higher concentration, you can

determine the source of the CO.

Persistent sources of CO, such

as malfunctioning combustion

equipment in occupied spaces, must

be serviced immediately. These can

be life threatening.

When searching for sources of CO,

make sure that you never put yourself

or anyone else in danger of excessive

exposure to CO. Overexposure to CO

can have long-term health eects and

can be fatal.

Average Switch

The average switch averages the

reading over the last two or three

seconds. This allows the user to read

more stable measurements.

Specifications

Sensor Type: Electrochemical (specic to CO)

Sensor Calibration: Factory calibrated @ 205 ppm CO

Range: 0 to 1000 ppm;

0 to 2000 ppm (less than 5 minute exposure time)

Initial Accuracy: @ 73°F±9°F, <75% R.H.

0-15ppm ±5% reading ±1 ppm after zeroing

16-35ppm ±5% reading ±2 ppm after zeroing

36-1000ppm ±5% reading ±5ppm after zeroing

Long Term Drift: less than 5% per year

(depending on use)

CO Air Sample Temperature Range: 32 to 105°F

Operating Environment: 32 to 122°F (0 to 50°C);

15 to 90% R.H., non-condensing

Storage Environment: 32 to 68°F (0 to 20°C) at

<80% R.H. with battery removed from meter.

Battery: 9V.

Battery Life: 150 hours typical alkaline.

Auto Power O: After 15 minutes.

Storage

To maintain sensor integrity, do

not store in areas containing solvent

vapors. This includes aerosols such

as air-freshener, wax polish, window

cleaner, and all organic solvents.

CO Detectors and

Cracked Heat

Exchangers

A CO detector cannot tell you

if a heat exchanger is good. A CO

detector can indicate that a heat

exchanger may be cracked only if

all of the following conditions occur

simultaneously:

1. The ame must generate high con-

centrations of CO (lack of oxygen,

excess fuel, high temp).

2. Enough exhaust gases must be emit-

ted from the heat exchanger crack.

3. The exhaust gases from the crack

must not be diluted too much

before coming in contact with the

sensor. A cracked heat exchanger

may leak CO in a small stream. You

may measure high concentrations

at one point but low concentrations

only an inch away.

4. The heat exchanger must be the only

possible source for the CO detected.

CO Exposure Effects

9 ppm

35 ppm

50 ppm Max for eight hours (OSHA).

100 ppm

200ppm

400 ppm

800 ppm

800 ppm In two to three hours: death.

1600 ppm In one hour: death.

6400 ppm In fteen minutes: death.

12800 ppm In three minutes: death.

Note: Eects can vary signicantly depending on

age, sex, weight, and overall health.

Minimal. Max allowable concentration

for eight hours (EPA and ASHRAE).

Max for continuous exposure for one

hour (EPA and ASHRAE).

Trips installed CO detectors. UL2034

species a max exposure of 100 min.

In two to three hours: slight

headache, tiredness, dizziness,

nausea. UL2034 species a max

exposure of 35 min.

In one or two hours: frontal

headaches. In three hours: life

threatening. UL2034 species a max

exposure of 15 minutes.

In forty ve minutes: dizziness,

nausea, and convulsions.

Page 2

Maintenance

Clean the exterior with a dry cloth.

Do not use liquid.

Battery Replacement

When "LO BATT" LED is flashing,

the battery should be replaced. Turn

your ACM4 off and replace the 9V

battery.

Check Your Sensor:

Coee Cup CO Test

and out of the mouth of the coffee

cup to just keep the ame alive. The

longer you keep the ame ickering,

the more CO you produce.

After 10 seconds of flickering,

extinguish the ame and put the CO

head in the mouth of the cup. You

should see readings in the 100s. Take

it out if it approaches 1000PPM.

CO Sensor Replacement

5. If the sensor is incorrectly installed,

"ON" LED and "LOW BATT" LED will

blink alternately and after 5sec, the

ACM4 will auto power o.

The ACM4 uses a carbon monoxide

To demonstrate that your CO

sensor works, turn a ceramic coffee

cup upside down and slide it over

the edge of a counter (or desk) to

expose about a third of the mouth of

the cup. Burn a cigarette lighter inside

the exposed mouth of the cup. Don't

burn the counter.

