Page 1

FZP 4001-B

Page 2

FZP 4001-B

2

1

English ................................................................................................................................................ 11 - 29

Čeština ................................................................................................................................................ 31 - 49

Slovenčina ....................................................................................................................................... 51 - 69

Magyarul .......................................................................................................................................... 71 - 90

Polski .................................................................................................................................................. 91 - 111

Русский ............................................................................................................................................ 119 - 135

Page 3

3

2

3 4

Page 4

FZP 4001-B

4

8

5 6

7

9 10

Page 5

5

14

11 12

13

15 16

(8)

Page 6

FZP 4001-B

6

19

18

20 21

Page 7

7

22 23

24

25 26

Page 8

FZP 4001-B

8

29

27 28

30 31

Page 9

9

35

32 33

34

36

Page 10

37

10

FZP 4001-B

Page 11

11

Contents

Chainsaw

INTSTRUCTIONS FOR USE

Thank you for buying this chainsaw. Before use, please be sure to carefully read these

instructions and keep them for possible future reference.

CONTENTS

VISUAL APPENDIX ........................................................................................................................... 2

GENERAL SAFETY GUIDELINES ............................................................................................... 13

1.

Important safety warnings

Package

Instructions for use

EXPLANATION OF INSTRUCTION LABELS ATTACHED TO THE MACHINE ............. 14

2.

MACHINE DESCRIPTION AND SCOPE OF DELIVERY .................................................... 16

3.

SAFETY INSTRUCTIONS ................................................................................................................. 16

4.

Before using your machine

Working equipment and clothing

OPERATION ....................................................................................................................................... 18

5.

Fuel handling instructions

Before starting the engine

Engine startup

Operation

MAINTENANCE ............................................................................................................................... 19

6.

Transport

GUIDE AND CHAIN INSTALLATION ...................................................................................... 20

7.

FUEL AND CHAIN LUBRICATION OIL .................................................................................... 21

8.

Fuel

Chain lubrication oil

MOTOR OPERATION ..................................................................................................................... 21

9.

Controls

Engine startup

Lubrication check

Carburettor setup

Carburettor anti-freeze device

Chain brake

Engine shutdown

EN

INTSTRUCTIONS FOR USECHAINSAW

Page 12

FZP 4001-B

12EN

Contents

SAWING .............................................................................................................................................. 24

10.

Kickback protection

Tree felling

MAINTENANCE ............................................................................................................................... 26

11 .

Maintenance after each use

Points of regular maintenance

CHAIN AND GUIDE MAINTENANCE ..................................................................................... 27

12.

Chain

Chain guide

SPECIFICATIONS ............................................................................................................................. 28

13.

DECLARATION OF CONFORMITY ........................................................................................ 29

14.

DISPOSAL ......................................................................................................................................... 30

15.

WARRANTY CERTIFICATE ......................................................................................................... 136

CONDITION OF GUARANTEE ................................................................................................ 137

Page 13

13 EN

INTSTRUCTIONS FOR USECHAINSAW

General safety instructions

1. . GENERAL SAFETY INSTRUCTIONS

Important safety warnings

Unpack the product carefully and be sure not to throw away any part of the package before

having found all components of the product.

Keep the product in a dry place out of reach of children.

Read all cautions and instructions. The failure to adhere to warning cautions and instructions

may result in an accident, fire and/or a serious injury.

Packaging

The product is placed in a package preventing damage during transport. This package is a raw

material therefore it can be handed-over for recycling.

Instructions for use

Before beginning to work with the machine, read the following safety rules and instructions for

use. Familiarize with operating elements and the proper use of the device. Keep the manual in a

safe place for future reference. We recommend keeping the original package including the inner

packaging materials, cash voucher and guarantee card for a period of warranty at minimum.

For a case of transportation, pack the machine into the original box from the manufacturer,

thus ensuring a maximum protection of the product during a possible transport (e.g. moving or

sending into a service station).

Note: If you hand the machine over to next persons, hand it over together with the manual.

Adherence to the attached instructions for use is a precondition for the proper use of the

machine. The operation manual includes also instructions for operation, maintenance and

repairs.

The manufacturer does not take any responsibility for accidents or damages

resulting from the failure to adhere to this manual.

Page 14

FZP 4001-B

14EN

Explanation of instruction labels attached to the machine

2. EXPLANATION OF INSTRUCTION LABELS

ATTACHED TO THE MACHINE

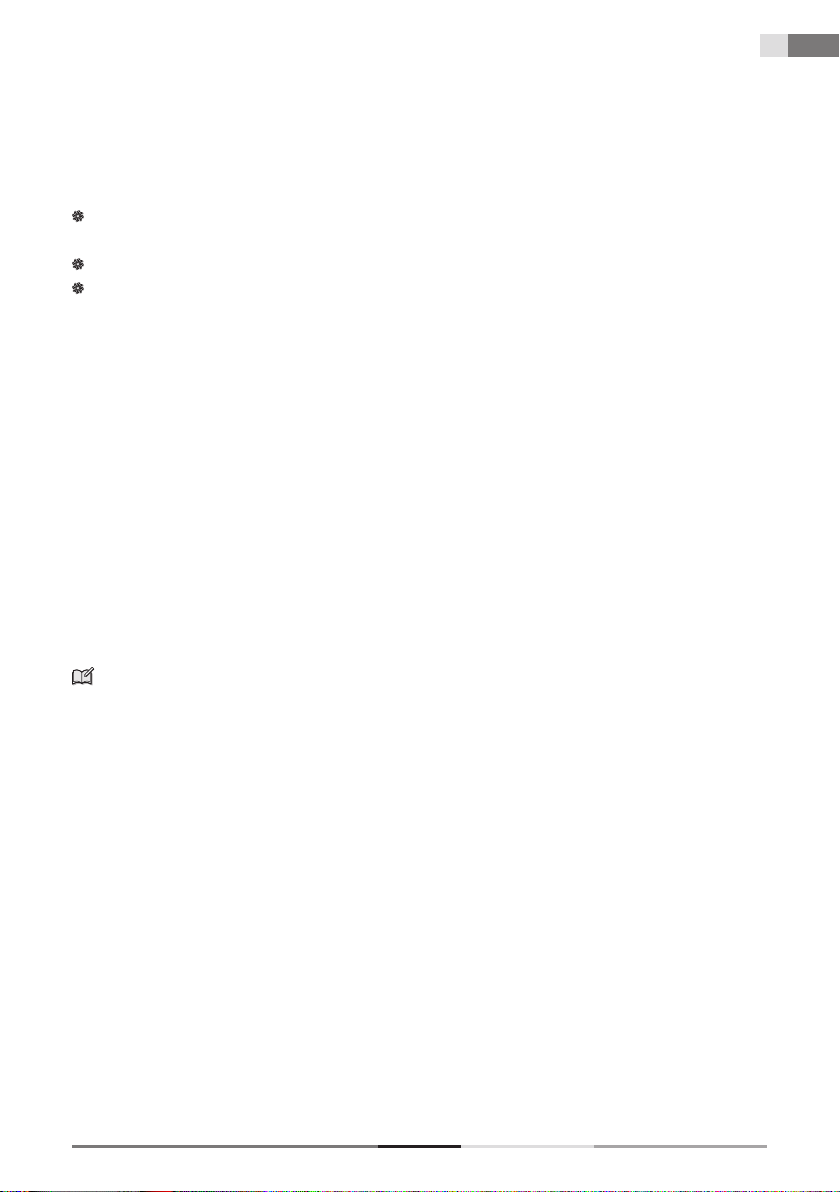

"FUEL MIXTURE" refueling icon - position:

fuel tank cap

"CHAIN LUBRICATION OIL" refilling icon position: oil tank cap

ON/OFF icon. The engine will switch to

the "O" (STOP) position and will stop.

Position: rear left of the unit

Choke icon. Pull the choke out half way

to close. Position: rear right of the unit

Chain lubrication oil injection icon

"MIN" direction - oil injection will

decrease; "MAX" direction - oil intake will

increase. Position: clutch bottom

Page 15

15 EN

INTSTRUCTIONS FOR USECHAINSAW

Explanation of instruction labels attached to the machine

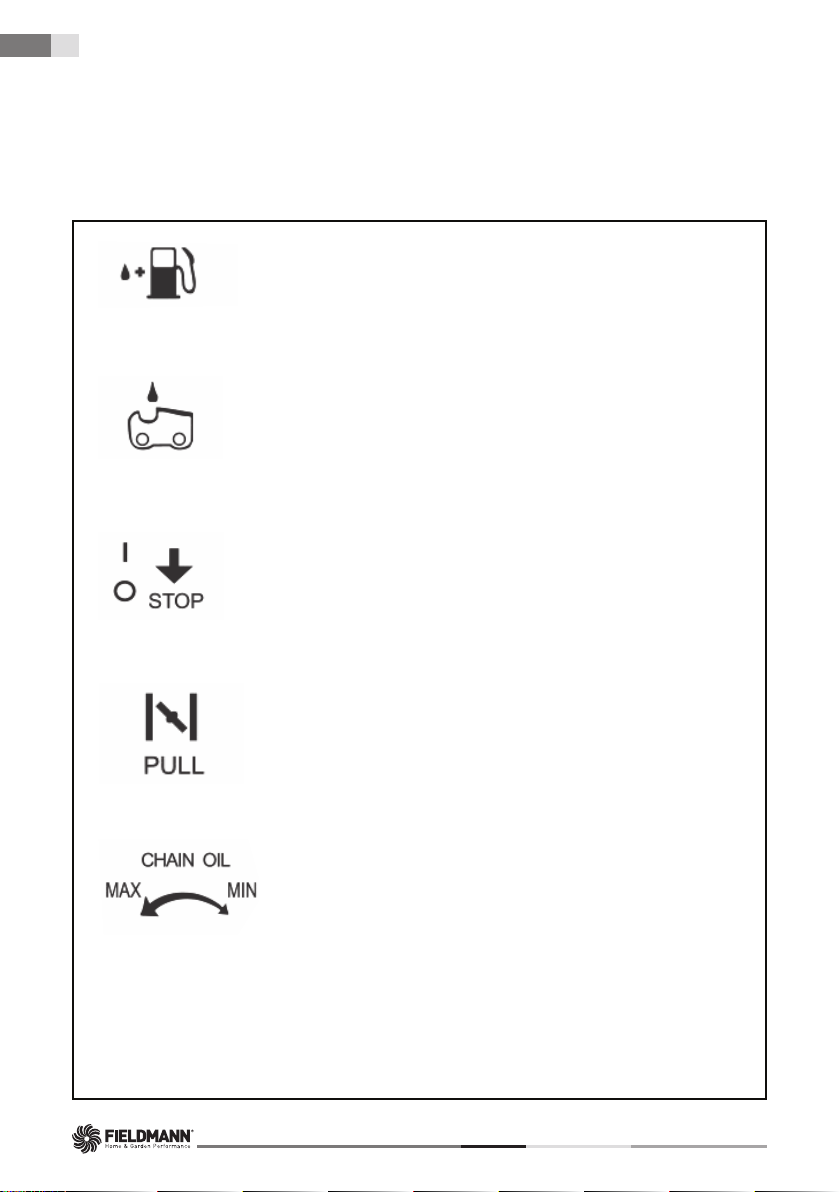

H position of the screw (used to set

high

speed)

L position of the screw (used to set low

speed)

The T position is used to set

idle speed.

Position: rear left of the unit

Please read the instructions for use

carefully before using the machine.

When operating the machine, please

wear protective aids such as glasses,

hearing protectors, etc.

Always use both hands when operating

your chainsaw.

Caution! Kickback hazard

Warning! Caution!

