Page 1

www.fetco.com

www.fetco.com

www.fetco.comwww.fetco.com

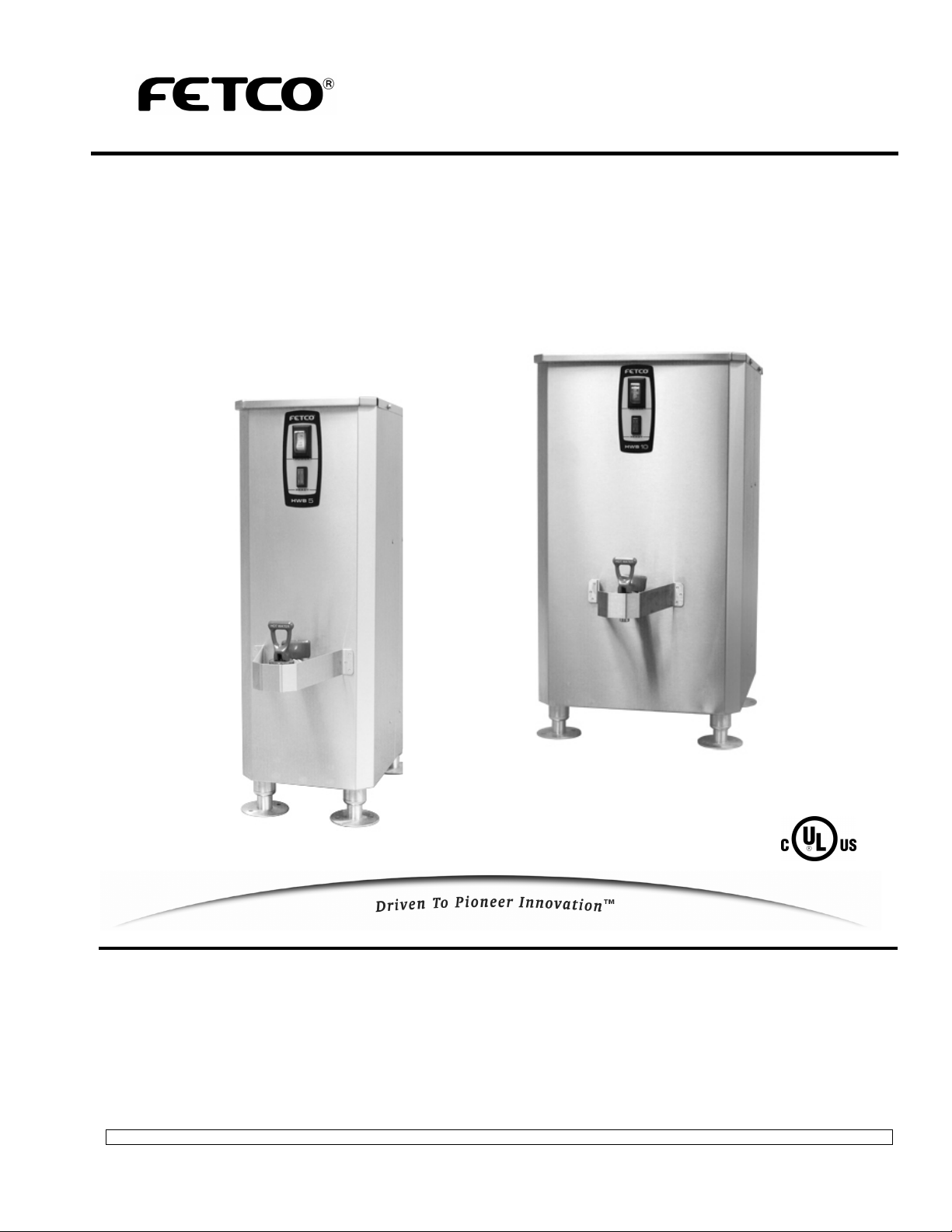

Hot Water Dispensers

Hot Water Dispensers

Hot Water DispensersHot Water Dispensers

Table of Contents

Contact Information ................................................... 2

Specifications............................................................. 2

Dimensions ................................................................ 3

Installation.................................................................. 4

User’s Guide

User’s Guide

User’s GuideUser’s Guide

Maritime Versions

Maritime Versions

Maritime VersionsMaritime Versions

Rated IP44

Rated IP44

Rated IP44 Rated IP44

Operating Instructions.................................................6

Programming ..............................................................7

Wiring Diagrams .........................................................8

Parts .........................................................................10

FETCO®, and Driven To Pioneer Innovation™ are trademarks or trade names of Food Equipment Technologies Company.

