Page 1

Festool GmbH

Wertstraße 20

73240 Wendlingen

Germany

www.festoolusa.com

Instruction manual

Page 6

IMPORTANT: Read all instructions before using.

Guide d’utilisation

Page 17

IMPORTANT: Lire toutes les instructions avant de démarrer les travaux.

Manual de instrucciones

Página 29

IMPORTANTE: Lea todas las instrucciones antes de usar.

707353_004

Instruction manual

Guide d’utilisation

Manual de instrucciones

LEX 3 77

LEX 3 150

Page 2

Page 3

Page 4

1-1

1-2

1-3

1-4

1-5

LEX 3 150

Page 5

Page 6

Contents

Settings................................................. 14

About this manual................................ 6

IMPORTANT SAFETY INSTRUCTIONS . 6

INSTRUCTIONS PERTAINING TO A

RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS .......................... 6

Other risks ........................................... 10

Health hazard by dust.......................... 10

Symbols ............................................... 11

Intended use ........................................ 11

Technical data...................................... 11

Functional description......................... 12

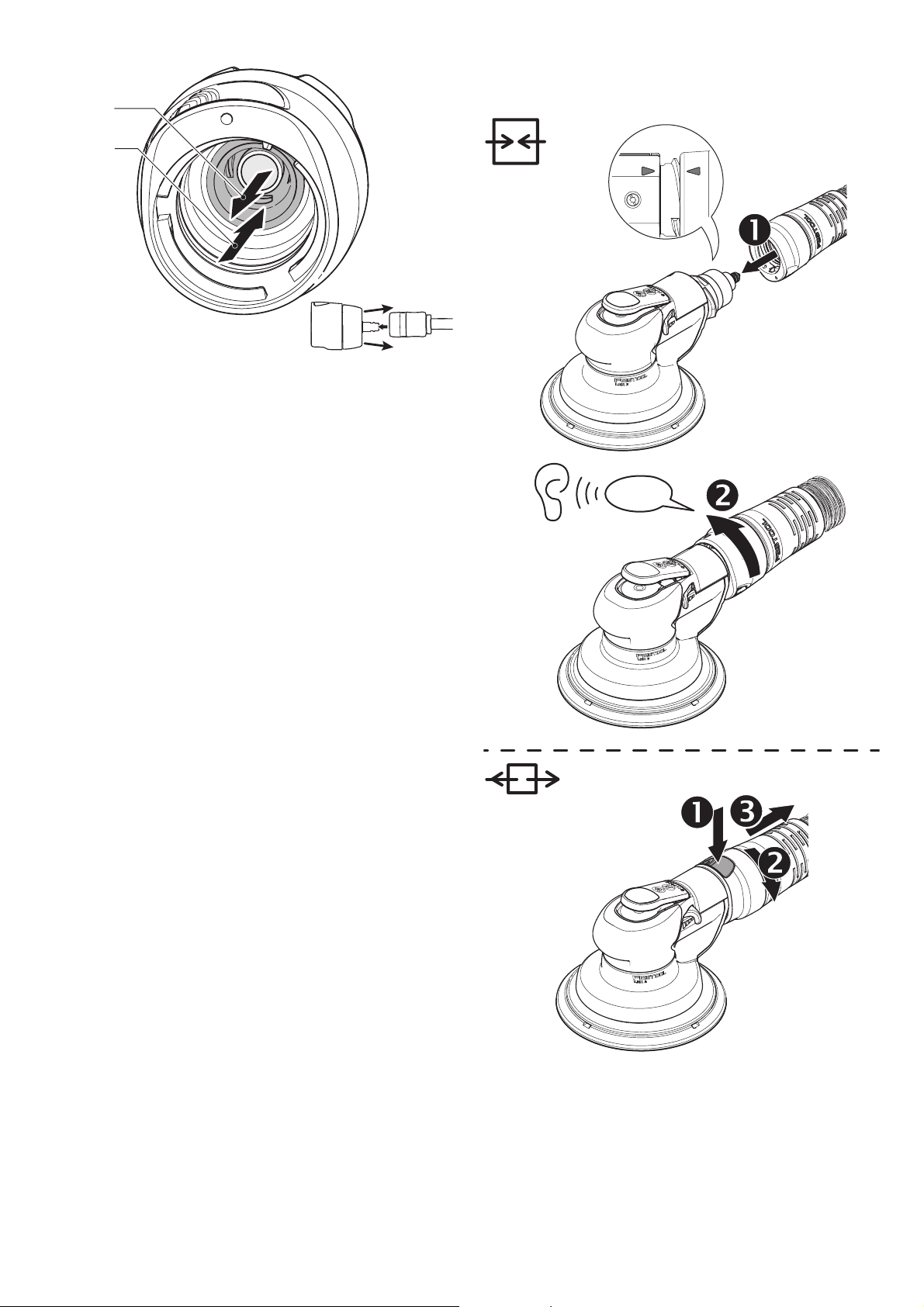

Compressed-air supply and commissioning 12

Compressed air preparation................ 12

Connection for IAS hose system.......... 12

Switch on/off ........................................ 13

Setting and adjusting the speed........... 14

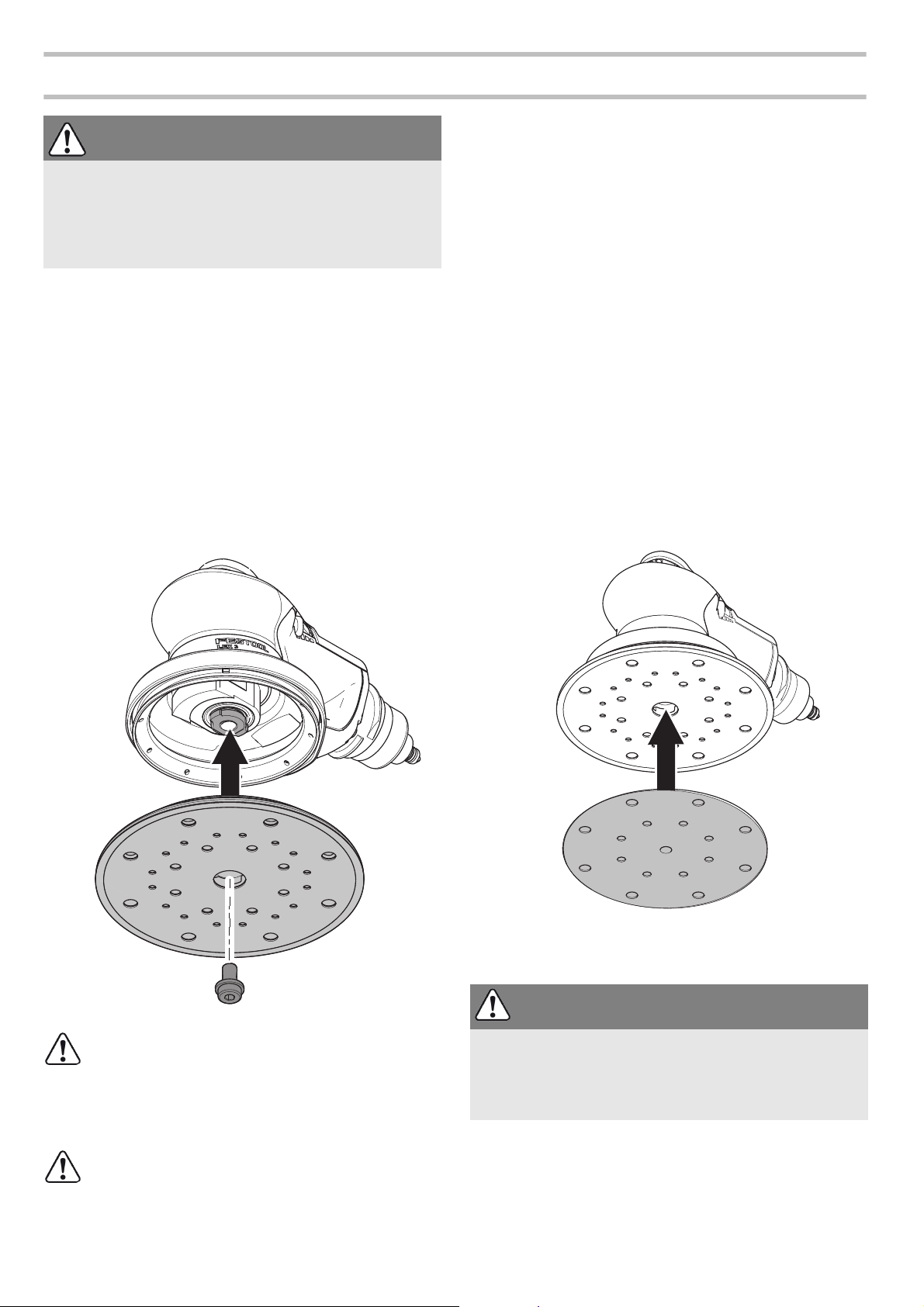

Replacing the sanding pad [4].............. 14

Attaching sanding accessories using

StickFix [5]............................................ 14

Dust extraction..................................... 14

Working with the machine ................... 15

Service and maintenance..................... 15

Vanes .................................................... 15

Replacing the silencer.......................... 15

Sanding pad brake................................ 15

Cleaning the extraction channels ........ 15

Accessories .......................................... 16

Environment......................................... 16

About this manual

Save these instructions

It is important for you to read and understand this manual. The information it contains relates to protecting

your safety

and

preventing problems

DANGER Description of imminent haz-

ard and failure to avoid hazard

will result in death.

WARNING Description of hazard and

possible resulting injures or

death.

CAUTION Description of hazard and

possible resulting injuries.

. The symbols below are used to help you recognize this information.

NOTICE Statement including nature of

hazard and possible result.

HINT Indicates information, notes,

or tips for improving your success using the tool.

IMPORTANT SAFETY INSTRUCTIONS

INSTRUCTIONS PERTAINING TO A RISK OF

FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS

WARNING! When using tools, basic precautions should always be followed, including

the following:

SAVE THESE INSTRUCTIONS

6

General

a.

To reduce the risks of electric shock, fire, and

injury to persons, read all the instructions before using the tool.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or battery-operated (cordless) power tool.

