Page 1

PRECISIO

Seen at Ideal Tools.

CS 50 EB

CS 50 EB Floor

Bedienungsanleitung 5 - 10

Operating Instructions 11 - 15

Mode demploi 16 - 21

Instrucciones de servicio 22 - 27

Istruzioni duso 28 - 33

Gebruiksaanwijzing 34 - 39

Bruksanvisning 40 - 44

Käyttöohje 45 - 49

Driftsvejledning 50 - 54

Bruksanvisning 55 - 59

Instruções de uso 60 - 65

Руководство по эксплуатации 66 - 71

Návod k obsluze 72 - 76

Instrukcja obs³ugi 77 - 82

Kezelési utasítás 83 - 87

464 688_005

ПдзгЯб лейфпхсгЯбт 88 - 93

Festool GmbH Wertstr. 20 D-73240 Wendlingen ( 07024/804-0

Page 2

Seen at Ideal Tools.

Page 3

Seen at Ideal Tools.

Page 4

Seen at Ideal Tools.

Page 5

1 Technical data

Seen at Ideal Tools.

Cutting depth at 90° / 45° 0 - 50 mm / 0 - 40 mm

Inclination -2° to 47°

max. drawing length 300 mm

Saw blade (diameter x cutting width) 190 x 2.6 mm

Idling speed 1600 - 4200 rpm

Power consumption 1200 W

Bench dimensions (length x width) 600 x 400 mm

Bench height with / without foldaway legs 900 mm / 375 mm

Weight without foldaway legs 19 kg

Weight of foldaway legs 2 kg

The specified illustrations can be found at the

beginning of the operating instructions.

2 Intended use

The PRECISIO is intended as a transportable

electric power tool for sawing wood, plastics,

board tools made of wood and materials similar

to wood. With the special saw blades for

aluminium offered by Festool, these machines

can also be used for sawing aluminium.

Materials containing asbestos must not be

processed. The user is liable for any damage

or accidents resulting from use not in

accordance with the intended use.

3 Before starting up, please observe

the following

3.1 Safety instructions

IMPORTANT! When electric power tools

are used, the following fundamental

safety measures are to be complied

with to protect against electric shocks

and the risks of injury and fire.

Read all of these instructions before

you use this electric power tool and

keep the safety instructions in a safe

place.

1. Keep your work area tidy

- Untidiness in work areas can lead to

accidents.

2. Take account of environmental

influences

- Do not expose electric power tools to rain.

- Do not use electric power tools in damp or

wet environments.

- Ensure that the work area is well lit.

- Do not use electric power tools where there

is a danger of fire or explosion.

3. Protect yourself against electric

shocks

- Avoid body contact with earthed parts (e.g.

pipes, radiators, electric cookers, cooling

devices).

4. Keep other people away

- Do not permit other people, in particular

children, to touch the electric power tool or

the power cable. Keep these people away

from your work area.

5. Store unused electric power tools in

a safe place

- Unused electric power tools should be stored

in a d r y pl a ce a t a c e rt a in h e ig h t o r in a l oc k ed

area, beyond the reach of children.

6. Do not overload your electric power

tool

- You work better and more safely within the

specified power range.

7. Use the right electric power tool

- No not use low-power machines for heavyduty work.

- Do not use the electric power tool for

purposes for which it is not intended. For

example, do not use a portable circular saw

to cut tree branches or billets of wood.

8. Wear suitable clothing

- Do not wear bulky clothing or jewellery; this

could be caught up in moving parts.

- When you are working outdoors, non-slip

shoes are recommended.

- If you have long hair, wear a hair net.

9. Use protective equipment

- Wear protective goggles

- For work that generates dust, wear a face

mask.

10. Connect the dust extraction facility

- If there are connections to dust extraction

and collection, ensure that these are correctly

connected and are used correctly.

11. Do not use the power cable for

purposes for which it is not intended

- Do not use the power cable to pull the mains

plug from the socket. Protect the power

cable against heat, oil and sharp edges.

11

Page 6

12. Secure the workpiece

Seen at Ideal Tools.

- If possible, use clamps or a vice to secure

the workpiece. This holds it more securely

than by hand.

13. Avoid abnormal body postures

- Ensure that you are standing securely and

keep your balance at all times.

14. Carefully maintain your tools

- Keep cutting tools sharp and clean in order

to be able to work better and more safely.

- Comply with the instructions for lubrication

and tool changes.

- Regularly check the connection cable of the

electric power tool. In the event of damage,

have it replaced by a recognised professional.

- Regularly check extension cables and replace

them if they are damaged.

- Keep the hand grips dry, clean and free of oil

and grease.

15. Pull the mains plug from the socket

- If the electric power tool is not being used,

prior to maintenance and when changing

tools, e.g. saw blade, drill bit, router bit.

