Fiat 124 User Manual

Engine Maintenance and Modification

Bradley Artigue

1st Edition

Engine Maintenance and Modification

Bradley Artigue

1st Edition

Engine Maintenance + Modification

FIAT 124 Spider

Contents

1. Introduction ......................................................................................................................................................5

2. Concepts............................................................................................................................................................6

2.1 The Otto Cycle .............................................................................................................................................6

2.2 Lambda ........................................................................................................................................................6

2.3 Carburetor ....................................................................................................................................................7

2.4 Fuel Injection (FI or EFI) ...............................................................................................................................7

2.5 Compression Ratio (CR)...............................................................................................................................7

2.6 Home Mechanic...........................................................................................................................................8

2.7 Shop Manuals and Guides ...........................................................................................................................8

3. Engine Identification ........................................................................................................................................9

4. Carburetion .....................................................................................................................................................11

4.1 Understanding Carburetors ........................................................................................................................11

4.2 Air Bleed Correction...................................................................................................................................12

4.3 Idle Speed Control .....................................................................................................................................13

4.4 Transition....................................................................................................................................................13

4.5 Acceleration Pump .....................................................................................................................................14

4.6 Cold Starting...............................................................................................................................................15

4.7 Multi-Barrel Synchronization ......................................................................................................................16

4.8 Carburetor Identification and Schematics ..................................................................................................18

4.9 Carburetor Tuning ......................................................................................................................................35

4.10 Diagnostics and Troubleshooting .............................................................................................................36

5. Fuel Injection...................................................................................................................................................38

5.1 Fuel injection Basics ..................................................................................................................................39

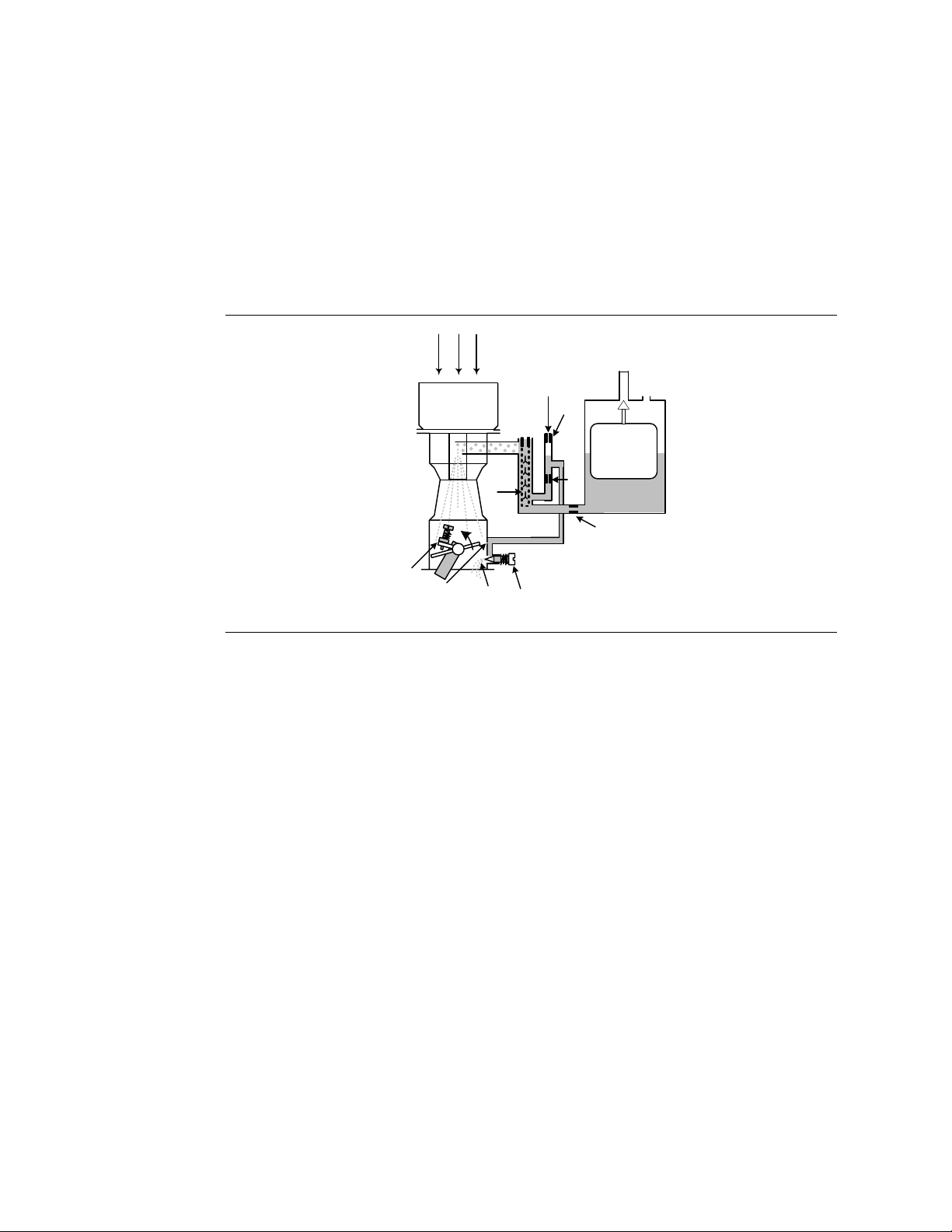

5.2 The Air Flow Meter and Fuel Pump ...........................................................................................................40

5.3 Cold Starting Components.........................................................................................................................41

5.4 Warm-Up Components ..............................................................................................................................42

5.5 Idle Speed Control Components ................................................................................................................42

5.6 Cruising, Accelerating, and Deceleration Modes .......................................................................................43

5.7 The Oxygen Sensor ...................................................................................................................................44

5.8 Other Components ....................................................................................................................................44

5.9 Component Reference...............................................................................................................................45

5.10 Fuel Injection Tuning................................................................................................................................48

5.11 Fuel Injection System Electrical Diagrams...............................................................................................50

5.12 Fuel Injection System Part Numbers .......................................................................................................53

5.13 Diagnostics and Troubleshooting .............................................................................................................54

6. The Cylinder Head ..........................................................................................................................................59

6.1 Cylinder Head Identification .......................................................................................................................61

7. Intake Manifolds .............................................................................................................................................63

8. Exhaust System..............................................................................................................................................64

8.1 Exhaust System Identification ...................................................................................................................64

9. Ignition ............................................................................................................................................................66

9.1 Ignition Components..................................................................................................................................66

9.2 Ignition System Identification ....................................................................................................................67

9.3 Ignition Advance ........................................................................................................................................68

9.4 Firing Order and Initial Timing ....................................................................................................................69

9.5 Ignition Electrical Diagrams........................................................................................................................72

3

Engine Maintenance + Modification

9.6 Diagnostics and Troubleshooting ...............................................................................................................74

10. The Major Tune Up.......................................................................................................................................76

10.1 Preparation...............................................................................................................................................76

10.2 Tuning Procedure.....................................................................................................................................79

11. Improvements*.............................................................................................................................................80

11.1 Cylinder Head Improvements ..................................................................................................................81

11.2 Intake Manifolds ......................................................................................................................................84

11.3 Ignition .....................................................................................................................................................84

11.4 Exhaust and Emissions Control ...............................................................................................................86

11.5 Carburetors ..............................................................................................................................................87

Figures .................................................................................................................................................................89

Tables ..................................................................................................................................................................90

FIAT 124 Spider

Copyright © 2007 Bradley James Artigue.

All Rights Reserved.

This guide and others in this series are for educational purposes. All are freely distributable in their original,

unedited, and complete form. The online home of this document is www.artigue.com/fiat

.

4

Engine Maintenance + Modification

FIAT 124 Spider

1. Introduction

Welcome to my guide on FIAT 124 Spider engine maintenance and modification.

Spiders are great cars, born in the mid 1960's when sports cars were fun to drive,

affordable, and easy to work on. They remain a hobbyists’ dream. In 2002 I started to

compile the various pieces of knowledge I obtained over the years into guides, first on

carburetion and intake/exhaust systems, then, in 2004, a guide (more like a pamphlet) on

fuel injection. I revised both guides over the years and finally compiled everything into

this single document. My goal is to help you enjoy your FIAT as much as I enjoy mine.

Acknowledgements and great thanks to…

Jennifer Artigue, who has always supported (or tolerated) my obsession with

these cars;

Richard Ridge reviewed this guide several times throughout its development and

has been instrumental in reviewing my other works as well;

Eli Caul maintains Mirafiori, the FIAT page (www.mirafiori.com

tirelessly in his support of the FIAT community;

Andrew Artigue disassembled, rebuilt, restored, and drove many Spiders with

me throughout the last ten or so years;

Troy McKaskle performed the final edits on the document and allowed his cars

to be as test cases long before any of us claimed to know what we were doing;

Pete Angel supplied diagrams and suggestions and reviewed sections of this

document throughout its development;

and Mike Richmond and Thad Kirk who wrote or reviewed sections of my

previous works, much of which was brought over to this document.

Thank you for keeping these cars on the road.

September 2007

) and has worked

5

Engine Maintenance + Modification

FIAT 124 Spider

2. Concepts

This section describes some of the basic things we’ll discuss throughout this guide.

2.1 The Otto Cycle

The most common type of operation for automotive engines is the four-stroke cycle, also

known as the Otto cycle. Conceptualized in the 1870's by Nicolaus Otto (and others),

the cycle has four stages of operation, beginning with the engine at Top Dead Center

(TDC), when the piston is furthest from the crankshaft:

• Intake: The intake valve opens and fuel and air are drawn into the engine as the

piston is drawn down.

• Compression: The intake valve is closed and the piston rises, compressing the

mixture.

• Power: The compressed mixture is ignited, the resulting explosion forces the

piston down.

• Exhaust: The exhaust valve opens and the spent gases are forced out as the

piston rises.

If you want to know more about the Otto Cycle theory and all of the mechanical

engineering concepts that are involved pick up a copy of “A Practical Treatise on the

‘Otto’ Cycle Gas Engine” by William Norris, Longman, Green, and Co., London, England,

1896. At the time of this writing it is available for download on books.google.com. It is a

very old book but is wonderful at describing the basic concepts of an automobile engine.

2.2 Lambda

Fuel Injection systems and Carburetors have a common goal – to reach an air to fuel ratio

of 14.7:1 and maintain that ratio through changing engine loads. The ratio is known as

the stoichiometric air-fuel ratio for gasoline. It is commonly referred to as lambda. Any

mixture less than 14.7:1 is considered rich; any mixture above is considered lean.

The air fuel mixture is established on a carburetor by setting mechanical devices, such as

air bleeders, fuel jets, and emulsion tubes. On a fuel injection system the mixture is

constantly adjusted by a computer that varies the amount of fuel sprayed into the

cylinder. Both systems rely on a stream of measured air, regulated by a throttle, to

deliver atomized fuel into the engine.

6

Engine Maintenance + Modification

FIAT 124 Spider

2.3 Carburetor

A carburetor is a device that mixes fuel and air together for use in an internal combustion

engine. A throttle regulates the amount of airflow into an engine and the subsequent

increase in air speed and drop in pressure. A restriction in the carburetor barrel, known

as a venturi, forces the air stream to increase in speed as it passes by a number of fueldelivering orifices. The orifices enrich the stream of air with fuel. The resulting mixture

is a near lambda combination of air and fuel.

2.4 Fuel Injection (FI or EFI)

A fuel injection system delivers a metered amount of fuel under high pressure into a

stream of air. Unlike carburetion, fuel injection does not rely on the pumping of the

engine to draw fuel into the air stream. Instead the fuel is forced through a small orifice

(a fuel injector) at very high pressure. The flexibility of fuel injection systems and

accuracy of fuel delivery leads to increased horsepower, better atomization of fuel,

reduction in emissions, and improved fuel economy.

