Page 1

1

Page 2

Getting The Most From The Festool VS-600 Jointing System

By: Jerry Work

Table of Contents

Page

3 Anatomy of a Dovetail Joint

9 The desired outcome – a perfect drawer every time

10 How the VS-600 system works

14 A perfect drawer using half blind dovetail joints

23 A perfect drawer using through dovetail joints

29 Perfect finger joints

31 Conclusion

32 One time setup

36 Using the metric system

40 Continuous improvement

41 What you need to know about the Festool templates

42 How to calculate drawer height for properly centered joints

43 Table of drawer heights for properly centered joints

43 Metric to approximate inch conversion

44 Meet the author

2

Page 3

Getting The Most From The Festool VS-600

Jointing System

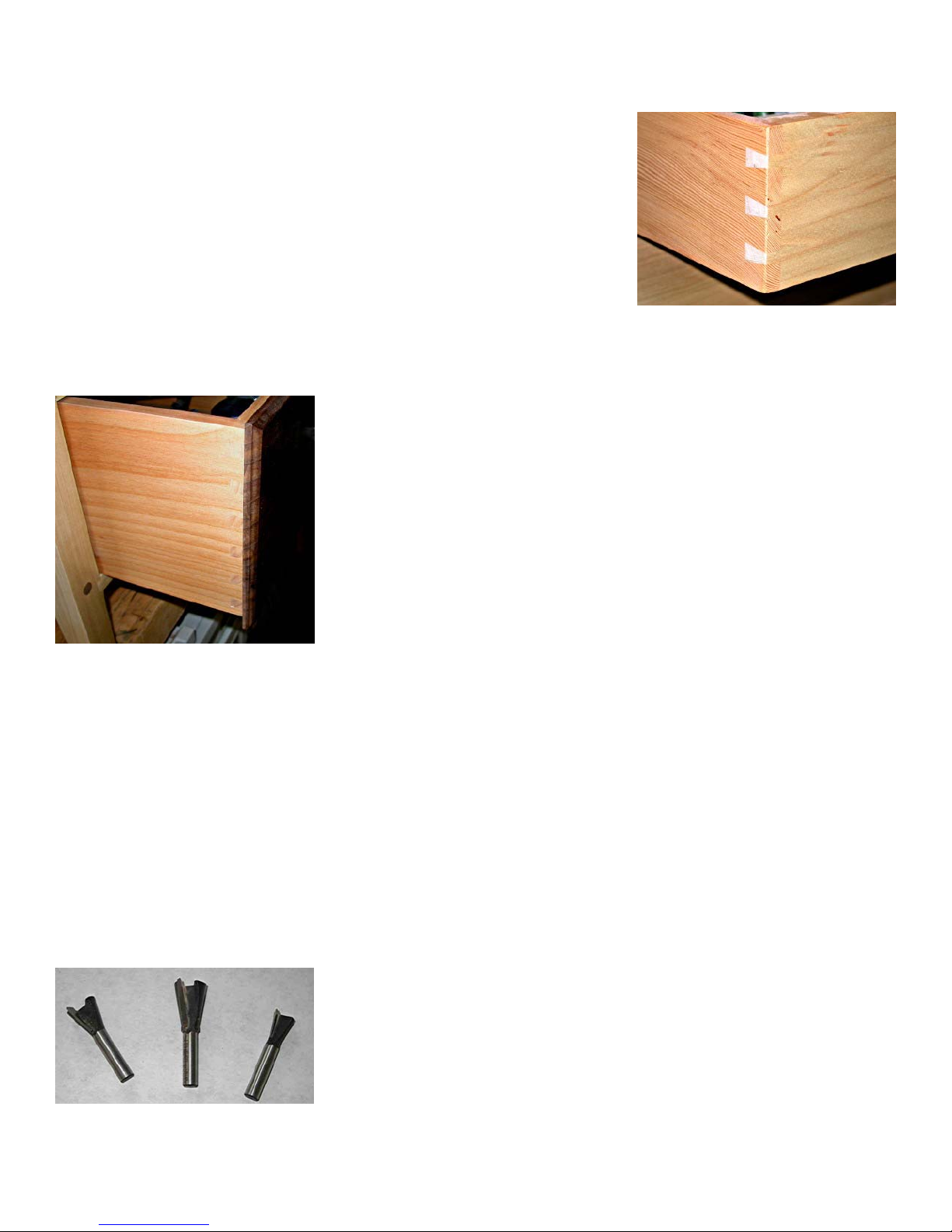

Few things in woodworking invoke the image of quality more than well cut dovetails

joining the sides of a drawer, box or cabinet. For thousands of years this simple, elegant

joint has been employed by the finest craftsmen for its inherent strength as well as for

its pleasing aesthetics. Watch a person who sees a fine piece of furniture for the first

time. Their hands will invariably rub over the dovetail joints as though to confirm that

this is truly a well crafted piece.

Anatomy of a

Dovetail Joint

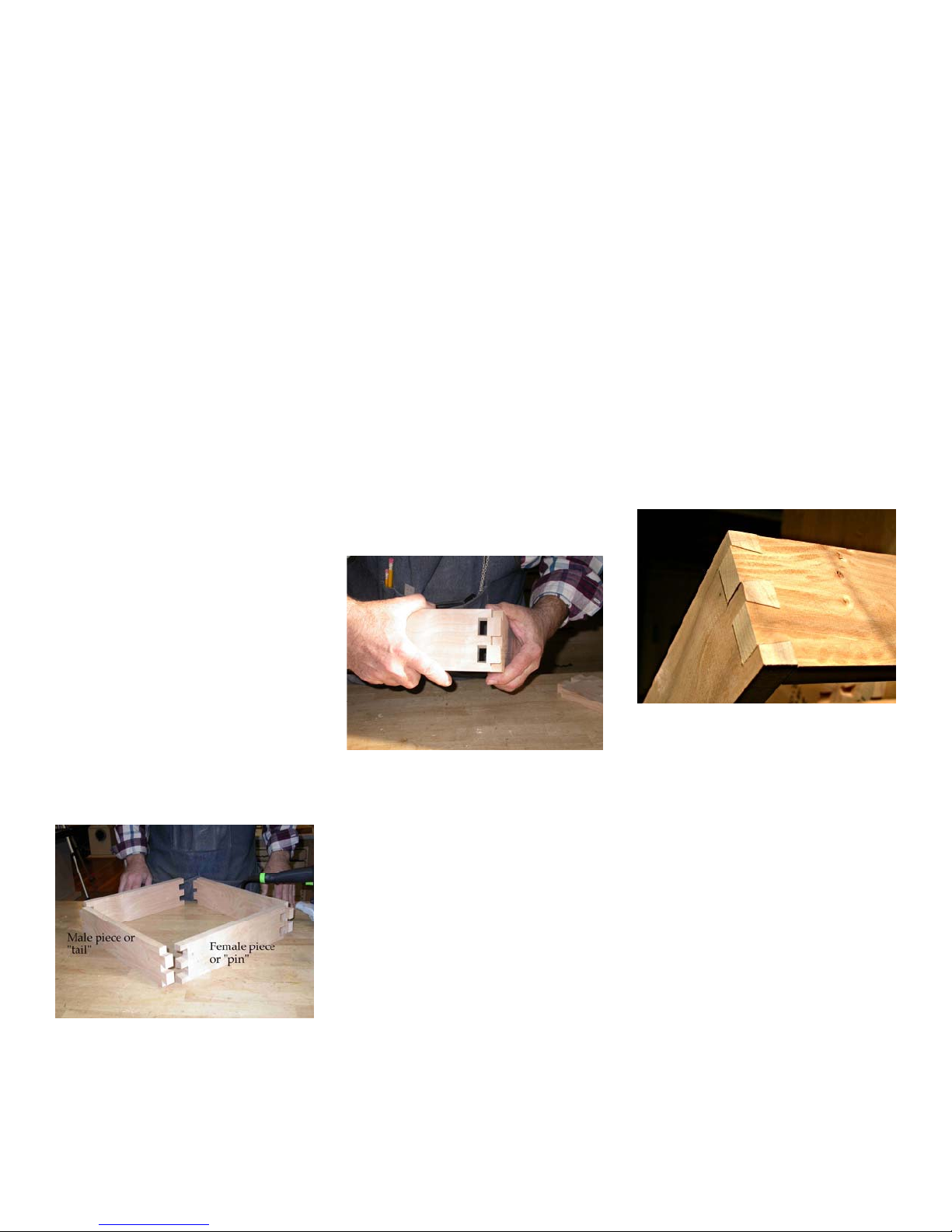

There are several different

types of joints that are all

called “Dovetail Joints”. They

get their name from a fan

shaped male piece that looks a

bit like the tail on a dove. That

fan shaped male fits into a

female recess of the same

shape.

By: Jerry Work

breaking the surrounding

wood.

The strength of the joint does

not rely on glue, nails or

screws. It comes from the

interference fit of the male and

female fan shapes. You simply

cannot pull them apart

without breaking the wood.

A dovetail joint requires at

least one fan shaped male tail

and at least one female fan

shaped recess. It may have

two, three or many more fan

shaped male tails and

corresponding female recesses,

but it must have at least one to

be a joint at all.

Once in place the joint cannot

be pulled apart without

3

Page 4

Before we start learning to use

dovetail joints to build perfect

drawers, boxes and cabinets

far faster than you ever

thought possible, let’s spend a

few moments discussing how

these different joints, all called

“dovetail joints,” differ one

from another.

All can be used to securely join

two pieces of wood end to end

or at right angles to one

another, but that is about

where the similarities end and

the differences begin.