© 2009 Food Equipment Technologies Company Part # P113 REV. 001

Page 2

Contact Information

Contact Information

FETCO®

Food Equipment Technologies Company

600 Rose Road

Lake Zurich • IL • 60047-0429 • USA

Internet: www.fetco.com

Contact InformationContact Information

Service & Support:

Hours: 7:00 AM - 6:00 PM Central, Monday - Friday

Phone: (800) 338-2699 (US & Canada)

(847) 719-3000

Fax: (847) 719-3001

Email: techsupport@fetco.com

Specifications

Specifications

SpecificationsSpecifications

Maritime Versions with IP44 Ingress Protection Rating

Water Requirements

Pressure: 20-75 psig

Minimum Flow Rate: 1.5 gpm

Water Temperature

Factory Setting: 96°C / 205°F

Range: 82° - 98°C / 180° - 208°F

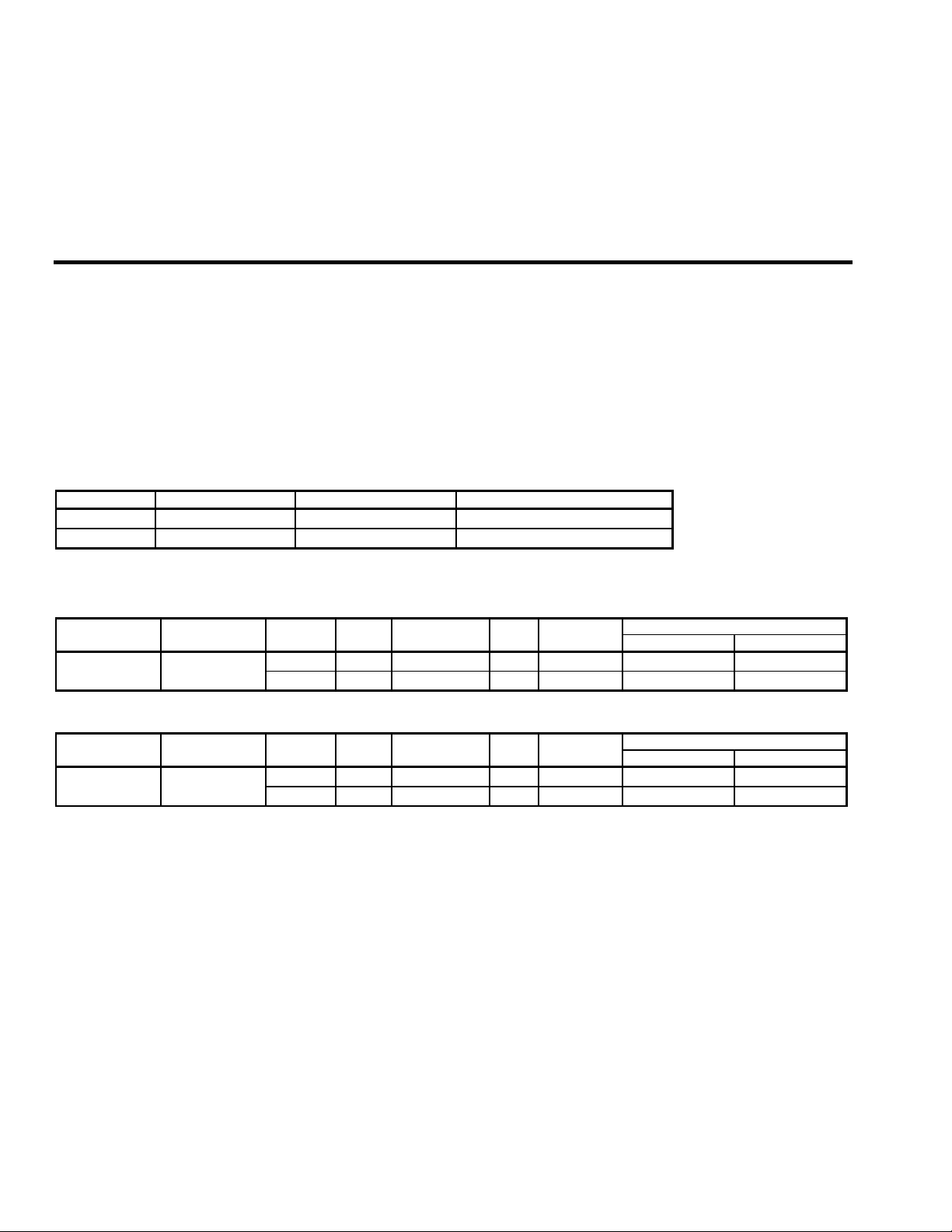

Weights & Capacities

Model Weight (empty) Water tank Capacity. Weight (full)

HWB-5 44 lbs. 5 Gallons 85 lbs.