16. Do not leave tool keys in the tool

- Before switching on, check that the key and

adjusting tools have been removed.

17. Avoid inadvertent start-ups

- Make sure that the switch is off when you

insert the plug in the socket.

18. Use extension cables for outdoors

- Outdoors, use only approved and

appropriately coded extension cables.

19. Pay attention

- Take care of what you do. Work sensibly. Do

not use electric power tools when you lack

concentration.

20. Check the electric power tool for

damage

- Before continuing to use the electric power

tool, protection devices or slightly damaged

parts must be carefully examined to ensure

that they function perfectly and in accordance

with their intended purpose.

- Check whether moving parts work perfectly

and that they do not jam, or whether parts

are damaged. All parts must be correctly fitted

and all conditions met to ensure perfect

operation of the electric power tool.

- Damaged protection devices and parts must

be properly repaired or replaced by a

recognised specialist workshop, unless otherwise specified in the operating instructions.

- Damaged switches must be replaced in a

customer service workshop.

- Do not use any electric power tools on which

the switch cannot be switched on and off.

21. IMPORTANT!

- The use of other tools and accessories can

represent a risk of injury.

22. Have your electric power tool repaired

by a qualified electrician

- This electric power tool complies with the

relevant safety regulations. Repairs may only

be carried out by a qualified electrician using

original spare parts; otherwise, accidents

involving the user can occur.

23. Machine-specific safety instructions

- Deformed or cracked saw blades and saw

blades with blunt or broken cutting edges

must not be used.

- The maximum speed specified on the tool is

to be complied with.

- The tool must be suitable for the material to

be processed.

- Saw blades made of High Speed Steel (HSS

steel) must not be used.

- The tools must be transported and stored in

a suitable container

- Wear suitable personal protection equipment:

Ear protection to reduce the risk of

damaging your hearing

Protective goggles

Face mask to reduce the risk of inhaling

harmful dust

Protective gloves when handling tools and

coarse materials

- To minimise the creation of dust, the machine

is to be connected to a suitable dust

extractor, and all the elements for dust

collection (extractor hood etc.) must be

properly set.

- When sawing wood, the machine is to be

connected to a dust extractor complying with

EN 60335-2-69, dust category M.

- To minimise noise development, the tool must

be sharpened and all elements for noise

reduction (covers etc.) must be properly set.

- The machine may only be used if all protection

devices are in the appropriate positions and

if the machine is in good condition and has

been properly serviced.

- Faults in the machine, including the separating

protection devices or in the tools, must be

reported immediately on discovery to

maintenance personnel. The machine may

only be used again once the faults have been

rectified.

- Rebating or grooving are only permitted with

a suitable protection device, e.g. a tunnel

protection device over the saw table.

- Circular saws must not be used for slotting

(groove completed in the workpiece).

- The upper protective hood may not be used

as a carrying handle!

- During transport of the machine, the upper

protective cover must cover the upper

section of the saw blade.

- Long workpieces are to be supported by a

suitable setup so that they lie horizontally.

12

Page 7

3.2 Noise and vibration information

Seen at Ideal Tools.

Sound pressure level

Idling / processing 84 / 90 dB(A)

Noise power level

Idling / processing 97 / 103 dB(A)

Measurement tolerance K = 4 dB

Wear ear protection!

3.3 Residual risks

In spite of compliance with all relevant design

regulations, dangers may still present themselves when the machine is operated, e.g.:

- Workpiece parts being thrown off,

- Parts of damaged tools being thrown off,

- Noise emission,

- Sawdust emission.

4 Setting up, commissioning

Ensure that the floor around the machine is

level, in good condition and free of loose

objects (e.g. chips and offcuts).