– Only trained and qualified persons are permitted

to set up, adjust and operate this compressed air

Page 7

tool. Persons without the relevant qualifications

and training are more likely to cause accidents.

– This compressed air tool may not be modified.

Modifications may reduce the effectiveness of

safety devices and pose a greater risk to operating personnel.

– Keep all of the attached documents and pass on

the documentation if the machine changes own-

ership.

– Never use a damaged compressed air tool.

– Regularly inspect compressed air tool. The com-

pressed air tool must be marked with clearly leg-

ible rated values and markings. Replacement

signs can be ordered from the manufacturer.

1 WORK AREA

a.

Keep the work area clean and well lighted.

Cluttered benches and dark areas increase the risks

of electric shock, fire, and injury to persons.

b.

Do not operate the tool in explosive atmospheres, such as in the presence of flammable

liquids, gases, or dust.

The tool is able to create

sparks resulting in the ignition of the dust or

fumes.

c.

Keep bystanders, children, and visitors away

while operating the tool.

Distractions are able to

result in the loss of control of the tool.

2 PERSONAL SAFETY

a.

Stay alert. Watch what you are doing and use

common sense when operating the tool. Do not

use the tool while tired or under the influence of

drugs, alcohol, or medication.

A moment of inattention while operating the tool increases the risk

of injury to persons.

b.

Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep hair, clothing,

and gloves away from moving parts.

Loose

clothes, jewelry, or long hair increases the risk of

injury to persons as a result of being caught in

moving parts.

c.

Avoid unintentional starting. Be sure the switch

is off before connecting to the air supply.

Do not

carry the tool with your finger on the switch or

connect the tool to the air supply with the switch

on.

d.

Remove adjusting keys and wrenches before

turning the tool on.

A wrench or a key that is left

attached to a rotating part of the tool increases

the risk of personal injury.

e.

Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance en-

ables better control of the tool in unexpected

situations.

f.

Use safety equipment.

A dust mask, non-skid

safety shoes and a hard hat must be used for the

applicable conditions.

g.

Always wear eye protection.

h.

Always wear hearing protection when using the

tool.

Prolonged exposure to high intensity noise

is able to cause hearing loss.

i.

Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool

may contact hidden wiring.

Contact with a "live"

wire will also make exposed metal parts of the

tool "live" and shock the operator.

j.

Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your

body is grounded.

k.

Explore the workpiece to avoid contact with hidden wiring.

Thoroughly investigate the workpiece

for possible hidden wiring before performing

work. Contact with live wiring will shock the operator.

3 TOOL USE AND CARE

a.

Use clamps or another practical way to secure

and support the workpiece to a stable platform.

Holding the work by hand or against the body is

unstable and is able to lead to loss of control.

b.

Do not force the tool.

Use the correct tool for the

application. The correct tool will do the job better

and safer at the rate for which the tool is designed.

c.

Do not use the tool if the switch does not turn

the tool on or off.

Any tool that cannot be controlled with the switch is dangerous and must be

repaired.

d.

Disconnect the tool from the air source before

making any adjustments, changing accessories,

or storing the tool.

Such preventive safety measures reduce the risk of starting the tool unintentionally.

e.

Store the tool when it is idle out of reach of children and other untrained persons.

A tool is dan-

gerous in the hands of untrained users.

f.

Maintain the tool with care.

Keep a cutting tool

sharp and clean. A properly maintained tool, with

sharp cutting edges reduces the risk of binding

and is easier to control.

g.

Check for misalignment or binding of moving

parts, breakage of parts, and any other condition that affects the tool’s operation.

If damaged,

have the tool serviced before using. Many acci-

7

Page 8

dents are caused by poorly maintained tools.

There is a risk of bursting if the tool is damaged.

h.

Use only accessories that are identified by the

manufacturer for the specific tool model.

Use of

an accessory not intended for use with the specific tool model, increases the risk of injury to

persons.

4 SERVICE

a.

Tool service must be performed only by qualified repair personnel.

b.

When servicing a tool, use only identical replacement parts. Use only authorized parts.

c.

Use only the lubricants supplied with the tool or

specified by the manufacturer.

5 AIR SOURCE

a.

Never connect to an air source that is capable of

exceeding 200 psi.

Over pressurizing the tool is

able to result in bursting, abnormal operation,

breakage of the tool or serious injury to persons.

Use only clean, dry, regulated compressed air at

the rated pressure or within the rated pressure

range as marked on the tool. Always verify prior

to using the tool that the air source has been adjusted to the rated air pressure or within the rated

air-pressure range.

b.

Never use oxygen, carbon dioxide, combustible

gases or any bottled gas as an air source for the

tool.

Such gases are capable of explosion and se-

rious injury to persons.

Danger from ejected parts

– In the event the workpiece, accessory or machine

parts break parts may be ejected at high speed.

– Wear impact-resistant protective goggles.

– Wear a helmet when doing overhead work. Also

assess the risks for other people.

– Secure the workpiece. Use clamping devices or a

vice to hold the workpiece firmly.

Risk of getting caught

– Wear suitable protective clothing! Do not wear

loose clothing or jewellery. They can be caught by

moving parts. Wear a hair net if you have long

hair.

Risks during operation

– Wear protective gloves.

– Operating and maintenance personnel must be

physically strong enough to handle the size,

weight and power of the machine.

– Hold the machine correctly. Prepare to counter-

act normal or sudden movements - hold the machine with both hands.

– Avoid abnormal posture. Ensure secure stance

and keep your balance at all times.

– Enable the command device for starting and

shutting down in case of an interruption to the

energy supply.

– The machine can only be operated with abrasives

which were developed for this purpose.

– Use only lubricants recommended by the manu-

facturer.

– Check sanding pad before each use. Do not use

the sanding pad if it is torn, broken or has fallen.

– Avoid direct contact with the sanding pad. Wear

suitable gloves as protection.

– Never use without an abrasive.

– Risk of an electrostatic discharge if the com-

pressed air tool is used on plastic and other non-

conductible materials.

– Potentially explosive atmosphere: If explosive or

self-igniting dust is produced during sanding of

certain materials, the processing instructions of

the material manufacturer must be observed un-

der all circumstances.

Risk through repeated movements

– The use of the compressed air tool may cause

unpleasant sensations in the hands and arms of

the operator, as well as in the neck and shoulder

area or other body parts.

– Adopt a comfortable posture. Change posture if

working continuously.

– If symptoms such as malaise, complaints, throb-

bing, pain, tingling, numbness, burning or stiff-

ness occur inform your employer and consult a

doctor.

Risk as a result of accessory parts

– Disconnect the compressed air hose from the

compressed air supply. In the event of non-use of

the compressed air tool, before maintenance and

when changing insertion tools.

– Avoid contact with the insertion tool during and

after use.

– Always use original accessories.

– Grinding wheels and cutting-off wheels are not

permitted.

– The permissible rotational speed of the accesso-

ry must be at least 1,000 rpm higher than the

maximum speed specified on the machine. Ac-

8

Page 9

cessories that rotate faster than the permissible

level can rupture.

– Self-adhesive abrasives must be attached con-

centrically on the sanding pad.

Risk at work station

– Slipping and tripping hazard! Pay attention to

slippery surfaces and tripping hazards as a result

of air pressure hoses.

– Not intended for use in explosive atmospheres

and not insulated against contact with electrical

power sources.

– Proceed with caution in unfamiliar surroundings

that may contain electrical or other supply cables

that harbour hidden dangers. Ensure that there

are no electrical cables, gas pipelines or similar

that, if damaged, could pose a hazard when the

machine is used.

Hazard as a result of dust and vapours

– If hazardous dust is produced during sanding, the

machine should be connected to an appropriate

extractor and the safety regulations that apply to

the working material should be observed.

– A risk assessment in relation to this hazard must

be carried out and corresponding control mechanisms implemented. Arising dust must be factored in.

– Connect the dust extractor. Make sure that avail-

able dust extraction equipment is connected and

used correctly. Observe the regional safety regulations for hazardous dusts and vapours. Operate

and service the compressed air tool as described

in the recommendations included in these instructions and use accessories and attachments

from Festool to minimise the release of dust and

vapours into the atmosphere. In dusty environments, make sure that the dissipation of exhaust

air does not disturb the dust.

– If necessary arising dust or vapours must be con-

trolled at the place of their release.

– All components must be fitted correctly and meet

all requirements to ensure that the compressed

air tool operates correctly.

– Select, maintain and replace accessories and

consumables according to these operating instructions.

– Wear a dust mask. Observe instructions from the

employer or occupational and health regulations.

Noise hazard

– Higher noise level can lead to permanent hearing

damage, loss of hearing or other problems if in-

adequate hearing protection is not worn or available.

– A risk assessment in relation to this hazard must

be carried out and corresponding control mechanisms implemented, e.g. the use of insulating

materials.

– Wear ear protection. Observe instructions from

the employer or occupational and health regulations.

– Operate and maintain compressed air tool ac-

cording to these operating instructions.

– Select, maintain and replace accessories and

consumables according to these operating instructions.

– Assure function of the silencer at the com-

pressed air tool.

Vibration hazard

– Vibrations can cause damage to nerves and prob-

lems with blood circulation in hands and arms.

– When working in cold environments wear warm

clothing and keep hands warm and dry.

– In the event of numbness, tingling or pains in fin-

gers or hands or white colouration of the fingers

or hands, cease work, inform employer and consult a doctor.

– Operate and maintain compressed air tool ac-

cording to these operating instructions.

– Do not hold the compressed air tool too tight, but

with a secure grip while observing the necessary

hand reaction forces. The vibration risk is greater

with increasing gripping strength.

Additional safety information for pneumatic machines

– Compressed air can cause serious injuries.

– Disconnect the compressed air hose from

the compressed air supply. In the event of

non-use of the compressed air tool, before

maintenance and when changing insertion tools.

– Never direct the air flow towards yourself

or other persons.

– Hoses flapping around can cause serious inju-

ries. Check whether hoses and their fixing devices have not suffered damage or become loose.

– The operating pressure should not exceed 6.2 bar

(90 psi).

– The machine must not be operated at a higher

speed than 6500 min

-1

– Never carry the compressed air tool by the com-

pressed air hose.

9

Page 10

Further safety information

–

Keep your work area tidy.

area can cause accidents.