2.5 Compression Ratio (CR)

The compression ratio is used to measure the performance of an internal combustion

engine. The compression ratio is calculated by taking the cylinder bore (diameter), piston

stroke, and volume of the combustion chamber prior to ignition. The formula looks like

this:

Where b is cylinder bore diameter, s is the piston stroke length, and Vc is the volume of

the combustion chamber. It is important to note that your author inserted this only to

demonstrate use of the pi (π) character and because formulas make guides like this one

look more scientific and authoritative.

FIAT Spiders had compression ratios that ranged from a low of 7.5:1 (Spider Volumex) to

a high of 9.8:1 (124 Sport Spider 1608). The Volumex relied on a supercharger to

increase the horsepower of the engine; therefore, it is notable that compression ratios

alone are not the sole indication of an engine’s capabilities. Generally speaking, and

since most of us would not install (and could not find) a Volumex supercharger on our

FIAT, mild increases in CR towards the 9.8:1 range result in good performance

increases. CR is typically increased with a piston swap, although other methods

(described later in this guide) will bump it up a point or two.

Pistons are available that will drive the CR of the engines upwards, all the way to 11:1. A

general rule about compression ratios is that the higher the CR the higher octane fuel

7

Engine Maintenance + Modification

you will need to keep the engine from knocking. These days most FIATs are recreational

vehicles, and pump-grade ‘super’ unleaded of 92 or higher octane will satisfy the CR of

any stock Spider up to 9.8:1.

FIAT 124 Spider

2.6 Home Mechanic

Throughout this guide I make references to the “home mechanic.” This is, most likely,

you. As these cars age finding a qualified professional mechanic is becoming more and

more difficult. Spiders are easy to work on and, with few exceptions, will not require

any specialized tools to make run correctly. Your best source for diagnostics is yourself;

if you must use a professional mechanic arm yourself with the ability to discuss the

problem.

2.7 Shop Manuals and Guides

A “shop manual” is referred to many times in this guide. There is only one shop manual

for your car, it was originally published by FIAT and is sold by FIAT parts vendors. There

were also numerous “guides” published by companies like Autobook, Haynes, Chilton’s,

and Drake. To avoid any confusion please note that unless explicitly stated, references

to the shop manual always indicate the FIAT shop manual.

8

Engine Maintenance + Modification

FIAT 124 Spider

3. Engine Identification

It is important to know what engine, cylinder head, carburetor, intake manifold, and

exhaust system you have on your FIAT. Understanding what you have allows you to

make an educated decision about what you need. If you are not 100% sure of what you

have then take a few moments to check - many have had engine, cylinder head,

carburetor, exhaust, ignitions, and all kinds of other parts swapped out. You need to

know what you’re running in order to get it running right or swap it for the right thing.

The engine identification number is stamped into the engine block near the oil filter. It is

sometimes covered in grime. Carburetor cleaner or degreaser and a brush will allow you

to read it. On the Spider 2000 engine (1979-1985) it is located just to the right of the oil

filter. On all Spiders manufactured prior to 1979 it is located above the oil filter. Check

your engine number with the chart on the next page. It is important to note that the last

few numbers may not match up - this usually indicates an engine swap at some point in

your car’s history. If the first digits (i.e. 132A1 is always a 1756) are correct then you

have the original displacement engine in your vehicle. If the last few digits (i.e. 031.5)

are correct then you have the original displacement and model year type.

Figure 1: Engine Identification

What if you don’t have the original engine? This situation is more common than you

might think – many owners installed larger motors to gain additional performance, a

common swap was the 1608cc for the 1438cc. Others had swaps due to necessity,

such as installing a 1978 engine in their 1975 because the original no longer worked.

Whether or not a swap was good is something you need to decide for yourself; if

originality is your goal then it may be worthwhile to seek out the original parts. If power

is more important then it might be worth keeping that 102 HP 1608cc instead of

installing a 91 HP 1438cc.

9

Engine Maintenance + Modification

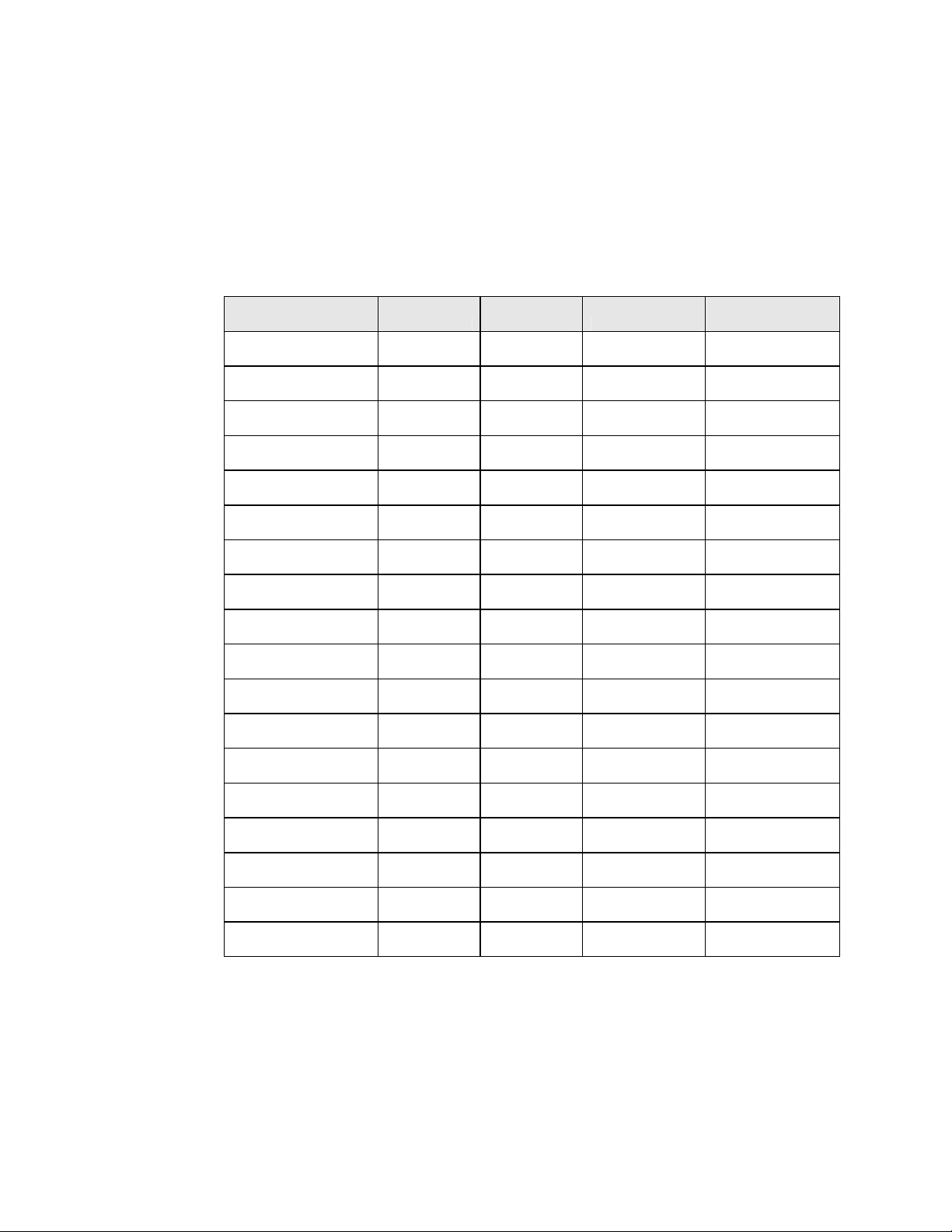

Table 1: Engine Identification Table

Model Year Series From S/N Engine Displacement

1967 – 1969 124AS 5619 124AC.040 1438cc

1970 – 1971 124BS 21861 124AC.040 1438cc

1971 - 1972 124BS1 33950 125BC.040 1608cc

1973 124CS 59592 125BC.040 1608cc

1973 124CS 63308 132AC.040.3 1592cc

1974 124CS1 71650 132A1.040.4 1756cc

FIAT 124 Spider

1975 124CS1 88792 132A1.040.5 1756cc

1975 124CS1 132A1.031.5 1756cc

1976 124CS1 99909 132A1.040.5 1756cc

1976 124CS1 132A1.031.5 1756cc

1977 124CS1 113343 132A1.040.5 1756cc

1978 124CS1 132A1.031.5 1756cc

1978 124CS1 126001 132A1.040.5 1756cc

1978 124CS1 132A1.031.5 1756cc

1979 124CS2 142514 132C2.040 1995cc

1980 124CS2 132C2.031 1995cc

1980 124CS2 157654 132C3.040 1995cc

1981 – 1985* 124CS0 171001 132C3.031 1995cc

* Pininfarina Sold the 124 as the “Azzura” and “Spidereuropa” after 1982

10

Engine Maintenance + Modification

FIAT 124 Spider

4. Carburetion

FIAT Spiders manufactured from 1967 through 1980 were equipped with carburetors,

except in California where the 1980 model year introduced fuel injection. Carburetors

were provided by Weber SpA (Italy). FIAT and Weber have a long history; in the 1920s

Eduardo Weber began producing carburetors for conversion kits intended for FIAT

vehicles. His designs were the first progressive twin-barrel types with one barrel smaller

than the other. Various updraft, downdraft, and sidedraft designs were produced by

Weber and the carburetors were installed on vehicles ranging from small engine street

cars to twelve cylinder racing cars. Weber carburetors are still used today in off-road,

racing, and street applications.

4.1 Understanding Carburetors

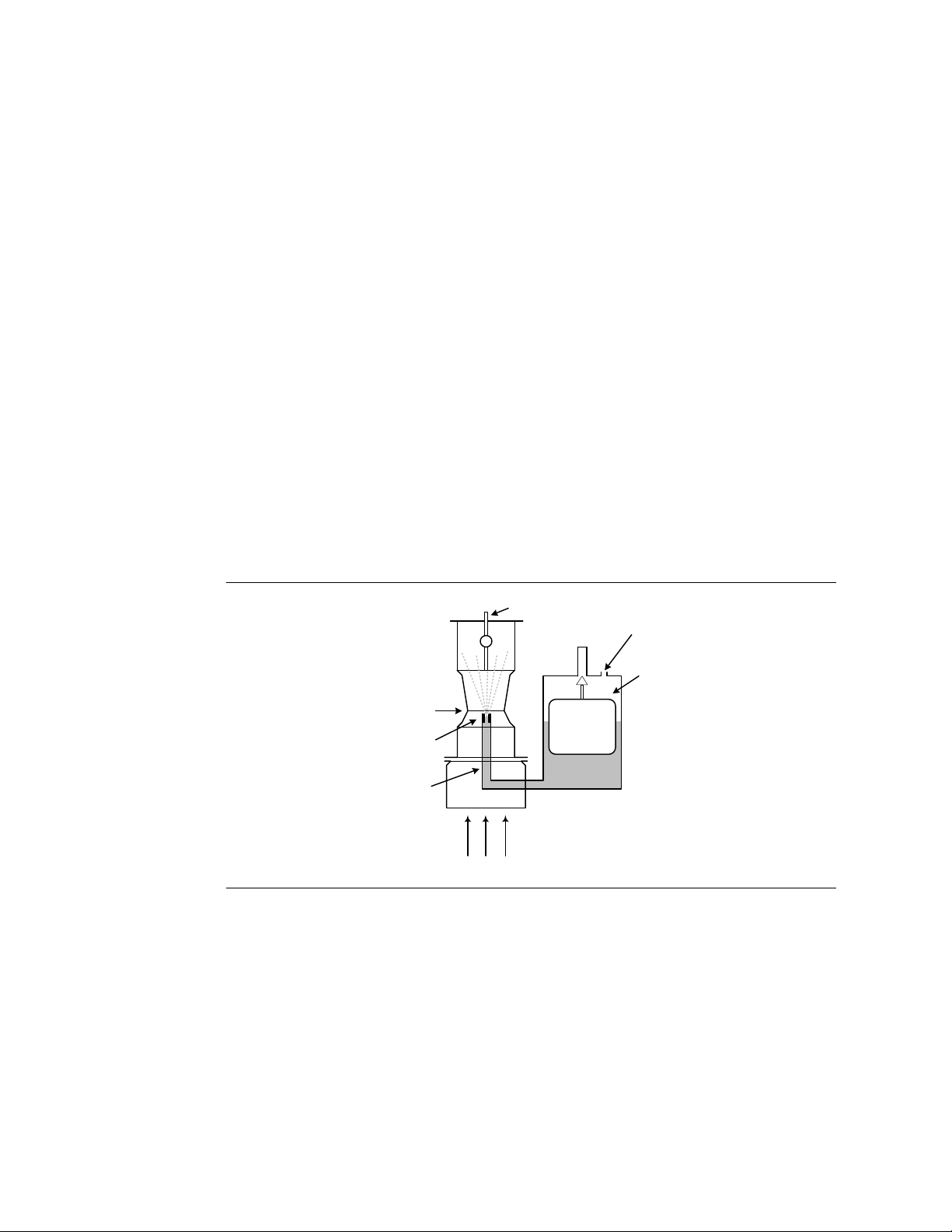

An easy way to understand how a carburetor works is to study a very simple type, the

