Page 1

LEX 2 150/3

LEX 2 150/7

LEX 2 185/7

Instruction manual

Page 2 - 6

IMPORTANT: Read and understand all instructions

before using.

Guide dutilisation

Page 7 - 11

IMPORTANT: Lire et comprendre toutes les

instructions avant de démarrer les travaux.

Manual de instrucciones

Página 12 - 16

IMPORTANTE: Lea y comprende todas las

instrucciones antes de usar.

464 111_001

Eccentric sander

Ponceuse excentrique

Lijadora excéntrica

Page 2

GENERAL SAFETY RULES

Read and understand all

instructions. Failure to follow all instructions

listed below may result in electric shock, fire and/

or serious personal injury.

SAVE THESE INSTRUCTIONS

Work area

1 Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

2 Keep bystanders, children, and visitors

away while operating a tool. Distractions can

cause you to lose control.

Personal safety

3 Stay alert, watch what you are doing

and use common sense when operating a

tool. Do not use while tired or under the

influence of drugs, alcohol, or medication.

A moment of inattention while operating tools

may result in serious personal injury.

4 Dress properly. Do not wear loose

clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from

moving parts. Loose clothes, jewellery, or long

hair can get caught in moving parts.

5 Avoid accidental starts. Before

connecting the air supply make sure that

the tool is switched off. Carrying tools with

your finger on the switch or plugging in tools

that have the switch on invites accidents.

6 Remove adjusting keys or tools before

turning the tool on. A wrench or key that is left

attached to a rotating part of the tool may result

in personal injury.

7 Do not overreach. Stand on both feet

and keep proper footing and balance at all

times. Proper footing and balance enables better

control of the tool in unexpected situations.

8 Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

Tool use and care

9 Do not abuse the hose. Never carry or

pull the tool by the hose. Keep hose away

from heat, sharp edges or moving parts.

Replace damaged hoses immediately.

Damaged hoses increase the risk of accidents.

10 Use clamps or other suitable means to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body is unstable and may lead to

loss of control.

11 Do not force tool. Use the correct tool

for your application. The correct tool will do

the job better and safer at the rate for which it is

designed.

12 Do not use tool if switch does not turn

it on or off. Any tool that cannot be controlled

with the switch is dangerous and must be

repaired.

13 Disconnect the compressed-air hose

from the tool before making any

adjustments, changing accessories, or

storing the tool. Such preventive safety

measures reduce the risk of starting the tool

accidentally.

14 Store idle tools out of reach of children

and other untrained persons. Tools are

dangerous in the hands of untrained users.

15 Maintain tools with care. Keep cutting

tools sharp and clean. Properly maintained

tools with sharp cutting edges are less likely to

bind and are easier to control.

16 Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools.

17 Use only accessories that are

recommended by the manufacturer for your

model. Accessories that may be suitable for one

tool may become hazardous when used on

another tool.

Service

18 Tool service may be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified personnel

could result in a risk of injury.

19 When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual. Use

of unauthorized parts or failure to follow the

Maintenance instructions may create a risk of

injury.

2

Page 3

arsenic and chromium from chemically-treated

Various dust created by power sanding, sawing,

grinding, drilling and other construction activities

contains chemicals known (to the State of

California) to cause cancer, birth defects or other

reproductive harm. Some examples of these

chemicals are:

lead from lead-based paints,

crystalline silica from bricks and cement and

other masonry products, and

lumber.

The risk from these exposures varies, depending

on how often you do this type of work.

To reduce your exposure to these chemicals:

Work in a well ventilated area,

and work with approved safety

equipment, such as dust masks

that are specially designed to

filter out microscopic particles.

Technical data

Sanding pad diameter: - LEX 2 150 150 mm / 6

- LEX 2 185 185 mm / 7

Drive Compressed-air vane motor

Operating pressure (flow pressure) 87 psi

No load speed 4,000 - 8,000 rpm

Orbits per minute 8,000 - 16,000 opm

Sanding stroke: - LEX 2 150/3 3 mm

- LEX 2 150/7, LEX 2 185/7 7 mm

Air consumption at nominal load 14 cfm

Weight: - LEX 2 150 1.3 kg / 2.8 lbs

- LEX 2 185 1.4 kg / 3 lbs

Symbols

n

0

rpm revolutions per minute

opm orbits per minute

no load speed (revolutions)

Use for intended purpose

As specified, the machines are designed for

sanding wood, plastic, metal, stone, composite,

paintwork, filler and similar materials. Material

containing asbestos must not be processed with

these tools.

