Page 1

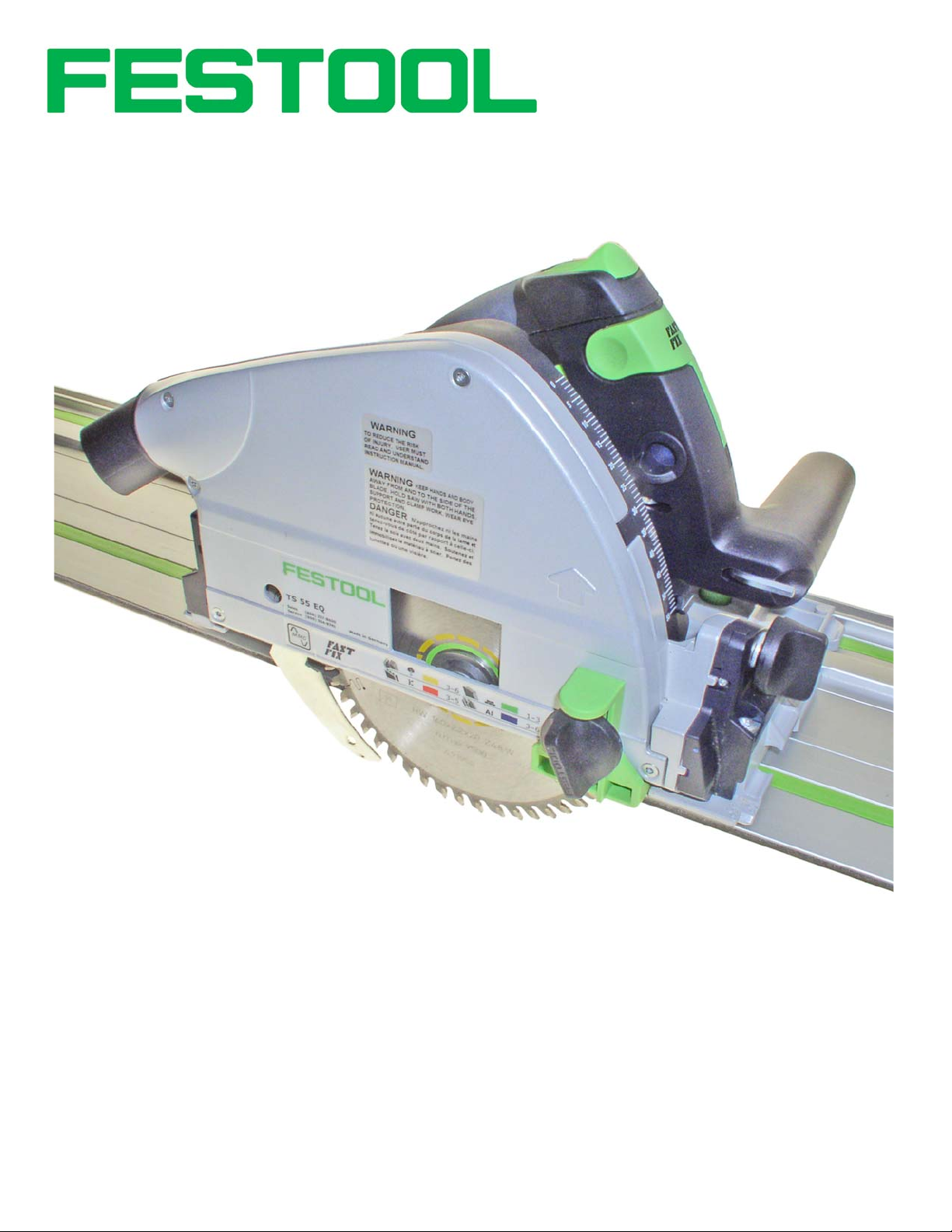

TS 55 EQ

Circular Saw Instruction Manual

Important: Read and understand all

instructions before using this tool.

Page 2

Warranty

Conditions of 1+2 Warranty

You are entitled to a free extended warranty (1 year + 2

years = 3 years) for your Festool power tool. Festool shall be

responsible for all shipping costs during the first year of the

warranty. During the second and third year of the warranty

Festool Limited Warranty

This warranty is valid on the pre-condition that the tool is

used and operated in compliance with the Festool operating

instructions. Festool warrants, only to the original consumer

purchaser, that the specified tool will be free from defects in

materials and workmanship for a term of one year from the

date of procurement. Festool makes no other warranty,

express or implied, for Festool portable power tools. No

agent, representative, distributor, dealer or employee of

Festool has the authority to increase or otherwise change the

obligations or limitations of this warranty. The obligations of

Festool in its sole discretion under this warranty shall be

limited to the repair or replacement of any Festool portable

power tool that is found to be defective as packaged with the

User Manual.

Excluded from coverage under this warranty are: normal

wear and tear; damages caused by misuse, abuse or neglect;

damage caused by anything other than defects in material

and workmanship. This warranty does not apply to

accessory items such as circular saw blades, drill bits, router

bits, jigsaw blades, sanding belts, and grinding wheels. Also

excluded are “wearing parts”, such as carbon brushes,

lamellas of air tools, rubber collars and seals, sanding discs

and pads, and batteries.

the customer is responsible for shipping the tool to Festool.

Festool will pay for return shipping to the customer using

UPS Ground Service. All warranty service is valid 3 years

from the date of purchase on your receipt or invoice.

Festool portable power tools requiring replacement or repair

are to be returned with the receipt of purchase to Festool

(call 800-554-8741 for address details).

IN NO EVENT SHALL FESTOOL BE LIABLE FOR ANY

CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR

BREACH OF THIS OR ANY OTHER WARRANTY,

EXPRESSED OR IMPLIED WHATSOEVER. ALL

WARRANTIES IMPLIED BY STATE LAW, INCLUDING

THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE, ARE

HEREBY LIMITED TO THE DURATION OF THREE

YEARS.

Some states in the U.S. and some Canadian provinces do not

allow the limitations on how long an implied warranty lasts,

so the above limitation may not apply to you. With the

exception of any warranties implied by state or province law

as hereby limited, the foregoing express limited warranty is

exclusive and in lieu of all other warranties, guarantees,

agreements and similar obligations of Festool. This warranty

gives you specific legal rights and you may also have other

rights which vary from state to state in the U.S., and

province to province in Canada.

Liability Statement

This product has been built to the high standards of Festool.

Please do not attempt to operate or repair this equipment

without adequate training. Any use, operation, or repair in

contravention of this document is at your own risk. By

acceptance of this system you hereby assume all liability

consequent to your use or misuse of this equipment. Festool

assumes no liability for incidental, special, or consequential

damage of any kind. Equipment specifications, applications,

and options are subject to change at the sole discretion of

Festool without notice.

Proprietary Notice

All drawings and information herein are the property of Festool, TTS Tooltechnic Systems AG & Co. KG. All unauthorized

use and reproduction is prohibited.

Written and Illustrated by Rick Christopherson.

© 2006 TTS Tooltechnic Systems AG & Co. KG

All rights reserved. Printed in the United States of America and Germany.

Festool is a trademark and service mark of TTS Tooltechnic Systems AG & Co. KG

www.festoolusa.com

2 TS 55 EQ Circular Saw

Page 3

Contents

Warranty ..............................................................................2

Conditions of 1+2 Warranty .........................................2

Festool Limited Warranty .............................................2

Liability Statement .........................................................2

Proprietary Notice..........................................................2

General Safety Rules...........................................................4

Work Area Safety .......................................................4

Electrical Safety ..........................................................4

Extension Cords .........................................................4

Personal Safety ...........................................................4

Tool Use and Care......................................................4

Service..........................................................................5

Specific Safety Rules for Circular Saws.......................5

Causes and Prevention of Kickback ........................5

Respiratory Exposure Warning................................5

Tool Description..................................................................6

Technical Specifications.................................................6

Intended Use ...................................................................7

Single-Point Entry ..........................................................7

Setup and Adjustments......................................................7

Setting up a New Saw....................................................7

Adjusting the Guide Rail Gib Cams ............................8

Trimming the Guide Rail Splinter Guard ...................8

Trimming the Outrigger Splinter Guard ....................9

Replacing and Adjusting the Riving Knife.................9

Changing the Sawblade...............................................10

Setting the Blade Perpendicular to the Sole Plate....11

Adjusting the 45º Bevel Stop.......................................12

Matching the TS 55 to an Existing Guide Rail..........12

Operation ...........................................................................13

Setting the Blade Depth...............................................13

Setting the Motor Speed ..............................................13

Turning On the Saw.....................................................14

Using the Outrigger Splinter Guard..........................14

Setting the Bevel Angle ...............................................15

Using the Guide Stop...................................................15

Using Dust Extraction..................................................16

Applications ......................................................................17

Straight-Lining Rough Lumber.................................. 17

Crosscutting and Trimming........................................18

Plunge Cutting.............................................................. 19

Cutting Non-Wood Materials..................................... 20

Soft Plastics ...............................................................20

Brittle Plastics ...........................................................20

Thin Aluminum........................................................20

Extruded Aluminum ...............................................20

Accessories.........................................................................21

Sawblades......................................................................21

Guide Rails ....................................................................22

Dust Cover ....................................................................22

Guide Rail Accessory Kit.............................................22

Rip Fence (Parallel Guide) ..........................................22

Systainer (System Container) .....................................23

Troubleshooting................................................................24

Maintenance ......................................................................25

Routine Maintenance................................................... 25

Replacing the Guide Rail Gib Cams ..........................26

Replacing the Guide Rail Splinter Guard .................26

Changing the Motor Brushes...................................... 27

Instruction Manual 3

Page 4

General Safety Rules

WARNING: Read and understand all instructions listed below.