HWB-10 66 lbs. 10 Gallons 149 lbs.

Electrical Configuration and Heating Efficiency

HWB-5

Electrical Heater Voltage Maximum Hourly Heating Capacity* (gallons)

Config. Code Configuration (AC) Phase Wires KW Amp Draw Cold Water Hot Water

H05041MIP 1 X 3.0 KW 220 1 ph. 2 + ground 2.5 11.6 6.2 14.4

240 1 ph. 2 + ground 3.0 12.6 7.4 17.2

HWB-10

Electrical Heater Voltage Maximum Hourly Heating Capacity* (gallons)

Config. Code Configuration (AC) Phase Wires KW Amp Draw Cold Water Hot Water

H10031MIP 2 X 3.0 KW 220 3 ph. 3 + ground 5.0 11.6 12.5 28.8

240 3 ph. 3 + ground 6.0 12.6 14.9 34.3

*Heating capacity is based on factory setting - 96°C / 205°F

2

Page 3

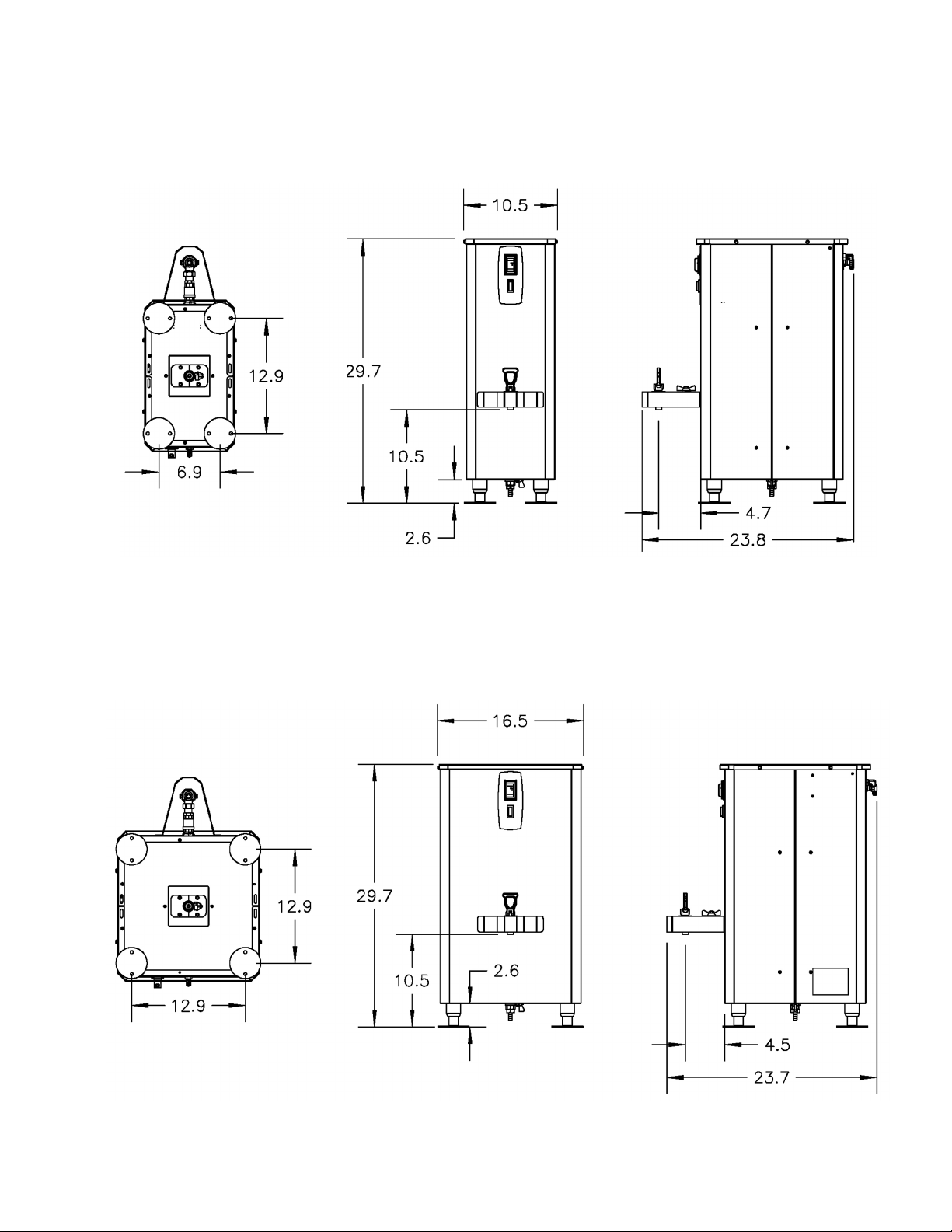

HWB-5

Dimensions

Dimensions

DimensionsDimensions

HWB-10

3

Page 4

necessary.