The user is liable for any damage

and injury resulting from incorrect usage!

Functional description

Connection and start-up

Make sure that the pneumatic

tool is switched off when you connect the

compressed-air supply.

Compressed-air treatment

The Festool service unit should always be used

to ensure that Festool pneumatic tools function

correctly. Consisting of a filter, control unit,

condensation drain and lubricator, the service

unit cleans and lubricates the compressed air

and keeps it free of condensation.

For thios tool, the lubricator should be set so

that a drop is applied to the compressed air

approx. every 7-10 minutes.

Damage that occurs as a result of incorrect

compressed-air treatment is excluded from

warranty claims.

We recommend a service unit with a 3/8"

connector for up to two Festool pneumatic tools.

The compressor used to supply the compressed

air should supply at 20 cfm and an operating

pressure of 87 psi. The diameter of the piping

system must be sufficiently large (at least 9mm

/ 1/2).

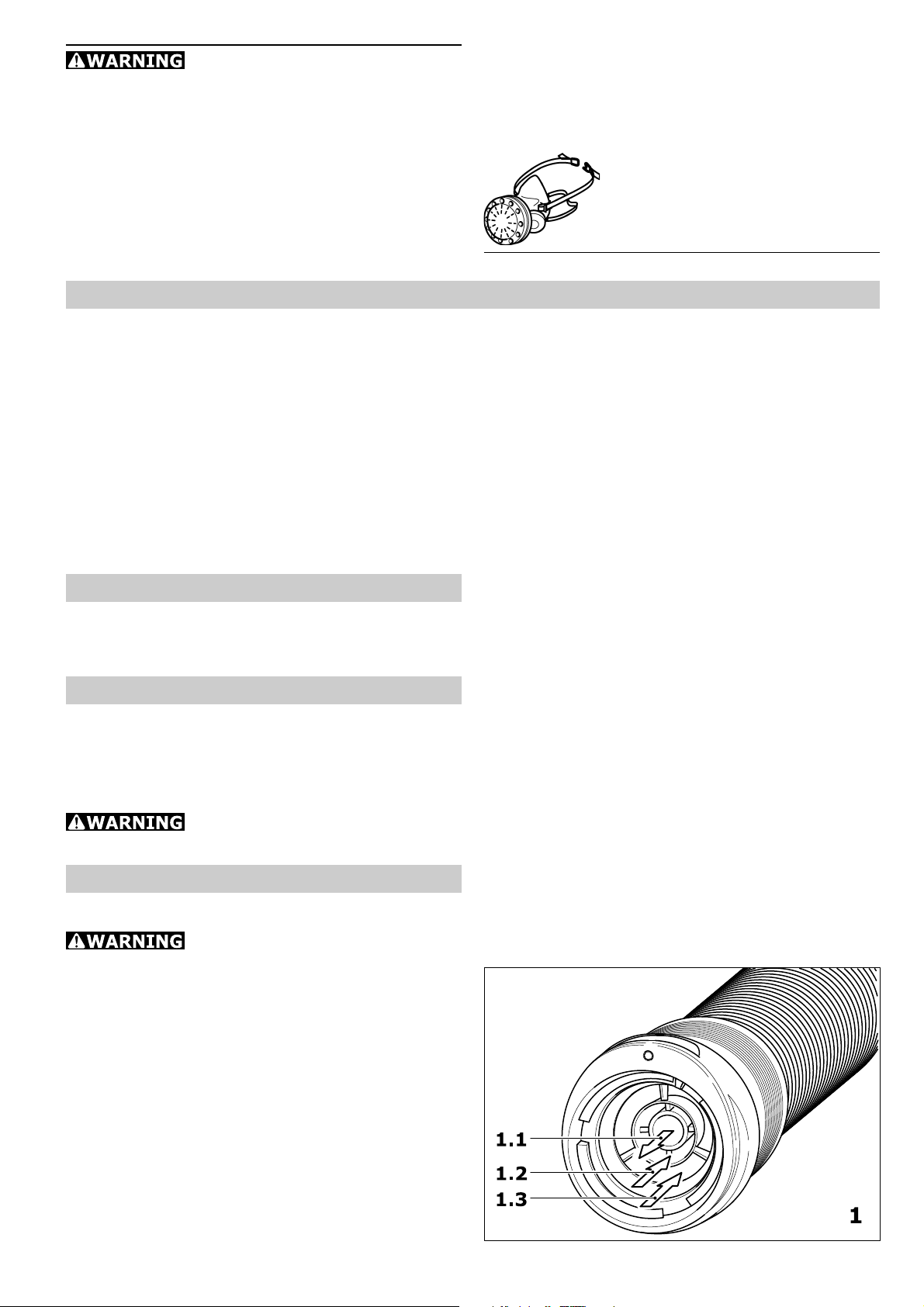

IAS 2 hose connector

The eccentric sander is a pneumatic tool for

connection to the Festool IAS 2 system.

This hose system combines three functions in

one hose:

- Compressed air supply (1.1)

- Exhaust air extraction (1.2)

- Dust extraction (1.3)