Failure to heed instructions may result in personal injury,

electrocution, or fire hazard.

Work Area Safety

► Keep your work area clean and well lit. Cluttered benches and

dark areas invite accidents.

► Do not operate power tools in explosive atmospheres, such as

in the presence of flammable liquids, gases, or dust. Power

tools create sparks which may ignite the dust or fumes.

Electrical Safety

► Double insulated tools are equipped with a polarized plug

(one blade is wider than the other). This plug will fit in a

polarized outlet only one way. If the plug does not fit fully into

the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install a polarized outlet. Do not change

the plug in any way. Double insulation eliminates the need for

the three wire grounded power cord.

Extension Cords

All due care should be practiced while using extension cords with

this tool.

► When operating a power tool outside, use an outdoor extension

cord marked “W-A” or “W”. These cords are rated for outdoor

use and reduce the risk of electric shock.

► Never use an extension cord that is damaged, such as cuts,

exposed wires, or bent/missing prongs.

► Use only extension cords rated for the purpose.

Personal Safety

► Stay alert, watch what you are doing, and use common sense

when operating a power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or medication. A moment

of inattention while operating power tools may result in serious

personal injury.

► Dress properly. Do not wear loose clothing or jewelry. Contain

long hair. Keep your hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry, or long hair can be caught

in moving parts.

► Avoid accidental starting. Be sure the switch is off before

plugging in the power cord. Carrying tools with your finger on

Tool Use and Care

► Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or

against your body is unstable and may lead to loss of control.

► Do not force the tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for

which it is designed.

► Do not use the tool if the switch does not turn it on or off. Any

tool that cannot be controlled with the switch is dangerous and

must be repaired.

► Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such

preventive safety measures reduce the risk of starting the tool

accidentally.

Save These Instructions

► Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control.

► Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of

electric shock if your body is grounded.

► Do not expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

► Do not abuse the cord. Never use the cord to carry the tools or

pull the plug from an outlet. Keep cord away from heat, oil,

sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

► Use only extension cords rated for the amperage of this tool

and the length of the cord. Using too small of an extension cord

can cause the router to lose power and damage the tool.

Extension Cord Ratings

Cord Length Size (AWG)

<50 Ft. 14

50-100 Ft. 12

100-150 Ft. 10

>150 Ft. Not recommended

the switch or plugging in tools that have the switch on invites

accidents.

► Remove adjusting keys or wrenches before turning the tool on.

A wrench or a key that is left attached to a rotating part of the

tool may result in personal injury.

► Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance enables better control of the tool in

unexpected situations.

► Use safety equipment. Always wear eye protection. Dust mask,

non-skid safety shoes, hard hat, or hearing protection must be

used for appropriate conditions. (Ordinary glasses are NOT

proper eye protection.)

► Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

► Maintain tools with care. Keep cutting tools sharp and clean.

Properly maintained tools with sharp cutting edges are less likely

to bind and are easier to control.

► Check for misalignment or binding of moving parts, breakage

of parts, and any other condition that may affect the tool's

operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

► Use only accessories that are recommended by the

manufacturer for your model. Accessories that may be suitable

for one tool may become hazardous when used on another tool.

4 TS 55 EQ Circular Saw

Page 5

Service

► Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

► When servicing a tool, use only identical replacement parts.

Specific Safety Rules for Circular Saws

!WARNING: Risk of personal injury.

► Keep hands away from the blade and cutting area. Keep your

second hand on the auxiliary handle. If both hands are holding

the saw, they cannot be cut by the blade.

► Keep your body positioned to either side of the saw blade, but

not in line with the saw blade. Kickback could cause the saw to

jump backward. (See “Causes and Prevention of Kickback”

below.)

► Do not reach underneath the workpiece. The blade is fully

exposed under the workpiece.

► Never use a dust extraction system when making cuts that can

result in sparks, such as cutting through nails and other ferrous

materials. Sparks and hot embers can cause a fire or explosion in

the dust extraction system.

Causes and Prevention of Kickback

Kickback is a sudden reaction to a pinched, bound, or misaligned saw

blade that causes an uncontrolled saw to lift up and out of the workpiece

toward the operator.

When the blade is pinched or bound tightly by the kerf closing down, the

blade stalls and the motor reaction drives the unit rapidly back toward

the operator.

If the blade becomes twisted or misaligned in the cut, the teeth at the

back edge of the blade can dig into the top surface of the wood, causing

the blade to climb out of the kerf and jump back toward the operator.

Kickback is the result of incorrect operating procedures or conditions

and can be avoided by taking proper precautions as described below:

► Never hold the piece being cut in your hands or across your

► Hold the saw by the insulated handles when performing an

► When ripping, always use a rip fence or straight edge guide.

► Always use blades with the correct size and shape arbor holes.

► Never use damaged or incorrect blade flanges or bolt. The blade

Use of unauthorized parts or failure to follow maintenance

instructions may create a risk of electric shock or injury.

leg. It is important to support the work properly to minimize

body exposure, blade binding, or loss of control.

operation in which the sawblade may contact hidden wiring or

its own cord. Contact with a “live” wire will make the exposed

metal parts of the tool “live” and shock the operator.

This improves the accuracy of cut and reduces the chance for

blade binding.

Blades that do not match the mounting hardware of the saw will

run eccentrically, causing loss of control.

flanges and bolt were specially designed for your saw for

optimum performance and safety of operation.

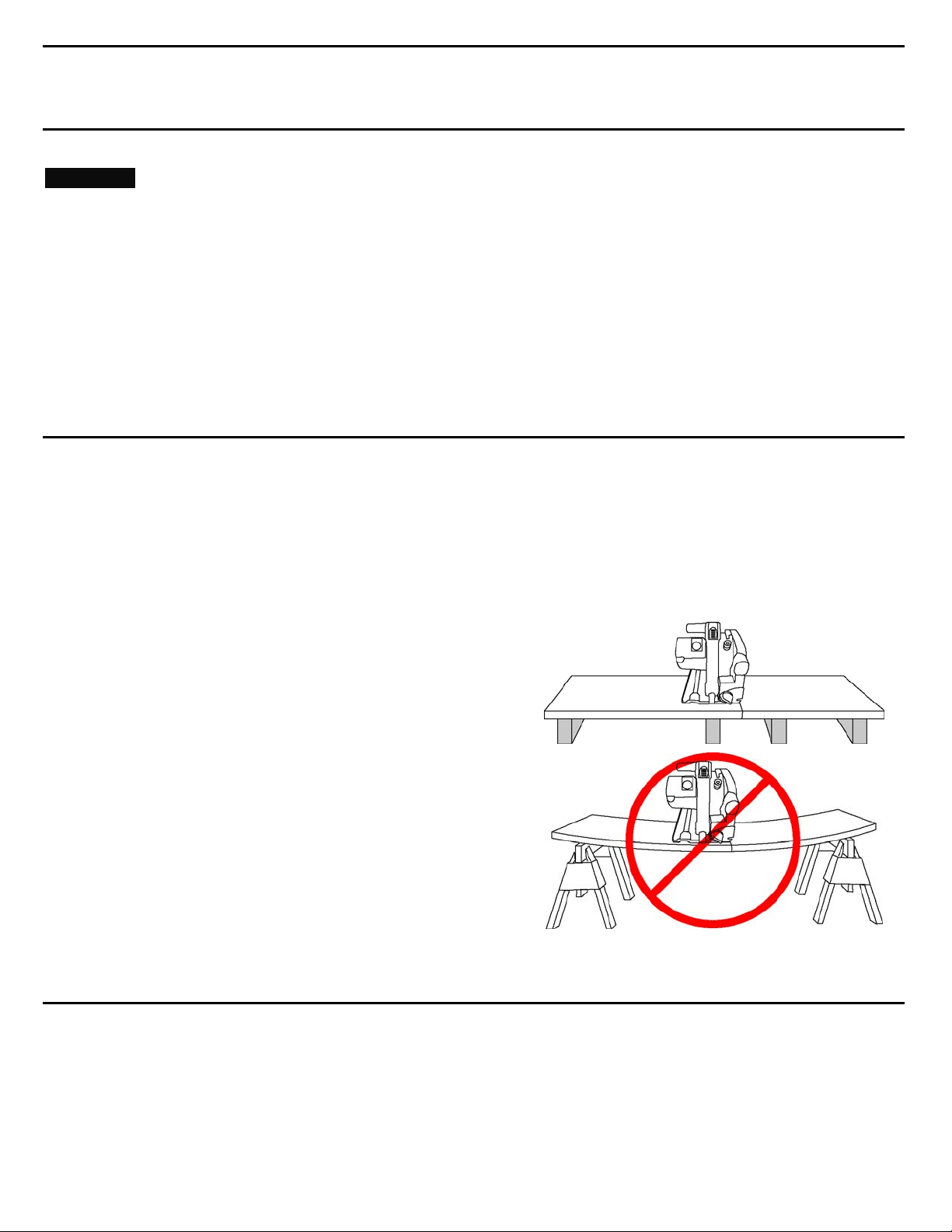

Supports must be placed under the panel on both sides,

near the line of cut and near the edge of the panel as

shown.

► The bevel adjusting knobs must be fully tightened before

making a cut. If the blade tilts during a cut, it will bind and

cause a kickback.

► Use extra caution when making a plunge cut into existing

walls or other blind areas. The protruding blade may cut

objects that can cause kickback.

► Maintain a firm grip with both hands on the saw and position your

body and arm to allow you to resist kickback forces. Kickback forces

can be controlled by the operator if proper precautions are taken.

► If the blade is binding or when interrupting a cut for any reason,

release the trigger and hold the saw motionless in the material until

the blade comes to a complete stop. Never attempt to remove the saw

from the work or pull the saw backward while the blade is in motion,

or kickback may occur. Investigate and take corrective actions to

eliminate the cause of blade binding.