–

Take into consideration environmental influences.

the rain.

–

Keep away from children!

touch the compressed air tool or the compressed

air hose. Keep others away from your work area.

–

Store your compressed air tools safely.

compressed air tools should be stored in a dry,

inaccessible or locked location, out of the reach

of children.

–

Do not use the compressed air hose for purposes for which it was not intended.

compressed air hose from heat, oil and sharp

edges. Check the compressed air hose regularly

and if it becomes damaged, have it replaced by an

approved specialist. The compressed air hose

cannot be used for application devices such as

atomising and spraying equipment as the safety

requirements against electrical hazards cannot

be satisfied.

–

Take good care of your tools.

sharp and clean to enable better and safer work.

Follow the maintenance regulations and the information about tool replacement. Keep handles

dry and free of oil and grease.

–

Do not leave any tool key inserted.

switching on check that key and adjustment tools

are removed.

–

Avoid unintended start-up

pressed air tool that is connected to a compressed air supply with your finger on the trigger.

When connecting the compressed air hose to a

compressed air supply, make sure that the switch

is not activated.

–

Be alert!

ways work with care.

Do not use the compressed air tool if you are not

able to concentrate properly.

–

Have

qualified specialist.This compressed air tool corresponds to the relevant safety regulations. Repairs should only be carried out by a qualified

specialist. The operator is otherwise at risk of an

accident.

–

Only work with correctly processed compressed

air.

this.

–

If the compressed air tool is dropped or falls,

check for damage to the machine and sanding

Do not leave compressed air tools out in

Pay attention to what you are doing. Al-

your compressed air tool repaired by a

Using the Festool supply unit VE guarantees

Untidiness in the work

Do not allow others to

Unused

Protect the

Keep the tools

Before

. Do not carry a com-

pad. Remove the sanding pad for closer inspec-

tion. Repair damaged parts before using again.

Broken sanding pads and damaged machines

can cause injuries and machine instability.

–

Clean work equipment soaked in oils, for exam-

ple sanding pad or polishing felt, with water and

allow to dry.

combust spontaneously.

–

Always use anti-static hoses and an earthed ex-

traction system. The system components of-

fered by Festool satisfy these requirements.

unearthed extractor system or hoses that are not

anti-static may cause electric shocks and severe

injuries.

Work equipment soaked in oil may

An

Other risks

In spite of compliance with all relevant design regulations, dangers may still present themselves

when the machine is operated, e.g.:

– Workpiece parts being thrown off,

– Parts of damaged tools being thrown off,

– Noise emissions,

–Dust emissions.

Health hazard by dust

WARNING!

sanding, sawing, grinding, drilling and other

construction activities contains chemicals

known (to the State of California) to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and

other masonry products, and

• arsenic and chromium from chemically treated

lumber.

proved safety equipment, such as dust masks that

are specially designed to filter out microscopic particles. Wash hands after handling.

Various dust created by power

The risk from these exposures

varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with ap-

WARNING

TO REDUCE THE RISK OF INJURY, USER MUST

READ INSTRUCTION MANUAL.

10

Page 11

Symbols

Warning of general danger

Risk of electric shock

Read the Operating Instructions/Notes!

Wear ear protection.

Wear eye protection.

Wear a dust mask.

Do not throw in the household waste.

n

0

.../min

-1

min

min minutes

lliter

bar bars

lb. pound

mm millimetre

’’ inch

kg kilograms

l/min liter per minute

psi pounds per square inch

°F degree Fahrenheit

Intended use

no-load speed

revolutions per minute

The compressed air eccentric sanders are suitable

for sanding wood, plastic, metal, stone, composites, acrylic-based mineral materials, paint/clear

coats, fillers and similar materials.

Materials containing asbestos must not be processed

Only

use with Festool hose system IAS 2 or IAS 3

and Festool sanding pads!

The user is liable for improper or non-intended use.

.

Technical data

Compressed air eccentric sander LEX 3 LEX 3 LEX 3 LEX 3

77/2.5 150/3 150/5 150/7

Drive Compressed-air vane motor

Sanding pad Ø 77 mm (3") 150 mm (6")

Sanding stroke 2.5 mm (3/32") 3 mm (1/8") 5 mm (3/16") 7 mm (9/32")

Idle engine speed n

0

Air consumption at rated load* 270 l/min 290 l/min 310 l/min

Air pressure

Max. inlet pressure 6.2 bar (90 psi)

10,500 rpm 10,000 rpm

Recommended minimum 5 bar (72.5 psi)

Compressed air quality i.a.w. DIN ISO

Class 5

8573-1

Recommended storage temperature

0° - 60° C / 10° - 40° C (0 °F - 140 °F / 50 °F - 104 °F)

/ operating temperature

Weight 0.7 kg (1.5 lbs) 1.0 kg (2.0 lbs)

* at 6 bar (87 psi) inlet pressure; n0, load 30N

11

Page 12

Functional description

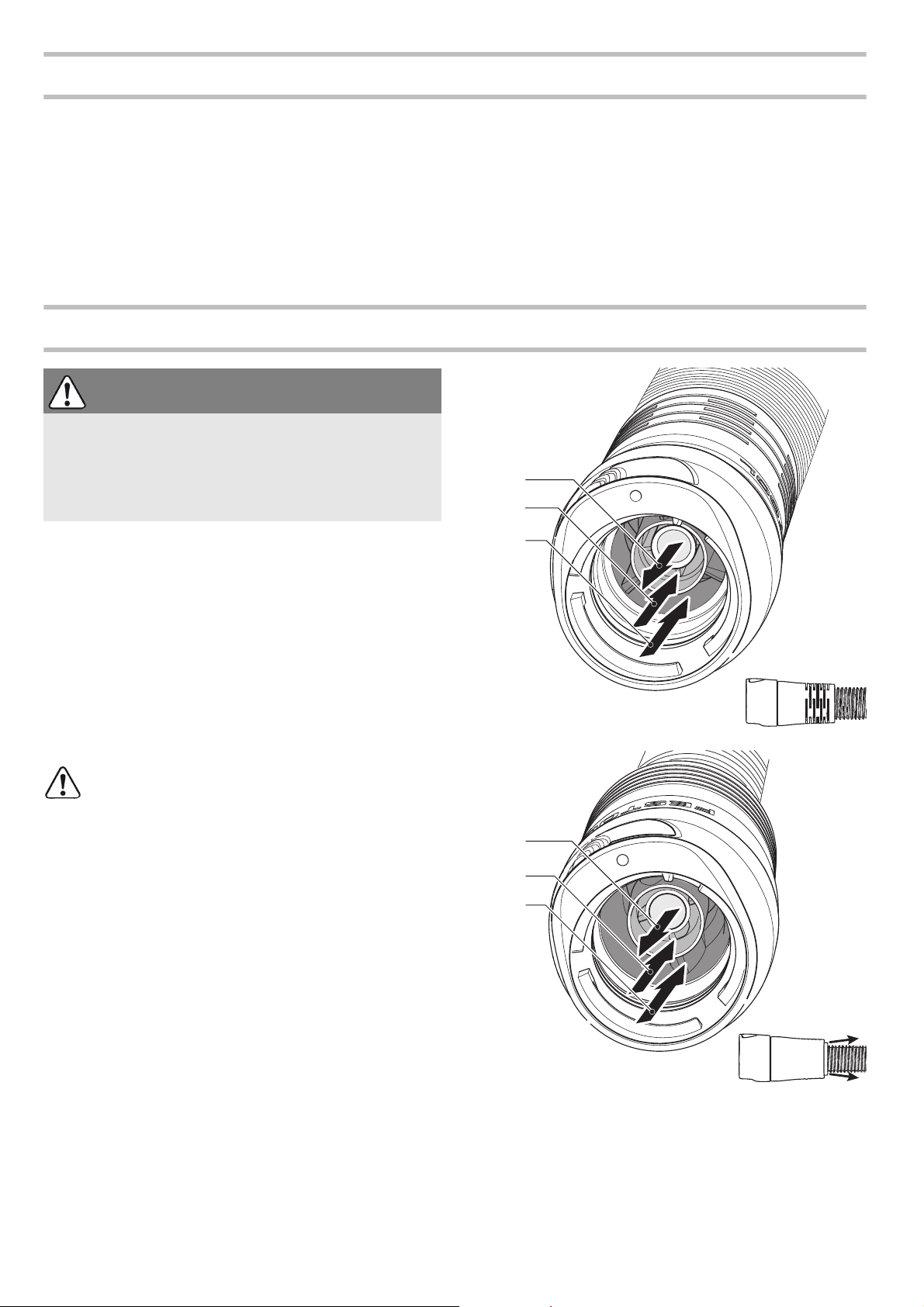

2-1

2-2

2-3

IAS-3/IAS-2

2-1

2-2

2-3

IAS-3 light

The pictures for the functional description are on a

fold-out page at the beginning of the instruction

manual. When reading of the manual you can fold

out this page for having always an overview of the

machine.

Accessories shown or described are sometimes not

included in the scope of delivery.

Compressed-air supply and commissioning

CAUTION

Risk of injury

Make sure that the pneumatic tool is switched

off when you connect the compressed-air supply.