Installation

Installation

InstallationInstallation

(For Qualified Service Technicians Only)

Keys To A Successful Installation

Electrical:

• The power switch has a built-in circuit breaker. To reset it, turn to the “OFF” position, and then back to the

“ON” position.

• The wiring diagram for the dispenser is located on the inside of the cover.

Plumbing:

• The water line must be flushed thoroughly prior to connecting it to the dispenser to prevent debris from

contaminating the machine. An in-line water filter is strongly recommended.

• Verify that the water line will provide at least 1.5 gallons per minute before connecting it to the dispenser.

• The end of the vent tube must be open to the air, not connected to anything or submerged in liquid.

General:

• The installation must comply with applicable federal, state, and local codes having jurisdiction at your

location.

• Utilize only qualified beverage equipment service technicians for installation. A Service Company Directory

may be found on our web site, http://www.fetco.com.

• Do not adjust the thermostat settings unless absolutely necessary. They are set at the factory for optimum

performance.

Installation Instrucions

Setup

1. Before placing the unit, verify that it will fit in the space intended for it, and

that the counter or table will support its’ weight.

2. Place the unit on its back and screw in the legs.

3. Place the unit on the counter or stand.

4. When the unit is in position, level it front to back as well as side-to-side by

adjusting the legs.

5. Mark the surface of the counter with the location of the mounting holes in the legs.

6. Drill ¼” diameter holes in the counter and secure the legs to the counter with bolts and nuts (not included).

Water Connection

1. The water inlet is a 3/8” male flare fitting.

2. The dispenser can be connected to cold or hot water. Cold water is preferred for best flavor, but hot water will

allow for faster recovery times. Use of an in-line water filter is strongly recommended.

3. Install a shut off valve near the unit to facilitate service. If an in-line water filter is used, it should be installed

after the water shut off valve and in a position to facilitate filter replacement.

4. Flush the water supply line and filter before connecting it to the unit.

5. Verify that the water line provides at least 1.5 GPM, and that the water pressure is between 20 and 75 psig.

Vent Tube Connection

1. Condensation and steam from the water tank is discharged from the 3/8-inch hose barb fitting on the back of

the unit.

2. Attach a hose (not provided) to the fitting and run it to a drain, sink or a container. The end of the vent tube must

be open to the air, not connected to anything or submerged in liquid.

Electrical Connection

1. Verify that the actual voltage at the electrical service connection is compatible with the specifications on the

unit’s serial number label.

2. The temperature and water tank fill level are pre-set at the factory. There is no need to turn off the heaters

during the installation process. The control board disables the heaters until the tank is full of water. The

heating process will start automatically when the tank has filled.

4

Warning: Legs are to be

adjusted only for

leveling the unit.

