Page 1

Instruction manual

Page 3

IMPORTANT: Read and understand all instructions before

using.

Guide d’utilisation

Page 15

IMPORTANT: Lire et comprendre toutes les instructions

avant de démarrer les travaux.

Manual de instrucciones

Pagina 27

IMPORTANTE: Lea y comprende todas las instrucciones

antes de usar.

Instruction manual

Guide d’utilisation

Manual de instrucciones

RO 125 FEQ

470288_005

Page 2

Page 3

Contents

Technical data

Safety instructions .......................... 3

Technical data ................................. 3

Symbols .......................................... 3

Intended use ................................... 5

Electrical connection and operation .5

Extension cord ................................. 6

Electronic control ............................ 6

Tool settings ................................... 7

Dust extraction ................................ 7

Edge protector ................................ 7

Sanding motion ................................ 7

Choice and installation of sanding pads 8

Attaching the abrasive ....................... 9

Securing polishing attachments .......... 9

Working with the tool ...................... 9

Metalworking ................................. 10

Systainer ....................................... 10

Maintenance and care ................... 10

Sanding pad brake .......................... 11

Accessories, tools .......................... 11

Warranty ....................................... 11

Conditions of 1+2 Warranty ............. 11

Festool Limited Warranty ................. 11

Table A: Sanding ........................... 13

Table B: Polishing .......................... 13

ROTEX RO 125 FEQ

Wattage 500 W

No load speed 3000 - 6000 rpm

Sanding stroke 3.6 mm (0.14 in.)

Sanding base dia. 125 mm (4.9 in.)

Weight 1.9 kg (4.2 lbs.)

Safety level

/II

Symbols

Warning of general danger

Read the Operating Instructions/

Notes!

Wear protective goggles

V Volts

A Amperes

Hz Hertz

W Watt

~ Alternating current

n

No load speed

0

Class II Construction

-1

min

rpm Revolutions per minute

Ø Diameter

Safety instructions

WARNING! Read all safety warnings and all instructions. Failure

to follow the warnings and instructions

may result in electric shock, fi re and/or

serious injury.

Save all warnings and instructions for

future reference.

The term “power tool” in the warnings

refers to your mains-operated (corded)

power tool or battery-operated (cordless)

power tool.

1 WORK AREA SAFETY

a) Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

b) Do not operate power tools in ex-

plosive atmospheres, such as in the

presence of fl ammable liquids, gases

or dust. Power tools create sparks which

may ignite the dust or fumes.

c) Keep children and bystanders away

while operating a power tool. Distractions can cause you to lose control.

2 ELECTRICAL SAFETY

a) Power tool plugs must match the out-

let. Never modify the plug in any way.

Do not use any adapter plugs with

earthed (grounded) power tools. Un-

modifi ed plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric shock

if your body is earthed or grounded.

3

Page 4

c) Do not expose power tools to rain or

wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the

cord for carrying, pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving

parts. Damaged or entangled cords in-

crease the risk of electric shock.

e) When operating a power tool out-

doors, use an extension cord suitable

for outdoor use. Use of a cord suitable

for outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply. Use of an RCD reduces the risk of

electric shock.

3 PERSONAL SAFETY

a) Stay alert, watch what you are doing

and use common sense when operating a power tool. Do not use a power

tool while you are tired or under the

infl uence of drugs, alcohol or medica-

tion. A moment of inattention while op-

erating power tools may result in serious

personal injury.

b) Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non skid

safety shoes, hard hat, or hearing protection used for appropriate conditions will

reduce personal injuries.

c) Prevent unintentional starting. En-

sure the switch is in the off-position

before connecting to power source

and/or battery pack, picking up or

carrying the tool. Carrying power tools

with your fi nger on the switch or energis-

ing power tools that have the switch on

invites accidents.

d) Remove any adjusting key or wrench

before turning the power tool on. A

wrench or a key left attached to a rotating

part of the power tool may result in personal injury.

e) Do not overreach. Keep proper foot-

ing and balance at all times. This enables better control of the power tool in

unexpected situations.

f) Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or long

hair can be caught in moving parts.

g) If devices are provided for the con-

nection of dust extraction and collection facilities, ensure these are

connected and properly used. Use of

dust collection can reduce dust-related

hazards.

4 POWER TOOL USE AND CARE

a) Do not force the power tool. Use the

correct power tool for your application. The correct power tool will do the

job better and safer at the rate for which it

was designed.

b) Do not use the power tool if the

switch does not turn it on and off. Any

power tool that cannot be controlled with

the switch is dangerous and must be repaired.

c) Disconnect the plug from the power

source and/or battery pack from the

power tool before making any adjustments, changing accessories, or storing power tools. Such preventive safety

measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach

of children and do not allow persons unfamiliar with the power tool

or these instructions to operate the

power tool. Power tools are dangerous in

the hands of untrained users.

e) Maintain power tools. Check for mis-

alignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool‘s

operation. If damaged, have the

power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with

sharp cutting edges are less likely to bind

and are easier to control.

g) Use the power tool, accessories and

tool bits etc. in accordance with these

instructions taking into account the

working conditions and the work to

be performed. Use of the power tool for

operations different from those intended

could result in a hazardous situation.

4

Page 5

5 BATTERY TOOL USE AND CARE

a) Recharge only with the charger speci-

fi ed by the manufacturer. A charger

that is suitable for one type of battery pack

may create a risk of fi re when used with

another battery pack.

b) Use power tools only with specifi cally

designated battery packs. Use of any

other battery packs may create a risk of

injury and fi re.

c) When battery pack is not in use, keep

it away from other metal objects like

paper clips, coins, keys, nails, screws,

or other small metal objects that can

make a connection from one terminal

to another. Shorting the battery termi-

nals together may cause burns or a fi re.

d) Under abusive conditions, liquid may

be ejected from the battery; avoid

contact. If contact accidentally occurs, fl ush with water. If liquid con-

tacts eyes, additionally seek medical

help. Liquid ejected from the battery may

cause irritation or burns.

6 SERVICE

a) Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

Various dust created by

power sanding, sawing, grinding, drilling

and other construction activities contains

chemicals known (to the State of California) to cause cancer, birth defects or other

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

and other masonry products,

• Arsenic and chromium from chemically-

treated lumber.

The risk from these exposures varies, de-

pending on how often you do this type of

work.

To reduce your exposure to

these chemicals work in a

well ventilated area and use

approved safety equipment,

such as dust masks that are

specially designed to fi lter out

microscopic particles.

TO REDUCE THE RISK OF

INJURY, USER MUST READ INSTRUCTION

MANUAL.

Intended use

The sanders are designed for sanding and

polishing wood, plastic, metal, composite

materials, paint/varnish, fi ller and similar

materials.

Do not use with materials containing asbestos.

The tools must not be used when wet or

Electrical connection and operation

damp, or operated in a damp environment,

for electrical safety reasons. Use this sander

only for dry sanding.

The user bears sole responsibility for any damage or accidents resulting

from incorrect use.

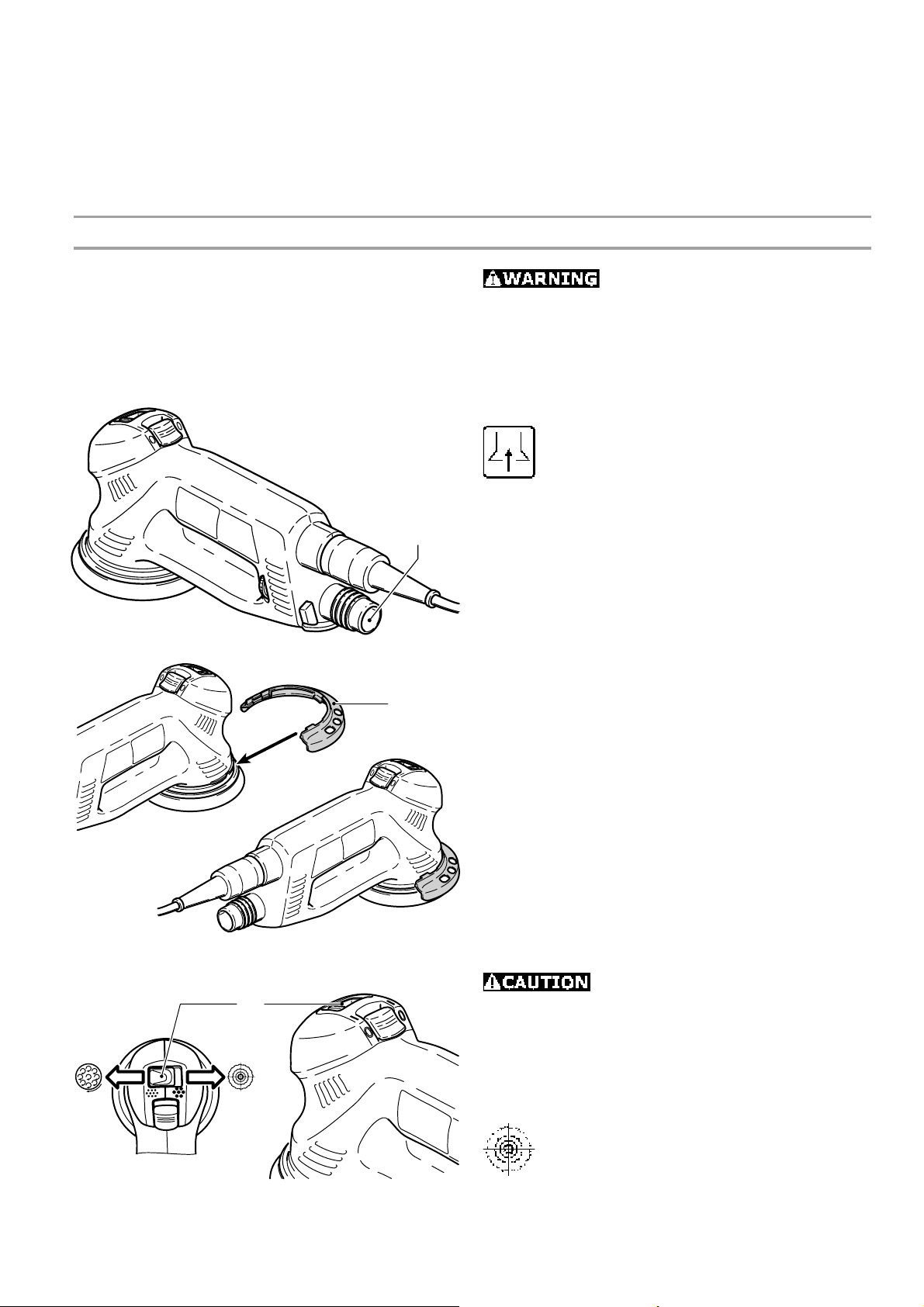

The mains voltage must correspond to the

voltage on the rating plate!