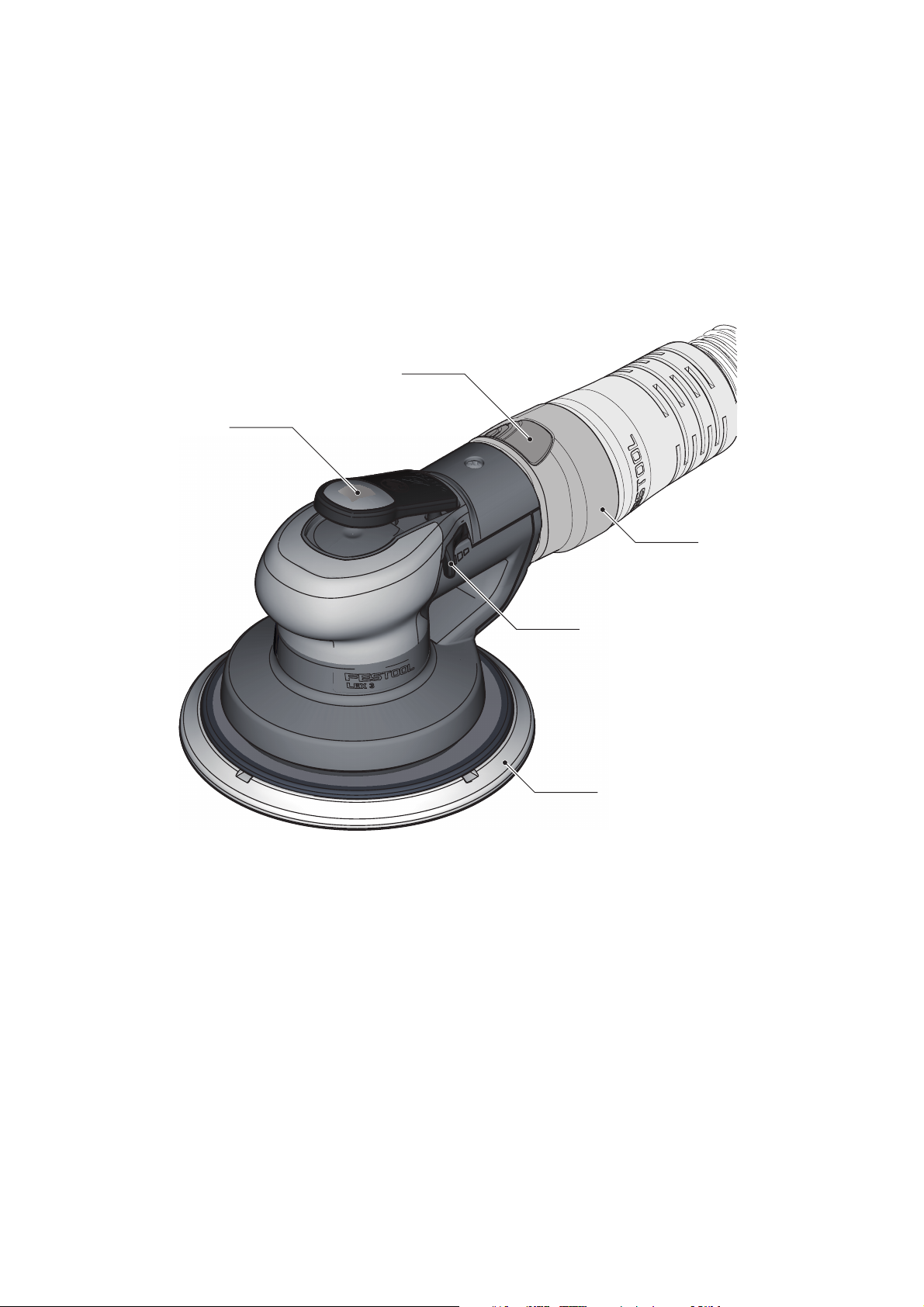

[1-1]

[1-2]

[1-3]

[1-4]

[1-5]

On/Off switch

Button for loosening the IAS connection

IAS connection adapter

Speed control

Sanding pad

Compressed air preparation

The machine is designed for lubricated operation

and must be operated with the Festool service unit.

Comprising a filter, controller, condensate outlet

and oiler, it ensures clean, oiled compressed air

free of condensation. The oiler must be adjusted so

that approx. every 15 minutes a drop of oil is added

to the compressed air. The correct setting depends

on the daily usage time.

Damage that occurs as a result of incorrect

compressed air processing is excluded from

warranty claims.

We recommend a service unit with a 3/8" connector,

when up to two Festool compressed air tools are

used.

A compressor that supplies at least 350 l/min at an

operating pressure of 6 bar (87 psi) should be used

to supply compressed air.

The diameter of the piping system must be sufficiently large (at least 9 mm (3/8")).

Connection for IAS hose system

The IAS hose system combines several functions in

one hose depending on the version:

– Compressed air supply

– Exhaust air extraction

– Dust extraction

12

[2-3]

[2-1]

[2-2]

Page 13

Connection and disconnection

2-1

2-2

IAS-3 SD

Click

see Fig.

[3]

.

3

Switch on/off

Switching-on: Press

Switching off: Release

[1-1]

switch.

[1-1]

switch.

13

Page 14

CAUTION

4

5

StickFix

Risk of injury

The machine should always be disconnected

from the compressed air supply before any work

is carried out on the machine.

Settings

Tuned to the surface being processed, the machine

can be equipped with three sanding pads of different hardnesses.

Hard:

ing edges.

Soft:

and convex surfaces.

Coarse and fine sanding on surfaces. Sand-

Universal for coarse and fine sanding, for flat

Setting and adjusting the speed

Can be adjusted at the control lever

LEX 3 77/2,5 7.800 - 10.500 rpm

LEX 3 150/3, 150/5, 150/7 7.000 - 10.000 rpm

This enables you to optimise the material removal

capacity to suit the respective material or application.

[1-4]

between

Replacing the sanding pad [4]

Extra-soft:

radii. Do not use on edges.

Fine sanding of moulded parts, arches,

Attaching sanding accessories using Stick-

Fix [5]

The suitable StickFix sandpaper and StickFix sanding cloth can be attached quickly and simply to the

StickFix sanding pad.

Press the self-adhesive sanding accessory onto

the sanding pad

[1-5]

.

An optimal work result can only be achieved

using original accessories and consumables.

The use of non-original accessories or consumables invalidates the right to claim under warranty.

Health risk: Fitting sanding pads of incorrect

size causes excessive vibration of the ma-

chine.

14

Dust extraction

WARNING

Dust hazard

Always work with a dust extractor.

Always observe country-specific regulations.

For use of a Festool mobile dust extractor

flow sensor

dust extractor to Ø 27 mm (1-1/16").

To guarantee optimal dust extraction, we recom-

: Adjust hose diameter of mobile

with

Page 15

mend using Festool extractors with automatic

6-2

6-1

6

switch-on/switch-off device for compressed air

machines.

Working with the machine

In order to prevent damage to the pneumatic

motor, dust extraction must not be carried

out on the pneumatic tool when it is at standstill.

Please observe all mentioned safety informations and the following rules when working:

– Always secure the workpiece in such a manner

that it cannot move while being processed.

Service and maintenance

WARNING

Risk of injury

The machine should always be disconnected

from the compresses air supply before any work

is carried out on the machine.

All maintenance and repair work which requires

the motor casing to be opened may only be carried out by an authorised service centre.

For work that generates dust, wear a dust

mask.

ing pad. This must be replaced if the braking effect

decreases.

Customer service and repair

through manufacturer or service

workshops: Please find the nearest

address at:

www.festoolusa.com/service

EKAT

4

Use only original Festool spare parts!

Order No. at:

5

3

2

1

www.festoolusa.com/service

Vanes

We recommend that the vanes on the motor be replaced after approx. 2000 operating hours.

Replacing the silencer

In order to maintain the power and performance of

the compressed air tool, replace the silencer on the

IAS hose systems at regular intervals.

Sanding pad brake

The rubber sleeve

pad and prevents uncontrolled turning of the sand-

[6-1]

brushes off the sanding

only

Cleaning the extraction channels

We recommend cleaning the extraction channels in

the machine roughly once a week (particularly if

sanding synthetic resin, in the case of wet sanding

and if sanding plaster)

brush or a cloth.

[6-2]

using a small flat

15

Page 16

Accessories

Use only original Festool accessories and Festool

consumable material intended for this machine because these components are designed specifically

for the machine. Using accessories and consumable material from other suppliers will most likely

affect the quality of your working results and limit

any warranty claims. Machine wear or your own

personal workload may increase depending on the

Environment

Do not dispose of the device together with domestic waste!

Dispose of machines, accessories and

application. Protect yourself and your machine, and

preserve your warranty claims by always using

original Festool accessories and Festool consumable material!

The order numbers of the accessories and tools can

be found in the Festool catalogue or on the Internet

under "www.festoolusa.com".

packaging at an environmentally responsible recycling centre. Observe the valid national regulations.

16

Page 17

Sommaire

Marche/Arrêt ....................................... 25

À propos de ce manuel ........................ 17

CONSIGNES DE SÉCURITÉ IMPORTANTES 17

INSTRUCTIONS CONCERNANT UN

RISQUE D'INCENDIE, DE CHOC ÉLECTRIQUE OU DE BLESSURES POUR

LES PERSONNES................................. 17

Autres risques...................................... 22

La poussière, un risque pour la santé. 22

Symboles.............................................. 22

Utilisation en conformité avec les instructions 23

Caractéristiques techniques................ 23

Description fonctionnelle..................... 23

Raccordement pneumatique et mise en ser-

vice ....................................................... 24

Traitement de l'air comprimé.............. 24

Raccord pour système de flexibles IAS 24

Réglages............................................... 26

Réglage de la vitesse........................... 26

Remplacement du plateau de ponçage

[4] ......................................................... 26

Fixation des accessoires de ponçage

avec StickFix [5]................................... 26

Aspiration............................................. 27

Travail avec la machine........................ 27

Entretien et maintenance..................... 27

Palettes................................................ 28

Remplacement du silencieux.............. 28

Frein de plateau................................... 28

Nettoyage des canaux d'aspiration ..... 28

Accessoires........................................... 28

Environnement ..................................... 28

À propos de ce manuel

Conservez ces instructions

Il est important pour vous de lire et de comprendre ce manuel. Les informations qu'il contient, se rapporte

à la protection

vous aider à reconnaître cette information.

DANGER Description du risque immi-

AVERTISSEMENT

ATTENTION

de votre sécurité

nent et l'incapacité à éviter

tout risque qui peut entraîner

la mort.

Description des dangers possibles et des blessures qui en

résultent ou la mort.

Description des dangers et

des éventuelles blessures qui

en résultent.

et

de prévention des problèmes

. Les symboles suivants sont utilisés pour

AVIS Déclaration incluant le type de

danger et conséquences possibles.

CONSEIL Indique des informations, des

notes ou des conseils pour

améliorer votre succès en utilisant l'outil.