Page 16

FZP 4001-B

16EN

Machine description and scope of delivery | Safety instructions

3. MACHINE DESCRIPTION AND SCOPE

OF DELIVERY

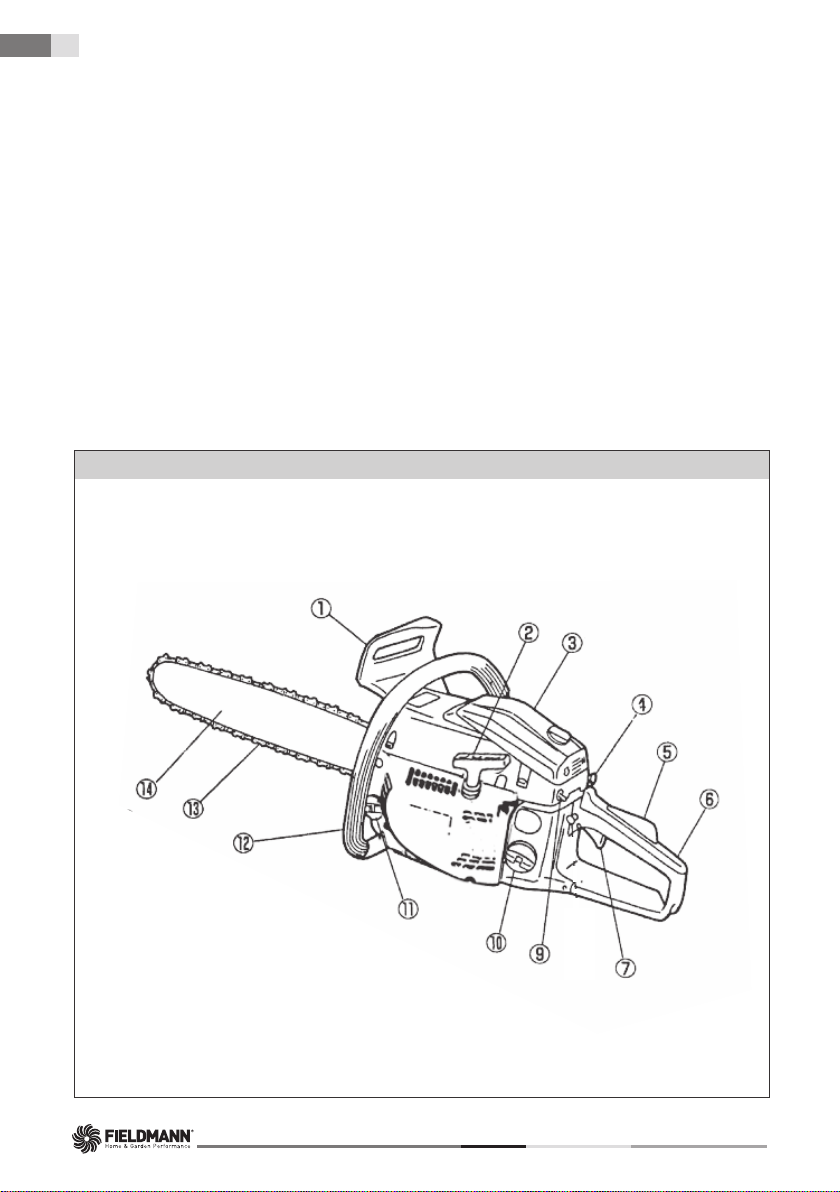

Machine description (see fig. 1)

Front hand guard

1 -

Starter

2 -

Air filter

3 -

Choke

4 -

Throttle safety lock

5 -

Rear handle

6 -

Throttle lever

7 -

A standard chainsaw package consists of the following components (fig. 1)

Drive unit

Bar cover

Guide

Chain

Spark plug wrench

Screw driver to adjust the carburettor

Screws and accessories

9 - Engine switch

10 - Fuel tank

11 - Oil tank

12 - Front handle

13 - Chain

14 - Guide

4. SAFETY INSTRUCTIONS

Caution! Safety guidelines in these instructions for use marked with the symbol

contain critical points that require attention to be paid when operating the machine to

prevent serious or fatal injuries. Please read through and observe the safety instructions

thoroughly.

Caution! This symbol marks instructions that must be observed in order to prevent

accidents which may lead to serious or fatal injuries.

Note: This symbol marks help or instructions that are useful when operating the machine.

Before using your machine

Please read the instructions for use carefully before using the machine.

Refrain from using the machine if you have used alcohol or addictive substances and/or if

you are tired or exhausted. Refrain from using the machine if you are on drugs that may affect

and/or limit your judgment abilities to safely operate the machine.

Refrain from using the machine in indoor space as the released gases contain hazardous

carbon monoxide.

Page 17

17 EN

INTSTRUCTIONS FOR USECHAINSAW

Safety instructions

Never use the machine under any of the following conditions:

- The work area is slippery or weather conditions do not allow you to keep stable position

when operating the machine.

- Under dark, strong fog or poor weather conditions that affect the work area visibility.

- In rain, storm or strong wind or other conditions that may be pose danger to using the

machine.

If you are using the chainsaw for the first time, please consult with a skilled worker before you

start.

Fatigue or physical exhaust may cause inattention that may lead to serious injury.

Please limit the machine operating time to about 10 minutes for a single use and try to have

10-20 minute rests between individual work sessions. Limit the total work amount to about 2

hours for a single day.

Make sure you always have the instructions for use with you to keep it ready when you need

it.

Make sure to include the instructions for use when selling, lending or transferring the

machine.

Never allow children or other persons who are not enough familiar with the instructions to use

the machine.

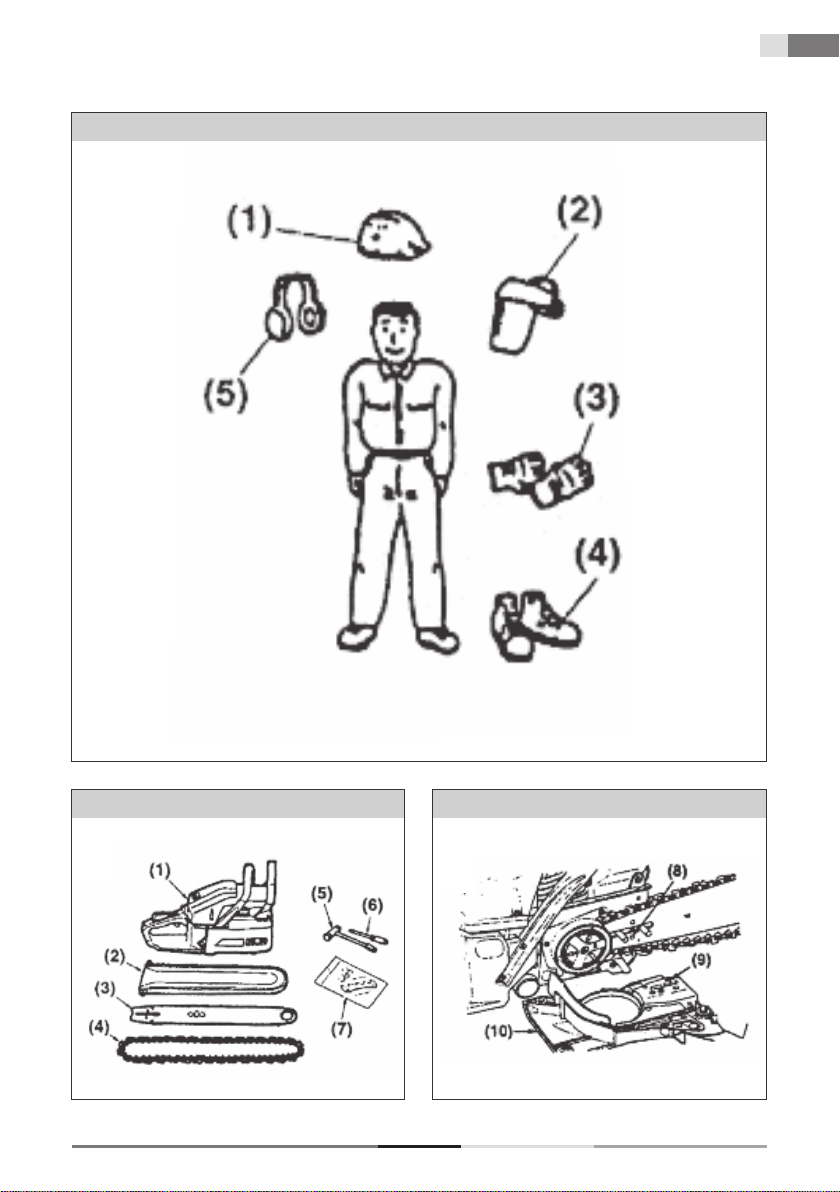

Working equipment and clothing (fig. 2)

You should wear the following working clothes and protective aids when operating the

chainsaw:

- Helmet (1)

- Face protective glasses or shield (2)

- Work gloves (3)

- Anti-slip work shoes (4)

- Hearing protection (5)

Also, you should take the following items with you:

- Attached tools and files

- Sufficient store of fuel and oil to lubricate the chain

- Accessories to delimit the work area (rope, warning signs)

- Whistle (to call help)

- Saw or axe (for possible removal of obstacles)

When working make sure you never wear loose clothes or jewels that might get caught on

the chainsaw. When working, never wear sandals or stay barefoot.

Page 18

FZP 4001-B

18EN

Operation

5. OPERATION

Fuel handling instructions

The machine‘s engine is designed to run on fuel mixture which is highly combustible. Never

store fuel containers or refuel in the vicinity of naked flame, stove, electrical installations,

welding jobs or other sources of heat or fire which may lead to inflammation.

It is forbidden to smoke when operating the machine or refueling.

When refueling, make sure that the machine is turned off and there are no sources of naked

flame in its vicinity.

Should the machine be stained with fuel, use a dry cloth to remove the stains.

After refueling, please screw back the tank cap, bring the machine at least 3m away from the

refueling place and then start it up.

Before starting the engine

Please check the work area, subject to be cut and cutting direction. Remove any obstacles.

Never launch any jobs until the work area is clean, you have secured a stable position and

have planned an escape route from a falling tree.

Please be very careful and keep passers-by and domestic animals out of the work area at a

distance of at least 2.5 times the length of the subject being cut.

Please check the machine for damaged, worn or missing parts. Please never use the

machine if damaged, improperly adjusted or incomplete. Make sure the chain stops rotating

when the throttle lever is released.

Engine startup

Always hold the chainsaw with both hands. Take a firm grip on the handle. When operating

the machine, keep all your body parts well away from the machine.

Before starting the engine, please make sure that the saw chain does not contact any

unwanted subject.

Operation

Keep the handles dry, clean and free of oil or fuel stains.

Do not touch damper, spark plug or other metal parts of the engine while the machine is

running or immediately after it stops - this poses risk of burning or electric shock.

Please pay extreme attention to cutting thin twigs and small trunks since such fragile material

may be caught by the chain, flung against the operator and thus result in a loss of balance.

When cutting sprung branches, remember they may be flung forward once their tension is

released by cutting the wood fibers.

Please check and remove any dry branches that might be released from the falling tree.

Please make sure the machine is shut down before you put it away.

Page 19

19 EN

INTSTRUCTIONS FOR USECHAINSAW

Operation | Maintenance

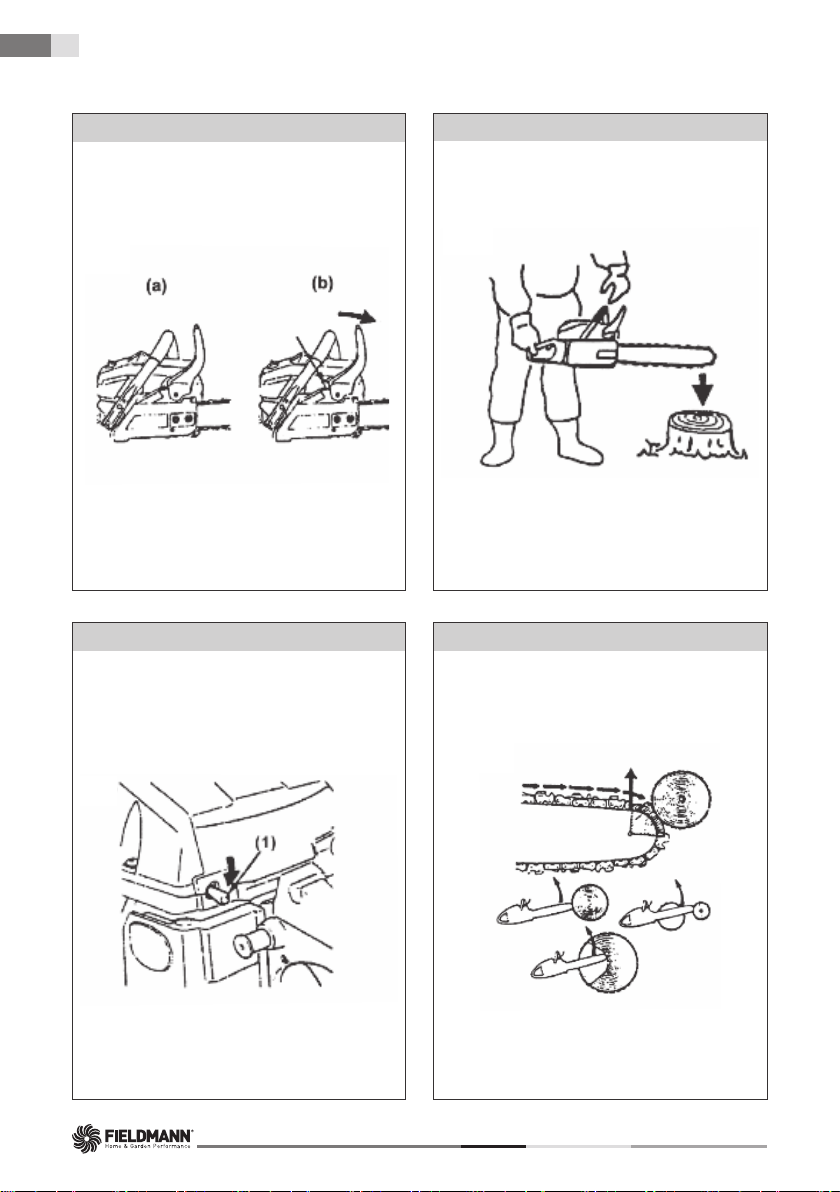

A kickback notice for the chainsaw user

CAUTION! A kickback may occur if the front of the bar comes into contact with the subject

or if the chain is clamped by material being cut in the section. Upon contacting the subject,

the saw may be flung backward with the bar moving up and back towards the operator.

Clamping the chain inside the section may lead to a fast flyback of the bar towards the

operator. Both of these reactions may result in losing your control over the saw with

subsequent serious injuries. Do not rely just on the saw safety elements. As the saw user, you

should always observe some rules to prevent accidents or damages.