3

Page 4

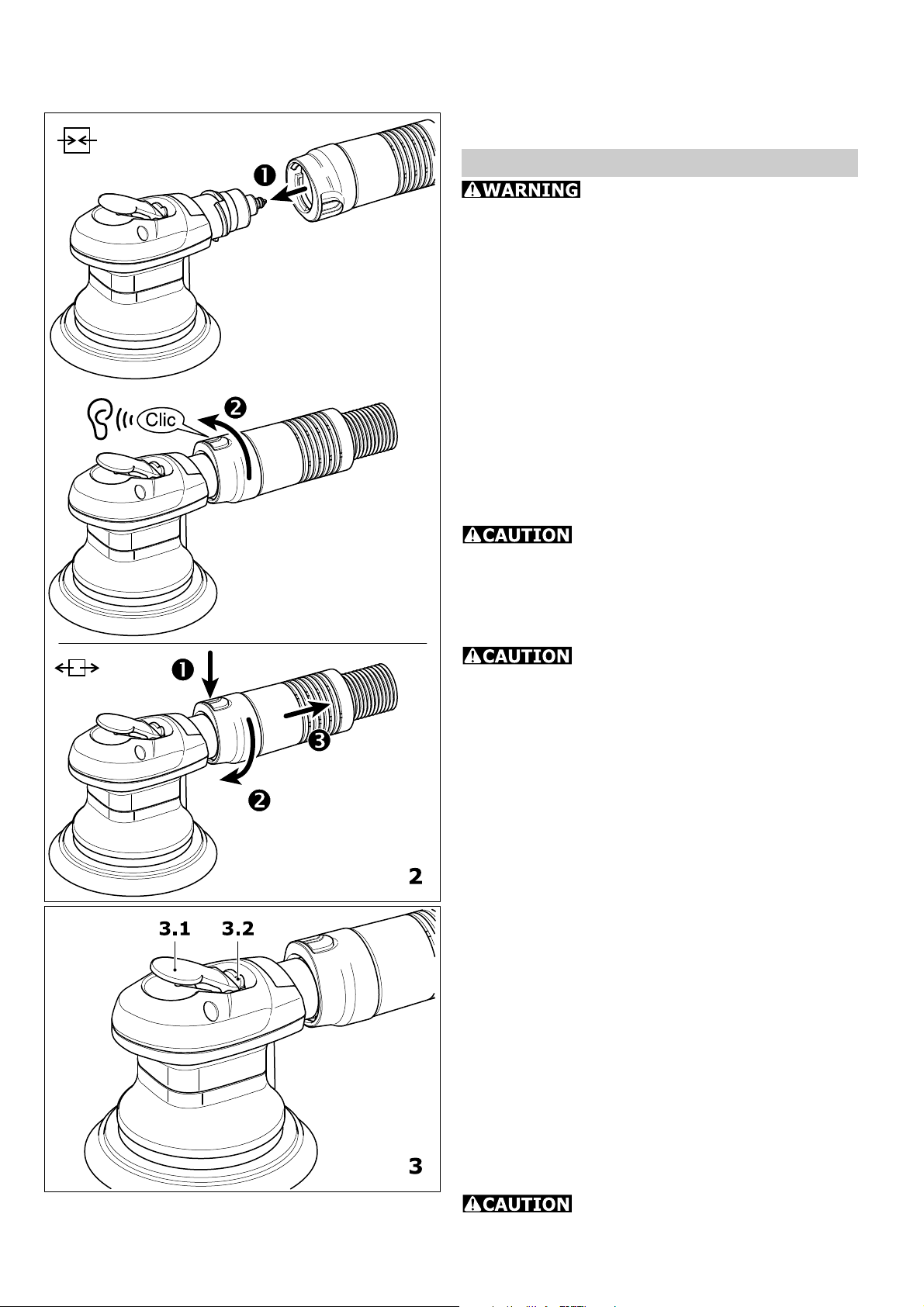

Connection and disconnection see Fig. 2.

IAS 2 connecting system see accompanying

instruction sheet.

Starting

Pressing the lever (3.1) switches on the

pneumatic tool. Releasing the lever switches

the tool off again.

Tool settings

Always disconnect the tool from

the compressed air supply before doing any

work on the tool.

Speed adjustment

You can regulate the sanding speed steplessly

between 4,000 and 8,000 rpm using the

adjusting wheel (3.2). This enables you to

optimize the speed to suit the material.

Suction unit

Sanding dust is extracted through the extraction

channels in the sanding pad and taken di-rectly

to the material removal point. To ensure

optimized dust extraction, we recommend using

a Festool dust extractor with automatic switchon/switch-off device for compressed-air tools.

In order to prevent damage to the

pneumatic motor, dust extraction must be

allowed to run through the pneumatic tool when

it is at standstill.