► When restarting a saw in the workpiece, center the saw blade in the

kerf and check that the saw teeth are not engaging the material. If the

saw blade is binding during a restart, it may climb up or kickback from

the workpiece.

► Do not use a dull or damaged blade. Dull or improperly sharpened

blades cause excessive friction, blade binding, and kickback.

► Support large panels to minimize the risk of the blade pinching and

causing a kickback. Large panels tend to sag under their own weight.

Respiratory Exposure Warning

Various dust created by power sanding, sawing, grinding, drilling

and other construction activities contains chemicals known (to the

State of California) to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

► lead from lead-based paints,

► crystalline silica from bricks, cement, and other masonry

products,

► arsenic and chromium from chemically-treated lumber.

The risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety

equipment, such as dust masks that are specially designed to filter

out microscopic particles.

Instruction Manual 5

Page 6

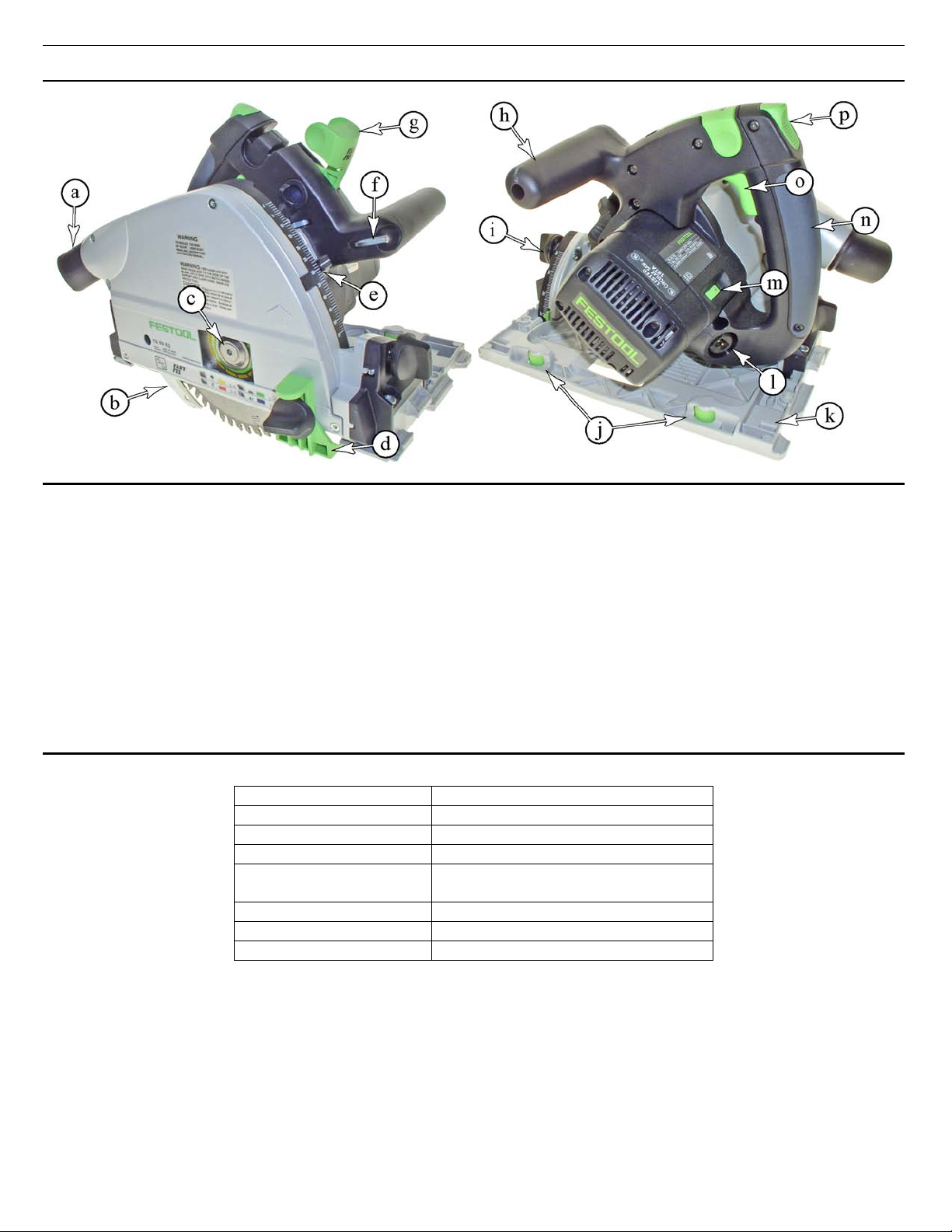

Tool Description

Figures 1a and 1b

a. Dust Collection Port.

b. Spring Loaded Riving Knife.

c. Arbor Bolt.

d. Outrigger Splinter Guard.

e. Depth Stop and Gauge.

f. Blade Wrench Storage.

g. FastFix Arbor/Plunge Lock.

h. Auxiliary Handle.

Technical Specifications

Power Consumption 1200 Watts (10 amps @ 120 volts)

Speed Range 2,000 to 5,200 RPM (no load)

Blade Diameter 160 mm

Arbor Diameter 20 mm/Round

Depth of Cut (without

guide rail)

Bevel Angle 0º to 45º

Weight 4.5 kg (9.9 lbs)

Certifications UL745, CSA C22.2/745

i. Bevel Gauge and Lock Knob.

j. Guide Rail Gib Cams.

k. Sole Plate.

l. Plug-it Power Cord Port.

m. Speed Control.

n. Main Handle.

o. Trigger (On/Off Switch).

p. Plunge Release and Trigger Safety Release.

55 mm (2.2") @ 90º/43 mm (1.7") @ 45º

All metric dimensions are binding. Sawblade dimensions are critical for safe

operation, and are presented in metric units only.

The TS 55 has several features to protect the motor from

misuse.

► The TS 55 has thermal overload protection. If the motor

overheats from extended heavy use, the electronic

controller will shut down the motor until it cools down.

This is to protect the motor from permanent damage.

Once the thermal overload has activated, simply wait a

few minutes for the motor to cool down before resuming

operation. The thermal overload resets automatically

when the temperature returns to normal.

► The TS 55 also has over-current protection. If the electrical

current to the motor exceeds the safe limit (such as what

happens with a pinched blade), the motor is temporarily

disabled to protect itself. The motor is automatically reset

when the power trigger is released.

6 TS 55 EQ Circular Saw

Page 7

Intended Use

The TS 55 EQ, hand-operated circular saw, is designed exclusively for sawing of wood, wood-like materials, and plastics.

The saw may also be used for cutting aluminum when a Festool aluminum-cutting sawblade is installed. The tool should not

be altered or used for any other purpose, other than as specified in these operating instructions. Using the tool in

contravention to this manual will void your warrantee and may lead to injury. The user shall be responsible and liable for

damages and accidents resulting from misuse or abuse of this saw.

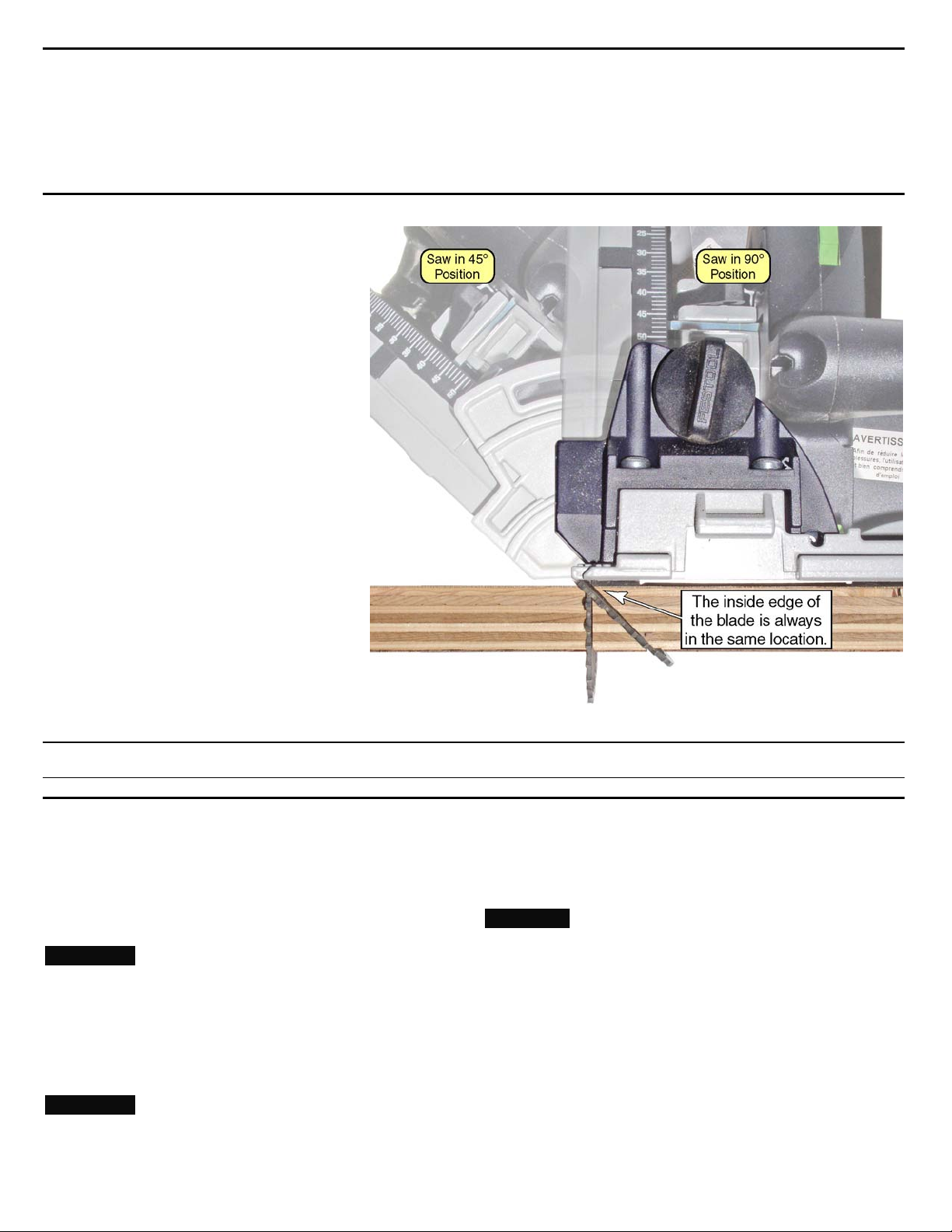

Single-Point Entry

Single point entry means that the sawblade

always enters the cut at the same location

regardless what the bevel angle is set to. The

pivot point of the bevel adjustment is

located at the bottom edge of the splinter

guard. This means that the cut will always

be along the splinter guard for any bevel

setting.

