Page 1

OPERATING

MANUAL

EN

FIBARO

ROLLER SHUTTER 3

FGR-223

CONTENTS

#1: Description and features 3

#2: Installation 4

#3: Adding the device 8

#4: Removing the device 9

#5: Positioning calibration 10

#6: Operating roller blinds 13

#7: Operating gate motors 14

#8: Menu 15

#9: Resetting to factory defaults 16

v1.0

#10: Power and energy consumption 17

#11: Associations 18

#12: Z-Wave range test 19

#13: Activating scenes 20

#14: Z-Wave specication 21

#15: Advanced parameters 24

#16: Specications 32

#17: Regulations 33

Page 2

2

Important safety information

Read this manual before attempting to install the device!

!

Failure to observe recommendations included in this manual

may be dangerous or cause a violation of the law. The manufacturer,

Fibar Group S.A. will not be held responsible for any loss or damage

resulting from not following the instructions of operating manual.

Danger of electrocution!

FIBARO Roller Shutter 3 is designed to operate in electrical

home installation. Faulty connection or use may result in re or electric shock.

All works on the device may be performed only by a qualied and

licensed electrician. Observe national regulations.

Even when the device is turned o, voltage may be present at its terminals. Any maintenance introducing changes into the conguration

of connections or the load must be always performed with disabled

fuse.

Caution

!

It is not recommended to operate all of the roller blinds simultaneously. For safety reasons, at least one roller blind should be controlled independently, providing safe escape route in case of emergency.

Page 3

#1: Description and features

FIBARO Roller Shutter 3 is a device designed to control roller blinds,

awnings, venetian blinds, gates and other single phase, AC powered

devices.

Roller Shutter 3 allows precise positioning of roller blinds or venetian

blind lamellas. The device is equipped with power and energy

monitoring. It allows to control connected devices either via the

Z-Wave network or via a switch connected directly to it.

3

Main features of FIBARO Roller Shutter 3:

• Compatible with any Z-Wave or Z-Wave+ Controller,

• Supports Z-Wave network Security Modes: S0 with AES-128

encryption and S2 Authenticated with PRNG-based encryption,

• To be installed with roller blind motors with electronic or

mechanical limit switches,

• Advanced microprocessor control,

• Active power and energy metering functionality,

• Works with various types of switches – momentary, toggle and

dedicated roller blind switches,

• To be installed in wall switch boxes.

FIBARO Roller Shutter 3 is a fully

compatible Z-Wave PLUS device.

NOTE

i

This device may be

used with all devices certied with

the Z-Wave Plus certicate and should be

compatible with such

devices produced by

other manufacturers.

All non-battery operated devices within

the network will act as

repeaters to increase

reliability of the network.

NOTE

i

The device is a Security Enabled Z-Wave

Plus product and a Security Enabled Z-Wave

Controller must be

used in order to fully

utilize the product.

DESCRIPTION AND FEATURES

Page 4

4

#2: Installation

Connecting the Roller Shutter 3 in a manner inconsistent

with this manual may cause risk to health, life or material

!

damage.

• Connect only in accordance with one of the diagrams,

• Do not connect DC powered motors, the device is dedicated to

operate AC powered electric motors,

• Do not connect the device to loads exceeding recommended

values,

• The device should be installed in a wall switch box compliant with

a relevant national safety standards and with depth no less than

60mm,

• Electrical switches used in installation should be compliant with the

relevant safety standards,

• Length of wires used to connect the control switch should not

exceed 20m,

• Connect roller blind motors with electronic or mechanical limit

switches only.

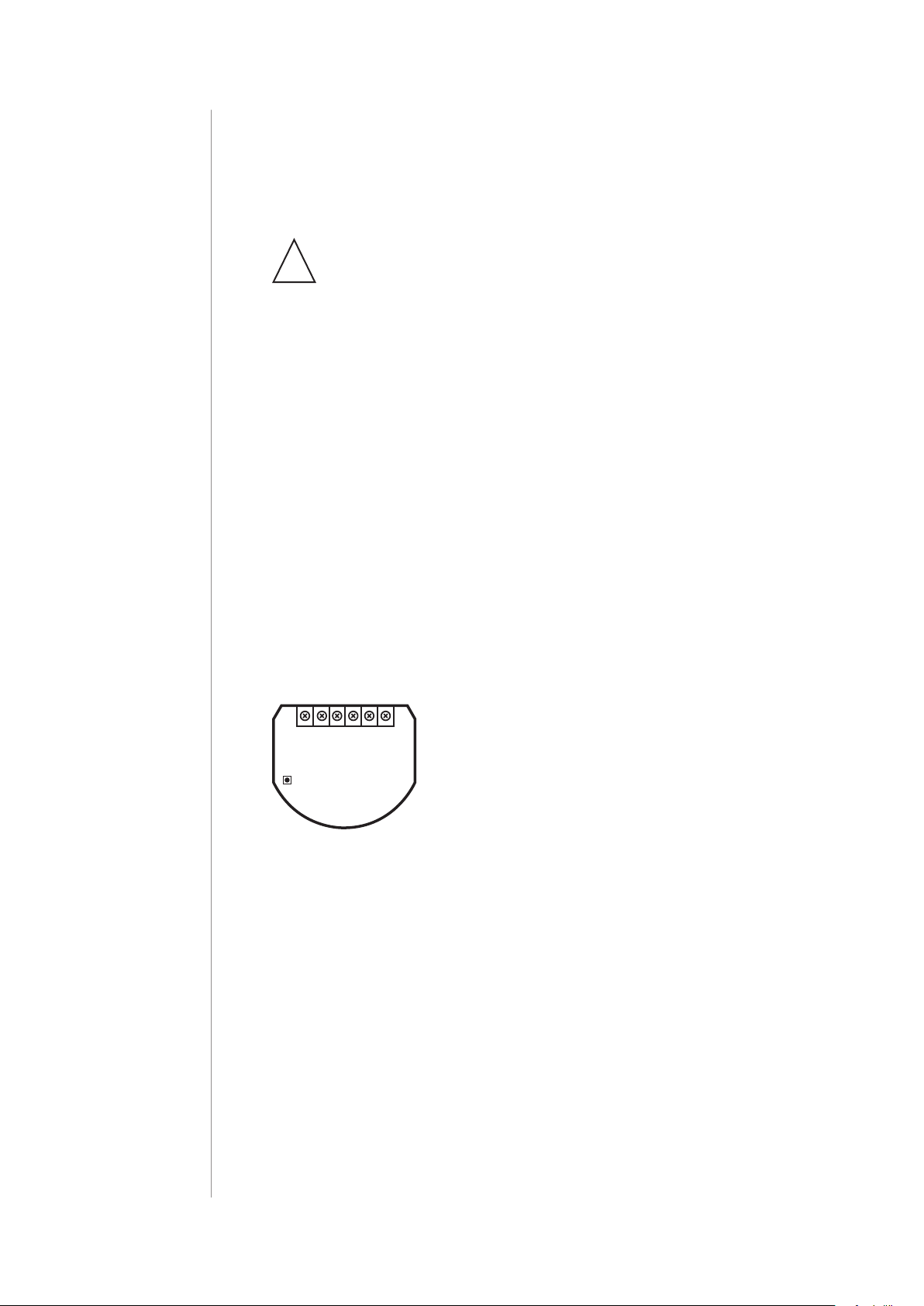

Notes for the diagrams:

S1 - terminal for 1st switch (used to add/remove

L NS1 S2 Q2

Q1

Roller

B

Shutter 3

Tips for arranging the antenna:

the device)

S2 - terminal for 2nd switch

Q2 - 2nd output terminal for shutter motor

Q1 - 1st output terminal for shutter motor

L - terminal for live lead

N - terminal for neutral lead

B - service button (used to add/remove the de-

vice and navigate the menu)

INSTALLATION

• Locate the antenna as far from metal elements as possible

(connecting wires, bracket rings, etc.) in order to prevent

interferences,

• Metal surfaces in the direct vicinity of the antenna (e.g. ush

mounted metal boxes, metal door frames) may impair signal

reception!

• Do not cut or shorten the antenna - its length is perfectly matched

to the band in which the system operates.

• Make sure no part of the antenna sticks out of the wall switch box.

Page 5

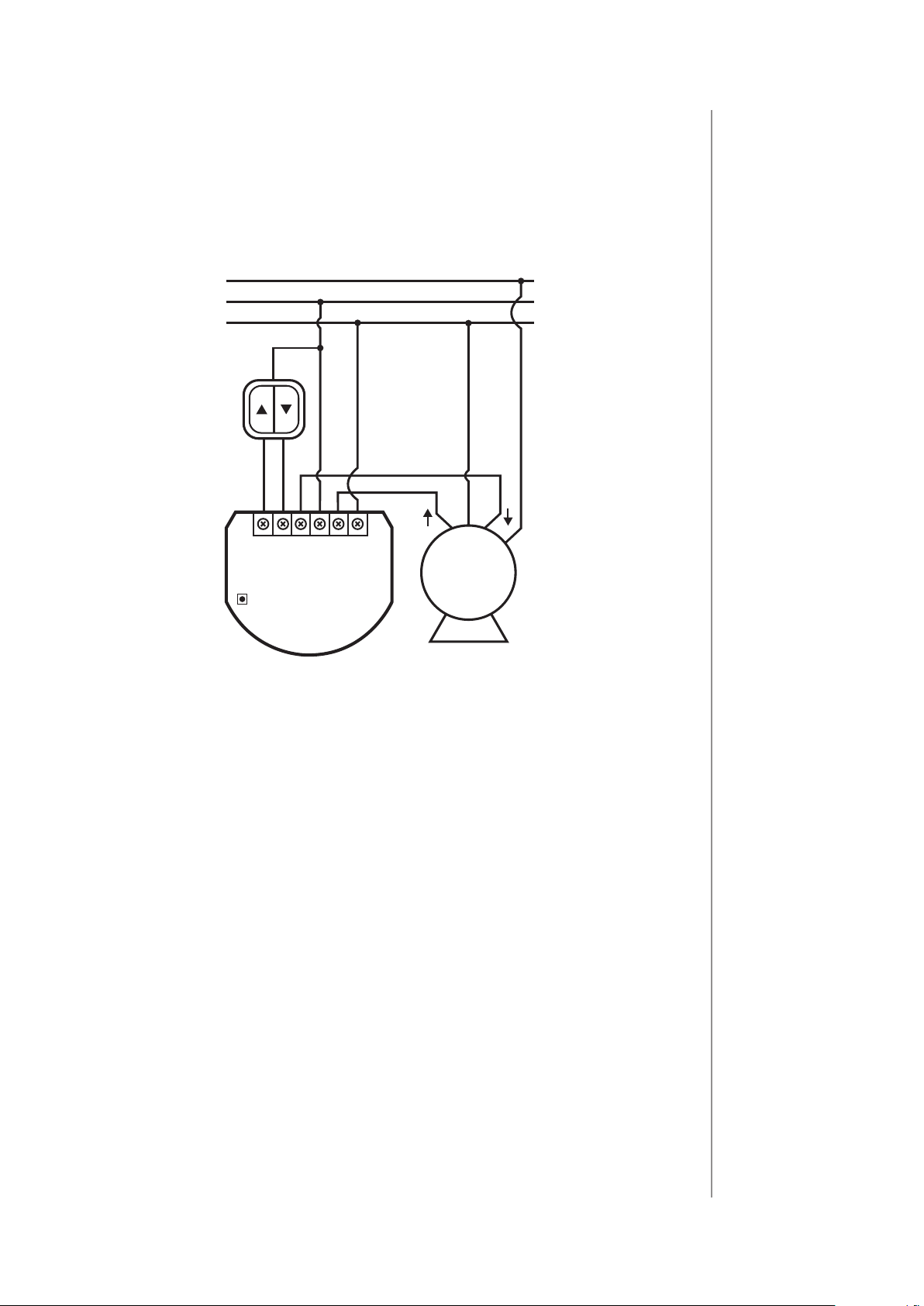

Installation with standard blinds:

PE

1. Switch o the mains voltage (disable the fuse).

2. Open the wall switch box.

3. Connect with the following the diagram:

L

N

N

5

L NS1 S2

Q2BQ1

Roller

M

Shutter 3

Wiring diagram - standard blinds

4. Verify if the device is connected correctly.

5. Arrange the device and its antenna in a wall switch box.

6. Close the wall switch box .

7. Switch on the mains voltage.

INSTALLATION

Page 6

6

PE

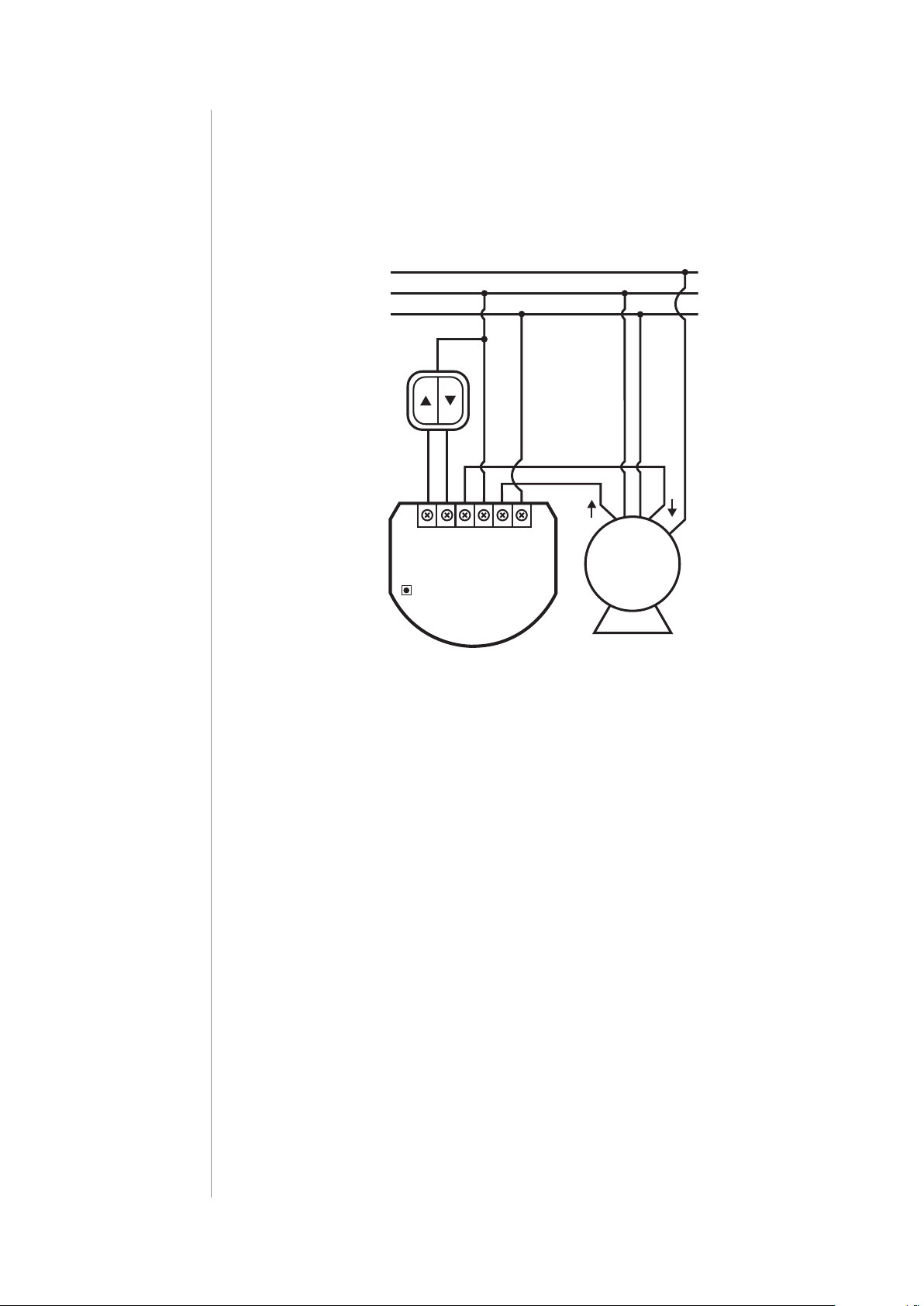

Installation with blinds with built-in driver:

1. Switch o the mains voltage (disable the fuse).

2. Open the wall switch box.

3. Connect with the following the diagram:

L

N

N

L

L NS1 S2

Q2BQ1

Roller

M

Shutter 3

Wiring diagram - blinds with built-in driver

4. Verify if the device is connected correctly.

5. Arrange the device and its antenna in a wall switch box.

6. Close the wall switch box .

7. Switch on the mains voltage.

INSTALLATION

Page 7

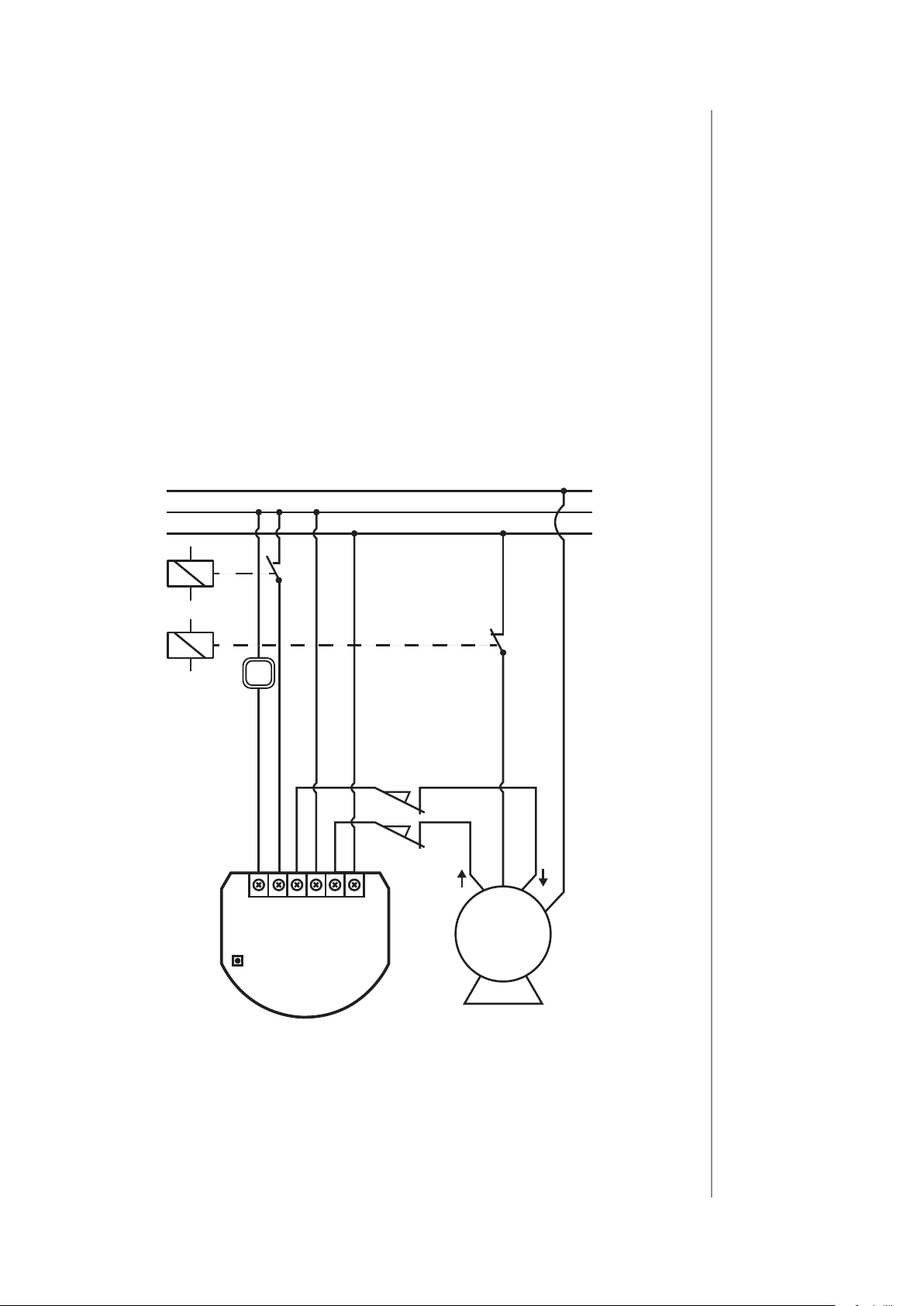

Installation with gate motors:

L

N

PE

• Installation of the gate driver may be performed only by certied

professionals.

