Page 1

FOOD EQUIPMENT TECHNOLOGIES COMPANY

640 Heathrow Drive • Lincolnshire • IL • 60069 • USA

Phone: (800) 338-2699 • (847) 821-1177 • Fax: (847) 821-1178

Emergency Service Only: (800) 660-0035 (U.S. & Canada)

E-mail: techsupport@fetco.com • Internet: http://www.fetco.com

3

User’s Guide

Installation - Operation - Service

Hot

Models: HWB-5

HWB-10

Water

HWB-15

HWB-25

Dispensers

Table of Contents

Introduction..................................................................... 2

Product Description/Features ........................................ 2

Technical Data ............................................................... 2

Specifications:............................................................. 2

Weights and Capacities.............................................. 2

Electrical Configuration and Heating Efficiency ......... 3

Installation ...................................................................... 3

Keys To A Successful Installation .............................. 3

Installation Check List................................................. 4

Dimensions..................................................................... 5

FETCO is a trademark and LUXUS is a registered trademark of Food Equipment Technologies Company.

Operating Procedures ....................................................6

Service............................................................................6

Warranty .....................................................................6

Principles of Operation ...............................................6

Adjustments ................................................................7

Basic Troubleshooting ................................................8

HWB Replacement Parts ...............................................9

Cleaning........................................................................10

Wiring Diagrams ...........................................................11

Part # P011 Revised November 4, 2002

Page 2

Introduction

Thank you for choosing one of FETCO's premium quality, hot water dispensers.

As a recognized industry leader in quality, performance, and price, FETCO designs and manufactures dispensers

that are designed to work -- day in and day out, without compromise.

With craftsman like execution, each FETCO product is evaluated for quality, pre-set for installation, and 100% tested

for performance prior to shipment.

If you have any questions about your new dispenser, please call FETCO at (800) 338-2699, or visit our web site at

http://www.fetco.com.

Product Description/Features

Hot Water Dispensers:

• Available in 5, 10, 15, and 25 gallon models • Total serviceability from the front and top

• All stainless steel construction • Drain valve

• Fully insulated side and top for operator safety • Guard protected gauges and faucets

• Compact space saver design

• Controlled refill - no recovery time

• Fully protected control system • Custom and export voltage

• Fully automatic • Drip tray

• All control components top mounted

Optional Features:

Technical Data

Specifications:

Water Requirements: 20-75 psig - 2.0 gpm Temperature

Ready light is set to turn off at 195°

Weights and Capacities

Model Weight

HWB-5 48 lbs 5 Gallons 90 lbs. 2.5 Gal. Minute 13.4 Gallons

HWB-10

HWB-15

HWB-25

Dispenser

⊕

⊕

⊕

Water tank

Capacity.

10 Gallons

15 Gallons

25 Gallons

not available at time of publication

⊕

Total Dispenser

Weight

⊕

⊕

⊕

:

205°F inside water tank (at sea level)