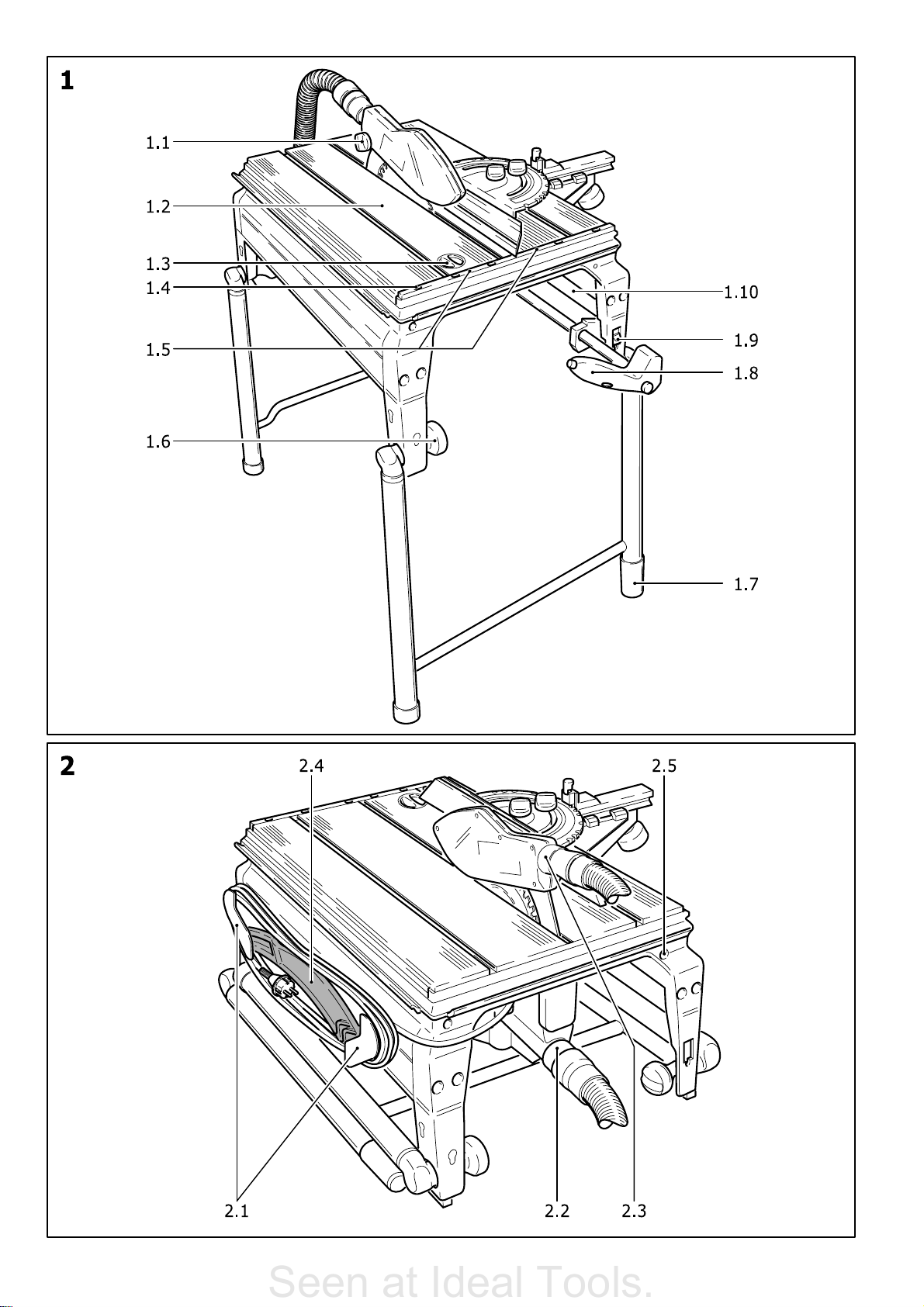

4.1 Mounting the machine

The machine can be set up with or without the

legs folded out (Fig. 1 and 2) (the Floor

model does not include folding legs).

To fold out the legs, open the four rotary knobs

(1.6) as far as they will go. After folding out

the legs, retighten the four rotary knobs.

So that the machine stands securely, the length

of one of the legs can be changed by turning

the cap on the end (1.7).

4.2 Applications

The machine can be used as a bench-mounted

circular saw or as a circular trimming saw.

a) Bench-mounted circular saw

(Fig. 1)

- Set the switch (1.9) to the lower position.

- Swing the hand grip (1.8) downwards, and

use the hand grip to pull the saw unit

forwards until it locks into place.

The saw unit is now in a central bench position

and the machine can be used as a benchmounted circular saw.