(Note that this is applicable only when the

guide rail is used. When the guide rail is not

under the saw, the bevel cut will move

slightly outward, away from the main body

of the saw.)

Setup and Adjustments

Setting up a New Saw

There are some simple setup procedures to follow before a

new saw can be used. Follow this sequence of inspections

and adjustments before using the saw for the first time. It is

important that these instructions be followed sequentially

before cutting the zero-clearance splinter guards.

!WARNING: Always disconnect the saw from the power

supply before making any adjustments to the saw or

installing or removing any accessory!

1. With the saw unplugged, inspect the blade for damage

and make sure it is properly secured to the arbor. (Refer

to "Changing the Sawblade" on page 10 for more

information).

!WARNING: Check regularly whether the saw blade is in

good condition. Saw blades which are cracked,

damaged, or deformed should no longer be used.

2. The riving knife is installed and adjusted at the factory,

however, you should verify that it is properly secured

and adjusted (refer to page 9 for more information).

!CAUTION: The riving knife is a safety feature of the saw to

prevent binding in the cut. All saw work should be

carried out only with the riving knife installed and

correctly set!

3. Install the power cord into the [Plug It] receptacle on the

saw (refer to page 14 for more information).

4. Perform the guide rail gib cam adjustment procedure

described on page 8.

5. After completing all of the inspections and adjustments

listed above, cut the zero-clearance splinter guards as

described on page 8.

Instruction Manual 7

Page 8

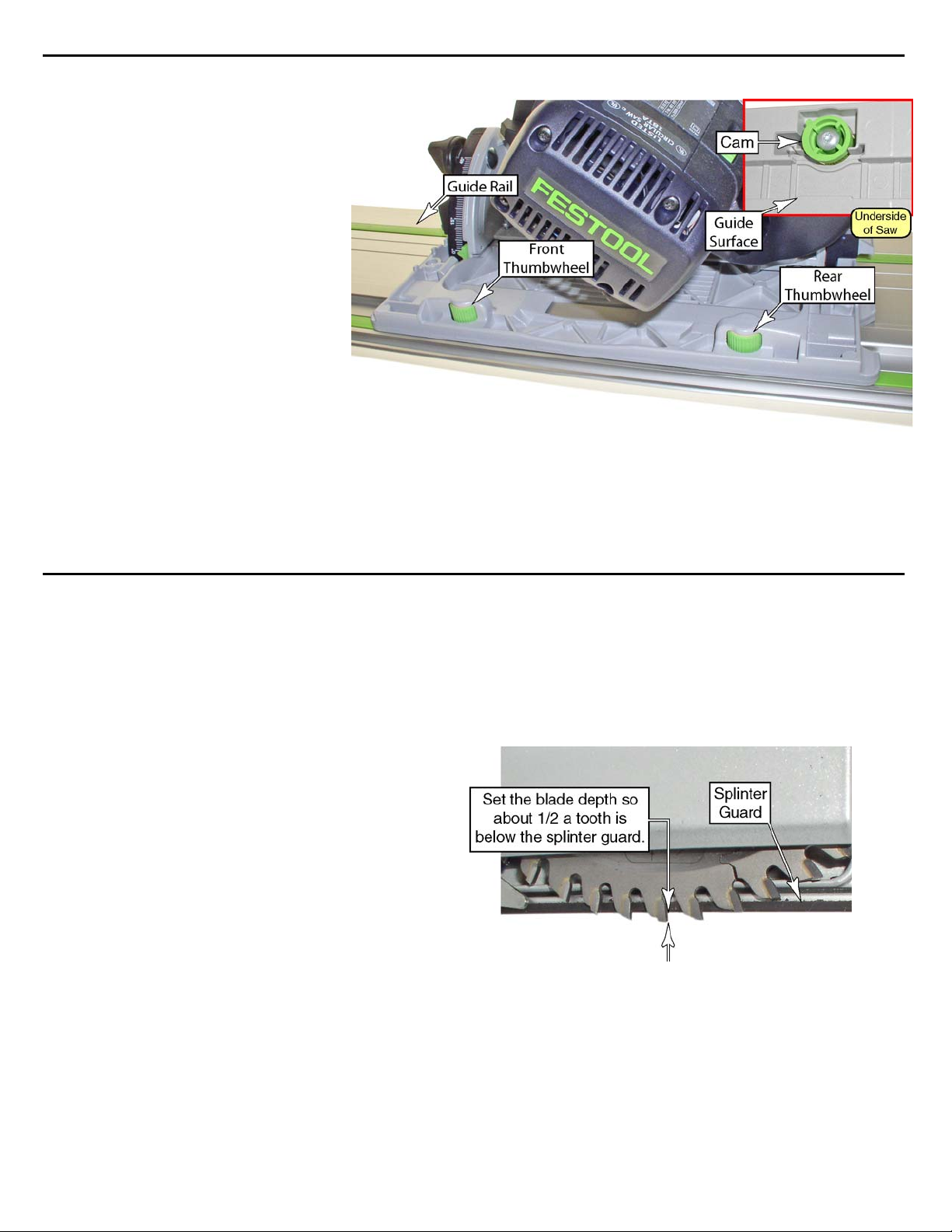

Adjusting the Guide Rail Gib Cams

The guide rail gib cams tighten against the rib of the guide

rail to remove any side-play from the saw during a cut.

Thumbwheels on the top of the cams permit easy

adjustment.

1. Place the saw on the guide rail.

2. Loosen both cams by rotating the

thumbwheels counterclockwise.

3. Working with one cam at a time, jiggle

the saw side-to-side while turning the

cam clockwise until the saw fits

snugly to the rail.

4. Repeat for the second cam.

5. Make sure the cams are not over

tightened by sliding the saw down the

guide rail. If the saw does not slide

easily, loosen the cams.

Notes:

► The cams do not need to be very tight for normal

operations. A tiny amount of side-play will not impact the

quality of a cut.

Trimming the Guide Rail Splinter Guard

The leading edge of the guide rail has a replaceable,

rubber, zero-clearance strip. The first time the saw is used

with the guide rail, this strip is trimmed to match the

sawblade. When trimmed to size, this strip reduces

chipping and tearout during normal cutting.

If you have more than one saw that uses the same

guide rail system, you want all of the tools to have

the same cutting path. Before cutting the splinter

guard, use the "Matching the TS 55 to an Existin

Guide Rail" procedure desc

match one tool to another.

1. at

Set the blade depth very shallow (6 to 7 mm) so th

the blade teeth pen

tooth, as shown.

etrate the strip by about half a

ribed on page 12 to

g

► The cam action of the gibs allows for a large force to be

applied to the gibs from a small amount of turning of the

thumbwheel.

► Over tightening the cams or operating the saw in abrasive

environments can cause premature wear. Periodically

inspect the cams for flat spots, and replace if necessary.

3. Place the guide rail on a stable surface with the strip

hanging over the edge so you don’t cut the table.

4. If necessary, adjust the guide rail gib cams as described on

page 8.

5. Cut the strip in a single, smooth, low-speed rip from one

end of the guide rail to the other.