Faucet Flow

Rate

2.5 Gal. Minute 24.9 Gallons

2.5 Gal. Minute 29.9 or 37.3 Gallons

2.5 Gal. Minute 69.6 Gallons

First Hour of Production

connected to cold water

2

Page 3

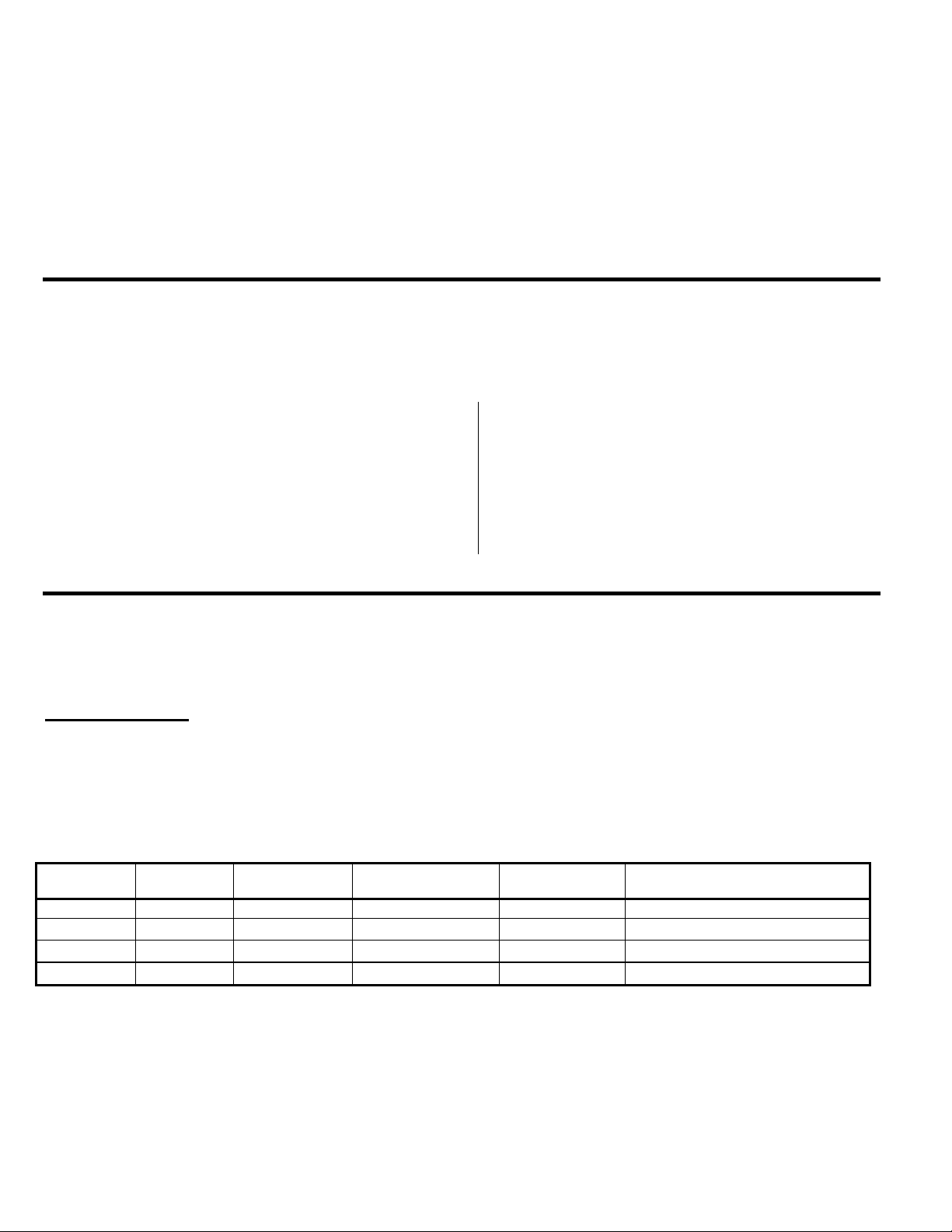

Electrical Configuration and Heating Efficiency

Heater Voltage Amp. Hourly Heating Capacity (gallons)