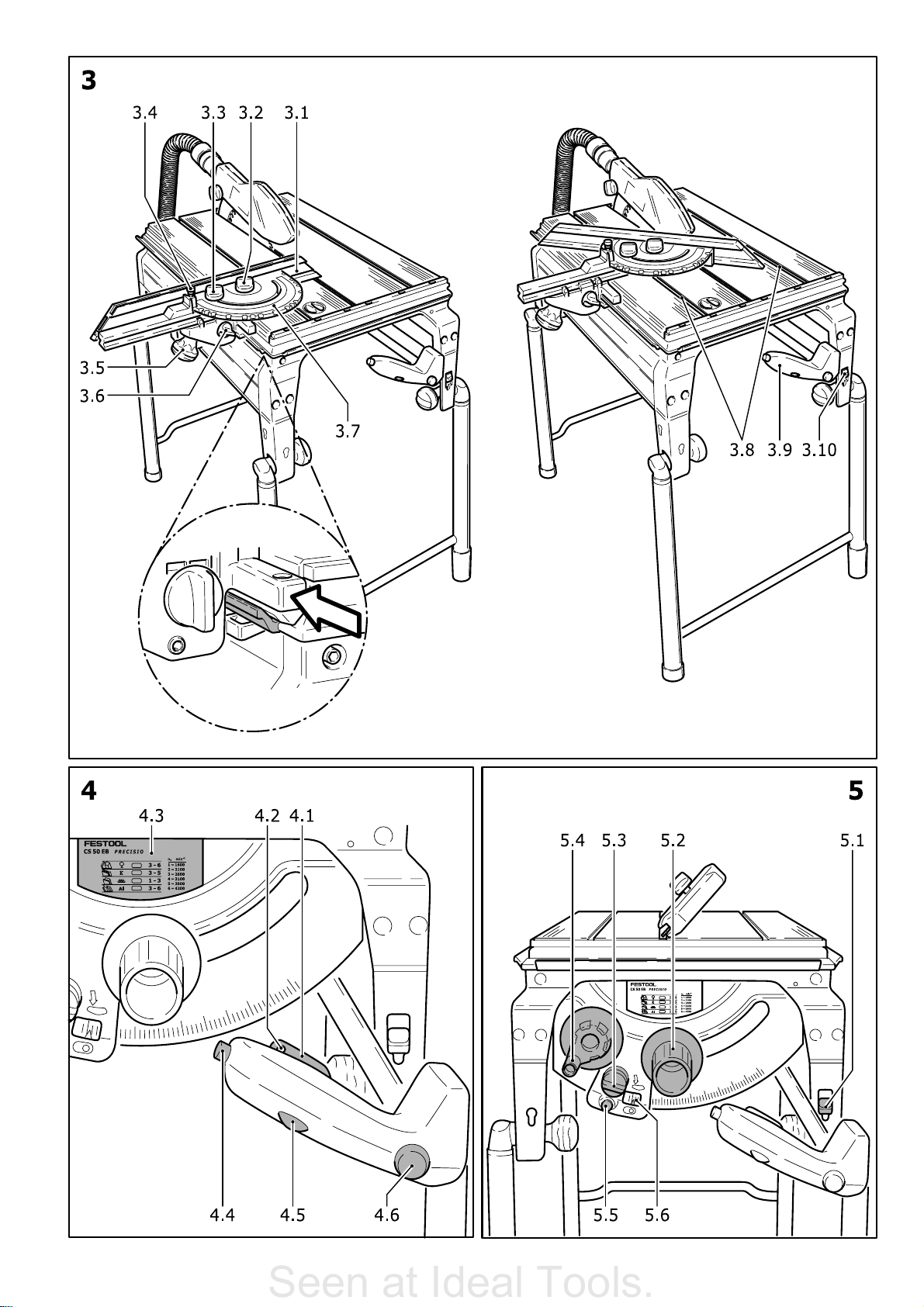

b) Circu l a r t r i mmi n g sa w (Fi g . 3)

- Set the switch (3.10) to the upper position.

If the hand grip (3.9) is swung downwards, it

can be used to move the saw unit backwards

and forwards for drawing cuts. The backward

movement is supported by spring force.

4.3 Dust extraction

The PRECISIO has two extraction

connections: the upper protective

cover (2.3) with a diameter of 27 mm,

and the lower protective cover (2.2)

with a diameter of 35 mm.

The extraction set CS 70 AB (488 292, included

in scope of delivery for CS 50 EB) joins both

of the extraction connections so that a Festool

extractor module can be connected.

4.4 Power supply and start-up

The mains voltage must correspond to the

specification on the rating plate.

On account of the performance capability of

the motor, we recommend a 16 A fuse.

To switch on, press the ON/OFF switch (4.1)

and the locking switch (4.4) simultaneously.

The machine runs as long as the ON/OFF switch

is pressed.

For continuous operation after switching on,

first press the ON/OFF switch (4.1) and then

let go of the locking switch (4.4). To switch off

continuous operation, either press the ON/OFF

switch again and let it go or press the red switch

(4.6). To protect against unauthorised

activation, a shackle type connector can be

inserted in the hole (4.2) of the ON/OFF switch.

5 Electronics

The machine has full-wave electronics

with the following features:

5.1 Smooth start-up

The smooth start-up ensures the router starts

up jolt-free.

5.2 Speed adjustment

You can regulate the speed steplessly between

1600 and 4200 min-1 using the adjusting

wheel (4.5). This enables you to optimise the

cutting speed to suit the material (4.3).

The pre-selected speed remains constant

whether the machine is in operation or in neutral position.