See the following fi gure for connection and

dis connection of the power cord.

5

Page 6

2.1

Always switch the tool off before connecting or disconnecting the power cord!

To switch on the tool, press the switch (2.1)

downwards and forwards until it locks into

place. To switch off, press the switch downwards - this releases the switch lock and it

goes into the OFF position.

Extension cord

If an extension cord is required, it must

have suffi cient cross-section to prevent an

excessive drop in voltage or overheating.

An excessive drop in voltage reduces the

output and can lead to failure of the motor.

The table below shows you the correct cord

diameter as a function of the cord length

for the RO 125 FEQ.

Total Extension Cord

Lenght (feed)

Cord Size (AWG) 18 16 16 14

25 50 100 150

Electronic control

Use only U.L. and CSA listed extension

cords. Never use two extension cords together. Instead, use one long one.

Note: The lower the AWG number, the

stronger the cord.

The tool has full-wave electronics with

the following features:

Smooth start-up

The smooth start-up ensures jolt-free

startup.

Speed adjustment

You can regulate the speed steplessly between 3000 and 6000 rpm using the adjusting wheel (3.1). This lets you optimize the

sanding speed to suit the material.

3.1

Constant speed

The pre-selected speed remains constant

whether the tool is in operation or in neutral position.

Temperature control

To prevent overheating, the safety elec-

6

Page 7

tronics switch the tool off when it reaches

a critical motor temperature. Let the tool

cool down for approx. 3-5 minutes before

using it again. The tool requires less time

to cool down if it is running, i.e. in neutral

position.

Tool settings

from the socket before carrying out any

work on the power tool.

Always connect the tool to a dust ex-

You can connect a Festool extractor with an

4.1

extractor hose diameter of 27 mm to the

dust extraction port (4.1).

Always remove the power plug

Dust extraction

tractor.

6.1

5.1

Edge protector

The edge protector (5.1) prevents the sanding pad from touching the edge perpendicular to a surface (e.g. when sanding along a

wall), thereby preventing the machine from

rebounding.

Assembly: Slide the edge protector onto the

machine until it latches into place.

Sanding motion

You can use the switch (6.1) to set two different sanding motions.

The change can only be made

when the sanding pad is stationary, as the

switch is locked in place during operation

for safety reasons.

Rotex rotary motion (coarse sanding,

polishing)

The Rotex rotary motion is a combi-

nation of rotary and eccentric motions. This motion is recommended

for sanding with aggressive material

7

Page 8

removal (coarse sanding) and polishing.

Slide the switch (6.1) into the right position.

Eccentric motion (fi ne sanding)

This motion is recommended for

sanding with low material removal for

a scratch-free fi nish (fi ne sanding).

Press the switch (6.1) down and push it into

the left-hand position.

Choice and installation of sand-

ing pads

Choice of sanding pad

The tool can be fi tted with three sanding

pads of different hardnesses depending on

the surface to be sanded.

Hard: Coarse sanding on surfaces, sanding

at edges.

Soft: Universal use for coarse and fi ne

sanding for fl at and curved surfaces.

Super-soft: Fine sanding on formed parts,

curves, radii. Do not use on edges!

7.1

7.2

7.3

Installation

The FastFix system enables tool-free replacement of the sanding pad:

- Set the switch (7.1) to the right for the

Rotex rotary motion,

- Press spindle stop (7.3), direction of movement fi rst to the side, then forwards,

- Turn the fi tted sanding disk (7.2) from the

spindle (right-handed thread),

- Keep the spindle stop pressed and screw

on the new sanding pad (in doing so, make

sure that the rubber collar (10.1) is correctly fi tted!),

- Let go of the spindle stop.

Actuate the spindle stop only

when the drive spindle is stationary. Do not

switch on the motor when the spindle stop

is pressed in.

8

Page 9

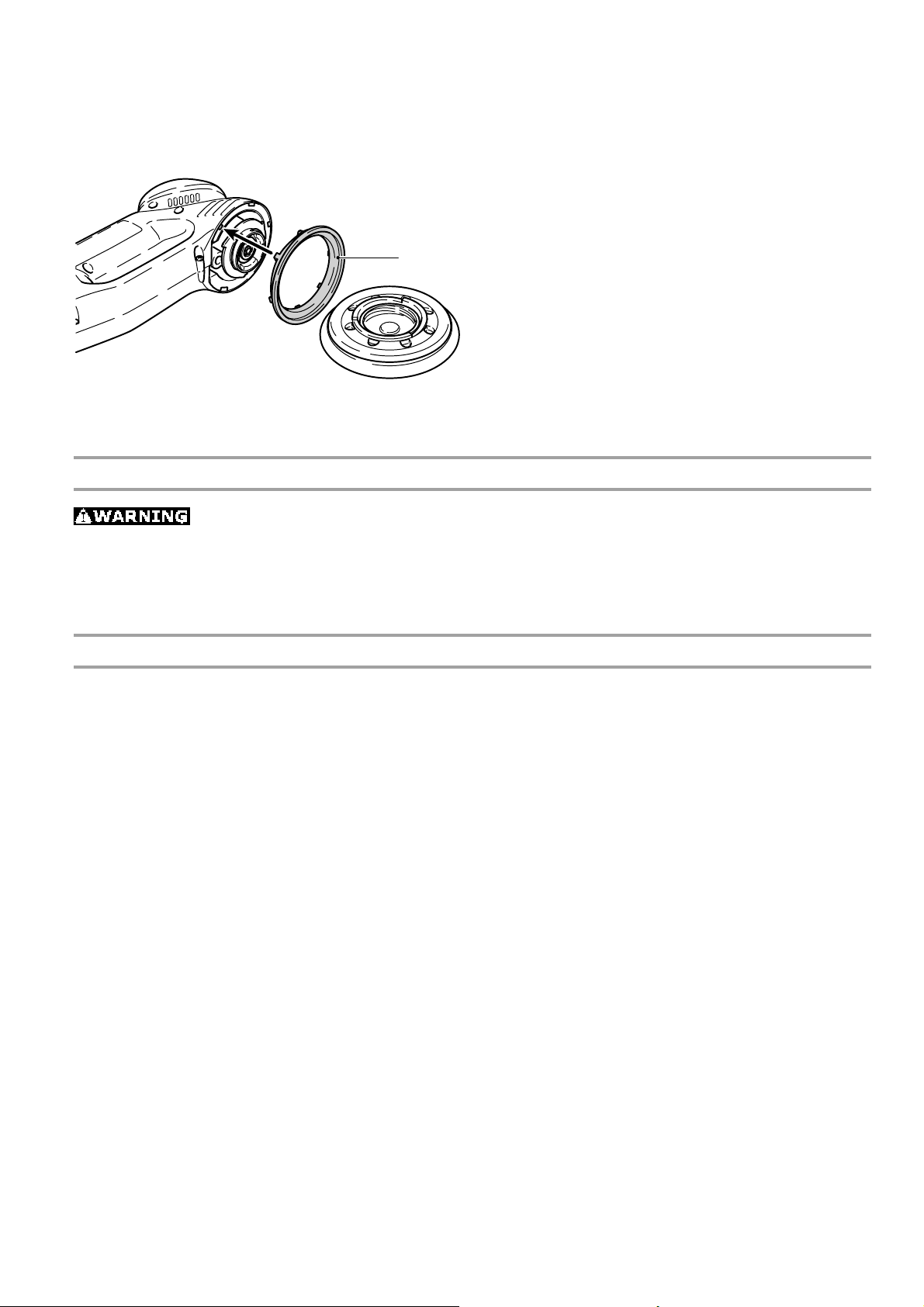

Attaching the abrasive

Stickfi x is a hook-and-loop fastening

system. Stickfi x sanding pads allow

the use of self-adhesive hook-andloop abrasives such as Stickfi x sand-

papers and sanding cloths.

Simply press the abrasive onto the sanding

pad (7.2) and pull it off again after use.

Please note: Use only abrasives with an

undamaged Stickfi x hook-and-loop coating.

Before use, check that the coating has not

been damaged by improper use (such as

over heating).

Securing polishing attachments

To prevent damage, use PoliStick polishing attachments (sponges, felt, lambswool

bonnets) only with the special polishing

pad fi tted on the tool instead of a sanding

pad. Like StickFix abrasives, the PoliStick

polishing attachments are simply pressed

onto the polishing pad and pulled off after

use.