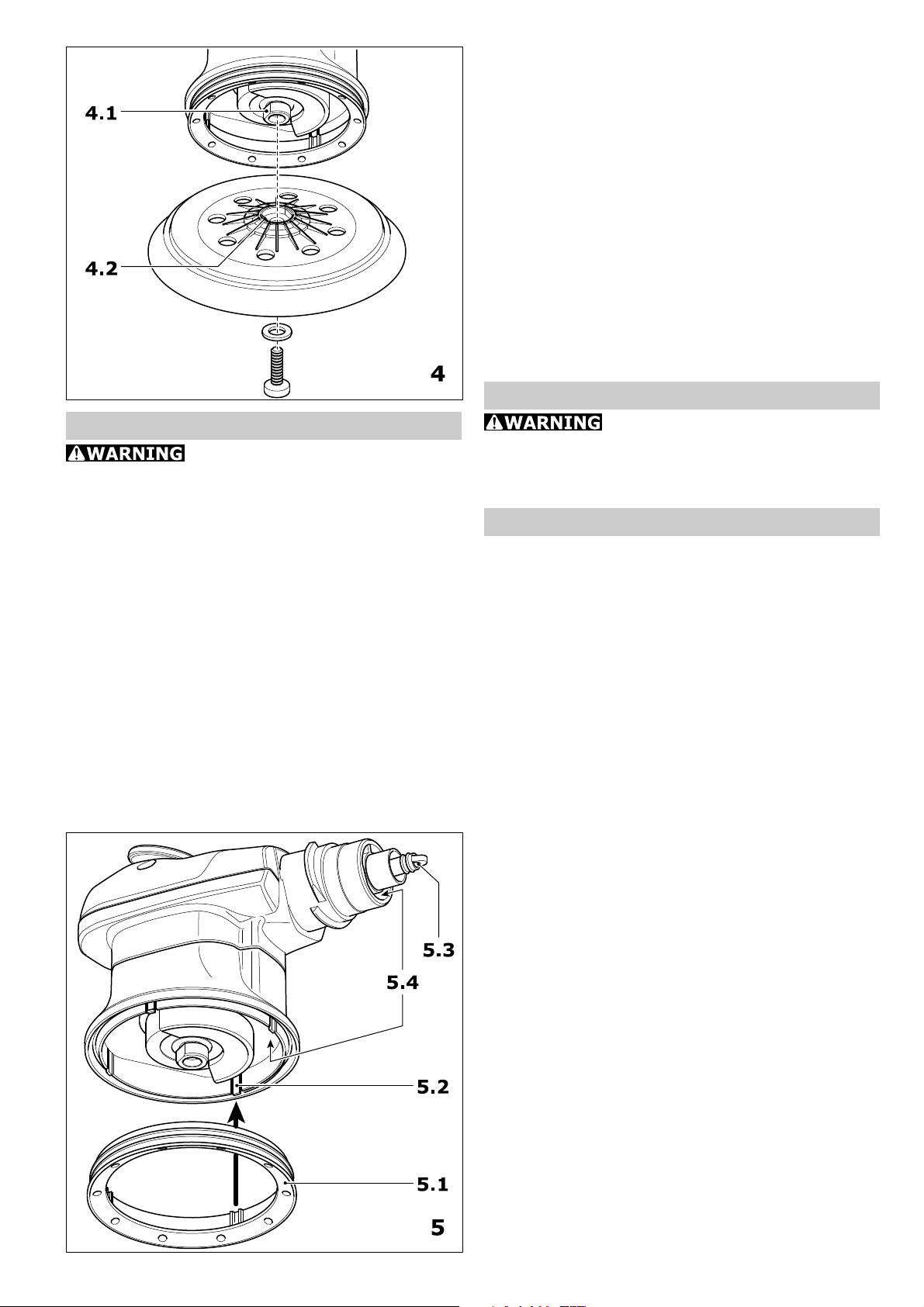

Sanding pads

Sanding pads have different

weights depending on their diameter. Using a

sanding pads of the incorrect size will cause

excessive vibration of the tool.

Only use sanding pads with an undamaged burr

layer.

Sanding pads are available in three degrees of

hardness to suit the type of application:

- Hard: high edge strength, for removing coarse

material from surfaces and for sanding edges.

- Soft: universal for coarse and fine sanding,

with elastic structure for even and curved

surfaces.

- Super soft: high elasticity, for smooth fine

sanding of moulded parts, curves, radii. Do

not use on edges.

Assembly - see Fig. 4. Make sure the positivefit supports on the sanding pad (4.1) are flush

with the ones on the tool (4.2).

Abrasive

Self-adhesive abrasives, such as Stickfix

sandpaper, and sanding cloths can be affixed

to the Stickfix sanding pads.

To affix the abrasive, simply press it onto the

sanding pad and remove it after use.

The abrasive must be centered on

the pad and the holes aligned with those on

the sanding pad.

4

Page 5

Lubrication

If the tool has not been used for an extended

period, such as a weekend, introduce 1 or 2

drops of lubricating oil into the compressed-air

supply (5.3) on the tool prior to use.

Replacing the silencer

The silencer on the IAS 2 connecting piece must

be replaced at regular intervals to maintain the

power of the pneumatic tool.

Cleaning the extraction channels

We recommend that the extraction channels in

the tool (5.4) be cleaned once a week using a

small pipe-cleaner brush or a cloth (especially

when sanding resin filler).

Accessories, tools

Maintenance and care

Always disconnect the tool from

the compressed air supply before doing any

work on the tool.

Any maintenance or repair work requiring the

motor housing to be opened may only be carried

out by an authorized service workshop.

Vanes

We recommend that the vanes on the motor

be replaced after approx. 500 operating hours.

Sanding pad brake

The collar (5.1) makes contact with the sanding

pad, thus preventing uncontrolled vibration of

the sanding pad. This collar wears out over time

and must be replaced should brake fading occur.

The sanding pad must be removed for this. You

can then remove the collar from the snap-on

fastener (5.2) and replace it with a new one.

For safety reasons, only use

original Festool accessories and tools!

Accessory and tool order numbers can be found

in your Festool catalog.