2. Set the motor speed to its lowest setting (setting 1).

8 TS 55 EQ Circular Saw

Page 9

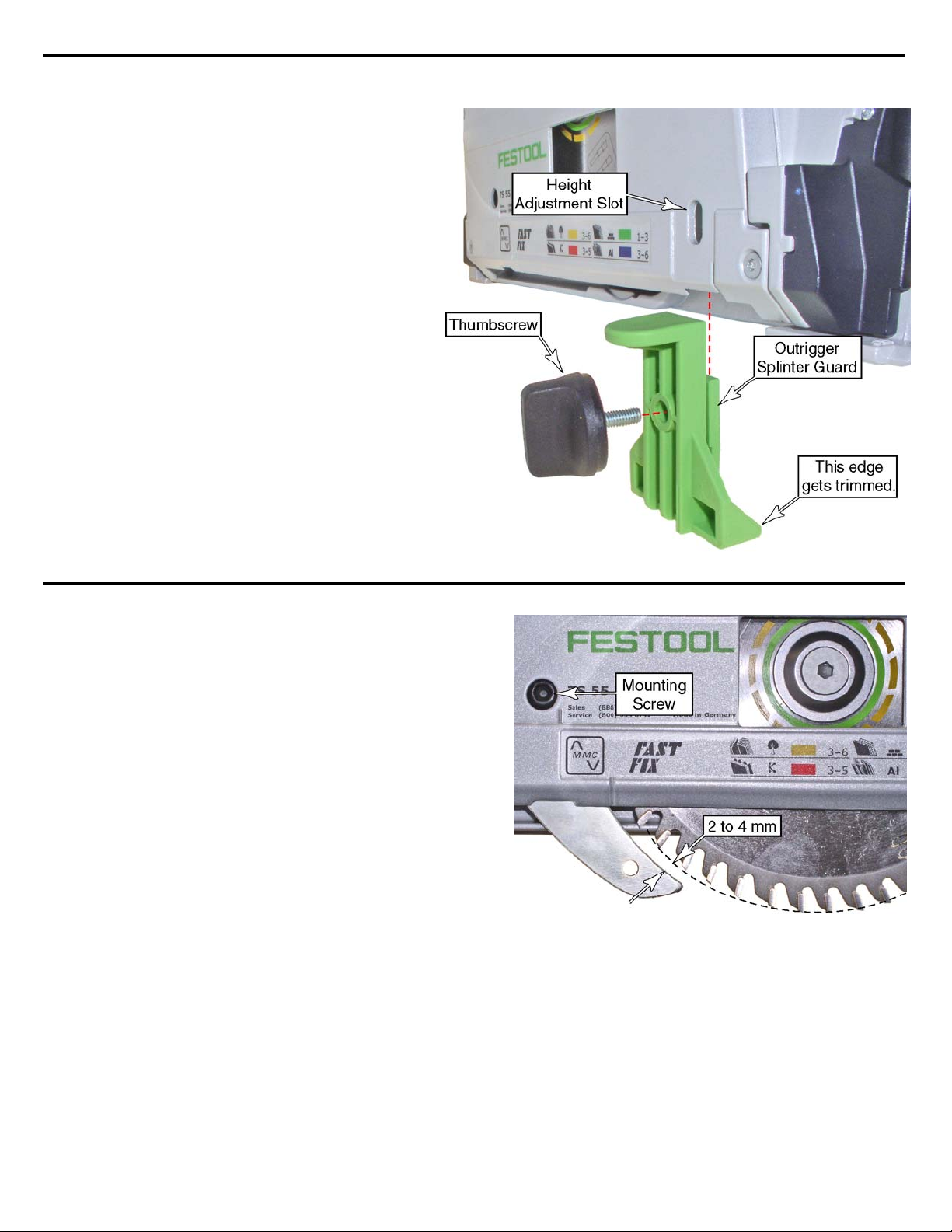

Trimming the Outrigger Splinter Guard

The outrigger splinter guard is used to prevent chipping on

the offcut side of the sawblade. The outrigger can be

retracted away from the workpiece when not needed.

Before the outrigger splinter guard is used for the first

time, it needs to be trimmed to fit the sawblade.

1. Remove the thumbscrew from the outrigger and

slide the outrigger on to the front edge of the blade

guard as shown.

2. Insert the thumbscrew through the outrigger,

through the height adjustment slot, and into the

captive nut on the back side of the outrigger.

3. Raise the outrigger to its top position and tighten

the thumbscrew.

4. Place the saw on a stable surface so that the blade

can be plunged down without cutting the surface

(or use a piece of scrap wood).

5. Set the motor speed to its lowest setting (setting 1).

6. Start the saw and slowly plunge the blade to full

depth.

Replacing and Adjusting the Riving Knife

Periodically inspect the riving knife to ensure it is not bent and

has proper clearance away from the blade. Replace if bent.

1. Unplug the saw for safety.

2. Raise the FastFix latch lever and plunge the saw until it locks

into position (see page 10 for more information on the

FastFix lever).

3. Using the arbor wrench (stored in the auxiliary handle)

loosen the riving knife mounting screw.

4. If the riving knife needs replacement, slide it out of its

mounting, and slide a new knife back in.

5. Raise or lower the riving knife so there is a 2 to 4 mm (3/32

to 5/32 inch) clearance between the knife and the blade.

6. Retighten the mounting screw.

Instruction Manual 9

Page 10

Changing the Sawblade

The TS 55 saw features the FastFix system for easier blade

changing. The FastFix system is engaged by raising the

FastFix latch lever and plunging the saw down. The

system includes the following features:

► For safety, the power switch is locked out.

► The plunge depth is locked in the position shown to the

right with the arbor bolt accessible through an opening

in the blade cover.

► The arbor is locked from turning.

► The riving knife mounting screw is accessible through

an opening in the blade cover.

Sawblade Checks and Warnings

► Use only sawblades that are approved for use with the

saw and appropriate for the type of material being cut.

► Use only sawblades with a diameter of 160 mm, and an

arbor bore of 20 mm.

► Do not use a sawblade that is bent or warped.

► Do not use a sawblade with missing or damaged teeth.

Removing the Sawblade

1. Unplug the saw for safety.

2. Although not required, you may wish to remove the

outrigger splinter guard for better clearance.

3. Raise the FastFix latch lever.

4. Press upward on the plunge lock release button and

plunge the saw down until it locks into position.

5. Using the arbor wrench (stored in the auxiliary handle)

loosen the arbor bolt by turning it counterclockwise.

6. Remove the arbor bolt and washer.

7. Retract the riving knife out of the way and remove the

blade from the saw.

Replacing the Sawblade

1. While retracting the riving knife, insert the blade into the

saw and over the arbor flange. Make sure the blade's teeth

are facing forward in the direction shown above.

2. Place the arbor washer over the arbor flange and rotate it

until the alignment keys engage with the arbor flange.

3. Replace the arbor bolt and tighten it firmly.

4. While pressing down on the auxiliary handle, lower the

FastFix latch, and slowly release the plunge.

10 TS 55 EQ Circular Saw

Page 11

Setting the Blade Perpendicular to the Sole Plate

This adjustment ensures that cuts are made square to the

workpiece surface. This adjustment is completed at the

factory and shouldn’t need to be adjusted unless the tool has

been modified or serviced.

The most accurate method for checking the square of the

blade is to make a cut with the saw and examine the

resulting cut.

For even greater accuracy, the procedure below uses a

method that amplifies a small measurement into a larger

measurement to make it easier to observe. This doubles the

accuracy of the adjustment.

Adjustment Procedure

1. Using the guide rail, carefully cut a small piece of wood

in half.

► This is a precision adjustment. Make sure the guide rail

and workpiece are securely clamped.

► The piece should be at least ¾ inch thick by 12 inches

square.

► The thicker the piece, the more accurate the adjustment

will be.

► For best results, the material should have a consistent

center, such as Medium Density Fiberboard (MDF),

plastic, or solid lumber.

2. Place the two pieces back together to verify that the

original cut-line is tight (Figure A). If the cut-line is not

tight, make a new cut.

3. Flip the offcut board end-for-end so the cut-line is still

together but the board is upside down. (Don't flip the

board that was under the saw.)

4. Inspect the joint between the two boards:

► If there is no gap then the adjustment is correct.

► If the gap is at the top of the two boards (Figure B), then

turn the adjustment screws clockwise.

► If the gap is at the bottom of the two

boards (Figure C), then turn the

adjustment screws counterclockwise.

5. Loosen the front and rear bevel lock

knobs (see image to the right).

6. Turn the two stop screws in the direction determined in

step 4. (Make sure to turn both screws the same

amount.) Each turn of the adjustment screw will have

the following effect:

► 1 turn equals 1 degree of adjustment.

► 1 turn equals ½ mm of gap between the boards shown

above (assuming ¾ inch thick boards).

7. Verify the adjustment setting by repeating steps 1

through 4.

Instruction Manual 11

Page 12

Adjusting the 45º Bevel Stop

The bevel setting has a positive stop at 45º and is

adjustable for accuracy. In most cases, the bevel

stop should be set for 45º, however, some users

may prefer to have the stop set slightly larger than

45º for tighter miter corners.

The most accurate method for measuring a 45º

angle is to make a box as shown. Any error in the

angle will be compounded with each cut made.

1. Take a piece of scrap wood and bevel both

sides (double-sided bevel, as shown to the

right).

► Make sure the cuts are parallel.

► The size of the wood is not critical, but should

be at least ¾ inch thick and about 5 inches

wide by 16 to 20 inches long.

2. Cut the piece of wood into 4 equal parts as

shown in the top image to the right.

3. Put the four pieces together to form a box.

4. Examine the gaps in the corners of the box:

► Gaps at the outside corners indicate the bevel

angle is less than 45º. Loosen the setscrew.

► Gaps at the inside corners indicate the bevel

angle is greater than 45º. Tighten the setscrew.

5. Verify any adjustments by repeating the

procedure.

Matching the TS 55 to an Existing Guide Rail

If you have more than one Festool saw, and you want them

to share the same guide rails, you can adjust the TS 55 to

match the cutting position of a previous saw.

1. Clamp your existing guide rail to a small scrap of wood

(about 12 inches long) so it cannot move.

2. Using your existing saw, cut the piece of wood. Do not

move the guide rail after the cut is finished.

3. Place the new TS 55 saw on the guide rail.

4. Loosen the four hinge block mounting screws (2-front

and 2-rear).

5. Plunge the blade to full depth and hold it there.

6. Slide the front of the sawblade up to the edge of the cut

piece of wood.

7. Slide the back of the sawblade up to the edge of the cut

piece of wood, except place a piece of paper between the

blade and the wood. This paper serves as a shim to

space the blade slightly away from the wood at the back

of the cut. The saw’s cutting is improved if the back of

the blade is skewed slightly away from the guide rail.

8. Retighten the hinge block mounting screws.

12 TS 55 EQ Circular Saw

Page 13

Operation

Setting the Blade Depth

The TS 55 is equipped with a depth stop for setting the

depth of the blade during a plunge cut. Using the correct

blade depth improves cutting safety, cut quality, and motor

efficiency.

Effects of Too Shallow of a Setting

► Higher drag on the sawblade, requiring more power and

effort to complete the cut.

► Increased chance for kickback.

► Increased chipping and splintering on the underside of the

cut, especially with melamine and veneers.

