Page 1

Festool Group GmbH & Co. KG

Wertstrasse 20

73240 Wendlingen

Germany

www.festoolusa.com

Instruction manual Orbit Sander

Page 3

IMPORTANT: Read and understand all instructions before using.

Guide d’utilisation Ponceuse vibrante

Page 12

IMPORTANT: Lire et comprendre toutes les instructions avant de

démarrer les travaux.

Manual de instrucciones Lijadora vibratoria

Pagina 22

IMPORTANTE: Lea y comprende todas las instrucciones antes de

usar.

Instruction manual

Guide d’utilisation

Manual de instrucciones

RS 2

RS 2E

701027_006

Page 2

Page 3

Contents

lose control.

SAFETY INSTRUCTIONS ................................. 3

General Power Tool Safety Warnings ............. 3

Machine-related safety instructions .............. 4

Technical data ................................................ 5

Symbols .......................................................... 5

Intended use .................................................. 5

Electrical connection and operation ...............5

Electronics (RS 2 E) ........................................ 6

Dust extraction .............................................. 6

Inboard extraction ........................................... 6

External extraction by an extraction unit ....... 6

Sanding pad ................................................... 7

Abrasives ....................................................... 7

Stickfix abrasives ........................................... 7

Clamped sandpaper ....................................... 7

Working with the machine .............................. 8

Metalworking .................................................. 8

Speed adjustment (RS 2 E).............................. 8

Maintenance and care ..................................... 9

Accessories, tools ........................................... 9

Additional handle ........................................... 9

Systainer ....................................................... 10

Warranty ...................................................... 10

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodifi ed plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet con-

ditions. Water entering a power tool will increase the

risk of electric shock.

d) Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords in-

crease the risk of electric shock.

e) When operating a power tool outdoors, use

an extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk

of electric shock.

SAFETY INSTRUCTIONS

General Power Tool Safety Warn-

ings

WARNING! Read all safety warnings and

all instructions. Failure to follow the warn-

ings and instructions may result in electric shock,

fi re and/or serious injury.

Save all warnings and instructions for future

reference.

The term “power tool” in the warnings refers

to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive at-

mospheres, such as in the presence of fl ammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while op-

erating a power tool. Distractions can cause you to

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the infl uence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment such

as a dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connecting to

power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your

fi nger on the switch or energising power tools that

have the switch on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better control of

3

Page 4

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair and clothing away from

moving parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

g) If devices are provided for the connection of

dust extraction and collection facilities, ensure

these are connected and properly used. Use of

dust collection can reduce dustrelated hazards.

h) Do not let familiarity gained from frequent

use of tools allow you to become complacent and

ignore tool safety principles. A careless action can

cause severe injury within a fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct power

tool will do the job better and safer at the rate for

which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must

be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the

power tool accidentally.

d) Store idle power tools out of the reach of chil-

dren and do not allow persons unfamiliar with

the power tool or these instructions to operate

the power tool. Power tools are dangerous in the

hands of untrained users.

e) Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition that

may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many

accidents are caused by poorly maintained power

tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions, taking

into account the working conditions and the work

to be performed. Use of the power tool for opera-

tions different from those intended could result in

a hazardous situation.

h) Keep handles dry, clean and free from oil

and grease. Slippery handles do not allow for safe

handling and control of the tool in unexpected situ-

ations.

5) Service

a) Have your power tool serviced by a qualifi ed

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

Machine-related safety instruc-

tions

– Harmful/toxic dusts can be produced during

your work (e.g. lead-containing paint, some

types of wood and metal). Contact with these

dusts, especially inhaling them, can represent

a hazard for operating personnel or persons in

the vicinity. Comply with the safety regulations

that apply in your country. Connect the electric

power tool to a suitable extraction system.

To protect your health, wear a P2 protective

mask.

Always wear protective goggles to protect

against sanding hazards.

Health hazard by dust

Various dust created by power

sanding, sawing, grinding, drilling and other

construction activities contains chemicals known

(to the State of California) to cause cancer, birth

defects or other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products,

• Arsenic and chromium from chemically-

treated lumber.

The risk from these exposures varies, depending

on how often you do this type of work.

To reduce your exposure to these

chemicals work in a well ventilated area and use approved safety equipment, such as dust masks

that are specially designed to fi lter out microscopic particles. Wash

hands after handling.

TO REDUCE THE RISK OF INJU

RY, USER MUST READ INSTRUCTION MANUAL.

4

Page 5

Technical data

Symbols

RS 2

Wattage W 330

No load speed rpm 10 000

No. of strokes spm 20 000

Sanding stroke mm (in.) 2.4 (0.1)

Sanding base mm (in.) 115 x 225 (4.53 x 8.86)

Weight kg (lbs) 2.5 (5.5)

Safety

/ II

RS 2 E

Wattage W 330

No load speed rpm 4 000 - 10 000

No. of strokes spm 8 000 - 20 000

Sanding stroke mm (in.) 2.4 (0.1)

Sanding base mm (in.) 115 x 225 (4.53 x 8.86)

Weight kg (lbs) 2.5 (5.5)

Safety

/ II

Warning of general danger

Read the Operating Instructions/

Notes!

Wear protective goggles

Wear a dust mask

V Volts

A Amperes

Hz Hertz

W Watt

~ Alternating current

n

No load speed

0

Class II Construction

rpm Revolutions per minute

spm Strokes per minute

Intended use

The sanders are designed for sanding wood,

plastic, metal, stone, composite materials, paint/

varnish, fi lling material and similar materials.

Materials with an asbestos content must not be

processed with these tools.

The machines must not be damp nor operated in

a damp environment for electrical safety reasons.

The machines may only be used for dry sanding.

The user bears sole responsibil-

1.21.1

ity for any damage or accidents resulting from

incorrect use.

Electrical connection and opera-

tion

The mains voltage must be the same as that

specifi ed on the ratings plate!

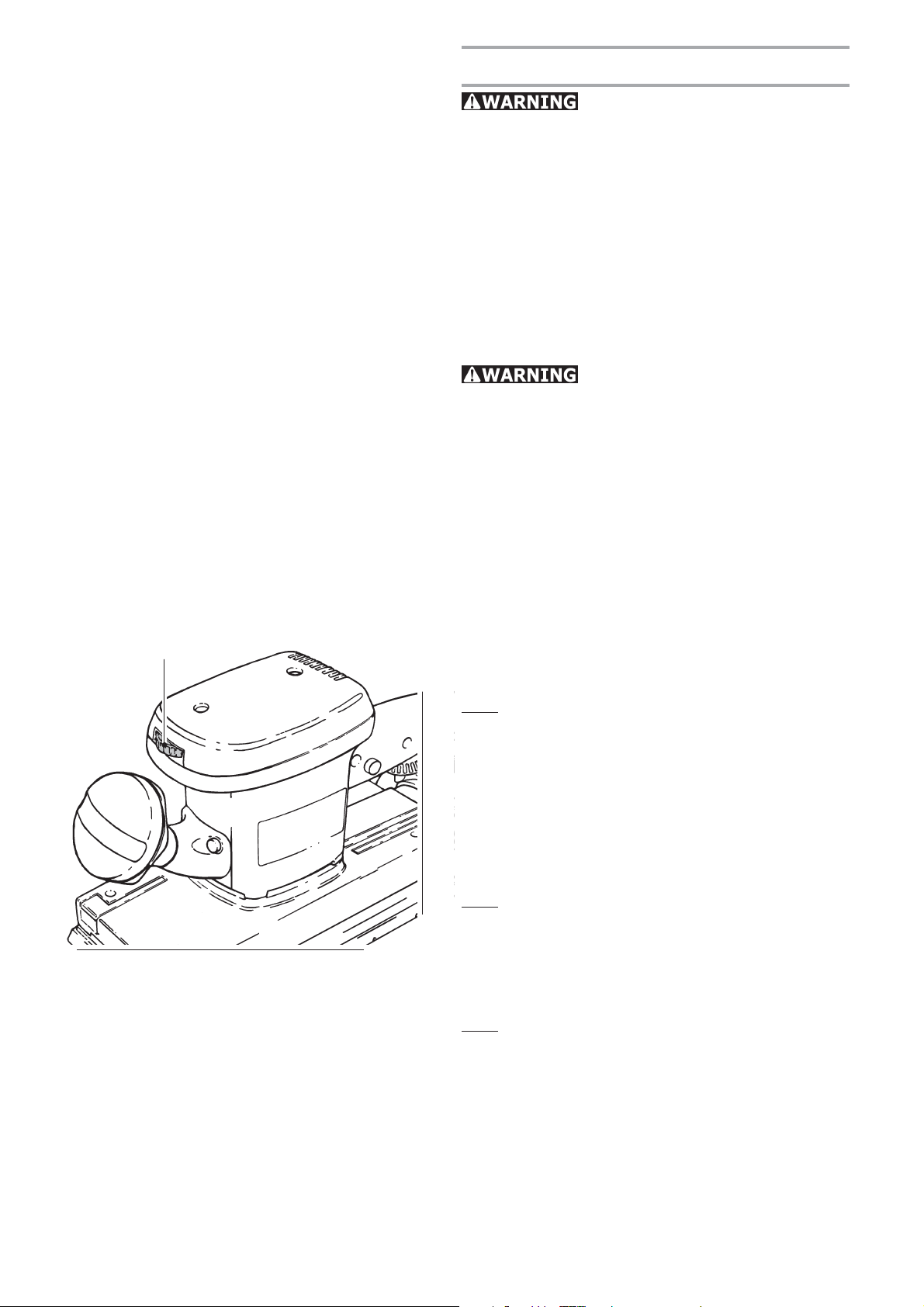

The switch (1.1) is used to switch the tool on and

off. The switch can be locked with the button (1.2)

on the side for continuous operation. The switch

can be released by pressing again.