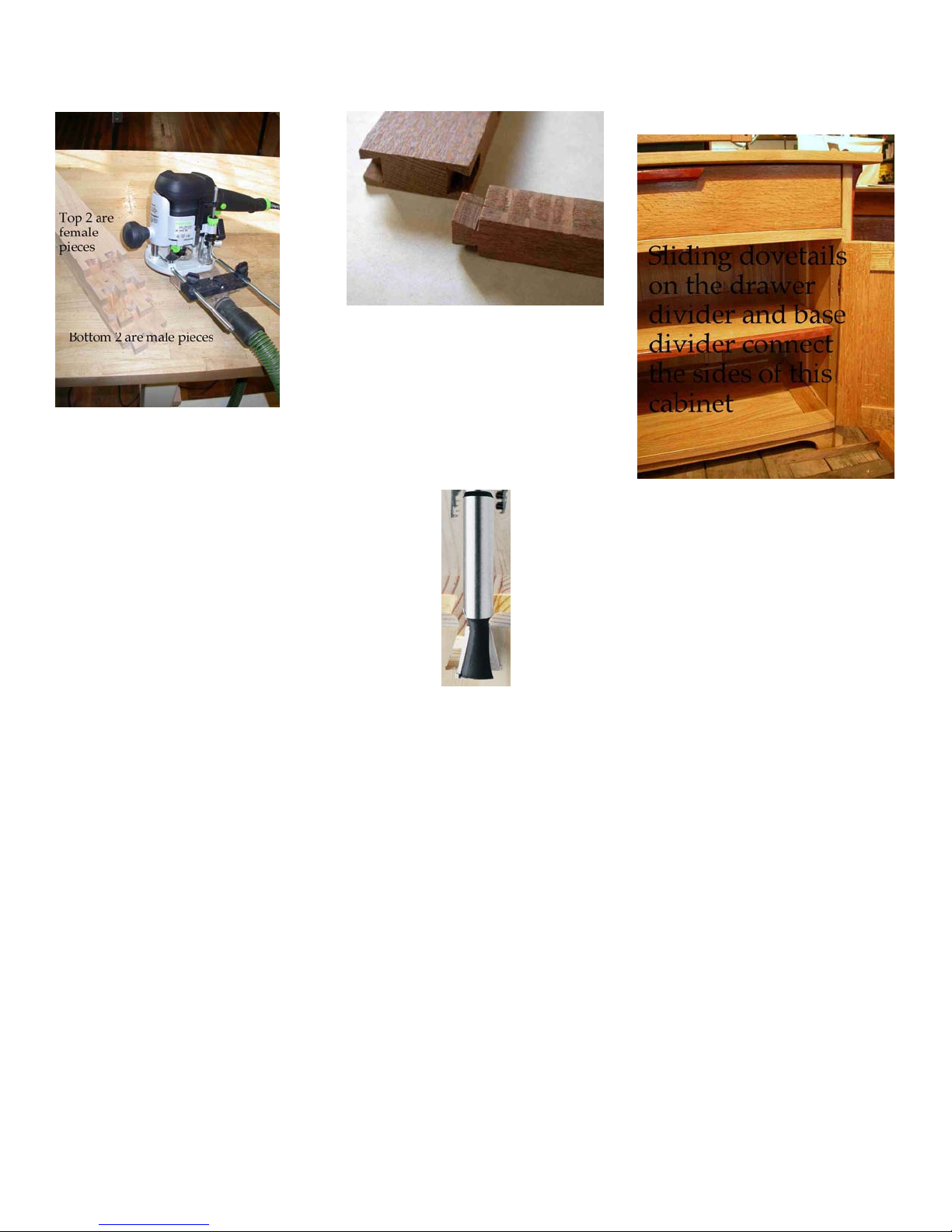

The Sliding Dovetail

Joint

called a dovetail joint is where

the male fan shape is cut

laterally along an edge or an

end of one work piece and the

female recess is grooved into

the other.

- The simplest joint

If these are both cut with

exactly the same slope on the

sides and to the same depth

the two pieces can slide

together to form a very strong,

self-locking joint called a

“sliding dovetail” joint.

These are most often cut with

a router bit with sloped sides

(called a “dovetail cutter”)

where the router is guided

past stationary work pieces in

a straight line. Sometimes this

is accomplished using a guide

rail (my favorite) and

sometimes by holding the

router stationary while the

work pieces slide by in a

straight line guided by a fence.

They also can be cut on jigs

which hold the work piece

stationary and slide the router

past the work piece.

I regularly use sliding

dovetails instead of dados to

join the two sides of a cabinet

together to form the door or

drawer openings as in the

picture above, or to hold

shelves that tie the two sides

together. I also use it for

fastening drawer guides to the

sides of a drawer opening, for

fastening the toe kick across

the bottom of a cabinet, to hold

the top to the sides, and for a

variety of situations when I

need two pieces joined at right

angles to one another in a very

secure and self-squaring joint.

4

Page 5

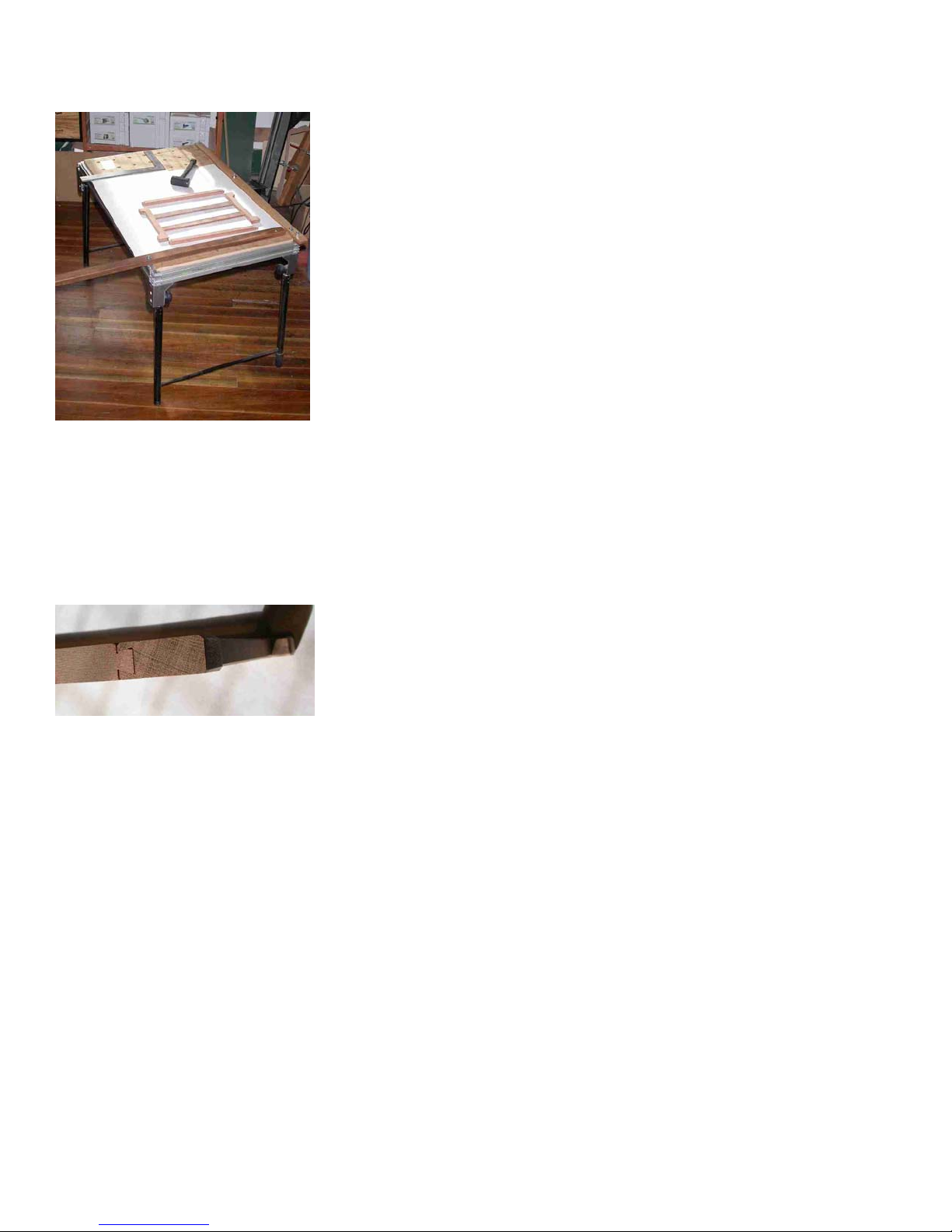

The pictures above and below

show a side slat assembly for a

large bookcase that is held

together with sliding

dovetails.

Once you start using sliding

dovetails you will rarely revert

to simple dados again.

5

Page 6

The Half-Blind Dovetail

Joint

joint that is called a “dovetail

joint” is where the female

recess is cut on the end of one

work piece and only part way

through the thickness of that

work piece forming a socket

into which the male fan shape

cut in the other work piece is

trapped.

Since the joint can only be seen

from the side where the fan

shape is cut, it is most

commonly called a “half

blind” dovetail joint. These

are most often cut by a

dovetail shaped router bit

guided by a template where

the male fan shape is cut with

that work piece held vertically

and the female socket cut with

that work piece held

horizontally.

- The second kind of

Often, like with the VS-600,

both parts of the joint can be

cut simultaneously, and the

joints in two sides of a drawer

or box can be set up and cut at

the same time. The manual for

the Festool VS-600 refers to

this as simply a “dovetail

joint”. We will talk a lot more

later about how to do these

joints quickly and accurately.

The Through Dovetail

Joint

“dovetail” joint is where the

male and female parts of the

joint are cut all the way

through the thickness of each

work piece. This is commonly

called a “through dovetail”

although the Festool VS-600

manual refers to this as an

“open dovetail tenon”. It is a

far more complex and

confusing joint to machine

than either a sliding dovetail

or a half blind dovetail. The

male fan shaped portion of the

joint is normally cut with a

dovetail shaped router bit with

the router guided by a

template with straight sides on

each finger of the template.

- The third kind of

The female recess portion of

the joint is normally cut with a

straight router bit guided by a

template where the sides of

each finger are angled at

exactly the same angle

designed into the dovetail

router bit.

The angle machined into the

template and the angle

machined on the router bit

must be exactly the same or

the two halves of the joint

simply will not fit together.

This is one reason I always

recommend using ONLY

router bits manufactured by

the same company that

produces the through dovetail

template.

Nothing can ruin your day

faster than to be frustrated by

the fact that the angle actually

cut by an off brand router bit is

slightly different from how it

is marked, and that is slightly

different from the angle on the

fingers of the template. No

matter how hard you try, you

will never get a good fitting

6

Page 7

joint out of a mismatched

combination.