When the flame starts to flicker,

you've burned up most of the oxygen

in the cup creating carbon dioxide

and now you're starting to produce

carbon monoxide. Bring the ame in

smart sensor. If you are seeing erratic

CO readings or no readings in a

known CO environment, you likely

need to replace the sensor.

1. Obtain replacement sensor model

RCM4 from your local distributor.

2. Remove sensor cap by removing the

4 screws.

3. Directly pull out old sensor.

4. Hold the new sensor by the sides.

While holding the sensor on the

sides; press down to secure the new

sensor. Do not press the new sensor

Carbon

Monoxide

Accessory

Head

from the top.

13 15 1814 1716

Carbon

Monoxide

Accessory

Head

ON

LOW BATT

ON

AVERAGE

Incor rect

Carbon

Monoxide

Accessory

Head

ON

LOW BATT

ON

AVERAGE

Sensor Disposal

The RCM4 Replacement carbon

monoxide smart sensor contains

sulfuric as well as precious metals. The

sensor should be recycled properly

through a local electronic waste

center.

Limited Warranty

This meter is warranted against

defects in material or workmanship

for one year from date of purchase.

Fieldpiece will replace or repair the

defective unit, at its option, subject

to verication of the defect.

This warranty does not apply to

defects resulting from abuse, neglect,

accident, unauthorized repair,

alteration, or unreasonable use of the

instrument.

Any implied warranties arising

from the sale of a Fieldpiece product,

including but not limited to implied

warranties of merchantability and

fitness for a particular purpose, are

limited to the above. Fieldpiece shall

not be liable for loss of use of the

instrument or other incidental or

consequential damages, expenses, or

economic loss, or for any claim of such

damage, expenses, or economic loss.

State laws vary. The above

limitations or exclusions may not

apply to you.

For Service

In the USA, call Fieldpiece

Instruments for one-price-x-all out

of warranty service pricing. Send

check or money order for the amount

quoted. Send the meter freight

prepaid to Fieldpiece Instruments.

Send proof of date and location of

purchase for in-warranty service. The

meter will be repaired or replaced,

at the option of Fieldpiece, and

returned via least cost transportation.

Outside of the USA, please visit www.

fieldpiece.com for service contact

information.