► Increased burning of the cut, especially in certain

hardwoods like cherry and maple.

► With the exception of underside chipping, all of these

effects are greatest with finer-toothed blades.

Effects of Too Deep of a Setting

► Increased danger with more of the blade exposed below

the workpiece.

► Increased sawtooth marks in the cut.

► Increased top-side chipping and splintering, especially

without using the guide rail and splinter guards.

Blade Depth Recommendations

There are no set rules for

setting the depth of the

blade with respect to the

underside of the cut.

However, a common

industry guideline is to

have the gullets of the b

workpiece. This will therefore be used as a baseline to

describe optional depth settings.

lade even with the underside of the

► If a material is prone to burning in the cut, increase the

depth slightly. This includes ripping hardwoods such as

cherry and maple.

► Using a combination blade in solid wood may perform

better with a slightly deeper setting.

► Using a coarse blade in sheet materials may be improved

with a shallower cut.

► Cutting dense and/or hard materials may require a deeper

setting to decrease heat and load on the tool.

► Cutting fragile or shatter-prone materials such as plastics

or countertop laminates is best with a shallow setting (and

low speed).

► Cutting aluminum may be improved with a semi-shallow

setting, but not too shallow.

► When Used with the Multi-Function Table (MFT) you may

wish to keep the blade

depth shallower.

► Cutting non-fragile, non-

shattering plastics such as

polypropylene or solidsurface countertops may

be improved with a deeper

cut.

► More aggressive blades,

such as the Panther

ripping blade, can be used

at a shallower setting.

Using the Depth Stop

► Press in on the index

pointer and slide it up or

down to the desired

setting.

► When used with the guide r

ail, add 5 mm to the desired

depth to account for the guide rail thickness.

Setting the Motor Speed

The TS 55 has electronic speed control with soft-start

circuitry. The electronic controller will maintain the m

otor

speed even as the load changes. The speed control is

infinitely variable from 2000 to 5200 RPM. The optim

al

speed of the saw is predominately determined by the typ

of material being cut.

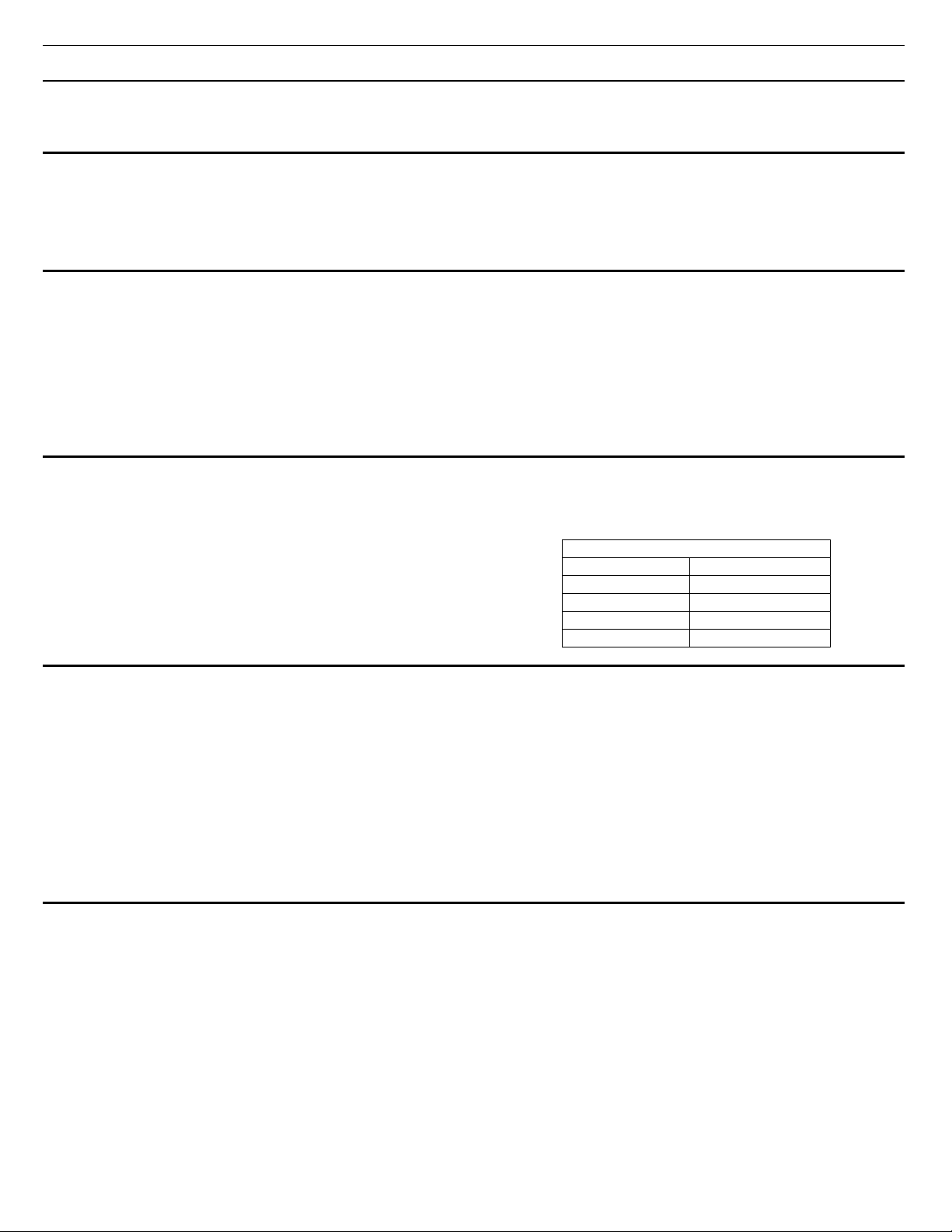

Material Speed

Soft wood products and veneer plywoods 6

Hardwood products 3-6

Plastic laminate countertops 6

Hard plastics 3-5

Soft plastics 1-4

Plaster and cementitious hardboard 1-3

Aluminum 4-6

Instruction Manual 13

Turn the speed control dial (shown on page 14) to the number

shown in the table to the left.

A Note About Speed Control

e

When you first turn on the saw and there is no load on the

sawblade, you may notice a slight “growling” sound from t

saw. This is normal, and is a result of the motor’s gears

reacting to the speed control.

The electronic controller in the

motor controls the motor speed

by turning it On and Off very rapidly. This form of speed

control is called "Pulse-Width Modulation" (PWM), and is

common in most power tools with a variable speed control.

When there is no load on the sawblade, the pulsations of the

motor cause the gears to rapidly engage and disengage (called

backlash), and this is the sound you are hearing.

he

Page 14

Turning On the Saw

To prevent unexpected start-ups, the power switch has an

integral safety interlock. Before the saw can be started, the

plunge release must be engaged.

1. Insert the Plug-it cord into the saw with the keyway lined

up with the key, and twist the end to lock it in place.

2. Press up on the plunge release lever.

3. Pull back on the power trigger.

Using the Outrigger Splinter Guard

The outrigger splinter guard is used when the cut to the

right of the blade needs to be chip-free. When not in use,

the outrigger can be raised out of the way. For bevel cuts,

the outrigger is easily removable.

1. Remove the thumbscrew from the outrigger and slide

the outrigger on to the front edge of the blade cover as

shown.

2. Insert the thumbscrew through the outrigger, through

the height adjustment slot, and into the captive nut on

the back side of the outrigger.

3. Place the saw on the guide rail, on the workpiece, and

lower the splinter guard down to the surface of the

workpiece.

4. Tighten the thumbscrew.

Notes

► Inspect the bottom of the outrigger for burrs that could

scratch the workpiece.

► Remove the outrigger when making bevel cuts.

► For plunge cuts, there is an index mark to indicate the

blade position when the blade is at full depth.

14 TS 55 EQ Circular Saw

Page 15

Setting the Bevel Angle

When used with the guide rail, the blade of the TS 55 enters

the workpiece at exactly the same location regardless of the

bevel angle (see the picture on page 7). However, when used

without the guide rail, the cut position moves outward

slightly as the bevel angle increases. (The small notch at the

front of the sole plate indicates the cut position when the

saw is used without the guide rail.)

1. Remove the outrigger splinter guard.

2. Loosen the front and rear lock knobs.

3. Tilt the saw until the index pointer is pointed to the

desired bevel angle setting.

4. Tighten the front and rear lock knobs.

For bevel angles greater than 30 degrees, most of

weight of the saw is beyond the edge of the sole

plate. Make sure to hold the sole plate do

cutting to preve

unexpectedly.

nt the saw from tipping

wn when

the

Using the Guide Stop

The guide stop serves two purposes: it controls the saw’s

position and prevents a kickback during a plunge cut. The

leading edge of the guide stop prevents the saw from

moving backward as the plunge begins. The anti-kickback

lip engages with the sole plate of the saw to prevent the

back of the saw from lifting up at the beginning of a plunge

cut.

1. Slide the guide stop onto the T-slot of the guide rail with

the embossed arrow pointing toward the front of the

saw.

2. Position the stop behind the starting position of the saw.

► When the blade is at full-depth, the guide stop is 3 ¾

inches behind the start of the cut.

► When the blade is less than full depth, the distance

between the blade (cut) and the guide stop will be

greater.

► For best results, you should always verify the blade’s

cutting position before staring the cut.

3. Tighten the thumbscrew on the guide stop.

Instruction Manual 15

Page 16

Using Dust Extraction

The TS 55 can be used with or without a dust extraction

system. The chip diverter swivels to direct the sawdust

away from the work area when a dust extraction system is

not used.

For best results, however, a dust extraction system (such as

the Festool CT 22 shown below) should be used. Festool

dust extractors have the added features of variable speed,

and sensing when the saw is turned on. The vacuum will

automatically start when the saw is turned on, and will

remain running for a couple of seconds after the saw turns

off to clear the remaining dust.