Do not extend them

higher than

Page 5

L1

L1L1

L1

GROUND LUG

GROUND LUGGROUND LUG

GROUND LUG

GROUND

GROUNDGROUND

GROUND

WIRE

WIREWIRE

WIRE

GROUND

GROUNDGROUND

GROUND

WIRE

WIREWIRE

WIRE

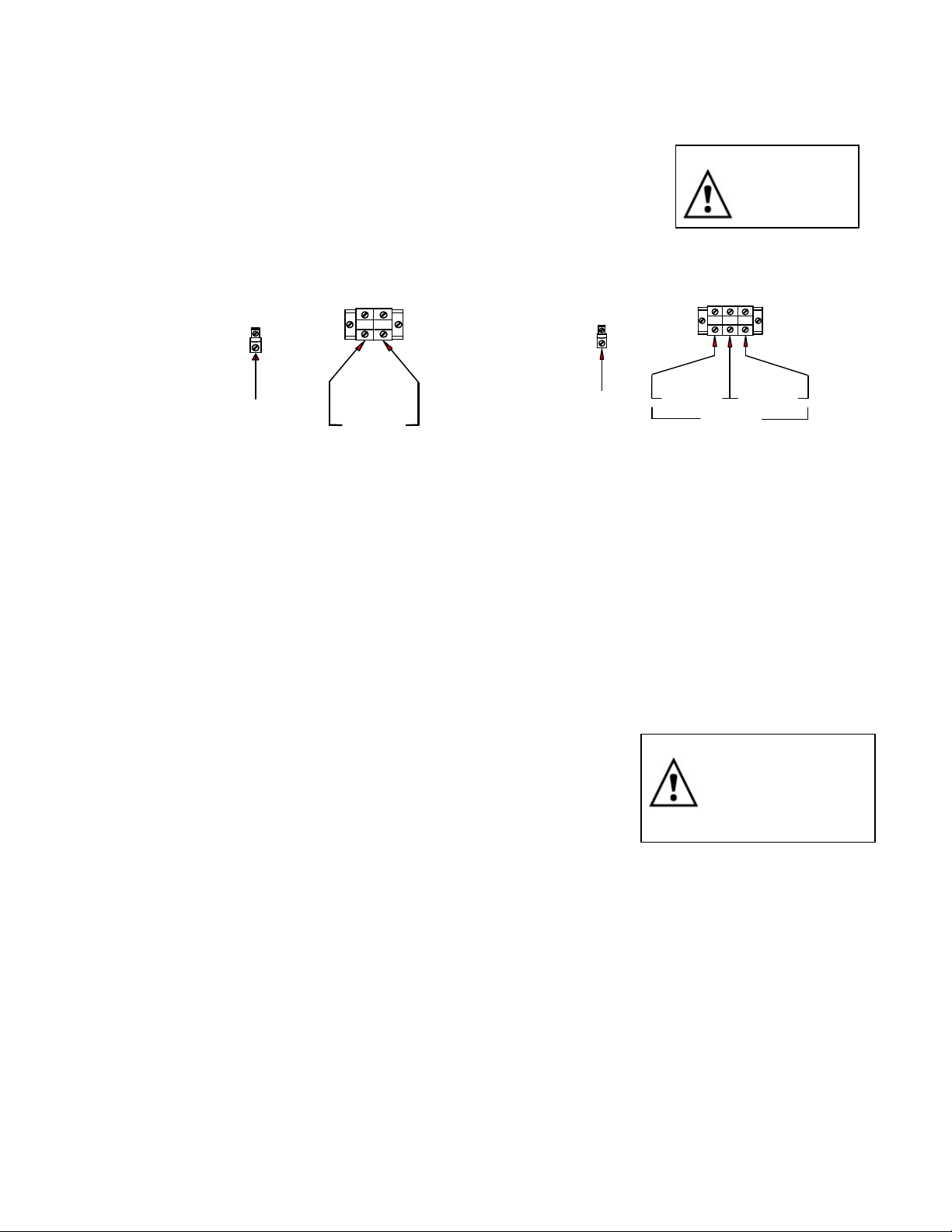

3. A terminal block is provided for connecting the incoming power wires. Consult local codes to determine if a cord

and plug can be installed, or if the unit must be hard wired.

4. A fused disconnect switch or circuit breaker on the incoming power line must be conveniently located near the

unit, and its location and markings known to the operators.

5. The body of the unit must be grounded to a suitable building ground. A ground

lug is provided next to the power terminal block. Use only 10 gauge copper

wire for grounding.

6. Electrical connections must be secured in-place within the unit to meet

Warning: To prevent

electrical shock,

this unit must be

properly grounded.

national and local standards.

7. Connect the incoming power wires to the terminal block in accordance with

applicable codes.

HWB

HWB----10 TERMINAL BLOCK

10 TERMINAL BLOCK

HWBHWB

HWB

HWB----5 TERMINAL BLOCK

5 TERMINAL BLOCK

HWBHWB

5 TERMINAL BLOCK5 TERMINAL BLOCK

L2

L2

L2L2

10 TERMINAL BLOCK10 TERMINAL BLOCK

GROUND LUG

GROUND LUG

GROUND LUGGROUND LUG

L1

L1 L2

L1L 1

L2 L3

L2L 2

L3

L3L 3

220

220----240V

240V 220-240V

220220

240V240V

220

220----240V

240V

220220

220

220----240V

240V

220220

240V240V

240V240V

Final Setup

1. Turn on the incoming water supply line and inspect both inside and outside of the unit for leaks in all fittings and

tubes.

2. Turn on the incoming power line and the power switch

3. Within 6 seconds, the water tank will begin filling until the probe at the top of the tank senses the water. The fill

valve will pulse off and on while the tank is filling. The heaters will be disabled until the water probe at the top of

the tank senses water.

