Page 1

t

∫

Touch Function Selector Technology

f

NOTICE TO INSTALLER: Please leave this book with the machine.

User’s Guide

HWD-2105

Hot Water Dispenser

Temperature On Demand US design patent applied for. Other Temperature On Demand US patents applied for.

FETCO®, is a trademark of Food Equipment Technologies Company.

© 2011 Food Equipment Technologies Company Part Number P115 April 2013

Page 2

FETCO® HWD-2105 Hot Water Dispenser

FETCO®

Food Equipment Technologies Company

600 Rose Road

Lake Zurich • IL • 60047-0429 • USA

Internet: www.fetco.com

Phone: (800) 338-2699 (US & Canada)

(847) 719-3000

Fax: (847) 719-3001

Email: sales@fetco.com

techsupport@fetco.com

Description & Features

Contact Information

Water temperature selectable to 158°-204°F/70-96°C English and Metric temperature ranges selectable

Maximum single dispense is 24ounces/700cc in 15 seconds maximum dispense time

Non-Temperature on Demand and Temperature on Demand (TOD) configurations is available as separate equipment.

Specifications

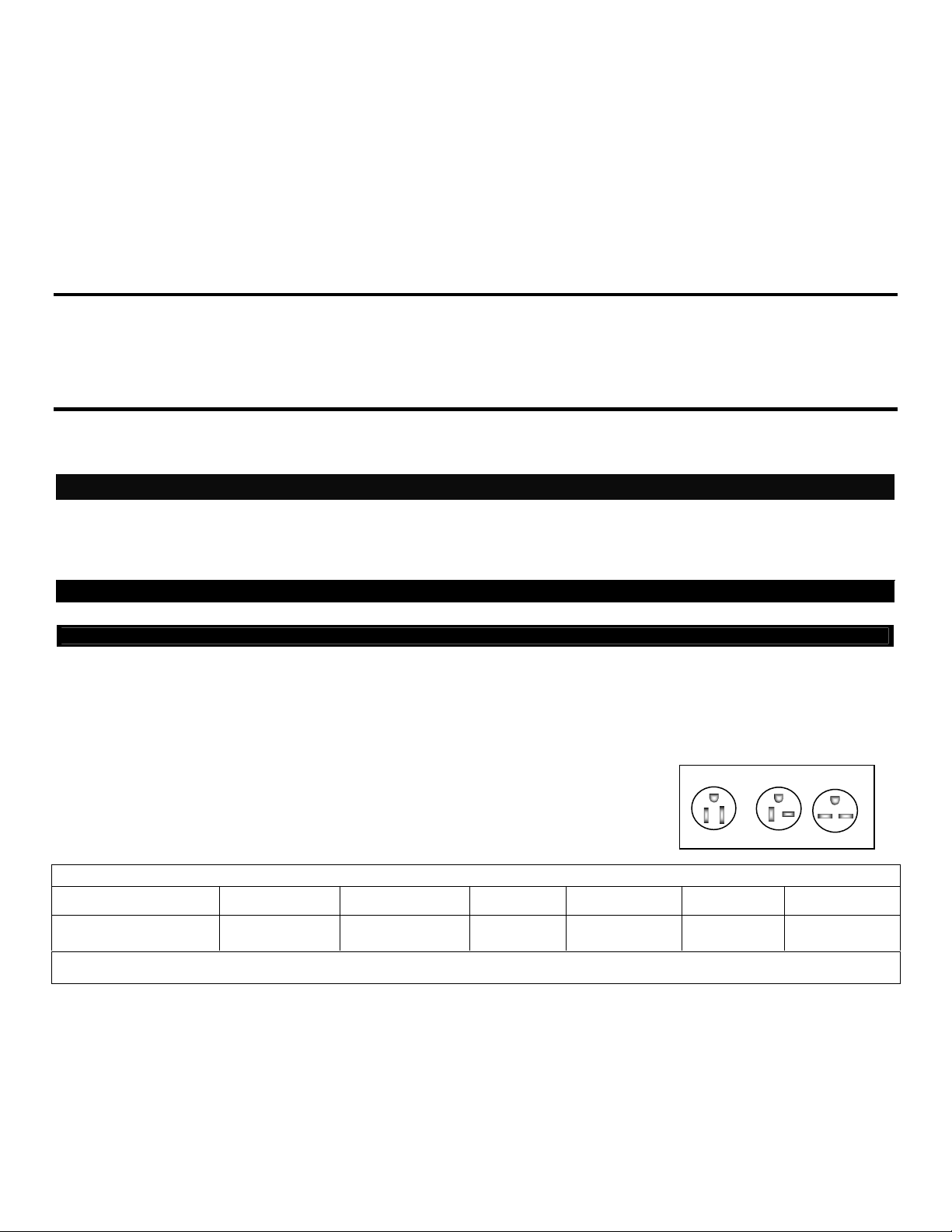

Standard Electrical Configurations-DOMESTIC & CANADA

Configuration

Code

H210511

H210521

Standard Electrical Configurations-DOMESTIC & SPECIALTY

H210531

Electrical Configurations- EXPORT & CANADA

H210541

Temperature range is selectable from 158°-207°F/70-97°C based on 207°F/97°C hot water tank temperature.

*Flow rate based on 65-70°F 18-21°C water mains supply temperature at lowest possible power supply current.

Selectable English and Metric temperature units. † For EXPORT, Cord without plug will be attached