8.1

Working with the tool

in such a manner that it cannot move while

being sanded.

ing too much pressure! The best sanding

results are achieved when applying mod-

8.2

erate pressure. Sanding performance and

quality depend primarily on the choice of

the right abrasive.

For safe guidance, hold the tool with one

hand on the motor housing (8.2) and the

other hand on the gear head (8.1).

Tables A and B show the settings we recommend for different sanding and polishing

work.

Always secure the workpiece

Never overload the tool by us-

9

Page 10

precautions when working on metals:

• Pre-connect a residual current circuit-

breaker (FI, PRCD).

• Connect the tool to a suitable dust extrac-

tor.

• Regularly clear out any dust accumula-

tions in the motor housing.

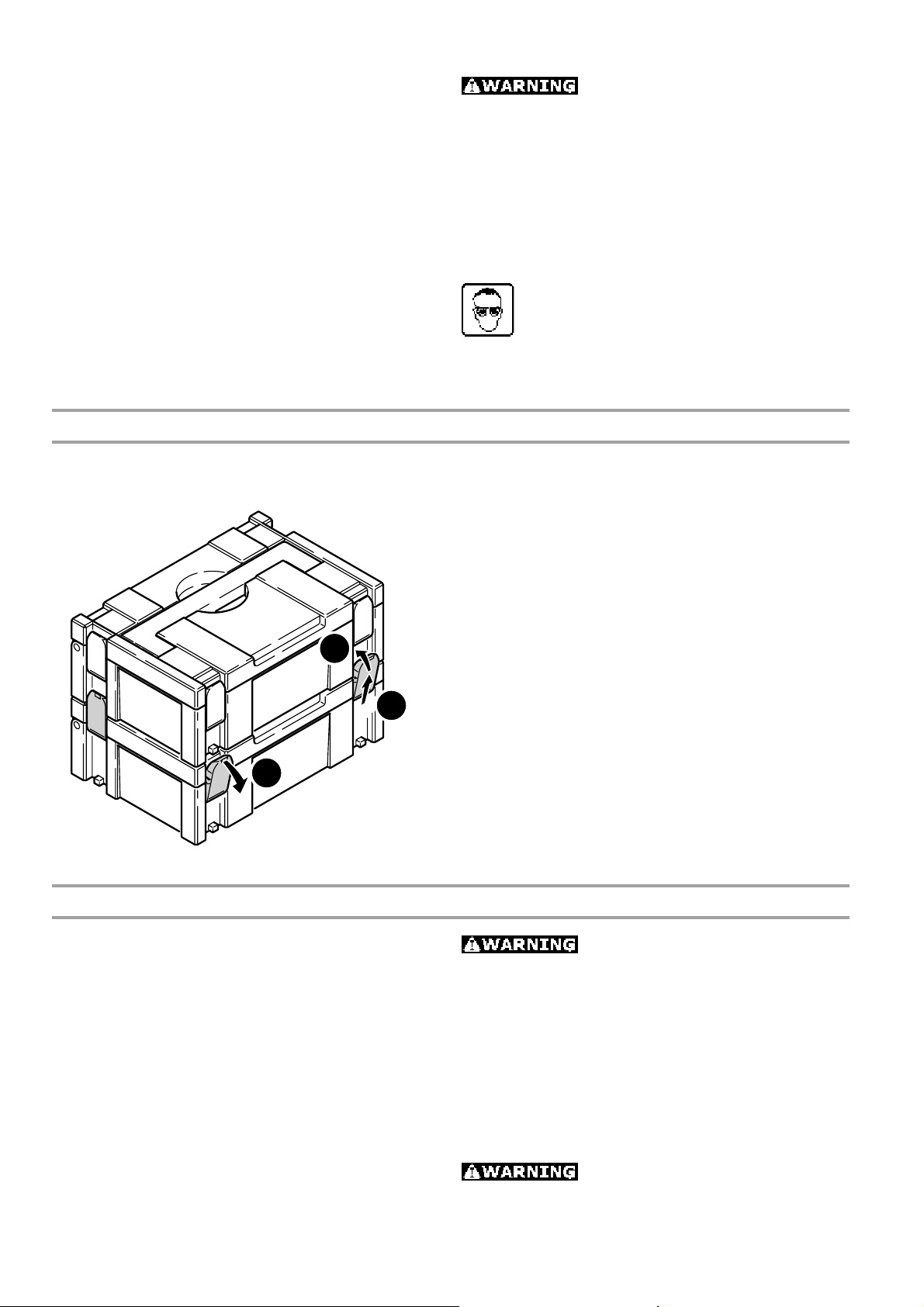

Systainer

Many Festool products are shipped in a

unique system container, called "Systainer".

This provides protection and storage for the

tool and accessories. The Systainers are

stackable and can be interlocked together.

They also can be interlocked atop Festool

CT dust extractors.

Metalworking

Observe the following safety

Wear protective goggles.

9.1

9.3

9.2

- Place one systainer on top of the other.

- Release all four latches on the lower sys-

tainer by pulling back at their top edges

(9.1).

- Slide all four latches upward (9.2).

- Snap all four latches back to their fl at po-

sition (9.3) so they engage the stacking

tabs of the upper systainer.

Maintenance and care

requiring the motor housing to be opened

must be carried out only by an authorized

service workshop. Maintenance or repair

work carried out by an unauthorized person can lead to the incorrect connection

of the wiring or other components, which

in turn can lead to accidents with serious

consequences.

All maintenance or repair work

Always remove the plug from

the mains supply socket before carrying out

any work on the machine!

10

Page 11

Always keep the tool and in particular the

ventilation slots clean.

Sanding pad brake

The rubber collar (10.1) prevents the sanding pad from revving up to maximum speed

10.1

in an uncontrolled manner during eccentric

motion (fi ne sanding) .

Because the collar wears down in the course

of time, it must be replaced by a new one

(order no. 463 357) as soon as there is any

reduction in the braking effect.

Accessories, tools

For safety reasons, only use

original Festool accessories and tools!

Warranty

Conditions of 1+2 Warranty

You are entitled to a free extended warranty

(1 year + 2 years = 3 years) for your Festool

power tool. Festool shall be responsible for

all shipping costs during the fi rst year of the

warranty. During the second and third year

of the warranty the customer is responsible

for shipping the tool to Festool. Festool will

pay for return shipping to the customer

using UPS Ground Service. All warranty

service is valid 3 years from the date of

purchase on your receipt or invoice.

Festool Limited Warranty

This warranty is valid only on condition that

the tool is used and operated in compliance

with the Festool operating instructions. Festool warrants, only to the original consumer

purchaser, that the specifi ed tool will be free

from defects in materials and workmanship

for a term of one year from the date of

procure ment. Festool makes no other war-

The accessory and tool order number can

be found in the Festool catalog or on the

Internet under www.festool-usa.com.

ranty, express or implied, for Festool portable power tools. No agent, representative,

distributor, dealer or employee of Festool

has the authority to increase or otherwise

change the obligations or limitations of this

warranty. The obligations of Festool in its

sole discretion under this warranty shall be

limited to the repair or replacement of any

Festool portable power tool that is found

to be defective as packaged with the User

Manual.

Excluded from coverage under this warranty are: normal wear and tear; damages

caused by misuse, abuse or neglect; damage caused by anything other than defects

in material and workmanship. This warranty

does not apply to accessory items such as

circular saw blades, drill bits, router bits,

jigsaw blades, sanding belts, and grinding

wheels. Also excluded are “wearing parts”,

such as carbon brushes, vanes of air tools,

rubber collars and seals, sanding discs and

pads, and batteries.

Festool portable power tools requiring re-

11

Page 12

placement or repair are to be returned with

the receipt of purchase to Festool (call 800554-8741 for address details).

IN NO EVENT SHALL FESTOOL BE LIABLE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES FOR BREACH

OF THIS OR ANY OTHER WARRANTY,

EXPRESSED OR IMPLIED WHATSOEVER. ALL WARRANTIES IMPLIED BY

STATE LAW, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY LIMITED TO THE

DURATION OF THREE YEARS.

Some states in the U.S. and some Canadian

provinces do not allow the limitations on

how long an implied warranty lasts, so the

above limitation may not apply to you. With

the exception of any warranties implied by

state or province law as hereby limited,

the foregoing express limited warranty is

exclusive and in lieu of all other warranties, guarantees, agreements and similar

obligations of Festool.

This warranty gives you specifi c legal rights

and you may also have other rights which

vary from state to state in the U.S. and

province to province in Canada.

12

Page 13

Table A: Sanding

Table B: Polishing

Sponge, fine,

honeycombed

13

Page 14

14

Page 15

Table des matières

Caractéristiques techniques

Consignes de sécurité.................... 15

Caractéristiques techniques .......... 15

Symbole ........................................ 15

Utilisation conforme ...................... 18

Raccordement électrique et mise en

service ........................................ 18

Câble de rallonge ............................ 19

Réglage électronique ..................... 19

Réglages de l'outil ......................... 20

Aspiration ...................................... 20

Protection des arêtes ..................... 20

Mouvement de ponçage ................... 20

Choix et montage des supports de pon-

çage ............................................. 21

Fixer l’abrasif ................................. 22

Fixation du produit de polissage ....... 22

Travailler avec l'outil ..................... 22

Traitement des métaux .................... 23

Systainer ....................................... 23

Entretien et maintenance .............. 24

Frein de patin ................................ 24

Accessoires et outils ...................... 24

Garantie ........................................ 24

Conditions de la garantie (1+2 ans) .. 24

Garantie limitée de Festool............... 25

Tableau A: Ponçage ....................... 26

ROTEX RO 125 FEQ

Puissance absorbée 500 W

Vitesse à vide 3 000 - 6 000 tr/min

Amplitude 3.6 mm (0.14 in.)