The through dovetail can also

be a confusing joint to cut

because when you look at the

work piece with the female

recesses you can either see the

recesses, or you may instead

see the uncut portion between

two recesses that are called the

“pins”. If those uncut portions

are between one side of the

outboard most recess and the

edge of the work piece, they

are called “half pins”. It is

hard, especially at first, to keep

straight which work piece is

the male (most often called the

“tail board”) and which is the

female (most often called the

“pin” board).

I’ll try to take a bit of the

confusion out of this when we

talk about how to cut perfect

through dovetails using the

Festool VS-600. The Festool

manual talks about the male

fan shaped portion as the

“dovetail” and the female

recess or pin board as the

“tenons”, terminology I find

confusing myself.

Fortunately, it is easy to see

the difference by looking at the

template used for these two

portions of the joint.

The male

portion is cut using a template

where the sides of the guide

fingers are straight while the

female portion is cut using a

template where the sides of the

guide fingers are angled.

In Festool speak, the template

for cutting the male fan shape

is labeled as an SZO-14-S or

SZO-20-S, while the template

with the angled fingers for

cutting the female recesses is

labeled as an SZO-14-Z or an

SZO-20-Z.

It really doesn’t matter what

you call these two as long as

you are clear that you will use

the S for cutting the fan

shaped male “tails,” as shown

in the picture above right, and

the Z for cutting the female

recesses separated by “pins.”

Throughout this manual I will

refer to the male and female

parts of the joint trying to

avoid the confusing tail and

pin descriptions.

Other joints also called

“dovetail” joints

are a few other joints that also

trap one work piece to another

by a male with angled sides

mating with a female recess

with the same angled sides. If

the male and female portions

are cut in the ends of two work

pieces they can be joined flat,

end to end and are usually

called a “flat dovetail” joint. If

the female portion is cut into

the ends of both work pieces

and a separate male piece is

machined with the fan shape

at each end, that joint is

usually called a “butterfly”

dovetail joint. We will not be

discussing these flat or

butterfly dovetail joints in this

manual.

– There

Advantages - Besides the

inherent strength of any of

these kinds of dovetail joints,

another great advantage of a

well machined dovetail joint is

that they are inherently selfaligning. The bottom of the

fan shaped male protrusion

ends in flats which are exactly

the same level as the surface

into which the female grove or

socket is cut in the mating side

of the joint. The flat on one

7

Page 8

piece is held tight against the

surface of the other thereby

holding the two parts

perpendicular to one another

on half-blind, through and

sliding dovetails, and exactly

end to end on flat dovetail or

butterfly joints.

If your cuts are made with

precision, when you assemble

your piece it will be nearly

perfectly square just from the

dovetail joints themselves.

So why are dovetail

joints so intimidating

for many?

Since these are self-aligning,

self-squaring joints of extreme

strength, why is it that they are

not regularly used by all

woodworkers as the preferred

method of joining two work

pieces together? And, why is

it that the term “dovetail joint”

also can strike such fear and

intimidation in so many

woodworkers?

One part of the answer is that

for the joint to work well both

the male and the female

portions of the joint have to be

cut with extreme precision. If

the angles and sizes of the

male fan shapes and the

corresponding female recesses

are not exactly the same the

joint will either not go together

at all or it will be so loose as to

be nearly useless.

Another part of the answer lies

in just how difficult it is to cut

these perfectly matching fan

shapes when you do more

than one of each on each of the

two parts to the joint. Now the

requirement for precision is

amplified since even if the

male and female fan shapes

are exactly the same size and

same angle, if they are not also

exactly the same distance

apart, the joint simply will not

go together no matter how

hard you try.

Given the requirements for

perfection in cutting these

highly useful joints, there is

little wonder why the dovetail

joint is considered so difficult

to cut properly and also why

there have been so many

techniques, jigs and fixtures

offered by different

manufacturers to cut them.

Each requires the user to learn

a specific, different set of steps

and techniques. Often the

steps and techniques are far

from intuitive and can involve

a rather long or steep learning

curve.

Maybe that is why you can go

into most any woodworking

shop and you are likely to find

at least one and often two or

more dovetail jigs stacked in

the corner unused, gathering

dust. The owner tried to learn

the steps and techniques

outlined in the manuals that

accompanied the jig or fixture,

and may even have done so at

one time. But, the next time

they tried to use the jig they

got confused and felt like they

had to start all over again from

scratch. Frustrated, they

tossed the jig into the corner

and there it sits today.

In this manual I am going to

try to reverse this trend by

showing you how to use the

exceptionally well engineered

Festool VS-600 dovetail jig to

make perfect drawers, boxes

and cabinets every time with

little or no “relearning”

required.

8

Page 9

Start with the desired

outcome in mind

Most manufacturers manuals,

including the Festool VS-600

manual, tell you a lot about

how to set up and adjust their

jig but do little to tell you how

to achieve the outcome you

want. Here we will start with

the outcome you want – a

perfect drawer, box or cabinet

– and show how to use the VS600 to achieve that outcome

quickly and easily every time.

In fact, by the time you finish

with this manual, I hope you

will find the VS-600 is in use

every day in your shop or

studio just like it is in mine.

When it becomes the best,

fastest and easiest way to

achieve your perfect drawer,

box or cabinet it will be the

“go-to” tool of choice for this

purpose and, believe me, will

gather no dust in your shop.

Making a “perfect”

drawer in less than

five minutes

Let’s start with what

constitutes a “perfect” drawer,

box or cabinet. Since the side

joints on all three are the same,

to save my typing and your

reading, from this point

onward I will use the term

“drawer” to mean either a

drawer, a box, or a cabinet

carcass. A little later on I will

also cover what else you need

to do besides the dovetailed

side joints that differentiate

one from another. And, still

further on we will talk a bit

about using the VS-600 to also

make slotted or box joints as

well as dovetail joints.

A “perfect” drawer is one that

is exactly the length, width

and depth you want, is

absolutely square, sits flat and

invokes an image of fine

craftsmanship from the minute

you assemble it -

No sanding to fit, no “make it

a bit bigger and cut it to fit

afterwards” and no “put a bit

of filler into the gaps to make

it look like it fits” even when it

doesn’t. Just perfectly made in

the first place.

A “perfect” drawer is also one

you can make day-in and dayout with beautifully cut half

blind dovetail corners in less

than 5 minutes. Yes, that is

right, five minutes from the

time you have the properly

prepared stock in front of you

to the time you are ready to

assemble.

Stock preparation and the

precise engineering of the VS600 base unit, template, guide

bushing and cutter are the

keys to your perfect box in five

minutes every time.

But, before we start we need to

understand how the system

works which we will do in the

next section.

9

Page 10

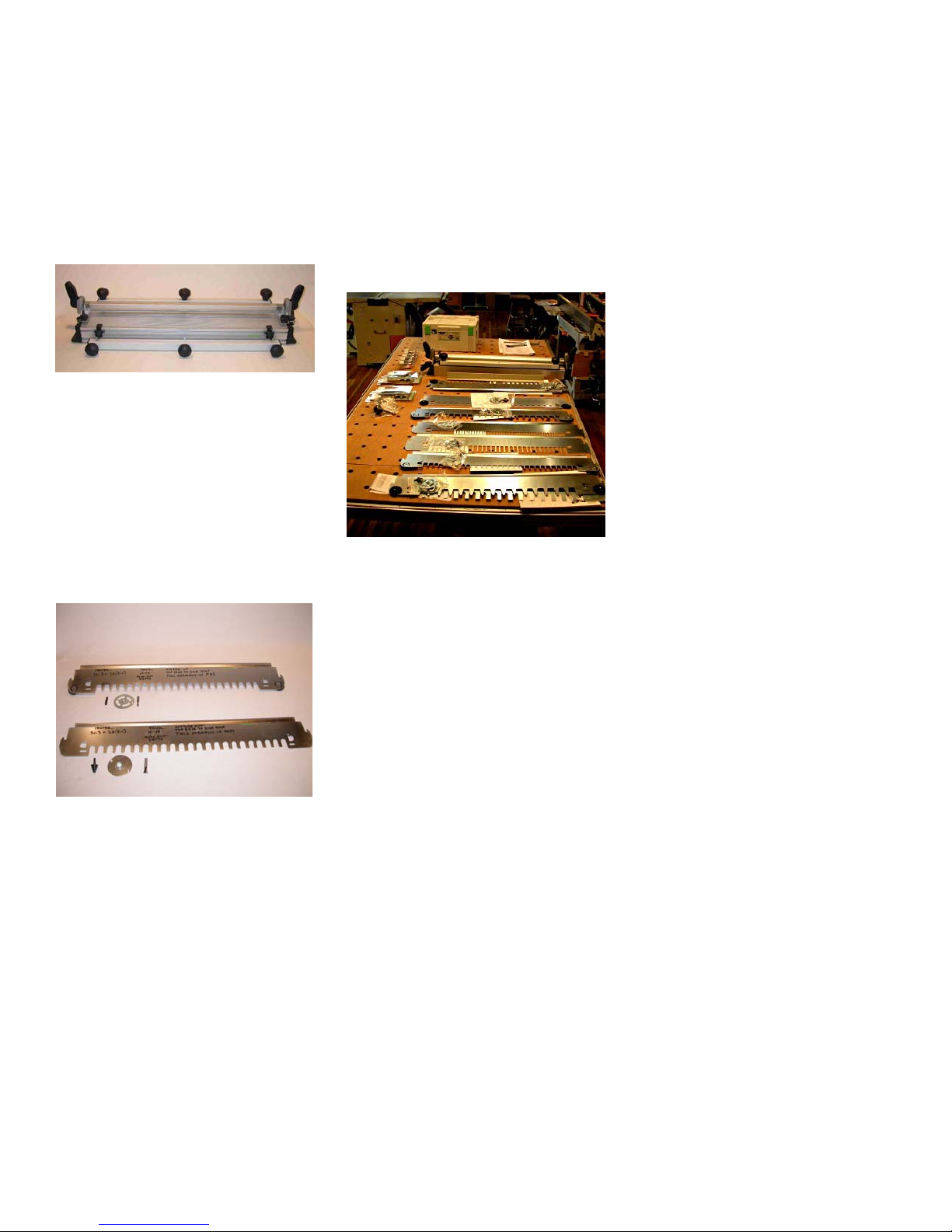

How the VS-600

System Works

The VS-600 is designed around

a base unit

which will hold your properly

prepared stock in exactly the

right location while you make

your cuts, a set of heavy,

machined metal templates

which will guide your router

to make the cuts in exactly the

right places,

a guide bushing which you

will attach to your router to

exactly follow the contours of

each template, and a cutter

that is of the exact size and

angles for which the template

was designed.