Single touch pad selectable hot water dispense temperature.

Water Requirements:

Dispenser Model

Hot Water Dispenser

HWD-2105

NOTE: Temperature accuracy of dispensed hot water may vary up to 3 ½ % of displayed temperature selection. Factors affecting accuracy include quantity of hot

water dispensed, ambient air temperature, distance of container from hot water faucet (pouring over longer distance causes more cooling)

NEW TECHNOLOGICAL FEATURES

The FETCO hot water dispenser uses new

t

∫

Touch Function Selector buttons (above and below display screen) alternately dim and brighten when selection is not active.

The

f

Dispensing and Feature Selections activate when touched. The front panel is clean and uncluttered.

Programming, display and error codes are interactive and more intuitive.

Float indicator is built into drip tray to help simplify maintenance and cleaning.

NOTE:

The HWD-2105 Digital Hot Water Dispenser cannot be modified into a HWD-2105 TOD Temperature on Demand Hot Water Dispenser

Heater

Configuration

Voltage Phase Wires

1 X 1.44 kW 120 1

1 X 2.1 kW 120 1

1 X 3.2 kW 200-240 1

1 X 3.2 kW 230 1

2+G

2+G

2+G

2+G

NEMA

Plug

NEMA 5-15P

NEMA 5-20P

NEMA 6-15P

Cord Only†

Pressure: 40-75 psig, (276-517kPa)

Minimum Flow Rate: 1½gpm (5.7lpm)

Water connection inlet: ¼ inch male flare fitting

Weights and Capacities

Weight

(empty)

24 lbs/10.9kg

Water tank

Capacity

3.2 gallon/12

liter

t

∫

Touch Function Selector Technology to operate the hot water dispenser.

f

Weight

(filled)