5.3 Overload protection

In the event of an extreme overload of the

machine, the power supply is reduced. If the

motor is blocked for a longer period, the power

supply is interrupted completely. After removal

of the blockage or switching on again, the

machine is operational once again.

5.4 Temperature protection

If the motor temperature becomes too high,

the power supply and speed are reduced. The

machine then only runs with reduced power

to enable rapid cooling by means of the motor

ventilation. After cooling down, the machine

accelerates again automatically.

5.5 Brake

After switching-off the tool, the saw blade is

electronically brought to a standstill in 1.5 2

seconds (only for 230 V - 240 V configuration).

5.6 Restart protection

The built-in undervoltage release prevents that

the machine restarts on its own in the continuous operation mode following a power cut. In

this case, the machine must first be switched

off and then on again.

13

Page 8

6 Machine settings

Seen at Ideal Tools.

Prior to any setting, maintenance or

repair, pull the mains plug!

To make setting easier, the saw unit can be

locked in the front position (Fig. 5): pull the

saw unit forwards as far as it will go and place

the switch (5.1) in the lower position.

The machine must not be used in the

front position!

6.1 Cutting depth

The cutting depth can be set steplessly (0 50 mm with 90° position of the saw blade) by

turning the crank handle (5.4).

6.2 Mitre

The saw blade can be pivoted between 0° and

45°:

- Open the rotary knob (5.3).

- Se t th e mit r e us ing th e sc a l e (5.6 ) by t u r ning

the handle (5.2).

- Close the rotary knob (5.3).

For exact fitting work (relief cutting on the

bordering), the saw blade can be pivoted 2°

beyond the two end positions. To do so, the

button (5.5) is pressed in the end position;

the saw blade can then be pivoted up to -2°

or 47°. On pivoting back, both end positions

are active once again.