CONSIGNES DE SÉCURITÉ IMPORTANTES

INSTRUCTIONS CONCERNANT UN RISQUE

D'INCENDIE, DE CHOC ÉLECTRIQUE OU DE

BLESSURES POUR LES PERSONNES

AVERTISSEMENT! Lors de l'utilisation d'outils, les précautions de base doivent tou-

jours être suivies, notamment ce qui suit:

CONSERVEZ CES INSTRUCTIONS

Général

a.

Pour réduire les risques de choc électrique,

d'incendie et de blessures, lire toutes les ins-

17

Page 18

tructions avant d'utiliser l'outil.

Le terme « outil électrique » utilisé dans les avertissements se réfère à votre outil électrique alimenté par secteur (câblé) ou par batterie (sans fil).

– Cet outil à air comprimé ne doit être mis en

place, réglé et utilisé que par des personnes formées et qualifiées. Sans qualification et formation, le risque d'accident augmente.

– Il est interdit de modifier cet outil à air comprimé.

Toute modification peut limiter l'efficacité des

mesures de sécurité et augmenter les risques

pour l'opérateur.

– Conservez précieusement tous les documents

fournis. En cas de cession de la machine, transmettez-les au nouveau propriétaire.

– N'utilisez jamais l'outil à air comprimé s'il est

endommagé.

– Inspectez régulièrement l'outil à air comprimé.

L'outil à air comprimé doit porter des marquages

et des autocollants bien lisibles indiquant les valeurs nominales. Il est possible de se procurer

des autocollants de rechange auprès du fabricant.

1 POSTE DE TRAVAIL

a.

Le poste de travail doit toujours être propre et

bien éclairé.

Le désordre et le manque de lumière augmentent le risque de choc électrique,

d'incendie et de blessures.

b.

N'utilisez pas l'outil dans des atmosphères explosives, par exemple en présence de liquides,

gaz ou poussière inflammables.

L'outil peut produire des étincelles et provoquer ainsi l'inflammation des poussières ou des vapeurs.

c.

Tenir les personnes tierces, les enfants et les

visiteurs à l'écart pendant l'utilisation de l'outil.

Le relâchement de l'attention peut entraîner une

perte de contrôle de l'outil.

2 SÉCURITÉ PERSONNELLE

a.

Restez vigilant. Concentrez-vous sur votre travail et faites preuve de bon sens durant l'utilisation de l'outil. N'utilisez pas l'outil si vous êtes

fatigué ou sous l'emprise de drogues, de l'alcool ou de médicaments.

Un moment d'inattention pendant l'utilisation de l'outil suffit pour

augmenter le risque de blessures.

b.

Portez des vêtements appropriés. Ne portez

pas de vêtements amples ni de bijoux. Si vous

avez des cheveux longs, attachez-les. Veillez à

tenir vos cheveux, vêtements et gants à distance des pièces mobiles.

Les vêtements

amples, les bijoux et les cheveux longs augmen-

tent le risque de blessures étant donné qu'ils

peuvent être happés par des pièces mobiles.

c.

Évitez un démarrage accidentel. Avant le branchement à l'alimentation pneumatique, assurez-vous que l'interrupteur est en position

Arrêt.

Ne portez pas l'outil en laissant votre doigt

sur l'interrupteur et ne branchez pas l'outil à

l'alimentation pneumatique lorsque l'interrupteur est en position Marche.

d.

Retirez les clés et outils de réglage avant de

mettre l'outil en marche.

Les clés ou outils de

réglage restés fixés à une pièce rotative de l'outil

augmentent le risque de blessures.

e.

Ne prenez aucun risque. Veillez à toujours avoir

une position stable et à rester bien en équilibre.

Une position stable et un bon équilibre permettent de mieux contrôler l'outil dans les situations inattendues.

f.

Utilisez un équipement de protection.

Un

masque antipoussières, des chaussures de sécurité antidérapantes ainsi qu'un casque de protection doivent être utilisés lorsque les conditions

d'utilisation l'exigent.

g.

Portez toujours une protection oculaire.

h.

Portez toujours une protection auditive lorsque

vous utilisez l'outil.

Une exposition prolongée à

un niveau sonore élevé peut entraîner une perte

auditive.

i.

Lors d'opérations impliquant un risque de

contact avec des câbles invisibles à l'œil nu, tenez l'outil par les parties isolées.

En cas de

contact avec un câble sous tension« actif », les

parties métalliques non isolées de l'outil sont

elles aussi « activées » et l'opérateur subit un

choc électrique.

j.

Évitez tout contact avec des objets mis à la terre

tels que tuyaux, radiateurs, cuisinières et réfrigérateurs.

Si votre corps est mis à la terre, le

risque de choc électrique augmente.

k.

Contrôlez la surface à travailler afin d'éviter un

contact avec des câbles invisibles à l'œil nu.

Avant de commencer à travailler, inspectez soigneusement la surface concernée afin de vous

assurer de l'absence de câbles invisibles à l'œil

nu. En cas de contact avec des câbles sous tension, l'opérateur subit un choc électrique.

3 UTILISATION DE L'OUTIL ET PRÉCAUTIONS À

PRENDRE

a.

Utilisez des mors de serrage ou autres accessoires pour fixer la pièce à un support stable et

la soutenir.

Maintenir la pièce à la main ou contre

18

Page 19

soi ne permet pas d'obtenir une stabilité suffisante et peut entraîner une perte de contrôle.

b.

Ne forcez pas sur l'outil.

Utilisez l'outil adapté à

l'application concernée. L'outil adapté permet

d'obtenir de meilleurs résultats et de travailler

dans des conditions plus sûres lorsqu'il est utilisé

à la vitesse pour laquelle il est conçu.

c.

N'utilisez pas l'outil s'il ne peut pas être mis en

marche ou à l'arrêt avec l'interrupteur.

Un appareil qui ne réagit pas à l'actionnement de l'interrupteur est dangereux et doit être réparé.

d.

Débranchez l'outil de l'alimentation pneumatique avant de procéder à des réglages ou à un

changement d'accessoires ou de ranger l'appareil.

Les mesures de sécurité préventive de ce

genre réduisent le risque de démarrage accidentel de l'outil.

e.

Si vous n'utilisez plus l'outil, conservez-le hors

de portée des enfants et autres personnes non

qualifiées.

Un outil est dangereux pour toutes les

personnes qui n'ont pas été formées à son utilisation.

f.

Entretenez l'outil avec soin.

Veillez à ce que les

outils de coupe soient toujours affûtés et propres.

Un outil bien entretenu, avec des arêtes de coupe

affûtées, réduit le risque de grippage et peut être

mieux contrôlé.

g.

Vérifiez la mobilité et le bon positionnement

des pièces mobiles ainsi que l'absence de

pièces cassées et de toute autre anomalie compromettant le bon fonctionnement de l'outil.

cas de dommages, faites réparer l'outil avant de

l'utiliser. De nombreux accidents sont dus à des

outils mal entretenus. L'endommagement de

l'outil provoque un risque de déflagration.

h.

Utilisez uniquement les accessoires indiqués

par le fabricant pour le modèle spécifique de

l'outil.

L'utilisation d'accessoires qui ne sont pas

destinés au modèle spécifique de l'outil augmente le risque de blessures.

4 ENTRETIEN

a.

L'entretien de l'outil doit uniquement être

confié au personnel de réparation qualifié.

b.

Pour l'entretien de l'outil, utilisez uniquement

des pièces de rechange identiques. Utilisez uniquement des pièces autorisées par le fabricant.

c.

Utilisez uniquement les lubrifiants fournis avec

l'outil ou indiqués par le fabricant.

En

5 ALIMENTATION PNEUMATIQUE

a.

Ne branchez jamais l'outil à une alimentation

pneumatique pouvant dépasser 200 psi.

Sous

l'effet d'une pression excessive, l'outil peut exploser, présenter des dysfonctionnements, se casser

ou provoquer des blessures graves. Utilisez uniquement de l'air comprimé propre, sec et régulé,

à la pression nominale ou dans la plage de pression nominale, comme indiqué sur l'outil. Avant

d'utiliser l'outil, vérifiez toujours que l'alimentation pneumatique est réglée sur la pression d'air

nominale ou dans la plage de pression d'air nominale.

b.

N'utilisez jamais d'oxygène, de dioxyde de carbone, de gaz combustibles ou de gaz en bouteille quelconques pour alimenter l'outil.

Ces

gaz peuvent exploser et provoquer des blessures

graves.

Danger de projections

– En cas de rupture de la pièce à usiner, de parties

de l'accessoire ou de l'outil, des pièces peuvent

être projetées à très grande vitesse.

– Portez des lunettes de protection résistant aux

chocs.

– Lors de travaux en hauteur, portez un casque. À

cette occasion, évaluez le danger pour les personnes tierces.

– Mettez la pièce à usiner en sécurité. Utilisez des

dispositifs de serrage ou un étau pour fixer la

pièce.

Danger lié à des vêtements amples

– Portez des vêtements de travail ! Ne portez pas

de vêtements amples ou de bijoux. Ils pourraient

se prendre dans les pièces en mouvement. Portez un filet à cheveux si vous avez des cheveux

longs.

Dangers pendant le fonctionnement

– Portez des gants de protection.

– L'utilisateur et le personnel de maintenance

doivent être physiquement capables de manipuler la taille, le poids et la puissance de l'outil

– Tenez l'outil correctement. Soyez prêt à accom-

pagner tout mouvement, habituel ou soudain ;

ayez les deux mains disponibles.

– Évitez toute position de travail anormale. Veillez

à maintenir une position stable et un bon équilibre à tout moment.

– En cas de coupure d'alimentation, déconnectez

le dispositif de commande pour la mise en

marche et l'arrêt.

19

Page 20

– Cet outil doit être utilisé uniquement avec un

abrasif prévu à cet effet.

– Utiliser uniquement le lubrifiant recommandé

par le fabricant.

– Portez des lunettes, des gants et des vêtements

de protection.

– Contrôler le plateau de ponçage avant chaque

utilisation. Ne l'utilisez pas s'il est fendu, cassé

ou tombé.

– Évitez le contact direct avec le plateau de pon-

çage. Portez des gants adaptés pour votre pro-

tection.

– Ne jamais utilisez l'outil sans abrasif.

– Risque de décharge électrostatique si l'outil

pneumatique est utilisé sur plastique ou sur tout

autres matériaux non conducteurs.