If you are familiar with the kickback principle, you can reduce or eliminate the moment of

being surprised. Abrupt reactions lead to accidents.

When the engine is running, take a firm grip on the saw with both hands holding the rear

handle with your right hand and the front handle with your left hand. Hug the saw handles

firmly with your thumb pressing against other fingers. A firm grip helps to limit the kickback

and keep control over the saw.

The workplace must be free of any obstacles. While operating the saw, the bar loose end

must not brush against branch, trunk or any other obstacle.

Always cut at the engine‘s high speed.

In order to prevent losing your stable position during cutting, always make sure you are not

cutting above the level of your shoulders.

Observe manufacturer instructions for chain lubrication and sharpening.

Use only manufacturer specified spare chains and bars or equivalents.

6. MAINTENANCE

To ensure long and reliable service of your chainsaw, ensure that regular maintenance and

service inspections are made.

Before starting any maintenance or test jobs, always make sure that the engine is turned off.

CAUTION! The saw metal parts remain hot even after turning the engine off.

Please have any repair other than described in the instructions for use made in an authorized

service center.

Transport

Please do not carry the saw unless the engine is turned off and the bar protective guard is

attached.

Page 20

FZP 4001-B

20EN

Guide and chain installation

7. GUIDE AND CHAIN INSTALLATION

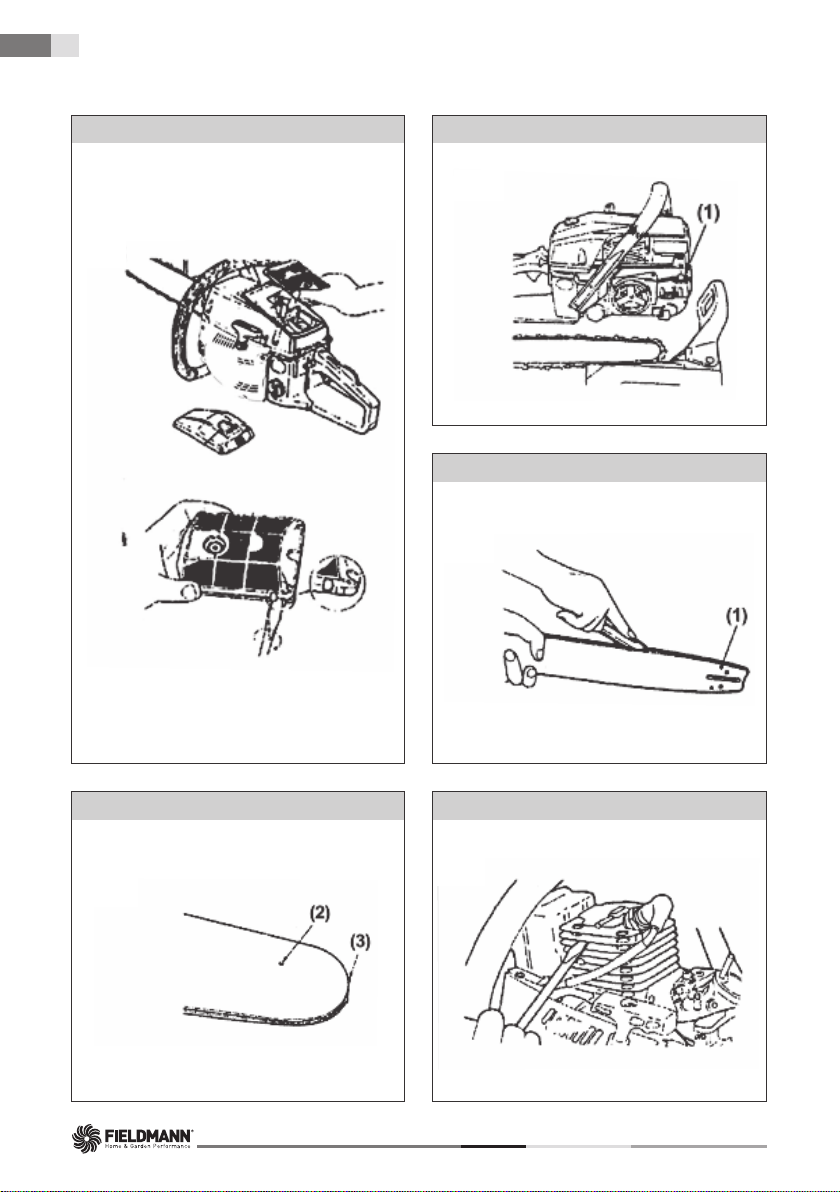

A standard chainsaw package consists of the following components (fig. 3):

Drive unit (1)

Bar cover (2)

Guide (3)

Chain (4)

Spark plug wrench (5)

Screw driver to adjust the carburettor (6)

Screws and accessories (7)

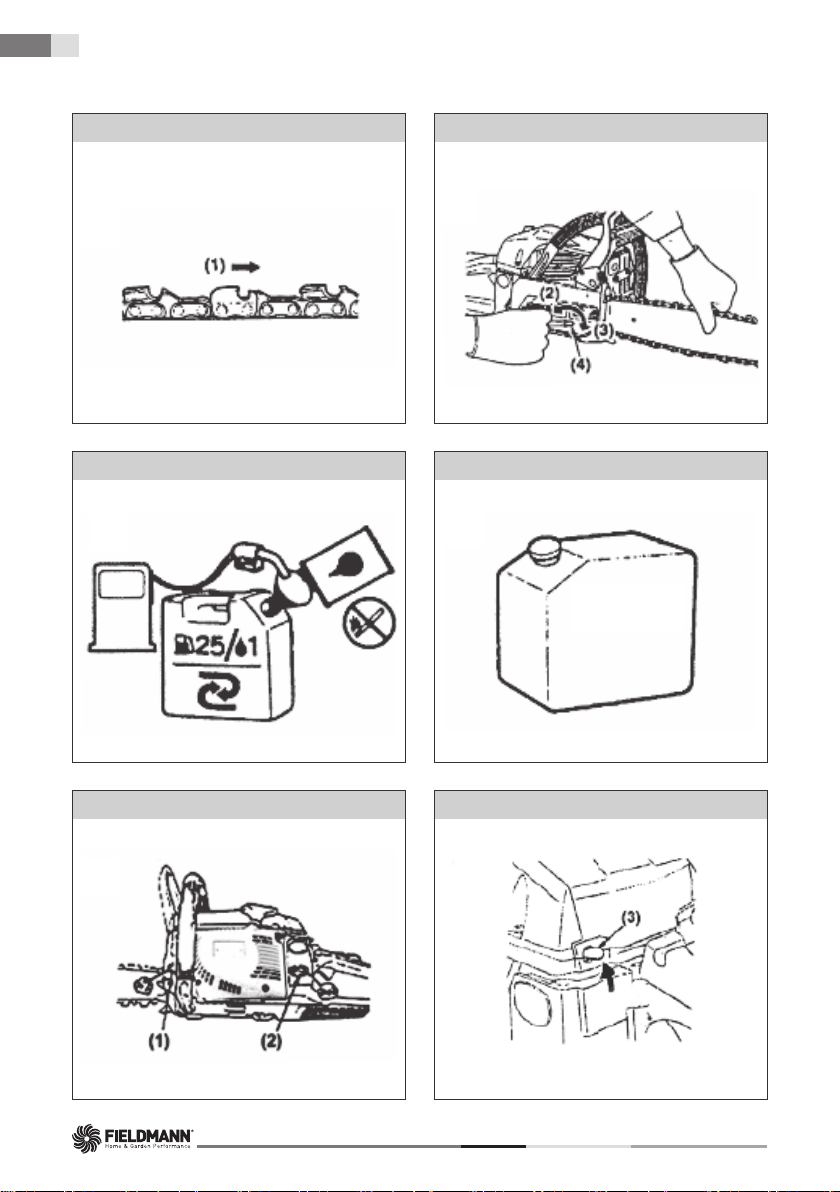

Remove the guide and the chain from the packaging and install them on the drive unit as follows:

CAUTION! The chain teeth are very sharp. For your safety, wear strong protective gloves.

Pull the protective frame toward the front handle to make sure that chain brake in not

engaged.

Loosen the nuts and remove the chain cover.

Install the attached spike on the drive unit.

Run the chain over the pinion and while holding the chain on the bar fix the bar on the drive unit.

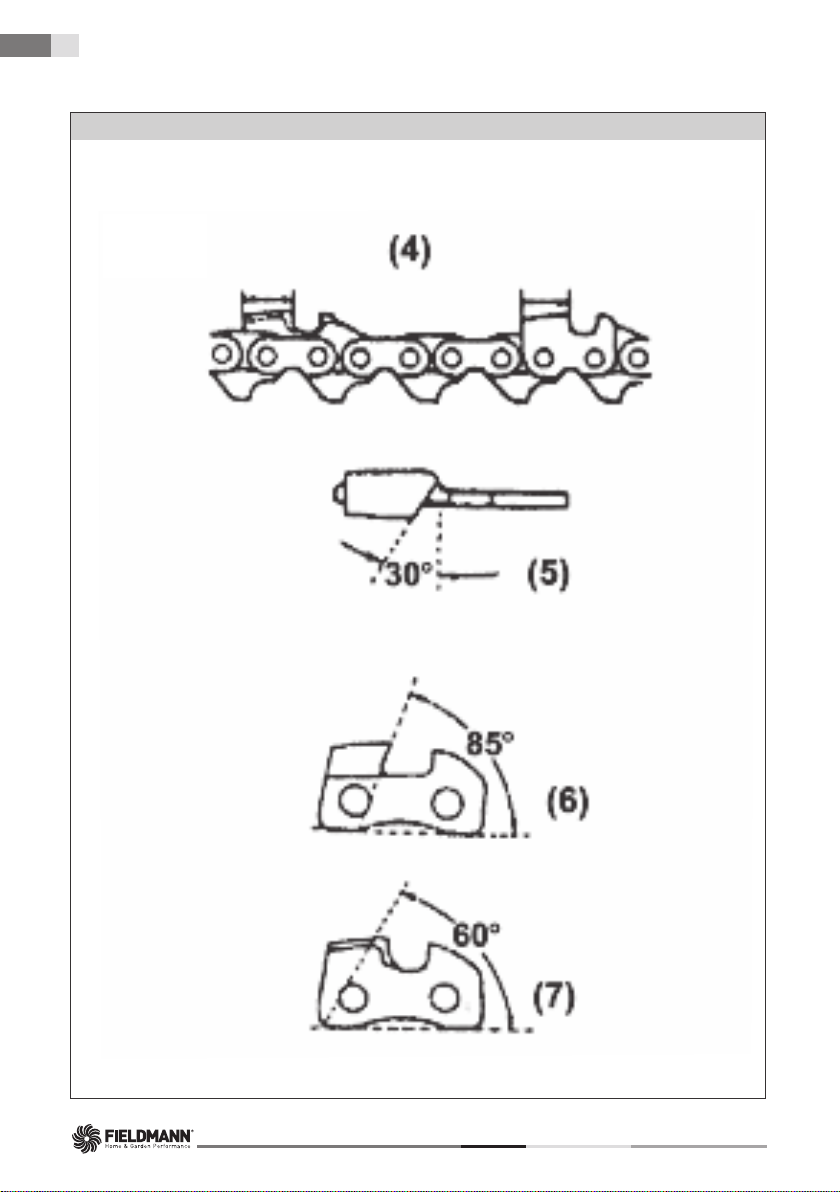

Tighten the chain cover tensioning nut down to the bottom hole on the guide (fig. 4):

Hole (8)

Tightening nut (9)

Chain cover (10)

Note: The chain must be attached to the bar in proper direction (fig. 4).

Moving direction

Attach the chain cover to the drive unit and tighten the nuts by hand.

Lift the bar loose end and turn the chain tensioning screw by a screwdriver, so that the chain

links will touch the bottom of the bar guide groove (fig. 6).

Lift the bar loose end and firmly tighten the bar nuts (12 - 15 Nm). While moving the chain by

hand, check free running and correct tensioning. Make any adjustments as necessary

Tighten the tensioning device bolt.

Loosen (2) (fig. 6).

Tighten (3) (fig. 6).

Tensioning device screw (4) (fig. 6).

Note: A newly installed chain will slightly extend after some time of use. Please check the

chain tensioning frequently as a loose chain may easily come out of the guide groove or

cause its fast wear.

Page 21

21 EN

INTSTRUCTIONS FOR USECHAINSAW

Fuel and chain lubrication oil | Motor operation

8. FUEL AND CHAIN LUBRICATION OIL

Fuel (fig. 7)

Mix common petrol (lead or lead-free, alcohol-free) with quality oil used in air-cooled two

stroke engines (manufacturer recommended oils).

Recommended fuel mixing ratios:

When using Petrol: Oil

up to 20 hours 20:1

over 20 hours 25:1

25:1 Mixing ratio table

Liters of petrol 1 2 3 4 5

Oil for two-stroke engines in ml 40 80 120 160 200

CAUTION! Do not smoke or use naked flame in fuel storage area and when handling the

fuel.Please mix and store the fuel in a dedicated petrol can only.

Note: Used fuel is the usual cause of most engine failures. Do not mix petrol with oil

designed for four-stroke engines.

Chain lubrication oil (fig. 8)

Please use engine oil SAE#10W~30 all year round, engine oil SAE#30~#40 in summer and

engine oil SAE#20 in winter (manufacturer recommended oils).