5

Page 6

2.1

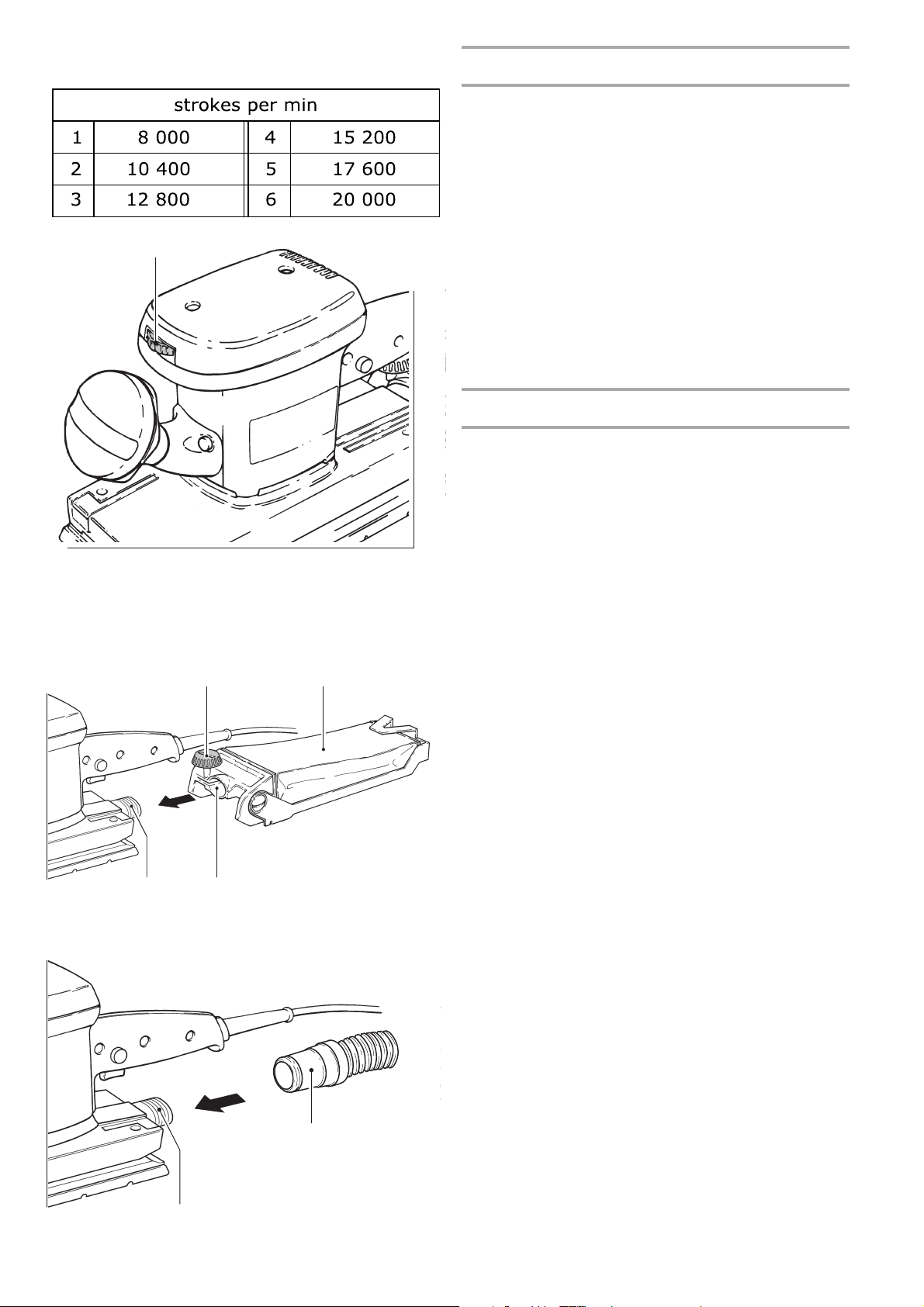

Electronics (RS 2 E)

The RS 2 E has an electronic control with which

the rotational speed can be varied step-free. This

allows the sanding speed to be adapted to the optimum level according to the material concerned.

The speed is set using the rotary control button

(2.1). The numbers on the rotary control button

represent approximately the following stroke/

orbit speeds:

Dust extraction

Dust extractors prevent large accumulations of

dust in the air in the working environment and

dirt collecting in the workplace.

3.1 3.2

3.33.4

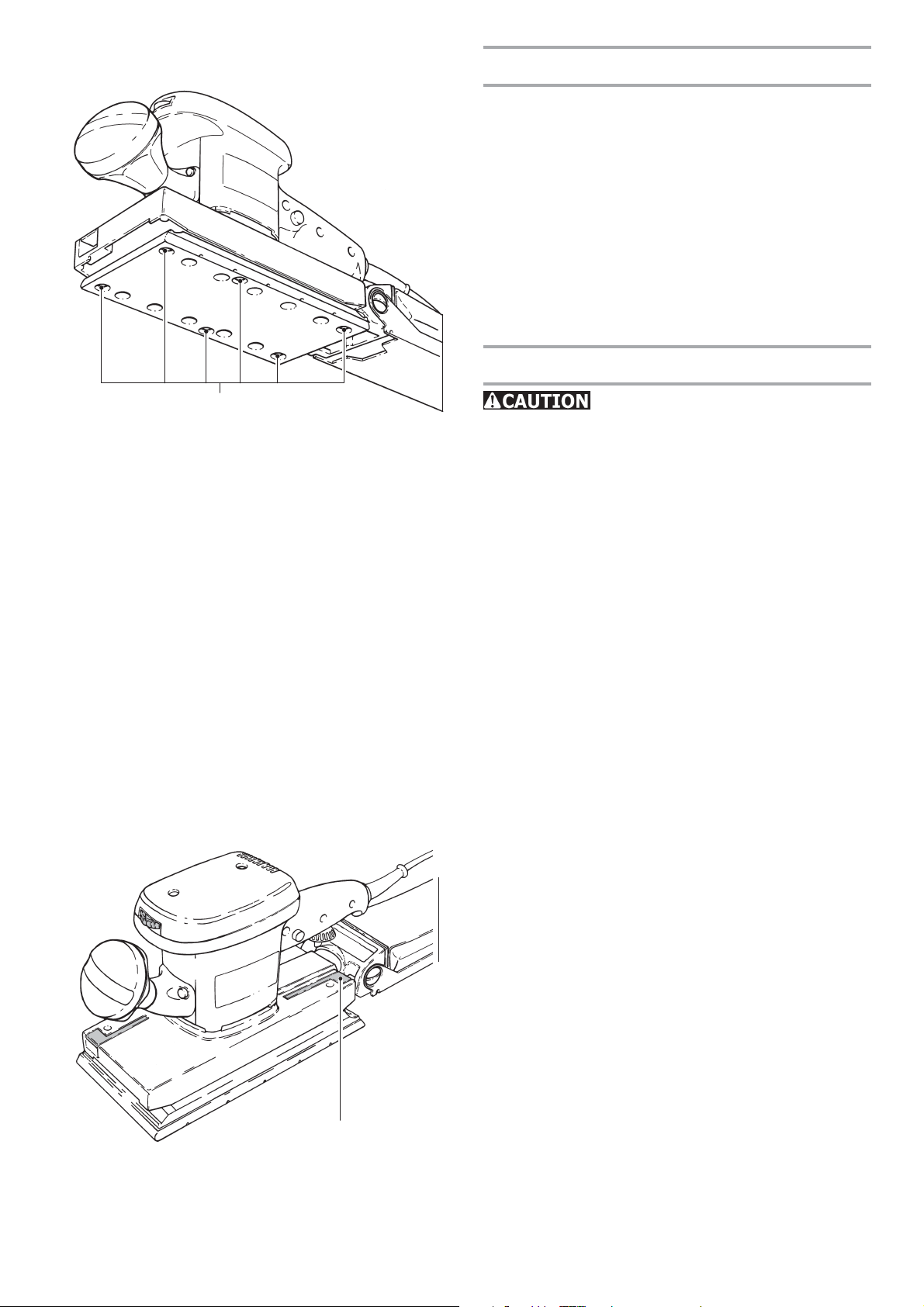

Inboard extraction

The machines are fi tted with inbuilt extraction as

standard. Push the fi lter holder (3.3) with its opening as far as it will go onto the extraction nozzle

(3.4) of the machine and clamp tight by turning

rotary knob (3.1).

The sanding dust is extracted through suction

openings in the sanding base and trapped in

the turbo-fi lter (3.2). The turbo-fi lter has to be

changed when it is so full of dust that the extraction power diminishes.

External extraction by an extrac-

tion unit

4.2

4.1

In order to avoid frequent changing of the turbofi lter when carrying longer sanding jobs, it is

possible to connect a Festool extractor to the unit

instead of using inbuilt extraction. Connect the

hose (Ø 27 mm (4.1) from a Festool dust extractor

to the extraction outlet on the tool (4.2).

6

Page 7

Sanding pad

The standard STF 115 x 225 mm Stickfi x sanding

pad can be exchanged for the 115 x 225 mm sanding pad for use with clamping paper. Loosen the

six fastening screws (5.1).

Both sanding pads (with and without Stickfi x covering) are also available with an edge protector

(KS) to protect the edge of the pad from premature

damage.

Abrasives

5.1

Always use original Festool sanding

materials!

Stickfi x abrasives

Self-adhesive abrasives such as Stickfi x sanding

disks and sheepskin polishers can be attached to

the Stickfi x sanding pads. Simply press the abrasives onto the sanding pads and remove after use.

Please note: Only use sanding pads with an

undamaged Stickfi x coating. Before use, check

whether the adhesive layer has been damaged

due to improper use (e.g. melting)

Clamped sandpaper

6.1

In addition to the Stickfi x abrasives, Festool also

offers perforated abrasives for clamp-fitting.

Unperforated sandpaper can be perforated with

the Festool “Lochfi x” punching device.

Start clamping the abrasive on the back of the

tool by raising the clamping lever (6.1) and thus

opening the clamping device. Insert abrasive up

to limit stop and lower clamping lever into initial

position. Place the abrasive on the sanding pad,

pull taught and clamp on the front.

7

Page 8

Working with the machine

Never overload the tool by using

too much pressure! The best sanding results are

achieved when applying moderate pressure.

The sanding performance and quality depend

mainly on the choice of the right sanding material.

Festool offers the appropriate sanding material

for all applications (see Festool catalogue).