– Atmosphères potentiellement explosives : si le

ponçage de certains matériaux génère des pous-

sières explosives ou inflammables, il convient

impérativement d'observer les consignes d'usi-

nage du fabricant du matériau.

Danger lié à des mouvements répétés

– L'utilisation de l'outil pneumatique peut provo-

quer chez l'utilisateur des sensations désa-

gréables dans les mains et les bras ainsi qu'au

niveau de la nuque et des épaules ou d'autres

parties du corps.

– Adoptez une position de travail confortable.

Changez de position de travail lors d'un travail de

longue durée.

– En cas de sentiment de mal à l'aise, de troubles,

de battements, de douleurs, de fourmillements,

de surdité, de brûlures ou de raideurs, informez

votre employeur et consultez un médecin.

Danger lié aux accessoires

– Séparez le tuyau d'air comprimé de l'alimenta-

tion en air comprimé. En cas de non utilisation de

l'outil pneumatique, avant la maintenance et lors

du changement de l'accessoire de travail.

– Évitez le contact direct avec l'accessoire pendant

et après son utilisation.

– Utilisez uniquement les accessoires d'origine.

– Les meules ou les disques à tronçonner ne sont

pas admis.

– La vitesse admissible de l'accessoire doit être

supérieure de 1 000 tr/min minimum par rapport

à la vitesse maximale indiquée sur l'outil. Les ac-

cessoires dépassant la vitesse admise peuvent

se briser.

– Posez les abrasifs autocollants de manière

concentrique sur le plateau de ponçage.

Danger sur le poste de travail

– Danger de glisser et de trébucher ! Soyez vigilant

sur les surfaces glissantes et veillez à ne pas trébucher sur les tuyaux d'air comprimé.

– Ne convient pas pour une utilisation en atmos-

phère explosive. N'est pas isolé contre le contact

avec une source électrique.

– En environnement inconnu, procédez avec pru-

dence. Des dangers au niveau de l'alimentation

électrique ou de toute autre conduite peuvent

être cachés. Assurez-vous qu'aucune conduite

électrique, de gaz, etc. n'est présente qui pourrait constituer un danger en cas d'endommagement par l'utilisation de l'outil.

Danger lié aux poussières et aux vapeurs

– Si le ponçage dégage des poussières nocives,

l'outil doit être raccordé à un dispositif d'aspiration approprié et les prescriptions de sécurité

applicable à cette substance doivent être respectées.

– Évaluez les risques liés à ce danger et adoptez

des mesures correspondantes. Tenez compte

des poussières formées.

– Raccordez l'aspirateur à poussières. Assurez-

vous que les dispositifs d'aspiration des poussières présents sont bien raccordés et correctement employés. Respectez les consignes de

sécurité régionales sur les poussières et vapeurs

nocives. Utilisez et effectuez la maintenance de

cet outil pneumatique conformément aux recommandations contenues dans cette notice d'utilisation et utilisez les pièces et accessoires

proposés par Festool pour réduire au minimum

la génération de poussières et de vapeur. Détournez l'air évacué de façon à ce que le tourbillon de

poussière soit maintenu aussi faible que possible

dans les lieux poussiéreux.

– Contrôlez le cas échéant les poussières et va-

peurs formées sur le lieu de leur émission.

– Toutes les parties doivent être correctement

montées et toutes les conditions doivent être

remplies pour un parfait fonctionnement de l'outil pneumatique.

– Sélectionnez, effectuez la maintenance et rem-

placez les accessoires et les consommables de

cette notice d'utilisation de façon appropriée.

– Portez une protection respiratoire ! Respectez

les consignes de l'employeur ou les directives

sur la santé au travail.

Danger lié au bruit

– Un niveau sonore élevé peut entraîner des dom-

mages et pertes auditives ou d'autres problèmes

20

Page 21

en l'absence de protection auditive non appropriée.

– Évaluez les risques liés à ce danger et adoptez

des mesures correspondantes telles que l'utilisation de matériaux isolants.

– Portez une protection auditive ! Respectez les

consignes de l'employeur ou les directives sur la

santé au travail.

– Utilisez et effectuez la maintenance de l'outil

pneumatique décrit dans cette notice d'utilisation de façon appropriée.

– Sélectionnez, effectuez la maintenance et rem-

placez les accessoires et les consommables de

cette notice d'utilisation de façon appropriée.

– Vérifiez l'état de fonction du silencieux de l'outil

pneumatique.

Danger lié aux vibrations

– Les vibrations peuvent provoquer des dommages

nerveux ou perturber la circulation sanguine

dans les mains et les bras.

– Lors de travaux en milieux froids, portez des vê-

tements chauds et veillez à ce que vos mains

restent chaudes et sèches.

– En cas de surdité, de fourmillements ou de dou-

leurs dans les doigts ou les mains, ou encore si

vos doigts ou mains deviennent blancs, cessez le

travail, informez votre employeur et consultez un

médecin.

– Utilisez et effectuez la maintenance de l'outil

pneumatique décrit dans cette notice d'utilisation de façon appropriée.

– Ne maintenez pas l'outil pneumatique avec trop

de force mais veillez à bien le tenir de façon à

maîtriser les mouvements brusques des mains.

Le risque de vibrations augmente en fonction de

la force appliquée sur l'outil.

Consignes de sécurité supplémentaires relatives

aux outils pneumatiques

– L'air comprimé peut provoquer des blessures

graves.

– Séparez le tuyau d'air comprimé de l'ali-

mentation en air comprimé. En cas de non

utilisation de l'outil pneumatique, avant la

maintenance et lors du changement de

l'accessoire de travail.

– N'orientez jamais le flux d'air vers vous ou

vers d'autres personnes.

– Les tuyaux sous pression peuvent provoquer de

sérieuses blessures. Vérifiez que les tuyaux et

leurs fixations ne sont pas endommagés ou ne se

sont pas ouvert.

– La pression de service ne doit pas dépasser 6,2

bars (90 psi).

– La machine ne doit pas fonctionner avec un ré-

gime supérieur à 6500 tr/min.

– Ne suspendez jamais l'outil pneumatique au

tuyau d'air comprimé.

Autres consignes de sécurité

–

Maintenez votre poste de travail en ordre.

Un

poste de travail en désordre peut être la cause

d'accidents.

–

Tenez compte des facteurs externes.

Ne laissez

pas d'outils pneumatiques sous la pluie.

–

Maintenez les enfants à distance !

Ne laissez

pas d'autres personnes manipuler l'outil pneumatique ou le tuyau d'air comprimé. Maintenez

les autres personnes à distance de votre poste de

travail.

–

Conservez vos outils pneumatiques dans un endroit sûr.

Les outils pneumatiques non utilisés

doivent être rangés dans un endroit surélevé, sec

et fermé, hors de portée des enfants.

–

N'employez pas le tuyau d'air comprimé à des

fins pour lesquelles il n'est pas prévu.

Protégez

le tuyau d'air comprimé contre la chaleur, l'huile

et les arêtes tranchantes. Contrôlez régulièrement le tuyau d'air comprimé et faites-le remplacer par un technicien compétent en cas

d'endommagement. Le tuyau d'air comprimé ne

doit pas être utilisé sur des dispositifs tels que

des pulvérisateurs. En effet, les consignes de sécurité relatives aux dangers électriques ne

peuvent dans ce cas pas être respectées.

–

Prenez soin de vos outils.

Maintenez les outils

affûtés et propres pour garantir un travail sûr et

de qualité. Observez les consignes d'entretien et

de remplacement de l'outil. Veillez à ce que les

poignées soient sèches et exemptes d'huile ou de

graisse.

–

Ne laissez pas de clé insérée.

Avant la mise en

marche, vérifiez que les clés et les outils de réglage ont été retirés.

–

Évitez tout démarrage involontaire

. Ne portez

pas un outil pneumatique raccordé à l'alimentation en air comprimé avec le doigt sur la gâchette. Assurez-vous que l'interrupteur est sur

la position Arrêt lors du raccordement du tuyau à

l'alimentation en air comprimé.

–

Soyez attentif !

Maintenez votre attention sur la

tâche accomplie. Travaillez dans un esprit de bon

sens.

21

Page 22

N'utilisez pas l'outil pneumatique si vous n'êtes

pas concentré.

–

Faites réparer votre outil pneumatique par un

technicien spécialisé.

pond aux dispositions de sécurité en vigueur. Les

réparations doivent être réalisées exclusivement

par un technicien spécialisé, des accidents

peuvent se produire pour l'utilisateur dans le cas

contraire.

–

Travaillez uniquement avec de l'air comprimé

correctement traité.

utilisation de l'unité de conditionnement Festool

VE.

–

En cas de chute, vérifiez que l'outil pneumatique et le patin de ponçage ne sont pas endommagés. Démontez le patin de ponçage pour un

examen minutieux. Faites réparer les pièces

endommagées avant toute utilisation.

tins de ponçage cassés et des machines endommagées peuvent causer des blessures et

compromettre la sûreté de la machine.

–

Nettoyez à l'eau les accessoires imprégnés

d'huile, comme par ex. le patin de ponçage ou le

feutre de polissage, et laissez-les sécher en les

étalant convenablement.

bés d'huile sont susceptibles de s'enflammer

spontanément.

–

Utilisez toujours des tuyaux antistatique et un

système d'aspiration mis à la terre. Les composants système proposés par Festool sont

conformes à ces exigences.

système d'aspiration non raccordé à la terre ou

de tuyaux non antistatiques peut aboutir à un

choc électrique et à des blessures graves.

Cet outil pneumatique ré-

Ceci est assuré pour une

Des pa-

Les accessoires imbi-

L'utilisation d'un

– projection de morceaux de pièce,

– projection de morceaux de pièce en cas d'outils

endommagés,

– émission acoustique,

– émission de poussières.

La poussière, un risque

pour la santé

AVERTISSEMENT!

créées par le ponçage mécanique, le sciage,

le meulage, le perçage et autres activités reliées à la construction contiennent des substances

chimiques connues (dans l’État de la Californie)

comme pouvant causer le cancer, des anomalies

congénitales ou représenter d’autres dangers pour

la reproduction. Voici quelques exemples de telles

substances:

• plomb provenant de peintures à base de plomb,

• silice cristallisée utilisée dans les briques, le ci-

ment et autres matériaux de maçonnerie, et

• arsenic et chrome du bois d’oeuvre traité avec un

produit chimique.