Note: Do not use already used or recycled oil; otherwise, oil pump damage could occur.

9. MOTOR OPERATION

Controls

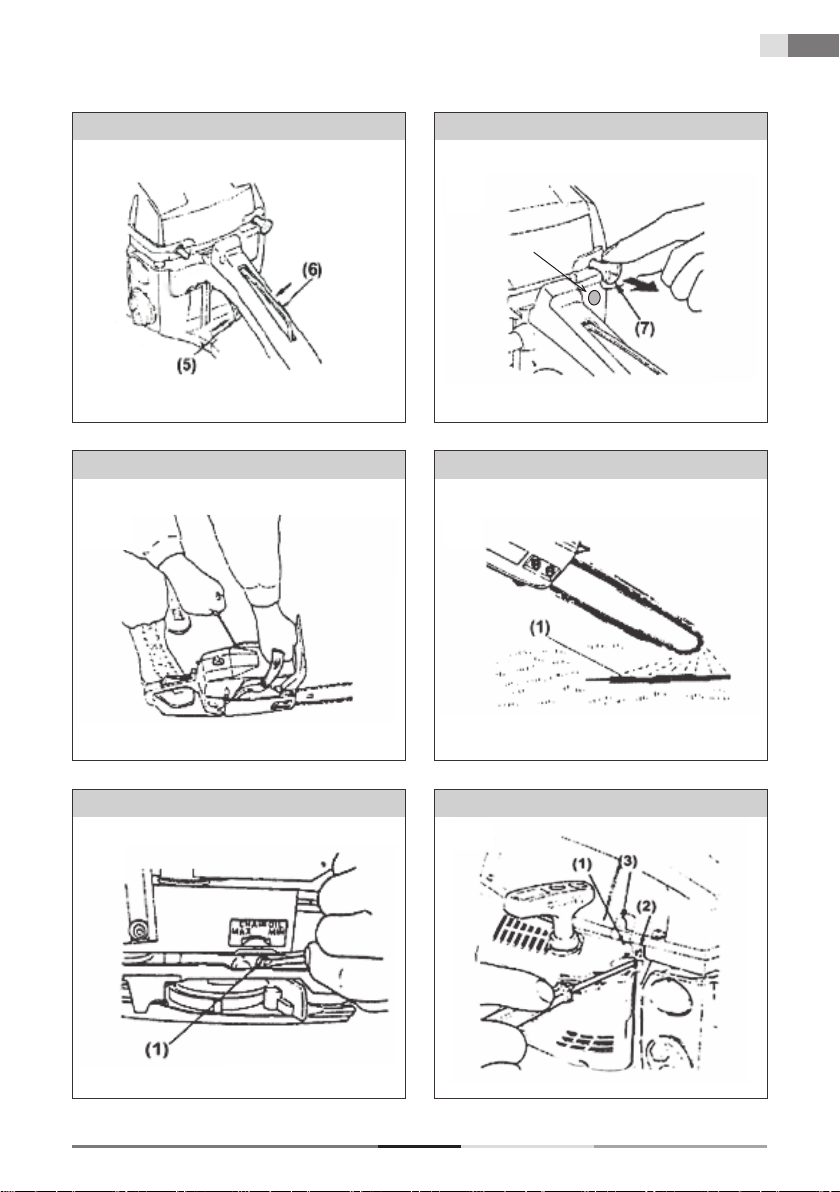

Hole for filling oil for chain lubrication (1) (Fig. 9)

Refuel hole (2) (Fig. 9)

Engine switch (3) (Fig. 10)

Accelerator control lever (5) (Fig. 11)

Safety lock of accelerator control lever (6) (Fig.11)

Choke (7) (Fig.12)

Fuel pump/primer (8) (Fig. 12)

Starter (2) (Fig. 1)

Page 22

FZP 4001-B

22EN

Motor operation

ENGINE STARTUP

Refuel and fill chain lubrication oil (1+2) (Fig. 9)

Set engine switch lever to position I (3) (Fig.10)

Rinse carburetor with pump / fuel primer, press 3 – 4 times (8) (Fig.12)

Pull out choke to the extreme position (7) (Fig.12)

Pull saw starter (2) (Fig. 1) until it show the signs of starting. Then switch off the choke by

pressing the accelerator control lever (5) (Fig. 11) (7) (Fig.12).

CAUTION! Never press the choke manually

Then pull the starter (2) (Fig. 1) until the engine starts

Before you start sawing, let the engine warm up

Note: When the engine is warm, there is no need to use choke at repeated start

CAUTION! DO NOT start the saw when you are holding it by your hands. This is very

dangerous as the chain might come into contact with your body.

If the engine failed to start, press the choke lever and pull the starter rope again.

Pull out the throttle control lever to allow the engine to warm up.

CAUTION! Keep away from the chain as the chain will start running once the engine is

started.

Lubrication check

Once the engine is started, allow the chain to run at low speed and check if the chain is

splashing oil, as shown on fig. 14.

Chain lubrication oil (1) (fig. 14).

The oil flow can be set with a screwdriver at the bottom hole on the clutch side. Set according

to your work conditions. (fig. 15).

Screw to set the oil flow (1) (fig. 15).

Note: When the fuel is consumed, the oil tank is almost empty. Please refill the oil tank on

each refueling.

Carburettor setup (fig. 16)

The carburettor comes adjusted from the factory. If it‘s necessary to make a new setting due

to altitude changing or working conditions, please have the saw adjusted by a qualified

dealer. Wrong setting may lead to machine damage. Before setting the carburettor, make sure

that the fuel and air filter is clean and the fuel is properly mixed. If you make the setup on your

own, please follow the procedure below carefully.

Note: Do not adjust the carburettor unless the chain is in place.

Page 23

23 EN

INTSTRUCTIONS FOR USECHAINSAW

Motor operation

Stop the engine and turn the H and L screws until they both stop. Do not apply excessive

force! Then, turn the screws back within the range below:

„H“ screw: 1 & ¼

„L“ screw: 1 & ¼

Start the engine and allow it to worm up by pulling out the throttle lever (i.e. at low speed).

Turn the L screw slowly clockwise up to the point where the idle speed reaches its maximum.

Then, turn the screw head back counterclockwise by a quarter of turn (¼) .

Turn the idle speed adjustment screw (T) counterclockwise until the chain stops. If the idle

speed is too low, turn the screw clockwise.

Perform a test cut and set the „H“ screw to an optimum performance, not to a maximum

speed.

L (1) screw (fig. 16)

H (2) screw (fig. 16)

Idle speed adjustment screw (3) (fig. 16)

Carburettor anti-freeze device

When operating the saw at temperatures of 0 to 5 °C and high humidity, ice may form inside

the carburettor. This leads to performance reduction or irregular machine running. Thus,

installing a dedicated accessory allows the saw to heat up the air fed from the right of the

cylinder head to prevent ice formation. Under normal conditions, the saw operates in default

mode, i.e. the one used right at the time of purchase. If ice formation occurs, the saw must be

switched to the anti-freeze mode before use (fig. 17).

Chain brake

This saw incorporates an automatic brake to stop the chain rotation after a kickback occurs

during cutting operation. The brake activates automatically by inertial force acting on the

weight located under the front cover. This brake can be also operated manually by lowering

the front protective frame towards the bar (fig. 18)

Lifting the front protective frame until a click is heard will release the brake again.

CAUTION! Before each use, check the chain brake correct function by following the

procedure below.

Turn the engine off.

Hold the saw horizontally, release your hand from the front handle and catch the front of the

bar on a stub or a wood chunk. The brake must engage. The braking intensity varies with the

bar length (fig.19). If the brake fails to operate, please have the saw repaired by an authorized

service. If the brake has engaged but the engine is still running at high speed, the clutch will

overheat and be damaged. If the brake engages during operation, release the throttle lever to

turn the engine off immediately

Page 24

FZP 4001-B

24EN

Motor operation | Cutting

Engine shutdown

Release the throttle lever and leave the engine running at idle speed for several minutes.

Set the switch to „0“ position (STOP). (fig. 20).

Switch (1) (fig. 20).

10. CUTTING

CAUTION! Please read the „Safe operation“ chapter before you continue. We recommend

that you gain some experience by cutting smaller chunks. In this way, you will become

familiar with the saw.

Always observe safety instructions. The chainsaw is designed to cut wood only. Cutting other

materials is inadmissible. Vibrations and kickback vary with different materials. Do not use

the saw as a lever to lift, move or destroy objects. Do not place the saw on fixed stands. It

is forbidden to attach parts or fixtures to the saw other than those specified in the technical

documentation.

You don‘t need to press the saw into the cut. When the engine is running at full throttle, apply

just a slight pressure on the saw.

If the chain gets caught inside the cut, don‘t try to pull to release but use a wedge or a lever to

expand the cut instead.

Kickback protection (fig. 21)

This saw incorporates a chain brake which immediately stops the chain should a kickback

occur if it works correctly. The chain brake function should be checked before each saw use.

Run the saw at full throttle for 1 - 2 seconds and then lower the front guard. The chain must

stop immediately even at full engine speed. If the chain stops slowly or doesn‘t stop at all,

please replace the brake jaws and the clutch drum before further use.

It is extremely important that the chain brake function and chain sharpening status should be

checked before each use in order to keep necessary safety level of the saw in case of a

kickback. Overriding safety devices, incorrect maintenance or using inappropriate bar or

chain may lead to serious injuries in case of a kickback.

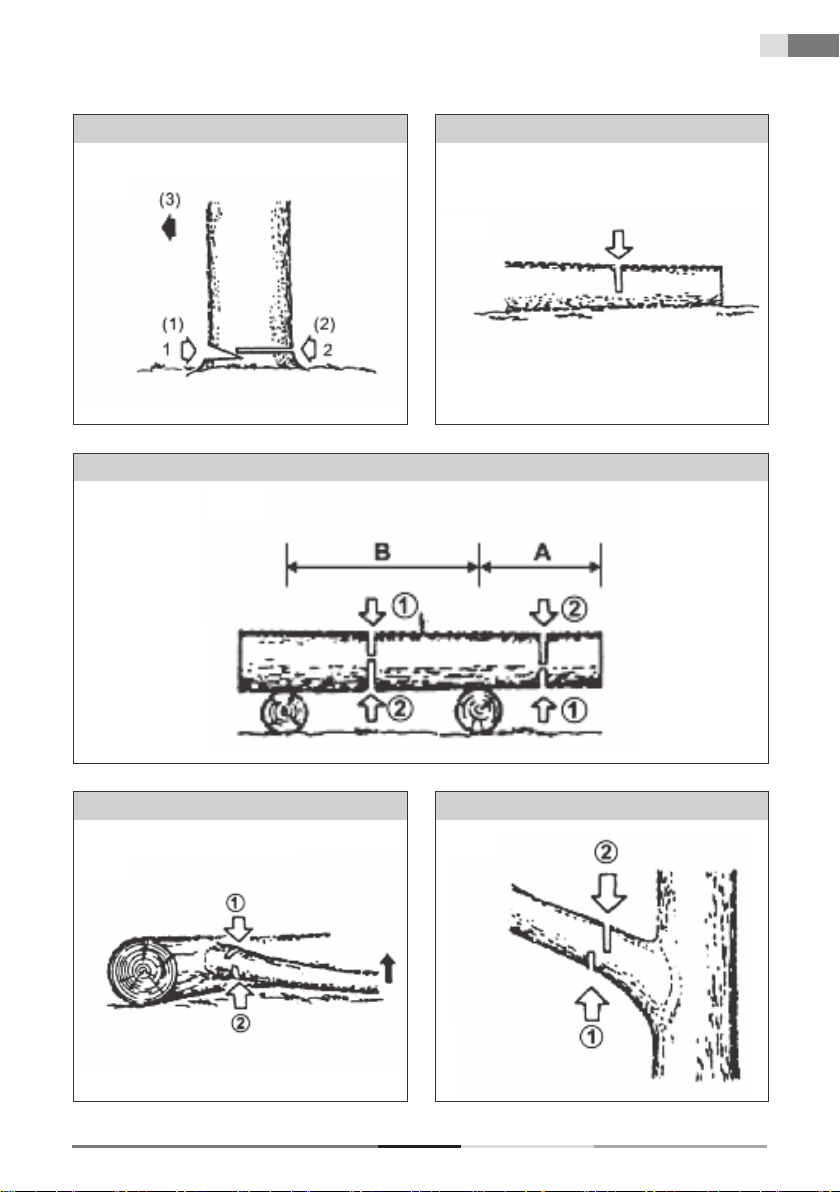

Tree felling (fig. 22)

Please determine the tree falling direction considering wind direction, tree inclination and

location of branches as well as all other factors before you start the work.

The tree surrounding area must be open, free of obstacles and allow your stable position to

be taken. The escape route must be passable.

Please make a wedge notch down to a third of the trunk diameter on the side where the tree is

supposed do fall.

On the opposite side, please make a separation cut above the wedge notch level.

Page 25

25 EN

INTSTRUCTIONS FOR USECHAINSAW

Cutting

CAUTION! When felling trees, please warn other persons in the neighborhood of a potential

hazard.

Wedge notch (1) (fig. 22)

Separation cut (2) (fig. 22)

Falling direction (3) (fig. 22)

Debranching and trunk felling

CAUTION! Always keep a stable position. Keep off the chunks.