4. Review the programming instructions and make any necessary adjustments.

5. Re-attach the cover after one final inspection for leaks.

Operator Training

Review the operating procedures with everyone who will be using the unit. Pay particular attention to the following

areas:

1. Demonstrate the hot water faucet.

2. Demonstrate the shut off valve behind the faucet, and review the safety

warning at right.

3. Show the location and operation of the water shut off valve and the circuit

breaker for the unit.

Warning: Do not disassemble the

faucet without first closing

the shut-off valve behind

the faucet.

Extremely hot water.

May cause serious burns.

5

Page 6

Operating Instructions

Operating Instructions

Turn the power switch to the ON position. The power switch will illuminate to indicate that the dispenser has power

and is operating.

When the ready light illuminates, the dispenser is fully up to temperature and ready to dispense hot water through

the faucet. The amount of time required to gain full operating temperature will vary depending on the electrical

configuration, and the temperature of the incoming water.

Safety Precautions:

• Do not hang containers or any other object from the faucet or faucet guard.

• Do not disassemble the faucet without closing the shut-off valve located behind the faucet.

Operating InstructionsOperating Instructions

Operating Principles

When hot water is drawn from the faucet, the fill valve pulses on and off every few seconds to slowly refill the tank.

(See %FV setting in the Programming section.)

By controlling the flow of incoming water, the amount of cold water entering the tank is synchronized with the rate at

which the water can be heated. This ensures an uninterrupted supply of hot water. When dispensing water at a rate

that exceeds the unit’s capacity to heat, the flow of water out of the faucet will be diminished to maintain the proper

temperature.

Maintenance

Quarterly:

• Inspect all fittings and hoses for leaks.

• Inspect inside of tank for lime deposits. De-lime tank and probes if necessary. This procedure should be

done by a qualified service technician.

6

Page 7

8 5 0 5

Programming

Programming

ProgrammingProgramming

The display shows the current water tank temperature in ° Celsius when

in normal operating mode.

Temperature may be set in either Celsius or Fahrenheit.

Service note: Whenever the digital temperature probe is replaced, it will be

necessary to reprogram all settings on the control board.

Remove the top cover of the unit.

The control board is located on the left side near the front.

Turn the power switch ON.

Press and hold the SET button for 3 seconds.

Temperature setting in °C will be displayed and °C indicator lamp will be lit.

To adjust, press and release SET quickly to advance one degree at a time.

Range: 82-98 °C

Press and hold SET for 3 seconds.

Temperature setting in °F will be displayed and °F indicator lamp will be lit.

To adjust, press and release SET quickly to advance one degree at a time.

Range 180-208 °F

Only the last 2 digits of the temperature will be displayed.

Example: 185°F is displayed as 205°F is displayed as

Press and hold SET for 3 seconds. The fill valve % will be displayed and the %FV

indicator lamp will be lit.

To adjust, press and release SET quickly to advance one percent at a time.

Refer to the chart below for the proper setting for your model and voltage.

Range: 15% – 100%.

The unit will automatically return to normal operating mode after 30 seconds

without programming activity.

Select the model and actual voltage to determine the correct %FV setting

for step 5.

Heater Actual %FV

Model Configuration Voltage Phase Setting

HWB-5 1 X 3000 watt 220 1 ph.

240 1 ph.

HWB-10 2 X 3000 watt 220 3 ph.

240 3 ph.

15

17

28

33

TEMPERATURE

CONVERSION

°°°°C °°°°F

82 180

83 181

83 182

84 183

84 184

85 185

85 186

86 187

87 188

87 189

88 190

88 191

89 192

89 193

90 194

90 195

91 196

92 197

92 198

93 199

93 200

94 201

94 202

95 203

95 204

96

97 206

97 207

98 208

factory setting

96°°°°C / 205°°°°F

205

7

Page 8

HWB-5

Wiring Diagrams

Wiring Diagrams

Wiring DiagramsWiring Diagrams

8

Page 9

HWB-10

9

Page 10

Figure 1 – HWB-5 – Main Assembly

Parts

Parts

PartsParts

10

Page 11

ITEM # QTY PART # DESCRIPTION

1

N/A N/A

2 2 03496 COVER, DRAIN OPENING, HW B'S, 304SS

3 1 104042 ASSEMBLY, TANK HWB-2005 (SEE FIG. 2)