Patin de ponçage, Ø 125 mm (4.9 in.)

Poids 1.9 kg (4.2 lbs.)

Sécurité

/II

Symbole

Avertissement de danger

Lire les instructions / les remarques !

Portez des lunettes de protection.

V Volt

A Ampère

Hz Hertz

W Watt

~ Tension alternative

Vitesse de rotation à vide

n

0

Construction de classe II

-1

min

tr/min Tours par minute

Ø Diamètre

Tableau B: Polissage ..................... 26

Consignes de sécurité

ATTENTION ! Lire toutes les

consignes de sécurité et indica-

tions. Le non-respect des avertissements

et instructions indiqués ci-après peut entraîner un choc électrique, un incendie et/

ou de graves blessures.

Conserver tous les avertissements et

toutes les instructions pour pouvoir

s'y reporter ultérieurement.

Le terme " outil " dans les avertissements

fait reference à votre outil électrique alimenté par le secteur (avec cordon d'alimentation) ou votre outil fonctionnant sur

batterie (sans cordon d'alimentation).

1 PLACE DE TRAVAIL

a) Maintenez l'endroit de travail propre

et bien éclairé. Un lieu de travail en dé-

sordre ou mal éclairé augmente le risque

d'accidents.

b) N'utilisez pas l'appareil dans un en-

vironnement présentant des risques

d'explosion et où se trouvent des liquides, des gaz ou poussières infl am-

mables. Les outils électroportatifs génè-

rent des étincelles risquant d'enfl ammer

les poussières ou les vapeurs.

c) Tenez les enfants et autres personnes

éloignés durant l'utilisation de l'outil

électroportatif. En cas d'inattention vous

15

Page 16

risquez de perdre le contrôle sur l'appareil.

2 SECURITE RELATIVE AU SYSTEME

ELECTRIQUE

a) La fi che de secteur de l'outil électro-

portatif doit être appropriée à la prise

de courant. Ne modifiez en aucun

cas la fi che. N'utilisez pas de fi ches

d'adaptateur avec des appareils avec

mise à la terre. Les fi ches non modifi ées

et les prises de courant appropriées réduisent le risque de choc électrique.

b) Evitez le contact physique avec des

surfaces mises à la terre tels que

tuyaux, radiateurs, fours et réfrigérateurs. Il y a un risque élevé de choc

électrique au cas où votre corps serait relié

à la terre.

c) N'exposez pas l'outil électroportatif à

la pluie ou à l'humidité. La pénétration

d'eau dans un outil électroportatif augmente le risque d'un choc électrique.

d) N'utilisez pas le câble à d'autres fi ns

que celles prévues, n'utilisez pas le

câble pour porter l'appareil ou pour

l'accrocher ou encore pour le débrancher de la prise de courant. Maintenez

le câble éloigné des sources de chaleur, des parties grasses, des bords

tranchants ou des parties de l'appareil en rotation. Un câble endommagé

ou torsadé augmente le risque d'un choc

électrique.

e) Au cas où vous utiliseriez l'outil élec-

troportatif à l'extérieur, utilisez une

rallonge autorisée homologuée pour

les applications extérieures. L'utilisa-

tion d'une rallonge électrique homologuée

pour les applications extérieures réduit le

risque d'un choc électrique.

f) Si l'usage d'un outil dans un emplace-

ment humide est inévitable, utiliser

une alimentation protégée par un dispositif à courant différentiel résiduel

(RCD). L'usage d'un RCD réduit le risque

de choc électrique.

3 SECURITE DES PERSONNES

a) Restez vigilant, surveillez ce que

vous faites. Faites preuve de bon en

utilisant l'outil électroportatif. N'utilisez pas l'appareil lorsque vous êtes

fatigué ou après avoir consommé de

l'alcool, des drogues ou avoir pris des

médicaments. Un moment d'inattention

lors de l'utilisation de l'appareil peut entraîner de graves blessures sur les personnes.

b) Portez des équipements de protec-

tion. Portez toujours des lunettes de

protection. Le fait de porter des équipe-

ments de protection personnels tels que

masque anti-poussières, chaussures de

sécurité antidérapantes, casque de protection ou protection acoustique suivant

le travail à effectuer, réduit le risque de

blessures.

c) Evitez une mise en service par mégar-

de. Assurez-vous que l'interrupteur

est effectivement en position d'arrêt

avant de retirer la fi che de la prise de

courant. Le fait de porter l'appareil avec

le doigt sur l'interrupteur ou de brancher

l'appareil sur la source de courant lorsque

l'interrupteur est en position de fonctionnement, peut entraîner des accidents.

d) Enlevez tout outil de réglage ou toute

clé avant de mettre l'appareil en fonctionnement. Une clé ou un outil se trou-

vant sur une partie en rotation peut causer

des blessures.

e) Ne surestimez pas vos capacités.

Veillez à garder toujours une position

stable et équilibrée. Ceci vous permet

de mieux contrôler l'appareil dans des situations inattendues.

f) Portez des vêtements appropriés. Ne

portez pas de vêtements amples, ni

de bijoux. Gardez les cheveux et les

vêtements à distance des pièces mobiles. Des vêtements amples, des bijoux

ou des cheveux longs peuvent être happés

par les pièces en mouvement.

g) Si des dispositifs servant à aspirer ou

à recueillir les poussières doivent être

utilisés, vérifi ez que ceux-ci soient

effectivement raccordés et qu'ils sont

correctement utilisés. L'utilisation de

tels dispositifs réduit les dangers dus aux

poussières.

4 UTILISATION ET EMPLOI SOIGNEUX

DE L'OUTIL ELECTROPORTATIF

a) Ne surchargez pas l'appareil. Utilisez

l'outil électroportatif approprié au

travail à effectuer. Avec l'outil électro-

16

Page 17

portatif approprié, vous travaillerez mieux

et avec plus de sécurité à la vitesse pour

laquelle il est prévu.

b) N'utilisez pas un outil électroportatif

dont l'interrupteur est défectueux. Un

outil électroportatif qui ne peut plus être

mis en ou hors fonctionnement est dangereux et doit être réparé.

c) Retirer la fi che de la prise de courant

avant d'effectuer des réglages sur

l'appareil, de changer les accessoires,

ou de ranger l'appareil. Cette mesure

de précaution empêche une mise en fonctionnement par mégarde.

d) Gardez les outils électroportatifs non

utilisés hors de portée des enfants.

Ne permettez pas l'utilisation de l'appareil à des personnes qui ne se sont

pas familiarisées avec celui-ci ou qui

n'ont pas lu ces instructions. Les outils

électroportatifs sont dangereux lorsqu'ils

sont utilisés par des personnes non initiées.

e) Prenez soin des outils électroporta-

tifs. Vérifi ez que les parties en mou-

vement fonctionnent correctement

et qu'elles ne soient pas coincées, et

contrôlez si des parties sont cassées

ou endommagées de telle sorte que

le bon fonctionnement de l'appareil

s'en trouve entravé. Faites réparer les

parties endommagées avant d'utiliser

l'appareil. De nombreux accidents sont

dus à des outils électroportatifs mal entretenus.

f) Maintenez les outils de coupe aiguisés

et propres. Des outils soigneusement entretenus avec des bords tranchants bien

aiguisés se coincent moins souvent et

peuvent être guidés plus facilement.

g) Utilisez les outils électroportatifs, les

accessoires, les outils à monter etc.

conformément à ces instructions et

aux prescriptions en vigueur pour ce

type d'appareil. Tenez compte également des conditions de travail et du

travail à effectuer. L'utilisation des outils

électroportatifs à d'autres fi ns que celles

prévues peut entraîner des situations dangereuses.

5 UTILISATION ET EMPLOI SOIGNEUX

DES APPAREILS SANS FIL

a) Ne chargez les accumulateurs que

dans des chargeurs recommandés

par le fabricant. Un chargeur approprié

à un type spécifi que d'accumulateur peut

engendrer un risque d'incendie lorsqu'il

est utilisé avec d'autres accumulateurs.

b) Dans les outils électroportatifs, n'uti-

lisez que les accumulateurs spécialement prévus pour celui-ci. L'utilisation

de tout autre accumulateur peut entraîner

des blessures et des risques d'incendie.

c) Tenez l'accumulateur non-utilisé à

l'écart de toutes sortes d'objets métalliques tels qu'agrafes, pièces de

monnaie, clés, clous, vis ou autres,

étant donné qu'un pontage peut provoquer un court-circuit. Un court-circuit

entre les contacts d'accu peut provoquer

des brûlures ou un incendie.

d) En cas d'utilisation abusive, du liquide

peut sortir de l'accumulateur. Evitez

tout contact avec ce liquide. En cas

de contact par mégarde, rincez soigneusement avec de l'eau. Au cas où

le liquide rentrerait dans les yeux,

consultez en plus un médecin. Le li-

quide qui sort de l'accumulateur peut entraîner des irritations de la peau ou causer

des brûlures.

6 SERVICE

a) Ne faites réparer votre outil électro-

portatif que par un personnel qualifi é

et seulement avec des pièces de rechange d'origine. Ceci permet d'assurer

la sécurité de l'appareil.

POUR RÉDUIRE LE

RISQUE DE DOMMAGES, L'UTILISATEUR

DOIT LIRE LE MANUEL D'INSTRUCTION.