1. Insert the extractor hose into the chip diverter (36 mm

inside diameter [1-7/16 in.])

2. Plug the TS 55 power cord into the auxiliary outlet on the

extractor (if so equipped).

3. Set the power switch on the extractor to “Auto.” (The

auxiliary power outlet is active only when the switch is

set to Auto.)

16 TS 55 EQ Circular Saw

Page 17

Applications

The TS 55 is capable of performing a wide variety of tasks. The following sections provide information on some of these

tasks. This is intended to be an introduction to the capabilities of the saw, but should not be considered as a comprehensive

list of its capabilities.

Straight-Lining Rough Lumber

Purchasing lumber directly from a saw mill is significantly

less expensive than buying from a home center. However,

part of the reason why the lumber is less expensive is

because it frequently has not been straight-line ripped.

Sawmills have special straight-line ripping tablesaws, but

they charge an extra fee for the service, and straight-lining

on a regular tablesaw is complicated.

The TS 55 can quickly and easily straight-line rough lumber

using the guide rail. Additionally, if the grain of the wood is

diagonal with the cut edge, the TS 55 can be used to re-cut

the lumber on a diagonal to match the natural wood grain

direction or to avoid defects.

Tips for Successful Straight-Lining

► Use the correct blade for the cut. The Panther ripping

blade will provide the easiest cutting in any hardwood. A

coarse combination blade may be used for softwoods, or

for a finer edge, but it will take more effort to rip the

wood.

► The Panther blade is aggressive enough that you do not

need to fully expose the whole gullet as shown on page

13. For cleaner cuts, expose ½ to a full tooth of the blade

below the wood. The deeper the setting, the easier the

cut will be.

► For a less aggressive, combination blade, you may need

to set the depth so the full gullet is exposed below the

wood.

► Choose the orientation of the guide rail to optimize the

board usage. This may have several different options:

► Align the cut with the natural wood grain orientation.

► Align the cut to avoid defects in the wood.

► Align the cut to maximize board width, while

eliminating curved edges.

► Place the board on sawhorses or elevate it from a work

table so you do not cut into your work table.

Instruction Manual 17

Page 18

Crosscutting and Trimming

No other saw on the market can outperform a Festool for

splinter-free, fine crosscutting. With other saws, the problem

is two-fold; getting a straight cut, and achieving a splinterfree cut. The TS 55 handles these problems effortlessly.

Tips for Successful Crosscutting

► Use the correct blade for the cut.

► Crosscutting fine veneered wood should use the fine

crosscut blade. The Alternate-Top-Bevel teeth will slice

the wood fibers best, with virtually no chipping.

► Crosscutting soft lumber, or lumber-core veneers should

use the combination blade. With fewer teeth than the

fine crosscut blade, this blade will be more aggressive

for cutting, yet still provide good chip-free cutting.

► Crosscutting thick hardwood lumber, and difficult to cut

lumber should use the coarse crosscut blade. The coarse

tooth-count of this blade provides very aggressive

cutting of difficult material, but won’t provide as

smooth of a finish as the finer blades.

► Cutting plastic-veneer countertops or solid surface

materials should use the fine laminate blade. The TripleChip-Grind of this blade lasts longer in hard materials

and reduces chipping in man-made materials. The

triple-chip-grind will provide good cuts in wood

veneers, but not as good as the alternate-top-bevel fine

crosscut blade.

► For small offcuts, overhang the workpiece from a work

table or saw horses (as shown below). For larger offcuts,

support both the primary piece and the offcut.

► If the offcut is reusable, use the outrigger splinter guard to

prevent chipping.

► Make sure the workpiece is secure. The lightweight door

shown in the example below would slide on the table if

not clamped down.

► Make sure the guide rail is secure if it can move during the

cut. In the example below, starting the cut with the saw

behind the workpiece can cause the guide rail to tip up

and move. (The guide rail clamps are below the guide rail,

and not visible.)

► Don’t start the cut by plunging the saw into the wood, as

this can lead to tearout at the bottom-back of the sawblade.

Start the cut with the blade down and behind the

workpiece, and advance the saw forward into the cut.

► Setting the blade depth too shallow (just barely

penetrating the underside of the workpiece) can cause

tearout on the underside of the cut.

18 TS 55 EQ Circular Saw

Page 19

Plunge Cutting

Plunge cutting is used when the cut does not start at the

edge of the workpiece; it starts in the middle of the

workpiece. There is a wide variety of applications for

plunge cuts. The example shown below is for insetting a

maple butcherblock into an existing countertop. A square

cutout is made in the middle of the countertop, and the

butcherblock piece is inserted into the cutout.

Notes

► Always use the guide stop when making a plunge cut to

prevent an unexpected kickback (see page 15).

► Whenever possible, put the guide rail on the side of the

cut that will be saved. If the guide rail is placed on the

offcut side, you must remember to account for the blade

thickness when positioning the guide rail (typically 2.2

mm).

► Whenever possible, set the saw depth to its maximum

setting to minimize the amount of material that is not cut

by the blade. Make sure there is nothing below the cut

that you don’t want to cut into.

► Mark the beginning and end of the cut (red tape in picture

below). If the blade is at full depth, there are index marks

on the saw that indicate where the blade is positioned.

► For cuts similar to the example below, support the offcut

piece before cutting all four sides to prevent it from

breaking the corners. Trim the corners (see image to the

left) with a handsaw.

General Procedure

1. Place the guide rail on the cutline.

2. Place the saw on the guide rail, and position it at the

start of the cut.

3. Install the guide stop on the guide rail, slide it up to the

back of the saw, and lock it in place.

4. Start the saw and slowly plunge it down.

5. Advance the saw through the cut until the end is

reached. Never back the saw up, as this can result in a

kickback.

Instruction Manual

19

Page 20

Cutting Non-Wood Materials

Soft Plastics

Soft plastics such as polypropylene won’t chip, but they will

melt. Therefore, a more aggressive cut with the blade set

deeper will reduce the melting.

► Too shallow of a blade depth and the plastic will be more

prone to melting.

► Too deep of a blade depth and the teeth marks from the

blade will be more prevalent.

► Any of the fine-tooth blades with a slow motor speed will

cut this material with good results.

► Clean up the cut edges with a cabinet scraper.

Brittle Plastics

Brittle plastics will both melt and chip, so cutting them is

problematic with most other saws. The TS 55 works great for

cutting this type of material.

► Set the blade depth very shallow to reduce chipping.

► Set the motor speed very low to reduce melting.

► Use any one of the finer tooth blades for good results, but

the negative hook aluminum and plastic blade provides the

best results.

► In clear plastics such as acrylic, if the cut is milky white, it is

a sign of melting. Note how the cut to the right is

transparent.

Thin Aluminum

The problem with cutting thin aluminum sheet is that the

blade teeth can catch the edge of the sheet, and cut more

aggressively than expected. To reduce this, you want the teeth

moving nearly parallel with the aluminum surface (a shallow

blade depth).

► The ultra-thin aluminum shown in the example was cut best

with the fine crosscut blade. The positive hook angle of the

blade kept the flexible aluminum tight to the guide rail in a

sheering cut.

► For slightly thicker, less flexible pieces of aluminum, the

negative hook angle, aluminum cutting blade works best

because it cuts less aggressively.

Extruded Aluminum

Care needs to be taken when cutting extruded aluminum

because the blade may cut more aggressively than expected

on the various surfaces of the stock. This is most noticeable

with thin-walled extrusions.

► With thin-walled extrusions, try to keep the blade teeth

parallel to the walls (see image above).

► With thick-walled extrusions, try to keep the blade teeth

perpendicular to the walls (see image to the right).

► Use the negative hook angle, aluminum-cutting blade, and

a moderate speed setting.

► Be prepared for the blade to catch unexpectedly as the

cutting angle changes with each facet of the extruded

shape.

20 TS 55 EQ Circular Saw

Page 21

Accessories

Sawblades

Description Coarse Crosscut Ripping (Panther) Combination

With a moderate tooth count and

hook angle, this blade provides good

results when a single blade is needed

for crosscutting and ripping.

Purpose

Tooth Type

Hook Angle

Item Number

With a low tooth count and a high

hook angle, this blade easily cuts

through general construction materials.

ATB, 12 teeth ATB, 14 teeth ATB, 28 teeth

20° 37° 15°

487 377 439 685 490 516

The high hook angle of the

Panther blade makes for effortless

ripping without burning the cut.

Description Fine Crosscut Fine Laminate Aluminum and Plastic

Purpose

Tooth Type

Hook Angle

Item Number

With a high tooth count, this blade

provides excellent, chip-free

crosscutting of lumber and fine

(cabinet-grade) plywood.

ATB, 48 teeth TCG, 48 teeth TCG, 56 teeth

12° 4° -5°

491 952 489 457 439 686

The ultra-hard TCG teeth on this

blade provide chip-free cutting of

laminates and solid surface

materials without dulling.

The negative hook angle and high

TCG tooth count of this blade

provides grab-free control for cutting

aluminum and hard plastic.

Notes

ATB: Alternate Top Bevel. The ATB type blade slices through wood fibers,

first on one side and then on the other for clean cuts in natural and

manmade materials.

TCG: Triple Chip Grind. The TCG type blade is designed to cut through hard

materials. The trapezoidal tooth cuts the center of the kerf and the flat

raker tooth cuts the edges. This type of blade design is more resistant to

dulling.

26-a Bevel Angle: All of the ATB-type blades shown above have a bevel

angle of 15°. This moderate bevel angle provides good chip-free cutting

without rapidly dulling.