• The motor must be equipped with the appropriate limit switches.

• It is recommended to connect a NC (normally closed) contact of

an IR barrier to S2 terminal. Opening the contact will stop the gate.

• In addition, it is recommended to connect an emergency stop

button to the motors neutral (N) wire. In emergency, pushing the

emergency stop button will cut the power and stop the gate.

1. Switch o the mains voltage (disable the fuse).

2. Open the installation box.

3. Connect with the following the diagram:

7

B

Shutter 3

sensor

NC

L NS1 S2 Q2 Q1

Roller

limit

switches

safety switch

NC

N

M

Wiring diagram - gate motors

4. Verify if the device is connected correctly.

5. Arrange the device and its antenna in the installation box.

6. Close the installation box.

7. Switch on the mains voltage.

INSTALLATION

Page 8

8

#3: Adding the device

Adding (Inclusion) - Z-Wave device learning mode, allowing to add

the device to existing Z-Wave network.

NOTE

i

In case of problems

with adding using the

S1 switch, use B-button instead (located

on the housing).

NOTE

i

SmartStart enabled products can be

added to SmartStart

enabled Z-Wave controller by scanning

the Z-Wave QR Code

present on the product. SmartStart product will be added

automatically within

10 minutes of being

switched on in the

network range.

To add the device to the Z-Wave network manually:

1. Power the device.

2. Identify the S1 switch.

3. Set the main controller in (Security/non-Security Mode) add mode

(see the controller’s manual).

4. Quickly, triple click the S1 switch.

5. If you are adding in Security S2 Authenticated, scan the DSK QR

code or input the 5-digit PIN code (label on the bottom of the

box).

6. Wait for the adding process to end.

7. Successful adding will be conrmed by the Z-Wave controller’s

message.

To add the device to the Z-Wave network using Smart Start:

1. Set the main controller in Security S2 Authenticated add mode

(see the controller’s manual).

2. Scan the DSK QR code or input the 5-digit PIN code (label on the

bottom of the box)

3. Power the device (turn on the mains voltage).

4. LED will start blinking yellow, wait for the adding process to end.

5. Successful adding will be conrmed by the Z-Wave controller’s

message.

ADDING THE DEVICE

Page 9

#4: Removing the device

9

Removing (Exclusion) - Z-Wave device learning mode, allowing to

remove the device from existing Z-Wave network.

Removing the device restores all the default parameters of the device, but does not reset power metering data.

To remove the device from the Z-Wave network:

1. Make sure the device is powered.

2. Identify the S1 switch.

3. Set the main controller in remove mode (see the controller’s

manual).

4. Quickly, triple click the S1 switch.

5. Wait for the removing process to end.

6. Successful removing will be conrmed by the Z-Wave controller’s

message.

NOTE

i

In case of problems

with removing using

the S1 switch, use

B-button instead (located on the housing).

NOTE

i

If parameter 40 enables scenes for triple

S1 click, disable it or

use B-button instead

to remove the device.

NOTE

i

If parameter 24 is set

to 1, use S2 switch instead to remove the

device.

REMOVING THE DEVICE

Page 10

10

#5: Positioning calibration

NOTE

i

If you notice the calibration process fail

(e.g. it does not start,

movement times are

really short or highly inaccurate), adjust

parameter 155 value

(e.g. reduce it by half).

Calibration is a process during which a device learns the position of

the limit switches and a motor characteristic.

Calibration is mandatory in order for the device to correctly recognize

a roller blind position.

The procedure consists of an automatic, full movement between the

limit switches (up, down, and up again).

Description:

– switch connected to the S1 terminal

– switch connected to the S2 terminal

Standard roller blind positioning

Calibration using connected momentary switch

1. Make sure:

• the device is supplied,

• momentary switch is connected to S1 and S2 terminals,

• the device added to the Z-Wave network,

• parameter 151 is set to 1 or 2.

2. Press and hold or switch for at least 3 seconds

3. Press and hold the same switch again for at least 3 seconds.

4. Press and hold the same switch again for at least 3 seconds.

5. The device will perform the calibration process, completing

full cycle – up, down and up again.

6. Test whether the positioning works correctly.

Calibration using the B-button

1. Make sure:

• the device is supplied,

• the device added to the Z-Wave network,

• parameter 151 is set to 1 or 2.

2. Press and hold the B-button.

3. Wait for the LED to glow white.

4. Quickly release and click the B-button again.

POSITIONING CALIBRATION

5. The device will perform the calibration process, completing

full cycle – up, down and up again

6. Test whether the positioning works correctly.

Page 11

Calibration using parameter

1. Make sure:

• the device is supplied,

• the device added to the Z-Wave network,

• parameter 151 is set to 1 or 2.

2. Set the parameter 150 value to 2

3. The device will perform the calibration process, completing

full cycle – up, down and up again

4. The parameter 150 value will be set to 1 after calibration nishes.

5. Test whether the positioning works correctly.

Slats positioning in venetian blinds mode

Calibration using connected momentary switch

11

1. Make sure:

• the device is supplied,

• momentary switch is connected to S1 and S2 terminals,

• the device added to the Z-Wave network,

• parameter 151 is set to 2,

• blinds are calibrated.

2. By default, time of transition between extreme positions is

set to 150 (1.5 seconds) in parameter 152.

3. Turn slats between extreme positions by holding or

switch:

• If after full cycle a blind starts moving up or down - decrease value of parameter 152,

• If after full cycle the slats does not reach end positions increase value of parameter 152,

4. Repeat previous step until satisfactory positioning is

achieved.

5. Test whether the positioning works correctly. Correctly congured slats should not force the blinds to move up or down.

POSITIONING CALIBRATION

Page 12

12

Roller blind with built-in driver positioning

1. Make sure:

• the device is supplied,

• momentary switch is connected to S1 and S2 terminals,

• the device added to the Z-Wave network,

• parameter 151 is set to 5 or 6.

2. By default, time of transition between extreme positions is

set to 600 (6 seconds) in parameters 155 and 156.

3. Move roller blinds between extreme positions by clicking

or switch:

• If roller blind stops before reaching top - increase value

of parameter 155,

• If roller blind does not stop after reaching top - decrease

value of parameter 155,

• If roller blind stops before reaching bottom - increase value of parameter 156,

• If roller blind does not stop after reaching bottom - decrease value of parameter 156,

4. Repeat previous step until satisfactory positioning is

achieved.

5. Test whether the positioning works correctly.

POSITIONING CALIBRATION

Page 13

#6: Operating roller blinds

13

The device allows for connecting switch to the S1 and S2 terminals.

These may be momentary (recommended) or toggle switches.

Switch buttons are responsible for managing the blind’s movement.