The templates mount on the

base unit. The guide bushing

and router bit mount on the

router.

Every part of a VS-600 system

is shown in the picture below.

While it may look a bit

intimidating, the pieces all

relate to one another quite

simply and you don’t need to

buy them all at the same time.

One of the beauties of the

Festool VS-600 system is that

you only need to do your set

up one time. And, all that

amounts to is (a) setting the

template in or out to get the

edges of the finished cut

perfectly flush with one

another and (b) setting the

router bit depth to get the fit of

the joint exactly as tight as you

want it.

From that point on, you only

need to mount the bit in your

router, set the depth the same

as on your test piece, and cut

away so long as the

component parts are within

the range each template is

designed to handle.

See the sidebar on “One Time

Setup” on page 32.

I have found that in most cases

the factory settings for in/out

on the templates and the

factory bit depth

recommendations for each

template are right on and little

adjustment is required. One or

at most two test cuts is all you

need to make.

When you get the fit you

want, keep the test pieces as

your depth gauge for all the

subsequent uses of that

template/bit combination,

perfect drawer after perfect

drawer.

I strongly recommend the use

of Festool guide bushings and

cutters to be sure these match

the templates properly. I also

recommend the use of the

excellent Festool routers.

They are lighter in weight than

most other routers to give you

ease of control. They are far

more powerful than their

small size would suggest. I

have yet to bog one down no

matter what I was cutting.

And, they offer excellent

chip/dust collection so you

can concentrate on producing

your perfect drawer in five

minutes, rather than worrying

about trying to work around

the mess most other routers

and jigs produce.

10

Page 11

Decoding the Festool

Catalog

Festool, like many tool

manufacturers who service a

world market, design their

tools around the metric

system. The numbers they use

are all in millimeters which I

will shorten in this manual to

“mm.” See “Using the Metric

System” on page 36.

As that note suggests, you

don’t have to think in the

metric system to gain all the

advantages of measuring in

the metric system.

But, to decode the Festool

catalog you will need to at

least understand that one inch

is a bit over 25 mm, and one

mm is a bit less than .040.”

Festool offers four different

combinations of templates,

guide bushings and cutters for

the VS-600 to allow you to cut

perfect half-blind and through

dovetails in stock of a range of

thicknesses.

In addition they also offer two

different templates, guide

bushings and cutters to allow

you to cut equally perfect box

joints in stock of different

widths, and even a doweling

jig to allow you to joint two

pieces of wood or man-made

materials with multiple

dowels if you wish.

The first time you look at their

catalog or web site, the section

on the “VS-600 jointing

system,” as they call it, will

appear to be a bit intimidating.

Let’s decode it.

The Base Unit

(item number 488-876) is the

base unit. You need one of

these no matter which/how

many templates you also buy.

The templates are all sold

separately. None come with

the base unit and the base unit

cannot be used to cut any joint

without at least one template.

The 600 refers to the maximum

width of work piece that you

can mount into the VS-600.

600mm is a bit less than 24” so

you can work on very large

drawers, boxes and cabinet

carcasses.

- The VS-600

Half-Blind Dovetail

Templates

half-blind dovetail templates.

They are given model

numbers beginning with the

letters SZ followed by a

number which refers to the

diameter of cutter expressed in

millimeters that template is

designed to use.

- There are two

11

Page 12

Do NOT try to use any cutter

other than the one specified. If

you do, your joints simply will

not work. Each of these two

templates is designed to cut

perfect half-blind dovetail

joints into stock that is within a

specified range of thicknesses.

Do NOT try to use stock of a

thickness outside of these

ranges. If you do, your joints

simply will not work.

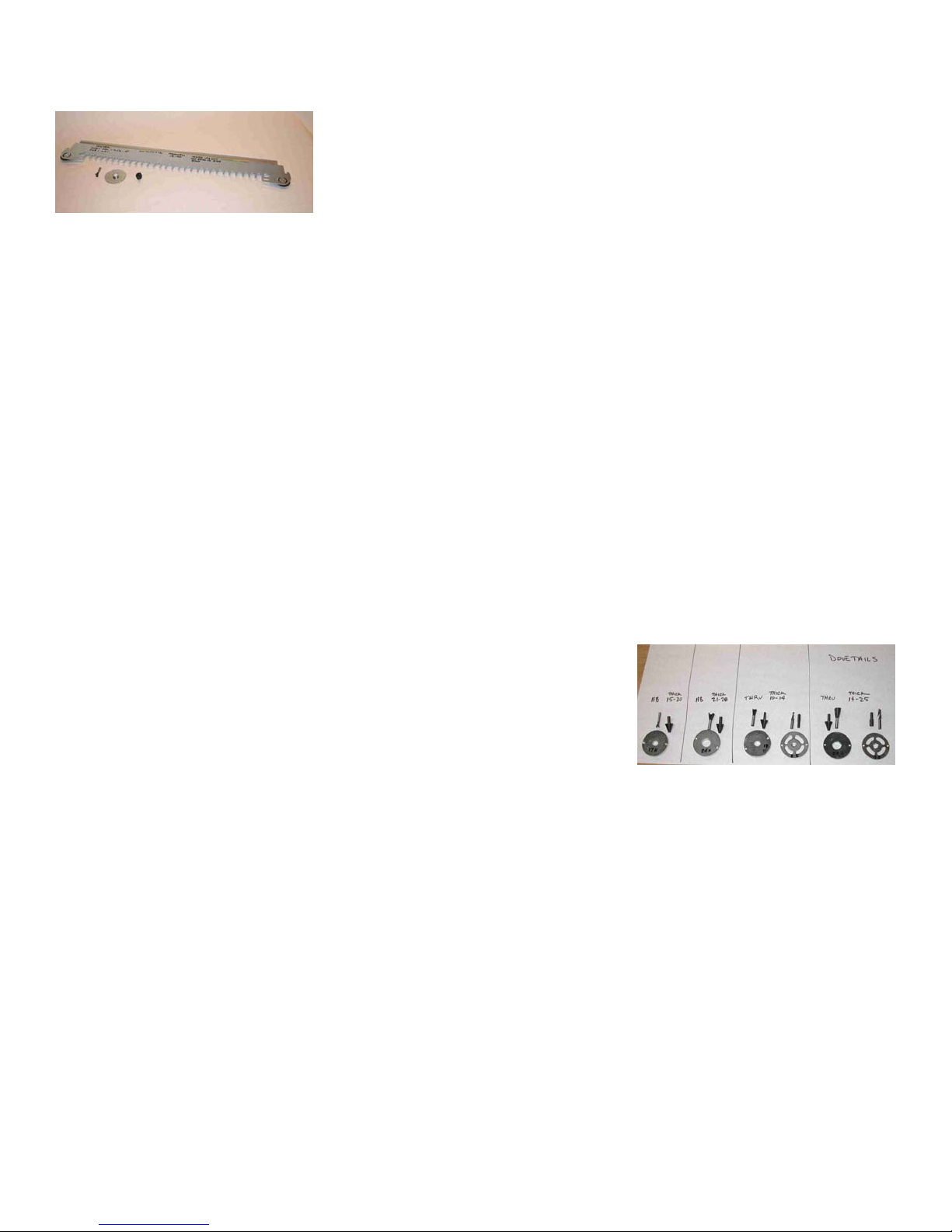

Template SZ-14 shown below

left is designed to cut halfblind dovetail joints in stock

from 15 to 20mm in thickness.

This is about 9/16” to a bit

over 3/4”. If you try to cut

half-blind dovetail joints in

stock outside this range, the

female recesses (sockets as

they are called) will either

bottom out too close to the

front or back of the drawer

leaving a thin, weak area, or

the male fan shaped tails will

be too short to be strong

enough.

You can cut half-blind dovetail

joints in stock where the front

and back components are

more than 20mm thick so long

as the sides are no more than

20mm. If you do, however,

most will think the joints

simply look shallow and out of

scale. So, stay within a stock

width of 15 to 20mm with this

template.

The proper guide bushing

(designed to fit only on Festool

routers) comes with each

template so you do not need to

buy these separately. Festool

calls guide bushings, “copy

rings”.

You can use other routers and

guide bushings so long as the

guide bushings have exactly

the same outside diameter as

their Festool counterparts.

You also need to buy the

cutters separately. Festool

calls their carbide tipped bits

HW while the high speed steel

bits are called HSS. I only use

the HW or carbide bits. I find

the Festool router bits to be

among the best I own and use

them every day. They are very

well machined, finely

polished, sharp right out of the

box, and have large carbides

which seem to stay sharp

longer than most bits. They

also are very well balanced

and centered so your cuts are

vibration free and “dead on”

accurate in both size and

angle.

The right cutter to use with

template SZ-14 is 490-992.

This has an overall diameter of

14.3mm with a cutting height

of 13.5mm set at a 15 degree

angle.

The shank diameter is 8mm

which I find ideal. It is much

stiffer than the ¼” shank bits

you might have used before,

yet small enough to produce a

pleasing dovetail size and

geometry. A ½” to 8mm collet

adapter is available from

Festool and others.

Template SZ-20 is designed to

cut half-blind dovetail joints in

stock from 21 to 28mm (26/32”

to 1 3/32”). The same caveats

on stock thickness apply. Use

cutter 490-996 which is 20mm

in overall diameter, has a

17mm long cutting height set

at 15 degrees.

All of the cutters, guide

bushings and alignment pins

used for all the Festool VS600 dovetail joints are shown

above with their guide

bushing centering mandrels.

The two groups on the left are

for half blind dovetails and the

two on the right are for

through dovetails. We will

cover the templates for

through dovetails in that

section.

12

Page 13

All the rest of the templates

and cutters are designed for

either box joints or dowel

joints. We will cover these

later in the manual.

