Page 1

Fieldpiece

Targe

ator

ator

ator

Exit T

Exit

Exit

e

Tar

Evaporat

E

Exit T

Exit

Exi

Ex

e

Targe

ator

ator

Tar

Evapor

at

emp

In-Duct

Psychrometer

and Air Velocity

Head

Model AAT3

Quick Start

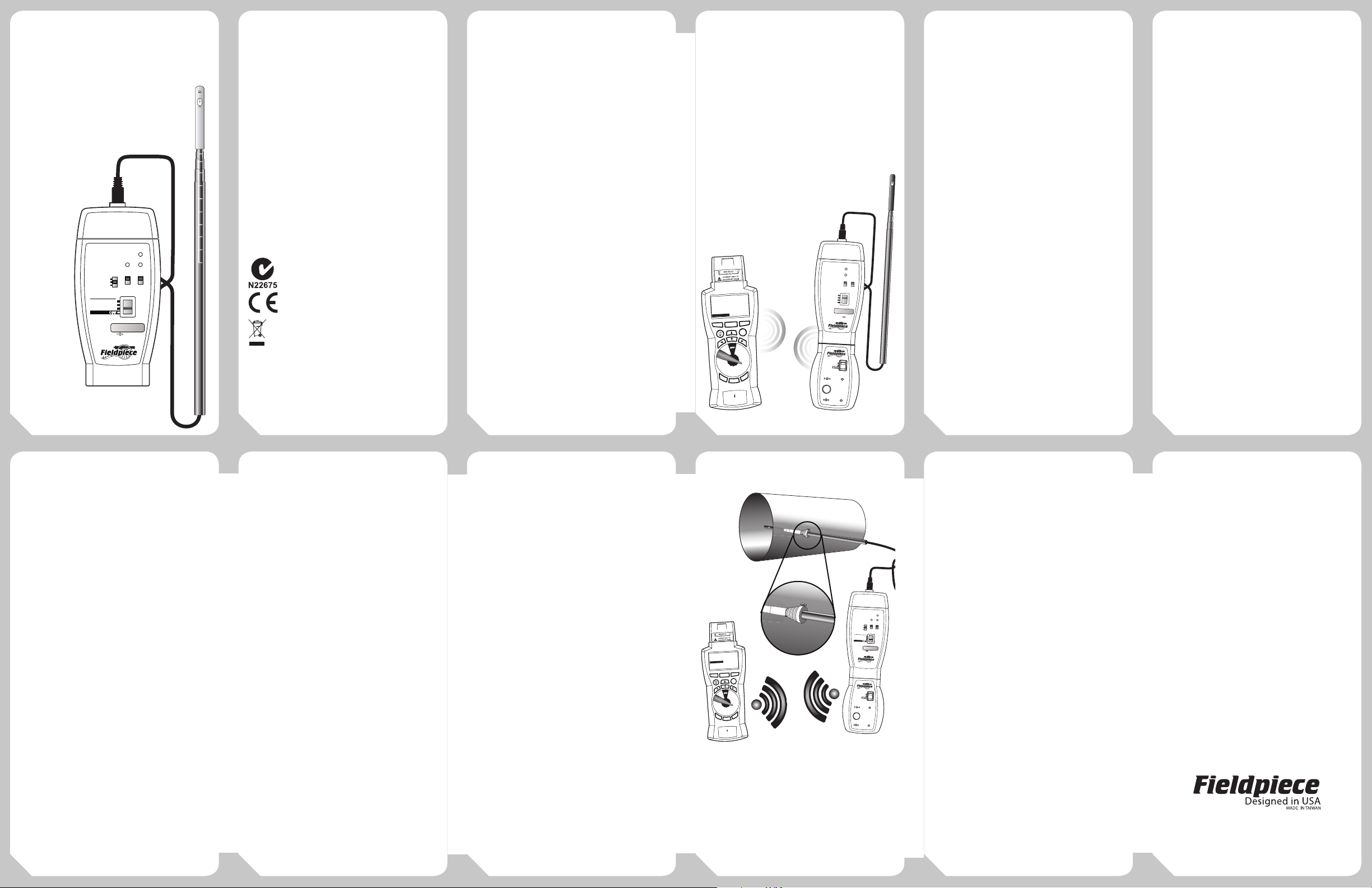

1. Connect AAT3 to Fieldpiece meter.

2. Select mVDC range on meter.

3. Remove vinyl slip cover from the

probe tip.