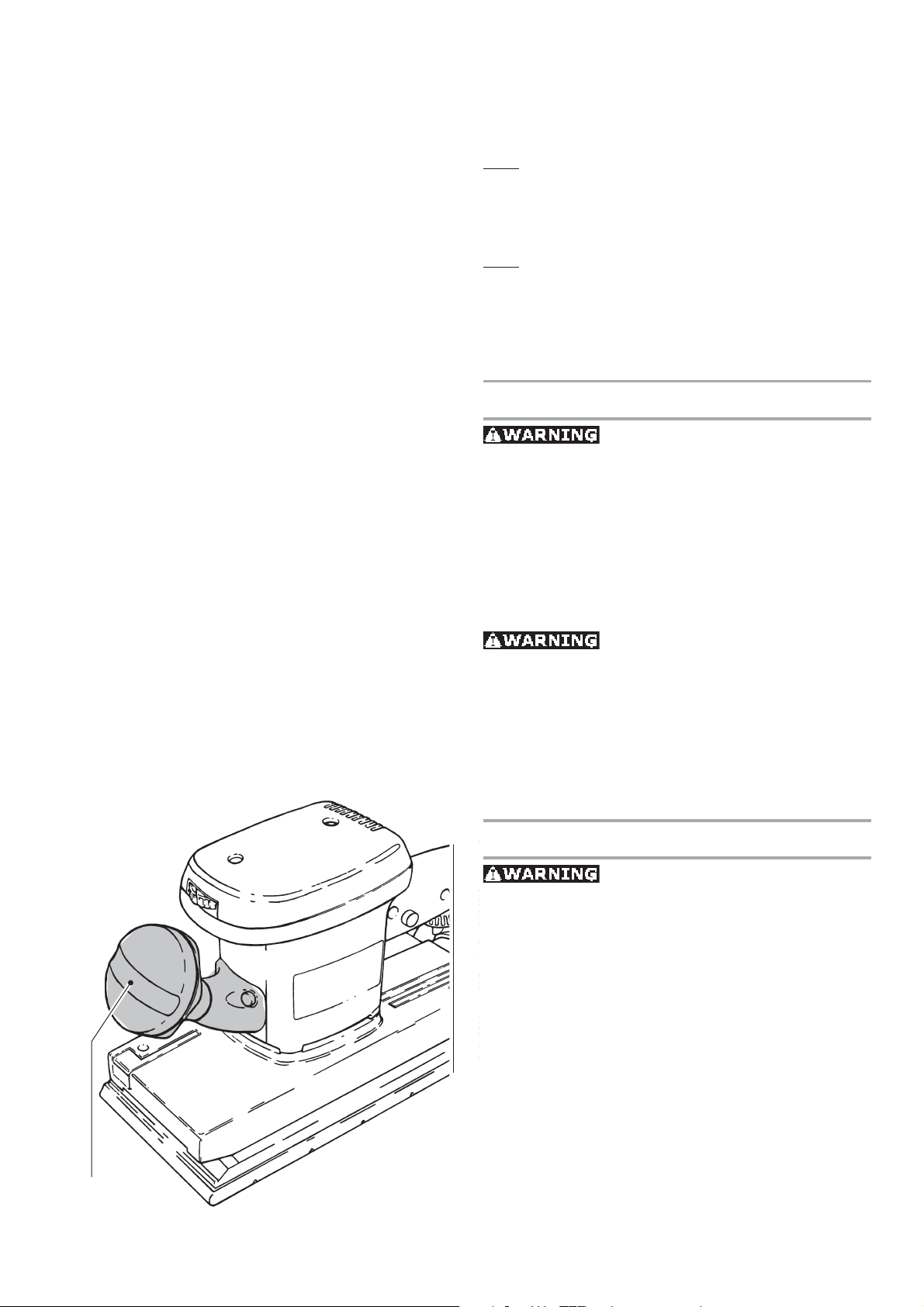

Metalworking

The following precautions are to be

taken when processing metals for safety reasons:

- connect a residual current operated device in

series before the tool,

- connect tool to a suitable dust extractor,

- clean tool regularly of dust accumulations in the

motor housing.

7.1

Speed adjustment (RS 2 E)

We recommend the following settings on the rotary control (7.1) for electronic machines:

5 - 6

- sanding with max. drive

- sanding old paint

- sanding wood and veneer prior to painting

- interim sanding of paint on surfaces

- removing rust from surfaces using sanding cloth

- partial sanding of V2A steel/sheet metal using

sanding cloth

4 - 5

- sanding of thinly applied primer

- sanding of wood with sanding vlies

- sanding edges on wooden parts

- smoothing primed wooden surfaces.

3 - 4

- sanding full wooden and veneer edges

- sanding in the grooves/rebates of windows and

doors

- interim paint sanding on edges

- pre-sanding natural wood windows with sand-

ing vlies

- smoothing wood surfaces with sanding felt prior

to staining

8

Page 9

- rubbing down stained surfaces with sanding

vlies

- rubbing down or removing excess lime paste

with sanding vlies

2 - 3

- interim paint sanding on stained surfaces

- cleaning natural wood window grooves with

sanding felt

1 - 2

- sanding stained edges

- sanding thermoplastic synthetics

Maintenance and care

Any maintenance or repair work

requiring the motor housing to be opened (including power cord replacement) may only be

carried out by an authorised service workshop.

Maintenance or repair work carried out by an

unauthorised person can lead to the wrong connection of the power leads or other components,

which in turn can lead to accidents with serious

consequences.

Always remove the plug from the

mains supply socket before carrying out any work

on the machine!

Always keep the machine and the ventilation slots

clean.

Accessories, tools

For safety reasons, only use original Festool accessories and tools!

The accessory and tool order number can be found

in the Festool catalogue or on the Internet under

www.festoolusa.com.

Additional handle

8.1

The additional handle (8.1) can be removed by unscrewing in an anticlockwise direction when sanding close to walls the front edge of the sanding pad.

9

Page 10

9

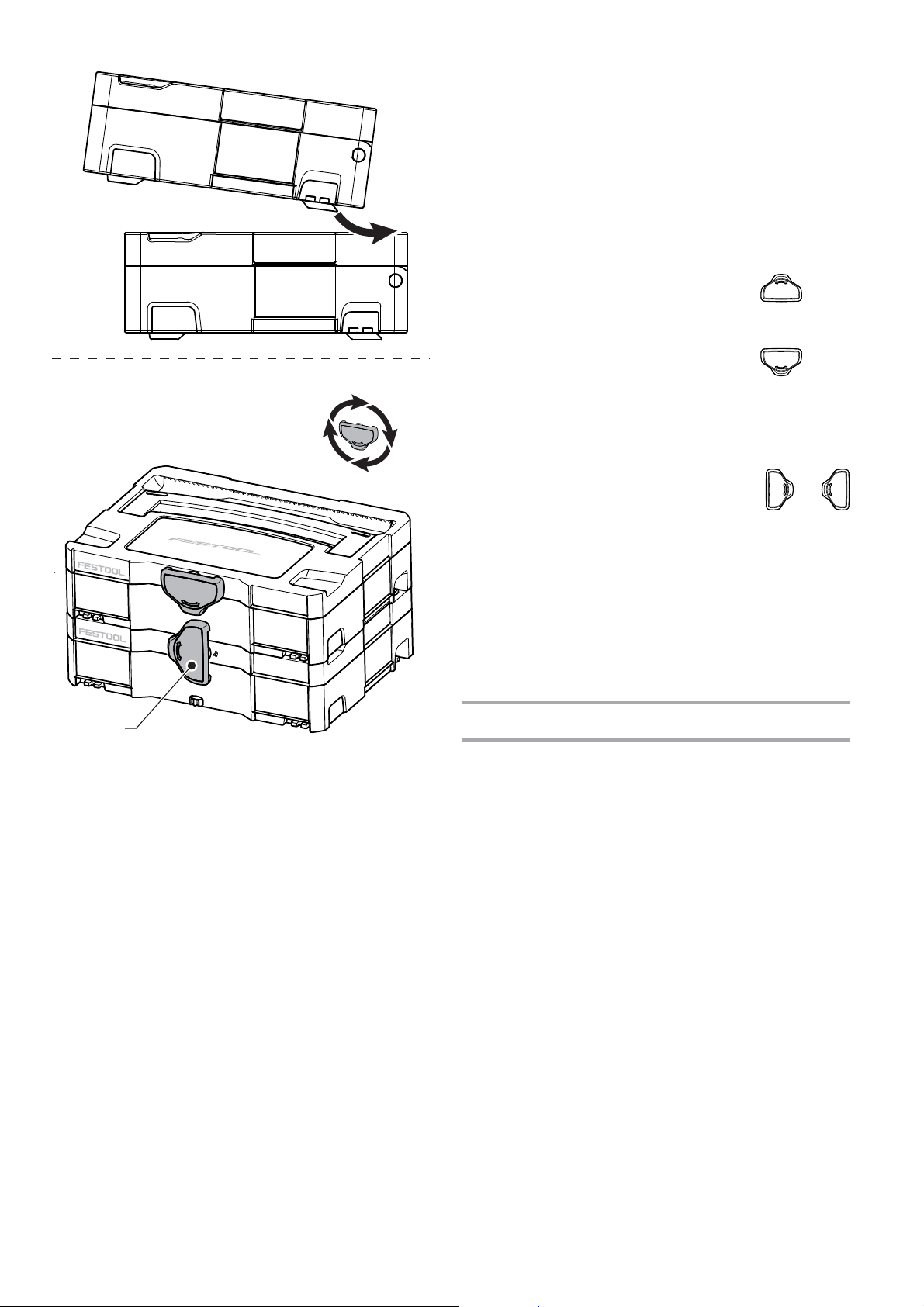

Systainer

Many Festool products are shipped in a unique

system container, called "Systainer".

This provides protection and storage for the tool

and accessories. The Systainers are stackable

and can be connected together. They also can be

conntected atop Festool CT dust extractors.

To open the Systainer:

A

B

9.1

connect

open

T-loc

lock

connect

– Turn the T-loc [9.1] to the position

.

To lock the Systainer:

– Turn the T-loc [9.1] to the position

.

To connect two Systainers:

– Place one Systainer on the top of the other

(Fig.9 A).

– Turn the T-loc [9.1] to the position

or

(Fig. 9 B).

The Systainers are connected and locked.

A new generation Systainer is connectable on

top of a previous generation Systainer by the

four latches of the previous Systainer.

Warranty

Festool offers a 3 year limited warranty, one of the

strongest in the industry. This warranty is valid on

the pre-condition that the tool is used and operated in compliance with the Festool operating

instructions. Festool warrants that the specifi ed

tool will be free from defects in materials and

workmanship for a term of 3 years from the date

of purchase.

Conditions of 1 + 2 warranty

All customers receive a free extended limited

warranty (1 year + 2 years = 3 Years) on new Festool power tools purchased from an authorized

retailer. Festool is responsible for all shipping

costs during the fi rst year of the warranty. During the second and third year of the warranty the

customer is responsible for shipping the tool to

Festool. Festool will pay for return shipping to the

customer using UPS Ground Service. All warranty

service is valid 3 years from the date of purchase

10

Page 11

on your receipt or invoice. Proof of purchase may

be required.