Description:

– switch connected to the S1 terminal

– switch connected to the S2 terminal

Using momentary switches:

Click switch – initiate up movement.

Click switch – initiate down movement.

If the blind is moving, clicking any button, will stop the movement.

Operating slats of venetian blinds

When operating venetian blinds it is possible to manage angle

of the slats.

Hold switch – initiate slats rotation up.

Hold switch – initiate slats rotation down.

NOTE

i

Momentary switch

After releasing the

switch a spring automatically pushes back

and disconnects the

switch)

Toggle switch

Operates as a two-position switch, it has no

spring that would set

one position of the

switch.

Using toggle switches:

Change switch state – initiate up movement.

Change switch state – initiate down movement.

Choosing a middle position stops the blinds.

OPERATING ROLLER BLINDS

Page 14

14

#7: Operating gate motors

NOTE

i

Momentary switch

After releasing the

switch a spring automatically pushes back

and disconnects the

switch)

The device allows to operate gate motors.

Gate motor should be connected to Q1 and Q2 terminals according

to installation diagram.

When operating gates a momentary switch may be connected to S1

terminal.

It is recommended to connect an IR barrier, an emergency stop button or any alarm mechanism to S2 terminal. Opening a contact in a

device connected to S2 terminal will always result in stopping a motor in current position.

Using momentary switch:

Click S1 switch – move gate in sequence:

OPEN -> STOP -> CLOSE -> STOP -> OPEN

Open S2 contact – stop movement

Automatic closing:

• After full opening – the gate will automatically start closing after

time specied in parameter 152,

• After opening S2 contacts – the gate will automatically start closing after time specied in parameter 154.

OPERATING GATE MOTORS

Page 15

#8: Menu

Menu allows to perform Z-Wave network actions. In order to use the

menu:

1. Switch o the mains voltage (disable the fuse).

2. Remove the device from the wall switch box.

3. Switch on the mains voltage.

4. Press and hold the B-button to enter the menu.

5. Wait for the LED to indicate the desired menu position with colour:

• WHITE - start calibration

• GREEN - reset energy consumption memory

• VIOLET - start range test

15

• YELLOW - reset the device

6. Quickly release and click the B-button again.

MENU

Page 16

16

#9: Resetting to factory defaults

NOTE

i

Resetting the device is

not the recommended way of removing

the device from the

Z-Wave network. Use

reset procedure only

if the primary controller is missing or

inoperable. Certain

device removal can

be achieved by the

procedure of removing described in “A dd ing the device” on

page 5.

Resetting the device to factory defaults:

Reset procedure allows to restore the device back to its factory settings, which means all information about the Z-Wave controller and

user conguration will be deleted.

1. Switch o the mains voltage (disable the fuse).

2. Remove the device from the wall switch box.

3. Switch on the mains voltage.

4. Press and hold the B-button to enter the menu.

5. Wait for the LED indicator to glow yellow.

6. Quickly release and click the B-button again.

7. After few seconds the device will be restarted, which is signalled

with the red LED indicator colour.

RESETTING TO FACTORY DEFAULTS

Page 17

#10: Power and energy consumption

17

The device allows for the active power and energy consumption monitoring. Data is sent to the main Z-Wave controller.

Measuring is carried out by the most advanced micro-controller technology, assuring maximum accuracy and precision (+/- 1% for loads

10W-1000W).

Electric active power - power that energy receiver is changing into a

work and heat. The unit of active power is Watt [W].

Electric energy - energy consumed by a device through a time

period. Consumers of electricity in households are billed by suppliers on the basis of active power used in given unit of time. Most

commonly measured in kilowatt-hour [kWh]. One kilowatt-hour is

equal to one kilowatt of power consumed over period of one hour,

1kWh = 1000Wh.

Resetting consumption memory:

The device allows to erase stored consumption data in three ways:

a) Using functionality of a Z-Wave controller (see the controller’s

manual).

b) Manually clearing the data using the following procedure:

NOTE

i

Power measurement

can contain mains

voltage uctuations

within +/- 10%.

CAUTION

!

The device stores periodically (every hour)

the consumption data

in the device memory. Disconnecting

the module from the

power supply will not

erase stored energy

consumption data.

1. Switch o the mains voltage (disable the fuse).

2. Remove the device from the wall switch box.

3. Switch on the mains voltage.

4. Press and hold the B-button to enter the menu.

5. Wait for the visual LED indicator to glow green.

6. Quickly release and click the B-button again.

7. Energy consumption memory will be erased.

c) By resetting the device (see “Operating the device” on page 13).

POWER AND ENERGY CONSUMPTION

Page 18

18

#11: Associations

Association (linking devices) - direct control of other devices within

the Z-Wave system network e.g. Dimmer, Relay Switch, Roller Shutter

or scene (may be controlled only through a Z-Wave controller).

The device provides the association of 3 groups:

1st association group – “Lifeline” reports the device status and al-

lows for assigning single device only (main controller by default).

2nd association group – “Roller Shutter” is assigned to shutter position control – UP/DOWN (uses Switch Multilevel command class).

3rd association group – “Slats” is assigned to slats position control

– UP/DOWN (uses Switch Multilevel command class).

The device in 2nd and 3rd group allows to control 5 regular or multichannel devices per an association group, with the exception of

“LifeLine” that is reserved solely for the controller and hence only 1

node can be assigned.

To add an association (using the Home Center controller):

1. Go to the device options by clicking the icon:

2. Select the „Advanced” tab.

3. Click the “Setting Association” button.

4. Specify to which group and what devices are to be associated.

5. Save the changes.

6. Wait for the conguration process to end.

Assocation groups mapping:

Root Endpoint

Association Group 2 Endpoint 1 Association Group 2

Association Group 3 Endpoint 2 Association Group 2

Association Group in

Endpoint

ASSOCIATIONS

Page 19

#12: Z-Wave range test

19

The device has a built in Z-Wave network main controller’s

range tester.

Follow the below instructions to test the main controller’s range:

1. Switch o the mains voltage (disable the fuse).

2. Remove the device from the wall switch box.

3. Switch on the mains voltage.

4. Press and hold the B-button to enter the menu.

5. Wait for the visual LED indicator to glow violet.

6. Quickly release and click the B-button again.

7. Visual indicator will indicate the Z-Wave network’s range (range

signalling modes described below).

8. To exit Z-Wave range test, click the B-button.

Z-Wave range tester signalling modes:

Visual indicator pulsing green - the device attempts to establish a

direct communication with the main controller. If a direct communication attempt fails, the device will try to establish a routed communication, through other modules, which will be signalled by visual

indicator pulsing yellow.

Visual indicator glowing green - the device communicates with the

main controller directly.

CAUTION

!

To make Z-Wave range

test possible, the device must be added

to the Z-Wave controller. Testing may stress

the network, so it is

recommended to perform the test only in

special cases.