4. Select desired switch position on

AAT3 for temperature, %RH, or air

velocity.

5. Read your measurement directly on

the display of the Fieldpiece meter.

Description

Your AAT3 is a portable,

psychrometer accessory head, with a

built in hot wire anemometer.

The compact probe tip makes

directly measuring in ducts a breeze.

The 38"(96cm) telescopic probe with

laser etched ruling and flattened

edges allows you to locate proper

measurement points within a duct and

ensures that your probe is properly

aligned for air velocity measurements.

The AAT3 can measure percent

In-Duct

Psychrometer

& Air Velocity

Head

DRY BULB

WET BULB

DEW POINT

ENGLISH METRIC

RH%

Ft/min

°F

RH%

M/s

AAT3

ON

LO BATTAVG

ENGLISH

AVG

METRIC

NORMAL

°C

AUTO OFF

80

Certifications

C-Tick (N22675)

CE

WEEE

RoHS Compliant

relative humidity, dry bulb, and air

velocity and can calculate wet bulb

and dew point.

The AAT3 snaps directly onto the

Fieldpiece HS series DMMs. For other

meters, use Fieldpiece ADLS2 test

leads or AHDL1 handle adapter.

Use your AAT3 with the HVAC Guide

to easily calculate in-duct CFM or

to perform Target Evaporator Exit

Temperature tests and get accurate

Target Superheat calculations.

OPERATOR'S MANUAL

01 03 0602 0504

Go wireless with your AAT3 by

using Fieldpiece wireless transmitters

(ET2W/EH2W) to send measurements

over-the-air to Fieldpiece wireless

receivers (HG3, LT17AW, EH4W)

anywhere on the jobsite.

AAT3 w/ ET2W

transmitting

wirelessly to HG3

In-Duct

ON

Psychrometer

Head

LO BATT

ON

°F

1%RH/mVDC

1°F/mVDC

1°C/mVDC

OFF

°C

TEMP

INPUT FORM

SH Table: Standard

Refrigerant: R-22

OD Dry Bulb: 85.4°F

Return WB: 63.0°F

SL Pressure: 52.4psig

SL Temp: 45.4°F

CustomerID: __JONES123

Sync

Input

SETUP

CFM

Target

CheckMe!

Evaporator

Exit Temp

Data

Logger

Superheat

Service

Light

SubcoolingCombustion

Clear

Recall

HVAC Guide

HG3

Fieldpiece

Output

Enter

Display

Save

WET BULB

DEW POINT

SEND

SYNC

RECEIVE

%RH

ARH5

ET2W

AC

DC

Wireless

Transmitter

AUTO OFF

ON

LO BATT

How to Use

General Instructions

1. Remove sensor cap from the telescoping

probe tip.

2. Connect directly onto any Fieldpiece

HS multimeter, data logget or the HG3 HVAC

guide. For most Fieldpiece SC and LT meters,

use Fieldpiece ADLS2 test leads plugged into

the COM and VΩ jacks.

3. Select mVDC range on multimeter.

4. Set switch position of AAT3 to °F and°C,

Ft/min and M/s, or %RH.

a.) For temperature set temp type switch

to DRY BULB, WET BULB or DEW POINT.

b.) For velocity measurements wait for 10

seconds as the AAT3 warms up.

5. Read the measurement directly on

the multimeter display.

What is Free Area?

How Do I Get It?

Free Area is the total area through

which air can ow on either a supply

outlet or a return grille. Free area

is also some times referred to as

"eective area" or "see through area."