Excluded from the coverage under this warranty

are: normal wear and tear, damages caused by

misuse, abuse, or neglect; damage caused by

anything other than defects in material and

workmanship. This warranty does not apply to

accessory items such as circular saw blades, drill

bits, router bits, jigsaw blades, sanding belts, and

grinding wheels. Operating a tool at a voltage

or frequency different from the tool’s rating will

void the warranty. This includes the usage of the

tool in combination with a transformer. Festool

does not condone nor support the use of any nonFestool engineered, designed, and manufactured

accessories or consumables with Festool products. Use of any non-Festool products may affect

performance or void the warranty. Festool is not

responsible for any damages or losses incurred

and user assumes all risk and responsibility with

non-Festool derived products. Also excluded are

"wearing parts," such as carbon brushes, lamellas of air tools, rubber collars and seals, sanding

discs and pads, and Festool gear (hats and shirts).

The obligations of Festool in its sole discretion

under this warranty shall be limited to repair or

replacement or a refund of the purchase price

for any Festool portable power tool that is found

to have a defect in materials or workmanship

during the warranty period. FESTOOL SHALL

NOT BE LIABLE FOR ANY CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES REGARDLESS

OF THE THEORY OF LAW ON WHICH THE CLAIM

IS BASED. ALL WARRANTIES IMPLIED BY STATE

LAW, INCLUDING THE IMPLIED WARRANTIES

OR MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE HEREBY LIMITED

TO THE DURATION OF THREE YEARS.

Some states in the U.S. and some Canadian provinces do not allow the limitations on how long an

implied warranty lasts, so the above limitation

may not apply to you. This warranty gives you

specifi c legal rights, and you may also have other

rights that vary from state to state in the U.S. and

from province to province in Canada.

With the exception of any warranties implied by

state or province law as limited above, the foregoing express limited warranty is exclusive and in

lieu of all other warranties, guarantees, agreements, and similar obligations of Festool. Festool

makes no other warranty, express or implied, for

Festool portable power tools. This warranty policy

is only valid for tools that are purchased in the US

and Canada. Warranty policies of other countries

may vary when obtaining warranty service outside

the US and Canada.Some countries do exclude

warranty for products bought outside their territory. Festool reserves the right to reject the repair of any tool that is not part of the US/Canada

product line. No agent, representative, distributor,

dealer, or employee of Festool has the authority

to increase or otherwise change the obligations

or limitations of this warranty.

11

Page 12

Sommaire

RÉGLES DE SÉCURITÉ .................................. 12

Régles de sécurité générales ...................... 12

Consignes de sécurité spécifiques à la

machine ......................................................... 14

Caracteristiques techniques ......................... 14

Symbole ........................................................ 14

Utilisation conforme aux prescriptions ........ 15

Raccordement électrique et mise en service 15

Electronique (RS 2 E) .................................... 15

Aspiration des poussières ........................... 16

Dispositif d’auto-aspiration .......................... 16

Aspiration extérieure à l’aide d’un aspirateur 16

Patins de ponçage spéciaux ......................... 16

Abrasifs ....................................................... 17

Abrasifs Stickfix ............................................ 17

Papiers de ponçage à tendre ....................... 17

Travailler avec la machine ........................... 17

Traitement des métaux : ............................... 18

Réglage de régime (RS 2 E) .......................... 18

Entretien et maintenance ............................. 19

Accessoires, outils........................................ 19

Poignée supplémentaire .............................. 19

Systainer ....................................................... 20

Garantie ........................................................ 20

RÉGLES DE SÉCURITÉ

Régles de sécurité générales

ATTENTION ! Lire toutes les consignes de

sécurité et indications. Le non-respect

des avertissements et instructions indiqués ciaprès peut entraîner un choc électrique, un incendie et/ou de graves blessures.

Conserver tous les avertissements et toutes les

instructions pour pouvoir s'y reporter ultérieurement.

Le terme "outil" dans les avertissements fait

reference à votre outil électrique alimenté par

le secteur (avec cordon d'alimentation) ou votre

outil fonctionnant sur batterie (sans cordon d'alimentation).

1 PLACE DE TRAVAIL

a) Maintenez l'endroit de travail propre et bien

éclairé. Un lieu de travail en désordre ou mal

éclairé augmente le risque d'accidents.

b) N'utilisez pas l'appareil dans un environne-

ment présentant des risques d'explosion et où

se trouvent des liquides, des gaz ou poussières

infl ammables. Les outils électroportatifs génèrent

des étincelles risquant d'enfl ammer les poussières ou les vapeurs.

c) Tenez les enfants et autres personnes éloi-

gnés durant l'utilisation de l'outil électroportatif. En cas d'inattention vous risquez de perdre le

contrôle sur l'appareil.

2 SECURITE RELATIVE AU SYSTEME

ELECTRIQUE

a) La fi che de secteur de l'outil électroportatif

doit être appropriée à la prise de courant. Ne

modifi ez en aucun cas la fi che. N'utilisez pas de

fi ches d'adaptateur avec des appareils avec mise

à la terre. Les fi ches non modifi ées et les prises de

courant appropriées réduisent le risque de choc

électrique.

b) Evitez le contact physique avec des surfaces

mises à la terre tels que tuyaux, radiateurs, fours

et réfrigérateurs. Il y a un risque élevé de choc élec-

trique au cas où votre corps serait relié à la terre.

c) N'exposez pas l'outil électroportatif à la pluie

ou à l'humidité. La pénétration d'eau dans un outil

électroportatif augmente le risque d'un choc électrique.

d) N'utilisez pas le câble à d'autres fins que

celles prévues, n'utilisez pas le câble pour porter

l'appareil ou pour l'accrocher ou encore pour le

débrancher de la prise de courant. Maintenez le

câble éloigné des sources de chaleur, des parties

grasses, des bords tranchants ou des parties de

l'appareil en rotation. Un câble endommagé ou

torsadé augmente le risque d'un choc électrique.

e) Au cas où vous utiliseriez l'outil électropor-

tatif à l'extérieur, utilisez une rallonge autorisée

homologuée pour les applications extérieures.

L'utilisation d'une rallonge électrique homologuée

pour les applications extérieures réduit le risque

d'un choc électrique.

f) Si l'usage d'un outil dans un emplacement

humide est inévitable, utiliser une alimentation

protégée par un dispositif à courant différentiel

résiduel (RCD). L'usage d'un RCD réduit le risque

de choc électrique.

3 SECURITE DES PERSONNES

a) Restez vigilant, surveillez ce que vous faites.

Faites preuve de bon en utilisant l'outil électroportatif. N'utilisez pas l'appareil lorsque vous

êtes fatigué ou après avoir consommé de l'alcool,

12

Page 13

des drogues ou avoir pris des médicaments.

Un moment d'inattention lors de l'utilisation de

l'appareil peut entraîner de graves blessures sur

les personnes.

b) Portez des équipements de protection. Por-

tez toujours des lunettes de protection. Le fait de

porter des équipements de protection personnels

tels que masque anti-poussières, chaussures de

sécurité antidérapantes, casque de protection ou

protection acoustique suivant le travail à effectuer,

réduit le risque de blessures.

c) Evitez une mise en service par mégarde. As-

surez-vous que l'interrupteur est effectivement

en position d'arrêt avant de retirer la fi che de la

prise de courant. Le fait de porter l'appareil avec

le doigt sur l'interrupteur ou de brancher l'appareil

sur la source de courant lorsque l'interrupteur est

en position de fonctionnement, peut entraîner des

accidents.

d) Enlevez tout outil de réglage ou toute clé

avant de mettre l'appareil en fonctionnement.

Une clé ou un outil se trouvant sur une partie en

rotation peut causer des blessures.

e) Ne surestimez pas vos capacités. Veillez à

garder toujours une position stable et équilibrée.

Ceci vous permet de mieux contrôler l'appareil

dans des situations inattendues.

f) Portez des vêtements appropriés. Ne portez

pas de vêtements amples, ni de bijoux. Gardez les

cheveux et les vêtements à distance des pièces

mobiles. Des vêtements amples, des bijoux ou des

cheveux longs peuvent être happés par les pièces

en mouvement.

g) Si des dispositifs servant à aspirer ou à re-

cueillir les poussières doivent être utilisés, vérifi ez que ceux-ci soient effectivement raccordés

et qu'ils sont correctement utilisés. L'utilisation

de tels dispositifs réduit les dangers dus aux poussières.

h) Ne devenez pas trop sûr de vous, par habitude

suite à une utilisation fréquente de l'appareil, de

manière à ne pas respecter les principes de sécurité de base de l'appareil. Une action imprudente

peut occasionner de graves blessures en l'espace

d'une fraction de seconde.

4 UTILISATION ET EMPLOI SOIGNEUX

DE L'OUTIL ELECTROPORTATIF

a) Ne surchargez pas l'appareil. Utilisez l'outil

électroportatif approprié au travail à effectuer.

Avec l'outil électroportatif approprié, vous travaillerez mieux et avec plus de sécurité à la vitesse

pour laquelle il est prévu.

b) N'utilisez pas un outil électroportatif dont

l'interrupteur est défectueux. Un outil électroportatif qui ne peut plus être mis en ou hors fonctionnement est dangereux et doit être réparé.

c) Retirer la fi che de la prise de courant avant

d'effectuer des réglages sur l'appareil, de changer les accessoires, ou de ranger l'appareil. Cette

mesure de précaution empêche une mise en fonctionnement par mégarde.

d) Gardez les outils électroportatifs non utilisés

hors de portée des enfants. Ne permettez pas

l'utilisation de l'appareil à des personnes qui ne

se sont pas familiarisées avec celui-ci ou qui n'ont

pas lu ces instructions. Les outils électroportatifs

sont dangereux lorsqu'ils sont utilisés par des personnes non initiées.

e) Prenez soin des outils électroportatifs. Véri-

fi ez que les parties en mouvement fonctionnent

correctement et qu'elles ne soient pas coincées, et contrôlez si des parties sont cassées ou

endommagées de telle sorte que le bon fonctionnement de l'appareil s'en trouve entravé. Faites

réparer les parties endommagées avant d'utiliser l'appareil. De nombreux accidents sont dus à

des outils électroportatifs mal entretenus.

f) Maintenez les outils de coupe aiguisés et

propres. Des outils soigneusement entretenus avec des bords tranchants bien aiguisés se

coincent moins souvent et peuvent être guidés plus

facilement.

g) Utilisez les outils électroportatifs, les acces-

soires, les outils à monter etc. conformément à

ces instructions et aux prescriptions en vigueur

pour ce type d'appareil. Tenez compte également

des conditions de travail et du travail à effectuer.