Warranty

Conditions of 1+2 Warranty

You are entitled to a free extended warranty (1

year + 2 years = 3 years) for your Festool power

tool. Festool shall be responsible for all shipping

costs during the first year of the warranty. During

the second and third year of the warranty the

customer is responsible for shipping the tool to

Festool. Festool will pay for return shipping to

the customer using UPS Ground Service. All

warranty service is valid 3 years from the date

of purchase on your receipt or invoice.

Festool Limited Warranty

This warranty is valid on the pre-condition that

the tool is used and operated in compliance with

these Festool operating instructions. Festool

warrants, only to the original consumer

purchaser, that the specified tool will be free from

defects in materials and workmanship for a term

of one year from the date of procurement. Festool

makes no other warranty, express or implied,

for Festool portable power tools. No agent,

representative, distributor, dealer or employee

of Festool has the authority to increase or

otherwise change the obligations or limitations

of this warranty. The obligations of Festool in its

sole discretion under this warranty shall be

limited to the repair or replacement of any Festool

portable power tool that is found to be defective

as packaged with this User Manual.

Excluded from coverage under this warranty are:

normal wear and tear; damages caused by

misuse, abuse or neglect; damage caused by

anything other than defects in material and

workmanship. This warranty does not apply to

5

Page 6

accessory items such as circular saw blades, drill

bits, router bits, jigsaw blades, sanding belts,

and grinding wheels. Also excluded are wearing

parts, such as carbon brushes, vanes of air tools,

rubber collars and seals, sanding discs and pads,

and batteries.

Festool portable power tools requiring

replacement or repair are to be returned with

the receipt of purchase to Festool (call 800-5548741 for address details).

IN NO EVENT SHALL FESTOOL BE LIABLE

FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES FOR BREACH OF

THIS OR ANY OTHER WARRANTY,

EXPRESSED OR IMPLIED WHATSOEVER.

ALL WARRANTIES IMPLIED BY STATE

LAW, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE,

ARE HEREBY LIMITED TO THE DURATION

OF THREE YEARS.

Some states in the U.S. and some Canadian

provinces do not allow the limitations on how

long an implied warranty lasts, so the above

limitation may not apply to you. With the

exception of any warranties implied by state or

province law as hereby limited, the foregoing

express limited warranty is exclusive and in lieu

of all other warranties, guarantees, agreements

and similar obligations of Festool.

This warranty gives you specific legal rights and

you may also have other rights which vary from

state to state in the U.S. and province to province

in Canada.

6

Page 7

RÉGLES DE SÉCURITÉ GÉNÉRALES

Assurez-vous que

vous lisez et comprenez bien toutes les

instructions. Le non-respect, même partiel, des

instructions ci-dessous entraîne un risque

d'électrocution, d'incendie et/ou de blessures

graves.

CONSERVEZ CES INSTRUCTIONS

Aire de travail

1 Veillez à ce que laire de travail soit

propre et bien éclairée. Le désordre et le

manque de lumière favorisent les accidents.

2 Tenez à distance les curieux, les enfants

et les visiteurs pendant que vous travaillez

avec un outil. Ils pourraient vous distraire et

vous faire une fausse manoevre.

Sécurité des personnes

3 Restez alerte, concentrez-vous sur

votre travail et utilisez votre bon sens.

Nutilisez pas loutil si vous êtes fatigué ou

sous linfluence de drogues, dalcool ou de

médicaments. Un instant dinattention peut

causer des blessures graves.

4 Portez des vêtements appropriés. Ne

portez pas de vêtements flottants ni de

bijoux. Confinez les cheveux longs.

Napprochez jamais les cheveux, les

vêtements ou les gants des pièces en

mouvement. Les vêtement flottants, les bijoux

ou les cheveux longs risquent dêtre happés par

les pièces en mouvement.

5 Attention aux démarrages accidentels.

Assurez-vous que loutil nest pas sous

tension quand l air comprimé est branché.

Ne portez pas loutil avec le doigt sur la gâchette

et ne branchez-pas un outil dont linterrupteur

est à la position MARCHE car c,est une source

daccident.

6 Enlevez les clés de réglage ou les

accessoires avant de mettre loutil en

marche. Une clé laissée dans une pièce tournante

de loutil peut provoquer des blessures.