The chunk being cut may roll away. Always stand above the chunk being cut especially when

working on a slope

Take precautions against the saw kickback by following the instructions described in the

„Safe operation“ chapter.

Before you start, please evaluate the direction of the cut trunk bending force. Make sure

you always make the final cut on the opposite side of the trunk bending force action to

prevent clamping the bar inside the section.

A Chunk lying on the ground (fig. 23).

Cut in half, then turn around and finish the cut from the opposite side.

B Chunk above the ground (fig. 24).

In the „A“ section, make a cut up to a third of the chunk from beneath, then finish the cut from

above. In the „B“ section, make a cut up to a third, then finish the cut from beneath.

Debranching a fallen tree (fig. 25).

At first, determine the direction in which the branch is bent. Then, make an initial cut from the

bending side and then finish the cut from the opposite side.

CAUTION! A bent branch may fling.

Debranching a standing tree (fig. 26).

Start cutting from beneath, finish from top downward.

CAUTION! When working, never use unstable platforms or ladders.

Do not lean.

Do not cut above the height of your shoulders.

Always hold the saw with both hands when cutting.

Page 26

FZP 4001-B

26EN

Maintenance

11. MAINTENANCE

CAUTION! Before cleaning, inspecting or repairing the saw it is required that the engine

should be turned off and cold and the glow plug removed in order to prevent inadvertent start.

Maintenance after each use

Air filter:

Loosen the nut and remove the air filter lid. Remove the filter element and brush away any

dust deposits. If the filter element is clogged by dust, split it into two parts and wash them in

petrol. If you are using compressed air, blow from inside. (fig. 27)

Lubrication hole:

Please remove the bar and check the lubrication hole continuity. (fig. 28)

Guide:

Once the bar is removed, please clear the dust from grooves and lubrication hole. (fig. 29)

Lubricate the pinion hub at the front of the bar through the lubrication hole. When assembling

the two parts, please press the hem

until it clicks. (fig. 30)

Lubrication hole (1) (fig. 28) (fig. 29)

Grease hole (2) (fig. 30)

Pinion (3) (fig. 30)

Other parts:

Please check for possible oil leaks, loose covers and damage to the main sections, mainly

at the mounting points of handle and bar. Any problems that are found must be fixed before

further use of the saw.

Points of regular maintenance

Cylinder ribwork:

Dust deposits on the cylinder ribwork causes the engine to overheat. Regularly check and

clean the cylinder ribwork. The air filter and the cylinder head cover must be removed before

this action. When reassembling the cover, the wiring with bushings must be positioned

correctly. (fig. 31)

Note: Make sure that the air inlet holes are clean.

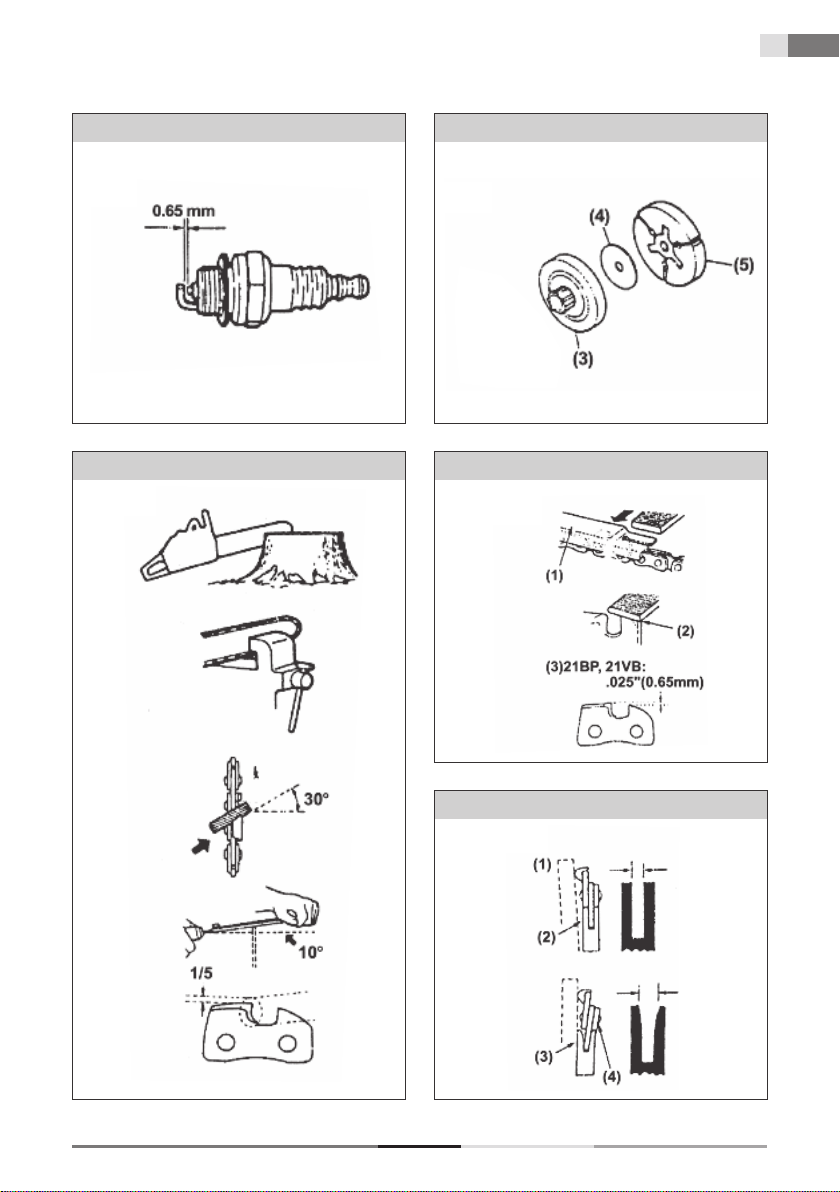

Spark plug (fig. 32):

If necessary, clean the electrodes with a wire brush and adjust the gap between them to

0,65 mm.

Geared pinion (fig. 33):

Check the pinion for flaws and excessive wear caused by the chain. Replace the pinion if the

wear is high. Never use a new chain together with a worn pinion or vice versa.

Page 27

27 EN

INTSTRUCTIONS FOR USECHAINSAW

Maintenance | Chain and guide maintenance

Fuel filter:

Disassemble the filter and wash in petrol or replace with new if necessary.

Oil filter:

Disassemble the filter and wash in petrol or replace with new if necessary.

12. CHAIN AND GUIDE MAINTENANCE

Chain

CAUTION To ensure safe and faultless saw operation, it is required that the chain should be

sharp at all times.

Chain sharpening rules:

CAUTION! Wear protective gloves

Before sharpening:

Apply the file to the cutting link and push directly forward. Keep the file in the position as

shown. (fig. 34) After sharpening of each link, check the depth using a feeler gauge; file down

to adjust as shown if necessary. (fig. 35).

CAUTION! The front edge must be round in order to reduce the risk of kickback or clamping

inside the section.

Suitable feeler gauge (1) (fig. 35)

Feeler gauge reference level (2) (fig. 35)

Link/edge standard depth (3) (fig. 35)

Each cutting link must have equal length and edge bevels as shown. (fig. 37)

Cutting link length (4) (fig. 37)

File angle (5) (fig. 37)

Vertical bevel (6) (fig. 37)

Edge cutting angle (7) (fig. 37)

Chain guide

Turn the chain guide over from time to time to prevent unilateral wear.

The bar groove must be rectangular at all times. Check the bar groove for wear. To check,

apply a ruler to the bar and the outer edge of the cutting links. If there is a gap between them,

the bar is OK. Otherwise, the bar is worn. This means the bar needs a repair or a replacement.

(fig. 36).

Ruler (1) (fig. 36).

Gap (2) (fig. 36).

Zero gap (3) (fig. 36).

The chain tilts (4) (fig. 36).

Page 28

FZP 4001-B

28EN

Specifications

13. SPECIFICATIONS

Chain saw type: ....................................................................................................................................... FZP 4001 B

Weight (without a guard and chain): ..................................................................................................... 4.3 (Kg)

Dimensions (without a guard and chain): ................................................................... 360x160x165 (mm)

Fuel: ......................................................................... mixture of regular petrol and two stroke oil in ratio 1:25

(oil recommended by the manufacturer)

Fuel tank capacity: ............................................................................................................................................ 310ml

Chain lubrication oil: ................................. loss lubrication oil (oil recommended by the manufacturer)

Oil tank capacity: ............................................................................................................................................... 210ml

Engine: ......................................................................................................................................................... 37.2 (cm3)

Maximum engine power: ........................................................................................................ 1.2 kW /8500rpm

Maximum engine speed with sawing accessories: .................................................................... 10,000rpm

Maximum engine speed at idling: ........................................................................................................ 2,600rpm

Sprocket (pinion): ....................................................................................................................................... 7Tx0.325

Chain pitch: .................................................................................................................................................. 0.325 (in)

Chain saw inclination: ...................................................................................................................................... 0.058

Strip dimension: ................................................................................................................................. 40cm /16 (in)

Oil injection system ............................................................................................. Automatic pump with a setter

Specified noise level: .......................................................................................................... 110 dB(A)Instructions

Manual - language version only.

Page 29

29 EN

INTSTRUCTIONS FOR USECHAINSAW

Declaration of conformity

14. DECLARATION OF CONFORMITY

EC Declaration of Conformity

Fast ČR, a.s., Černokostelecká 251 01 Říčany u Prahy, phone: 323204111, declares with binding

effect, that petrol, chain saw Fieldmann FZP 4001-B (the year of manufacture is indicated on a

type label and is followed by a serial number of the machine), complies with the requirements of

DIRECTIVE OF THE COUNCIL:

No. 2006/42/EC, 2006/95/EC, (approval certificate no.: MTS/ICL/E11070719)

No. 2004/26/EC, exhaust emission,

and has been tested in compliance with the following standards:

EN ISO 11681-2:2009

EN ISO 12100:2010

The company FAST ČR, a.s. is entitled to act on behalf of the manufacturer.

CE label: 13

Říčany, 29 November 2013

name stamp signature

Petr Uher

quality manager

Page 30

FZP 4001-B

30

EN Disposal

15. DISPOSAL

INSTRUCTIONS AND INFORMATION ON USED PACKAGE DISPOSAL

Put the used packaging material to the place designated for waste disposal by a

municipality.

The machine and its accessories are made of various materials, e.g. of

metal and plastics. Hand-over damaged components to sorted waste. Get

yourselves informed at a respective authority.

This product meets all fundamental requirements of EU directives relating to it.

Changes of the text, design and technical specifications can be done without prior notice

and we reserve the right for the changes.

Page 31

Obsah

Řetězová pila

NÁVOD K OBSLUZE

Děkujeme vám, že jste si zakoupili tuto řetězovou pilu. Než ji začnete používat,

přečtěte si, prosím, pozorně tento návod k obsluze a uschovejte jej pro případ dalšího

použití.

OBSAH

OBRAZOVÁ PŘÍLOHA ..................................................................................................................... 2

VŠEOBECNÉ BEZPEČNOSTNÍ PŘEDPISY .............................................................................. 33

1.

Důležitá bezpečnostní upozornění

Obal

Návod k použití

VYSVĚTLENÍ ŠTÍTKŮ S POKYNY NA STROJI .......................................................................... 34

2.

POPIS STROJE A OBSAH DODÁVKY ...................................................................................... 36

3.

BEZPEČNOSTNÍ POKYNY ............................................................................................................ 36

4.

Před použitím stroje

Pracovní vybavení a oděv

OBSLUHA ............................................................................................................................................ 37

5.

Pokyny při manipulaci s palivem

Před nastartováním motoru

Startování motoru

Obsluha

ÚDRŽBA .............................................................................................................................................. 39

6.

Přeprava

INSTALACE VODÍCÍ LIŠTY A ŘETĚZU ....................................................................................... 39

7.

PALIVO A OLEJ PRO MAZÁNÍ ŘETĚZU ................................................................................. 41

8.

Palivo

Olej pro mazání řetězu

OBSLUHA MOTORU ...................................................................................................................... 41

9.

Ovládací prvky

Startování motoru

Kontrola mazání

Nastavení karburátoru

Mechanismus proti zamrzání karburátoru

Brzda řetězu

Vypnutí motoru

CZ31

ŘETĚZOVÁ PILA NÁVOD K OBSLUZE

Page 32

FZP 4001-B

CZ 32

Obsah

ŘEZÁNÍ ................................................................................................................................................ 44

10.

Ochrana proti zpětnému rázu

Kácení stromu

ÚDRŽBA .............................................................................................................................................. 46

11 .

Údržba po každém použití

Místa pravidelné údržby

ÚDRŽBA ŘETĚZU A VODÍCÍ LIŠTY ............................................................................................ 47

12.

Řetěz

Vodící lišta řetězu

TECHNICKÉ ÚDAJE ........................................................................................................................ 48

13.

PROHLÁŠENÍ O SHODĚ .............................................................................................................. 49

14.

LIKVIDACE ......................................................................................................................................... 50

15.