17

Page 18

Certaines poussières

créées par le ponçage mécanique, le

sciage, le meulage, le perçage et autres

activités reliées à la construction contiennent des substances chimiques connues

(dans l’État de la Californie) comme

pouvant causer le cancer, des anomalies

congénitales ou représenter d’autres

dangers pour la reproduction. Voici quelques exemples de telles substances:

• plomb provenant de peintures à base de

plomb,

• silice cristallisée utilisée dans les briques,

le ciment et autres matériaux de maçonnerie, et

Utilisation conforme

• arsenic et chrome du bois d’œuvre traité

avec un produit chimique.

Le risque d’exposition à de tels produits

varie selon la fréquence à laquelle vous

faites ce genre de travail.

Pour réduire les risques d’ex-

position à ces substances

chimiques : travaillez dans un

endroit adéquatement ventilé et utilisez un équipement

de sécurité approuvé, tel que

masques antipoussières spécialement conçus pour fi ltrer

les particules microscopiques.

L'outil est conçu pour le ponçage et le polissage des matériaux suivants : bois, plastique, métal, aggloméré, peinture/laque,

mastic et matériaux similaires.

Il est interdit de travailler des matériaux

contenant de l'amiante.

Pour des raisons de sécurité électrique,

Raccordement électrique et mise en service

l'outil ne doit pas être humide ni fonctionner

dans un endroit humide. Il ne faut utiliser

l'outil que pour un ponçage sec.

En cas d’une utilisation non conforme, la responsabilité des

dommages et accidents incombe à l’utilisateur.

La tension du réseau doit correspondre à

celle indiquée sur la plaque signalétique!

Voir la connexion et la déconnexion du câble de raccordement secteur sur la fi gure

ci-dessous.

Avant de brancher ou

de débrancher le câble de raccordement

secteur, il est absolument indispensable de

toujours éteindre l'outil!

2.1

Pour mettre l'outil en marche, appuyez

sur l'interrupteur (2.1) et poussez-le vers

l'avant jusqu'à ce qu'il s'encliquette. Pour

l'arrêter, appuyez sur l'interrupteur - ce

dernier se déverrouille et revient à la position « OFF ».

18

Page 19

Câble de rallonge

Si une rallonge électrique est nécessaire,

elle doit présenter une section suffi sante

pour éviter une chute de tension excessive

ou une surchauffe. Une chute de tension

excessive réduit la puissance et peut entraîner une défaillance du moteur. Le tableau

suivant vous présente la section correcte

du câble en fonction de sa longueur pour

la norme RO 125 FEQ.

Longueur totale

rallonge (pieds)

Section du câble

(AWG)

25 50 100 150

18 16 16 14

Réglage électronique

Utilisez exclusivement des rallonges recommandées par les organismes U.L. et CSA.

N'utilisez jamais deux rallonges branchées

l'une après l'autre, mais remplacez-les par

une rallonge plus longue.

Remarque : plus le numéro AWG est petit,

plus la section du câble est grande.

Cet outil contient un dispositif

électroni que à double alternance

présentant les caractéristiques suivantes :

Démarrage progressif

Le démarrage progressif assure un fonctionnement sans à-coups de l'outil.

3.1

Réglage de la vitesse

Le régime est réglé en continu au moyen

de la molette (3.1) entre 3 000 et 6 000

tr/min. Vous pouvez ainsi adapter de façon optimale la vitesse de coupe à chaque

matériau.

Régime constant

Le régime sélectionné reste constant pendant que l'outil est en fonctionnement ou

en position neutre.

Contrôle de la température

Pour assurer une protection contre la surchauffe, le système électronique de sécurité

arrête l'outil dès que le moteur atteint une

certaine température. Après une période de

refroidissement de 3 à 5 minutes environ,

l'outil est à nouveau prêt à être utilisé. Le

temps de refroidissement diminue lorsque

l'outil fonctionne (marche à vide).

19

Page 20

Réglages de l'outil

entretien sur l'outil, débranchez-le!

Raccordez toujours l'outil à un cap-

teur de poussière.

4.1

Vous pouvez raccorder un aspirateur Festool doté d'un embout fl exible de 27 mm

(4.1).

Protection des arêtes

5.1

La protection des arêtes (5.1) évite que les

bords du plateau de ponçage n'entrent en

contact avec une surface quelconque (par

exemple lors du ponçage le long d'un mur),

ce qui empêche également tout rebond

éventuel de l'outil.

Montage : faites glisser la protection des

arêtes jusqu'à ce qu'elle s'enclenche sur

l'outil.

Avant de faire quelque

Aspiration

6.1

Mouvement de ponçage

Le commutateur (6.1) permet de régler

deux mouvements de ponçage différents.

Le réglage ne peut être

effectué que lorsque le patin de ponçage est

immobile car, pour des raisons de sécurité,

le commutateur est verrouillé pendant le

travail.

Mouvement rotatif Rotex (dégrossissage, polissage)

Le mouvement rotatif Rotex est une

combinaison de mouvements rotatifs

et excentriques. Cette position est

conçue pour un ponçage grossier (dégrossissage) et au polissage.

Poussez le commutateur (6.1) vers la

droite.

20

Page 21

Mouvement excentrique (ponçage

fi n)

Cette position est conçue pour un dé-

grossissage moins puissant pour une

sur face exempte de rayures (ponçage

fi n).

Appuyez sur le commutateur (6.1) et poussez-le vers la gauche.

Choix et montage des supports

de ponçage

Choix des supports de ponçage

L’appareil peut être équipé de trois disques

de ponçage de dureté différente en fonction

de la surface à traiter.

Dur : ponçage grossier sur des surfaces,

meulage des arêtes.

Souple : universel pour ponçage grossier et

fi n pour les surfaces planes et bombées.

Très souple : ponçage fi n sur des pièces

formées, des cintres, des rayons. Ne pas

utiliser sur des arêtes!

7.1

7.2

7.3

Montage

Le système FastFix permet de changer le

patin de ponçage sans outil :

- Poussez le commutateur (7.1) vers la

droite (mouvement rotatif Rotex).

- Poussez le blocage d'arbre (7.3), d'abord

latéralement - sens du mouvement, puis

vers l'avant.

- Faites tourner le plateau de ponçage (7.2)

autour de l’arbre (fi letage à droite).

- Maintenez le blocage d’arbre appuyé et

vissez le nouveau patin de ponçage (veillez

alors à ce que le manchon en caoutchouc

(10.1) soit monté correctement !).

- Relâchez le blocage d’arbre.

Actionnez le blocage de

l'arbre uniquement lors de l'arrêt total de

l'arbre moteur. N'actionnez jamais le moteur lors du blocage.

21

Page 22

Fixer l’abrasif

Stickfi x est un système de fi xation de

type auto-agrippant. Sur les patins de

ponçage Stickfi x, vous pouvez fi xer

tous les types d'abrasif auto-agrippants.

Posez-le simplement sur le patin (7.2) et

retirez-le après utilisation.

Attention : Utilisez uniquement des patins

Stickfi x dont l'état de la surface auto-agrip-

pante est impeccable. Avant l'utilisation,

vérifi ez si la surface n'a pas subi de dégra-

dation suite à un échauffement.

Fixation du produit de polissage

Afi n d’éviter toute détérioration, les pro-

duits de polissage PoliStick (éponge, feutre,

peau d’agneau) ne doivent être utilisés

que sur le plateau de polissage spécifi que

à monter sur l'outil à la place du patin de

ponçage. Les produits de polissage PoliStick, tout comme l’abrasif Stickfi x, doivent

simplement être appliqués sur le plateau de

polissage puis retirés après utilisation.

8.1

Travailler avec l'outil

de manière à ce qu’elle ne puisse pas bouger pendant le traitement.

en appuyant trop fort ! Vous obtiendrez

8.2

le meilleur résultat de ponçage avec une

pression d’application moyenne. Le rendement et la qualité du ponçage dépendent

essentiellement de la sélection de l’abrasif

adéquat.

Pour un guidage sûr, tenez l'outil à deux

mains au niveau du carter (8.2) et de la

tête de la ponceuse (8.1).

Fixez la pièce à usiner

Ne surchargez pas l'outil

22

Page 23

Les tableaux A et B montrent les réglages

que nous conseillons pour différents travaux

de ponçage et de polissage.

Traitement des métaux

Lors du traitement des

métaux, il est indispensable de respecter

les mesures suivantes afi n de travailler en

toute sécurité :

• Installer un commutateur de sécurité à

courant de défaut (FI, PRCD).

• Raccordez l’outil à un aspirateur appro-

prié.

• L'outil doit régulièrement être nettoyé

pour éliminer les dépôts de poussières

accumulées dans le corps du moteur.

Portez des lunettes de protection.

9.1

9.3

Systainer

De nombreux produits Festool sont fournis

dans une caisse exclusive, appelée "Systainer". Celle-ci permet de protéger et de

ranger des outils et des appareils complémentaires. Les Systainer sont empilables

et peuvent être solidarisés. En outre, il se

fi xent sur les aspirateurs CT Festool.

- Poser deux Systainer l'un sur l'autre,

- défaire les quatre éléments de verrouillage

du Systainer inférieur en les tirant en arrière par leur bord supérieur (9.1).

9.2

- pousser les quatre éléments de verrouilla-

ge vers le haut (9.2)

- manoeuvrer les quatre éléments de ver-

rouillage (9.3) de sorte qu'ils s'enclenchent au niveau des éléments récepteurs

du Systainer supérieur.

23

Page 24

Entretien et maintenance

et de réparation nécessitant une ouverture

du carter moteur ne doivent être effectués

que par le personnel d'un atelier autorisé du

service après-vente. La maintenance ou la

réparation de l'outil par des personnes non

autorisées peut entraîner un branchement

incorrect de câbles électriques ou d'autres

composants, ce qui peut provoquer des

accidents avec blessures graves.

tout entretien.