Model Configuration Connection Phase Wires KW draw Cold Water * Hot Water **

HWB-5 (-1) 1 X 3000 watt 120/208 1 ph. 3 + ground 2.4 11.3 5.6 12.9

120/220 1 ph. 3 + ground 2.7 12.4 6.5 14.9

120/240 1 ph. 3 + ground 3.1 13.0 7.4 17.2

HWB-10 (-1) 2 X 3000 watt 120/208 1 ph. 3 + ground 4.6 22.1 11.2 25.8

120/220 1 ph. 3 + ground 5.3 24.2 12.9 29.9

120/240 1 ph. 3 + ground 6.1 25.5 14.9 34.3

HWB-15 (-1) 2 X 3000 watt 120/208 1 ph. 3 + ground 4.6 22.1 11.2 25.8

120/220 1 ph. 3 + ground 5.3 24.2 12.9 29.9

120/240 1 ph. 3 + ground 6.1 25.5 14.9 34.3

HWB-15 (-2) 3 X 3000 watt 120/208 3 ph. 4 + ground 6.9 19.2 16.7 38.6

120/220 3 ph. 4 + ground 7.9 21.0 19.4 44.8

120/240 3 ph. 4 + ground 9.1 22.2 22.3 51.5

HWB-25 (-1) 6 X 3000 watt 120/208 3 ph. 4 + ground 13.6 38.0 33.5 77.3

120/220 3 ph. 4 + ground 15.8 41.6 38.8 89.6

120/240 3 ph. 4 + ground 18.1 43.8 44.6 103.0

HWB-25 (-2) 6 X 4000 watt 120/208 3 ph. 4 + ground 18.1 50.5 44.6 103.0

120/240 3 ph. 4 + ground 24.1 58.2 59.5 137.4

(special order)

120/220 3 ph. 4 + ground 21.0 55.3 51.8 119.5

Installation

(For Qualified Service Technicians Only)

Keys To A Successful Installation

FETCO dispensers are rugged and reliable machines that will provide many years of service. However, if not

installed correctly by qualified personnel, the unit will not operate properly and damage may result. Damages resulting

from improper installation are not covered by the warranty.

Here are the key points to consider before installation:

Electrical: All FETCO dispensers require NEUTRAL. Ground is not an acceptable substitute. Installation

without neutral will almost certainly cause damage to the electronic components.

The power connection to L1 on the terminal block must be at least 105 volts. Less than 105 volts will cause

erratic behavior.

The power switch has a built-in circuit breaker. To reset it, turn to the “off” position, and then back to the “on”

position.

The electrical drawing for the dispenser is located on the inside of the cover.

Plumbing: This equipment is to be installed to comply with the applicable federal, state, or local plumbing codes.

The water line must be flushed thoroughly prior to connecting it to the dispenser to prevent debris from

contaminating the machine.

Verify that the water line will provide at least 2 gallons per minute before connecting it to the dispenser.

General: Utilize a qualified beverage equipment service technician for installation.

Do not adjust the thermostat settings unless absolutely necessary. They are set at the factory for optimum

performance.

3

Page 4

Installation Check List

The installation must comply with applicable federal, state, and local codes having jurisdiction at your location. Check

with your local inspectors to determine what codes will apply to the installation and operation of FETCO products.

1. Review the Dimensional Drawings (page 5) and the Operating Procedures (page 6) for the unit you are installing.

Verify the dispenser will fit in the space intended for it. Verify that the counter or table will support the weight of

the dispenser when filled.

2. Verify that the actual voltage at the electrical service connection is compatible with the specifications on the

dispenser’s serial number plate. Make sure the electrical service includes neutral. Refer to the "Electrical

Configurations " section, (page 3) to determine how the dispenser will perform on other voltages. Ensure at this

time that the circuit breaker to the dispenser and the power switch on the dispenser are in the off position

3. The thermostat and the water tank fill level are pre-set at the factory. There is no need to turn off the heaters

during the installation process. The heaters are disabled by the liquid level control board until water is sensed.

The heating process will start automatically when the tank has filled with water

5. Place the dispenser on a suitable counter or stand, ensuring it is strong enough. Refer to the dispenser weights

and capacities chart (page 2) for dry and wet weights.

6. When the dispenser is in position for use, level the dispenser front to back as well as side to side by adjusting

the feet.

8.

Remove the cover.

9.

Water connection:

• Water inlet is a 3/8 inch compression fitting on HWB-25, 1/4 inch compression fitting on all other models.

• The dispenser can be connected to a cold or hot water line. Cold water is preferred for best flavor, but hot

water will allow for faster recovery times.