For now, let’s concentrate

on building your perfect

drawer with half-blind

dovetail joints in under

five minutes.

These are the most commonly

used dovetail joints for

drawers and boxes and are

also quite useful for cabinet

carcasses.

Once you master half-blind

dovetails and consistently

produce a perfect drawer in

under five minutes, then you

can branch out to the other

types of joints as you wish.

Don’t make this

Just don’t make the mistake I see

first time users of dovetail jigs

make all the time. They pull their

new purchase out of the box, do a

cursory glance through the jig

manufacturers manual and start

butchering wood. They cut a few

poor half-blind dovetail joints,

then several really poor through

dovetail joints and maybe an illfitting box joint or two. When

they see the mayhem they have

created, they usually give up in

frustration. Stay with the halfblind dovetail joint until it

becomes almost automatic for

you. Then, and only then, branch

out to also learn to cut the other

types of joints.

mistake

13

Page 14

A Perfect Drawer

Using Half-Blind

Dovetail Joints

Earlier I said stock

preparation, along with the

precise engineering of the

Festool VS-600 templates,

guide bushings and cutters

was the key to achieving the

desired outcome of creating a

perfect drawer with half blind

dovetails in under five

minutes.

I use primarily solid woods for

all my furniture so will spend

some time outlining how to

get properly prepped solid

wood components.

If you want to use man-made

materials, stick to a good

grade of multi-ply plywood

like Baltic Birch. That usually

comes in 5’ x 5’ sheets. The

plain old softwood plywood

sold in 4’ x 8’ sizes has too few

plys and too many interior

voids to make for anything

approaching a perfect drawer.

Hardwood plywood is usually

much better and can be used

with some success.

Don’t try to use chip board or

compressed board as they

generally are too weak to work

well.

MDF can be used but know

that the male fan shapes can be

quite fragile until the piece is

assembled and glued up.

Once assembled with a good

quality wood glue, MDF

makes for a strong drawer, box

or cabinet carcass. Without

glue the joints in MDF are

simply too weak to be useful.

Half blind dovetail joints cut in

solid wood are strong with or

without glue.

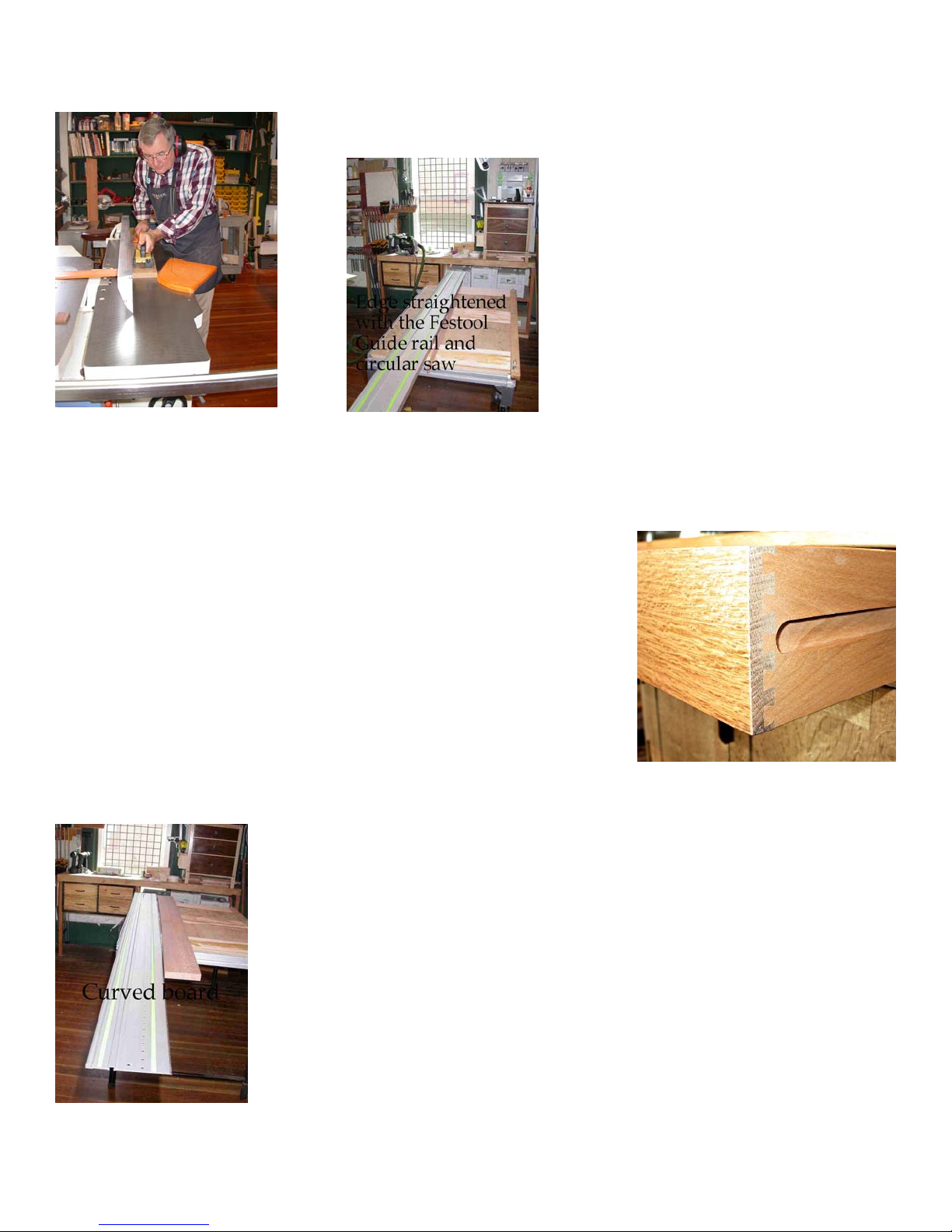

To prep solid wood you

almost must have a jointer

and a planer.

Seldom is the wood you buy

pre-surfaced really straight,

flat or of equal thickness over

its length. It may look that

way in the store but often will

have some cupping, twist,

warp or curve.

You can see it if you look at

the end of the board to see if it

is flat side to side or whether it

bows across its width

somewhere along the length.

That bow up or down is called

“cupping.” The board often

also will have some twist. This

is where the flat face of the

board is not parallel along its

entire length. Or, it may be

warped enough that

individual components are not

flat over their length.

The only way to effectively

take out cupping, twist or

warp is with a jointer. If you

run a warped, twisted or

cupped board through a

planer, the pinch rollers will

temporarily flatten the board

right under the planner knives.

The warp, cup or twist will

reappear again as it exits,

leaving you with a warped,

cupped or twisted board that

is simply thinner.

14

Page 15

If you joint one face flat first,

you will take out the warp,

cup or twist. Now, when you

run it through the planer to get

it the thickness you want, it

will come out still flat.

Don’t worry too much if a

board is flat but not straight. It

is easy to cut the curve out of

one edge and then cut/plane

the other edge to be straight

and parallel to the first and of

the width you want as shown

in the before & after shots

below.

Cutting the drawer

components to the

proper size

Height - Centered

Dovetails Look Best

with the height

want.

All fixed template half blind

dovetail jigs, including the

Festool VS-600, are inherently

designed around drawers of a

height that is an even

increment of twice the finger

spacing.

In the case of the SZ-14

template, the distance between

each finger is exactly 22mm. If

your dovetails are properly

centered on the drawer side,

when you look at the finished

drawer from the side you will

see an 11mm half pin at both

the top and the bottom edges

and all the other dovetails will

be exactly 22mm apart.

Hence, the set of dovetails will

be centered over the height of

the drawer.

of drawer you

– Start

15

Page 16

This is the most pleasing

arrangement to the eye and

also the strongest joint.

If your drawer height is not an

even increment of twice the jig

finger spacing, you will still

have an 11mm half pin at the

top and either more or less

than that at the bottom edge of

the drawer. That unbalanced

arrangement looks awkward

to most people and the lower

pin can become so small as to

be weak and break off during

assembly or use.

The easiest way to calculate

the height of a drawer on

which half blind dovetails will

be properly centered is simply

to multiply the template

spacing (22mm for the SZ-14)

times twice the number of the

male fan shaped tails or female

recesses showing. If your

drawer will show only one

male fan shaped tail when

viewed from the side, the

drawer will have an 11mm

half pin at the top and bottom

and one 22mm female recess in

the middle so it will be 44mm

high (about 1 ¾”). This is

about as small as it is practical

to make a drawer and still

leave room for a bottom.

Drawer height for

template SZ-14 = 44 x t

Drawer height for

template SZ-20 = 64 x t

where t = the number of tails

(and female recesses) showing

from the side.

See the “Table of Drawer

Heights Which Will Result in

Properly Centered Joints” on

page 43 for these calculations

from one tail showing to the

maximum size drawer which

can be built on the VS-600

using these templates.

One more note on drawer

height: The slot you will cut

into the inside of the front,

back and drawer sides to

receive the drawer bottom will

be centered on one half the

template spacing up from the

bottom of the drawer

components (11mm for the

22mm spacing on the SZ-14

and 16mm for the 32mm

spacing on the SZ-20).

So, the actual inside depth of

your perfect drawer cut with

the SZ-14 template will be

11mm plus one half of the

thickness of the drawer bottom

less than the overall height of

your drawer. The distance

from the bottom edge of the

drawer sides, front and back to

the underside of the drawer

bottom will be 11mm less one

half of the thickness of the

drawer bottom -- nice and

strong while still maximizing

inside depth for your prefect

drawer.

Cutting the slot on a center

line that is 11mm from the

bottom edge will put the

drawer bottom slot (or dado as

some might prefer to call it)

exactly in the center of the

male fan shaped tails and

female recesses so it will not

show from the outside of the

drawer and will be as strong

as possible.

So, pick a drawer height that

is an even increment of twice

the template finger spacing,

44mm (2 x 22mm) for the SZ-14

template & 64mm (2 x 32mm)

for the SZ-20 template. Cut

all your flat stock to that

width.

Thickness - The two sides

must be the same thickness,

which can be of any thickness

within the range of thicknesses

16

Page 17

available for each template (15

to 20mm for the SZ-14

template). The front and back

can be of a different thickness

than the sides but the front

and the back pieces need to

each be the same thickness and

within the 15-20mm range. A

very pleasing drawer to the

eye, and also a very common

size, is one where front and

back are 19mm (about ¾”) and

the sides are 15mm (about

9/16”).