26-b Hook Angle: The higher the hook angle, the more the tooth grabs the

material and pulls it into the cut. Ripping blades have a very high hook

angle to cut aggressively. Lower hook angles are used for harder

materials where greater control is needed.

Tooth Count: The more teeth a blade has, the smoother it will cut. Conversely,

blades with fewer teeth cut more aggressively.

Instruction Manual 21

Page 22

Guide Rails

Additional guide rails are available in lengths from 32 inches

to 197 inches.

Dust Cover

Item Number: 491 750

The dust cover is for improved dust collection by covering the

openings in the side of the blade cover.

Guide Rail Accessory Kit

Item Number: 492 396

Contains: Miter Gauge, Splinter Guard, Guide Stop, Cord

Guide, Guide Rail Connection Bars, Guide Rail Clamps,

Systainer.

Rip Fence (Parallel Guide)

Item Number: 491 469

Use the rip fence instead of the guide rail for making a rip

using the edge of the workpiece as a reference.

22 TS 55 EQ Circular Saw

Page 23

Systainer (System Container)

Every Festool product is shipped in its own unique system container, called a "Systainer." This provides protection and

storage for the tool and accessories. All Systainers are stackable and can be interlocked together, including stacking and

locking atop Festool dust extractors.

Parts of the Systainer

► Carrying Handle. The carrying handle folds flat when not

in use.

► Cover Latches. The two green latches on the front of the

Systainer secure the cover. (These are also used for

stacking Systainers, as described below.)

► Stacking Latches. The two gray latches on the sides of the

Systainer are used for stacking one or more systainers

together.

► Stacking Tabs. The stacking tabs are used to lock two

systainers together. There are four sets of tabs (two on the

front and two on the sides) of each systainer.

Stacking Systainers

For convenience in transporting Festool tools and

accessories, the systainers can be stacked and locked

together. The systainers are locked together using the

stacking tabs and latches.

1. Place one systainer on top of the other.

2. Release all four latches on the lower systainer by pulling

back at their top edges (step A to the right).

3. Slide all four latches upward (step B) as depicted by the

two views.

4. Snap all four latches back to their flat position (step C) so

they engage the stacking tabs of the upper systainer.

The image to the right shows two accessory systainers

stacked together.

Instruction Manual 23

Page 24

Troubleshooting

Symptom Possible Causes

Motor does not start 1. Check that the cord is properly plugged into an outlet.

2. Make sure the outlet has power. Check the circuit breaker or try another outlet.

3. If used with a Festool dust extractor, make sure the selector switch is pointing to

"Auto". The auxiliary outlet on the dust extractor has power only when the

selector is at Auto.

4. Inspect the power cord (including extension cords) for damage or missing

prongs.

5. The motor brushes may have worn and need replacement.

The guide rail gib cams won’t stay

tight

The saw makes a "Growling" sound

when it is first turned on or idling.

The saw makes wavy cuts ► Make sure the guide rail gib cams are properly adjusted.

Saw cuts are burning ► Make sure to use the correct blade for the material.

Excessive chipping on the lower

edge of the cut

Excessive chipping on the top edge

of the cut

► The cams may be worn and have a flat-spot. Replace the cams.

► The friction washers may be worn or missing.

This sound is normal and expected. It is the result of the gears in the saw's heavy

duty drivetrain reacting to the speed control of the motor.

The electronic controller in the motor controls the motor speed by turning it On

and Off very rapidly. This form of speed control is called "Pulse-Width

Modulation" (PWM), and is common in most power tools with a variable speed

control. When there is no load on the sawblade, the pulsations of the motor cause

the gears to rapidly engage and disengage (called backlash), and this is the sound

you are hearing.

► Inspect the blade for damage.

► Make sure the sole plate is not rocking on the guide rail.

► Keep the blade depth consistent during the cut; don’t raise and lower the blade.

► Forcing an ATB-type blade into the cut too fast can cause the blade to deflect.

► Make sure the blade is sharp.

► Make sure the blade is installed correctly (not turning backward).

► Reduce the motor speed.

► If possible, increase the blade depth.

► Make sure to use the correct blade for the type of material and type of cut.

► A very shallow blade depth can cause chipping on the underside if the teeth are

barely protruding below the surface. Increase the blade depth.

► Make sure to use the correct blade for the type of material and type of cut.

► Inspect the splinter guard. Make sure it is flush with the cut line for its entire

length.

► Materials prone to splintering may splinter more if the blade is set too deep.

24 TS 55 EQ Circular Saw

Page 25

Maintenance

Routine Maintenance

Any maintenance or repair work that requires opening of

the motor or gear housing should be carried out only by an

authorized Customer Service Center (name supplied by your

dealer)! Maintenance or repair work carried out by an

unauthorized person can lead to improper connection of

electrical wires or other components, which can result in

injury.

To prevent injury or electrocution, always unplug the tool

from the power supply outlet before performing any

maintenance or repair work on the tool!

► Keep the bevel hinges clean of dust using compressed air

or cotton swabs. If the hinges wear due to abrasive

particles, the saw will not perform optimally.

► Keep the blade area and dust extraction port clean of

debris. Debris can cause wear and reduce the effectiveness

of the dust extraction system.

Keep the Sawblades Sharp

Using a dull sawblade can be extremely dangerous and

provide poor cut quality.

Do not use compressed air to clean the motor housing of the

tool, as you could inject foreign objects into the motor

through the ventilation openings. Compressed air may be

used on other components, but personal safety protection

should be employed (hearing, vision, and respiratory).

Certain cleaning agents and solvents are harmful to plastic

parts. Some of these include, but are not limited too:

Gasoline, Acetone, Methyl Ethyl Ketone (MEK), Carbonyl

Chloride, cleaning solutions containing Chlorine, Ammonia,

and household cleaners containing Ammonia.

To ensure proper cooling of the tool and motor, the cooling

vents in the motor housing must always be kept clear and

clean.

Keep the Saw Clean

Dust and debris from some materials can be extremely

abrasive and cause components within the saw to wear

prematurely. It is important to keep moving parts cleared of

abrasive dusts.

► As a general rule, keep the saw clean of all dust and

debris. Even soft-wood dust can be abrasive over time.

► Examine all moving parts for dust and debris.

► Never attempt to sharpen a sawblade manually. Special

equipment is necessary to properly sharpen a circular

sawblade. An improperly sharpened sawblade can injure

the operator, destroy the saw, and damage the workpiece.

► The sawblades should be sharpened regularly, and only

by a qualified sharpening service.

► Improper grinding of the carbide teeth of a sawblade can

result in serious injury to the saw operator.

Adjust and Inspect the Saw

To ensure the saw is in proper working order, periodically

inspect the operation of the saw and ensure it is properly

adjusted.

► Observe the function of the saw during normal operation.

► Unusual sounds are indicative of pending problems.

► A reduction in the cut quality indicates the saw is either

improperly adjusted or not functioning properly.

► A reduction in cutting power or speed may indicate a dull

blade or a motor problem.

► If any of the safety devices on the saw are inoperable or

disabled, immediately stop using the saw and have it

serviced.

► Periodically inspect the guide rail gibs cams for wear and

proper adjustment. If the cams are worn or misadjusted,

the saw will not cut straight.

Instruction Manual 25

Page 26

Replacing the Guide Rail Gib Cams

If the gib cams are over tightened, or the saw is used in an

environment with abrasive dust, the cams may develop flat

spots and should be replaced. Maintaining proper

adjustment and keeping the saw clean will increase the life

of the cams.

► Unplug the saw for safety, and lay the saw on its side on

a stable work surface.

► Using a T-15 Torx

each cam to the sole plate, and remove the cam and

friction washer.

► The replacement parts kit will

include 2-cams, 2-friction washers,

and 2-screws.

► Install the new cams and friction

washers with the screws provided.

► Make sure the limit tabs are

pointing away from the guide rail

slot as shown.

► Tighten the screws enough to

compress the friction washers, but

take care not to over tighten the

screws.

®

driver, remove the screw that secures

► Adjust the cams according to the procedure on page 8.

Replacing the Guide Rail Splinter Guard

The splinter guard prevents splintering and chipping of the

workpiece by holding the top edge of the workpiece down as

the teeth of the sawblade move upward against it. The

splinter guard needs to be replaced if it becomes damaged or

worn.

1. Peel the original splinter guard away from the guide rail.

2. As needed, clean residual adhesive and debris from the

guide rail.

3. Peel off the plastic backing from the new splinter guard

to expose the adhesive.

4. Without stretching the rubber, carefully place the new

splinter guard on the underside of the guide rail tight to

the alignment rib (14-b).

5. Make sure the splinter guard is firmly pressed down to

the guide rail.

6. Trim the splinter guard as described on page 8.

26 TS 55 EQ Circular Saw

Page 27

Changing the Motor Brushes

The motor brushes wear out over time and need to be

replaced by an authorized service center. Festool does not

condone brush replacement by the end-user.

this procedure by an unauthorized service center will void

the tool's warranty.

The motor brushes are graphite bars that provide an

electrical connection between the motor controller and the

rotating armature. When the brushes have worn past their

useful length, spring loaded wear pins are exposed that

separate the brush from the armature contacts. This disables

the motor to prevent damage. For a shorter break-in period

without excessive arcing, new brushes have ribs that quickly

form to the curve of the armature.

Procedure

CAUTION! Make sure the power cord is unplugged

before beginning this procedure.

1. Remove the four screws that secure the access cover

to the motor, and remove the cover.

Completion of

2. Lift the wire connectors off the terminals on the brushes.

3. Remove the screw that secures each brush to the motor

housing. Be careful not to drop the screws into the motor.

4. Carefully lift the brushes up to remove them.

5. Insert the new brushes into the motor, and reassemble the

saw by reversing the previous steps.

Instruction Manual 27

Loading...

Loading...