4 1 13083 SHANK REAR HWB-2000'S

5 1 84007 NUT, 3/4-16 HEX JAM

6 1 34007 VALVE, BALL, 1/2" HWB-2000

7 1 13082 SHANK FRONT HWB-2000'S

8 1 71036 C - RING

9 1 31045 NUT, UNION 1-1/8 HEX

10 1 71078 FAUCET, HWB-2000

10 1 71035 FAUCET SEAT CUP, ES

10 1 71079 FAUCET UPPER ASSEMLBY, RED HANDLE, HWB

11 1 24012 GASKET, S-53 FILL VALVE

12 1 31078 FITTING, S-53 FILL VALVE INLET

13 1 03074 BRACKET, S-53

14 4 82020 SCREW, S-53 FILL VALVE

15

N/A N/A

16 1 31117 LOCKNUT 1/4"-18 NPT

17 1 25107 TUBE, 5/8"OD X 3/8"ID X 4.5"LG,COLD WATER, HWB-2005

18 2 86007 CLAMP, HOSE, .593"-.656" DIA RANGE

19 1 25108 TUBE, 1/2"OD X 1/4"ID X 7.0"LG VENT. HWB-2005

20 1 102213 ASSEMBLY, DIGITAL TEMP. PROBE, 12.0"LG/34"LG WIRE

21 1 102222 ASSEMBLY, WATER LEVEL PROBE, HWB-2000

22 1 45085 OVERLAY, HWB-2005

23 1 58006 LAMP, BREW 120VAC

24 1 52076 BREAKER,CIRCUIT 120VAC ROCKER SWITCH 6 AMP

25 8 83076 WASHER,#8 SCREW SIZE, CUSHION AND SEALING

26 2 29020 SPACER, HOT WATER VALVE

27 1 102221 ASSEMBLY, HEAT SINK HWB-2005

28 1 108013 ASSY. BOARD, CONT.& SOFT, HWB-2000, 230VAC

29 4 15007 STANDOFF, MALE-FEMALE, THREADED HEX 4-40-1/2"

30 1 65002 CONNECTOR, COPPER LUG

31 1 22077 INSULATION, TANK FRONT, HWB-2005

32 1 22078 INSULATION, TANK BACK, HWB-2005

33 2 22079 INSULATION, TANK, SIDE, HWB-2005/2010

34 1 22092 INSULATION, TANK TOP, HWB-2005

35 1 44004 LABEL GROUND

36 1 402141 HARNESS, LOW AMP, HWB-2005

37 1 22076 INSULATION, TANK BOTTOM, HWB-2005

38 1 402142 HARNESS, HIGH AMP, HWB-5, IP44, HALOGEN FREE

39 1 102223 ASSEMBLY, WATER LEVEL PROBE, HWB-2000, CBS-70'S

40 1 401370 W IR.DIAG., HW B-5, L1, L2+GRND,240VAC, 1 HTR

41 1 58086 BOOT, PROTECTIVE, NEON LAMP, IP44

42 1 52093 BOOT, PROTECTIVE, POWER SWITCH, IP44

43

N/A N/A

44 4 73021 LEG, INSERT, ADJ. FOOT S/S FLANGED W/ HOLES

45 1 002461 W ELDMENT, COVER, HWB-5, 304 S.S.

46 1 402145 GROUND WIRE, HALOGEN FREE

47 1 52050 TERMINAL BLOCK

48

N/A N/A

49 1 57059 FILL VALVE, S53, .75GPM, 240V EXPORT

NOT AVAILABLE FOR SALE

NOT AVAILABLE FOR SALE

NOT AVAILABLE FOR SALE

NOT AVAILABLE FOR SALE

11

Page 12

Figure 2 – HWB-5 – Tank Assembly, Part # 104042

ITEM # QTY PART # DESCRIPTION

1 1 004027 WELDMENT, TANK HWB-2005

2 1 53071 THERMOSTAT, SINGLE SHOT, 25A

3

4

N/A N/A

N/A N/A

5 5 31117 LOCKNUT 1/4"-18 NPT

6 1 107004 ASSEMBLY, HEATER, IMMERSION, 3000W/240VAC

7 1 24002 O-RING, TANK COVER

8 1 102013 ASSEMBLY, TANK COVER

9 1 102224 ASSEMBLY, TANK DRAIN, HWB-2000

10 1 32067 TUBE, 3/8"OD X 13.0LG COLD WATER INLET HWB-2000

NOT AVAILABLE FOR SALE

NOT AVAILABLE FOR SALE

12

Page 13

Figure 3 – HWB-10 – Main Assembly

13

Page 14

ITEM # QTY PART # DESCRIPTION

1

2 1 104044 ASSEMBLY, TANK HWB-2010 (SEE FIG. 4)