The fastest, easiest thing is to

simply make all four drawer

components the same

thickness, but you do not have

to.

Length of the Front and

Back Pieces

and back pieces to be exactly

the length you want for the

finished width of your drawer.

If your perfect drawer would

be 400mm wide (a bit under

16”), cut the front and back

pieces to that length.

- Cut the front

Length of the Side Pieces

The length of each drawer side

piece will be the desired

overall depth front to back of

your perfect drawer less the

thickness of the front piece,

less the thickness of the back

piece plus twice the depth

setting for your router bit

which is 12mm for the SZ-14

and 15mm for the SZ-20.

Side piece length = desired

front to back dimension – 2

times (thickness of F or B –

depth of router bit)

If you want a drawer that

measures 500mm (about 20”)

front to back using the SZ-14

(which calls for a router bit

depth setting of 12mm) and

want to use front/back

components that are 20mm

thick, cut each side component

to be 484mm long.

484 = 500 – 2(20 – 12) or 484 =

500 – 2(8) or 484 = 500 - 16

This is really easy to calculate

using the metric system but

can be a bit confusing if you

insist on staying with the base

eight “inch” system where you

will have to add and subtract

some fractions.

See “Sidebar on Using the

Metric System” on page 36 of

this manual for my take on

this question.

Now cut the half blind

dovetails at each corner

If you prepare your stock as

indicated, the cutting of the

half blind dovetail joints to

make a perfect box in less than

five minutes every time is

really simple. With the Festool

VS-600 you only need to

mount the work pieces into the

jig twice to make all eight

parts of the dovetail joints on

the four corners. That is

because for half-blind dovetail

joints made on the VS-600 you

can cut two different corners at

the same time. And, you only

need to set up and align the

template once so there is little

chance for error.

Once you have done your one

time set up procedure to adjust

the template to the VS-600,

mounting it and starting to

make your perfect drawer is

simple and fast.

See the sidebar note on “One

Time Setup” on page 32.

Mount the SZ-14 or SZ-20

template into the VS-600 base

17

Page 18

unit with the in/out adjusting

wheels at each end against the

front edge of the VS-600.

Loosen the rotary knobs on the

two sides stops. Drop the

template down and align the

side stops to the inside of the

“D” shaped hole cut in each

side of the template.

Tighten the two rotary knobs

to hold the side stops in place.

Turn the side stop fingers so

SZ-14 or SZ-20 is facing

INWARD, towards the center

of the VS-600. The jig is now

ready to use.

So, how do you know

which piece goes where

and how they are

oriented on the VS-600?

Start by ignoring the drawings

and piece numbering text on

page 21 of the Festool VS-600

manual. I will show you a

much simpler method that you

can far more easily remember.

Place the drawer components

in front of you, standing

upright just like they will be

on your finished drawer with

the front of the drawer facing

you. Take a moment to look at

grain patterns and any defects

to determine the inside and

outside faces for each

component and which edge

should be the top of your

drawer. When you like the

arrangement, mark the

INSIDE FACE of each

component and mark the edge

that is to be the TOP. I do this

by drawing a triangle with the

point up on the inside of each

component. Mark which is the

FRONT piece and which is the

BACK piece of your perfect

drawer. I write “f” or a “b”

inside the triangle to indicate

that to myself.

All of the cuts will take place

with the INSIDE face of each

component facing out, away

from the VS-600, and with the

TOP edge against the side

stops on the VS-600. The

Front and Back will be cut

horizontally clamped under

the top clamp bar. The sides

will be cut vertically clamped

under the front clamp bar.

You can’t go wrong if you

always have the inside face

away from the jig with the top

edge aligned with a side stop.

The front and back of your

drawer will always be cut

horizontally clamped by the

top clamp bar. The sides will

always be cut vertically

clamped by the bar on the

front of the VS-600. The order

in which you make your cuts

18

Page 19

is not important so long as the

inside face is away from the

VS-600 and the top edge is

against a side stop.

I am in the habit of first raising

the template all the way up to

get it out of the way. Now I

slide the front piece

horizontally into the upper

clamp on the left side of the

VS-600 with its TOP edge

against the left side stop.

600 with this template) and

slide it vertically under the

front clamp and clamp it

lightly.

Since the template pivots even

when clamped in place, it is

easy to pivot it out of the way

while you line up the end of

the vertical piece to be exactly

flush with the top of the

horizontal piece that will

become the front or back of

your drawer.

Now I place the router on top

of the template and plunge the

cutter to the exact depth of the

test piece. That is all the router

set-up you need to do.

vertical work pieces are flush

with the top edge of the

horizontal work pieces as

shown in the picture to the left

and clamp them down.

Recheck to make sure

everything is nice and square

and securely clamped in place.

The horizontal work pieces

that will become the front and

back of your drawer should

butt tightly up against the

vertical pieces that will

become the sides of your

drawer.

I then place the back piece

horizontally into the upper

clamp on the right side of the

VS-600 with its top edge

against the right side stop.

Clamp those down.

Set the template on top of

these two components snugly

and clamp it in place. Then I

take the router bit depth gauge

(the female component from

the test piece we made when

originally setting up the VS-

Remove the router bit depth

test piece from the clamp bar

on the front of the VS-600 and

replace it with the two side

components. One will clamp

to the right side of the VS-600

and one will clamp to the left

side. Make sure the INSIDE

face is away from the VS-600

pointing towards you with the

TOP edge against the side

stop. Use a flat piece of scrap

to make sure the ends of these

The end of the vertical work

pieces (the sides) should be

exactly flush with the upward

face of the horizontal work

pieces (the front/back pieces).

All pieces should have their

INSIDE face away from the

VS-600 and their top edge

aligned with a side stop. Pivot

the template down and into

place. Make the cuts.

Now simply rearrange the

work pieces to cut the other

two corners. As before, the

top and bottom are held under

19

Page 20

the upper clamp bar with their

top edges against the side stop

and the inside face is away

from the VS-600 and pointing

up at you. The side pieces are

mounted under the front

clamp bar with their top edge

against the side stops and

inside faces pointing away

from the VS-600 and facing

you with their upper edge

flush with the top (inside) face

of the front/back components.

Make the second set of

cuts and you are done!

The reality is this all takes

less time to do than to

describe. Practice a few times

and you will make a perfect

drawer with finely machined

half blind dovetail corners in

less than five minutes, and you

will do it every time.

The drawer sides will come

out exactly the size you

wanted and will be square,

and the piece will be ready to

receive the admiring looks

from your customers, friends

or family who enjoy this

hallmark of fine

craftsmanship.

Machine the Dado to

Receive the Drawer

Bottom Before Assembly

Before you assemble your

drawer, take a few moments to

machine the dado which will

hold the drawer bottom in

place. Center it up from the

bottom edge of the drawer

one-half of the template

spacing (11mm in the case of

the SZ-14 template which uses

a 22mm finger spacing and

16mm for the SZ-20 which

uses a 32mm finger spacing).

That way the dado will not

show from the outside of the

drawer.

If you want the bottom to be

removable, cut the bottom of

the BACK piece off at the

height of the top edge of the

drawer bottom dado. Now the

bottom can slide in from the

back side and can be held in

place by a screw through a slot

cut into the back edge of the

bottom piece.

I recommend making your

bottom 2mm smaller than the

inside measurement of the

dado both side to side and

front to back. That way the

1mm spacing all around will

take up any shrinking or

swelling of the drawer sides

due to normal seasonal

changes in humidity. If you

use a solid wood drawer

bottom, allow 2mm on each

edge across the grain since

wood moves far more across

its grain than with its grain.

I nearly always use solid wood

for the drawer bottom and like

to keep it from rattling by

putting a dollop of waterbased contact adhesive or

caulk in the middle of the

three trapped sides (and the

back if it is also trapped).

Neither contact adhesive nor

caulk sets up solid so the

components can still move

relative to one another, but

they do prevent the bottom

from rattling when in very dry

climatic conditions.

20

Page 21

If your drawer components are

all made from man-made

materials which move either

not at all or far less than solid

woods, you can safely glue the

drawer bottom in place if you

wish.

21

Page 22

Here is a quick

summary of the steps

to make your perfect

half blind dovetailed

drawer using the

Festool VS-600

One time only for each

template you will do a test cut

to determine the proper router

bit depth setting and the

template in/out setting to get

the fit you want. Save the test

pieces to use as a router depth

gage for all subsequent uses of

that template. From then on:

• Prep your stock to be

flat, true and exactly the

thickness you want.

The front and back

components must be

the same thickness and

within the range of the

template you are using

(15-20mm for the SZ-14

and 21-28mm for the

SZ-20). The side

components can be a

different thickness so

long as that is also

within the range of the

template you are using.

• Cut all components to a

width that is an even

increment of twice the

half blind template

spacing if you want

properly centered

dovetails. For the SZ-14

the template spacing is

22mm and for the SZ-20

32mm.

• Cut the front and back

component to exactly

the width you want the

finished drawer to be.

Cut the side

components shorter

than the depth you

want your drawer to be

by 2 times the thickness

of the front/back

components less the

specified router bit

depth of cut (12mm for

the SZ-14 and 15mm for

the SZ-20).

• Mark the top edge and

inside face of each

component.

• Cut the joints in any

sequence, but always

align the top edge

against the side stop

with the inside face

away from the VS-600.

Always clamp the front

and back components

horizontally under the

top clamp bar and the

side components

vertically under the

front clamp bar.

• Dado the groove for the

drawer bottom centered

up from the bottom

edge of the drawer by

one half the template

spacing (11mm for the

SZ-14 and 16mm for the

SZ-20).

• Cut the drawer bottom

2mm to 4mm smaller

than the opening from

the bottom of the dados

both side to side and

front to back to allow

for expansion and

contraction of the

components with

normal seasonal

changes in humidity.

Do not rigidly glue the

bottom in place. Let it

float in the dados. A

dollop of rubber cement

or soft caulk will

prevent rattling.

• Brush glue onto the

long grain portions of

both sides of the

dovetail joints, assemble

and square it up.