ZÁRUČNÍ LIST ................................................................................................................................. 136

ZÁRUČNÍ PODMÍNKY ................................................................................................................ 137

Page 33

CZ33

ŘETĚZOVÁ PILA NÁVOD K OBSLUZE

Všeobecné bezpečnostní předpisy

1. VŠEOBECNÉ BEZPEČNOSTNÍ PŘEDPISY

Důležitá bezpečnostní upozornění

Výrobek pečlivě vybalte a dejte pozor, abyste nevyhodili žádnou část obalového materiálu

dříve, než najdete všechny součásti výrobku.

Výrobek uchovávejte na suchém místě mimo dosah dětí.

Čtěte všechna upozornění a pokyny. Zanedbání při dodržování varovných upozornění

a pokynů mohou mít za následek úraz elektrickým proudem, požár a/nebo těžká poranění.

Obal

Výrobek je umístěn v obalu bránícím poškozením při transportu. Tento obal je surovinou a lze jej

proto odevzdat k recyklaci.

Návod k použití

Než začnete se strojem pracovat, přečtěte si následující bezpečnostní předpisy

a pokyny k používání. Seznamte se s obslužnými prvky a správným používáním zařízení. Návod

pečlivě uschovejte pro případ pozdější potřeby. Minimálně po dobu záruky doporučujeme

uschovat originální obal včetně vnitřního balicího materiálu, pokladní doklad a záruční list.

V případě přepravy zabalte stroj zpět do originální krabice od výrobce, zajistíte si tak maximální

ochranu výrobku při případném transportu (např. stěhování nebo odeslání do servisního

střediska).

Poznámka: Předáváte-li stroj dalším osobám, předejte jej společně s návodem.

Dodržování přiloženého návodu k obsluze je předpokladem řádného používání stroje. Návod

k obsluze obsahuje rovněž pokyny pro obsluhu, údržbu a opravy.

Výrobce nepřebírá odpovědnost za nehody nebo škody vzniklé následkem

nedodržování tohoto návodu.

Page 34

FZP 4001-B

CZ 34

Vysvětlení štítků s pokyny na stroji

2. VYSVĚTLENÍ ŠTÍTKŮ S POKYNY NA STROJI

Symbol pro doplnění „SMĚS PALIVA“

Umístění: víko palivové nádrže

Symbol pro doplnění „OLEJE PRO

MAZÁNÍ ŘETĚZU“ Umístění: víko olejové

nádrže

Symbol pro vypnutí/zapnutí. Motor se

přepne do pozice „O“ (STOP) a zastaví

se. Umístění:levá zadní část jednotky

Symbol pro sytič. Povytažením sytiče se

sytič zavře. Umístění: pravá zadní část

jednotky

Symbol pro vstřikování oleje pro

mazání řetězu

Směr „MIN“ – vstřikování oleje se sníží

Směr „MAX“ – přísun oleje se zvýší

Umístění: spodní část spojky

Page 35

CZ35

ŘETĚZOVÁ PILA NÁVOD K OBSLUZE

Vysvětlení štítků s pokyny na stroji

Pozice H šroubu (slouží k nastavení

vysokých otáček)

Pozice L šroubu (slouží k nastavení

nízkých otáček)

Pozice T slouží k nastavení

volnoběžných otáček

Umístění: levá zadní část jednotky

Před použitím stroje si pozorně přečtěte

návod k obsluze.

Při obsluze stroje noste ochranné

pomůcky jako ochranné brýle,

sluchátka apod.

Při obsluze řetězové pily používejte

vždy obě ruce.

Pozor! Nebezpečí zpětného rázu

Varování! Pozor!

Page 36

FZP 4001-B

CZ 36

Popis stroje a obsah dodávky | Bezpečnostní pokyny

3. POPIS STROJE A OBSAH DODÁVKY

Popis stroje (viz obr. 1)

Ochranný kryt přední ruky

1 -

Startér

2 -

Vzduchový filtr

3 -

Sytič

4 -

Bezpečnostní pojistka plynu

5 -

Zadní rukojeť

6 -

Páčka plynu

7 -

Standardní balení řetězové pily sestává z těchto součástí (obr. 1)

Pohonná jednotka

Kryt lišty

Vodící lišta

Řetěz

Klíč na zapalovací svíčku

Šroubovák pro nastavení karburátoru

Závrtné šrouby s příslušenstvím

9 - Spínač motoru

10 - Palivová nádrž

11 - Olejová nádrž

12 - Přední rukojeť

13 - Řetěz

14 - Vodící lišta

4. BEZPEČNOSTNÍ POKYNY

Pozor! Bezpečnostní pokyny uvedené v tomto návodu k obsluze označené symbolem

obsahují kritické body, na které je potřeba dát pozor při obsluze stroje, aby nedošlo k vážným

či smrtelným poraněním. Přečtěte si prosím důkladně bezpečnostní instrukce a dodržujte je.

Pozor! Tento symbol označuje pokyny, které musí být dodržovány, aby nedošlo k nehodám,

které mohou mít za následek vážné či smrtelné zranění.

Poznámka: Tento symbol označuje nápovědu nebo pokyny užitečné při obsluze přístroje.

Před použitím stroje

Před použitím stroje si pozorně přečtěte návod k obsluze.

Přístroj nepoužívejte, jste-li pod vlivem alkoholu nebo omamných látek, jste-li unavení nebo

vyčerpaní. Přístroj nepoužívejte v případě užívání léků, které by mohly ovlivnit a omezit vaše

rozhodovací schopnosti při bezpečné obsluze stroje.

Nepoužívejte stroj ve vnitřních prostorách, uvolněné plyny obsahují škodlivý oxid uhelnatý.

Nikdy nepoužívejte přístroj za podmínek uvedených níže:

- Pokud je pracovní plocha kluzká nebo v případě, že klimatické podmínky Vám nedovolují

při obsluze stroje udržet stabilní postoj.

Page 37

CZ37

ŘETĚZOVÁ PILA NÁVOD K OBSLUZE

Bezpečnostní pokyny | Obsluha

- Pokud je tma, silná mlha, nebo za špatných klimatických podmínek, které omezují viditelnost

pracovní plochy.

- Za deště, bouřky, silného větru nebo za jiných podmínek, kterou mohou být nebezpečné

při používání stroje.

Pokud pilu používáte poprvé, před začátkem prací se prosím poraďte se zkušeným

pracovníkem.

V důsledku únavy nebo fyzického vyčerpání může dojít k nepozornosti, která může mít

za následek vážné poranění

Omezte dobu obsluhy stroje na cca 10 minut v případě jednoho použití a snažte se mezi

jednotlivými pracemi zhruba 10-20 minut odpočívat. Omezte celkové množství prací během

jednoho dne na zhruba 2 hodiny.

Ujistěte se, že máte návod k obsluze při sobě, pokud byste jej potřebovali použít.

Pokud přístroj prodáváte, půjčujete nebo předáváte, ujistěte se, že jej předáváte spolu

s návodem k obsluze.

Nikdy nedovolte dětem, nebo jiným osobám, které nejsou dostatečně seznámeny s návodem

k obsluze, aby používali tento přístroj.

Pracovní vybavení a oděv (obr. 2)

Při obsluze řetězové pily byste měli nosit následující pracovní oblečení a ochranné pomůcky:

- Helmu (1)

- Ochranné brýle nebo ochranný štít na obličej (2)

- Pracovní rukavice (3)

- Protiskluzové pracovní boty (4)

- Ochranná sluchátka (5)

A dále byste sebou měli mít

- Přiložené nástroje a soubory

- Dostatečnou rezervu paliva a oleje pro řetěz

- Pomůcky, kterými vyznačíte pracovní oblast (lano, varovné značky)

- Píšťalku (pro přivolání pomoci)

- Pilu nebo sekeru (pro případné odstranění překážek)

Při práci nikdy nepoužívejte volný oděv, šperky, které by mohly být zachyceny pilou. Při práci

nepoužívejte sandály nebo nepracujte naboso.

5. OBSLUHA

Pokyny při manipulaci s palivem

Motor stroje je navržen tak, že využívá směs paliva, která je vysoce hořlavá. Nikdy neskladujte

nádoby s palivem nebo nedoplňujte palivo v blízkosti otevřeného ohně, kamen, elektrických

rozvodů, svařovacích prací nebo jiného zdroje tepla nebo ohně, které by mohlo vézt

ke vznícení.

Page 38

FZP 4001-B

CZ 38

Obsluha

Při obsluze stroje nebo při doplňování paliva je zakázáno kouřit.

V případě doplňování paliva se ujistěte, že je stroj vypnutý a že se v jeho blízkosti nevyskytuje

žádný zdroj otevřeného ohně.

Pokud dojde k potřísnění přístroje palivem, použijte suchý hadřík a skvrny vysušte.

Po doplnění paliva zašroubujte uzávěr palivové nádrže a odneste přístroj do vzdálenosti

minimálně 3m od místa, kde bylo palivo doplněno a poté stroj nastartujte.

Před nastartováním motoru

Zkontrolujte pracovní plochu, předmět řezání a směr řezání. Odstraňte překážky.

Nikdy nezačínejte práce, pokud není pracovní plocha čistá, nemáte zajištěn stabilní postoj

a nemáte naplánovánu únikovou cestu před padajícím stromem.

Dbejte zvýšené opatrnosti a udržujte kolemjdoucí a domácí zvířata mimo pracovní prostor

a to ve vzdálenosti minimálně 2,5 násobku vzdálenosti řezaného objektu.

Zkontrolujte poškozené, opotřebené nebo chybějící součásti stroje. Nikdy stroj nepoužívejte,

je-li poškozený, nesprávně seřízený nebo je nekompletní. Ujistěte se, že řetěz se přestane točit,

je-li páčka plynu uvolněná.

Startování motoru

Pilu vždy držte oběma rukama. Rukojeť držte pevně stisknutou. Při práci s přístrojem udržujte

všechny části těla v dostatečné vzdálenosti od přístroje.

Před nastartováním motoru dbejte na to, aby se řetěz pily nedostal do kontaktu s nežádoucím

objektem.

Obsluha

Udržujte rukojeti suché, čisté a bez skvrn od oleje nebo paliva.

Nedotýkejte se tlumiče, zapalovací svíčky nebo jiných kovových částí motoru, pokud je stroj

zapnutý nebo těsně po jeho vypnutí - hrozí riziko popálení nebo úrazu elektrickým proudem.

Věnujte mimořádnou pozornost řezání tenkých větví a kmínků, protože křehký materiál může

být zachycen řetězem, vymrštěn proti obsluze a může tak způsobit ztrátu rovnováhy.

Při řezání napružených větví pamatujte na možnost jejich vymrštění po uvolnění napětí

přeříznutím vláken dřeva.

Zkontrolujte a odstraňte suché větve, které by se mohly uvolnit z padajícího stromu.

Pokud přístroj odkládáte, ujistěte se, že je vypnutý.

Upozornění uživatele řetězové pily na zpětný ráz

POZOR! Ke zpětnému rázu může dojít, když se přední část lišty dostane do kontaktu

s objektem nebo když řezaný materiál sevře řetěz v řezu. Při kontaktu s objektem může dojít

k vymrštění pily nazad se současným pohybem lišty nahoru a vzad směrem k obsluze.

Sevření řetězu v řezu může vést k rychlému zpětnému pohybu lišty směrem k obsluze. Obě

Page 39

CZ39

ŘETĚZOVÁ PILA NÁVOD K OBSLUZE

Obsluha | Údržba | Instalace vodící lišty a řetězu

tyto reakce mohou vést ke ztrátě kontroly nad pilou s následnými těžkými úrazy. Nespoléhejte

pouze na bezpečnostní zařízení pily. Jako uživatel pily musíte neustále dodržovat několik

pravidel k předcházení úrazům nebo škodám.

Pokud jste seznámeni s principem zpětného rázu, můžete snížit nebo vyloučit moment

překvapení. Nečekané reakce vedou k nehodám.

Je-li motor v chodu, pilu pevně uchopte oběma rukama, pravou ruku na zadní rukojeti a levou

ruku na přední. Rukojeti pily pevně obemkněte palcem směřujícím proti ostatním prstům.

Pevné uchopení pomůže omezit zpětný ráz a udržet pilu pod kontrolou.

Na pracovišti nesmějí být žádné překážky. Volný konec lišty nesmí při práci s pilou zavadit

o větev, kmen nebo jinou překážku.

Řezejte při vysokých otáčkách motoru.

Při řezání nesmí dojít ke ztrátě stabilního postoje, řezání provádějte nejvýše do výšky ramen.

Dodržujte pokyny výrobce k mazání a ostření řetězu.

Používejte pouze náhradní řetězy a lišty uvedené výrobcem nebo jejich ekvivalenty.

6. ÚDRŽBA

Chcete-li, aby Vám řetězová pila dlouho a spolehlivě sloužila, dbejte na pravidelnou údržbu

a dodržujte pravidelné servisní prohlídky.

Před zahájením údržbových a kontrolních prací se vždy ujistěte, že je motor vypnutý.

POZOR! Kovové části pily zůstávají i po vypnutí motoru horké.

Každou jinou opravu, která není uvedena v návodu k obsluze, svěřte kompetentnímu

servisnímu středisku.

Přeprava

Pilu přenášejte pouze za předpokladu, že je motor vypnutý, a lišta chráněna ochranným

krytem.