If there is no grille or restriction on

the area through which air is owing

then the free area is equal to the actual

area. This would be the case if you are

performing an in-duct measurement

or if you were to remove the grille

from a supply or return.

If you are measuring airow where

there is an obstruction present then

the free area is the total area minus

area covered by the ns or grating.

Free Area is published by grille

manufacturers and is the most

accurate representation of the Free

Area of a duct. Use manufacturer's

data whenever available.

Specifications

Operating environment:

Air Velocity: -4°F to 140°F (-20°C to 60°C)

Temperature: -4°F to 140°F (-20°C to 60°C)

Relative humidity: 32°F to 131°F (0 to 55°C)

Storage temp: -4°F to 140°F (-20°C to 60°C) <80%

R.H. (Batteries removed)

Output impedance: approx. 1KΩ

Temperature coecient: 0.1 x (specied accuracy)

per °C (<18°C or >28°C) (<64°F or >82°F)

AIR VELOCITY

Range: 40-3940 ft/min (0.20-20.00 m/s)

Note 1: To use full range AAT3 must be connected to a

DMM with a 4000 mVDC range or greater.

Note 2: For m/s, divide the reading on the display by

10 for actual measurement. Tip: Move the decimal

point one place to the left.

Accuracy: ± (5%+1 dgt) reading or ± (1%+1dgt)

full scale.

RELATIVE HUMIDITY

Range: 0% to 100% RH

Accuracy:

±2.5% @ 73.4°F (23°C), 10% to 90% RH

±5% @ 73.4°F (23°C), <10% RH, >90% RH

Sensor Response Time: 60 seconds typical for 90%

of total range.

Sensor Hysteresis: ±1%RH typical

TEMPERATURE

Range: -4°F to 140°F (-20°C to 60°C)

Accuracy: ±1°F 32°F to 113°F

±2°F -4°F to 32°F, 113°F to 140°F

±0.5°C 0°C to 45°C

±1°C -20°C to 0°C, 45°C to 60°C

Sensor type:

Air velocity: Tiny glass bead thermistor.

Relative Humidity: Capacitance polymer lm.

Temperature: Precision thermistor.

Battery: 9V

Battery life: 20 -35 hours typical

Battery indication: Red Lo Batt LED

Auto Power o: after 15 minutes of inactivity if APO

is active.

Dimensions: 144mm(H) x 67mm(W) x 32mm(D).

Weight: approx. 240g including battery.

Maintenance

Clean the exterior with a dry cloth.

Do not use liquid.

Battery Replacement

When Lo Batt LED lights up replace

old battery with new 9V battery.

Sensor Care

When not in use it is best to protect

this sensors with the vinyl slip cover

included with the AAT3.

Extreme conditions or exposure to

solvent vapors may oset the RH%

sensor. If this happens, place the

sensor in a controlled envrionment of

75%RH and between 68°F - 86°F for a

period of 24 hours.

To create a 75%RH environment

moisten a small amout of table salt,

in an open container such as a clean

2 liter bottle cap.

Place the container with the salt

solution and the AAT3 probe in a

sealable plastic bag, and leave the bag

in a room temperature location where

it will not be disturbed for 24 hours.

Note: It is important that the salt

solution does not come in direct

contact with the sensor, as this may

permenantly damage the sensor.

Optional accessories

In-Duct

ON

Psychrometer

& Air Velocity

LO BATTAVG

Head

ENGLISH

AVG

DRY BULB

WET BULB

DEW POINT

METRIC

NORMAL

ENGLISH METRIC

RH%

RH%

Ft/min

M/s

°F

°C

INPUT FORM

SH Table: Standard

Refrigerant: R-22

OD Dry Bulb: 85.4°F

Return WB: 63.0°F

SL Pressure: 52.4psig

SL Temp: 45.4°F

CustomerID: __JONES123

Output

Sync

Input

Enter

SETUP

CFM

Target

CheckMe!