L'outil et les orifi ces de ventilation doivent

toujours rester propres.

Les travaux d'entretien

Débranchez l'outil avant

10.1

Accessoires et outils

Pour des raisons de

sécurité, il faut utiliser exclusivement des

accessoires et outils d’origine Festool!

Frein de patin

Le manchon en caoutchouc (10.1) permet,

lors du mouvement excentrique (ponçage

fi n), de limiter la vitesse du patin de ponçage.

La collerette étant soumise à l’usure avec le

temps, l’effet de blocage s’affaiblit, et elle

doit être remplacée par une neuve (référence 463 357).

Vous trouverez les numéros de pièce

des accessoires et outils dans le

catalogue Festool, ou sur le site Web

www.festool-usa.com.

Garantie

Conditions de la garantie (1+2

ans)

Vous avez droit à une prolongation de garantie gratuite (1 an + 2 ans = 3 ans) sur

votre outil électrique Festool. Festool assumera tous les coûts d’expédition pendant

la première année de la garantie alors que

les deuxième et troisième années, les coûts

devront être assumés par le client. Festool

paiera les frais de retour de l’outil au client

par service de livraison terrestre UPS. La

garantie est valable pour une période de 3

ans à compter de la date d’achat indiquée

sur votre reçu ou votre facture.

24

Page 25

Garantie limitée de Festool

Cette garantie est valable à condition

que l’outil soit utilisé conformément aux

instructions de Festool. Festool garantit,

à l’acheteur initial seulement, que l’outil

indiqué sera exempt de tout défaut de

matériau et de fabrication pendant un an

à compter de la date d’achat. Festool ne

donne aucune garantie supplémentaire,

implicite ou explicite, sur les instruments

portables électriques Festool. Aucun agent,

représentant commercial, distributeur, vendeur ou employé de Festool n’est autorisé

à prolonger ou à modifi er les obligations

ou restrictions de la présente garantie. Les

obligations de Festool sont, à son entière

discrétion, limitées à la réparation ou à

l’échange des outils portables électriques

Festool trouvés défectueux dans le présent

emballage, tels que fournis avec le présent

Guide d’utilisation.

Cette garantie exclut l’usure normale, les

dommages causés par un usage impropre,

les abus ou la négligence, ou tout dommage

autre que ceux attribuables à des défauts

de matériau et de fabrication. Cette garantie ne s’applique pas aux accessoires

tels que lames de scie circulaire, mèches

de perceuse et vilebrequin, lames de scie

sauteuse, bandes abrasives et meules.

Sont également exclues les pièces d’usure,

telles que balais de charbon, lamelles pour

outils à air comprimé, joints et manchons

de caoutchouc, disques et patins ponceurs,

ainsi que les piles.

Les outils électriques portables Festool à

remplacer ou à réparer doivent être retournés avec le reçu d’achat à Festool (appelez

au 800-554-8741 pour connaître l’adresse

d’expédition).

FESTOOL N’EST EN AUCUN CAS RESPONSABLE DES DOMMAGES DIRECTS

OU INDIRECTS, IMPLICITES OU EXPLICITES, DÉCOULANT DE LA RUPTURE

DE CETTE GARANTIE OU DE TOUTE

AUTRE GARANTIE. TOUTES LES GARANTIES IMPLICITES, Y COMPRIS LES

GARANTIES IMPLICITES DE QUALITÉ

MARCHANDE ET D’ADÉQUATION À UN

USAGE PAR TICULIER, SONT LIMITÉES

À UNE PÉRIODE DE TROIS ANS.

Certains états américains et certaines

provinces canadiennes ne permettent pas

la limitation des garanties implicites; il se

pourrait donc que les limites indiquées cidessus ne s’appliquent pas dans votre cas.

À l’exception de certaines garanties implicites des provinces ou des états indiquées

ici, la présente garantie est exclusive et

remplace toute autre garantie, convention

et obligation similaire de Festool.

Cette garantie vous confère des droits

légaux spécifi ques, et vous pouvez aussi

avoir d’autres droits pouvant varier d’un

état à l’autre, ou d’une province à l’autre

au Canada.

25

Page 26

Tableau A: Ponçage

Tableau B: Polissage

Eponge fine, gaufrée

26

Page 27

Contenido

Datos técnicos

Indicaciones de seguridad ............ 27

Datos técnicos ............................... 27

Símbolos ....................................... 27

Uso conforme a la destinación ....... 30

Conexión eléctrica y operación ...... 30

Cable de extensión ......................... 30

Regulación electrónica .................. 31

Ajustes en la máquina ................... 32

Extracción de polvo ......................... 32

Protección de cantos (protector) ...... 32

Movimiento de lijado ....................... 32

Selección y montaje de los platos de

lijar .............................................. 33

Fijación de la lija ............................ 34

Fijación de agentes de pulido ........... 34

Trabajo con la lijadora ................... 34

Trabajo en metal ............................ 35

Systainer ....................................... 35

Mantenimiento y cuidados ............. 36

Freno de plato de lijado ................... 36

Accesorios, herramientas .............. 36

Garantiá ........................................ 36

Condiciones de la Garantía 1 + 2 ...... 36

Garantía limitada de Festool ............. 37

Tabla A: Lijar ................................. 38

Tabla B: Pulir ................................. 38

ROTEX RO 125 FEQ

Potencia absorbida 500 W

Velocidad sin carga 3000 - 6000 rpm

Orbita de lijado 3.6 mm (0.14 in.)

Plato de lijado, Ø 125 mm (4.9 in.)

Peso 1.9 kg (4.2 lbs.)

Seguridad

/II

Símbolos

Aviso ante un peligro general

¡Leer las instrucciones e indicaciones!

Use gafas de protección.

V voltios

A amperios

Hz hertzios

W vatios

rensión alterna

n0 revoluciones por minuto en vacío

Clase II Construcción

-1

min

rpm revoluciones por minuto

Ø Diámetro

Indicaciones de seguridad

¡ATENCIÓN! Lea íntegramente las

instrucciones e indicaciones de

seguridad. El incumplimiento de dichas

instrucciones e indicaciones puede dar lugar

a descargas eléctricas, incendios o lesiones

graves.

Guardar todas las advertencias de

peligro e instrucciones para futuras

consultas.

El término herramienta eléctrica empleado

en las siguientes advertencias de peligro

se refiere a herramientas eléctricas de

conexión a la red (con cable de red) y a

herramientas eléctricas accionadas por

acumulador (o sea, sin cable de red).

1 PUESTO DE TRABAJO

a) Mantenga limpio y bien iluminado su

puesto de trabajo. El desorden y una ilu-

minación defi ciente en las áreas de trabajo

pueden provocar accidentes.

b) No utilice la herramienta eléctrica en

un entorno con peligro de explosión,

en el que se encuentren combustibles

líquidos, gases o material en polvo.

Las herramientas eléctricas producen

chispas que pueden llegar a infl amar los

materiales en polvo o vapores.

c) Mantenga alejados a los niños y otras

personas de su puesto de trabajo al

emplear la herramienta eléctrica. Una

27

Page 28

distracción le puede hacer perder el control sobre el aparato.

2 SEGURIDAD ELÉCTRICA

a) El enchufe del aparato debe corres-

ponder a la toma de corriente utilizada. No es admisible modifi car el

enchufe en forma alguna. No emplear

adaptadores en aparatos dotados con

una toma de tierra. Los enchufes sin

modifi car adecuados a las respectivas to-

mas de corriente reducen el riesgo de una

descarga eléctrica.

b) Evite que su cuerpo toque partes co-

nectadas a tierra como tuberías, radiadores, cocinas y refrigeradores. El

riesgo a quedar expuesto a una sacudida

eléctrica es mayor si su cuerpo tiene contacto con tierra.

c) No exponga las herramientas eléc-

tricas a la lluvia y evite que penetren

líquidos en su interior. Existe el peligro

de recibir una descarga eléctrica si penetran ciertos líquidos en la herramienta

eléctrica.

d) No utilice el cable de red para trans-

portar o colgar el aparato, ni tire de

él para sacar el enchufe de la toma

de corriente. Mantenga el cable de

red alejado del calor, aceite, esquinas

cortantes o piezas móviles. Los cables

de red dañados o enredados pueden provocar una descarga eléctrica.

e) Al trabajar con la herramienta eléctri-

ca en la intemperie utilice solamente

cables de prolongación homologados

para su uso en exteriores. La utilización

de un cable de prolongación adecuado

para su uso en exteriores reduce el riesgo

de una descarga eléctrica.

f) Si fuese imprescindible utilizar la

herramienta eléctrica en un entorno

húmedo, es necesario conectarla a

través de un fusible diferencial. La

aplicación de un fusible diferencial reduce

el riesgo a exponerse a una descarga eléctrica.

3 SEGURIDAD DE PERSONAS

a) Esté atento a lo que hace y emplee la

herramienta eléctrica con prudencia.

No utilice la herramienta eléctrica si

estuviese cansado, ni tampoco después de haber consumido alcohol,

drogas o medicamentos. El no estar

atento durante el uso de una herramienta

eléctrica puede provocarle serias lesiones.

b) Utilice un equipo de protección y en

todo caso unas gafas de protección.