single-barrel, updraft carburetor. After this brief introduction we’ll work through

subsequent improvements to arrive at carburetors similar to the one on your FIAT.

F

A

B

E

D

C

Figure 2: Updraft Carburetor. A Float Chamber Vent , B Fuel Bowl or Chamber, with Float , C Spray Tube,

D Fuel Jet , E Venturi , F Throttle

Referring to figure 2, an updraft carburetor has the following features:

• A fuel bowl or chamber (A) in which a float-controlled needle valve keeps the

fuel constantly at a level 5-6mm lower than the fuel in jet (D).

11

Engine Maintenance + Modification

FIAT 124 Spider

• A Venturi (E). The purpose of the venturi is to increase the depression acting on

jet (D) to favor the vaporization of the gasoline sprayed from the jet during

engine operation.

• A spray tube or nozzle (C) through which fuel flows from float chamber to

calibrated jet (D).

• A throttle (F) that regulates the amount of fuel/air mixture drawn in by the

engine.

Updraft carburetors were understandably impractical. Carburetors quickly progressed to

down draft types, with an important improvement known as air bleed correction.

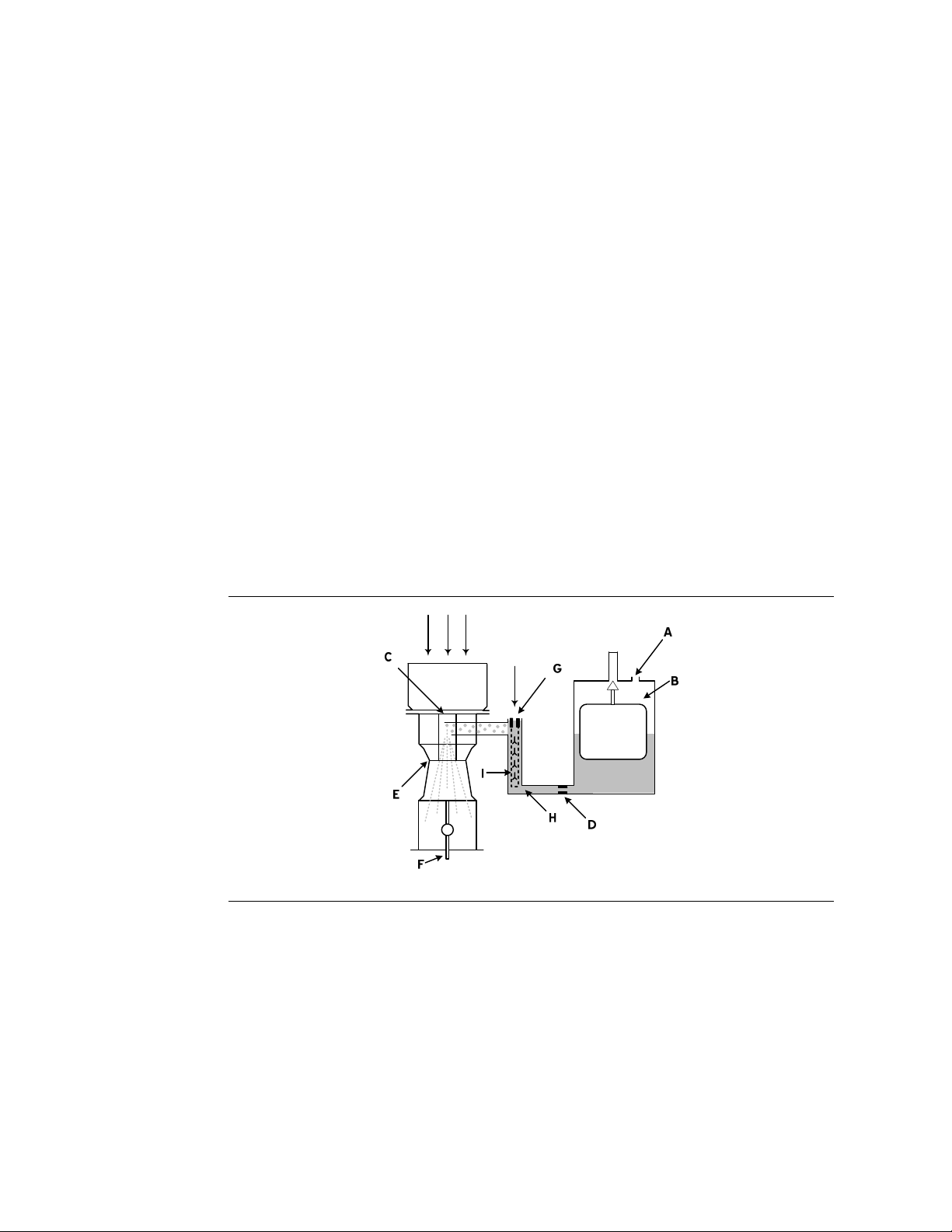

4.2 Air Bleed Correction

Emulsion tubes mixed air with the fuel prior before entering the carburetor. This air

bleed correction (figure 3) made operation more efficient.

Figure 3: Air Bleed Correction. A Float Chamber Vent , B Fuel Bowl or Chamber, with Float , C Spray

Tube, D Fuel Jet , E Venturi , F Throttle , G Air bleed jet, H Well for emulsion tube, I Emulsion Tube

A perforated emulsion tube (I) enables air and fuel to be mixed prior to being sprayed

into the carburetor barrel. This results in fuel “misting” into the barrel. The arrangement

allows for larger jets and supply tubes and a wider range of tuning. Air enters the

emulsion tube through an air bleed correction jet. The jet is removable, allowing for

precise adjustment of how much air is allowed into the emulsion tube well. There is one

well, emulsion tube, and jet per carburetor barrel.

12

Engine Maintenance + Modification

FIAT 124 Spider

4.3 Idle Speed Control

An additional improvement is an idle speed device (figure 4). This device allows your

engine to maintain the lowest rpm rate at which it will keep running.

Da

T

Db

D

4

2

Figure 4: Idle Speed Circuit. D main fuel jet, Da idle speed air jet, Db idle speed fuel jet, 1 idle speed

mixture orifice, 2 transition device, 3 idle speed mixture adjusting screw, 4 throttle setting or idle speed

1

3

adjusting screw

The throttle is nearly closed and fuel is drawn from below the throttle plate, rather than

from the main jetting. The idle speed device is an independent circuit on the carburetor,

sharing the fuel bowl with the main circuit but having its own mixture setting, jetting,

and an idle speed screw to regulate throttle position and engine speed.

4.4 Transition

We’ve reviewed the main and idle stages of a carburetor, so let’s take a look at how your

carburetor transitions smoothly from the idle stage to the main stage. In the side of your

carburetor barrel are holes, known as progression holes or transition orifices. Movement

of the throttle past these holes draws fuel into the engine (specifically, a drop in pressure

draws fuel through the holes as the throttle passes), creating additional speed while

building up to the main stage.

13

Engine Maintenance + Modification

FIAT 124 Spider

Idle Transition

Main

C

E

2

D

Figure 5: Transition Stage. 1 idle mixture orifice, 2 transition orifice, C spray nozzle, E venturi, F throttle

1

As the throttle continues to move the idle circuit, fuel feed to the progression holes will

cut off, and the engine will run entirely on the main circuit. Figure 5 depicts a carburetor

with a single transition orifice; in reality your carburetor may have several to make a

smooth transition. Without these holes the engine would stutter between the idle and

main stages.

Holes in the side of the carburetor are not enough to keep the transition and power

curves smooth. Your FIAT Spider has a “quick throttle,” meaning that throttle

movements can be fast enough to cause a lean condition. To compensate for this your

carburetor is fitted with an accelerator pump, used to inject additional fuel during the

transition stage.

4.5 Acceleration Pump

FIATs use a diaphragm-type accelerating pump, as depicted in figure 6. A roller under

the throttle mechanicals rests on a plate. When the throttle is moved the plate turns

against the roller, causing an arm to press the diaphragm in and force fuel through the

pump jet and into the stream of air passing through the carburetor. This richens the

mixture of fuel to compensate for the lean condition caused during quick throttle

movement.

14

Engine Maintenance + Modification

FIAT 124 Spider

L

K

J

N

2

3

M

F

4

5

Figure 6: Diaphragm-type accelerating pump – 1 Control lever, 2 Pump spring, 3 diaphragm return spring,

4 Cam lever, 5 Roller, F Throttle, J inlet valve, K Delivery valve, L Pump jet, M pump drain jet, N Pump

diaphragm

1

4.6 Cold Starting

On a cold morning your FIAT may be hard to start. If things are working properly you will

do one of three things to set the cold start device. You may pull a knob under your

dashboard. This knob is connected to a cable that moves a metal plate over the top of

your carburetor. If you have a later model FIAT (specifically those fitted with the ADHA

or ADFA carburetor) you might press the accelerator to the floor before starting the car

and then release it. This sets a semi-automatic, water-controlled mechanism in place.

This mechanism moves a metal plate over the top of your carburetor as well. Finally,

you might do nothing, meaning that you have an electric choke on a non-standard

carburetor. In case you’re wondering the electric choke also moves a metal plate over

the top of the carburetor. In all types this metal plate “chokes” the carburetor,

restricting the amount of air entering the engine but having no effect on the amount of

fuel. This causes a very rich condition, conducive to cold starting.