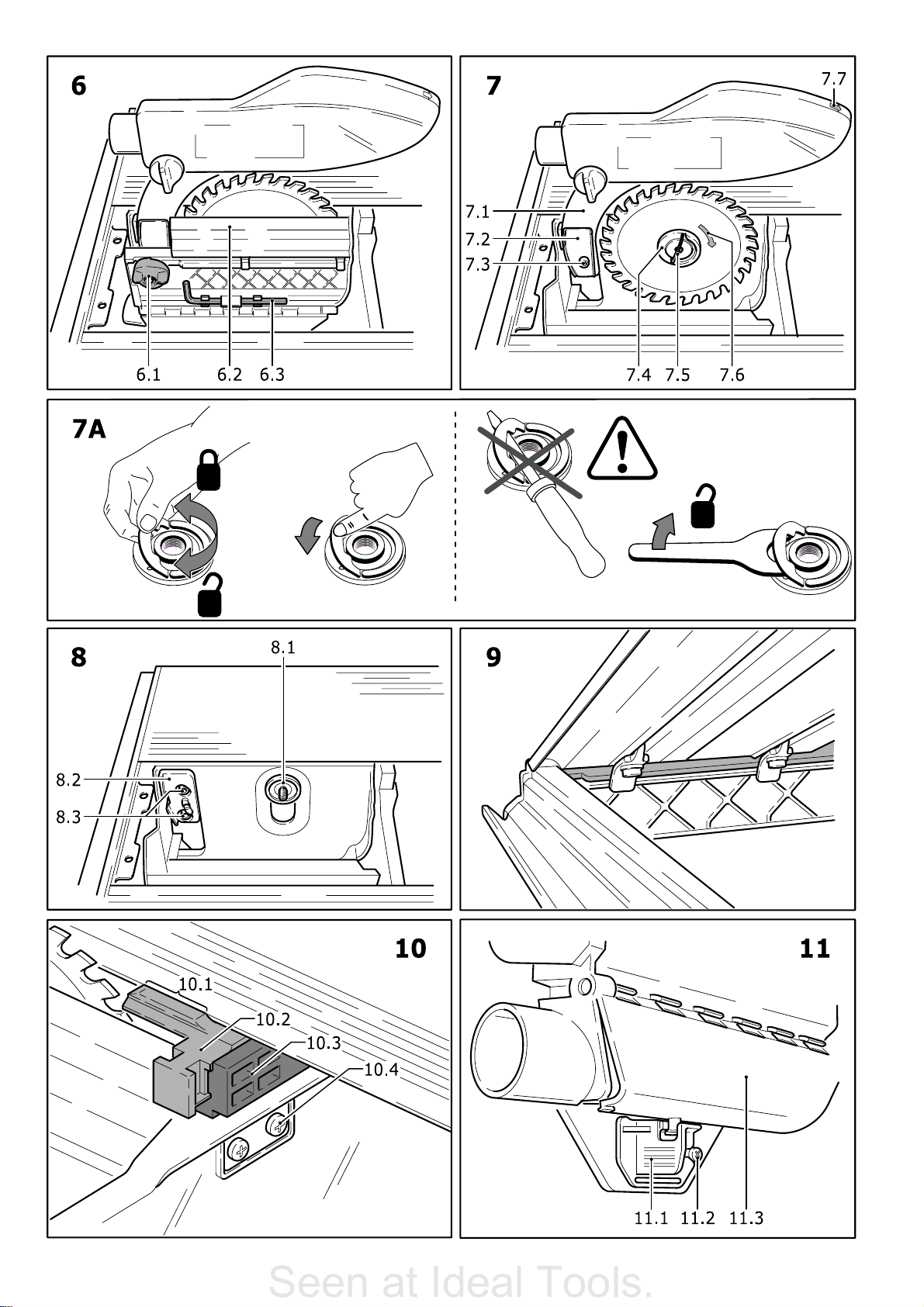

6.3 Changing tools

Safety Instructions Fast-Fix

Tension Nut (see Fig. 7 A).

After tensioning, close the handle bow.

Only tighten or loosen the Fast-Fix

Tension Nut by hand. Under no

circumstances use the handle bow with

aid of screwdrivers, pliers, or other

tools for tightening or loosening.

If the nut cannot be loosened by hand,

only use a pin-type face spanner for

support.

Never continue to use the Fast-Fix nut,

in case the handle bow is loose or

damaged.

Due to the special shank, only the saw

blades offered by Festool for this

machine may be used.

- Open the locking mechanism (1.3) and

remove the bench insert (1.2) upwards

- Open the locking mechanism (6.1) and swing

the saw blade cover (6.2) down. This

automatically locks the tool spindle

- Shift the lever (7.5) and turn clockwise (left-

hand thread) to open the Fast-Fix clamp

(7.4)

- Change the tool. In doing so, bear in mind:

The Fast-Fix clamp (7.4), flange (8.1) and

saw blade must be clean

The direction of rotation on the saw blade

(7.6) must match the direction of rotation

of the machine (7.7)

Place the saw blade on the centre of the

flange (8.1) and turn until the contour of

the flange and the saw blade hole lock.

- Firmly tighten the Fast-Fix clamp (7.4)

anticlockwise; shift the lever (7.5)

- Swing the saw blade cover (6.2) upwards

and close the locking mechanism (6.1)

- Insert the bench insert with the rear edge

first (see Fig. 9) and close the locking

mechanism (1.3).

6.4 Setting the riving knife

The spacer wedge (7.1) is to be set in such a

way t h at the gap to the c h uck of the saw bla d e

is 3 to 5 mm.

- Use the Allen key (6.3) to remove the screw

(7.3) and take it out together with the

clamping element (7.2),

- After both of the screws (8.3) have been

opened, the guide element (8.2) can be

shifted vertically to set the gap between the

spacer wedge and saw blade.

- After completion of the setting, fit the spacer

wedge and clamping element again and

tighten all screws.

6.5 Guide

As shown in Fig. 3, the supplied guide can be

secured to all four sides of the machine.

The guide offers the following adjustment

options:

Adjustment parallel to the bench edge - open

the rotary knob (3.5).

Adjustment vertical to the bench edge - open

the rotary knob (3.6).

Adjustment of the sliding fence (3.1) in a lon-

gitudinal direction - open the rotary knob

(3.2). The sliding fence can be clamped onto

the holder in a low position for thin

workpieces (Fig. 1), or in a high position for

thick workpieces (Fig. 3).

Angle adjustment using the scale (3.7) - open

the rotary knob (3.3) and raise the fixing pin

(3.4). The rotating fixing pin locks into place

in the most common angle positions.

This means that the guide can be used as a

parallel guide (Fig. 1) or as a cross guide or

angle guide (Fig. 3).

Prior to all work, make sure that all

rotary knobs of the guide are

tightened. The guide may only be used

in a fixed position and not to shift the

workpiece.

6.6 Scale for cutting width

The two scales (1.5) specify the cutting width

for longitudinal cuts.

If required, the scales can be realigned after

opening the screws (1.4).

6.7 Mounting the splinterguard

The splinterguard (10.2) prevents breakouts

on the lower cutting edge of the workpiece.

The splinterguard can be used for all mitres,

but a separate splinterguard must be fitted and

sawn in for each angle:

14

Page 9

- Set saw blade to minimum cutting depth.

Seen at Ideal Tools.

- Open the locking mechanism (1.3) and

remove the bench insert (1.2) upwards.

- Open the locking mechanism (6.1) and swing

the saw blade cover (6.2) down. This

automatically locks the tool spindle.

- Push splinterguard (10.2) from the side into

the holder (10.3) up to the stop.