7. INSTALACE VODÍCÍ LIŠTY A ŘETĚZU

Standardní balení řetězové pily sestává z těchto součástí (obr. 3) :

Pohonná jednotka (1)

Kryt lišty (2)

Vodící lišta (3)

Řetěz (4)

Klíč na zapalovací svíčku (5)

Šroubovák pro nastavení karburátoru (6)

Závrtné šrouby s příslušenstvím (7)

Page 40

FZP 4001-B

CZ 40

Instalace vodící lišty a řetězu

Vyjměte vodící lištu a řetěz z obalového materiálu a instalujte na pohonnou jednotku následujícím

způsobem :

POZOR! Zuby řetězu pily jsou velmi ostré. Pro svoji bezpečnost použijte silné ochranné

rukavice.

Zatažením za ochranný rám směrem k přední rukojeti se ujistěte, že není sepnutá brzda

řetězu.

Povolte matice a sejměte kryt řetězu.

Namontujte přiložený hrot na pohonnou jednotku

Řetěz navlékněte na pastorek a při současném přidržování řetězu na liště, namontujte lištu

k pohonné jednotce. Dotáhněte napínací matici na krytu řetězu ke spodnímu otvoru vodící lišty

(obr. 4) :

Otvor (8)

Napínací matice (9)

Kryt řetězu (10)

Poznámka: Řetěz musí být na lištu nasazen ve správném směru (obr. 4).

Směr pohybu

Na pohonnou jednotku nasaďte kryt řetězu a matice dotáhněte rukou.

Přizvedněte volný konec lišty a šroubovákem otáčejte šroubem pro napínání řetězu tak,

aby se články řetězu dotýkaly spodní strany vodicí drážky v liště (obr. 6).

Volný konec lišty přizvedněte a pevně dotáhněte matice lišty (12 – 15 Nm). Řetěz posouvejte

rukou, zkontrolujte volný chod a správné napnutí řetězu. Pokud je třeba, upravte nastavení.

Utáhněte šroub napínacího zařízení.

Uvolnit (2) (obr. 6).

Utáhnout (3) (obr. 6).

Šroub napínacího zařízení (4) (obr. 6).

Poznámka: Nově instalovaný řetěz se po určité době používání mírně prodlouží. Napnutí

řetězu kontrolujte často, protože volný řetěz se snadno může vyvléknout z vodicí drážky nebo

způsobit její rychlé opotřebení.

Page 41

CZ41

ŘETĚZOVÁ PILA NÁVOD K OBSLUZE

Palivo a olej pro mazání řetězu | Obsluha motoru

8. PALIVO A OLEJ PRO MAZÁNÍ ŘETĚZU

Palivo (obr. 7)

Smíchejte běžný benzín (olovnatý či bezolovnatý, bezalkoholový) s kvalitním olejem

používaným pro vzduchem chlazené 2-taktní motory (oleje doporučené výrobcem).

Doporučený poměr paliva:

Při požití Benzín: Olej

do 20 hodin 20:1

přes 20 hodin 25:1

25:1 Tabulka poměru mísení

Litrů benzínu 1 2 3 4 5

Olej pro 2-taktní motory v ml 40 80 120 160 200

POZOR! V místech skladování paliva a při manipulaci s palivem nekuřte a nepoužívejte

otevřený oheň. Palivo míchejte a skladujte pouze ve speciálním benzínovém kanystru.

Poznámka: Příčinou většiny poruch motoru je zpravidla použité palivo. Nemíchejte benzín

s olejem určeným pro 4 - taktní motory.

Olej pro mazání řetězu (obr. 8)

Celoročně používejte motorový olej SAE#10W~30, motorový olej SAE#30~#40 v létě, a v

zimě SAE#20 (oleje doporučené výrobcem).

Poznámka: Nepoužívejte již použitý olej, ani olej regenerovaný; hrozí poškození olejového

čerpadla.

9. OBSLUHA MOTORU

Ovládací prvky

Otvor pro doplnění oleje na mazání řetězu (1) ) (obr. 9)

Otvor pro doplnění paliva (2) (obr. 9)

Spínač motoru (3) (obr. 10)

Ovládací páčka plynu (5) (obr. 11)

Pojistka páčky plynu (6) (obr.11)

Sytič (7) (obr.12)

Pumpička paliva/primer (8) (obr. 12)

Startér (2) (obr. 1)

Page 42

FZP 4001-B

CZ 42

Obsluha motoru

Startování motoru

Doplňte palivo a olej na mazání řetězu (1+2) ) (obr. 9)

Páčku spínače motoru nastavte do polohy I(3) (obr.10)

Propláchněte karburátor pomocí pumpičky / primer paliva, stlačte 3x – 4x(8) (obr.12)

Vytáhněte sytič do krajní polohy(7) (obr.12)

Tahejte za startér pily (2) (obr. 1) do té doby, než motor projeví tendenci nastartovat. Poté

stiskem ovládací páčky plynu (5) (obr. 11) vypněte sytič (7) (obr.12).

POZOR! Sytič nikdy nezamačkávejte manuálně

Poté tahejte za startér (2) (obr. 1) dokud motor nenaskočí

Před započetím samotného řezání nechte motor zahřát

Poznámka: Při opětovném startu, je-li motor zahřátý, není již potřeba používat sytič

POZOR! Pilu NESPOUŠTĚJTE, pokud ji držíte v rukou. Je to velmi nebezpečné, protože řetěz

by se mohl dostat do kontaktu s vaším tělem.

Jestliže motor nenaskočil, zamáčkněte páčku sytiče a opět zatáhněte za startér.

Povytáhněte ovládací páčku plynu, aby se motor zahřál.

POZOR! Udržujte odstup od řetězu, protože po spuštění motoru se řetěz rozeběhne.

Kontrola mazání

Po spuštění motoru nechejte řetěz běžet na nízké otáčky a kontrolujte, zda řetěz rozstřikuje

olej, jak je znázorněno na obrázku (obr. 14).

Olej na mazání řetězu (1) (obr. 14)

Průtok oleje lze nastavit šroubovákem v otvoru ve spodní části na straně spojky. Nastavte

podle pracovních podmínek. (obr. 15).

Šroub pro nastavení průtoku oleje (1) (obr. 15)

Poznámka: Při spotřebování paliva je olejová nádrž téměř prázdná. Olejovou nádrž

doplňujte při každém doplňování paliva.

Nastavení karburátoru (obr. 16)

Karburátor je nastaven z výroby. Pokud je třeba provést změnu nastavení kvůli změně

nadmořské výšky nebo v důsledku pracovních podmínek, předejte pilu k nastavení

zkušenému prodejci. Chybné nastavení může vést k poškození zařízení. Před nastavováním

karburátoru se ujistěte, že palivový a vzduchový filtr je čistý a palivo je řádně promícháno.

Pokud provádíte nastavení svépomocí, postupujte pečlivě podle níže uvedeného popisu.

Poznámka: Karburátor nastavujte s nasazeným řetězem.

Page 43

CZ43

ŘETĚZOVÁ PILA NÁVOD K OBSLUZE

Obsluha motoru

Zastavte motor a otáčejte šrouby H a L do té doby, až se oba zastaví. Nepoužívejte přílišnou

sílu! Následně jimi otočte zpátky v níže uvedeném rozsahu:

Šroub „H“ 1 & ¼

Šroub „L“ 1 & ¼

Spusťte motor tak, abych se zahřál povytažením páčky plynu (tj. při nízkých otáčkách).

Šroubem L pomalu otáčejte po směru hodinových ručiček až do bodu, kdy volnoběžné otáčky

dosáhnou maxima. Poté hrot šroubu otočte o čtvrt (¼) otáčky nazpět proti směru hodinových

ručiček.

Šroub volnoběžných otáček (T) nastavujte v protisměru chodu hodin tak, až se řetěz zastaví.

Pokud jsou volnoběžné otáčky příliš nízké, otáčejte šroubem ve směru chodu hodinových

ručiček.

Proveďte zkušební řez a nastavte šroub H na optimální výkon, ovšem nikoliv na maximální

otáčky.

Šroub L (1) (obr. 16)

Šroub H (2) (obr. 16)

Seřizovací šroub volnoběhu (3) (obr. 16)

Mechanismus proti zamrzání karburátoru

Při práci s pilou při teplotách 0 až 5 °C a současně vysoké vlhkosti se může v karburátoru

tvořit led. Tím dojde ke snížení výkonu nebo k neklidnému chodu stroje.Proto pila umožňuje

instalací příslušného doplňku ohřívat vzduch přiváděný z pravé strany hlavy válce a zabránit

tak tvorbě ledu. Za obvyklých podmínek se pila používá v normálním pracovním režimu, tzn.

v režimu ve kterém byla bezprostředně při nákupu. Pokud dochází k tvorbě ledu, je nutné pilu

před použitím přepnout do režimu ochrany proti zamrzání (obr. 17).

Brzda řetězu

Tato pila je vybavena automatickou brzdou, která zastaví rotaci řetězu poté, co během

provozu při řezání dojde k zpětnému nárazu (tzv. kickback). Brzda je spouštěna automaticky

působením setrvačné síly na závaží umístěné pod předním krytem. Tuto brzdu lze také

obsluhovat ručně sklopením předního ochranného rámu dolů směrem k liště (obr. 18)

Brzda se opět uvolní zdvižením předního ochranného rámu až do slyšitelného zaklapnutí.

POZOR! Před každým použitím si následujícím způsobem ověřte, že je brzda řetězu funkční.

Vypněte motor.

Pilu držte vodorovně, uvolněte ruku z přední rukojeti a přední částí lišty zachyťte za pařez

nebo kus dřeva. Brzda musí sepnout. Intenzita brzdění se liší podle délky lišty (obr. 19).

Pokud je brzda neúčinná, předejte pilu k opravě do specializovaného servisu. Pokud brzda

zabrzdila, ale motor se dále točí vysokými otáčkami, dojde k přehřátí a poškození spojky.

Jestliže se brzda aktivuje při práci, ihned motor vypněte uvolněním páčky plynu.

Page 44

FZP 4001-B

CZ 44

Obsluha motoru | Řezání

Vypnutí motoru

Uvolněte páčku plynu a motor nechejte po několik minut běžet na volnoběh.

Spínač nastavte do polohy „0“ (STOP). (obr. 20)

Spínač (1) (obr. 20)

10. ŘEZÁNÍ

POZOR! Než budete pokračovat, přečtěte si kapitolu „Bezpečná obsluha“. Doporučujeme

získat zkušenosti při řezáním menších polen. Tím se také s pilou seznámíte.

Vždy dodržujte bezpečnostní pokyny. Řetězovou pilu lze používat pouze k řezání dřeva.

Je zakázáno řezat jiné materiály. Vibrace a zpětný ráz se pro různé materiály liší. Pilu

nepoužívejte jako páku ke zvedání, přemisťování nebo rozbíjení objektů. Pilu neumisťujte

na pevná stanoviště. Je zakázáno k pile připevňovat součásti nebo přípravky jiné než

uvedené v technické dokumentaci.

Pilu není nutné do řezu tlačit. Když motor běží na plný plyn, pilu přitlačujte jen zlehka.

Dojde-li k zachycení řetězu v řezu, nezkoušejte jej uvolnit tahem, ale řez roztáhněte klínem

nebo pákou.

Ochrana proti zpětnému rázu (obr. 21)

Tato pila je vybavena brzdou řetězu, která, pokud pracuje správně, v případě zpětného rázu

ihned řetěz zastaví. Činnost brzdy řetězu je nutno zkontrolovat před každým použitím pily. Pilu

spusťte na plný plyn po dobu 1 - 2 sekund a poté sklopte přední ochranný kryt. Řetěz se musí

ihned zastavit i při plných otáčkách motoru. Pokud se řetěz zastavuje pomalu nebo nezastaví

vůbec, před dalším použitím vyměňte čelisti brzdy a buben spojky.

Je mimořádně důležité před každým použitím zkontrolovat funkčnost brzdy řetězu a stav

nabroušení řetězu, aby byla zachována potřebná úroveň bezpečnosti pily při zpětném rázu.

Odstranění bezpečnostního příslušenství, při nesprávné údržbě či při použití nevhodné lišty

nebo řetězu může v případě zpětného rázu dojít k těžkým úrazům.

Kácení stromu (obr. 22)

Rozhodněte o směru pádu stromu s přihlédnutím ke směru větru, náklonu stromu a poloze

větví a zvažte také všechny ostatní faktory, před započetím práce.

Plocha okolo stromu musí být volná, bez překážek, musí umožňovat stabilní postoj. Úniková

cesta musí být průchozí.

Do třetiny průměru kmenu proveďte klínový zářez z té strany, na kterou má strom spadnout.

Z opačné strany proveďte oddělovací řez v úrovni nad klínovým zářezem.

POZOR! Při kácení stromů upozorněte ostatní osoby v okolí na potenciálně hrozící

nebezpečí.

Page 45

CZ45

ŘETĚZOVÁ PILA NÁVOD K OBSLUZE

Řezání

Klínový zářez (1) (obr. 22)

Oddělovací zářez (2) (obr. 22)

Směr pádu (3) (obr. 22)

Odvětvování, krácení kmenů

POZOR! Vždy udržujte stabilní postoj. Nestoupejte na polena.

Řezané poleno se může odvalovat. Zejména při řezání ve svahu stůjte vždy nad řezaným

polenem.