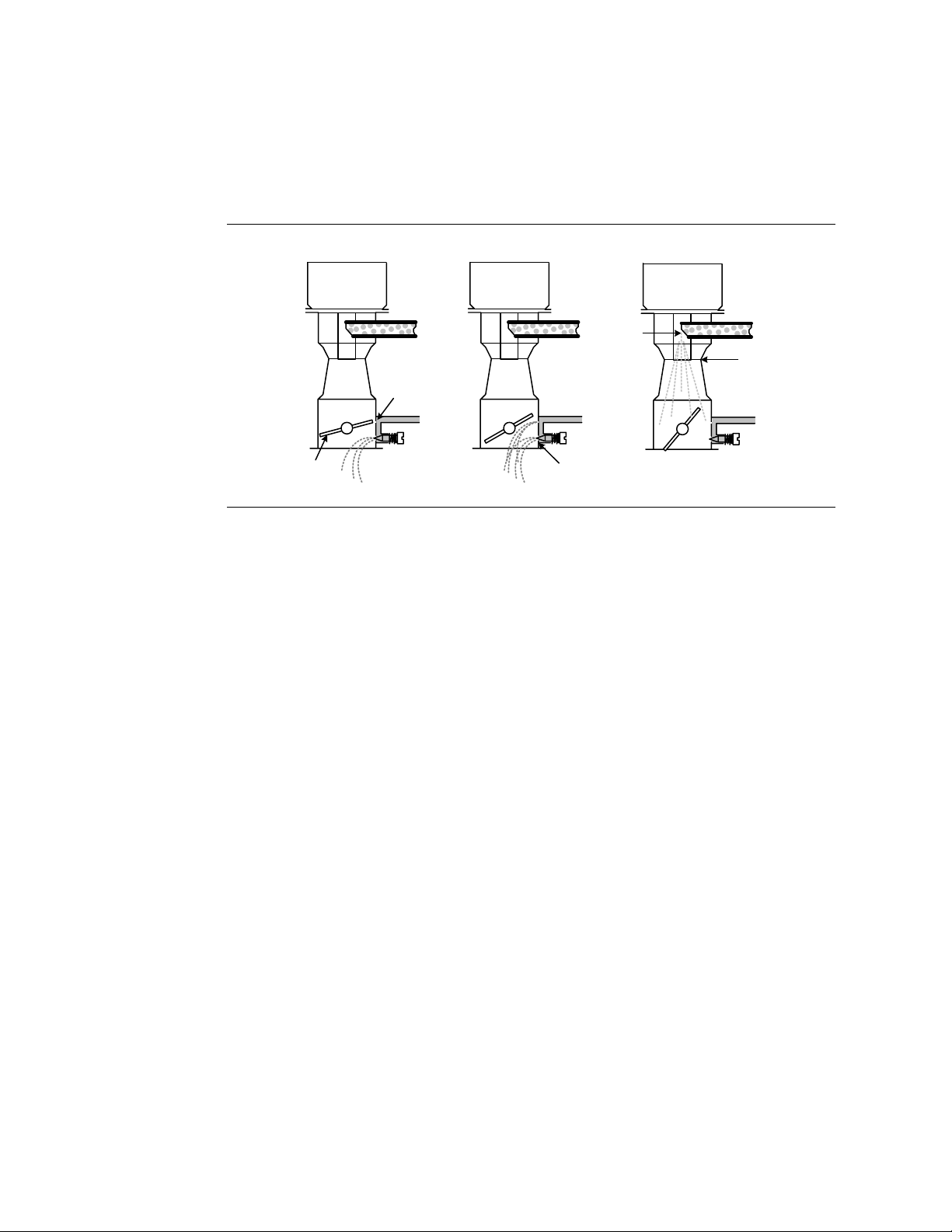

In figure 7 a simple choke is depicted. A plate moves upward, restricting airflow into the

barrel but not fuel. Once engine operating temperature is reached the choke is disabled

and normal airflow returns. Improvements in chokes over the years made them more

convenient and efficient. An automatic choke will vary the position of the restricting

plate as engine temperature increases, until the choke plate is fully open at normal

operating temperature. Weber refers to this as an “anti-flooding device” as flooding an

engine will occur if a choke is left fully “on” during normal temperatures.

15

Engine Maintenance + Modification

FIAT 124 Spider

O

P

C

E

F

Engaged Disengaged

Figure 7: Offset choke, P choke valve, C spray nozzle, E venturi, F throttle, O calibrated spring

4.7 Multi-Barrel Synchronization

We now move into the final discussion on carburetor operation, the multi-barrel

carburetor. Multi-barrel - in our case dual barrel - carburetors were designed to solve

several problems. Efficient fuel delivery into a four cylinder engine is difficult with one

single barrel carburetor. Fitting multiple single barrel carburetors, such as one per

cylinder or one per two cylinders would achieve good efficiency but introduce complex

(and expensive) throttle assemblies, complicate the fuel line plumbing, etc.

A dual-barrel carburetor provides for sharing of common components, such as the fuel

bowl and throttle mechanicals. There is also a single idle circuit in a dual-barrel

carburetor, simplifying tuning and making low-speed operation (such as driving in city

streets) more efficient. Dual-barrel carburetors work through the synchronization of the

throttle plates in each barrel.

16

Engine Maintenance + Modification

FIAT 124 Spider

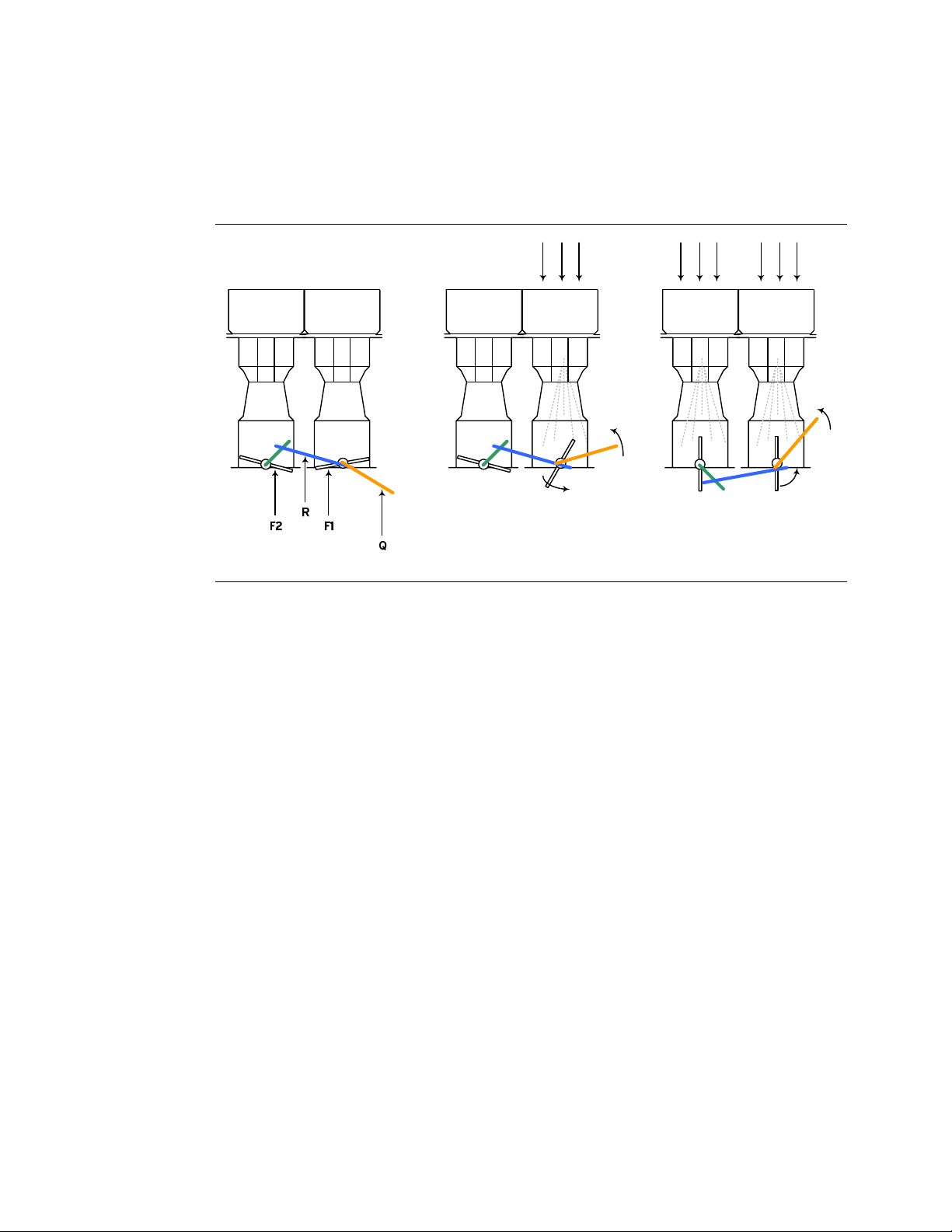

Figure 8: Mechanically controlled differential opening of the throttles. F1 Primary throttle, F2 Secondary

throttle, Q Accelerator level integral with primary throttle F1, R Intermediate lever for control of secondary

throttle F2

The synchronization is established through a mechanical or vacuum linkage that activates

the secondary barrel when the primary barrel is approximately 2/3 open.

In figure 8, our carburetor starts with the throttles at rest. A throttle arm (A) rotates the

primary throttle (F1), bringing the carburetor through idle and progression phases. An

intermediate lever (L) is activated at a mechanically set point, connecting the primary and

secondary (F2) throttles. As the main throttle reaches wide open throttle the secondary

is also fully open, with both barrels running on their main circuits.

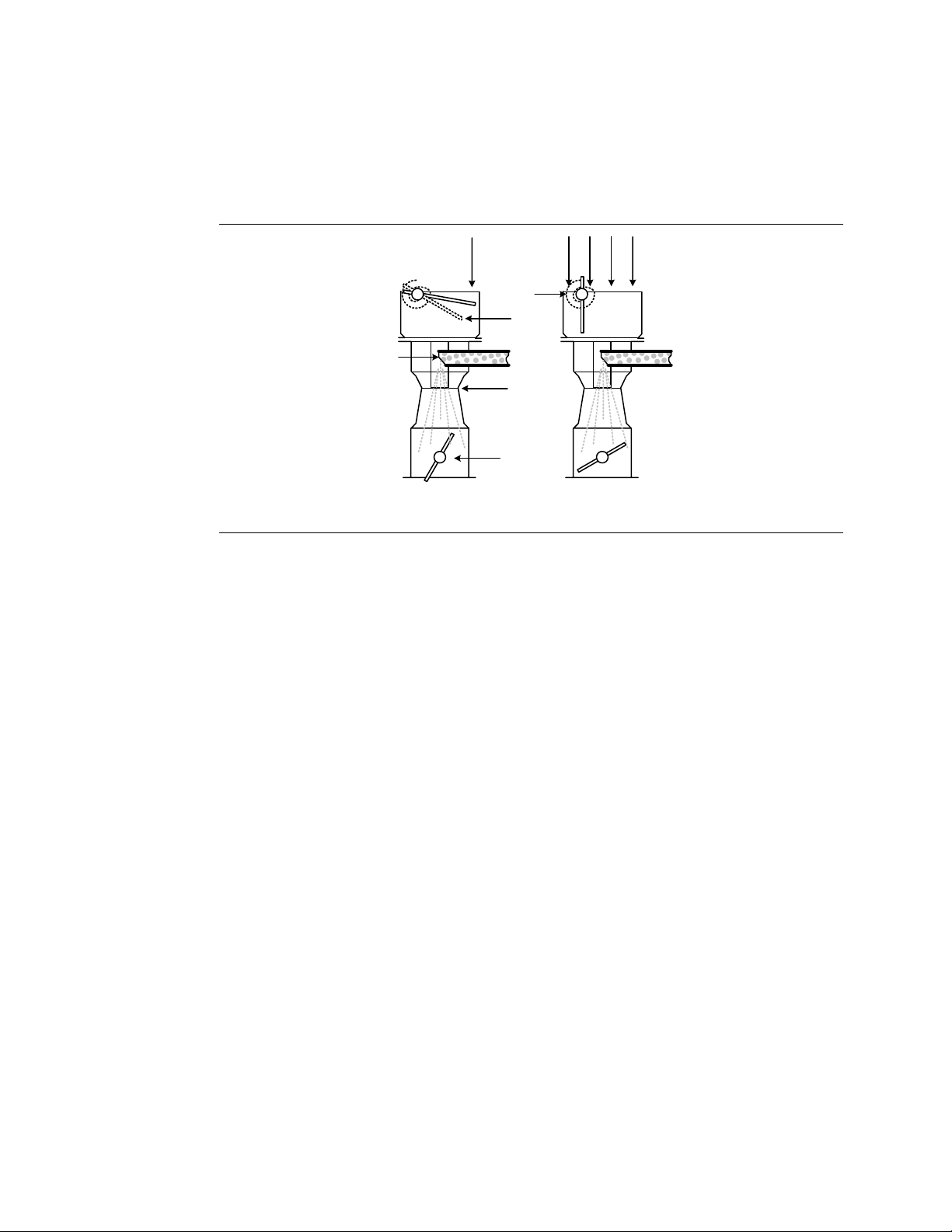

A vacuum carburetor (figure 9) achieves the same goal in a different manner. Instead of

a lever in between the main and secondary throttles, a diaphragm is connected to the

secondary barrel. When a sufficient pressure drop is reached in the primary barrel the

secondary barrel begins to open. Progression of the secondary throttle is always

controlled by the pressure drop in the primary barrel, making the vacuum carburetor

somewhat less “snappy” than the mechanical type.