49 lbs/22kg

Maximum

KW

Amp Draw

Gallons/Hour

1.5 12.0 4.0 gallon*/15 liter

2.2 17.5 5.7 gallon*/22 liter

2.3-3.3 11.2-13.4 6-8.7gallon*/22.7-33 liter

2.9 12.8 7.8 gallon*/29.5 liter

Power Plug Configurations

Height

Inches/cm

24 1/2 in/62

cm

NEMA PLUG CONFIGURATION

G

W

NEMA 5-15P NEMA 5-20P NEMA 6-15P

Wide

Inches/cm

9 in/23 cm

G

W

18 1/2 in/47 cm

Deep

Inches/cm

2

Page 3

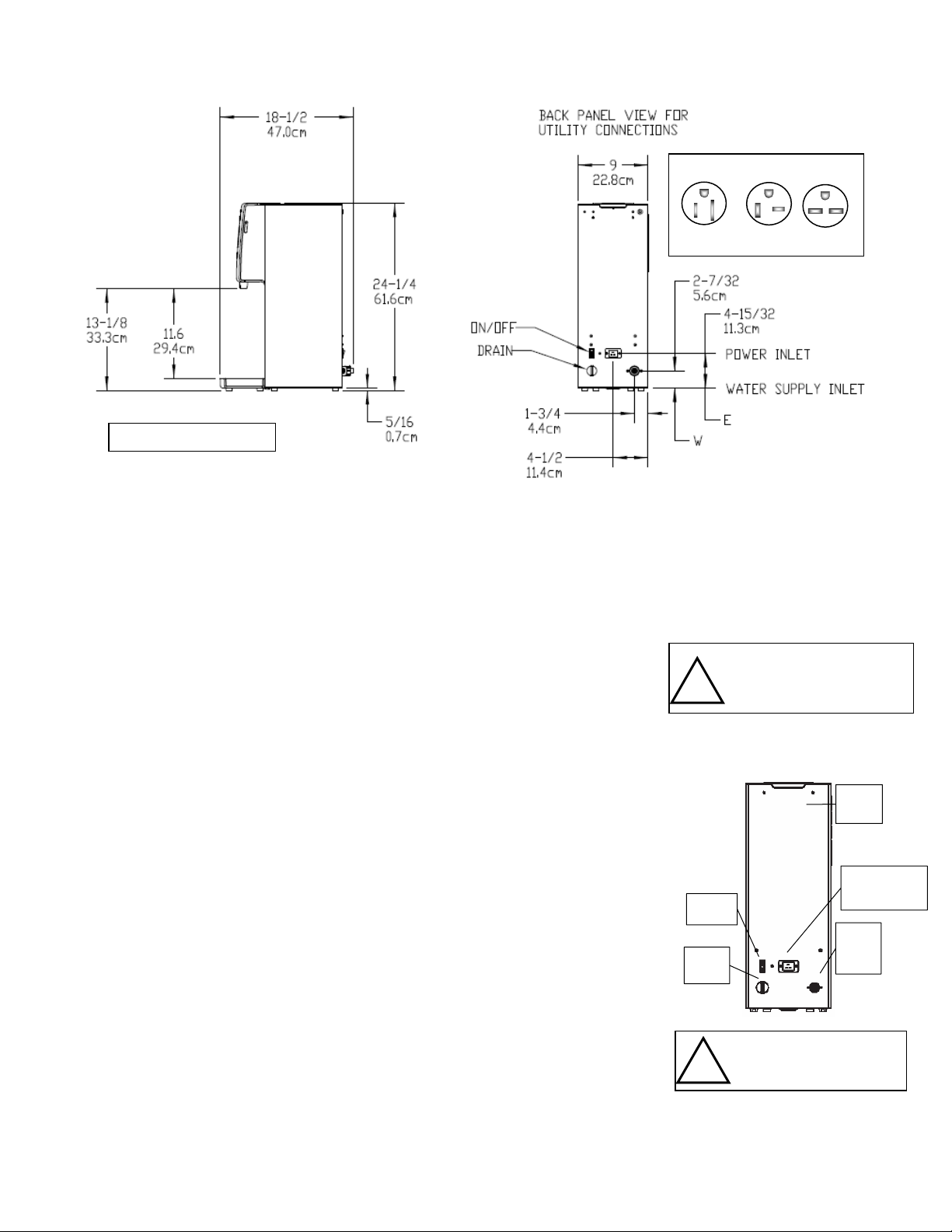

Dimensions & Utility Connections

A

Drawing # 1201.00001.00

Water inlet fitting: ¼ inch male flare fitting

NEMA PLUG CONFIGURATION

G

W

NEMA 5-15P NEMA 5-20P NEMA 6-15P

G

W

Installation

The installation must comply with applicable federal, state, and local codes having jurisdiction at your location. Utilize only

qualified beverage equipment service technicians for installation.

A Service Company Directory may be found on our website, http://www.fetco.com.

Setup

1. Before placing the unit, verify that it will fit in the space intended for it, and that

!

Warning: Legs are to be adjusted

only to level the unit. Do not extend

them higher than necessary

the counter or table will support the weight of the HWD-2105 when filled.

2. When the unit is in position, use a bubble level to level it front to back and side

to side by adjusting the legs.

Water Connection

1. Water inlet is a ¼ inch male flare fitting.

2. Install a shut off valve near the unit to facilitate service.

Back panel of HWD-2105

Tank

Vent

3. Install a backflow prevention device. A spring loaded double check valve such as a

WATTS® SD-2 or SD-3, two models accepted by most zoning authorities. The

check valve should be as close to the water supply inlet as possible.

4. An inline water filter is highly recommended. It should be installed after the water

shutoff valve and in a position to facilitate filter replacement.

5. Flush the water supply line and filter before connecting it to the unit.

6. Verify that the water line provides at least 1½ gpm (5.7lpm), and that the water

pressure is between 40-75 psig (276-517kPa).