Evaporator

Exit Temp

Display

Data

Logger

Superheat

Service

Light

SubcoolingCombustion

Clear

Save

Recall

HVAC Guide

HG3

Fieldpiece

RCONE1 and AAT3 working with

ET2W and HG3 to wirelessly log

Wetbulb for target superheat testing.

AUTO OFF

AAT3

ET2W

AC

DC

SEND

ON

Wireless

SYNC

Transmitter

RECEIVE

LO BATT

Limited Warranty

This meter is warranted against

defects in material or workmanship

for one year from date of purchase.

Fieldpiece will replace or repair the

defective unit, at its option, subject

to verication of the defect.

This warranty does not apply to

defects resulting from abuse, neglect,

accident, unauthorized repair,

alteration, or unreasonable use of

the instrument.

Any implied warranties arising

from the sale of a Fieldpiece product,

including but not limited to implied

warranties of merchantability and

tness for a particular purpose, are

limited to the above. Fieldpiece shall

not be liable for loss of use of the

instrument or other incidental or

consequential damages, expenses, or

economic loss, or for any claim of such

damage, expenses, or economic loss.

State laws vary. The above

limitations or exclusions may not

apply to you.

For Service

In the USA, call Fieldpiece

Instruments for one-price-x-all out of

warranty service pricing. Send check or

money order for the amount quoted.

Send the meter freight prepaid to

Fieldpiece Instruments. Send proof

of date and location of purchase for

in-warranty service. The meter will be

repaired or replaced, at the option of

Fieldpiece, and returned via least cost

transportation. Outside of the USA,

please visit www.eldpiece.com for

service contact information.

www.eldpiece.com

©Fieldpiece Instruments, Inc 2015;v13

07 09 1208 1110

Page 2

90°

D (<10”)

D (>10”)

0.032D

0.135D

0.321D

0.679D

0.865D

0.968D

0.019D

0.077D

0.153D

0.217D

0.361D

0.639D

0.783D

0.847D

0.923D

0.981D

D (<10”)

0.032D

0.135D

0.321D

0.679D

0.865D

0.968D

90°

D (<10”)

D (>10”)

0.032D

0.135D

0.321D

0.679D

0.865D

0.968D

0.019D

0.077D

0.153D

0.217D

0.361D

0.639D

0.783D

0.847D

0.923D

0.981D

90°

90°

90

85

80

Diagnostic Tests

Wireless Return Wet Bulb

for Target Superheat

The AAT3 with a wireless transmitter

(ET2W, EH4W, or LT17AW) allows to

you monitor the return wet bulb while

you are at the condensor. Send this

real-time WB measurement wirelessly

to the INPUT FORM of the HVAC Guide

(HG3) to calculate a real-time target

superheat.

1. Sync your transmitter with AAT3 to

2. Punch or drill a small 3/8" hole in

3. Input an outdoor dry bulb manually

4. Press OUTPUT on HG3 to see your

the Return WB INPUT line in Super-

heat Test of the HG3.

the return plenum to insert AAT3

probe. Press ENTER on the HG3 to

lock reading.

or with an ATH4 at the consdensor

into the OD Dry Bulb INPUT line in

the Superheat Test of the HG3.

target superheat calculations.

Target Evaporator Exit

Temp with the HVACGuide

The AAT3 with Fieldpiece HVAC

Guide, allows you to easily perform

a Target Evaporator Exit Temperature

(TEET) test to determine if the

evaporator is getting the optimum

airow.

1. Slide AAT3 onto the top of the HVAC

Guide. Select TEET switch position.

2. In the INPUT FORM, highlight Return

DB. Set the AAT3 to the Temperature

switch position and select dry bulb.

Press ENTER to measure air tem-

perature going into the evaporator

Drill a small 3/8" hole in the return

plenum and insert the AAT3 probe.

Press ENTER to lock reading. Take

measurements as close to the air

handler as possible. Seal any holes

before leaving the jobsite.