NOTE

i

Communication mode

of the device may

switch between direct

and one using routing, especially if the

device is on the limit

of the direct range.

Visual indicator pulsing yellow - the device tries to establish a routed communication with the main controller through other modules

(repeaters).

Visual indicator glowing yellow - the device communicates with

the main controller through the other modules. After 2 seconds the

device will retry to establish a direct communication with the main

controller, which will be signalled with visual indicator pulsing green.

Visual indicator pulsing violet - the device does communicate at the

maximum distance of the Z-Wave network. If connection proves successful it will be conrmed with a yellow glow. It’s not recommended

to use the device at the range limit.

Visual indicator glowing red - the device is not able to connect to

the main controller directly or through another Z-Wave network device (repeater).

ZWAVE RANGE TEST

Page 20

20

#13: Activating scenes

The device can activate scenes in the Z-Wave controller by sending

scene ID and attribute of a specic action using Central Scene Command Class.

By default scenes are not activated, set parameters 40 and 41 to enable scene activation for selected actions.

Switch Action Scene ID Attribute

Switch clicked once 1 Key Pressed 1 time

Switch clicked twice 1 Key Pressed 2 times

Switch clicked

thrice

to S1 terminal

Switch connected

to S2 terminal

Switch connected

* Not available for toggle switches.

Switch held* 1 Key Held Down

Switch released* 1 Key Released

Switch clicked once 2 Key Pressed 1 time

Switch clicked twice 2 Key Pressed 2 times

Switch clicked

thrice

Switch held* 2 Key Held Down

Switch released* 2 Key Released

1 Key Pressed 3 times

2 Key Pressed 3 times

ACTIVATING SCENES

Page 21

#14: Z-Wave specication

Endpoint 1:

Generic Device Class: GENERIC_TYPE_SWITCH_MULTILEVEL

Specic Device Class: SPECIFIC_TYPE_CLASS_B_MOTOR_CONTROL

Description: represents switch connected to the S1 terminal.

Endpoint 2:

Generic Device Class: GENERIC_TYPE_SWITCH_MULTILEVEL

Specic Device Class: SPECIFIC_TYPE_CLASS_B_MOTOR_CONTROL

Description: represents switch connected to the S2 terminal.

Switch Multilevel Command Class values refers to:

• 0x00 - fully close

21

• 0x63 - fully open

Supported Command Classes:

Command Class Version Secure

ZWAVEPLUS_INFO [0x5E] V2

SWITCH_MULTILEVEL [0x26] V4 YES

ASSOCIATION [0x85] V2 YES

MULTI_CHANNEL_ASSOCIATION [0x8E] V3 YES

ASSOCIATION_GRP_INFO [0x59] V2 YES

TRANSPORT_SERVICE [0x55] V2

VERSION [0x86] V2 YES

MANUFACTURER_SPECIFIC [0x72] V2 YES

DEVICE_RESET_LOCALLY [0x5A] V1 YES

POWERLEVEL [0x73] V1 YES

SECURITY [0x98] V1

SECURITY_2 [0x9F] V1

SUPERVISION [0x6C] V1

METER [0x32] V3 YES

CONFIGURATION [0x70] V1 YES

CRC_16_ENCAP [0x56] V1

NOTIFICATION [0x71] V8 YES

PROTECTION [0x75] V2 YES

MULTI_CHANNEL [0x60] V4 YES

CENTRAL_SCENE [0x5B] V3 YES

FIRMWARE_UPDATE_MD [0x7A] V4 YES

APPLICATION_STATUS [0x22] V1

BASIC [0x20] V1 YES

ZWAVE SPECIFICATION

Page 22

22

Multichannel Command Class:

Command Class Version Secure

Endpoint 1

ZWAVEPLUS_INFO [0x5E] V2

SWITCH_MULTILEVEL [0x26] V4 YES

ASSOCIATION [0x85] V2 YES

MULTI_CHANNEL_ASSOCIATION [0x8E] V3 YES

ASSOCIATION_GRP_INFO [0x59] V2 YES

SECURITY [0x98] V1

SECURITY_2 [0x9F] V1

SUPERVISION [0x6C] V1

METER [0x32]

NOTIFICATION [0x71] V8 YES

APPLICATION_STATUS [0x22] V1

Endpoint 2

ZWAVEPLUS_INFO [0x5E] V2

SWITCH_MULTILEVEL [0x26] V4 YES

ASSOCIATION [0x85] V2 YES

MULTI_CHANNEL_ASSOCIATION [0x8E] V3 YES

ASSOCIATION_GRP_INFO [0x59] V2 YES

SECURITY [0x98] V1

SECURITY_2 [0x9F] V1

SUPERVISION [0x6C] V1

APPLICATION_STATUS [0x22] V1

V3 YES

ZWAVE SPECIFICATION

Notication Command Class:

The device uses Notication Command Class to report dierent events

to the controller (“Lifeline” group).

Notication

Type

Power

Management

[0x08]

System

[0x09]

Over-current detected

[0x06]

System Hardware Failure

[0x03]

Event Event Parameters

Device overheat

[0x01]

Page 23

Protection CC:

Protection Command Class allows to prevent local or remote control of

the device.

Type of protection State Description

Unprotected - The device is not pro-

Local 0

Local 2

RF (remote) 0

RF (remote) 1

tected, and may be operated normally

via S1 or S2

No operation possible – S1 and S2

cannot change relay state, any other

functionality is available (menu)

Unprotected - The device accepts and

respond to all RF Commands

No RF control – command class Basic

and Switch Binary are rejected, every

other command class will be handled

23

Meter Command Class:

Same for Root, Endpoint 1 and Endpoint 2.

Meter Type Scale Rate Type Precision Size

Electric

[0x01]

Electric

[0x01]

Electric_kWh

[0x00]

Electric_W

[0x02]

Import

[0x01]

Import

[0x01]

2 4

1 2

ZWAVE SPECIFICATION

Page 24

24

#15: Advanced parameters

FIBARO Roller Shutter 3 allows to customize its operation to user’s

needs. The settings are available in the FIBARO interface as simple

options that may be chosen by selecting the appropriate box.

In order to congure the module (using the Home Center controller):

1. Go to the device options by clicking the icon:

2. Select the „Advanced” tab.

INPUT/OUTPUT CONFIGURATION

NOTE

i

If parameter 20 is set

to 1 (toggle switch),

change value of parameter 153 to 0 for

slats to work properly.

20. Switch type

This parameter denes as what type the device should treat the

switch connected to the S1 and S2 terminals.

This parameter is not relevant in gate operating modes (parameter

151 set to 3 or 4). In this case switch always works as a momentary

and has to be connected to S1 terminal.

Available settings: 0 – momentary switches

1 – toggle switches

2 – single, momentary switch (the switch

should be connected to S1 terminal)

Default setting: 2 Parameter size: 1 [byte]

24. Inputs orientation

This parameter allows reversing the operation of switches connected

to S1 and S2 without changing the wiring.