- Swing the saw blade cover (6.2) upwards

and close the locking mechanism (6.1).

- Insert the bench insert with the rear edge

first (see Fig. 9) and close the locking

mechanism (1.3).

- Switch on tool and slowly move the saw blade

up to the maximum cutting depth this cuts

the splinterguard to shape.

For a optimum function the raised part (10.1)

of the splinterguard should protrude slightly

(approx. 0.3 mm) above the surface of the

base runner. For this purpose the height of the

holder (10.3) can be adjusted after releasing

both screws (10.4).

interrupted automatically and the router comes

to a standstill.

Service your machine regularly to ensure that

it functions properly:

- Vacuum off dust deposits

- Keep the guide bars (1.10) clean and grease

them regularly

- A worn or damaged bench insert is to be

replaced

- The slider (11.1) can be used to open the

hatch (11.3) to enable removal of cutting

residues from the lower protective cover. In

order to remove larger deposits, the hatch

can be opened completely by removing the

screw (11.2). Prior to commissioning, the

hatch must be closed again!

- On completion of your work, wind the power

cable around the holders (2.1).

- A damper means that the saw unit runs back

evenly across the entire drawing length. If

this is not the case, the damper can be

adjusted through the hole (2.5).

7 Working with the machine

When working with the machine,

comply with all safety instructions.

Adjust the protective hood so that it rests on

the workpiece and clamp it in this position with

the knob (1.11).

7.1 Bench-mounted circular saw

Use the guide as a parallel guide (Fig. 1) to

guide the workpiece. The cutting width can be

set using the scales (1.5). Guide the workpiece

into place by hand. Use the workpiece holder

(2.4) to guide the workpiece safety past the

saw blade. When not in use, place the workpiece holder in the storage compartment (2.1).

7.2 Circular trimming saw

Use the guide as a cross guide or as an angle

guide (Fig. 3) to apply and secure the workpiece. Alternatively, clamps (489 570) can be

inserted in the grooves (3.8) to secure the

workpiece. Perform the sawing cut by swinging

the hand grip (3.9) downwards and using the

hand grip to pull the saw unit forwards.

After making the sawing cut, move the saw

unit right back again into its initial position before

you take the workpiece from the guide.

8 Maintenance and care

Prior to any setting, maintenance or

repair, pull the mains plug!

All maintenance and repair work which

requires the motor casing to be opened

may only be carried out by an

authorised service centre.

The routers are fitted with special carbon

brushes with automatic-switch-off. When the

brushes reach their wear limit the current is

9 Accessories, tools

Festool offers a comprehensive range of

accessories that ensures versatile and effective

deployment of your machine, e.g. table

widening, table lengthening, sliding table, mitre

guide, transport rollers, extraction set.

In order to be able to saw different materials

quickly and cleanly, Festool offers saw blades

that are specially designed for your machine.

The accessory and tool order number can be

found in the Festool catalogue or on the

Internet under www.festool.com.

10 Warranty

Our equipment is under warranty for at least

12 months with regard to material or

production faults in accordance with national

legislation. In the EU countries, the warranty

period is 24 months (an invoice or delivery

note is required as proof of purchase).

Damage resulting from, in particular, normal

wear and tear, overloading, improper handling,

or caused by the user or other damage caused

by not following the operating instructions, or

any fault acknowledged at the time of

purchase, is not covered by the warranty.

Complaints will only be acknowledged if the

equipment has not been dismantled before

being sent back to the suppliers or to an

authorised Festool customer support workshop. Store the operating instructions, safety

notes, spare parts list and proof of purchase

in a safe place. In addition, the manufacturers

current warranty conditions apply.

Note

We reserve the right to make changes to the

technical data contained in this information as

a result of ongoing research and development

work.

15

Page 10

EG-Konformitätserklärung. Wir erklären in alleiniger

Seen at Ideal Tools.

Verantwortung, dass dieses Produkt mit den

folgenden Normen oder normativen Dokumenten

übereinstimmt:

EN 61 029, EN 55 014, EN 61 000 gemäß den Bestimmungen

der Richtlinien 98/37/EG, 89/336/EWG.

CE-Konformitetserklæring. Vi erklærer på eget

ansvar at dette produktet er i overensstemmelse med

følgende normer eller normative dokumenter: EN 61 029,

EN 55 014, EN 61 000 i henhold til bestemmelsene i direktivene

98/37/EF, 89/336/EØF.

EC-Declaration of Conformity: We declare at our sole

responsibility that this product is in conformity with

the following standards or standardised documents:

EN 61 029, EN 55 014, EN 61 000 in accordance with the

regulations 98/37/EC, 89/336/EEC.