El riesgo a lesionarse se reduce considerablemente si, dependiendo del tipo y la

aplicación de la herramienta eléctrica empleada, se utiliza un equipo de protección

adecuado como una mascarilla antipolvo,

zapatos de seguridad con suela antideslizante, casco, o protectores auditivos.

c) Evite una puesta en marcha fortui-

ta del aparato. Cerciorarse de que

el aparato esté desconectado antes

conectarlo a la toma de corriente. Si

transporta el aparato sujetándolo por el

interruptor de conexión/desconexión, o

si introduce el enchufe en la toma de corriente con el aparato conectado, ello puede dar lugar a un accidente.

d) Retire las herramientas de ajuste o

llaves fi jas antes de conectar la he-

rramienta eléctrica. Una herramienta o

llave colocada en una pieza rotante puede

producir lesiones al ponerse a funcionar.

e) Sea precavido. Trabaje sobre una

base fi rme y mantenga el equilibrio

en todo momento. Ello le permitirá con-

trolar mejor la herramienta eléctrica en

caso de presentarse una situación inesperada.

f) Utilice ropa adecuada. No utilice ropa

ancha ni objetos de joyería o bisutería. Mantenga el pelo y la ropa alejada

de las piezas en movimiento. La ropa

suelta o el pelo largo pueden quedar atrapados por piezas en movimiento.

g) Siempre que sea posible utilizar unos

equipos de aspiración o captación

de polvo, asegúrese que éstos estén

montados y que sean utilizados correctamente. El empleo de estos equipos

reduce los riesgos derivados del polvo.

4 TRATO Y USO CUIDADOSO DE HERRA-

MIENTAS ELÉCTRICAS

a) No sobrecargue el aparato. Use la

herramienta prevista para el trabajo

a realizar. Con la herramienta adecuada

podrá trabajar mejor y más seguro dentro

del margen de potencia indicado.

b) No utilice herramientas con un inte-

rruptor defectuoso. Las herramientas

28

Page 29

que no se puedan conectar o desconectar

son peligrosas y deben hacerse reparar.

c) Saque el enchufe de la red antes

de realizar un ajuste en el aparato,

cambiar de accesorio o al guardar el

aparato. Esta medida preventiva reduce

el riesgo a conectar accidentalmente el

aparato.

d) Guarde las herramientas fuera del

alcance de los niños y de las personas

que no estén familiarizadas con su

uso. Las herramientas utilizadas por per-

sonas inexpertas son peligrosas.

e) Cuide sus aparatos con esmero. Con-

trole si funcionan correctamente,

sin atascarse, las partes móviles del

aparato, y si existen partes rotas o

deterioradas que pudieran afectar al

funcionamiento de la herramienta.

Si la herramienta eléctrica estuviese

defectuosa haga repararla antes de

volver a utilizarla. Muchos de los acci-

dentes se deben a aparatos con un mantenimiento defi ciente.

f) Mantenga los útiles limpios y afi lados.

Los útiles mantenidos correctamente se

dejan guiar y controlar mejor.

g) Utilice herramientas eléctricas, acce-

sorios, útiles, etc. de acuerdo a estas

instrucciones y en la manera indicada

específi camente para este aparato.

Considere en ello las condiciones de

trabajo y la tarea a realizar. El uso de

herramientas eléctricas para trabajos diferentes de aquellos para los que han sido

concebidas puede resultar peligroso.

5 TRATO Y USO CUIDADOSO DE APA-

RATOS ACCIONADOS POR ACUMULADOR

a) Solamente cargar los acumuladores

con los cargadores recomendados por

el fabricante. Existe riesgo de incendio al

intentar cargar acumuladores de un tipo

diferente al previsto para el cargador.

b) Solamente emplee los acumuladores

previstos para la herramienta eléctrica. El uso de otro tipo de acumuladores

puede provocar daños e incluso un incendio.

c) Si no utiliza el acumulador, guárdelo

separado de clips, monedas, llaves,

clavos, tornillos o demás objetos metálicos que pudieran puentear sus

contactos. El cortocircuito de los contac-

tos del acumulador puede causar quemaduras o un incendio.

d) La utilización inadecuada del acumu-

lador puede provocar fugas de líquido. Evite el contacto con él. En caso

de un contacto accidental enjuagar

el área afectada con abundante agua.

En caso de un contacto con los ojos

recurra además inmediatamente a un

médico. El líquido del acumulador puede

irritar la piel o producir quemaduras.

6 SERVICIO

a) Únicamente haga reparar su herra-

mienta eléctrica por un profesional,

empleando exclusivamente piezas de

repuesto originales. Solamente así se

mantiene la seguridad de la herramienta

eléctrica.

Algunos polvos creados

por lijadoras motorizadas, aserraderos,

trituradores, perforadoras y otras actividades de construcción contienen sustancias químicas que se sabe (en el Estado

de California) causan cáncer, defectos

de nacimiento u otros daños al sistema

reproductivo. Algunos ejemplos de estas

sustancias químicas son:

• Plomo de las pinturas con base de plo-

mo

• Sílice cristalino de los ladrillos y cemento

y otros productos de mampostería, y

• Arsénico y cromo de madera tratada con

sustancias químicas

El riesgo de exposición a estas sustancias

varía, dependiendo de cuantas veces se

hace este tipo de trabajo.

Para reducir el contacto con

estas sustancias químicas:

trabaje en un área con buena

ventilación y trabaje con equipo de seguridad aprobado,

como mascarillas para el polvo

diseñadas espe cí fi camente

para fi ltrar partículas microscó-

picas.

PARA REDUCIR EL

RIESGO DE LESIÓN, EL USUARIO DEBE

LEER EL MANUAL DE INSTRUCCIÓN.

29

Page 30

Uso conforme a la destinación

La herramienta está diseñada para lijar y

pulir madera, plástico, metal, materiales

compuestos, pintura / barniz, emplaste y

materiales similares.

No debe usarse con materiales que contiene

asbestos.

La lijadora no debe ser operada cuando

está mojada o húmeda ni debe operarse en

Conexión eléctrica y operación

ambiente húmedo por razones de seguridad

eléctrica. Utilice este lijadora solamente

para lijado en seco.

El usuario se responsabilizará en el caso de daños y accidentes

durante un uso no conforme a lo predeterminado.

El voltaje de las líneas de alimentación deben coincidir con el voltaje indicado en la

placa de características.

Vea la fi gura siguiente para enchufar y des-

enchufar el cable de conexión.

Longitud total del

cable (pies)

Diámetro de cable

(AWG)

2.1

25 50 100 150

18 16 16 14

Siempre apague la máquina antes de conectar o desconectar el

cable.

Para poner en marcha la máquina, pulse el

interruptor (2.1) hacia abajo y hacia delante hasta que encaje. Para apagarla, pulse

el interruptor hacia abajo: de este modo

se desbloquea el interruptor y vuelve a la

posición de apagado.

Cable de extensión

Cuando se necesite un cable de extensión,

éste tiene que disponer de una sección sufi -

ciente a fi n de evitar una excesiva caída de

voltaje o un sobrecalentamiento. Una caída

excesiva del voltaje reduce la potencia y

puede conducir a falla del motor.

En la tabla de abajo indica el diámetro correcto del cable para la RO 125 FEQ, a saber,

en función de la longitud de cable.

Emplee únicamente los cables de extensión

listados por U.L. y CSA. No emplear nunca

dos cables de extensión conectados el uno

con el otro. En lugar de ello, emplee uno

correspondientemente largo.

30

Page 31

Observación: Cuanto más bajo es el número AWG, tanto mayor es el diámetro del

cable.

Regulación electrónica

La máquina dispone de un sistema

electrónico de onda plena con las

siguientes características:

Arranque suave

El arranque suave proporciona una puesta

en marcha de la máquina sin sacudidas.

Regulación del número de revoluciones

Las revoluciones pueden regularse de modo

continuo con la rueda de ajuste (3.1) entre

3000 y 6000 r.p.m.. Esto le permite optimizar la velocidad de lijado para adaptarse

de forma óptima a cada material.

3.1

Revoluciones constantes

Las revoluciones preseleccionadas se mantendrán constantes con la marcha en marcha o en neutral..

Dispositivo protector contra sobretemperaturas

Cuando el motor alcanza una temperatura

crítica, el sistema electrónico de seguridad

desconecta la máquina para prevenir un

sobrecalentamiento. Después de un tiempo de enfriamiento de aprox. 3-5 minutos,

la máquina está preparada para volver a

funcionar. Si la máquina está en marcha

(marcha en vacío) el tiempo de enfriamiento se reduce.

Ajustes en la máquina

¡Antes de realizar cualquier trabajo en la lijadora se debe desconectar el enchufe del tomacorriente!

Extracción de polvo

Conecte siempre la máquina al ex-

tractor de polvo.

31

Page 32

4.1

5.1

Ud. puede conectar un aparato de aspiración Festool con una manguera de aspiración con un diámetro 27 mm al puerto de

extracción de polvo (4.1).

Protección de cantos (protector)

La protección de cantos (5.1) impide que

el perímetro del plato lijador toque la superfi cie (p. ej. al lijar una pared) y que se

produzca un contragolpe de la máquina.

Montaje: empuje la protección de cantos

hasta que encaje en la máquina.

Movimiento de lijado

Con el interruptor (6.1) pueden ajustarse

dos movimientos de lijado diferentes.

6.1

El cambio sólo se puede

realizar con el plato fi jador parado ya que,

mientras está en marcha, el interruptor está

bloqueado por motivos de seguridad.

Movimiento rotatorio Rotex (lijado

grueso, pulido)

El movimiento rotatorio Rotex es una

combinación de movimiento excéntrico y de rotación. Se recomienda

este movimiento para quitar material

agresivamente (lijado grueso) y para

pulir.

Para ello coloque el interruptor (6.1) en la

posición de la derecha.