www.eldpiece.com

©Fieldpiece Instruments, Inc 2013; v08

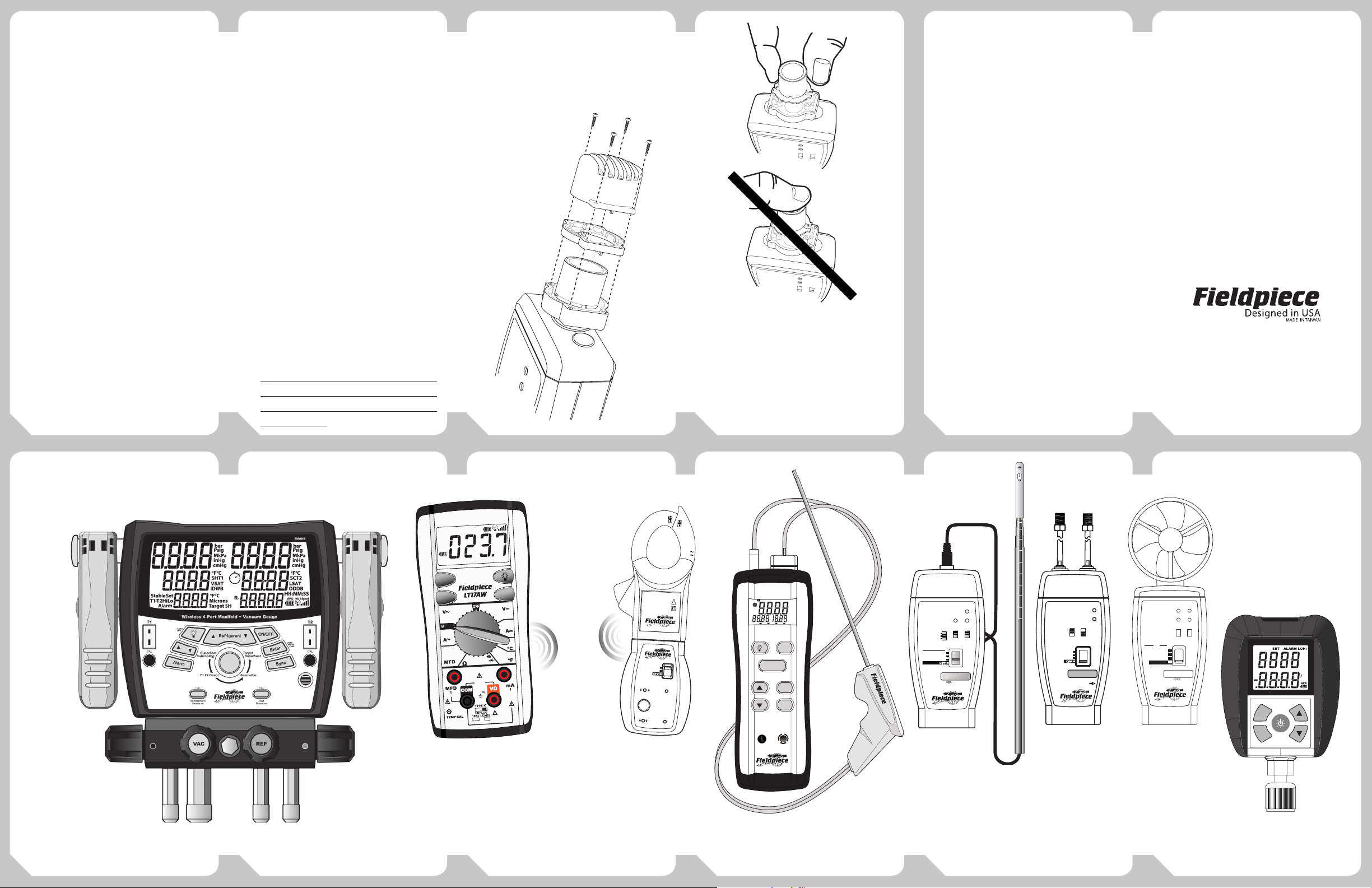

More Instruments

from Fieldpiece

AUTO-OFF

WIRELESS

ENABLED

MAX/MIN

SYNC HOLD

500m

RECV

500µ

50m

200m

5000m

FUSED

600600

500

50

500

50

K

2

200

20

M

20

200

15 SEC FOR

K

RANGE

CAT.III

600V

5000m

500

1400

K

2

200

V

m

500

MAX

30V

MAX

500m

500µ

50m

200m

500

750

FUSED

A

m

200

MAX

Wireless Measurements

CLAMP

CAT.III

SEND

SYNC

RECEIVE

AC Current

Clamp

1AAC / 1mVAC

400AAC MAX

ACH4

ET2W

AC

DC

Wireless

Transmitter

LO BATT

300V

400A

P1 P2

!

ON

APO MAXMIN HOLD SET

°F %

°C

Natural

Oil#2PropaneCustom

Gas

AUTO-OFF

MEASURE/HOLD

ENTER

°F

°C

Combustion

Check

Excess Air,

and %O

%CO

2

TEMP CAL

SOX3

ON/OFF

PRESS FOR

1 SECOND

SET CUSTOM

FUEL

MAX/MIN

2

EXHAUST

%

CO

2

MAX

EA

CLEAR

In-Duct

Psychrometer

& Air Velocity

Head

DRY BULB

WET BULB

DEW POINT

ENGLISH METRIC

RH%

Ft/min

°F

ON

LO BATTAVG

ENGLISH

AVG

METRIC

NORMAL

RH%

M/s

°C

AUTO OFF

AAT3

80

Dual-Port

Manometer

Accessory

Head

Resolution

P1-P2

(LCD/10)

P2

P1

ZERO

ADMN2

ON

Lo Batt

0.1

ENGLISH

0.01

METRIC

AUTO

OFF

AirVelocity

&Temperature

Head

English Metric

Ft/min M/s

ºF ºC

OFF

KM/hrMPH

AAV3

English

AUTO-

LCDX

100

ON

READLOBATT

Average

(16sec)

Real

Metric

time

VACUUM

GAUGE

SVG3

MIN

OFF

MICRONS OF MERCURY

ALARM

ENTER

Accessory Heads

Digital Refrigerant Manifolds

19 21 2420 2322

Combustion Check with AutoPump

Vacuum Gauge

Loading...

Loading...