17

Engine Maintenance + Modification

FIAT 124 Spider

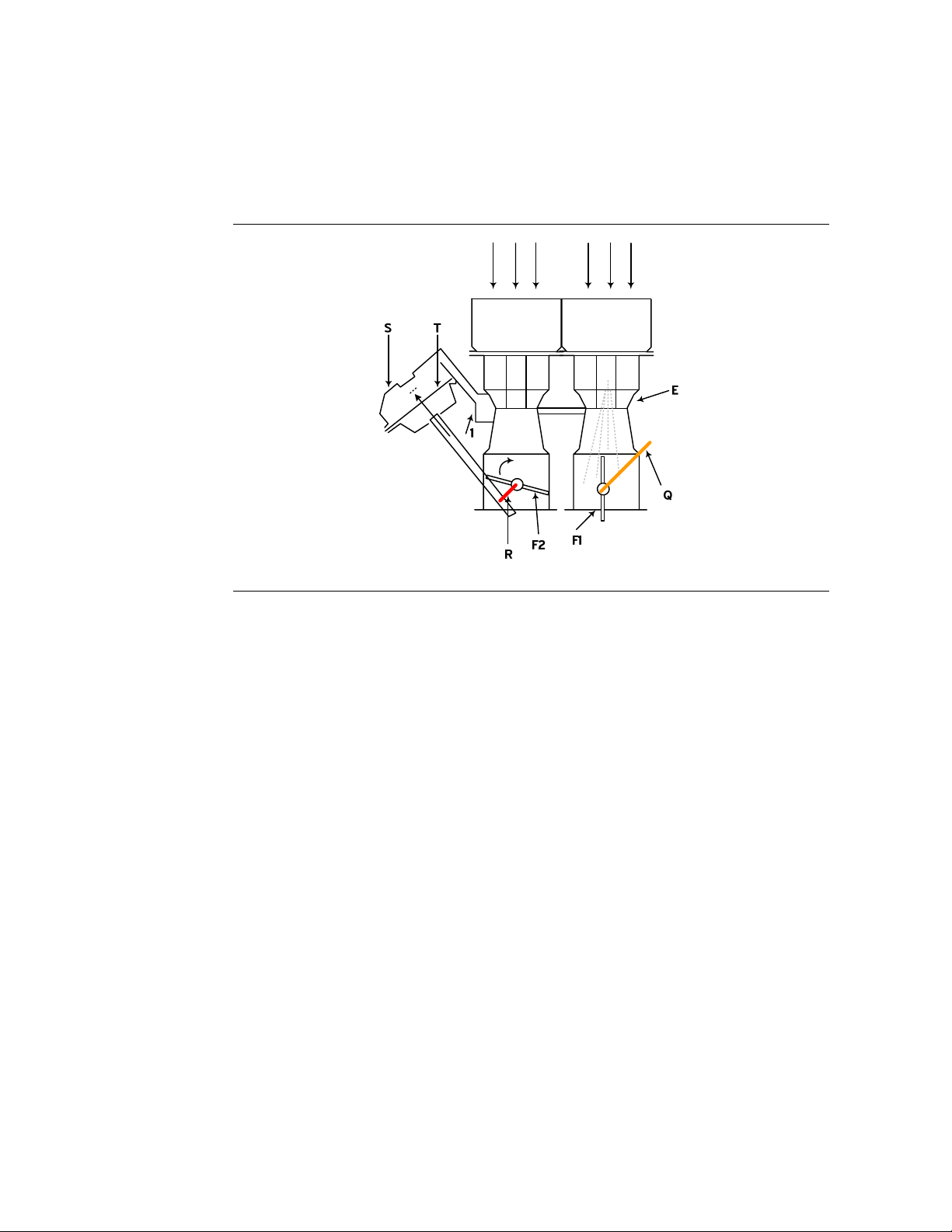

Figure 9: Vacuum controlled differential opening of the throttles – 1 Interconnection between primary

venturi E and diaphragm S, E Venturi, F1 Primary throttle, F2 Secondary throttle, S Diaphragm for

operation of secondary throttle F2, Q accelerator level integral with primary throttle F1 –R intermediate

level for control of secondary throttle F2 activated by the movement of diaphragm T integral to vacuum

operated spring mechanism S

4.8 Carburetor Identification and Schematics

Weber stamped an identification number on your carburetor body. Depending on the

construction of the carburetor body, this number may be between the middle and lower

halves of the carburetor, or on the lowest mounting flange on the “front” (facing the

fender) or “back” (facing the cylinder head) side. It may in a different location altogether

but should be fairly easy to spot. The number may be quite long, but the primary

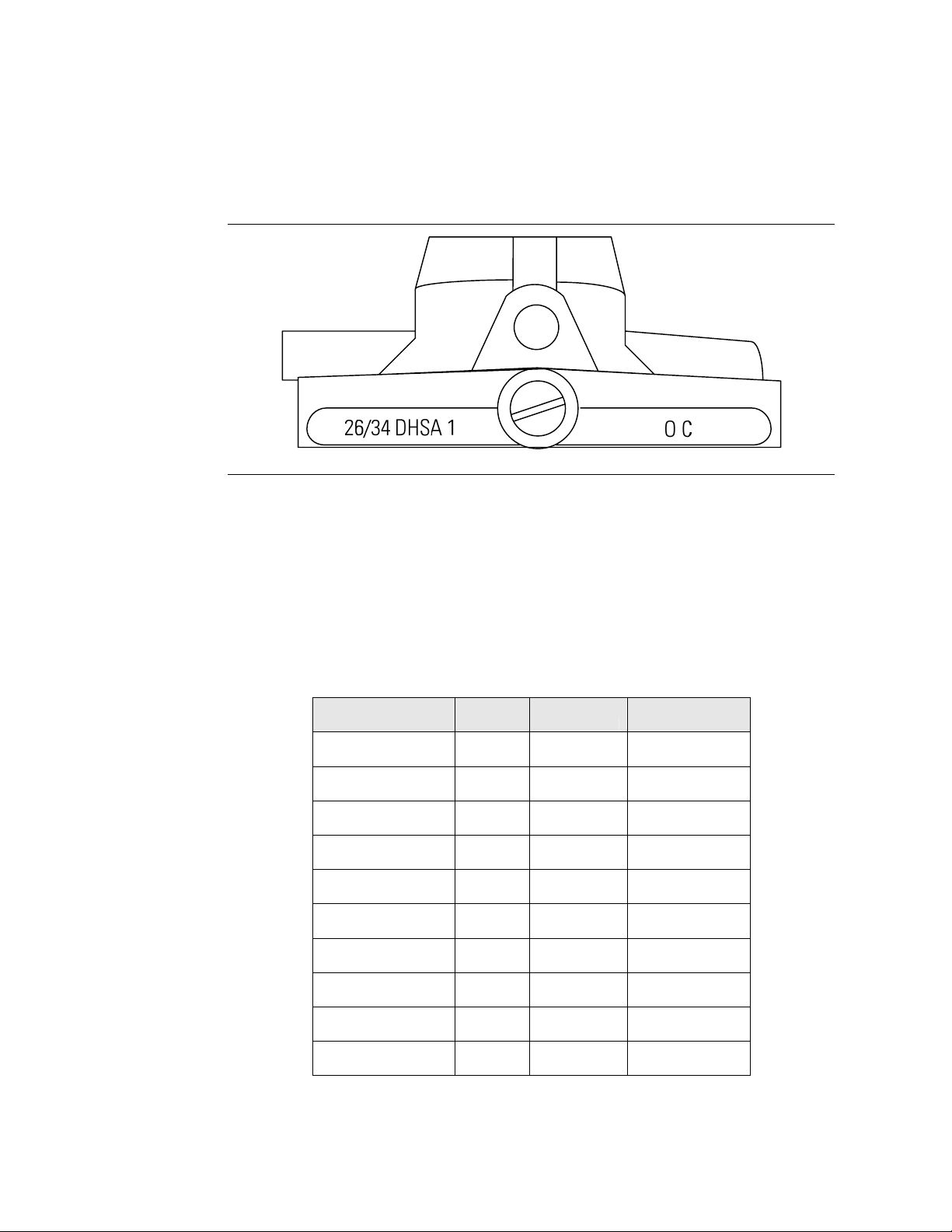

information is in the first few positions. Figure 10 shows the base of a 1970 Weber

26/34 DHSA1.

18

Engine Maintenance + Modification

FIAT 124 Spider

Figure 10: DHSA1 Carburetor Base Plate

Weber nomenclature is not easy to decipher. The important thing to note is the

numbers before the letters and the letters themselves. If you read “26/34 DHSA 1 OC”

then you can simply note that you have a “26/34 DHSA”. The numbers following the

letters indicate things like barrel size, factory jetting, emissions control modifications,

etc. The variations are minor but almost impossible to track. Using the chart below,

note whether or not your carburetor was original equipment on your engine:

Table 2: Carburetor Identification

Vehicle Year Displacement Carburetor

124 Spider 66-67 1438 34 DFH

124 Spider 68-69 1438 26/34 DHSA1

124 Spider 70-71 1438 26/34 DHSA1

124 Sport Spider 71-73 1608 28/36 DHSA2 or 3

124 Sport Spider 71-73 1608 Dual 40 IDF

124 Sport Spider 73 1592 28/36 DHSA2 or 3

124 Spider 1756 74 1756 34 DMSA

124 Spider 1756 75-76 1756 32 ADFA

124 Spider 1756 77-78 1756 32 ADFA

Spider 2000 79-80 1995 28/32 ADHA

19

Engine Maintenance + Modification

FIAT 124 Spider

4.8.1 Weber DFH

The DFH was used on early production 1438cc Spiders. It is not a common item on cars

imported into the United States. The DFH is operationally similar to the DHSA carburetor

fitted on later models.

4.8.2 Weber DHSA

The DHSA was used on the 1438 and 1608 motors. Vehicles imported into the United

States received the 26/34 DHSA1 and the 28/36 DHSA2. The numbers refer to the

primary (26 or 28) and secondary (34 and 36) barrel sizes.