Power

Switch

Tank

Drain

ppliance Inlet

(attach power cord)

Water

Supply

Inlet

Electrical Connection

1. Check serial number plate for the maximum wattage and verify that the actual

voltage at the electrical outlet is compatible with the unit’s specifications.

2. Plug unit in. Note that the plug is NEMA 5-15P or NEMA 5-20P (domestic).

3. The temperature and water tank fill level are pre-set at the factory and there is

no need to turn off the heater during the installation process.

To prevent electrical shock, this

!

unit must be properly grounded.

Warning:

The heating process will start automatically when the tank is filled enough to

cover the heating element

WARNING-Do not plug-in this equipment or attempt to operate without all covers in place all and screws fastened.

3

Page 4

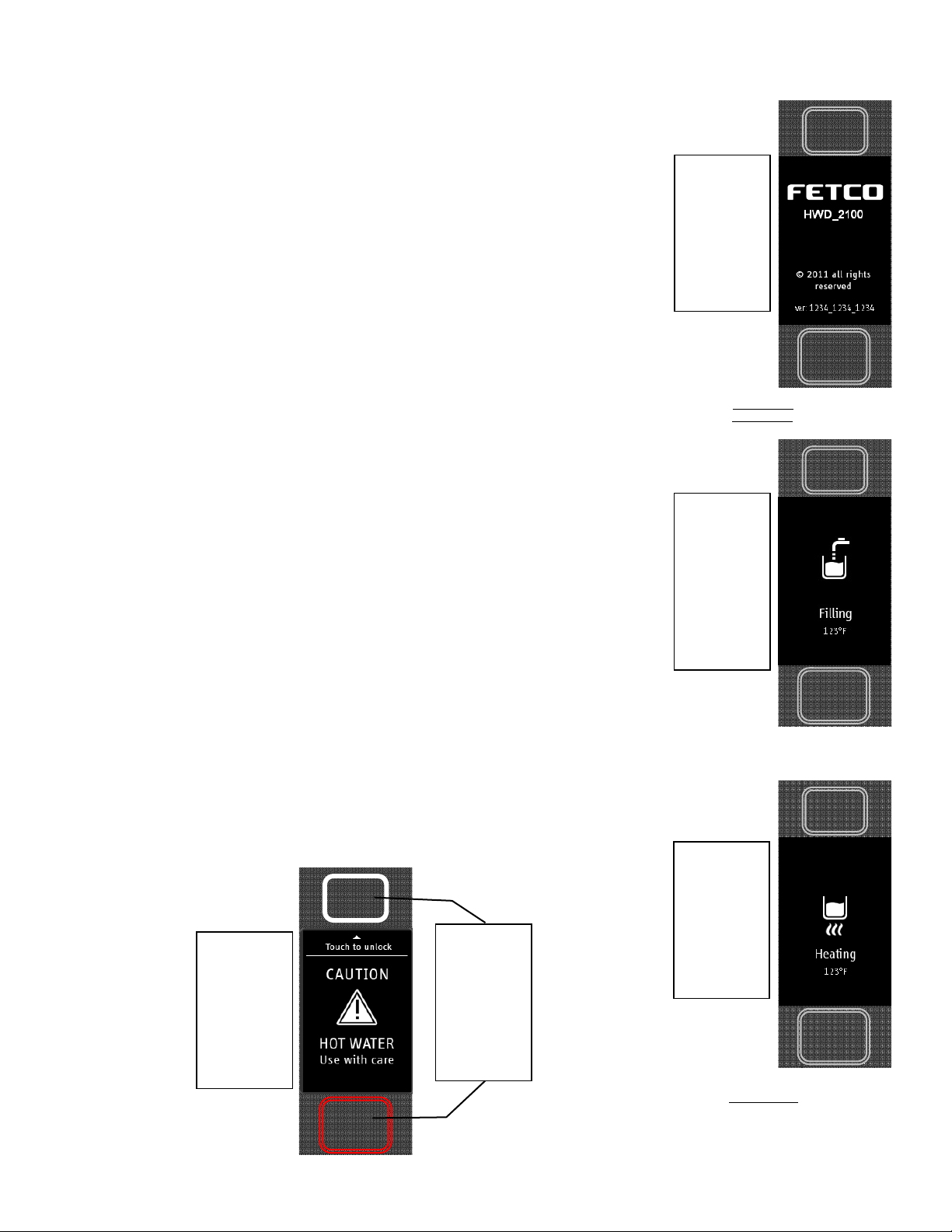

Final Setup-Fill and Initial Heating

1. Turn on the incoming water supply line and inspect both inside and outside of

the unit for leaks in all fittings and tubes.