Available settings: 0 - default (S1 - 1st channel, S2 - 2nd channel)

1 - reversed (S1 - 2nd channel, S2 - 1st channel)

Default setting: 0 Parameter size: 1 [byte]

ADVANCED PARAMETERS

25. Outputs orientation

This parameter allows reversing the operation of Q1 and Q2 without

changing the wiring (in case of invalid motor connection) to ensure

proper operation.

Available settings: 0 - default (Q1 - 1st channel, Q2 - 2nd channel)

1 - reversed (Q1 - 2nd channel, Q2 - 1st channel)

Default setting: 0 Parameter size: 1 [byte]

Page 25

ALARM CONFIGURATION

25

30. Alarm conguration - 1st slot

This parameter determines to which alarm frames and how the device

should react. The parameters consist of 4 bytes, three most signicant

bytes are set according to the ocial Z-Wave protocol specication.

Available settings: 1B [MSB] - Notication Type

2B - Notication Status

3B - Event/State Parameters

4B [LSB] - action:

0 - no action

1 - open blinds

2 - close blinds

Default setting: [0x00, 0x00, 0x00, 0x00]

(disabled)

Parameter size: 4 [bytes]

31. Alarm conguration - 2nd slot (Water)

This parameter determines to which alarm frames and how the device

should react. The parameters consist of 4 bytes, three most signicant

bytes are set according to the ocial Z-Wave protocol specication.

NOTE

i

Alarm with lower

number has the higher priority, thus rst

alarm will override

other alarms with the

same type.

NOTE

i

Setting Notication

Value to 0xFF will result in launching the

action twice: when

alarm occurs and is

cancelled.

Available settings: 1B [MSB] - Notication Type

2B - Notication Status

3B - Event/State Parameters

4B [LSB] - action:

0 - no action

1 - open blinds

2 - close blinds

Default setting: [0x05, 0xFF, 0x00, 0x00]

(Water Alarm, any notication, no action)

Parameter size: 4 [bytes]

ADVANCED PARAMETERS

Page 26

26

32. Alarm conguration - 3rd slot (Smoke)

This parameter determines to which alarm frames and how the device

should react. The parameters consist of 4 bytes, three most signicant

bytes are set according to the ocial Z-Wave protocol specication.

Available settings: 1B [MSB] - Notication Type

2B - Notication Status

3B - Event/State Parameters

4B [LSB] - action:

0 - no action

1 - open blinds

2 - close blinds

Default setting: [0x01, 0xFF, 0x00, 0x00]

(Smoke Alarm, any notication, no action)

Parameter size: 4 [bytes]

33. Alarm conguration - 4th slot (CO)

This parameter determines to which alarm frames and how the device

should react. The parameters consist of 4 bytes, three most signicant

bytes are set according to the ocial Z-Wave protocol specication.

Available settings: 1B [MSB] - Notication Type

2B - Notication Status

3B - Event/State Parameters

4B [LSB] - action:

0 - no action

1 - open blinds

2 - close blinds

Default setting: [0x02, 0xFF, 0x00, 0x00]

(CO Alarm, any notication, no action)

Parameter size: 4 [bytes]

ADVANCED PARAMETERS

Page 27

34. Alarm conguration - 5th slot (Heat)

This parameter determines to which alarm frames and how the device

should react. The parameters consist of 4 bytes, three most signicant

bytes are set according to the ocial Z-Wave protocol specication.

Available settings: 1B [MSB] - Notication Type

2B - Notication Status

3B - Event/State Parameters

4B [LSB] - action:

0 - no action

1 - open blinds

2 - close blinds

Default setting: [0x04, 0xFF, 0x00, 0x00]

(Heat Alarm, any notication, no action)

Parameter size: 4 [bytes]

27

SCENE TIGGERING CONFIGURATION

40. S1 switch - scenes sent

This parameter determines which actions result in sending scene IDs

assigned to them.

Available settings: 1 - Key pressed 1 time

2 - Key pressed 2 times

4 - Key pressed 3 times

8 - Key hold down and key released

Default setting: 0 Parameter size: 1 [byte]

41. S2 switch - scenes sent

This parameter determines which actions result in sending scene IDs

assigned to them.

Available settings: 1 - Key pressed 1 time

2 - Key pressed 2 times

4 - Key pressed 3 times

8 - Key hold down and key released

Default setting: 0 Parameter size: 1 [byte]

NOTE

i

Parameter 40 values

may be combined,

e.g. 1+2=3 means that

scenes for single and

double click are sent.

NOTE

i

Enabling triple click

for S1 in parameter 40

disables the ability to

add/remove via S1.

NOTE

i

Parameter 41 values

may be combined,

e.g. 1+2=3 means that

scenes for single and

double click are sent.

ADVANCED PARAMETERS

Page 28

28

POWER AND ENERGY REPORTING CONFIGURATION

60. Measuring power consumed by the device itself

This parameter determines whether the power metering should include the amount of active power consumed by the device itself.

Available settings: 0 - function inactive

1 - function active

Default setting: 0 Parameter size: 1 [byte]

61. Power reports - on change

This parameter determines the minimum change in consumed power

that will result in sending new power report to the main controller.

For loads under 50W, the parameter is not relevant and reports are

sent every 5W change.

Power report are sent no often then every 30 seconds.

Available settings: 0 - reports are disabled

1-500 (1-500%) - change in power

Default setting: 15 (15%) Parameter size: 2 [bytes]

62. Power reports - periodic

This parameter determines in what time intervals the periodic power

reports are sent to the main controller

pend on power change (parameter 61).

Available settings: 0 - periodic reports are disabled

30-32400 (30-32400s) - report interval

Default setting: 3600 (1h) Parameter size: 2 [bytes]

65. Energy reports - on change

This parameter determines the minimum change in consumed energy that will result in sending new energy report to the main controller.

Available settings: 0 - reports are disabled

1-500 (0.01 - 5 kWh) - change in energy

Default setting: 10

66. Energy reports - periodic

(0.1 kWh)

. Periodic reports do not de-

Parameter size: 2 [bytes]

ADVANCED PARAMETERS

This parameter determines in what time intervals the periodic energy

reports are sent to the main controller

pend on energy change (parameter 65).

Available settings: 0 - periodic reports are disabled

30-32400 (30-32400s) - report interval

Default setting: 3600 (1h) Parameter size: 2 [bytes]

. Periodic reports do not de-

Page 29

ROLLER SHUTTER OPERATION CONFIGURATION

150. Force calibration

By setting this parameter to 2 the device enters the calibration mode.

The parameter relevant only if the device is set to work in positioning

mode (parameter 151 set to 1, 2 or 4).

Available settings: 0 - device is not calibrated

1 - device is calibrated

2 - force device calibration

Default setting: 0 Parameter size: 1 [byte]

151. Operating mode

This parameter allows adjusting operation according to the connected device.