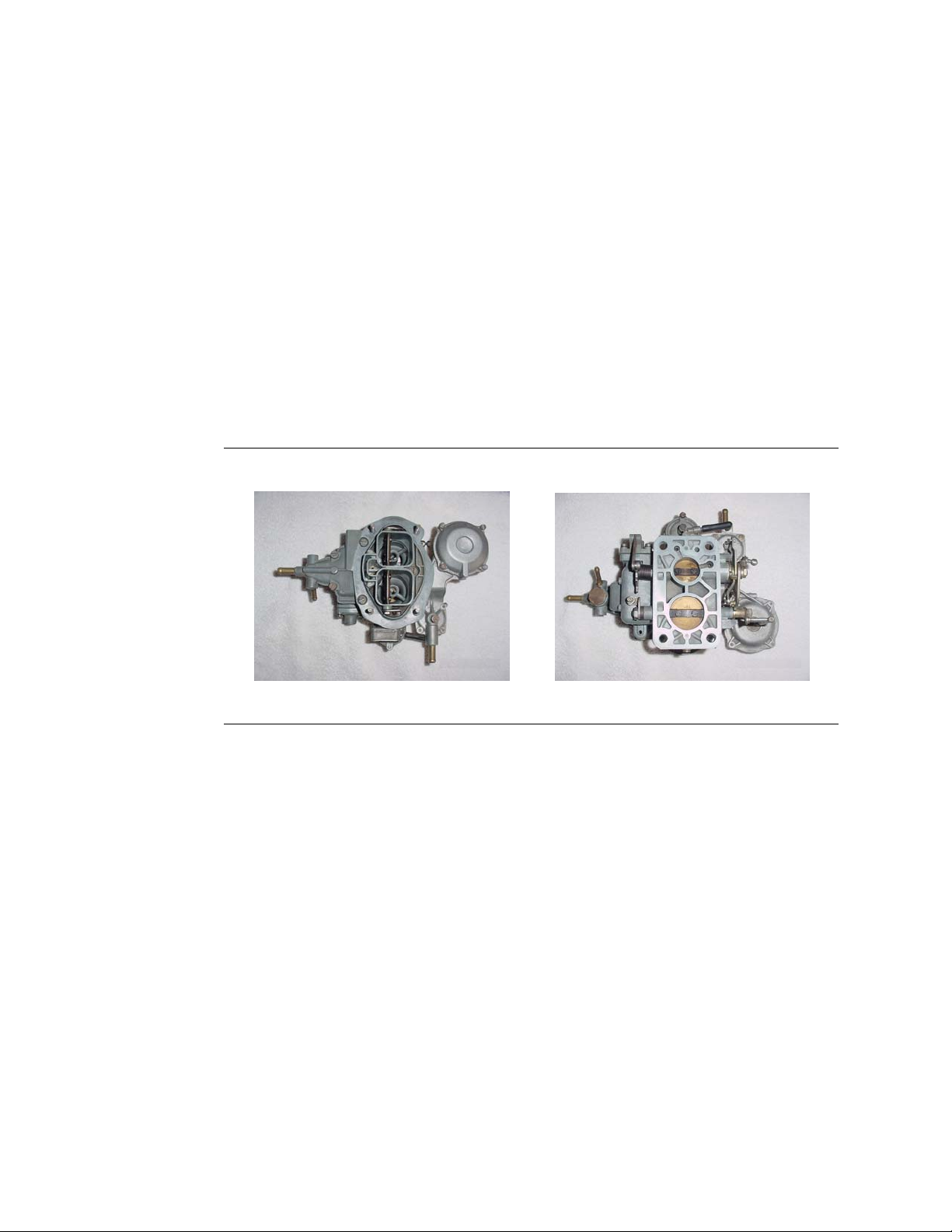

Figure 11: DHSA2 Carburetor

The DHSA is a progressive two-barrel carburetor with a vacuum operated secondary.

This secondary throttle opens when the primary throttle is fully open. This opening is

controlled by a diaphragm mounted on the side of the carburetor and linked to the

secondary throttle shaft (refer to figure 9 in the previous section). The different DHSA

models are directly interchangeable with each other and with the DMS and DMSA

carburetors.

The DHSA has a mechanically operated choke, meaning that a cable connects the choke

plate to a knob. The driver pulls the knob, activating the plate, and restricting airflow into

the carburetor.

There are two additional small diaphragms that are electrically activated by the position

of the clutch. These devices are also attached to fast idle speed controller, electronically

linked to the clutch assembly and to a switch on the transmission. When you shift into

or out of 3

The actual speed at which the controller engages is set by a switch in the engine

compartment.

rd

, 4th, and 5th gears the controller keeps the engine speed around 1500 RPM.

20

Engine Maintenance + Modification

FIAT 124 Spider

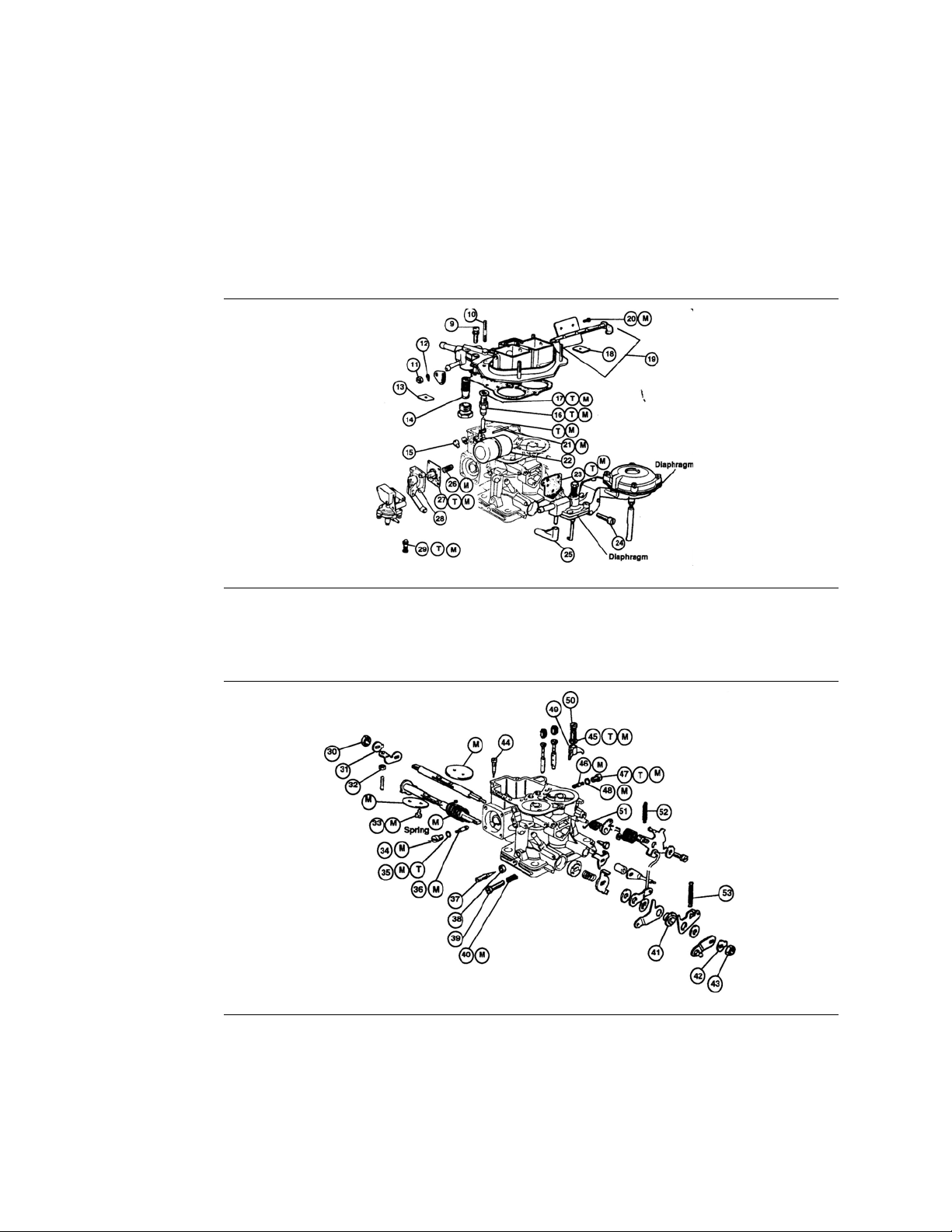

The diagrams on the following pages show the exploded views of the DHSA carburetor.

For a description of the operation of the carburetor refer to the section on the DMSA.

The DMSA is operationally similar with the exception of the vacuum secondary.

Figure 12: DHSA External Parts, Float Mechanisms, and Choke Assembly

Figure 13: DHSA Jetting, Throttle Mechanisms, and Internal Parts

21

Engine Maintenance + Modification

FIAT 124 Spider

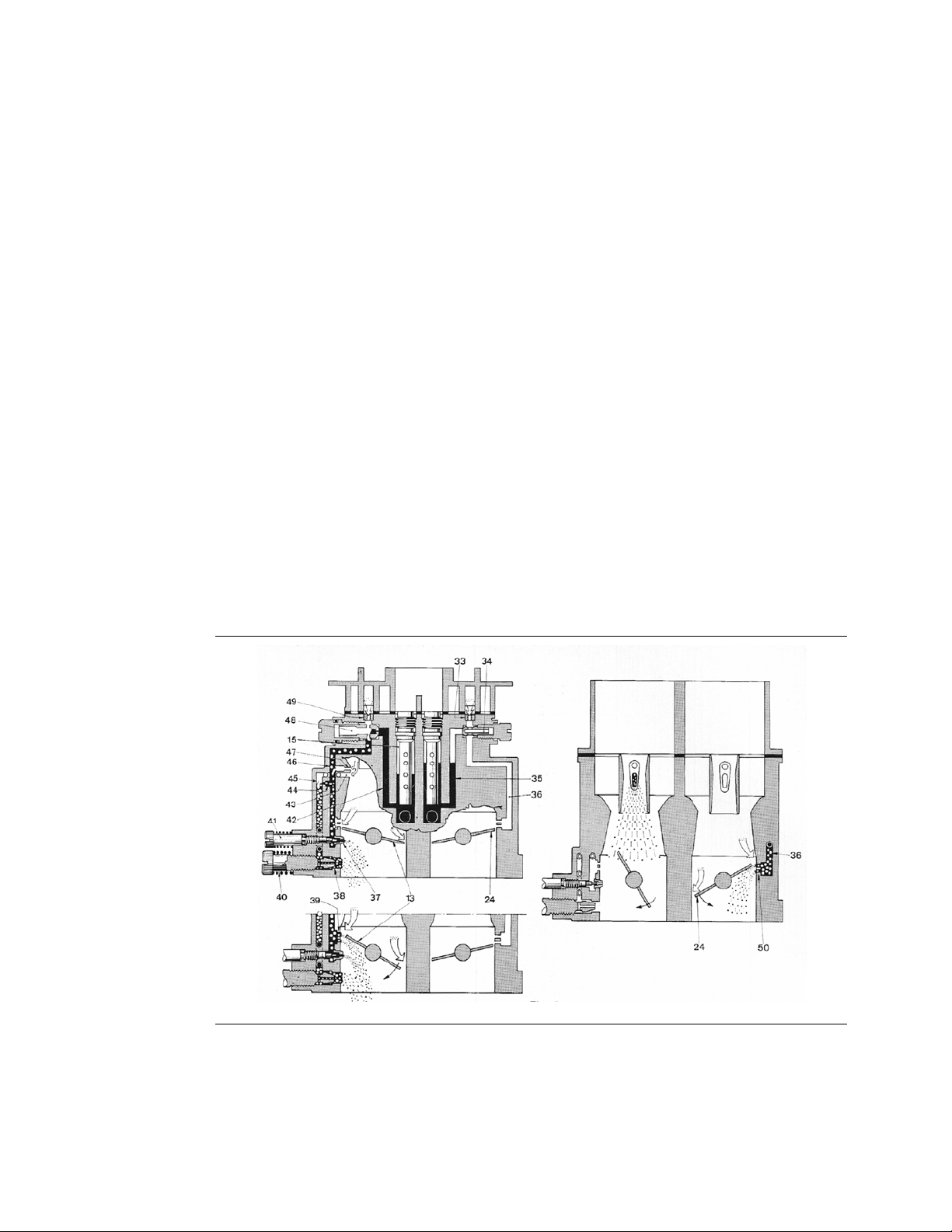

4.8.3 Weber IDF

European 1608 Sport Spiders produced from 1971 until 1973 were fitted with dual

Weber 40 IDF carburetors. Although never an option for U.S. cars many of the manifolds

and carburetor pairs were installed on Spiders of virtually every engine displacement

from 1608 to 2000. Although no FIAT manifold directly fit the 1438 series, an Abarth

manifold was produced that would allow for IDFs on that engine.