3 1 22107 INSULATION, TANK BOTTOM, HWB-2010

4 1 102223 ASSEMBLY, WATER LEVEL PROBE, HWB-2000, CBS-70'S

5 1 102213 ASSEMBLY, DIGITAL TEMP. PROBE, 12.0"LG/34"LG WIRE

6 1 102222 ASSEMBLY, WATER LEVEL PROBE, HWB-2000

7

8 2 03496 COVER, DRAIN OPENING, HW B'S, 304SS

9 8 83076 WASHER,#8 SCREW SIZE, CUSHION AND SEALING

11 1 84007 NUT,3/4-16 HEX JAM

12 1 13083 SHANK REAR HWB-2000'S

13 1 34007 VALVE, BALL, 1/2" HWB-2000

14 1 13082 SHANK FRONT HWB-2000'S

15 1 71036 C - RING

16 1 31045 NUT, UNION 1-1/8 HEX

17 1 71078 FAUCET, HWB-2000

17 1 71035 FAUCET SEAT CUP, ES

17 1 71079 FAUCET UPPER ASSEMBLY, RED HANDLE, HWB

18 4 29020 SPACER, HOT WATER VALVE

19 2 102221 ASSEMBLY, HEAT SINK HWB-2005

22 1 108013 ASSY. BOARD, CONT.& SOFT, HWB-2000, 230VAC

24 4 15007 STANDOFF, MALE-FEMALE, THREADED HEX 4-40-1/2"

25 1 52050 TERMINAL BLOCK

26 1 65002 CONNECTOR, COPPER LUG

27 1 44004 LABEL GROUND

28 1 57059 FILL VALVE, S53, .75GPM, 240V EXPORT

29 1 24012 GASKET, S-53 FILL VALVE

30 1 31078 FITTING, S-53 FILL VALVE INLET

31 1 03074 BRACKET, S-53

32

34 1 31117 LOCKNUT 1/4"-18 NPT

36 1 25107 TUBE, 5/8"OD X 3/8"ID X 4.5"LG,COLD WATER, HWB-2005

37 1 25108 TUBE, 1/2"OD X 1/4"ID X 7.0"LG VENT. HWB-2005

38 2 86007 CLAMP, HOSE, .593"-.656" DIA RANGE

39 1 45086 OVERLAY, HWB-2010

40 1 52076 BREAKER,CIRCUIT 120VAC ROCKER SWITCH 6 AMP

41 1 52093 BOOT, PROTECTIVE, POWER SWITCH, IP44

42 1 58086 BOOT, PROTECTIVE, NEON LAMP, IP44

43 1 58006 LAMP, BREW 120VAC

44 1 24061 GRIP, FLAT, RED 0.25 X 2 X 1.125

45 1 402144 HARNESS, HIGH AMP, HWB-10, IP44, HALOGEN FREE

46 1 402143 HARNESS, LOW AMP, HWB-10, IP44, HALOGEN FREE

47 1 002465 WELDMENT, COVER, HWB-10, 304 S.S., IP-44

48 4 82020 SCREW, S-53 FILL VALVE

49 1 22108 INSULATION, FRONT, TANK, HWB-2010

50 2 22079 INSULATION, TANK, SIDE, HWB-2005/2010

51

54 1 22109 INSULATION, TANK BACK, HWB-2010

55 1 22093 INSULATION, TANK, TOP, HWB-2010

57 1 402145 GROUND WIRE, HALOGEN FREE

58 4 73021 LEG, INSERT

59 1 401368 WIRING, DIAGRAM HWB-2010

N/A N/A

N/A N/A

N/A N/A

N/A N/A

NOT AVAILABLE FOR SALE

NOT AVAILABLE FOR SALE

NOT AVAILABLE FOR SALE

NOT AVAILABLE FOR SALE

14

Page 15

Figure 4 – HWB-10 – Tank Assembly, Part # 104044

ITEM # QTY PART # DESCRIPTION

1 1 004028 WELDMENT, TANK HWB-2010

2 1 53071 THERMOSTAT, SINGLE SHOT, 25A

3

4

N/A N/A

N/A N/A

NOT AVAILABLE FOR SALE

NOT AVAILABLE FOR SALE

5 5 31117 LOCKNUT 1/4"-18 NPT

6 2 107004 ASSEMBLY, HEATER, IMMERSION, 3000W/240VAC

7 1 24002 O-RING, TANK COVER

8 1 102013 ASSEMBLY, TANK COVER

9 1 102224 ASSEMBLY, TANK DRAIN, HWB-2000

10 1 32067 TUBE, 3/8"OD X 13.0LG COLD WATER INLET HWB-2000

15

Page 16

Loading...

Loading...