2. Plug the unit into the appropriate electrical outlet.

3. Turn on the unit’s main power switch (located on the back).

Screen one-the FETCO Home Screen will display.

4. Within 6 seconds, the water tank will begin filling until tank probe senses water

Screen two, the “FILLING” will display.

5. Water will cover heating element or when tank water is heating from cold,

Screen three-the “HEATING” Screen will display.

The upper and lower “Touch Function Selector” will not light.

6. After the water has reached the set temperature, the lower “Touch Function

Selector” will light red color to signal READY

(The touch selector buttons will alternately dim and brighten when selection is not active)

7. The display will read the four temperature settings as the tank temperature

rises. More detailed operation information follows

8. The upper “Touch Function Selector” will light when the pre-set is ready

9. Re- inspect for leaks.

Operating Instructions

1. Turn the main power switch on.

2. Touch the upper “Touch Function Selector”, tapping finger to scroll to select

3. When a temperature is enlarged and brightened - that temperature is available.

Touch the lower red selector to dispense hot water.

4. Maximum continuous “ON” is fifteen seconds in a single activating touch

5. Maximum dispense is approximately 1quart/1 liter.

Approximately three 1quart/1 liter batches may be dispensed in succession.

6. Unit returns to inactive “Enabled Screen” if no water is dispensed in 3 seconds

7. Steam and condensation from the water tank is released into the vent

whenever the unit is on. Access the vent barbed fitting located on the upper

back to run gravity drain. For venting to a drain, tubing requirement is ¼” I.D.

(To prevent vacuum backflow, do not place discharge end of vent drain tube

into drain sump)

Operator Training

Review the operating procedures with everyone who will be using the unit.

Pay particular attention to the following areas:

1. How to change temperature settings (See page 7) & dispensing water

2. Scrolling and selecting temperatures and operating the hot water faucet.

Pay particular attention to the safety warnings. (See page 6 & 7)

3. Refer to cleaning procedures and drip tray, listed on the following page.

4. Show the location of the on/off switch, water shut off valve and the utility power

supply circuit breaker for the unit. (See page 3)

DISPENSE

ENABLED

SCREEN

Icon appears after

tank fill and

heating. At least

one temperature

is available for

dispensing

Upper Touch

Function Selector

scrolls the menu

selection option

Lower Touch

Function Selector

selects and

activates selected

The three primary screens for HWD-2105 start up

Home Screen

when power is

turned on.

(Three screens in

“Standby Mode”Controls inoperative)

Above-Screen One-FETCO Home Screen

Below-Screen Two

Hot Water Tank is

filling.

Upper and lower

Touch Function

Selectors will

disappear, dim, or

brighten while in

standby or while

filling or heating.

(Controls inoperative)

Hot Water Tank is

heating.

Icon appears from

first fill or during

reheating from an

unheated state or

depleted tank.

(Controls inoperative)

Above-Screen Three-HWD Status Screen

-HWD Status Screen

4

Page 5

Operating Principles

The dispense valve assembly delivers precision temperature water at selected temperatures.

When hot water is drawn from the faucet, the fill valve pulses on and off every few seconds to replenish the tank.

By controlling the flow of incoming water, the amount of cold water entering the tank is synchronized with the rate

at which the water can be heated. This ensures an uninterrupted supply of hot water.

When dispensing water at a rate that exceeds the unit’s capacity to heat, the screen will show that the

temperature is not available.

If hot water tank supply is depleted during high use, faucet will temporary “lockout” to allow the hot water tank to

reheat for an adequate hot water supply. The “HEATING” screen will display at this time.

Cleaning & Maintenance

Daily:

• Check the drip tray and empty if necessary.

Quarterly:

• Inspect all fittings and hoses for leaks.

• Inspect inside of tank for lime deposits. De-lime tank and probes if necessary. This procedure should

be performed by a qualified service technician

Notice:

• Turn off power to the HWD-2105 before any cleaning procedure, including wiping the exterior for

appearance reasons. Dry the exterior, especially the face panel, before turning on power.

WARNING:

• Do not apply any type of spray cleaner on the face panel of this equipment.

• Never use any solvent based cleaner or polish on this equipment.

• Dry the face of the HWD-2105 before turning on power.

• WARNING-Do not plug-in this equipment or attempt to operate without all covers in place and all

screws fastened.