You’re done! A

perfect drawer with

half blind dovetail

joints in less than five

minutes, time after

time.

22

Page 23

Making Your Perfect

Drawer Using

Through Dovetail

Joints

Through dovetails are

considerably more

sophisticated and complicated

joints to cut than are half blind

dovetails. The male fan shape

has to be cut by a dovetail

shaped router bit guided by a

template with straight fingers

with the work piece held

vertically.

The female recesses are cut

with the work piece held

vertically using a straight

router bit guided by a

template with angled fingers.

To fit, the angle on the dovetail

bit and the angle on the pin

template fingers must be

exactly the same. Also, the

spacing must be exactly the

same.

Fortunately, the superbly

engineered Festool VS-600

does most of the work for you

once you prep your work

pieces as described above and

determine the correct sizes to

cut your component parts.

As discussed earlier, I strongly

recommend the use of Festool

router bits and guide bushings

when cutting through

dovetails on this jig.

Length - Determining the

correct lengths for your perfect

drawer sides, front and back is

easy. Just cut them to the

exact length you want for the

outside width of the drawer

and for its depth, front to back.

Height - centered

dovetails look best

Calculating the correct height

for your drawer to make sure

your dovetails are properly

centered is a bit more

involved.

You want half pins at the

upper and lower sides of your

–

drawer.

This drawer has the dovetail

shaped male pieces shown

from the front, normally they

would show from the side.

These are the outboard most

sides of the female recess at

the top and the bottom of the

drawer no matter how many

female recesses there are in the

drawer side. If you get an

equal sized half pin top and

bottom, you will automatically

have evenly spaced, centered

dovetails that will look good

and hold tight for generations.

The trick is understanding the

template spacing, the side

offset and the maximum

diameter of the dovetail cutter

used to cut the male fan

shapes.

These male fan shapes or tails

are usually cut in the sides of

the drawer using the template

SZO-14-S or SZO-20-S. The

female recesses and pins are

usually cut in the front and

back of the drawer using

template SZO-14-Z or SZO-20Z.

23

Page 24

Page 25

pieces, you need to make sure

they are within the thickness

range of the SZO-14 (10mm to

14mm) or the SZO-20 (14mm

to 25mm). Be sure the front

and back pieces are the SAME

thickness and the side pieces

are the SAME thickness. The

front/back can be a different

thickness than the sides.

Make your cuts

Now you are ready to cut. For

strength you want the male

fan shape tails to be cut on the

sides of the drawer and the

female recesses to be cut in the

front and back work pieces.

Once you get the hang of

through dovetails don’t be

afraid of experimenting by

reversing these to get a

different look to your joints.

In the traditional trough

dovetail the characteristic fan

or tail shape shows only from

the side of the drawer. From

the front it looks like a simple

box joint. If you reverse these

and put the male fan shaped

tails on the front and back

work pieces, the characteristic

dovetail shape will show from

the front and back. From the

sides it will look like a simple

box joint.

You will always cut the male

fan shaped tail pieces held

vertically under the front

clamp bar with the OUTSIDE

face pointing out away from

the VS-600.

Work pieces set to cut the

male fan shapes in the “tail

board”

The female recesses cut with

the angled template will

always be held vertically

under the front clamp bar with

the OUTSIDE face pointing

out away from the VS-600. In

all cases the top edge of the

drawer components will be

against the side stops as you

make your cuts. The order or

sequence does not matter.

Work pieces set to cut the

female recesses in the “pin

board”.

Cut the Male Fan Shaped

Tails (normally in the

pieces that will be the

sides of your drawer) –

I am in the habit of cutting the

male fan shaped tail pieces

first. To do so, mount the

straight fingered template

SZO-14-S or SZO-20-S on the

VS-600. It is self aligning and

needs no adjustment. Lower it

down and align the side stops

to the opening in the template

just as you did before with the

half blind templates. Be sure

to turn the SZO-14 or SZO-20

side stop fingers inwards

towards the center of the VS600 ON BOTH SIDES of the

template. Mount the correct

guide bushing and the correct

dovetail shaped cutter in the

router.

Place scrap pieces that are at

least 5mm THICKER than the

pieces which will have the

25

Page 26

female recesses cut in them

(usually the front and back

components) horizontally

under the top clamp bar

against the side stops and snug

them down. Be sure they are

wider than the pieces you

intend to cut the male fan or

tail into. These scrap pieces

will hold the male work piece

high enough that the bottom of

the dovetail shaped router bit

will not hit the base of the VS600 and they will help prevent

tear out on what will become

the inside of your drawer.

receive the female recesses.

Since the scrap is at least 5mm

thicker, this will allow your

router bit to miss the

aluminum bed of the V

S-600 as

you make your cuts.

ote that the proper depth of

N

cut is the thickness of the piece

into which this piece will

mate.

the picture below, the router

In

is zeroed to the top of the

work piece. Now set the

proper depth, plunge and

make the cuts in both piece

s.

ealign the work pieces by

R

rotating them side-to-side an

d

cut the male fan or dovetail

shapes on the other end.

end flush with the top of the

scrap piece.

ou are finished with the male

Y

fan shaped tail components.

Align the top edge of the

pieces which will have the

male fan or tail shape cut in

them (usually the side pieces)

with the TOP face of your

scrap piece, outside face

pointing out away from the

VS-600 and the top edge

against the side stop.

Set Router Bit Depth of

Cut

– With the template

lowered onto the scrap pieces,

place the router on the top of

the template. Set your router

depth of cut to be exactly the

width of the pieces which will

.

sure the OUTSIDE face

Be

points away from the VS-60

the top edge of your drawer is

against the side stop, and the

0,

26

Page 27

Cut the Female Recesses

or Pins (normally in the

front & back pieces of

your drawer)–

Remove the SZO-14-S or SZO20-S and mount the SZO-14-Z

or SZO-20-Z template with the

in/out adjustment wheels on

each end against the bed of the

VS-600.

Align the side stops with the

inside of the “D”shaped hole

stamped into each end of the

template and lock them down.

The very first time you use

either the SZO-14-Z or SZO20-Z you will make a test cut

to set the proper in/out setting

on the two depth setting

wheels on either end of the

template. After that you only

need to mount the template,

align your work pieces and

make the cuts.

Fit the proper guide bushing

and straight router bit into the

router. As you did for the

male tail cuts, mount a scrap

piece at least 5mm THICKER

than the router bit depth of cut

horizontally under the top

clamp bar so you do not hit the

body of the VS-600 while

cutting the female recesses.

Mount the work pieces under

the front clamp bar with the

OUTSIDE facing away from

the VS-600, the top of the

drawer against the side stops,

and the ends flush with the

top edge of the scrap pieces.

Drop the template on top of

the scrap pieces and clamp it

in place. Place the router on

top of the template and set the

depth of cut to be exactly the

thickness of the pieces into

which you just cut the male

fan shaped tails.

Make your cuts following the

angled sides of the template

fingers. Be sure to also route

out the area between the

angled sides of each template

finger.

Note that the proper depth of

cut is the thickness of the piece

into which this piece will

mate.

Reset the work pieces to cut

the other two sides of the joint

and you are done.

27

Page 28

A perfect drawer with through

dovetails in under fifteen

minutes.

Because you have to use two

different templates, two

different guide bushings, two

different router bits and do

two set-ups to make through

dovetail joints, it will take

about fifteen minutes per

drawer instead of the five

minutes per drawer required

for half blind dovetail joints.

In both cases your drawer will

be “perfect” right out of the

VS-600 joining system. It will

be exactly the length, width

and depth you want it to be,

will be absolutely square, sit

flat and invoke an image of

fine craftsmanship from the

minute you assemble it.

No sanding to fit, no “make it

a bit bigger and cut it to fit

afterwards” and no “put a bit

of filler into the gaps to make

it look like it fits” even when it

doesn’t.

28

Page 29

Perfect Finger Joints

Are Also Easy and

Fast

A finger joint is simply a series

of male fingers and female

recesses of the same size and

spacing cut all the way across

the ends of the work piece. By

cutting these so the male

fingers on one piece fit into the

female recesses on the other a

strong corner joint with a

relatively large gluing area can

be established quite quickly.

Some, including Festool, also

call this a “box” joint because

it is very easy to automate for

rapid assembly of functional

boxes.

On the VS-600, finger or box

joints of two sizes can be

quickly cut in work pieces

from 6mm to 28mm in

thickness and up to 600mm

wide. The joint will look the

same from either side. If you

like the look of finger joints,

they can be cut very quickly

and accurately every time.

Two corners can be cut with

each set up (so long as the

pieces are less than 300mm

wide) and only one template,

one guide bushing and one

cutter are required for all the

cuts.

The only set-up required is

setting the depth of cut made

by the straight router bit to be

equal to the thickness of the

work pieces.

Prep your stock just as you did

for the dovetail joints. You

want stock that is uniform in

thickness, flat, square, of the

size you want and within the

thickness range of the template

you are using.

Centering the Fingers - As

with dovetail joints, the best

looking finger joints are when

the fingers are centered over

the height of the box. You will

have one half finger at the top

of the box and one half finger

at the bottom of the box.

Avoid boxes with less than or

more than half a finger at the

bottom as these tend to be

quite weak as well as

awkward looking.

The proper height of the box to

have centered fingers is any

even increment of twice the

template spacing.

Festool sells two different

finger joint templates, FZ-6

and FZ-10. The numbers refer

to both the size in mm of the

straight router bit used to

make the cuts and also to the

side spacing. The template

spacing is twice the diameter

of the router bit so calculating

the height of a box with

centered fingers is quite easy.

It is any even increment of

twice the template spacing, ie:

12, 24, 36, etc. for the FZ-6 and

20, 40, 60, etc. for FZ-10.

Width and Length – With

finger joints the fingers go all

the way through each piece so

simply cut the front, back, and

side work pieces to exactly the

lengths you want for your

finished box.

Set up is similar to what you

did for through dovetails.

Mount scrap pieces under the

top clamp bar that are at least

5mm THICKER than your

work pieces to allow the router

bit to pass above the bed of the

VS-600 when you make your

cuts.