• Install a water shut off valve near the dispenser to facilitate service. If an in-line water filter is used, it should

be installed after the water shut off valve and in a position to facilitate filter replacement.

• Flush the water supply line and filter before connecting it to the dispenser.

• Verify that the water line will provide at least 2 gallons per minute and that the water pressure is between 20

and 75 psig.

• Use a wrench on the factory fitting when connecting the incoming water line. This will reduce stress on the

internal connections and reduce the possibility of leaks developing after the installation has been completed.

10.

Vent tube connection:

• Vent tube connection is a 3/8 inch hose barb.

• The end of the vent tube should be open to the air, not connected or submerged.

11.

Power connection:

• A fused disconnect switch or circuit breaker on the incoming power line must be conveniently located near

the dispenser, and its location and markings known to the operators.

• All dispensers require neutral. Damage to the dispenser may result if neutral is not present.

• The body of the dispenser must be grounded to a suitable building ground. A ground lug is provided in the

dispenser next to the power terminal block. Use only 10 gauge copper wire for grounding.

• Electrical connections must be secured in-place within the unit to meet national and local standards.

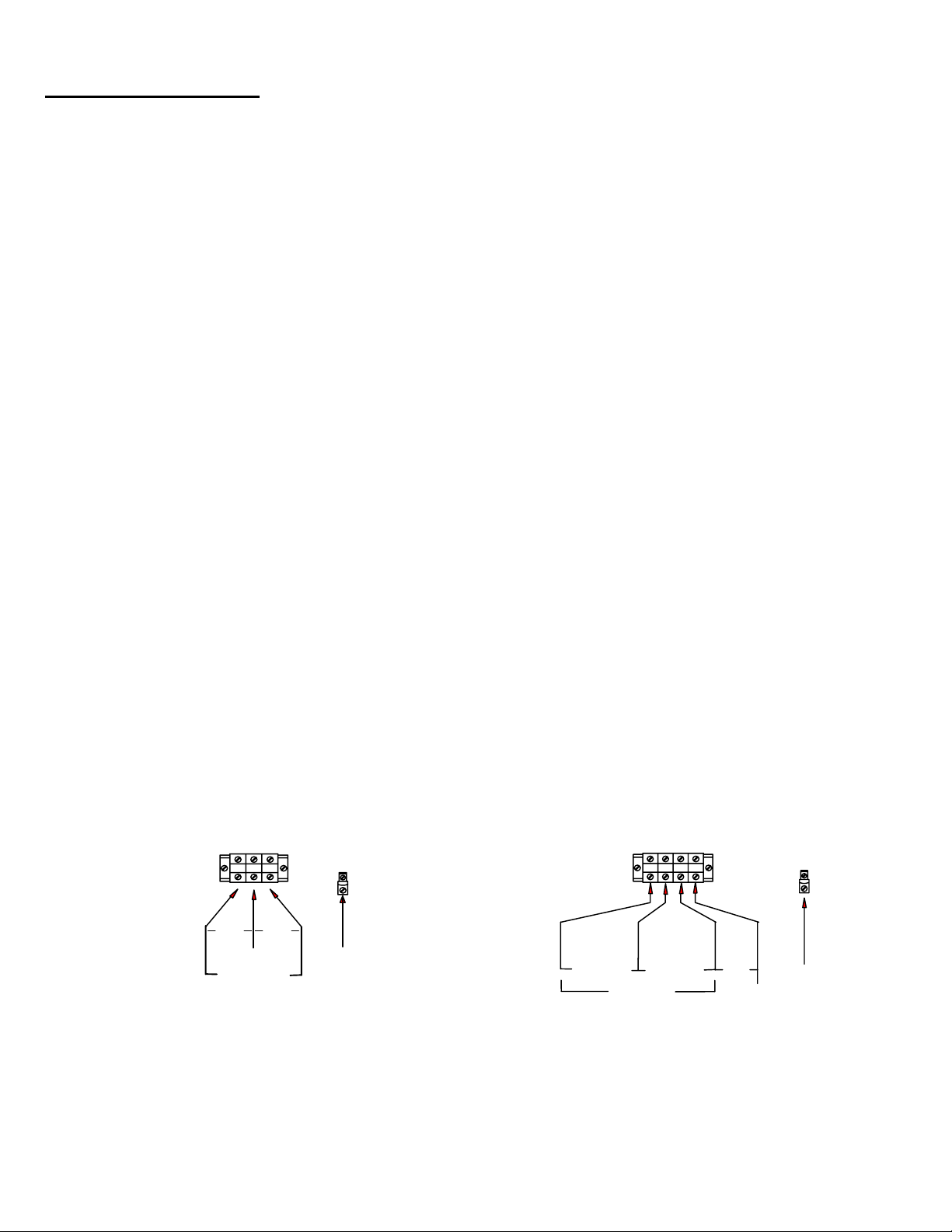

SINGLE PHASE

TERMINAL BLOCK

L1L2N

GROUND LUG

3 PHASE

TERMINAL BLOCK

L1L2L3

N

GROUND LUG

120V 120V

N

208-240V

GROUND

WIRE

208-240V 208-240V

208-240V

120V

GROUND

N

WIRE

Domestic Electrical Configurations

4

Page 5

11. Turn on the incoming water supply line and inspect both inside and outside of the dispenser for leaks in all

fittings and tubes.

12. Turn on the incoming power line and the dispenser’s on/off switch.

• Within 6 seconds, the hot water tank will begin filling until the water is sensed by the water probe at the top

of the tank.

• The heaters will be disabled by the L.L.C. board until water is sensed by the water probe at the top of the

tank.

The dispenser will be ready for operation as soon as the ready light comes on to signify that the water tank is up

to temperature. The minimum temperature is set at 195°F and the maximum is set at 205°F. The time required to reach

the proper temperature will vary according to the electrical configuration ordered.