Le risque d’exposition à de tels

produits varie selon la fréquence à laquelle vous faites

ce genre de travail. Pour réduire les risques d’exposition à

ces substances chimiques :

travaillez dans un endroit adéquatement ventilé et

utilisez un équipement de sécurité approuvé, tel

que masques antipoussières spécialement conçus

pour filtrer les particules microscopiques.

Certaines poussières

Autres risques

Certains risques restent inhérents à la conduite de

la machine, malgré le respect de toutes les prescriptions de sécurité, comme par exemple :

Symboles

Avertissement de danger général

Risque d'électrocution

Lire les instructions / les remarques !

Portez une protection auditive !

22

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE DE DOMMAGES,

L'UTILISATEUR DOIT LIRE LE MANUEL D'INSTRUCTION.

Portez une protection des yeux !

Porter un masque de protection !

Ne pas jeter dans la poubelle domestique!

n

Vitesse à vide

0

Page 23

.../min

-1

min

tours par minute

mm millimètre

’’ pouce

min minute

llitre

bar bar

lb. livre

Utilisation en conformité avec les instructions

Les ponceuses excentriques pneumatiques

conviennent au ponçage des matériaux suivants :

bois, plastique, métal, pierre, aggloméré, matériaux minéraux à liant acrylique, peinture/laque,

mastic et matériaux similaires.

L'usinage de l'amiante est formellement interdit.

Caractéristiques techniques

kg kilogramme

l/min litre par minute

psi livre par pouce carré

°F degrés Fahrenheit

Utilisez

uniquement

avec les systèmes de flexibles

Festool IAS 2 ou IAS 3 et les plateaux de ponçage

Festool !

L'utilisateur est responsable des dommages

provoqués par une utilisation non conforme.

Ponceuse excentrique pneumatique LEX 3 LEX 3 LEX 3 LEX 3

77/2.5 150/3 150/5 150/7

Entraînement Moteur pneumatique à piston rotatif à palettes

Ø plateau de ponçage 77 mm (3") 150 mm (6")

Course de ponçage 2.5 mm (3/32") 3 mm (1/8") 5 mm (3/16") 7 mm (9/32")

Vitesse de rotation à vide n

0

Consommation d’air à charge nominale*

10,500 tr/min 10,000 tr/min

270 l/min 290 l/min 310 l/min

Pression d'air

Pression d'entrée max. 6.2 bar (90 psi)

Minimum conseillée 5 bars (72.5 psi)

Catégorie de qualité de la pression d'air

classe 5

selon DIN ISO 8573-1

température de stockage conseillée /

0° - 60° C / 10° - 40° C (0 °F - 140 °F / 50 °F - 104 °F)

température de fonctionnement

Poids 0.7 kg (1.5 lbs) 1.0 kg (2.0 lbs)

* pression d'entrée de 6 bars (87 psi) ; n0, charge 30N

Description fonctionnelle

Des eléments fournis sont disponibles sur le volet

qui se trouve au début de cette notice d'utilisation.

Vous pouvez ainsi déplier cette page et visualiser

en permanence les différentes parties de l'outil

lorsque vous lisez la notice.

Les accessoires illustrés ou décrits ne sont partiel-

lement pas contenus dans le volume de livraison.

23

Page 24

[1-1]

2-1

2-2

2-3

IAS-3/IAS-2

2-1

2-2

2-3

IAS-3 light

[1-2]

Interrupteur de marche/arrêt

Touche d'extraction du raccord IAS

[1-4]

[1-5]

Régulation de la vitesse

Plateau de ponçage

[1-3]

Adaptateur pour raccord IAS

Raccordement pneumatique et mise en service

ATTENTION

Risque de blessures

Lors du raccordement à l'alimentation en air

comprimé, veillez à ce que l'outil pneumatique

soit hors service.

Traitement de l'air comprimé

La machine est conçue pour un fonctionnement

avec huile et avec l'unité d'alimentation VE Festool.

Composée d'un filtre, d'un régulateur, d'un purgeur

de condensat et d'un huileur, l'unité d'alimentation

délivre un air comprimé propre, sans condensat et

huilé. L'huileur doit être réglé de sorte qu'une

goutte d'huile soit ajoutée à l'air comprimé env.

toutes les 15 minutes. Le réglage correct dépend

de l'utilisation au quotidien.

Les dommages résultant d'un traitement

inapproprié de l'air comprimé sont exclus de

la garantie.

En cas d'emploi de deux outils pneumatiques Festool au maximum, nous recommandons l'unité

d'alimentation avec un raccord 3/8“.

Pour l'alimentation en air comprimé, choisir un

compresseur délivrant au moins 350 l/min à une

pression de service de 6 bars (87 psi).

La canalisation doit avoir un diamètre suffisamment grand (9 mm (3/8") min.).

Raccord pour système de flexibles IAS

Ce système de flexible regroupe plusieurs fonctions dans un seul flexible selon le modèle :

– Alimentation en air comprimé

– Évacuation de l’air

– Aspiration des poussières

[2-2]

[2-1]

[2-3]

24

Page 25

Branchement et débranchement

2-1

2-2

IAS-3 SD

Click

voir figure.

[3]

.

3

Marche/Arrêt

Mise en marche : appuyer sur l'interrupteur

[1-1]

Arrêt : relâcher l'interrupteur

.

[1-1]

.

25

Page 26

ATTENTION

4

5

StickFix

Risque de blessures

Avant toute intervention sur l'outil, il faut toujours débrancher l'outil de l'alimentation en air

comprimé.

Réglage de la vitesse

Réglages

Le réglage se fait au moyen du levier de réglage

4]

entre

LEX 3 77/2,5 7.800 - 10.500 min

LEX 3 150/3, 150/5, 150/7 7.000 - 10.000 min

Vous pouvez adapter de façon optimale la puissance d'enlèvement à chaque matériau ou chaque

application.

Remplacement du plateau de ponçage [4]

Pour obtenir un résultat exceptionnel, utiliser uniquement les accessoires et consom-

mables d'origine. En cas de non-utilisation

des accessoires et consommables d'origine, les

dommages qui pourraient s'ensuivre ne sont pas

couverts par la garantie.

Risque pour la santé :

teau de ponçage de taille inappropriée

conduit à des vibrations inadmissiblement

élevées sur l'outil.

En fonction de la surface à traiter, cet outil peut être

équipé de trois plateaux de ponçage de duretés différentes.

Surfaces dures :

çage fin sur des surfaces. Ponçage des chants.

ponçage dégrossissant et pon-

le montage d'un pla-

-1

-1

[1-

Fixation des accessoires de ponçage avec

StickFix [5]

Le plateau de ponçage StickFix permet de fixer des

abrasifs et des feutres StickFix adaptés de manière

simple et rapide.

Placez l'accessoire de ponçage auto-agrippant

sur le plateau de ponçage

[1-5]

et appuyez bien.

Surfaces tendres :

çage dégrossissant et ponçage fin, pour surfaces

planes et incurvées.

Surfaces super tendres :

pièces de forme, bombages, rayons. Ne pas employer sur chant !

26

accessoire universel pour pon-

pour ponçage fin sur

Page 27

Aspiration

AVERTISSEMENT

Risques pour la santé dus aux poussières

Ne travaillez jamais sans aspiration.

Respectez toujours les prescriptions nationales

en vigueur.

Travail avec la machine

Pour l'utilisation d'un aspirateur mobile Festool

avec contrôle du débit

: régler le diamètre du

flexible sur l'aspirateur sur Ø 27 mm (1-1/16").

Pour assurer une aspiration des poussières optimale, nous recommandons l'emploi d'aspirateurs

Festool dotés d'une commande marche/arrêt automatique pour outils pneumatiques.

Pour éviter des dommages sur le moteur à

air comprimé, l'outil pneumatique ne doit

pas être aspiré à l'arrêt.

Lors des travaux, observez toutes les

consignes de sécurité indiquées en introduction ainsi que les règles suivantes :

– Fixez la pièce à usiner de manière à ce qu'elle ne

puisse pas bouger pendant l'usinage.

Entretien et maintenance

AVERTISSEMENT

Risque de blessures

Avant toute opération de réparation ou d'entretien sur l’outil, il faut toujours débrancher l’outil

de l’alimentation en air comprimé.

Toute opération de réparation ou d'entretien nécessitant l'ouverture du carter moteur ne peut

être entreprise que par un atelier de service

après-vente agréé.

EKAT

1

Utilisez un masque pour les travaux dégageant de la poussière.

Seuls le fabricant et un atelier homologué sont habilités à effectuer

réparation ou service

. Les adresses à

toute

proximité sont disponibles sur:

www.festoolusa.com/service

4

Utilisez uniquement des pièces de rechange Festool d‘origine. Référence

5

3

2

sur: www.festoolusa.com/service

27

Page 28

Palettes

6-2

6-1

6

Il est recommandé de faire changer les palettes du

moteur après 2000 heures de service environ.

Remplacement du silencieux

Pour préserver la performance de l'outil pneumatique, remplacer à intervalles réguliers le silencieux sur les systèmes de flexibles IAS.

Frein de plateau

Le manchon en caoutchouc

teau de ponçage et évite ainsi une montée en vitesse incontrôlée du plateau de ponçage. Il doit être

remplacé lorsque l'effet de freinage se fait moins

efficace.

[6-1]

effleure le pla-

Nettoyage des canaux d'aspiration

Nous recommandons de nettoyer environ une fois

par semaine (surtout en cas de ponçage de mastic

synthétique, de ponçage à l'eau ou de plâtre) les canaux d'aspiration dans l'outil

brosse plate ou avec un chiffon en tissu.

Utilisez uniquement les accessoires Festool et

consommables Festool d'origine prévus pour cette

machine, car ces composants systèmes sont parfaitement adaptés les uns par rapport aux autres.

Si vous utilisez des accessoires et consommables

d'autres marques, la qualité du résultat peut être

dégradée et les recours en garantie peuvent être

soumis à des restrictions. L'usure de la machine ou

votre charge personnelle peuvent augmenter selon

[6-2]

avec une petite

Accessoires

chaque application. Pour cette raison, protégezvous, votre machine et vos droits à la garantie en

utilisant exclusivement des accessoires Festool et

des consommables Festool d'origine !