All four work pieces will be

mounted vertically under the

front clamp bar. Two work

29

Page 30

pieces will be clamped on top

of each other with their

OUTSIDE faces TOGETHER

and what will be the TOP edge

of the box against each of the

two side stops. The top edge

of these pieces will be flush

with the top of the scrap pieces

and up against the bottom of

the template.

Where this gets a bit tricky is

that one piece will stop against

the side stop finger while the

other will stop against the

round portion outboard from

the side stop finger.

In the pictures above I have

removed the scrap piece from

behind the two work pieces to

make it easier to see.

Once the four work pieces are

mounted under the front

clamp bar and flush with the

top of a scrap piece that is at

least 5mm thicker than the

router bit depth of cut, rotate

the template down and place

the router on top of the

template. Set the depth of cut

to be equal to the thickness of

the work pieces.

Make the cuts. If the thickness

of your work pieces is greater

than the diameter of the router

bit, make the cuts in multiple

passes with each pass cutting

no more than the diameter of

the router bit.

Rearrange the work pieces

under the front clamp bar

stacked with the OUTSIDE

faces together and the TOP

against the side stops.

Make the cuts and you are

done. A perfect box with

finger joints in less than five

minutes!

The concept of centering a box

joint is a bit different from

centering dovetail joints. A

properly centered box or

finger joint will show a certain

number of whole fingers on

one side with one fewer than

that number of whole fingers

plus two half fingers on the

other side.

An unbalanced, yet still

considered centered by some,

finger joint will show the same

number of whole fingers on

each side. On one side there

will be a half finger at the top

and on the other side a half

finger at the bottom.

Which you prefer is a matter of

taste. I like the properly

centered finger joints the best.

30

Page 31

Conclusion

At the beginning of this manual we talked about how the dovetail joint is recognized the world over

as one of the hallmarks of fine craftsmanship. We also talked a bit about how difficult many find it is

to cut perfect dovetail joints or to get a dovetailed drawer, box or cabinet carcass just the size you

want it in the first place. And, we touched on why so very many dovetail jigs sit gathering dust in

the corner because they can be far from intuitive to set up and use properly when you only use them

once in a while.

I hope that you now have far more confidence that you, too, can make a perfect drawer with half

blind dovetails (or finger joints) in less than five minutes and with through dovetail joints in under

fifteen minutes using the well engineered Festool VS-600 jointing system. Once this becomes your

preferred means of creating perfect drawers, boxes and cabinet carcasses you will be amazed at how

often you find yourself doing so. Day in, day out there simply is no better way I know of to add

value and longevity to your furniture projects.

Whether you make your living doing so, as I do, or whether you build furniture for family and

friends just because you love to, adding a Festool VS-600 jointing system to your shop or studio will

prove to be one of the best investments you can make in working faster, better and more efficiently.

Enjoy!

Jerry

31

Page 32

One-Time Set-Up

All four of the Festool VS-600

dovetail templates require a

one time set-up to make sure

the in/out adjustment wheels

are set to cut a perfectly flush

joint and to establish a router

depth setting that will provide

the tightness of fit you want.

You only need to do this the

first time you use a particular

template. After that, the

template will clamp in place

with the correct in/out setting

and, if you save the test pieces,

you can quickly set the correct

bit depth.

This one time set-up is fast and

easy to do since you really

don’t care what length and

width the work pieces are or

how thick they are so long as

they are within the range for

which each template is

designed. For the two half

blind dovetail templates, SZ-14

and SZ-20, just mount the

template with the cam shaped

underside of the black in/out

adjustment wheel against the

front edge of the VS-600. Start

with the wheel set to the zero

position.

Loosen the holding screw to

turn the wheel while the rotary

knob that holds the template is

loose enough that the template

can slide in and out. When

you have the in/out

adjustment wheel at BOTH

sides of the template set to the

same zero mark, tighten the

holding screws.

Now push the template

towards the VS-600 so the cam

shape on the under side of the

black in/out adjustment wheel

is against the front edge of the

VS-600 and tighten the rotary

knobs which fasten the

template to the VS-600.

Next, move the two side stops

to fit the inside of the “D”

shaped opening stamped into

the template. Turn the side

stop so the fingers matching

the template face inward,

toward the center on both ends

of the VS-600.

Mount one scrap piece

horizontally under the top

clamp bar and another

vertically under the front

clamp bar. Be sure each piece

is within the thickness range

specified for the template you

are adjusting. Also, make sure

each piece is against the side

stop and the end of the

vertically mounted piece is

flush with the top of the

horizontally mounted piece.

The pivot action of the

templates makes this easy to

do if you hold a scrap piece on

top of the horizontal work

piece while you push the

vertical work piece up against

it.

32

Page 33

Position the template on top of

these two and clamp it down.

Set your router depth of cut to

the factory specified 12mm for

the SZ-14 and 15mm for the

SZ-20. Festool routers are easy

to adjust by zeroing the router

bit on top of the horizontal

work piece while the router is

in cutting position on top of

the template. Then you can

simply move the depth

indicator to the 12mm or

15mm mark, plunge the router

and you are ready to cut.

Be careful here. Note that this

is NOT 12mm from the base of

the router, it is 12mm lower

than the bit when it is

positioned on top of the

horizontal work piece with the

router sitting in cutting

position on top of the

template.

If you use some other brand of

router be sure you can set the

depth of cut from a bit zeroed

on top of the work piece. Do

not try to set the bit depth of

cut with the router on the

bench as it will not be correct

and your joints will be way off.

Once the router bit depth is

set, make the cuts. Remove

the pieces and try the fit.

Usually the depth setting will

produce a properly tight fit,

but if it is off a bit lower the bit

to make it tighter and raise the

bit to loosen the joint fit.

Check how flush the joint is

when driven all the way home.

If the vertical piece (what will

normally be the side of your

drawer) stands proud of the

edge of the horizontal piece

(which normally will be the

front or back of your drawer),

then loosen the two holding

screws and turn each in/out

adjusting wheel to the same

mark in the + direction. Note

that the well engineered VS600 is calibrated so each mark

represents an 0.1mm

movement. If your edge

stands proud by 0.2mm, move

the wheels two marks and

tighten them down. If the

sides go in too far, move both

wheels in the – direction by

the proper amount.

It is a good idea to do one

more test cut if you needed to

adjust either the router bit

depth setting or the template

in/out setting. You only need

to do this once and that

template will forever be set to

produce your prefect drawer

no matter what length, width

or thickness of work pieces

you use (so long as the

thickness is within the range

specified for each template

and you continue to use the

same router bit).

When you have the fit you

want, save the pieces to use as

a router depth of cut gauge for

all subsequent uses of this

template.

The “right” fit is a matter of

personal taste. I like the joint

to go together with only a light

tapping with my hand or a

mallet. That will provide a

good bonding surface for the

glue and still show a tight,

artful joint. If the joint is

33

Page 34

overly tight and requires

heavy blows to get it together

then the glue will either get

scraped off when you

assemble, or will get trapped

in the bottom of the female

recesses and lock the joint

open, or you will break

something during assembly.

While many of my colleagues

will disagree with me on this

point, with today’s glues I

think it is better to error on the

side of being too loose than too

tight for half blind dovetails.

The one time adjustment for

the SZO-14 and SZO-20

through dovetail template sets

is very much the same. You

will, however, have to cut the

two test pieces separately. The

template with the straight

fingers will cut the male fan

shaped tails using the

specified dovetail cutter and

the template with the angled

fingers will cut the female

recesses and surrounding pins

with the specified straight

cutter.

Be sure you place a scrap piece

under the top clamp bar that is

at least 5mm thicker than your

horizontally mounted test

work piece to avoid cutting

into the VS-600!

As before, once you make your

test cuts put the two pieces

together and observe the fit.

proud from the end of your

drawer front/back (the piece

you cut with the angled finger

template), loosen the securing

screws and turn the two

in/out adjustment wheels to

create a perfectly flush joint.

If the ends of one or the other

of the two pieces protrude

beyond the outside edge of the

joint, reduce the depth of cut

setting until they are both

exactly flush. Since you have

to adjust the depth of cut for

both templates and the in/out

on one, plan on doing a couple

of test cuts.

Remember, you are only going

to do this once for each

through dovetail template set

so take your time and do it

right.

If the edge of what would

normally be your drawer side

(the piece cut with the straight

fingered template) stands

34

Once you have a correct fitting

joint the template in/out

setting will be correct for all

further use of that template.

Save BOTH test pieces to use

in setting the correct router bit

depth whenever you use this

template set in the future.

Page 35

You are done with set up and

your templates are all ready to

use at a moment’s notice. Just

mount the template making

sure the cam on the bottom of

the black in/out adjustment

wheels is against the VS-600

when you tighten the two

rotary knobs to secure the

template in place. Position

your work pieces under the

clamps as outlined in this

manual, set the router bit

depth using the test pieces you

saved and you are “good to

go.”

From this point

forward, you will

cut perfect halfblind dovetailed

drawers in under

five minutes and

through-dovetailed

drawers in under

fifteen minutes.

Cut the work pieces

to the proper size,

mount them as

indicated and make

perfect joints every

time.

35

Page 36

My Take On Using

the Metric System

Most of the tools we use every

day were designed for a world

market. Most everywhere but

in the US the metric system is

employed for weights and

measures. So, it is no surprise

that many tool manufacturers

design their tools around the

metric system and then

convert them to show inch

scales for the US market.

While few of us in the USA

grew up with the metric

system, and certainly do not

think in metric length terms,

learning to measure using the

metric system is far easier than

using the base 8 “inch” system

for building furniture. There,

everything is a fraction of an

even multiple of 8; one eighth,

one sixteenth, one thirty

second, etc. While we have

learned to add and subtract

odd fractions over the years,

the process is still very time

consuming and error prone.

On the other hand, measuring

using the base 10 metric

system is very straight

forward. You never deal with

fractions, only whole numbers.

The process is much faster and

far less error prone. As an

example, lets say you want to

build a rail, stile and panel

door for a project. You want

the door to be 19 3/8” wide.

The rail and stile pieces are 2

5/8” wide by ¾” thick and all

the groves are 3/8” deep. You

want to know how long to cut

the top rail piece. Lets see, it

will be 19 3/8” less 5 1/4” (the

width of the two stiles on

either side) plus ¾” for the

tenons on each end. Think