Depending on the cost of electricity in your area, very little savings may be had by turning the dispenser off

between shifts. The water tank is well insulated and may actually use less electricity to keep the tank hot, than re-heating

the tank from a cold condition. Leaving the dispenser in the on position will also avoid delays at the beginning of shifts for

the dispenser to reach operating temperature.

15. Re-attach the cover after one final inspection for leaks

16. Review the entire operating procedures with whoever will be using the dispenser. Be sure to show the location

and operation of the water shut off valve as well as the circuit breaker for the dispenser.

Dimensions

HWB-5 HWB-10 HWB-15 HWB-25

IN. CM IN. CM IN. CM IN. CM

31 77 31 77 31 77 34 84

A

10 25 16 40 20 50 28 70

B

16 40 16 40 20 50 20 50

C

5

Page 6

Operating Procedures

Turn the dispenser power switch to the on position The power switch will illuminate to indicate that the dispenser has

power and is operating.

When the ready light illuminates, the dispenser is fully up to temperature and ready to dispense hot water through

the faucet. The amount of time required to gain full operating temperature will vary depending on the electrical

configuration that was ordered, and the temperature of the incoming water.

Safety Precautions:

• Do not hang containers or any other object from the faucet or faucet guard.

• Do not disassemble the faucet without first draining the tank below the level of the faucet.

This should be done as follows:

-Turn the power switch off.

-Open the faucet and allow water to drain out until the flow stops completely.

-Perform the necessary service to the faucet.

-Do not turn the power switch on until the faucet has been completely re-assembled.

• Do not disassemble the sight gauge without first closing the sight gauge valve. The valve is located at the

bottom of the sight gauge, on the right side. To close the valve, turn the valve handle ¼ turn until it is horizontal.

After the sight gauge is serviced and re-assembled, be sure to open the valve by returning the handle to the

vertical position.

Service

Warranty

All FETCO dispensers come with a limited warranty. A detailed warranty statement is packaged separately

with each dispenser.

All warranty service must be pre-authorized by calling the FETCO Service Department at (800) 338-2699.