3. In the INPUT FORM, highlight Re-

turn WB. Press ENTER to measure

wet bulb temperature going into

the evaporator by inserting AAT3

return and selecting the appropriate

switch position on the AAT3. Press

ENTER to lock reading.

4. In the INPUT FORM, highlight Supply DB. Press ENTER to measure

air temperature coming out of the

evaporator. Punch or drill a small

3/8" hole in the supply plenum and

insert ARH5 wand in the center of

the plenum to take measurement.

Press ENTER to lock reading.

5. Press OUTPUT to view results.

probe through the same hole at the

13 15 1814 1716

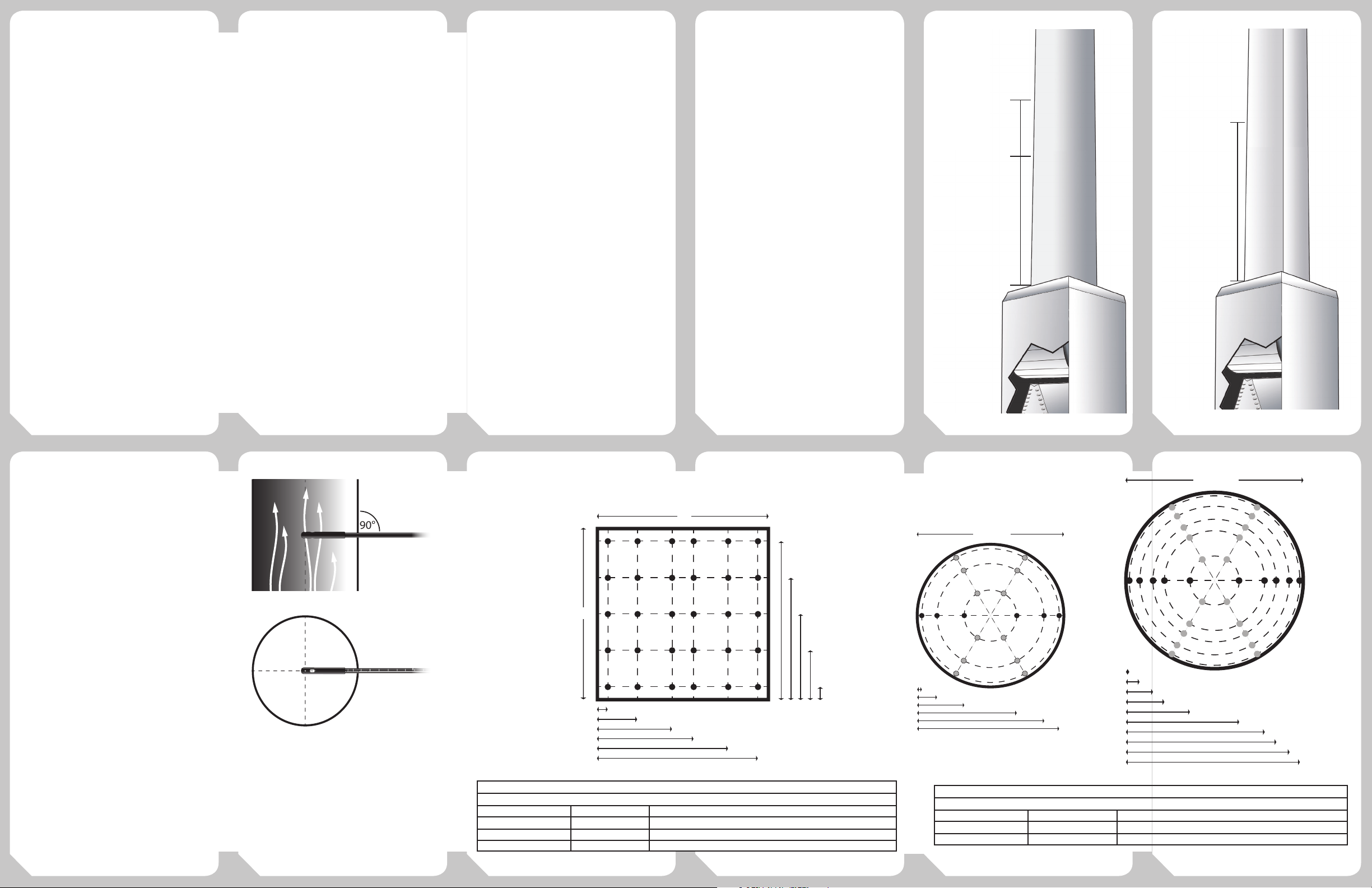

Measuring Accurate

Airow

Find a Suitable Location

for a Traverse

1. The cross sectional area at, before and after the

traverse location should be a either rectangular

or round.

2. Make sure you have sucient access around

the traverse location so that the duct may be

traversed at multiple angles.

3. The traverse location should be chosen so as to

minimize the eects of leaks in the portion of

the system between the fan and the traverse

location.

4. The traverse location should be located far

enough downstream of the fan to allow the

airow to come to a uniform distribution.

To determine an eective length, assume a

minimum of 2.5 duct diameters for 2500 ft/

min or less and add 1 duct diameter for each

additional 1000 ft/min measured. (For a

rectangular duct the equivalent diameter can

be calculated as D=√(4hw/π) where “h” is the

height of the duct and “w” is the width.)

5. Locations directly downstream from

obstructions, bends or sudden changes in the

duct are not good locations for a traverse.

Ex. 8” round duct

D=8”

2.5D=20“

2.5D+1D=28”

Traverse here if

velocity is 3500ft/min

Traverse here if

velocity is 2500ft/min

*Not to Scale

1 D

Ex. 24”x 8” duct

H=24

W=8

D=√(4HW/π)

D=16” (approx.)

2.5D= 40” (approx.)

Traverse here if

velocity is

2500ft/min

2.5 D

2.5 D