Les références des accessoires et des outils figurent dans le catalogue Festool ou sur Internet

sous "www.festoolusa.com".

Environnement

Ne jetez pas l'appareil avec les ordures ménagères !

emballages de façon compatible avec l'environne-

28

Eliminez l'appareil, les accessoires et les

ment. Respectez les prescriptions nationales en vigueur.

Page 29

Índice

Sobre este manual............................... 29

INSTRUCCIONES DE SEGURIDAD IMPOR-

TANTES ................................................ 29

INSTRUCCIONES RELACIONADAS

CON UN RIESGO DE INCENDIO, DESCARGA ELÉCTRICA O LESIONES A

PERSONAS ........................................... 29

Riesgos residuales............................... 34

Riesgos para la salud producidos por

el polvo ................................................. 34

Símbolos .............................................. 35

Uso conforme a lo previsto.................. 35

Datos técnicos...................................... 35

Descripción de las funciónes............... 36

Conexión de aire comprimido y puesta en ser-

vicio ...................................................... 36

Preparación del aire comprimido........ 36

Conexión al sistema de mangueras

IAS........................................................ 36

Conexión y desconexión....................... 37

Ajustes .................................................. 38

Regular el número de revoluciones.... 38

Cambiar el plato lijador [4].................. 38

Fijar los accesorios de lijado con Stic-

kFix [5] ................................................. 38

Aspiración............................................ 38

Trabajo con la máquina ........................ 39

Mantenimiento y cuidado ..................... 39

Lamas .................................................. 39

Cambio del silenciador........................ 39

Freno de plato...................................... 40

Limpieza de los canales de aspiración 40

Accesorios ............................................ 40

Medio ambiente.................................... 40

Sobre este manual

Guarde estas instrucciones

Es importante que usted lea y entienda este manual. La información que contiene se relaciona con la protección de

a reconocer esta información.

su seguridad

PELIGRO Descripción de peligro inmi-

ADVERTENCIA

PRECAUCIÓN

y

la prevención de problemas

nente y fracaso para evitar

riesgos que podran causar la

muerte.

Descripción de peligro y posibles lesiones resultantes o la

muerte.

Descripción de peligro y posibles lesiones resultantes.

. Los símbolos que siguen se utilizan para ayudarlo

AVISO Declaración incluyendo el tipo

de riesgo y posible resultados.

CONSEJO Indica informaciónes, notas, o

consejos para mejorar su

éxito con la herramienta.

29

Page 30

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

INSTRUCCIONES RELACIONADAS CON UN

RIESGO DE INCENDIO, DESCARGA ELÉC-

TRICA O LESIONES A PERSONAS

ADVERTENCIA! Cuando se utilizan herramientas, se deben seguir siempre las pre-

cauciones básicas, incluyendo las siguientes:

CONSERVE ESTAS INSTRUCCIONES

General

a.

Para reducir los riesgos de descarga eléctrica,

incendio y lesiones personales, lea todas las

instrucciones antes de usar la herramienta.

Cuando en los avisos aparece el término «herramienta eléctrica», se hace referencia tanto a las

herramientas que funcionan enchufadas a la red de

suministro eléctrico (con cable) como a las que funcionan con baterías (sin cable).

– Esta herramienta de aire comprimido debe ser

instalada, ajustada y utilizada exclusivamente

por personal cualificado y que cuente con la formación apropiada. Las personas sin cualificación

ni formación son más propensas a causar accidentes.

– Se prohíbe modificar esta herramienta de aire

comprimido. Su modificación podría reducir la

efectividad de las medidas de seguridad y aumentar los riesgos para las personas que utilicen la máquina.

– Todos los documentos adjuntos se deben con-

servar. Si la máquina cambia de propietario, junto con esta se debe entregar toda la

documentación.

– Si la herramienta de aire comprimido presenta

algún daño, no se debe usar en ningún caso.

– Inspeccionar con regularidad la herramienta de

aire comprimido. La herramienta de aire comprimido debe estar identificada con sus valores nominales (que deben ser claramente legibles) y

con marcas. Se pueden pedir al fabricante señales de repuesto.

1 ÁREA DE TRABAJO

a.

El área de trabajo se debe mantener limpia y

bien iluminada.

trabajo y las zonas oscuras aumentan el riesgo

de descarga eléctrica, incendio y lesiones personales.

b.

No hacer funcionar la herramienta en atmósferas explosivas, ni tampoco en presencia de lí-

El desorden en los bancos de

quidos, gases o polvo de naturaleza inflamable.

La herramienta puede generar chispas, con el

riesgo consiguiente de ignición del polvo o los gases.

c.

Los espectadores, niños y visitantes se deben

mantener apartados durante el funcionamiento

de la herramienta.

provocar la pérdida de control de la herramienta.

2 SEGURIDAD PERSONAL

a.

Es imprescindible estar alerta. Mientras se maneja la herramienta, es preciso fijarse en lo que

se está haciendo y usar el sentido común. No

usar la herramienta si se está cansado o bajo

los efectos de las drogas, el alcohol o algún medicamento.

el manejo de la herramienta aumenta el riesgo

de lesiones personales.

b.

Usar prendas de vestir apropiadas. No usar

ropa holgada ni joyas. Si se lleva melena, mantenerla recogida. El cabello, las prendas y los

guantes se deben mantener apartadas de las

piezas móviles.

y la melena pueden ser atrapadas por las piezas

móviles, lo que aumenta el riesgo de lesiones

personales.

c.

Evitar que la herramienta se ponga en marcha

inadvertidamente. Antes de conectar la herramienta al suministro de aire, es imprescindible

asegurarse de que el interruptor esté desconectado.

apoyado en el interruptor ni conectar la herramienta al suministro de aire con el interruptor

conectado.

d.

Retirar las llaves de ajuste antes de poner en

marcha la herramienta.

a una pieza rotativa aumenta el riesgo de lesiones

personales.

e.

No forzar la postura. Mantener el equilibrio y un

buen apoyo en todo momento.

librio y un buen apoyo permite controlar mejor la

herramienta en situaciones inesperadas.

f.

Usar el equipo de protección individual.

prescindible usar una máscara antipolvo, calzado

de seguridad antideslizante y un casco de seguridad que sean apropiados para las condiciones

aplicables.

g.

Usar siempre un sistema de protección ocular.

h.

Siempre que se use la herramienta es imprescindible usar un sistema de protección auditiva.

Un momento de distracción durante

No llevar la herramienta con el dedo

Las distracciones pueden

Las prendas holgadas, las joyas

Dejar una llave acoplada

Mantener el equi-

Es im-

30

Page 31

La exposición prolongada a ruido de alta intensidad puede provocar una pérdida de audición.

i.

Cuando se lleve a cabo una operación en la que

la herramienta de corte pueda entrar en contacto con cableado oculto, sujetar la herramienta por las superficies de agarre aisladas.

herramienta entrase en contacto con un cable

sometido a tensión eléctrica, las piezas metálicas

descubiertas de la herramienta también quedarían sujetas a dicha tensión eléctrica y el operador sufriría una descarga.

j.

Evitar que el cuerpo entre en contacto con superficies conectadas a tierra, como tuberías,

radiadores, cocinas y frigoríficos.

Si el cuerpo

está conectado a tierra, el riesgo de descarga

eléctrica aumenta.

k.

Inspeccionar la pieza de trabajo para evitar el

contacto con cables ocultos.

Antes de llevar a

cabo ningún trabajo, investigar a fondo la pieza de

trabajo para detectar posibles cables ocultos. Entrar en contacto con un cable sometido a tensión

eléctrica provoca que el operador sufra una descarga eléctrica.

3 USO Y CUIDADOS DE LA HERRAMIENTA

a.

Sujetar la pieza de trabajo a una plataforma estable usando bridas o algún otro elemento que

ofrezca la seguridad suficiente.

Sostener la pieza de trabajo con la mano o contra el cuerpo es

muy inestable y puede dar lugar a una pérdida de

control.

b.

No forzar la herramienta.

Usar la herramienta

adecuada para la aplicación. La tarea en cuestión

siempre se resuelve mejor y con más seguridad si

se usa la herramienta apropiada y se hace funcionar a la potencia para la que ha sido diseñada.

c.

No usar la herramienta si el interruptor no permite encenderla o apagarla.

Si la herramienta

no se puede controlar con el interruptor, su uso

representa un peligro y se debe reparar sin falta.

d.

Antes de hacer algún ajuste en la herramienta,

de cambiar accesorios en esta o de guardarla,

desconectarla del suministro de aire.

Estas medidas de seguridad preventivas reducen el riesgo

de poner la herramienta en marcha inadvertidamente.

e.

Cuando la herramienta no esté en uso, guardarla fuera del alcance de los niños y otras personas que no dispongan de la formación

adecuada.

El uso de la herramienta por parte de

Si la

personas que no dispongan de la formación adecuada es un peligro.

f.

La herramienta debe ser objeto de un mantenimiento cuidadoso.

Las herramientas de corte se

deben mantener afiladas y limpias. Una herramienta cuyo mantenimiento sea correcto y que

tenga los cantos de corte bien afilados reduce el

riesgo de agarrotamiento y es más fácil de controlar.

g.

Comprobar si hay alguna pieza móvil desalineada o agarrotada, así como alguna pieza rota u

otras alteraciones que puedan afectar al funcionamiento de la herramienta.

Si la herramienta

está dañada, es imprescindible solicitar su revisión al servicio técnico antes de usarla. Muchos

accidentes tienen su origen en un mantenimiento

deficiente de las herramientas. Si la herramienta

está dañada, existe riesgo de explosión.

h.

Únicamente se deben usar los accesorios que el

fabricante haya identificado como adecuados

para el modelo concreto de herramienta.

plear un accesorio que no esté destinado a ser

usado con el modelo concreto de herramienta

aumenta el riesgo de lesiones personales.

4 SERVICIO TÉCNICO

a.

El servicio técnico de las herramientas debe ser

prestado exclusivamente por personal de reparación que cuente con una cualificación apropiada.

b.