Principles of Operation

Fill System

The fill system consists of a liquid level control board, a water level probe at the top of the tank, a fill valve, and a fill

tube. As the water rises and touches the probe, continuity is established between the probe tip and the tank body, and

the fill valve closes.

When water is dispensed, the water level drops below the probe. After a 5 second delay, the fill valve opens until the

water touches the probe again.

The 5 second delay, and the speed that water refills the tank during brewing, results in many short bursts of water.

The sound made by these repetitive bursts will let you know the fill system is functioning normally.

The fill system is designed to protect the heaters during both the installation and a loss of the water supply. During

initial installation, or whenever the power switch is turned on, voltage will not be supplied to the thermostat until the tank

fills and water touches the water level probe.

During operation, when water is dispensed and the water level drops below the probe, a fill signal is sent to the fill

valve. If no water is sensed by the probe after 40 seconds, the voltage to the thermostat and the heaters is removed.

Water enters the tank through the fill tube. A hole is drilled in the upper portion of the fill tube to prevent water from

being siphoned from the tank. The fill tube extends to the bottom area of the tank. This introduces cold incoming water

directly to the heaters and away from the dispense assembly.

The water tank can be drained by opening a valve on the bottom of the dispenser.

6

Page 7

Temperature System:

The temperature system consists of an electronic thermostat and probe to control the temperature of the dispensed

water, a mechanical thermostat and probe to control the ready light, and heating elements. The system is enabled by

the liquid level control board. (See the previous section - Fill Circuit.)

When the water level probe is in contact with water, power is delivered to the electronic thermostat through the liquid

level control board. If the temperature probe senses that the water is below the set point, the thermostat energizes the

heating elements through the mercury relay and the water is heated.

This thermostat is factory set at 205°F. (Slightly lower for high altitude installations.)

The function of the mechanical thermostat is to control the ready light. If the water temperature drops below 195°F,

the ready light will turn off, indicating that the water is too cold.

The combination of the two thermostats ensures that the water temperature will be between 195°F and 205°F

whenever the ready light is on.

Adjustments

Thermostat Adjustment:

The thermostats are factory set at the optimum temperatures. Adjustments should not be necessary unless new

thermostats are installed, or the factory settings have been changed.

There are two thermostats in the control circuit of the unit.

• High limit thermostat - Located on the left side of the unit, this is an electronic thermostat that controls the

dispensed water temperature. It is factory set at 205°F.

• Low limit thermostat - Located on the right side of the unit, this is a mechanical thermostat that turns off the

“ready” light if the water temperature drops below its set point. It is factory set at 195°F.

To measure the water temperature, with the “ready” light “on”, dispense water from the faucet for at least 15 seconds,

then hold a thermometer in the stream of water flowing out of the faucet. The temperature should be between 195°F and

205°F.

Adjusting the high limit thermostat:

• Remove the cover of the unit.

• The high limit thermostat is on the left side. Locate the adjustment stem, which is taped to the thermostat.

• Remove the black plastic cover on the outside of the dispenser and carefully insert the stem into the

adjustment hole through the front of the unit.

• Turn the stem clockwise to increase the temperature until it stops. This thermostat is normally set at the

maximum setting except at very high altitudes.

• Replace the adjustment stem, the cover and the plastic cap.

Adjusting the low limit thermostat is more complicated. First you must change the settings of both

195°F, then re-adjust the high level thermostat to 205°F.

Note: The low limit thermostat used on units manufactured after September 2000 is not adjustable.

It is permanently set at 195°F.

• Turn the main power switch off.

• Remove the cover of the unit, the round tank cover, and the black plastic caps of both thermostats.

• Use a small screwdriver to turn the low limit thermostat, located on the right side, to its lowest setting, fully

counter-clockwise.

• Turn the stem on the high limit thermostat counter-clockwise to decrease the temperature approximately 1/8

turn.

• Drain several gallons of water from the dispenser.