Tank Drain

The water tank must be drained before maintenance procedures, and when the unit is to be relocated or shipped.

1. Disconnect power to the unit.

2. Move the unit near a sink or obtain a container to large enough to hold the four gallons of water from the tank.

3. Remove the tank cover and allow the tank to cool to a safe temperature.

4. The tank drain is located on the back of the unit. Turn the drain plug one-quarter turn in either direction.

5. Pull the plug out far enough to expose the silicone tube.

6. Using pliers loosen the hose clamp and move it back over the tube.

7. Crimp the tube an inch or two away from the drain plug to prevent water from flowing.

8. Use the other hand to pull the drain plug out of the tube.

9. Release the crimped tube and allow the water to flow into the sink or container.

5

Page 6

Control and Operational Screens

The FETCO® Hot Water Dispenser uses a digital display screen and illuminated touch pads to control the set-up and on-off

water functions.

-Upper and lower pads are lighted when ready, and may alternately brighten and dim.

-Touch lower (red) pad to activate.

-“WARNING-HOT WATER” screen will light for two to three (2-3) seconds

-The upper (white) selector pad will light when selected temperature is ready

-Touch and hold lower (red) pad to dispense hot water.

-Maximum single dispense is 24ounces/700cc in 15 seconds maximum dispense time

-When dispensing an amount of water- (“DISPENSE ENABLED SCREEN”) displays after five (3) seconds inactivity.

HOME SCREEN First screen on start-up HEATING

No temperatures ready

DISPENSE ENABLED

Touch to go to next screen

Hot water dispense

enabled

Fault state, Error.

Screen will pulse

and lock out dispense

6

Page 7

Programming and diagnostic screens

g(°F)

To enter Programming and Diagnostics dialog screens

Turn power switch on lower back of unit “OFF”

Turn power switch “ON” and when first screen is displayed touch lower (red) pad to activate

The First Programming screen will display. Displayed are the default settings

Touch upper “Touch Function Selector” to scroll through the programming lines.

Touch lower (red) pad to scroll through the screens and active outputs.

Setting as displayed will be saved on exit.

EXIT Programming and Diagnostics dialog by selecting EXIT and touching the lower (red) pad

Programming for

hot water tank

temperature setting

(also dispense

temperature)

and display units (°C

or °F)

PROGRAMMED

Tank Temperature

and Dispense

Internal tank functions

Verify probe readings

for tank temperature,

and water level.

Show status of liquid

level probes for tank

water level.

Touch pad verification

( instructions in

following section)

Output TOD functions

And test points.

Will activate

selection for 2-3

seconds.

Service technician

error report for fault

and software

diagnostics and

upgrade

Temperature are

the same

000 000 201

0510 0102 1122

Error Code Screen

Error codes are cleared by

selecting the “OTHER “ screen.

Scroll and press the upper

control to “Reset Error Codes”.

Press the lower selector to clear.

Error codes

050 Shorted temperature probe - tank

051 Open temperature probe - tank

052 Outlet temperature sensor shorted

053 Outlet temperature sensor open

100 Initial fill error (not filled in 6 minutes after power up)

101 Error on refill (The tank has not refilled in 1 minutes-

Possibly faulty solenoid or issue with the water line)

102 Unwanted fill (Possibly tank or internal leak)

103 Overflow error (float switch activated)

104 Lower (longer) liquid level probe fault

105 Upper (shorter) liquid level probe fault

200 Flat line temperature

201 Heater open (heater or triac failure)

Touch pad function test

Tests the Upper and Lower touch pads for proper sensitivity.

Use after servicing to check functionality of the touch pad

When selected - the indicator will display the key being touched.

The example to the right shows the UPPER -White key is active.

Touching the LOWER-Red pad will highlight the red key marker

Circuit logic digits may display variable number. Used for manufacturing

programmed into the equipment

Chart to correct for boiling point for altitude

in tank water temperature.

See INPUT Screen

Altitude (ft.)