Movimiento excéntrico (lijado fi no)

Esta movimiento se recomienda para

lijar quitar poco material y tener un

acabado sin estrías (lijado fi no).

Para ello pulse el interruptor (6.1) hacia

abajo y colóquelo en la posición izquierda.

Selección y montaje de los pla-

tos de lijar

Selección de los platos de lijar

Se le pueden instalar tres platos de lijado al

RO 125 EQ con diferentes grados de dureza,

32

Page 33

7.1

7.2

7.3

dependiendo de la superfi cie a lijar.

Duro: Para un lijado grueso de superfi -

cies, así como para el lijado de bordes y

cantos.

Suave: Uso universal para un lijado grueso

y fi no en superfi cies planas y curvas.

Supersuave: Para un lijado fi no de piezas

perfi ladas, superfi cies curvas y radios. ¡No

lo emplee en bordes o cantos!

Instalación

El sistema FastFix hace posible el cambio

del plato lijador sin usar herramientas:

- Coloque el interruptor (7.1) a la derecha

en el trazado en curva Rotex,

- Presione el bloqueo del husillo (7.3), moviéndolo primero lateralmente y después

hacia adelante,

- Gire el disco lijador (7.2) desde el husillo

(rosca derecha),

- Mantenga pulsado el bloqueo del husillo y

enrosque el plato lijador nuevo (observe

al mismo tiempo que el retén de goma

(10.1) esté montado correctamente),

- Suelte el bloqueo del husillo.

Solo accionar al bloqueo

del husillo cuando el motor esté parado.

No encienda el motor cuando el bloqueo de

husillo está accinoado.

Fijación de la lija

Stickfi x es un sistema de sujeción de

gancho y lazo. Los platos de sujeción

Stickfi x se pueden utilizar para fi jar

lijas autoadherentes de gancho y lazo

como las hojas de lijar Stickfi x y el

vellón de lijado.

Simplemente oprima la lija sobre el plato

de lijado (7.2) y levántelo después de su

uso.

Atención: Sólo utilice lijas que tengan el

recubrimiento Stickfi x intacto. Inspecció-

nelos antes de usarse para asegurase que

el recubrimiento autoadhesivo no ha sufrido algún daño por su uso incorrecto (por

ejemplo, por sobrecalentamiento).

33

Page 34

8.1

Fijación de agentes de pulido

Para evitar desperfectos, sólo deben colocarse agentes de pulir PoliStick (esponjas,

fi eltros, piel de cordero) únicamente con

el plato pulidor especial montado sobre la

herramienta en vez del plato lijador. Los

agentes de pulir PoliStick, como los abrasivos Stickfi x, se colocan fácilmente en el

plato pulidor y se vuelven a quitar después

de usarse.

Trabajo con la lijadora

siempre de forma que no se pueda mover

cuando se esté lijando.

quina presionándola demasiado sobre el

objeto a lijar. Un resultado óptimo de lijado

lo conseguirá trabajando con una presión

8.2

moderada. La capacidad y calidad de lijado

dependen pri mordialmente de la elección

de la lija correcta.

Fije la pieza de trabajo

No sobrecargue la má-

Sujete la máquina para un guiado seguro

con una mano sobre la carcasa del motor

(8.2) y la otra sobre el cabezal del engranaje (8.1).

Las tablas A y B muestran las posiciones

que nosotros recomendamos para los diferentes trabajos de lijado y pulido.

Trabajo en metal

Por motivos de seguridad observe las siguientes medidas al trabajar el metal:

• Agregar un interruptor de corriente de

defecto (FI-, PRCD-).

• Conecte la lijadora a un extractor de polvo

apropiado.

• Limpie periódicamente la máquina para

eliminar las aglomeraciones de polvo en

el cárter del motor.

34

Use gafas de protección.

Page 35

9.3

Systainer

Muchos de los productos Festool se entregan en un embalaje exclusivo denominado

"Systainer" que sirve de protección a la herramienta y sus complementos, además de

facilitar su almacenamiento. Los Systainer

pueden apilarse y encajan unos con otros.

Además se adaptan sin problema a cualquier aparato de aspiración CT de Festool.

9.2

- Coloque un Systainer sobre otro.

- Abra los cuatro enganches del Systainers

de abajo tirando de sus extremos supe-

9.1

riores (9.1).

- Deslice los cuatro enganches hacia arriba

(9.2).

- Presione los cuatro enganches hasta que

que den planos (9.3) y puedan así acoplarse en los soportes del Systainer colocado

encima.

Mantenimiento y cuidados

mantenimiento y de reparación, para los

que se tiene que abrir la carcasa del motor,

sólo deben ser llevados a cabo por un taller

de servicio de asistencia técnica autorizado.

El mantenimiento o reparación de la máquina por personas no autorizadas puede ser

la causa de una conexión incorrecta de los

cables conductores de corriente eléctrica o

de otros componentes, lo cual puede ser la

causa de accidentes con lesiones graves.

Todos los trabajos de

10.1

¡Siempre desenchufe el

enchufe macho del tomacorriente antes de

realizar trabajos en la máquina!

Siempre mantenga limpias la herramienta

y espcialmente las ranuras de ventilación.

Freno de plato de lijado

El collarín de goma (10.1) impide que el

plato lijador se acelere descontroladamente

durante el movimiento excéntrico (lijado

fi no).

Debido a que este collarín se desgasta con el

tiempo, debe reemplazarse con uno nuevo

35

Page 36

(núm. de pedido 463 357) en cuanto exista

una reducción en el efecto de frenado.

Accesorios, herramientas

¡Por razones de seguridad,

solamente deben emplearse accesorios y

herramientas originales de Festool!

Garantiá

Condiciones de la Garantía 1 + 2

Usted tiene derecho a una garantía extendida gratuita (1 año + 2 años = 3 años) para

su herramienta motorizada Festool. Festool

se hará responsable por los gastos de envío

durante el primer año de garantía. Durante

el segundo y tercer año de garantía el cliente es responsable por el costo del envío de

la herramienta a Festool. Festool pagará el

embarque de regreso al cliente usando UPS

Ground Service. Todo el servicio de garantía

es válido por 3 años desde la fecha de la

compra de acuerdo a la fecha de su recibo

o factura de compra.

Garantía limitada de Festool

Esta garantía es válida únicamente con la

condición previa de que la herramienta se

usa y opera de conformidad con las instrucciones de operación de Festool. Festool

garantiza, sólo al comprador original, que

la herramienta especifi cada estará libre de

defectos de fabricación y materiales durante

un periodo de un año a partir de la fecha de

compra. Festool no otorga otras garantías,

ni explícitas ni implícitas para ninguna de

las herramientas motorizadas portátiles

Festool. Ningún agente, representante,

distribuidor, comerciante o empleado de

Festool está autorizado para extender o

modifi car de cualquier manera las obliga-

ciones o limitaciones de esta garantía. Las

obligaciones de Festool, a su propia entera

discreción, están limitadas a la reparación

o sustitución de cualquier herramienta

Los números de pedido para los respectivos

accesorios y herramientas se encuentran

en su catálogo Festool o en la Internet,

www.festool-usa.com.

portátil Festool que se encuentre estar defectuosa en el momento de ser embalada

junto con el manual de usuario.

Quedan excluidos de la cobertura en esta

garantía: el desgaste normal; los daños

causados por uso indebido, el abuso o negligencia; los daños causados por cualquier

otra causa que no sean defectos del material o de la fabricación. Esta garantía no

aplica a accesorios como cuchillas de sierras

circulares, brocas de taladro, barrenas de

buriladora, cuchillas de sierra, cuchillas

para sierras de calado, correas de lijadoras

y ruedas de esmeril. También se excluyen

las partes que se desgastan como cepillos

de carbón, álabes de las herramientas de

aire, collarines de hule y sellos, discos y

platos de lijado, y baterías.

Las herramientas motorizadas portátiles

Festool que requieran de reemplazo o reparación deben devolverse con el recibo de

compra a Festool (llame al 800-554-8741

para los detalles de la dirección).

EN NINGÚN CASO FESTOOL SE HARÁ

RESPONSABLE POR LOS DAÑOS

SECUNDA RIOS O CONSECUENTES

OCASIONADOS POR LA VIOLACIÓN

DE ESTA O CUALUQUIER OTRA GARANTÍA, SEA EXPLÍCITA O IMPLÍCITA.

TODAS LAS GARANTÍAS IMPLICADAS

POR LEYES ESTATALES, INCLUYENDO LAS GARAN TÍAS IMPLICADAS DE

COMERCIALI ZACIÓN Y ADECUACIÓN A

UN PROPÓSITO PARTICULAR, QUEDAN

LIMITADAS A TRES AÑOS DE DURACIÓN.

36

Page 37

Algunos estados de EE.UU. y algunas provincias de Canadá no permiten las limitaciones en cuanto a la duración de las garantías

implícitas, de modo que la limitación arriba

indicada puede que no le afecte. A excepción de algunas garantías implicadas por

leyes estatales o provinciales, limitadas por

la presente, la anteriormente citada garan-

Tabla A: Lijar

tía, expresamente limitada, es exclusiva y

sustituye a cualquier otra garantía, acuerdo

u obligación similar de Festool.

Esta garantía le concede derechos legales

específi cos y usted podría tener otros de-

rechos legales que varían de estado a estado en EE.UU. y de provincia a provincia

en Canadá.

Tabla B: Pulir

Esponja fina, gofrado

37

Page 38

NOTES/ NOTACIONS/ NOTAS

38

Page 39

NOTES/ NOTACIONS/ NOTAS

39

Page 40

NOTES/ NOTACIONS/ NOTAS

40

Loading...

Loading...