• Turn the main power switch back on, and allow the tank to fill. The ready light will remain off during the next

few steps.

• Wait for the water in the tank to heat until the sound of the tank rumbling stops.

• Measure the water temperature by inserting a thermometer directly into the top of the tank. If the

temperature is below 195°F, turn the stem slightly clockwise, wait for the tank to stop heating, and measure

the temperature again.

• Repeat the previous step until the temperature in the tank is 195°F.

• Next, use a small screwdriver to turn the low limit thermostat clockwise slowly just until the ready light comes

on, but no further.

• Finally, turn the stem on the high limit thermostat fully clockwise to return it to 205°F.

• Turn the power switch off and replace the adjustment stem, tank cover, dispenser cover, and the plastic

caps.

thermostats to

7

Page 8

Water Inlet Flow Rate Adjustment:

Hot water dispensers can be connected to 208, 220, or 240 volts, depending on the electrical configuration of the

building. By controlling the incoming water pressure, the amount of fresh water entering the tank is synchronized with

the rate at which the water can be heated. This ensures a uninterrupted supply of water within the range of the

thermostat settings, 195°-205°F. When dispensing water at a rate which exceeds the unit’s capacity to heat, the flow of

water out of the faucet will be diminished to maintain the proper temperature.

The dispenser’s static water pressure is factory set at the proper setting for a 220 volt power supply, unless otherwise

ordered. If it is necessary to change this setting, remove the cover and locate the pressure gauge near the back of the

unit. The adjusting screw is located directly behind the gauge. With the power switch on, and the water tank full, turn the

adjusting screw until the PSI setting matches the chart below for your particular model.

There is no flow rate adjustment for the HWB-25. This model has a device that restricts the flow of water to 0.8

gallons per minute.

Supplied Static Pressure PSI Settings on the pressure gauge

VAC HWB-5 HWB-10 HWB-15 1ph HWB-15 3ph HWB-25

208 VAC

*220 VAC

240 VAC

⊕

30 30

30 35 35

⊕

*

normal factory setting

50 50

not available at time of publication

⊕

⊕

⊕

⊕

N/A

N/A

N/A

Basic Troubleshooting

HWB-5 / 10 / 15 / 25 Gallon Hot Water Dispensers

Dispensing Problem Possible Cause Solution

Faucet drips Worn seat cup

Broken Faucet spring

Ready Light not “ON” Not up to set Temperature yet Wait at least 30 minutes (depends on

Internal circuit breaker tripped Turn the power switch on the front of

No power to the dispenser Reset circuit breaker on the wall. Off

Not hot enough Using water faster than dispenser can

recover

Thermostat set to low Adjust thermostat per Users Guide

Sight Gauge leaks Loose sight gauge cap Tighten chrome cap on top of gauge

Broken gauge tube or gasket Turn off sight gauge valve located at

When you have replacement parts,

turn the power off on the dispenser.

Drain water from the faucet until it

stops. This may be a large volume.

When water stops you may now

safely remove the upper assembly

and replace parts.

the size) after turning the dispenser

ON.

the dispenser OFF then back ON

again to reset.

then On.

Always insure that the ready light is

on before drawing water. If problem

persists purchase larger size

dispenser.

the base of the gauge. ON = posts up

and down.

= posts front to back.

OFF

Tighten or replace parts as required

and open valve

8

Page 9

HWB Replacement Parts

For US & Canada Versions – 120/208-240 VAC

Part

Number Description

54014 liquid level control board, 120V

2010 water level probe, short

2051 water level probe, long

21026 water level probe housing (2 required)

58035 pressure switch, 2 PR

53046 thermal fuse, 152 degrees C.