-500 207 212.9

0 207 212.0

500 207 211.1

1000 205 210.2

2000 204 208.4

2500 203 207.5

3000 200 206.6

3500 197 205.7

4000 195 204.8

4500 194 203.9

5000 194 203.0

5500 193 202.0

6000 192 201.1

6500 191 200.2

7000 190 199.3

7500 188 198.3

8000 187 197.4

Suggested

Settin

Boiling

point (° F)

7

Page 8

Drawing 1109.00026.00

HWD-2105 NON-TOD Service Parts

PARTS LIST FOR HWD-2105 NON TOD Service Parts Drawing 1109.00026.00

ITEM NO PART NO DESCRIPTION QTY

1 1023.00131.00 TOP COVER HWD-2105 1

2 1023.00136.00 LEG HWD-2100 4

3 1023.00147.00 PLUG, TANK SERVICE DRAIN for 18GA AND UP BODY 1

4 1024.00040.00 CARD PLUG, HWD-2100 1

5 1025.00039.00 TUBE, 5/8" OD X 3/8 ID X 10" LG, DRAIN 1

6 1025.00040.00 TUBE, 1/4" OD X .125" ID X 16" LG, VENT 1

7 1025.00041.00 TUBE, 3/4" OD X 1/2" ID X 2.75" LG, DISPENSE 1

8 1025.00042.00 TUBE, 5/8" OD X 3/8" ID X 2" LG, BOTTOM TANK 1

9 1025.00044.00 TUBE, SILICONE, 5/16" OD X 3/16" ID X 10.5" LG, TANK VENT 1

10 1025.00046.00 TUBE, 5/8" OD X 3/8" ID X 5.0" LG, DOUBLE VALVE 1

11 1029.00002.00 FITTING, HOSE BARB TEE, SIZE 3/8" , NYLON 1

12 1029.00017.00 FAUCET, SILICONE, HWD-2100 1

13 1029.00023.00 FITTING, SINGLE BARBED ELBOW, 1/4", KYNAR 1

14 1057.00043.00 SOLENOID VALVE, SINGLE, 180 DEG, 24VDC 1

15 1058.00020.00 SWITCH, POWER ROCKER RED, ILLUMINATED 250V 1

8

Page 9

16 1063.00001.00 CORD, POWER, IEC-320-19, 20A/125VAC 1

16 1063.00002.00 CORD, POWER, IEC-320-19, 15A/125VAC 1

17 1065.00001.00 CONNECTOR, IEC POWER EN60320 C20, 0722 SERIES 1

18 1086.00002.00 CLAMP, HOSE, SIZE "G" NYLON 2

19 1086.00003.00 UNICLAMP, 15.9 HOSE OD CLAMP 6

20 1102.00153.00 FRONT PANEL TOP, ASSEMBLY HWD-2100 1

21 1102.00156.00 DRIP TRAY ASSEMBLY, HWD-2100 1

22 1102.00159.00 POWER SUPPLY ASSEMBLY, HWD-2100 1

23 1102.00160.00 BOARD AND DISPLAY ASSEMBLY, HWD-2100 1

24 1102.00164.00 ADAPTER ASSEMBLY, 3/4" BSP X 1/4 SAE FLARE 1

25 1102.00167.00 DISPENSE VALVE ASSEMBLY, HWD-2100 1

26 1104.00018.00 TANK ASSEMBLY, 2100W/120V, HWD-2105 1

26 1104.00031.00 TANK ASSEMBLY, 1440W/120V, HWD-2105 1

26 1104.00032.00 TANK ASSEMBLY, 3200W/200-230V, HWD-2105 1

27 1402.00020.00 HARNESS, UNIVERSAL, HWD-2105 1

9

Page 10

1109.00030.00

SERVICE PARTS, TANK, HWD-2105

PARTS LIST FOR HWD-2105 With TOD Hot Water Tank Drawing 1104.00018.00

ITEM# PART# DESCRIPTION QTY

1 1107.00008.00 HEATER ASSEMBLY, IMMERSION 2100W/120VAC 1

1 1107.00014.00 HEATER ASSEMBLY, IMMERSION 1440W/120VAC 1

1 1107.00015.00 HEATER ASSEMBLY, IMMERSION 3200W/200-230VAC EXPORT 1

2 1059.00001.00 TRIAC 40A, 600V 1

3 1053.00004.00 THERMOSTAT, SINGLE SHOT, 25A 1

4 1024.00007.00 O-RING, DASH #344, TANK COVER 1

5 1102.00007.00 TANK COVER ASSEMBLY 1

6 1054.00006.00 FILL SENSOR, HWD TOD 1

7 1051.00016.00 BOARD, TRIAC DRIVE WITH RC FILTER 1

8 1102.00161.00 PROBE ASSEMBLY, TEMP. AND LLC, HWD-2105 1

10

Page 11

11

Loading...

Loading...