*Not to Scale

FAN

Execute the Traverse

1. Determine the appropriate measurement

2. Set the average switch on the AAT3 to AVG to

3. Insert the probe tip of the AAT3 into the duct

4. Use the laser etched ruler on the side of the

5. Record a point measurement (Either manually or

6. Use the recorded velocity measuremtents

19 21 2420 2322

points by measuring either the diameter of

the duct or the width and height. Then use the

appropriate table (See table 1 and 2) to calculate

the insertion depth where each of the point

measurements should be recorded.

display a 16 second running average.

and use the at edges of the probe to align the

sensor with the airow direction. Check that

the direction of airow is at 90° to the probe by

making sure that the probe is at a right angle to

the side of the duct.

probe probe to measure the insertion depth and

nd the locations you determined in step 1.

by using the Fieldpiece HG3, or DL3) at each of

the locations determined in step 1.

to calculate the airow by rst detemining

the average velocity of the traverse and then

multiplying by the free area of the duct.

Proper Measurement

Points for Rectangular/

Square Ducts

W

H

0.061W

0.235W

Traverse locations using log-Tchebyche rule in a rectangular duct

Length of Side # of Traverse Lines Distance from Inner Wall in % of Length of Side

< 30 in (76 cm) 5 7.4%, 28.8%, 50%, 71.2%, 92.6%

30-63in (76-160cm) 6 6.1%, 23.5%, 43.7%, 56.3%, 76.5%, 93.9%

>63in (160cm) 7 5.3%, 20.3%, 36.6%, 50%, 63.4%, 79.9%, 94.7%

0.437W

0.563W

TABLE 1

Proper Measurement

Points for Round Ducts

0.926H

0.712H

0.500H

0.288H

0.074H

0.765W

0.939W

TABLE 2

Log linear rule for traverse points on two diameter for a round duct

Diameter # of points per diameter Distance from inner wall in % of diameter

<10in (25.4cm) 6 3.2%, 13.5%, 32.1%, 67.9%, 86.5%, 96.8%

≥ 10in (25.4cm) 10 1.9%, 7.7%, 15.3%, 21.7%, 36.1%, 63.9%

Loading...

Loading...