The FIAT Abarth Spider CSA (1972), a rare factory produced street version of an Abarth

race car, was also fitted with dual IDFs. The actual racing version had dual 44 IDFs

carburetors or mechanical fuel injection.

Figure 14: IDF Carburetor Side View

Through needle valve (6) fuel passes into bowl (2) where float (3), hinged on pivot pin (1),

controls needle (5) stroke to keep the fuel level constant. Needle (5) is connected to the

lug of float (3) via return latch (4).

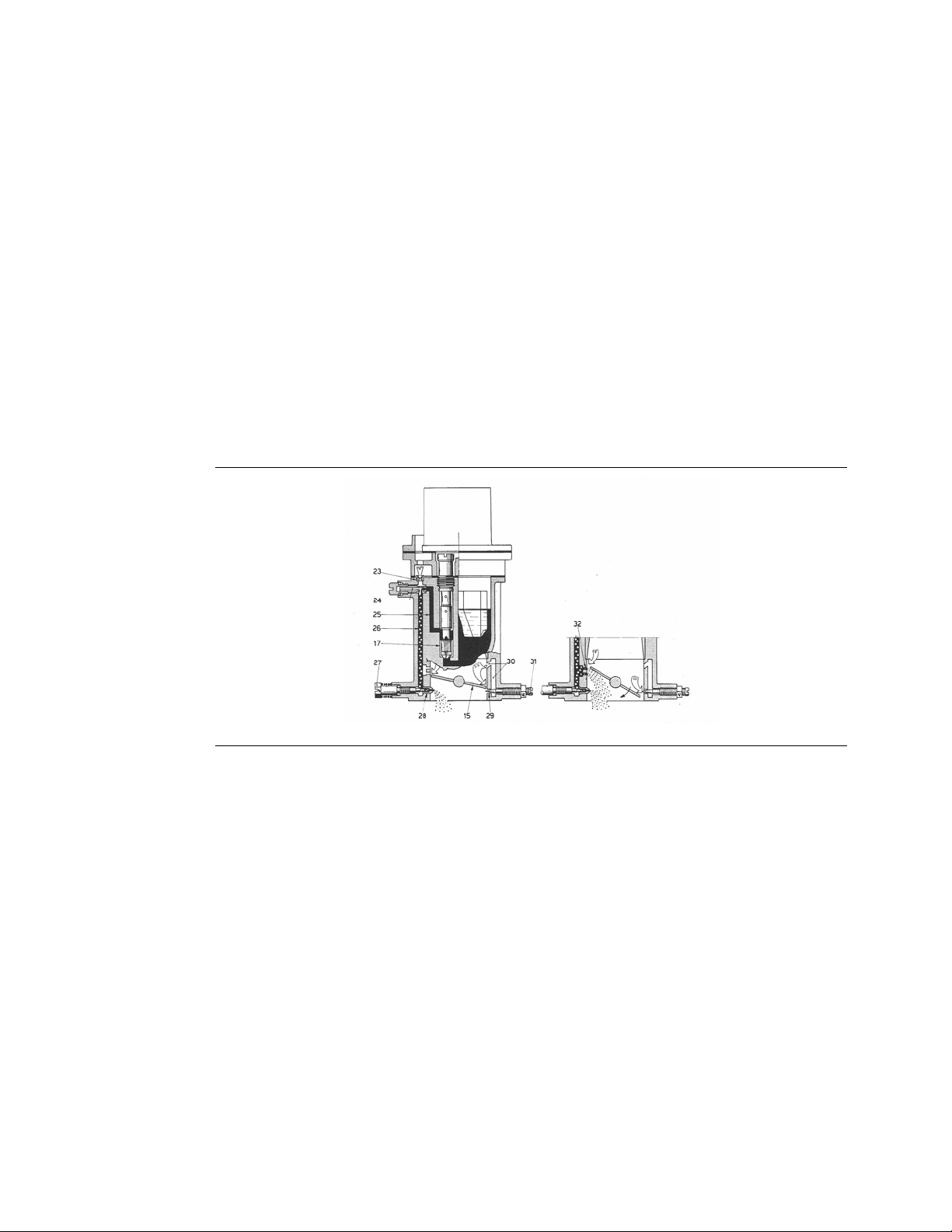

Figure 15: IDF Normal Operation

22

Engine Maintenance + Modification

FIAT 124 Spider

From bowl (2), through main jets (18), fuel reaches wells (17). After mixing with the air

from emulsion tubes (16) and air corrector jets (9), the fuel reaches the carburetion area

consisting of auxiliary venturis (11) and main venturis (12) via nozzle (10). The carburetors

incorporate a mixture enriching device whose principle of operation is as follows: Fuel is

drawn from bowl (2) through calibrated holes in tubes (8) and into the carburetor through

spray tubes (7) during high speed operation.

The illustration shows also the crankcase emission control system — diagrams A and B

—. The crankcase emission control system consists of a rotary blanking disc (22) driven

by spindle shaft (14) controlled by lever (13). Through slot (21) the blanking disc connects

blow-by gas tube (19) with the downstream side of butterfly valves (15). Even with

butterflies (15) in idling speed position gas suction is controlled by calibrated hole (20).

Figure 16: IDF Progression

From wells (17) fuel passes to idle jets (24) via ducts (25). Emulsified with the air coming

from calibrated bushes (23) through ducts (26) and bushes (28), adjustable by means of

screws (27), the mixture reaches carburetor ducts on downstream side of butterflies

(15).

Bushes (28) are calibrated to control idling speed output.

Starting from idle condition, when butterflies (15) are progressively opened the mixture

reaches the carburetor ducts via progression holes (32) to bring about an increase in

engine angular velocity. To obtain a consistent air feed in both carburetor ducts with

butterflies (15) in idle position, a variable volume of air from ducts (30), depending on the

position of screws (31), is fed to the downstream side of butterflies (15) through holes

(29) situated in alignment with adjusting screws (31).

23

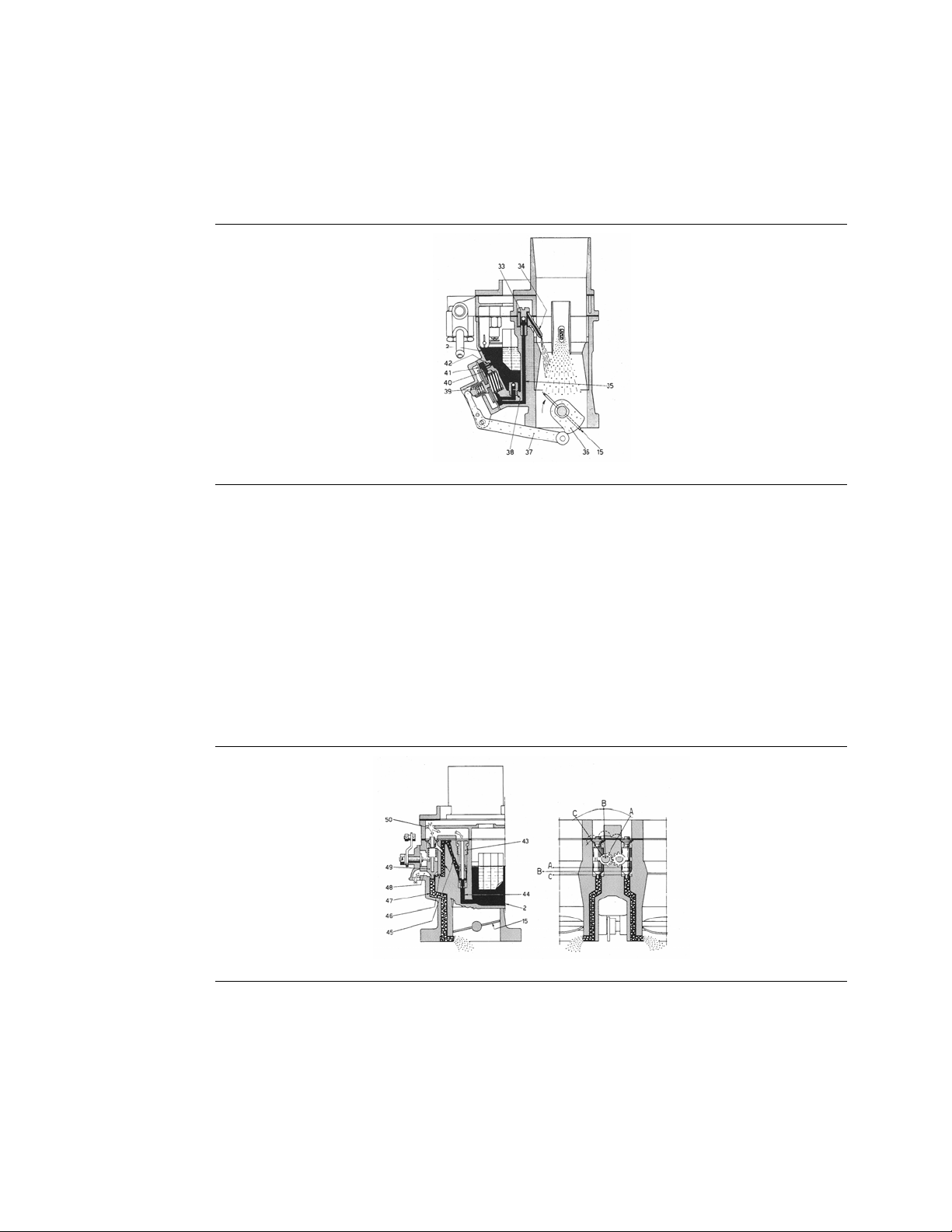

Figure 17: IDF Acceleration

Engine Maintenance + Modification

FIAT 124 Spider

Upon closing butterflies (15) lever (37) frees diaphragm (41) which, under the pressure of

spring (40), draws fuel from bowl (2) through ball valve (38).

Upon opening butterflies (15) diaphragm (41) under the action of cam (36) and lever (37)

injects fuel into carburetor ducts through ways (35), delivery valves (33) and pump jet

nozzles (34). Spring (39) dampens any sudden butterfly opening and prolongs fuel

delivery.

The excess fuel delivered by the accelerating pump is exhausted into bowl (2) together

with the pump chamber vapours, through calibrated bush (42).