L'utilisation des outils électroportatifs à d'autres

fi ns que celles prévues peut entraîner des situations dangereuses.

h) Gardez les poignées dans un état sec, propre

et exempt d'huile et de graisse. Des poignées

glissantes ne permettent pas une prise en main

sûre et le contrôle de l'outil électrique dans des

situations inattendues.

5 SERVICE

a) Ne faites réparer votre outil électroportatif

que par un personnel qualifi é et seulement avec

des pièces de rechange d'origine. Ceci permet

d'assurer la sécurité de l'appareil.

13

Page 14

Consignes de sécurité spécifi ques

à la machine

Caracteristiques techniques

– Au cours du travail, des poussières nocives/

toxiques peuvent être générées (comme les

poussières de peintures au plomb ou certaines

poussières de bois ou de métal). Le contact ou

l'inhalation de ces poussières peut présenter

un danger pour l'utilisateur ou les personnes

se trouvant à proximité. Veuillez respecter les

prescriptions de sécurité en vigueur dans votre

pays. Raccordez l'outil électrique à un dispositif

d'aspiration adapté.

Pour votre santé, portez un masque de

protection respiratoire de classe P2.

Portez systématiquement des lunettes de

protection pour vous protéger des risques

inhérents au ponçage.

La poussière, un risque pour la

santé

Certaines poussières

créées par le ponçage mécanique, le sciage, le

meulage, le perçage et autres activités reliées

à la construction contiennent des substances

chimiques connues (dans l’État de la Californie)

comme pouvant causer le cancer, des anomalies

congénitales ou représenter d’autres dangers pour

la reproduction. Voici quelques exemples de telles

substances:

• plomb provenant de peintures à base de plomb,

• silice cristallisée utilisée dans les briques, le

ciment et autres matériaux de maçonnerie, et

• arsenic et chrome du bois d’œuvre traité avec

un produit chimique.

Le risque d’exposition à de tels produits varie

selon la fréquence à laquelle vous faites ce genre

de travail.

Pour réduire les risques d’exposition

à ces substances chimiques : travaillez dans un endroit adéquatement

ventilé et utilisez un équipement de

sécurité approuvé, tel que masques

antipoussières spécialement conçus

pour fi ltrer les particules microscopiques.

RS 2

Puissance absorbée W 3 3 0

Vitesse à vide tr/min 10 000

Nombre d'oscillations tr/min 20 0 00

Amplitude mm (in.) 2.4 (0.1)

Patin de ponçage mm(in.) 115 x 225 (4.53 x 8.86)

Poids kg (lbs) 2.5 (5.5)

Classe de protection

/ II

RS 2 E

Puissance absorbée W 3 3 0

Vitesse à vide tr/min 4 000 – 10 000

Nombre d'oscillations tr/min 8 000 – 20 000

Amplitude mm (in.) 2.4 (0.1)

Patin de ponçage mm(in.) 115 x 225 (4.53 x 8.86)

Poids kg (lbs) 2.5 (5.5)

Classe de protection

/ II

Symbole

Avertissement de danger

Lire les instructions / les remarques !

Porter des lunettes de protection

Débrancher la fi che secteu

V Volt

A Ampère

Hz Hertz

W Watt

~ Tension alternative

n

Vitesse de rotation à vide

0

Classe II conception

tr/min Tours par minute

POUR RÉDUIRE LE RISQUE

DE DOMMAGES, L'UTILISATEUR DOIT LIRE LE

MANUEL D'INSTRUCTION

14

Page 15

Utilisation conforme aux prescrip-

tions

Les ponceuses sont destinées à poncer le bois,

les matières plastiques, le métal, la pierre, les

matériaux composites, la peinture et la laque, le

mastic et des matériaux semblables.

Du matériau comportant de l’amiante ne doivent

pas être usinés.

Pour des raisons de sécurité électrique, les machines ne doivent pas être humides ni fonctionner

dans un environnement humide. Il ne faut utiliser

les machines que pour un ponçage sec.

En cas d’une utilisation

non conforme, la responsabilité des dommages

1.21.1

et accidents incombe à l’utilisateur.

2.1

Raccordement électrique et mise

en service

La tension du réseau électrique doit correspondre

à l’indication fi gurant sur la plaque signalétique!

Un commutateur (1.1) fait offi ce d’interrupteur

Marche/Arrêt. Pour une utilisation en continu, le

commutateur peut être bloqué en position Marche

par l’intermédiaire d’un bouton de verrouillage

latéral (1.2). En actionnant de nouveau le commutateur, le verrouillage est de nouveau libéré.

Electronique (RS 2 E)

La ponceuse RS 2 E possède un réglage lectronique permettant une variation progressive de la

vitesse de rotation. Ceci permet une adaptation

optimale de la vitesse du ponçage aux différents

matériaux.

La vitesse de rotation est réglée par la molette

(2.1). Les chiffres de la molette correspondent

approximativement aux nombres de courses ciaprès:

15

Page 16

3.1 3.2

3.33.4

Aspiration des poussières

L’aspiration de la poussière empêche des lourdes

charges de l’air environnant par des poussières

et des fortes salissures du lieu de travail.

Dispositif d’auto-aspiration

Les machines sont équipées en série d’un dispositif d’auto-aspiration. Placer le porte-fi ltre

(3.3) avec l’orifi ce jusqu’à l’arrêt sur le manchon

d’aspiration (3.4) de la machine et serrer à l’aide

du bouton tournant (3.1).

La poussière de ponçage est aspirée à travers

les orifi ces d’aspiration du patin de ponçage puis

collectée dans le fi ltre turbo (3.2). Lorsque le fi ltre

turbo est rempli de poussières, la performance

d’aspiration baisse et il faut le remplacer.

4.2

5.1

4.1

Aspiration extérieure à l’aide d’un

aspirateur

Afi n d’éviter d’avoir à remplacer souvent le fi ltre

turbo, on peut raccorder un aspirateur Festool à

la place du dispositif d’auto-aspiration. A cet effet,

il convient d’enfi cher le tuyau fl exible (Ø 27 mm

(4.1)) d’un appareil d’aspiration Festool sur la

tubulure d’aspiration de l’appareil (4.2).

Patins de ponçage spéciaux

Le patin de ponçage faisant partie du matériel

fourni d’origine STF 115 x 225 mm peut être

remplacé par le patin de ponçage 115 x 225 mm

destiné à des papiers de ponçage à tendre. Pour

cela, il faut dévisser les six vis de fi xation (5.1) au

moyen d’un tournevis.

Les deux patins de ponçage (avec et sans revêtement Stickfi x) sont également disponibles avec

un protecteur latéral de chants afi n de protéger

le plateau contre une détérioration prématurée

lors du ponçage de chants.

16

Page 17

Abrasifs

N’utilisez que des produits

abrasifs originaux Festool!

Abrasifs Stickfi x

Sur le patin de ponçage Stickfi x, on peut monter

de l’abrasif auto-adhésif tel que Stickfi x en papier

et en texture de Nylon. L’abrasif est simplement

posé sur le patin de ponçage et retiré après utilisation.

Veuillez observer ce qui suit: Utilisez uniquement des patins de ponçage dont le revêtement

adhérant Stickfi x n’est pas endommagé. Avant

l’utilisation, contrôlez si le revêtement Velcro n’a

pas été détérioré par une utilisation non conforme

(par exemple parties fondues).

6.1

Papiers de ponçage à tendre

Outre les abrasifs Stickfi x, Festool présente également des abrasifs non perforés. Le papier abrasif non perforé peut être perforé avec le gabarits

Festool «Lochfi x».

Commencez à tendre le papier abrasif au dos de

l’appareil en ouvrant le dispositif de fi xation en

rabattant le levier de serrage (6.1). Poussez le

papier abrasif jusqu’à la butée puis rabattez le

levier sur sa position d’origine. Déposez le papier

abrasif sur le patin de ponçage, tirez-Ie bien vers

l’avant puis tendez-Ie sur la partie avant.

Travailler avec la machine

Ne surchargez pas la

machine en appuyant trop fort! Vous obtiendrez

le meilleur résultat de ponçage avec une pression

d’application moyenne.

Le rendement et la qualité du ponçage dépendent

essentiellement de la sélection de l’abrasif adéquat. Festool propose l’abrasif approprié à chaque

cas d’utilisation (cf. le catalogue Festool).

17

Page 18

7.1

Traitement des métaux :

Lors du traitement des

métaux, il est indispensable de respecter les

mesures suivantes afin de travailler en toute

sécurité :

- un interrupteur de sécurité (FI) doit être monté

en amont,

- la machine doit être raccordée à un aspirateur

convenable,

- la machine doit régulièrement être nettoyée

pour éliminer les dépôts de poussières accumulées dans le corps du moteur.

Réglage de régime (RS 2 E)

Pour des machines électroniques nous pré-conisons les réglages ci-après de la molette (7.1):

5 – 6

- Ponçage à entraînement max.

- Ponçage d’anciennes peintures

- Ponçage de bois et de contreplacage avant

application du vernis

- Ponçage intermédiaire du vernis de surfaces

- Dérouillage sur surface avec texture Nylon

- Ponçage de tôle d’acier V2A avec texture Nylon

4 – 5

- Ponçage d’un enduit appliqué en fi ne couche

- Ponçage de bois à l’aide du non-tissé de ponçage

- Réalisation de chants sur des pièces en bois

- Lissage de surfaces en bois à enduit

3 – 4

- Ponçage de bordures en bois massif et contre-

plaquées

- Ponçage dans la rainure de fenêtres et de portes

- Ponçage intermédiaire du vernis de chants

- Ponçage de fenêtres en bois nature à l’aide du

non-tissé de ponçage

- Lissage de la surface en bois avant le décapage

à l’aide du non-tissé de ponçage

- Ponçage de surfaces décapées à l’aide du non-

tissé de ponçage

- Ponçage ou enlèvement de la pâte de chaux

superfl ue à l’aide du non-tissé de ponçage

2 – 3

- Ponçage intermédiaire de vernis de surfaces

décapées

- Nettoyage de rainures de fenêtres en bois à l’aide

18

Page 19

du non-tissé de ponçage

1 – 2

- Ponçage de chants décapés

- Ponçage de matières synthétiques thermoplastiques

Entretien et maintenance

Les travaux d’entretien et

de réparation nécessitant une ouverture du carter moteur (incluant le remplacement du câble

d'alimentation) ne doivent être effectués que

par le personnel d’un atelier autorisé du service

après-vente. La maintenance ou la réparation

de la machine par des personnes non autorisées

peut entraîner un branchement incorrect de

câbles électriques ou d’autres composants, ce

qui peut provoquer des accidents avec de graves

blessures.