52054 relay, DP/DT, 120V

57060 fill valve, 120V, 1/32” orifice

57062 fill valve, 120V, 3/64” orifice

57064 fill valve, 120V, 1/16” orifice

57001 fill valve assy., S-45, 120V, 1.5 gpm

31163 inline strainer, 3/8"

32064 tube, water inlet

57068 pressure gauge

57066 pressure regulator

52004 relay, mechanical, 30amp

52017 relay, mercury, 30amp DP 120V

52033 relay, mercury, 30amp TP 120V

52025 relay, mercury, 60amp TP 120V

53011 heater element assy., 3000W, 240V

53045 heater element assy., 4000W, 240V

53003 thermostat, mechanical (low limit)

53012 thermostat, 120V (high limit)

53015 temperature probe, 14"

102013 tank cover assy.

24002 tank cover gasket

52012 switch, power w/circuit breaker, 120 V

58027 lamp, "ready", 120V

71067 sight gauge tube, 8 7/8", glass

71017 sight gauge washer, lower

71018 sight gauge washer, upper

71025 sight gauge vent plug

71024 sight gauge cap

71070 sight gauge valve

71035 faucet seat cup

71078 faucet, complete, red handle, ES

71079 faucet upper assy, red handle, ES

71080 faucet handle, red, ES

Used On

HWB-5 HWB-10 HWB-15 HWB-25

9

Page 10

Cleaning

Job

Cleaning Agent Comments

Stainless Steel

(These procedures were developed by NAFEM and Packer Engineering.)

1. Use the proper tools. Don’t use; steel pads, wire brush, or scrapers

scouring pads will not harm the steels passive layer. Stainless steel pads can also be used but the scrubbing motion

must be in the direction of the manufacturers polishing marks. Step 2 tells you how to find the polishing marks.

When cleaning your stainless steel products, take care to use non-abrasive tools. Soft cloths and plastic

2. Clean with the polish lines.

Some stainless steels come with visible polishing lines or “grain.” When visible lines are present, you should

always scrub in a motion that is parallel to them.

When the grain cannot be seen, play it safe and use a soft cloth or plastic scouring pad.

3. Use alkaline, alkaline chlorinated or non-chloride containing cleaners.

While many traditional cleaners are loaded with chlorides, the industry is providing and ever increasing choice of

non-chloride cleaners. If you are not sure of your cleaner’s chloride content contact your cleaner supplier. If they tell you

that your present cleaner contains chlorides, ask if they have an alternative. They probably will. Also, avoid cleaners

containing quaternary salts as they also can attack stainless steel and cause pitting and rusting.

4. Treat your water.

filters that can be installed to remove distasteful and corrosive elements. Salts in a properly maintained water softener

are your friend. If you are not sure of the proper water treatment, call a treatment specialist.

Though this is not always practical, softening hard water can do much to reduce deposits. There are certain

5. Keep your equipment clean.

Use alkaline, alkaline chlorinated or non-chloride cleaners at recommended strength. Clean frequently to avoid

build-up of hard, stubborn stains.

6. Rinse, Rinse, Rinse.

If chlorinated cleaners are used you must rinse, rinse, rinse and wipe dry immediately. The sooner you wipe off

standing water, especially when it contains cleaning agents, the better. After wiping the equipment down, allow it to air

dry for the oxygen helps maintain the stainless steel's passivity film.

7. Never use hydrochloric acid (muriatic acid) on stainless steel.

8. Regularly restore / passivate stainless steel.

Recommended cleaners for specific situations.

Routine cleaning Soap, ammonia, detergent Medallion Apply with cloth or sponge

Fingerprints & Smears Arcal 20, Lac-O-Nu, Ecoshine Provides better film

Stubborn stains and discoloration Cameo, Talc, Zud, First Impression Rub in the direction of the polish lines

Grease and fatty acids, blood etc. Easy-off, De-Grease It, Oven Aid Excellent removal on all finishes

Grease and Oil Any good commercial detergent Apply with sponge

Restoration / Passivation Benefit, Super Sheen

Reference: Nickel Development Institute, Diversey Lever, Savin, Ecolab

10

Page 11

11

Page 12

12

Loading...

Loading...