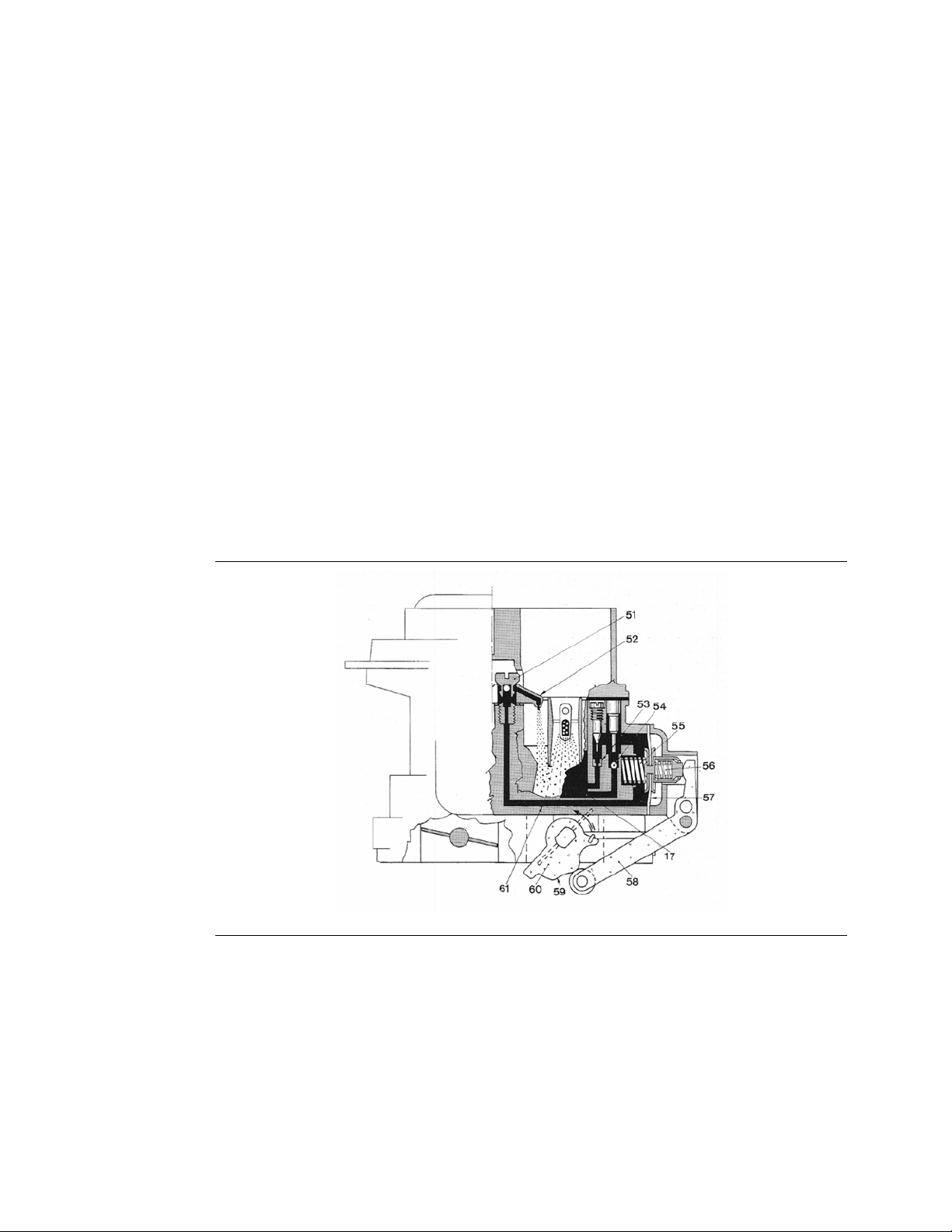

Figure 18: IDF Cold Start Devices

From bowl (2) fuel passes to the starting device through ducts (44) and starting jets (43).

Emulsified with the air from holes (50), fuel reaches the recess of valves (49) through

ducts (45) and holes (46). Then, completely emulsified with the air drawn from holes

24

Engine Maintenance + Modification

FIAT 124 Spider

(48), the mixture is conveyed to carburetor ducts on downstream side of butterflies (15)

via ducts (47).

Starting with a cold engine - Starting device ON - position A.

Starting with a semi-warm engine - Starting device partially ON - Position B.

Engine warm-up - During this stage, even with the vehicle in motion, disengage the

starting device gradually.

Normal operation - Starting device OFF - Position C to be restored as soon as the engine

reaches normal operating temperature.

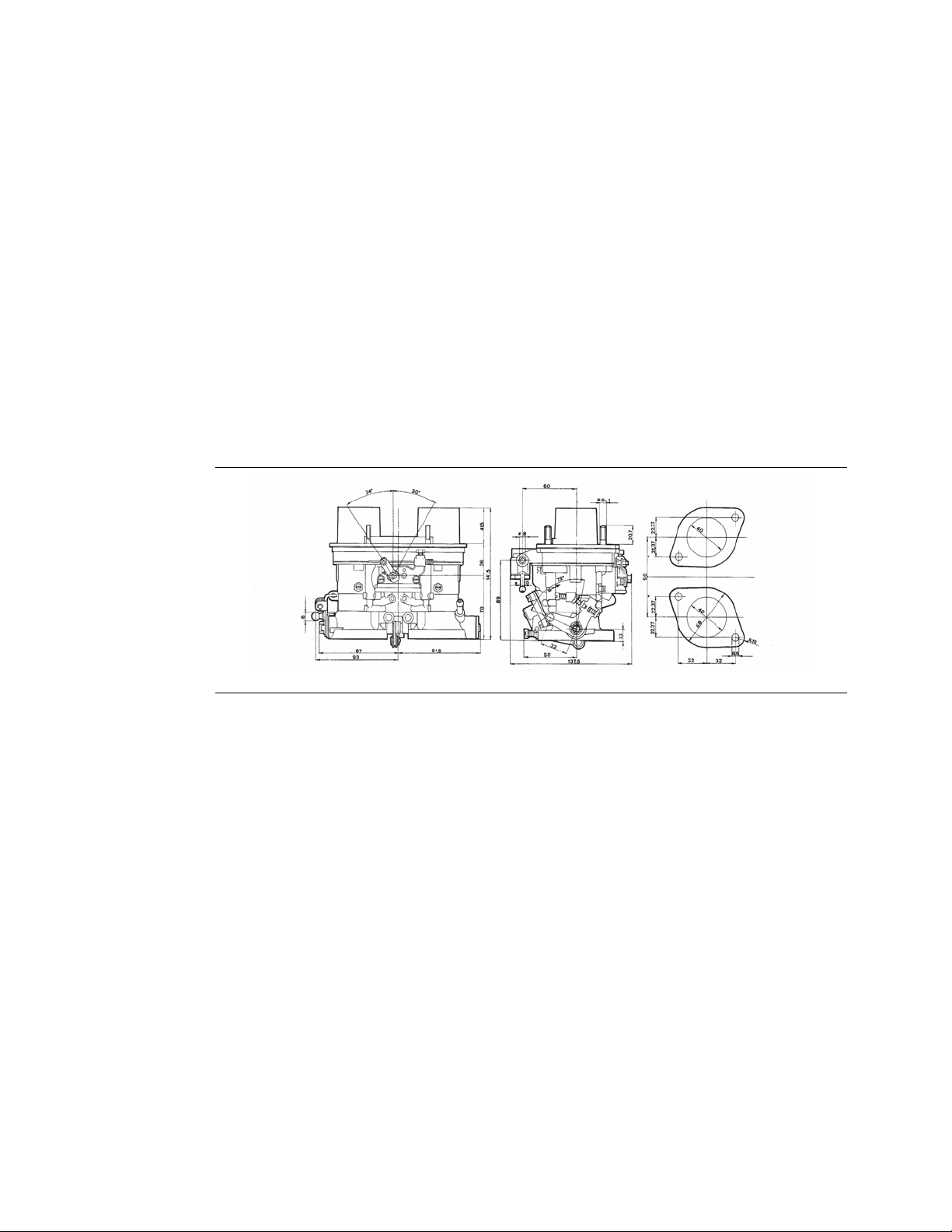

Figure 19: IDF Dimensions

4.8.4 Weber DMSA

The DMSA was used for a single year (1974). It is virtually identical to a DHSA except it

lacks the vacuum operated secondary. DMSA has a mechanically-operated secondary

and the largest primary and secondary throttles of any carburetor installed on the

Spiders. The advantage over the DHSA is there is no time lag during heavy acceleration

for manifold pressure to pull open the secondary. The DMSA is a slightly larger

carburetor than the DHSA2; this was to accommodate for the larger 1756cc engine

introduced in 1974.

25

Engine Maintenance + Modification

FIAT 124 Spider

Figure 20: DMS Carburetor Side View

The DMSA and DMS are popular upgrades for DHSA owners. Problems with the

vacuum-operated secondary unit (typically stemming from a misunderstanding of how it

works) would lead to cars that ran poorly. The DMS, with a direct mechanical

connection between the throttle plates, eliminated these problems. As DHSA

carburetors wore out they were often replaced with brand new DMS units.

Figure 21: DMS Normal Operation

Through needle valve (1) fuel passes into bowl (17) where the float (18) hinged on pivot

pin (20) sets the needle (2) opening to keep level constant: the needle (2) is connected to

float tab (18) via return hook (19). From bowl (17) through main jets (16) fuel reaches

well (15). After mixing with the air from orifices of emulsion tubes (14) and air corrector

jets (5), through nozzles (9) fuel reaches the carburetion area consisting of auxiliary

venturis (10) and main venturis (11). This carburetor is provided with a mixture-enriching

26

Engine Maintenance + Modification

FIAT 124 Spider

device on the primary (34 DMS/201) or secondary barrel (34 DMS 1/201 - 34 DMS

2/201): from bowl (17) the fuel metered by a calibrated bush (3) get mixed with the air

coming from calibrated orifice (4).

The mixture thus formed through duct (6) and calibrated bush (7) is drawn via duct (8) into the carburetor primary or secondary barrel during high speed running.

The figure also shows the device for differentiated opening of throttle valves. Upon

actuating throttles control lever (25) the tab (26) of the lever plate (22) fixed on primary

shaft (12) turns and the primary throttle (13) opens by an equivalent angle whilst the

secondary throttle (24) on spindle (23) remains closed.

Subsequently, tab (26) contacts the lug (27) of idle lever (21) which, by shifting the lever

(28), rotates the secondary spindle (23) until both throttles are simultaneously wide open.

The figure above also shows the device for gases aspiration from engine crankcase schemes A and B. It consists of a rotary blanking disc (31) driven by primary shaft (12)

which through groove (32) connects the tube (29) - conveying gases to be aspirated with the area downstream of primary throttle (13). Even with throttles in idle position,

conveyance of aspirated gases still takes place and is metered by the calibrated orifice

(30).

Figure 22: DMS Progression

27

Engine Maintenance + Modification

FIAT 124 Spider

From emulsion tube (15) the fuel is drawn to idle jet (48) through duct (42): emulsified

with the air from calibrated bush (49) via duct (46) it get mixed with the air from

calibrated orifice (47) and reaches the carburetor primary barrel downstream of throttle

(13) through the calibrated bush (37) adjustable by screw (41).

Mixture reaches the primary barrel also from duct (45) through calibrated hole (44) where

it is further emulsified with the air entering from hole (43) and conveyed downstream of

throttle (13) via the hole (38) adjustable by screw (40) - (by-pass idling).

Starting from idle rate and gradually opening throttle (13) mixture flows to primary barrel

also from progression holes (39) thus allowing a smooth increase in engine angular

speed.

When opening the secondary throttle (24), the fuel coming from secondary emulsion

tube passes to idle jet (34) through the duct (35): emulsified with the air from calibrated

bush (33) via duct (36) it flows to secondary barrel through progression holes (50) placed

at throttle (24) level which allow a steady increase in engine angular speed.

Figure 23: DMS Acceleration

Upon closing throttles, the lever (58) frees diaphragm (57) which through action of the

spring (55) draws fuel from the bowl (17) through ball valve (54). Upon opening throttles

by means of cam (59) lever (60) and lever (58), the diaphragm (57) injects fuel in

carburetor primary barrel via duct (61), delivery valve (51) and pump jet (52). Spring (56)

absorbs quick opening of throttles and extends fuel delivery stage. Any excess fuel

28