Avant toute intervention

sur la machine il faut retirer la fi che de la prise

de courant!

La machine et ses ouïes de refroidissement doivent toujours rester propres.

Accessoires, outils

Pour des raisons de sécurité, il faut utiliser exclusivement des accessoires

et outils d’origine Festool!

Les références des accessoires et outils fi gurent

dans le catalogue Festool ou sur Internet sous

www.festoolusa.com.

8.1

Poignée supplémentaire

Au cas il serait nécessaire de poncer avec le bord

avant de la plaque de ponçage à proximité d’un

mur, il est possible de dévisser la poignée supplémentaire (8.1) en la tournant vers la gauche.

19

Page 20

9

Systainer

De nombreux produits Festool sont fournis dans

une caisse exclusive, appelée "Systainer". Celle-ci

permet de protéger et de ranger des outils et des

appareils complémentaires. Les Systainer sont

empilables et peuvent être solidarisés. En outre,

il se fi xent sur les aspirateurs CT Festool.

Pour ouvrir le Systainer:

A

B

9.1

connecter

ouvrir

T-loc

fermer

connecter

– Tournez le T-loc (9.1) à la position

.

Pour fermer le Systainer:

– Tournez le T-loc (9.1) à la position

.

Pour connecter deux Systainers:

– Placez un Systainer au dessus de l’autre

(Fig.9A).

– Tournez le T-loc (9.1) à la position

ou

(Fig.9B).

– Les Systainers sont combinés.

Un Systainer de la nouvelle génération peux

être attaché au dessus d’ un Systainer de

l’ancienne génération par les quatre loquets

de l’ancien Systainer.

Garantie

Festool offre une garantie restreinte de trois ans,

une des plus longues de l’industrie. La présente

garantie est valide à la condition préalable que

l’outil soit utilisé et exploité en conformité avec

les consignes d’utilisation de Festool. Festool

garantit que l’outil spécifi é sera exempt de vices

de matériel ou de malfaçon durant une période

de 3 ans à compter de la date d’achat.

Conditions de la garantie1 + 2

Tous les clients reçoivent une extension de garantie restreinte gratuite (1an+ 2ans= 3ans) pour

tous les outils électriques achetés auprès d’un

détaillant agréé. Festool est responsable de tous

les frais d’expédition durant la première année

de la garantie. Durant la deuxième et la troisième

année de la garantie, le client a la responsabilité

d’expédier l’outil à Festool. Festool paiera les frais

d’expédition de retour au client en utilisant le service terrestre d’UPS. Tout service de garantie est

20

Page 21

valide 3ans à compter de la date d’achat indiquée

sur votre reçu ou votre facture. La preuve d’achat

peut être exigée.

Sont exclus de la couverture au titre de la présente garantie: usure normale, dommage causé

par un usage impropre, un usage abusif ou de

la négligence ; dommage causé par toute autre

chose qu’un vice de matériel ou de malfaçon. La

présente garantie ne s’applique pas aux articles

accessoires tels que lames de scie plongeante,

forets de perceuse, forets de défonceuse, lames

de scie sauteuse, bandes abrasives et meules.

L’utilisation d’un outil à une tension ou fréquence

différente de la puissance nominale de l’outil

annule la garantie. L’annulation de garantie inclut

l’utilisation de l’outil avec un transformateur.

Festool ne tolère ni n’approuve aucune utilisation

d’accessoires ou de consommables d’ingénierie,

de conception et de fabrication autres que Festool sur des produits Festool. Toute utilisation

de produits autres que Festool peut affecter

le rendement de l’outil et annuler la garantie.

Festool ne peut être tenu responsable de tous

dommages ou pertes subis, l’utilisateur assumant

tous les risques et l’entière responsabilité liés à

l’utilisation de produits qui ne sont pas d’origine

Festool.Sont également exclues toutes les «

pièces d’usure » telles que les balais de carbone,

les lamelles de l’outillage pneumatique, les manchons et joints de caoutchouc, les disques abrasifs

et les patins de ponçage, ainsi que les vêtements

Festool (chapeaux et t-shirts).

Certains états américains et certaines provinces

canadiennes ne permettent pas de restrictions

quant à la durée d’une garantie implicite, de sorte

que la restriction qui précède peut ne pas s’appliquer à vous. La présente garantie vous confère

des droits légaux spécifi ques, et il se peut que

vous ayez d’autres droits variant d’un état à l’autre

aux É.-U. et d’une province à l’autre au Canada.

En dehors de toute garantie imposée par une loi

d’état ou une loi provinciale telle que restreinte

ci-dessus, la garantie restreinte qui précède

est exclusive et aux lieu et place de toute autre

garantie, engagement formel, entente et autre

obligation similaire de Festool. Festool ne fait

aucune autre garantie, expresse ou implicite,

à propos des outils électriques. La présente

garantie est valide uniquement pour les outils

achetés aux É.-U. et au Canada. Les régimes de

garantie d’autres pays peuvent varier pour les

cas de service obtenus en dehors des É.-U. et

du Canada.Certains pays peuvent exclure de la

garantie les produits achetés en dehors de leur

territoire. Festool se réserve le droit de refuser la

réparation de tout outil ne faisant pas partie de la

gamme de produits des É.-U. et du Canada. Aucun

agent, représentant, distributeur, concessionnaire

ou employé de Festool n’a l’autorité d’augmenter

ou d’autrement modifi er les obligations ou les

restrictions de la présente garantie.

Les obligations de Festool aux termes de la présente garantie se limitent, à sa seule discrétion, à

la réparation ou au remplacement ou au remboursement du prix d’achat de tout outil électrique

Festool portable jugé comme faisant montre

d’un vice de matériel ou de malfaçon durant la

période de la garantie. FESTOOL NE PEUT ÊTRE

TENU RESPONSABLE DE QUELQUE DOMMAGE

CONSÉCUTIF, ACCESSOIRE OU PARTICULIER

INDÉPENDAMMENT DU PRINCIPE DE DROIT SUR

LEQUEL SE FONDE LA DEMANDE. TOUTES LES

GARANTIES IMPLICITES AUX TERMES DE LA LOI

ÉTATIQUE, Y COMPRIS LES GARANTIES IMPLICITES DE QUALITÉ MARCHANDE ET D’ADAPTATION À UN USAGE PARTICULIER, SONT PAR

LES PRÉSENTES RESTREINTES À UNE DURÉE

DE TROIS ANS.

21

Page 22

Índice de contenidos

NORMAS DE SEGURIDAD .............................. 22

Indicaciones de seguridad generales .......... 22

Normas de seguridad específicas ............... 23

Datos técnicos .............................................. 24

Símbolos ....................................................... 24

Uso conforme a la destinación ..................... 25

Conexión eléctrica y puesta en servicio ....... 25

Electronic (RS 2 E) ....................................... 25

Aspiración .................................................... 25

Dispositivo autoaspirador ............................. 26

Dispositivo de aspiración externa, con

aspirador ....................................................... 26

Tacos esmeriladores ................................... 26

Materia abrasiva .......................................... 27

Materia abrasiva Stickfix .............................. 27

Papel abrasivo para tensar .......................... 27

Trabajo con la máquina................................. 27

Elaboración de metal: ................................... 28

Ajuste de la velocidad (RS 2 E) ...................... 28

Mantenimiento y conservación ..................... 29

Accesorios, herramientas ............................ 29

Asidero adicional .......................................... 29

Systainer ....................................................... 30

Garantiá ........................................................ 30

NORMAS DE SEGURIDAD

Indicaciones de seguridad genera-

les

¡ATENCIÓN! Lea íntegramente las instrucciones e indicaciones de seguridad. El

incumplimiento de dichas instrucciones e indicaciones puede dar lugar a descargas eléctricas,

incendios o lesiones graves.

Guardar todas las advertencias de peligro e

instrucciones para futuras consultas.

El término herramienta eléctrica empleado en

las siguientes advertencias de peligro se refi ere a

herramientas eléctricas de conexión a la red (con

cable de red) y a herramientas eléctricas accionadas por acumulador (o sea, sin cable de red).

1 PUESTO DE TRABAJO

a) Mantenga limpio y bien iluminado su puesto

de trabajo. El desorden y una iluminación defi -

ciente en las áreas de trabajo pueden provocar

accidentes.

b) No utilice la herramienta eléctrica en un en-

torno con peligro de explosión, en el que se encuentren combustibles líquidos, gases o material

en polvo. Las herramientas eléctricas producen

chispas que pueden llegar a infl amar los materiales en polvo o vapores.

c) Mantenga alejados a los niños y otras perso-

nas de su puesto de trabajo al emplear la herramienta eléctrica. Una distracción le puede hacer

perder el control sobre el aparato.

2 SEGURIDAD ELÉCTRICA

a) El enchufe del aparato debe corresponder a la

toma de corriente utilizada. No es admisible modifi car el enchufe en forma alguna. No emplear

adaptadores en aparatos dotados con una toma

de tierra. Los enchufes sin modifi car adecuados

a las respectivas tomas de corriente reducen el

riesgo de una descarga eléctrica.

b) Evite que su cuerpo toque partes conecta-

das a tierra como tuberías, radiadores, cocinas

y refrigeradores. El riesgo a quedar expuesto a

una sacudida eléctrica es mayor si su cuerpo tiene

contacto con tierra.

c) No exponga las herramientas eléctricas a la

lluvia y evite que penetren líquidos en su interior.

Existe el peligro de recibir una descarga eléctrica

si penetran ciertos líquidos en la herramienta eléctrica.

d) No utilice el cable de red para transportar o

colgar el aparato, ni tire de él para sacar el enchufe de la toma de corriente. Mantenga el cable

de red alejado del calor, aceite, esquinas cortantes o piezas móviles. Los cables de red dañados o

enredados pueden provocar una descarga eléctrica.

e) Al trabajar con la herramienta eléctrica en la

intemperie utilice solamente cables de prolongación homologados para su uso en exteriores. La

utilización de un cable de prolongación adecuado

para su uso en exteriores reduce el riesgo de una

descarga eléctrica.

f) Si fuese imprescindible utilizar la herramien-

ta eléctrica en un entorno húmedo, es necesario

conectarla a través de un fusible diferencial. La

aplicación de un fusible diferencial reduce el riesgo

a exponerse a una descarga eléctrica.