CE-Déclaration de conformité communautaire. Nous

déclarons sous notre propre responsabilité que ce

produit est conforme aux normes ou documents de

normalisation suivants: EN 61 029, EN 55 014, EN 61 000

conformément aux prescriptions des directives

98/37/CE, 89/336/CEE.

CE-Declaración de conformidad. Declaramos bajo

nuestra exclusiva responsabilidad que este

producto corresponde a las siguientes normas o documentos

normalizados: EN 61 029, EN 55 014, EN 61 000 conforme a

las prescripciones estipuladas en las directrices 98/37/CE,

89/336/CEE.

CE-Dichiarazione di conformità. Dichiariamo sotto

la nostra esclusiva responsabilità che il presente

prodotto è conforme alle norme e ai documenti normativi

seguenti: EN 61 029, EN 55 014, EN 61 000 conformemente

alle normative delle direttive 98/37/CE, 89/336/CEE.

CE-Declaração de conformidade: Declaramos, sob

a nossa exclusiva responsabilidade, que este

produto corresponde às normas ou aos documentos

normativos citados a seguir: EN 61 029, EN 55 014,

EN 61 000 segundo as disposições das directivas

98/37/CE, 89/336/CEE.

Заявление о конформности СЕ. Мы заявляем в

единоличной ответственности, что данное изделие

соответствует требованиям следующих стандартов или

нормативов: EN 61 029, EN 55 014, EN 61 000 в соответствии

с постановлениями директив ЕС 98/37, ЕЭС 89/336.

Prohláení o souladu s normami CE. Prohlaujeme

na vlastní zodpovìdnost, e tento výrobek odpovídá

následujícím normám nebo normativním dokumentùm:

EN 61 029, EN 55 014, EN 61 000 v souladu s ustanoveními

smìrnic 98/37/EHS, 89/336/EHS.

Owiadczenie o zgodnoci CE. Niniejszym

owiadczamy z ca³¹ odpowiedzialnoci¹, ¿e wyrób

ten odpowiada nastêpuj¹cym normom wzglêdnie dokumentom

normatywnym: EN 61 029, EN 55 014, EN 61 000 zgodnie z

postanowieniami wytycznych 98/37/EG, 89/336/EWG.

EG-conformiteitsverklaring. Wij verklaren op eigen

verantwoordelijkheid dat dit produkt voldoet aan de

volgende normen of normatieve documenten. EN 61 029,

EN 55 014, EN 61 000 conform de richtlijnen 98/37/EG,

89/36/EEG.

EG-konformitetsförklaring. Vi förklarar i eget ansvar,

att denna produkt stämmer överens med följande

normer och normativa dokument: EN 61 029, EN 55 014,

EN 61 000 enligt bestämmelserna i direktiven 98/37/EG,

89/336/EEG.

EY-standardinmukaisuusvakuutus. Vakuutamme

yksinvastuullisina, että tuote on seuraavien

standardien ja normatiivisten ohjeiden mukainen: EN 61 029,

EN 55 014, EN 61 000 direktiivien 98/37/EY, 89/336/EY

määräysten mukaan.

EF-konformitetserklæring: Vi erklærer at have alene

ansvaret for, at dette produkt er i overensstemmelse

med de følgende normer eller normative dokumenter:

EN 61 029, EN 55 014, EN 61 000 i henhold til bestemmelserne

af direktiverne 98/37/EF, 89/336/EØF.

CE-konformitás-nyilatkozat.Kizárólagos

felelõsségvállalás mellett ezennel tanúsítjuk, hogy

a jelen termék megfelel az alábbi szabványoknak ill.

szabványdokumentációnak: EN 61 029, EN 55 014,

EN 61 000 a 98/37EG, 89/336/EWG irányvonalak

rendelkezései szerint.

Дзлщуз ухммьсцщузт ЕК. Ме бнЬлзшз фзт

ухнплйкЮт ехиэнзт дзлюнпхме, ьфй фп рбсьн рспйьн

ухмцщнеЯ ме фб рбсбкЬфщ рсьфхрб кбй ме фб

рсьфхрб рпх бнбцЭспнфбй уфб учефйкЬ Эггсбцб ЕН 61 029,

ЕН 55 014, EN 61 000 уэмцщнб ме фпхт кбнпнйумпэт

98/37ЕК, 89/336/ЕПК.

Leitung Forschung und Entwicklung

Management Research and Development

Direction de recherce et développement

Festool GmbH

Wertstr. 20

D-73240 Wendlingen

Dr. Johannes Steimel

449 699/170703

Page 11

Festool GmbH

Seen at Ideal Tools.

Postfach 1163

D-73236 Wendlingen

Wertstraße 20

D-73240 Wendlingen

) (07024) 804-0

Fax (07024) 804-608

http://www.festool.com

Loading...

Loading...