Předcházejte zpětnému rázu pily postupováním v souladu s instrukcemi uvedenými v kapitole

„Bezpečná obsluha“.

Před zahájením práce zhodnoťte směr síly způsobující ohýbání řezaného kmene. Závěrečný

řez vždy provádějte z opačné strany, než působí ohýbající síla, aby nedošlo k sevření lišty

v řezu.

A Poleno ležící na zemi (obr. 23)

Přeřízněte do poloviny, poté otočte a dořízněte z opačné strany.

B Poleno nad zemí (obr. 24)

V části „A“ proveďte řez zdola do třetiny polena a poté řez dokončete shora. V části „B“

proveďte řez shora do třetiny a poté řez dokončete zdola.

Odvětvování padlého stromu (obr. 25)

Nejdříve zjistěte, na kterou stranu je větev ohnutá. Poté proveďte počáteční řez ze strany

ohybu a poté dokončete řez z opačné strany.

POZOR! Ohnutá větev se může vymrštit.

Odvětvování stojícího stromu (obr. 26).

Začínejte řezem zespodu, dokončujte shora dolů.

POZOR! Při práci nepoužívejte nestabilní plošiny nebo žebříky.

Nevyklánějte se.

Řezání provádějte nejvýše do výšky ramen.

Při řezání vždy držte pilu oběma rukama.

Page 46

FZP 4001-B

CZ 46

Údržba

11. ÚDRŽBA

POZOR! Před čištěním, kontrolou nebo opravou pily musí být motor vypnutý a studený

a musí být vyjmutá žhavící svíčka, aby nemohlo dojít k neplánovanému spuštění.

Údržba po každém použití

Vzduchový filtr:

Povolte matici a sejměte víko vzduchového filtru. Vyjměte vložku filtru a kartáčem odstraňte

ulpělý prach. Je-li vložka filtru zanesená prachem, rozložte je na 2 části a properte je v

benzínu. Pokud používáte stlačený vzduch, provádí se vyfoukání směrem zevnitř. (obr. 27)

Mazací otvor:

Demontujte lištu a zkontrolujte průchodnost mazacího otvoru. (obr. 28)

Vodící lišta:

Po demontáži lišty odstraňte prach z drážek a mazacího otvoru. (obr. 29)

Mazacím otvorem namažte náboj pastorku v přední části lišty. Při skládání obou částí stlačte

lem až do zaskočení. (obr. 30)

Mazací otvor (1) (obr. 28) (obr. 29)

Otvor pro mazací tuk (2) (obr. 30)

Pastorek (3) (obr. 30)

Ostatní části:

Zkontrolujte případné úniky oleje, uvolněné úchyty a poškození hlavních částí, zejména v

místech uchycení rukojeti a lišty. Případně zjištěné závady musejí být před dalším použitím

pily opraveny.

Místa pravidelné údržby

Žebrování válce:

Prach usazený na žebrování válce způsobuje přehřívání motoru. Žebrování válce pravidelně

kontrolujte a čistěte. Před tím je potřeba sejmout vzduchový filtr a kryt hlavy válce. Při zpětné

instalaci krytu je nutné správně umístit vodiče a jejich průchodky. (obr. 31)

Poznámka: Ujistěte se, že otvory pro vstup vzduchu jsou volné.

Zapalovací svíčka (obr. 32):

V případě nutnosti očistěte elektrody drátěným kartáčem a nastavte mezeru mezi nimi na

0,65 mm.

Ozubený pastorek (obr. 33):

Zkontrolujte výskyt trhlin a nadměrného opotřebení řetězem. Pokud je opotřebení velké,

pastorek vyměňte. Nikdy nepoužívejte nový řetěz s opotřebeným pastorkem a opačně.

Palivový filtr:

Filtr rozeberte a properte v benzinu, anebo jej v případě potřeby, nahraďte novým.

Olejový filtr:

Filtr rozeberte a properte v benzinu, anebo jej, v případě potřeby, nahraďte novým.

Page 47

CZ47

ŘETĚZOVÁ PILA NÁVOD K OBSLUZE

Údržba řetězu a vodící lišty

12. ÚDRŽBA ŘETĚZU A VODÍCÍ LIŠTY

Řetěz

POZOR! Pro zajištění bezpečného a bezvadného provozu pily je nezbytné, aby byl řetěz

stále ostrý.

Pravidla pro broušení řetězu:

POZOR! Používejte ochranné rukavice

Před broušením:

Pilník přiložte k řezacímu článku a zatlačte přímo vpřed. Pilník udržujte ve vyobrazené pozici.

(obr. 34) Po nabroušení každého řezného článku zkontrolujte hloubku spárovou měrkou;

v případě potřeby ji upravte pilníkem podle obrázku. (obr. 35).

POZOR! Přední hrana musí být zaoblená, aby se snížilo riziko zpětného rázu nebo sevření

v řezu.

Vhodná spárová měrka (1) (obr. 35)

Vztažná úroveň měrky (2) (obr. 35)

Standardní hloubka článku/hrany (3) (obr. 35)

Každý řezný článek musí mít shodnou délku a úhly hran podle obrázku. (obr. 37)

Délka řezného článku (4) (obr. 37)

Úhel pilníku (5) (obr. 37)

Svislý úkos (6) (obr. 37)

Řezný úhel hrany (7) (obr. 37)

Vodící lišta řetězu

Lištu příležitostně překlápějte, aby se předešlo jednostrannému opotřebení.

Drážka v liště musí být stále pravoúhlá. Kontrolujte opotřebení drážky v liště. Kontrolu

provádějte přiložením pravítka k liště a k vnější hraně řezných článků. Pokud je mezi nimi

mezera, je lišta v pořádku. V opačném případě je lišta opotřebená. Pak je nutno lištu opravit

nebo vyměnit. (obr. 36).

Pravítko (1) (obr. 36).

Mezera (2) (obr. 36).

Nulová mezera (3) (obr. 36).

Řetěz se naklání (4) (obr. 36).

Page 48

FZP 4001-B

CZ 48

Technické údaje

13. TECHNICKÉ ÚDAJE

Typ řetězové pily ...................................................................................................................................... FZP 4001 B

hmotnost (bez ochranného krytu a řetězu) .......................................................................................... 4.3 (Kg)

Rozměry (bez ochranného krytu a řetězu) .................................................................. 360x160x165 (mm)

Palivo ............................ Směs Natural a dvoutaktní olej v poměru 1:25 (oleje doporučený výrobcem)

Kapacita palivové nádrže ............................................................................................................................... 310ml

Olej pro mazáni řetězu ...................................... Olej pro ztrátové mazání (oleje doporučený výrobcem)

Kapacita olejové nádrže ................................................................................................................................. 210ml

Motor ........................................................................................................................................................... 37,2 (cm3)

Maximální výkon motoru ..........................................................................................................1,2 kW /8500rpm

Maximální rychlost motoru s řezacím příslušenstvím ................................................................ 10 000rpm

Maximální rychlost motoru při volnoběhu ......................................................................................... 2 600rpm

Ozubené kolo (pastorek) ......................................................................................................................... 7Tx0.325

Rozteč zubů řetězu .................................................................................................................................... 0.325 (in)

Sklon řetězové pily ............................................................................................................................................. 0.058

Rozměr lišty ......................................................................................................................................... 40cm /16 (in)

Systém vstřikovaní oleje ...................................................................... Automatická pumpa se seřizovačem

Deklarovaná úroveň hluku ...................................................................................................................... 110 dB(A)

Návod k použití v originálním jazyce.

Page 49

CZ49

ŘETĚZOVÁ PILA NÁVOD K OBSLUZE

Prohlášení o shodě

14. PROHLÁŠENÍ O SHODĚ

ES Prohlášení o shodě

Fast ČR, a.s., Černokostelecká 251 01 Říčany u Prahy, tel.:323204111, závazně prohlašujeme,

že benzínová, řetězová pila Fieldmann FZP 4001-B (rok výroby je vyznačen na typovém štítku a je

následován výrobním číslem stroje, splňuje předpisy SMĚRNICE RADY:

ES č. 2006/42/EC, 2006/95/IEC, (číslo schvalovacího certifikátu:MTS/ICL/E11070719)

ES č.2004/26/ES emise výfukových plynů

a byl testován ve shodě s níže uvedenými normami:

EN ISO 11681-2:2009

EN ISO 12100:2010

Firma FAST ČR, a.s. je oprávněna jednat jménem výrobce.

CE label: 13

V Říčanech dne 29. 11. 2013

jméno razítko podpis

Petr Uher

manažer kvality

Page 50

CZ 50 Likvidace

15. LIKVIDACE

POKYNY A INFORMACE O NAKLÁDÁNÍ S POUŽITÝM OBALEM

Použitý obalový materiál odložte na místo určené obcí k ukládání odpadu.

Stroj a jeho příslušenství jsou vyrobeny z různých materiálů, např. z kovu a

plastů. Poškozené součástky odevzdejte do tříděného sběru. Informujte se u

příslušného úřadu.

Tento výrobek splňuje veškeré základní požadavky směrnic EU, které se na něj

vztahují.

Změny v textu, designu a technických specifi kací se mohou měnit bez předchozího

upozornění a vyhrazujeme si právo na jejich změnu.

FZP 4001-B

Page 51

51

Obsah

Reťazová píla

NÁVOD NA OBSLUHU

Ďakujeme vám, že ste si zakúpili túto reťazovú pílu. Skôr, než ju začnete používať,

prečítajte si pozorne tento návod na obsluhu a uschovajte ho na ďalšie použitie.

OBSAH

OBRAZOVÁ PRÍLOHA ..................................................................................................................... 2

VŠEOBECNÉ BEZPEČNOSTNÉ PREDPISY ............................................................................. 53

1.

Dôležité bezpečnostné upozornenia

Obal

Návod na použitie

VYSVETLENIE ŠTÍTKOV S POKYNMI NA STROJI ................................................................. 54

2.

POPIS STROJA A OBSAH DODÁVKY .................................................................................... 56

3.

BEZPEČNOSTNÉ POKYNY ......................................................................................................... 56

4.

Pred použitím stroja

Pracovné vybavenie a odev

OBSLUHA ............................................................................................................................................ 58

5.

Pokyny pri manipulácii s palivom

Pred naštartovaním motora

Štartovanie motora

Obsluha

ÚDRŽBA .............................................................................................................................................. 59

6.

Preprava

INŠTALÁCIA VODIACEJ LIŠTY A REŤAZE .............................................................................. 60

7.

PALIVO A OLEJ NA MAZANIE REŤAZE .................................................................................. 61

8.

Palivo

Olej na mazanie reťaze

OBSLUHA MOTORA ..................................................................................................................... 61

9.

Ovládacie prvky

Štartovanie motora

Kontrola mazania

Nastavenie karburátora

Mechanizmus proti zamŕzaniu karburátora

Brzda reťaze

Vypnutie motora

SK

REŤAZOVÁ PÍLA

NÁVOD NA OBSLUHU

Page 52

FZP 4001-B

52SK

Obsah

REZANIE .............................................................................................................................................. 64

10.

Ochrana proti spätnému rázu

Rúbanie stromu

ÚDRŽBA ............................................................................................................................................. 66

11 .

Údržba po každom použití

Miesta pravidelnej údržby

ÚDRŽBA REŤAZE A VODIACEJ LIŠTY ..................................................................................... 67

12.

Reťaz

Vodiaca lišta reťaze

TECHNICKÉ ÚDAJE ...................................................................................................................... 68

13.

VYHLÁSENIE O ZHODE ................................................................................................................ 69

14.

LIKVIDÁCIA ....................................................................................................................................... 70

15.

ZÁRUČNÝ LIST ............................................................................................................................... 136

ZÁRUČNÉ PODMIENKY ............................................................................................................ 137

Page 53

53

REŤAZOVÁ PÍLA

SK

Všeobecné bezpečnostné predpisy

1. VŠEOBECNÉ BEZPEČNOSTNÉ PREDPISY

Dôležité bezpečnostné upozornenia

Výrobok starostlivo vybaľte a dajte pozor, aby ste nevyhodili žiadnu časť obalového materiálu

skôr, ako nájdete všetky súčasti výrobku.

Výrobok uschovávajte na suchom mieste mimo dosahu detí.

Čítajte všetky upozornenia a pokyny. Zanedbanie pri dodržovaní varovných upozornení a

pokynov môžu mať za následok úraz elektrickým prúdom, požiar a/alebo ťažké poranenia.

Obal

Výrobok je umiestnený v obale brániacom poškodeniu pri transporte. Tento obal je surovinou a je

možné ho preto odovzdať na recykláciu.

Návod na použitie

Kým začnete so strojom pracovať, prečítajte si nasledujúce bezpečnostné predpisy a pokyny

na používanie. Zoznámte sa s obslužnými prvkami a správnym používaním zariadenia. Návod

starostlivo uschovajte pre prípad neskoršej potreby. Minimálne počas záruky odporúčame

uschovať originálny obal vrátane vnútorného baliaceho materiálu, pokladničný doklad a

záručný list. V prípade prepravy zabaľte stroj späť do originálnej škatule od výrobcu, zaistíte si

tak maximálnu ochranu výrobku pri prípadnom transporte (napr. sťahovaní alebo odoslaní do

servisného strediska).

Poznámka: Ak odovzdávate stroj ďalším osobám, odovzdajte ho spoločne s návodom.