3 SEGURIDAD DE PERSONAS

a) Esté atento a lo que hace y emplee la herramienta eléctrica con prudencia. No utilice la

herramienta eléctrica si estuviese cansado, ni

22

Page 23

tampoco después de haber consumido alcohol,

drogas o medicamentos. El no estar atento du-

rante el uso de una herramienta eléctrica puede

provocarle serias lesiones.

b) Utilice un equipo de protección y en todo caso

unas gafas de protección. El riesgo a lesionarse se

reduce considerablemente si, dependiendo del tipo

y la aplicación de la herramienta eléctrica empleada, se utiliza un equipo de protección adecuado

como una mascarilla antipolvo, zapatos de seguridad con suela antideslizante, casco, o protectores

auditivos.

c) Evite una puesta en marcha fortuita del apa-

rato. Cerciorarse de que el aparato esté desconectado antes conectarlo a la toma de corriente.

Si transporta el aparato sujetándolo por el interruptor de conexión/desconexión, o si introduce

el enchufe en la toma de corriente con el aparato

conectado, ello puede dar lugar a un accidente.

d) Retire las herramientas de ajuste o llaves

fi jas antes de conectar la herramienta eléctrica.

Una herramienta o llave colocada en una pieza

rotante puede producir lesiones al ponerse a funcionar.

e) Sea precavido. Trabaje sobre una base fi rme

y mantenga el equilibrio en todo momento. Ello le

permitirá controlar mejor la herramienta eléctrica

en caso de presentarse una situación inesperada.

f) Utilice ropa adecuada. No utilice ropa ancha

ni objetos de joyería o bisutería. Mantenga el pelo

y la ropa alejada de las piezas en movimiento. La

ropa suelta o el pelo largo pueden quedar atrapados por piezas en movimiento.

g) Siempre que sea posible utilizar unos equipos

de aspiración o captación de polvo, asegúrese

que éstos estén montados y que sean utilizados

correctamente. El empleo de estos equipos reduce

los riesgos derivados del polvo.

h) No debe jamás confi arse por el uso frecuente

de las máquinas e ignorar los principios de seguridad de la herramienta. Un manejo imprudente

puede ocasionar lesiones graves en fracciones de

segundo.

4 TRATO Y USO CUIDADOSO DE HERRA-

MIENTAS ELÉCTRICAS

a) No sobrecargue el aparato. Use la herramienta prevista para el trabajo a realizar. Con la

herramienta adecuada podrá trabajar mejor y más

seguro dentro del margen de potencia indicado.

b) No utilice herramientas con un interruptor

defectuoso. Las herramientas que no se puedan

conectar o desconectar son peligrosas y deben

hacerse reparar.

c) Saque el enchufe de la red antes de realizar

un ajuste en el aparato, cambiar de accesorio o al

guardar el aparato. Esta medida preventiva reduce

el riesgo a conectar accidentalmente el aparato.

d) Guarde las herramientas fuera del alcance de

los niños y de las personas que no estén familiarizadas con su uso. Las herramientas utilizadas por

personas inexpertas son peligrosas.

e) Cuide sus aparatos con esmero. Controle si

funcionan correctamente, sin atascarse, las partes móviles del aparato, y si existen partes rotas

o deterioradas que pudieran afectar al funcionamiento de la herramienta. Si la herramienta eléctrica estuviese defectuosa haga repararla antes

de volver a utilizarla. Muchos de los accidentes se

deben a aparatos con un mantenimiento defi ciente.

f) Mantenga los útiles limpios y afi lados. Los

útiles mantenidos correctamente se dejan guiar y

controlar mejor.

g) Utilice herramientas eléctricas, accesorios,

útiles, etc. de acuerdo a estas instrucciones y en

la manera indicada específi camente para este

aparato. Considere en ello las condiciones de

trabajo y la tarea a realizar. El uso de herramien-

tas eléctricas para trabajos diferentes de aquellos

para los que han sido concebidas puede resultar

peligroso.

h) Mantenga las empuñaduras secas, limpias y

libres de aceite y grasa. Las empuñaduras resbaladizas no permiten una manipulación y un control

seguros de la herramienta eléctrica en situaciones

inesperadas.

5 SERVICIO

a) Únicamente haga reparar su herramienta

eléctrica por un profesional, empleando exclusivamente piezas de repuesto originales. Solamen-

te así se mantiene la seguridad de la herramienta

eléctrica.

Normas de seguridad específi cas

– Al trabajar puede generarse polvo perjudicial/

tóxico (p. ej., de pintura de plomo, algunos tipos

de madera y metal). El contacto o la inhalación

de este polvo puede suponer una amenaza para

la persona que realiza el trabajo o para aquellas

que se encuentren cerca. Observe las normativas de seguridad vigentes en su país. Conecte la

herramienta eléctrica a un equipo de aspiración

apropiado.

23

Page 24

Utilice por el bien de su salud una masca-

rilla de protección respiratoria con fi ltro

P2.

Ante el peligro que supone el lijado, lleve

siempre gafas de protección.

Riesgos para la salud producidos

por el polvo

Algunos polvos creados por

lijadoras motorizadas, aserraderos, trituradores,

perforadoras y otras actividades de construcción

contienen sustancias químicas que se sabe (en el

Estado de California) causan cáncer, defectos de

nacimiento u otros daños al sistema reproductivo.

Algunos ejemplos de estas sustancias químicas

son:

• Plomo de las pinturas con base de plomo

• Sílice cristalino de los ladrillos y cemento y

otros productos de mampostería, y

• Arsénico y cromo de madera tratada con sus-

tancias químicas

El riesgo de exposición a estas sustancias varía,

dependiendo de cuantas veces se hace este tipo

de trabajo.

Datos técnicos

RS 2

Potencia absorbida W 330

Velocidad sin carga rpm 10 000

Orbitas por minuto opm 20 000

Orbita de lijado mm (in.) 2.4 (0.1)

Plato de lijado mm(in.) 115 x 225 (4.53 x 8.86)

Peso kg (lbs) 2.5 (5.5)

Clase de protección

/ II

RS 2 E

Potencia absorbida W 330

Velocidad sin carga rpm 4 000 - 10 000

Orbitas por minuto opm 8 000 - 20 000

Orbita de lijado mm (in.) 2.4 (0.1)

Plato de lijado mm (in.) 115 x 225 (4.53 x 8.86)

Peso kg (lbs) 2.5 (5.5)

Clase de protección

/ II

Símbolos

Para reducir el contacto con estas

sustancias químicas: trabaje en un

área con buena ventilación y trabaje

con equipo de seguridad aprobado,

como mascarillas para el polvo diseñadas espe cí fi camente para fi ltrar

partículas microscópicas.

PARA REDUCIR EL RIESGO

DE LESIÓN, EL USUARIO DEBE LEER EL MAN

UAL DE INSTRUCCIÓN.

Aviso ante un peligro general

¡Leer las instrucciones e indicaciones!

Utilizar gafas de protección

Utilizar protección respiratoria

V voltios

A amperios

Hz hertzios

W vatios

~ rensión alterna

n

revoluciones por minuto en vacío

0

Clase II Construcción

rpm revoluciones por minuto

opm orbitas por minuto

24

Page 25

Uso conforme a la destinación

En cuanto a su determinación de uso, las lijadoras están previstas para el lijado de madera,

plástico, metal, piedra, materiales compuestos,

pintura / barniz, masilla de emplaste y materiales

similares.

Con este útil no se deben trabajar materiales que

contengan amianto.

A causa de la seguridad eléctrica, las máquinas no

deben ser operadas estando húmedas y tampoco

1.21.1

en un ambiente húmedo. Las máquinas solamente se deben emplear para un lijado en seco.

El usuario se responsa bilizará

en el caso de daños y accidentes durante un uso

no conforme a lo predeterminado.

Conexión eléctrica y puesta en

2.1

servicio

¡La tensión de red debe coincidir con la indicación

de tensión en la placa indicadora de potencia!

Un interruptor (1.1) sirve para activar y desactivar.

Para el servicio permanente se puede enclavar el

interruptor con el botón de fi jación lateral (1.2).

Volviendo a activar el interruptor se desenclava

la fi jación.

Electronic (RS 2 E)

Para elaborar las diferentes superfi cies es conveniente adaptar la velocidad de esmerilado al

material correspondiente.

Las cifras indicadas en el regulador del número

de revoluciones (2.1) corresponden aproximadamente a los valores de marcha en vacío siguientes:

Aspiración

El dispositivo de aspiración de polvo evita altas

cargas de polvo en el aire de trabajo y ensuciamientos considerables en el puesto de trabajo.

25

Page 26

Dispositivo autoaspirador

3.1 3.2

3.33.4

Las máquinas están equipadas como equipo de

serie con un dispositivo autoaspirador. Meter el

soporte del fi ltro (3.3) con la abertura hasta el

tope sobre la tubuladura de aspiración (3.4) de

la máquina y fi jarlo con el botón giratorio (3.1).

El polvo de lijado es aspirado por las aberturas

de aspiración que se encuentran en el plato de

lijado y es recogido en el turbofi ltro (3.2). Cuando

el turbofi ltro se ha llenado hasta el punto de que

se nota una merma de la capacidad de aspiración,

se deberá proceder a su cambio.

Dispositivo de aspiración externa,

4.2

con aspirador

A fi n de evitar un frecuente cambio del turbofi ltro

durante trabajos de lijado relativamente largos,

en lugar del dispositivo autoaspirador se puede

conectar un aspirador Festool. Para ello se coloca

el tubo fl exible (Ø 27 mm (4.1)) de un aparato de

aspiración Festool sobre la tubuladura de empalme del aparato de aspiración (4.2).

4.1

Tacos esmeriladores

El taco esmerilador de serie Stickfi x STF 115 x 225

mm puede ser sustituido por el taco esmerilador

115 x 225 mm para papeles tensados. Para ello

se requieren seis tornillos de sujeción (5.1) que

se fi jan con un destornillador de ranura.