Available settings: 1 – roller blind (with positioning)

2 – Venetian blind (with positioning)

29

3 – gate (without positioning)

4 – gate (with positioning)

5 – roller blind with built-in driver

6 – roller blind with built-in driver (impulse)

Default setting: 1 Parameter size: 1 [byte]

152. Venetian blind - time of full turn of the slats

For Venetian blinds (parameter 151 set to 2) the parameter determines time of full turn cycle of the slats.

For gates (parameter 151 set to 3 or 4) the parameter determines time

after which open gate will start closing automatically (if set to 0, gate

will not close).

The parameter is irrelevant for other modes.

Available settings: 0-90000 (0 - 900s, every 0.01s) - time of turn

Default setting: 150 (1.5s) Parameter size: 4 [bytes]

ADVANCED PARAMETERS

Page 30

30

NOTE

i

If parameter 20 is set

to 1 (toggle switch),

change value of parameter 153 to 0 for

slats to work properly.

153. Set slats back to previous position

For Venetian blinds (parameter 151 set to 2) the parameter determines

slats positioning in various situations.

The parameter is irrelevant for other modes.

Available settings: 0 – slats return to previously set position only in

case of the main controller operation.

1 – slats return to previously set position in case

of the main controller operation, momentary

switch operation, or when the limit switch is

reached.

2 – slats return to previously set position in

case of the main controller operation, momentary switch operation, when the limit switch is

reached or after receiving the Switch Multilevel

Stop control frame

Default setting: 1 Parameter size: 1 [byte]

154. Delay motor stop after reaching end switch

For blinds (parameter 151 set to 1, 2, 5 or 6) the parameter determines

the time after which the motor will be stopped after end switch contacts are closed.

For gates (parameter 151 set to 3 or 4) the parameter determines time

after which the gate will start closing automatically if S2 contacts are

opened (if set to 0, gate will not close).

Available settings: 0-600 (0 - 60s) - time

Default setting: 10

(1s)

Parameter size: 2 [bytes]

155. Motor operation detection

Power threshold to be interpreted as reaching a limit switch.

Available settings: 0 - reaching a limit switch will not be detected

1-255 (1-255W) - report interval

Default setting: 10(10W) Parameter size: 2 [bytes]

156. Time of up movement

This parameter determines the time needed for roller blinds to reach

the top

.

For modes with positioning value is set automatically during calibration, otherwise it must be set manually.

Available settings: 1-90000 (0.01 - 900.00s, every 0.01s) - move-

ment time

Default setting: 6000 (60s) Parameter size: 4 [bytes]

ADVANCED PARAMETERS

Page 31

157. Time of down movement

This parameter determines time needed for roller blinds to reach the

bottom

For modes with positioning value is set automatically during calibration, otherwise it must be set manually.

Available settings: 1-90000 (0.01 - 900.00s, every 0.01s) - move-

Default setting: 6000 (60s) Parameter size: 4 [bytes]

.

ment time

31

ADVANCED PARAMETERS

Page 32

32

#16: Specications

NOTE

i

Radio frequency of

individual device

must be same as your

Z-Wave controller.

Check information

on the box or consult

your dealer if you are

not sure.

Power supply:

Rated load current:

Supported motor type:

Required limit switches:

Power consumption:

Operating temperature:

Operating humidity:

Active element:

For installation in boxes:

Radio protocol:

Radio signal power:

Radio frequency:

Range:

100-240V~ 50/60 Hz

4.2A for lamps and resistive loads

1.7A for motors with compensated

power factor (inductive loads)

single-phase AC motors

electronic or mechanic

up to 0.8W

0-35°C

10-95%RH without condensation

micro-gap relay switch

Ø ≥ 50mm, depth ≥ 60mm

Z-Wave (500 series chip)

EIRP up to 6dBm

868.4 or 869.8 MHz EU;

908.4 or 916.0 MHz US;

921.4 or 919.8 MHz ANZ;

869.0 MHz RU;

up to 50m outdoors

up to 40m indoors

(depending on terrain and building

structure)

Dimensions (L x W x H):

Compliance with EU directives:

42.5 x 38.25 x 20.3 mm

RoHS 2011/65/EU

RED 2014/53/EU

SPECIFICATIONS

Page 33

#17: Regulations

This device complies with Part 15 of the FCC Rules

Operation is subject to the following two conditions:

1. This device may not cause harmful interference

2. This device must accept any interference received, including interference that may cause undesired operation. This equipment has been

tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference

to radio or television reception, which can be determined by turning

the equipment o and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

33

Changes and modications not expressly approved by the manufacturer or registrant of this equipment can void your authority to operate

this equipment under Federal Communications Commission’s rules.

Industry Canada (IC) Compliance Notice

This device complies with Industry Canada license-exempt RSSs. Operation is subject to the following two conditions: (1) this device may

not cause interference, and (2) this device must accept any interference, including interference that may cause undesired operation of the

device.

Cet appareil est conforme aux normes d’exemption de licence RSS d’Industry Canada. Son fonctionnement est soumis aux deux conditions

suivantes : (1) cet appareil ne doit pas causer d’interférence et (2) cet

appareil doit accepter toute interférence, notamment les interférences

qui peuvent aecter son fonctionnement.

Legal Notices

All information, including, but not limited to, information regarding the

features, functionality, and/or other product specication are subject

to change without notice. Fibaro reserves all rights to revise or update its products, software, or documentation without any obligation to

notify any individual or entity.

FIBARO and Fibar Group logo are trademarks of Fibar Group S.A. All

other brands and product names referred to herein are trademarks of

their respective holders.

REGULATIONS

Page 34

34

DGT Warning Statement

Article 12

Without permission, any company, rm or user shall not alter the frequency, increase the power, or change the characteristics and functions

of the original design of the certied lower power frequency electric

machinery.

Article 14

The application of low power frequency electric machineries shall not

aect the navigation safety nor interfere a legal communication, if an

interference is found, the service will be suspended until improvement

is made and the interference no longer exists.

第十二條

經型式認證合格之低功率射頻電機,非經許可,公司、商號或使用

者均不得擅自變更頻率、加大功率或變更原設計之特性及功能。

第十四條

低功率射頻電機之使用不得影響飛航安全及干擾合法通信;經發現

有干擾現象時,應立即停用,並改善至無干擾時方得繼續使用。

前項合法通信,指依電信法規定作業之無線電通信。

低功率射頻電機須忍受合法通信或工業、科學及醫療用電波輻射性

電機設備之干擾。

Declaration of conformity

Hereby, Fibar Group S.A. declares that the device is in compliance with the essential requirements and other relevant

provisions of Directive 2014/53/EU. The full text of the EU

declaration of conformity is available at the following internet address:

www.manuals.baro.com

WEEE Directive Compliance

Device labelled with this symbol should not be disposed with

other household wastes. It shall be handed over to the applicable collection point for the recycling of waste electrical and

electronic equipment.

REGULATIONS

Loading...

Loading...