Ambos tacos (con y sin capa de Stickfi x) también

están disponibles con protección de cantos lateral (KS) para evitar el deterioro prematuro de la

superfi cie esmeriladora al pulir cantos.

5.1

26

Page 27

Materia abrasiva

¡Emplee únicamente material

abrasivo original de Festool !

Materia abrasiva Stickfi x

En los tacos esmeriladores Stickfi x se pueden

fijar materiales abrasivos adherentes, como,

por ejemplo, papel abrasivo Stickfi x y la lámina

abrasiva. Las materias abrasivas simplemente se

colocan presionando sobre el taco esmerilador y,

tras su uso, se sacan inmediatamente.

Atención: Utilice Vd. sólo tacos esmeriladores con

capa adhesiva de Stickfi x que no esté deteriorada. Controle antes de su uso si la capa de motas

no ha tomado daño por causa de una utilización

adecuada (p. ej., confundición).

6.1

Papel abrasivo para tensar

Junto a las materias abrasivas Stickfi x Festool

ofrece también materias abrasivas no perforadas.

Papel abrasivo sin agujeros puede perforarse con

el perforador Festool ”Lochfi x”.

Comience tensando el papel en el lado posterior

del aparato tras abrir el dispositivo de fi jación

girando la palanca de tensión (6.1). Introduzca el

papel hasta el tope y vuelva a poner la palanca

en la posición inicial. Coloque el papel sobre el

taco, estírelo hasta delante hasta quedar tensado

y engánchelo aliado anterior.

Trabajo con la máquina

No sobrecargue la máquina

presionándola demasiado sobre el objeto a lijar.

Un resultado óptimo de lijado lo conseguirá trabajando con una presión de apriete moderada.

La capacidad y calidad de lijado dependen esencialmente de la elección del material abraviso

correcto. Festool ofrece material adhesivo apropiado para todo caso de aplicación (ver el catálogo

Festool).

Page 28

7.1

Elaboración de metal:

Por motivos de seguridad

deberán tomarse las medidas siguientes al elaborar metal:

- conexión previa de un interruptor protector de

corriente de defecto (FI),

- conexión de la máquina a un aparato de aspira-

ción adecuado,

- limpieza periódica en la máquina para eliminar

las aglomeraciones de polvo en el cárter del

motor.

Ajuste de la velocidad (RS 2 E)

Para máquinas con sistema electrónico recomendamos realizar los siguientes ajustes de la rueda

de ajuste (7.1):

5 - 6

- Lijado con accionamiento máximo

- Lijado de pinturas viejas

- Lijado de madera y de enchapados antes del

barnizado

- Lijado intermedio de barniz sobre superfi cies

- Quitar óxido de superfi cies con lámina esmeri-

ladora

- Pulir acero/chapa V2A con lámina esmeriladora

4 - 5

- Lijado de barnizado previo de aplicación fi na

- Lijado de madera con velo de lijar

- Redondeado de cantos en piezas de madera

- Alisado de superfi cies de madera con pintura

de imprimación

3 - 4

- Lijado de cantos de madera maciza y de madera

enchapada

- Lijado de encajes de ventanas y puertas

- Lijado intermedio de barniz en cantos

- Lijado inicial de ventanas de madera natural

con velo de lijado

- Alisado de la superfi cie de madera antes del

barnizado, empleando velo de lijado

- Frotado de superfi cies barnizadas empleando

velo de lijado

- Abrasión o desprendimiento de pasta de cal

sobrante empleando el velo de lijado

2 - 3

- Lijado intermedio de pinturas sobre superfi cies

28

Page 29

barnizadas (coloreadas con nogalina)

- Limpieza de encajes de ventanas de madera

natural con velo de lijado

1 - 2

- Lijado de cantos pintados/coloreados con nogalina

- Esmerilado de termoplásticos.

Mantenimiento y conservación

Todos los trabajos de mantenimiento y de reparación, para los que se tiene

que abrir la carcasa del motor (incluido el reemplazo del cable de red), sólo deben ser llevados a

cabo por un taller de servicio de asistencia técnica

autorizado. Un mantenimiento o reparación de la

máquina por personas no autorizadas puede ser

la causa de una conexión errónea de los cables

conductores de corriente eléctrica o de otros componentes, lo cual puede ser la causa de accidentes

con lesiones graves.

¡Desenchufar el enchufe de

la toma de corriente antes de realizar trabajos

en la máquina!

Mantener siempre limpias las ventanas de refrigeración.

Accesorios, herramientas

¡Por razones de seguridad,

solamente deben emplearse accesorios y herramientas originales de Festool!

Los números de pedido para los respectivos

accesorios y herramientas se encuentran en su

catálogo Festool o en la dirección de Internet

www.festoolusa.com.

8.1

Asidero adicional

Si hay que pulir/lijar hasta una posición cercana

a la pared por la parte delantera del aparato, se

puede desenroscar el asidero adicional girándolo

a la izquierda (8.1).

29

Page 30

9

Systainer

Muchos de los productos Festool se entregan en

un embalaje exclusivo denominado "Systainer"

que sirve de protección a la herramienta y sus

complementos, además de facilitar su almacenamiento. Los Systainer pueden apilarse y encajan

unos con otros. Además se adaptan sin problema

a cualquier aparato de aspiración CT de Festool.

Para abrir el Systainer:

– Gire el T-loc [9.1] a la posición

A

abrir

encajar

T-loc

cerrar

encajar

Para cerrar el Systainer:

– Gire el T-loc [9.1] a la posición

Para encajar dos Systainer:

– Ponga el Systainer sobre un otro (Fig. 9 A).

– Gire el T-loc [9.1] a la posición

.

.

o

(Fig.9B).

– Los Systainers estan encajados y cerrados.

Un Systainer de la nueva generación es enca-

jable encima de un Systainer de la generación

anterior con los cuatro enganches del Systainer

anterior.

9.1

B

Garantiá

Festool ofrece una garantía limitada de 3 años,

una de las más sólidas de la industria. Esta garantía será válida con la condición previa de que la herramienta se utilice conforme a las instrucciones

de funcionamiento de Festool. Festool garantiza

que la herramienta especifi cada no presentará

defectos de material o de acabado durante un

periodo de 3 años a partir de la fecha de compra.

Condiciones de la garantía 1+2

Al adquirir una herramienta eléctrica nueva de

Festool en un distribuidor autorizado, todos los

clientes recibirán de forma gratuita una garantía

limitada ampliada (1 año + 2 años = 3 años). Festool será responsable de todos los gastos de envío

durante el primer año de vigencia de la garantía.

Durante el segundo y tercer año, el cliente será

responsable del envío de la herramienta a Festool.

Festool pagará la devolución al cliente utilizando

el servicio UPS Ground. Todos los servicios de ga-

30

Page 31

rantía serán válidos durante 3 años a partir de la

fecha de compra que fi gura en el recibo o factura.

Puede que se precise una prueba de compra.

Quedan excluidos de la cobertura de la presente

garantía el desgaste normal, los daños ocasio-

nados por un uso indebido, abuso o negligencia;

los daños provocados por otra causa que no sea

un defecto de material o de acabado. La presente

garantía no es aplicable a elementos accesorios

tales como hojas de sierra circulares, brocas,

puntas de fresadora, hojas de calar, bandas lijadoras y ruedas de amolar.El hecho de utilizar

la herramienta a una tensión o una frecuencia

diferentes de los valores nominales anulará la

garantía. Esto incluye el uso de la herramienta

combinada con un transformador. Festool no

aprueba ni apoya el uso, con productos Festool, de

accesorios o consumibles que no hayan sido construidos, diseñados y fabricados por Festool.La

utilización de cualquier producto que no sea de

Festool puede afectar al rendimiento o anular la

garantía.Festool no se responsabilizará de ningún

daño o pérdida y el usuario asumirá los riesgos

y la responsabilidad por el uso de productos no

derivados de Festool.Se excluyen asimismo las

“piezas de desgaste” como, por ejemplo, cepillos

de carbón, láminas de herramientas neumáticas,

abrazaderas y juntas de caucho, platos lijadores y

artículos de ropa de Festool (gorras y camisetas).

Las obligaciones de Festool, según su propio

criterio y de acuerdo con la presente garantía, se

limitarán a la reparación, sustitución o reembolso

del precio de compra de cualquier herramienta

eléctrica portátil de Festool en la que se haya

detectado un defecto de material o de acabado

durante el periodo de garantía. FESTOOL NO

SERÁ RESPONSABLE DE NINGÚN DAÑO CONSECUENCIAL, INCIDENTAL O ESPECIAL, INDEPENDIENTEMENTE DEL FUNDAMENTO LEGAL

EN EL QUE SE BASE LA RECLAMACIÓN. TODAS

LAS GARANTÍAS IMPLÍCITAS DE ACUERDO CON

LA LEGISLACIÓN ESTATAL, INCLUIDAS LAS DE

COMERCIALIZACIÓN Y ADECUACIÓN PARA UN

FIN PARTICULAR, SE LIMITARÁN POR LA PRESENTE A UNA DURACIÓN DE TRES AÑOS.

En determinados estados de EE.UU. y provincias

de Canadá, las limitaciones de duración de una

garantía implícita no están permitidas, de modo

que es posible que la limitación anterior no sea

aplicable en su caso. La presente garantía le

otorga derechos legales específi cos; además, es

posible que goce de otros derechos que varíen

en los diferentes estados de EE.UU. y provincias

de Canadá.

A excepción de cualquier garantía implícita de

acuerdo con la legislación estatal o provincial y

limitada según lo expuesto anteriormente, la garantía limitada expresa precedente será exclusiva

y sustituirá a todas las demás garantías, acuerdos

y obligaciones similares de Festool. Festool no

concede ninguna otra garantía, ya sea expresa o

implícita, para sus herramientas eléctricas portátiles.Esta póliza de garantía únicamente será

válida para aquellas herramientas que se hayan

adquirido en EE.UU. y Canadá. Las pólizas de

garantía de otros países podrán diferir al acudir

al servicio de garantía fuera de EE.UU. y Canadá.Determinados países excluyen de la garantía

los productos adquiridos fuera de su territorio.

Festool se reserva el derecho de rechazar la reparación de cualquier herramienta que no forme

parte de la línea de productos de EE.UU./Canadá.

Ningún agente, representante, distribuidor, proveedor o empleado de Festool estará autorizado

a incrementar o modificar las obligaciones o

limitaciones estipuladas en la presente garantía.

31

Page 32

Loading...

Loading...