7 Ne vous penchez pas trop en avant.

Gardez toujours une position stable et bien

équilibrée. Un bonne stabilité vous permet de

mieux réagir à une situation inattendue.

Utilisez des accessoires de sécurité. Portez

toujours des lunettes ou un masque de

sécurité. Selon les conditions, portez aussi un

masque antipoussière, des chaussures de

sécurité antidérapantes, un casque protecteur

et/ou une protection acoustique.

Utilisation et entretien des outils

9 Ne maltraitez pas le tuyau. Évitez de

tirer ou de porter lappareil par le tuyau.

Nexposez pas le tuyau à la chaleur, à des

arêtes vives ou à des pièces en

mouvement. Remplacez immédiatement le

tuyau sil est endommagé. Un tuyau

endommagé augmente le risque daccident.

10 Immobilisez la pièce de travail avec un

serre-joint ou tout autre moyen approprié

sur une surface stable . Ne tenez pas la pièce

avec la main ou contre votre corps car ce nest

pas stable et cela peut causer un dérapage de

loutil.

11 Ne forcez pas . Utilisez loutil appropríé

à la tâche. Un bon outil fonctionne mieux et de

façon plus sécuritaire. Respectez aussi la vitesse

de travail qui lui est propre.

12 Nutlisez pas un outil si son interrupteur

est bloqué. Un outil dont linterrupteur ne

fonctionne pas est dangereux et doit être réparé.

13 Débranchez la fiche de loutil avant

deffectuer un réglage, de changer

daccessoire ou de ranger loutil. Ces

mesures préventives de sécurité réduisent le

risque de démarrage accidentel de loutil.

14 Rangez les outils hors de portée des

enfants et des personnes inexpérimentées.

Les outils sont dangereux dans les mains de

novices.

15 Entretenez bien les outils. Les outils de

coupe doivent toujours être bien affûtés et

propres. Des outils bien entretenus, dont les

arêtes sont bien tranchantes, sont moins

susceptibles de coincer et plus faciles à contrôler.

16 Soyez attentif à tout désalignement ou

coincement des pièces en mouvement, à

tout bris ou à toute autre condition

préjudiciable au bon fonctionnement de

loutil. Si loutil est endommagé, faites-le

réparer avant de vous en servir. De

nombreux accidents ont pour cause le mauvais

état des outils

17 Nutilisez que des accessoires

recommandés par le fabricant pour votre

modèle doutil. Certains accessoires peuvent

convenir à un outil, mais être dangereux avec un

autre.

Réparation

18 Faites réparer les outils par un

réparateur qualifié. Lentretien ou la réparation

dun outil électrique par un amateur peut avoir

des conséquences graves.

19 Pour la réparation dun outil,

nemployez que des pièces de rechange

dorigine. Suivez les directives données à

la section Réparation de ce manuel.

Lemploi de pièces non autorisées ou le nonrespect des instructions dentretien peut créer

des blessures.

7

Page 8

arsenic et chrome du bois d'uvre traité avec

Les poussières provenant du sablage, dusciage,

du meulage, du perçage et des autres activités

reliées à la construction contiennent des

substances chimiques reconnues (dans l'État de

la Californie) comme pouvant causer le cancer,

des anomalies congénitales ou d'autres dangers

pour la reproduction. Voici quelques exemples

de telles substances:

plomb provenant de peintures à base de

plomb,

silice cristallisée utilisée dans les briques, le

ciment et autres matériaux de maçonnerie, et

un produit chimique.

Le risque d'exposition à de tels produits varie

selon la fréquence du travail.

Pour réduire les risques

d'exposition à ces substances

chimiques : travaillez dans un

en-droit bien ventilé et utilisez

un équipement de sécurité

approuvé, tel que des masques

antipoussières spécialement

conçus pour filtrer les particules

microscopiques.

Données techniques

Diamètre du plateau de sablage: - LEX 2 150 150 mm / 6

- LEX 2 185 185 mm / 7

Entraînement Moteur pneumatique à piston rotatif à palettes

Pression de service (pression découlement) 87 psi

Vitesse à vide 4,000 8,000 tr/min

Mouvements orbitaux 8,000 - 16,000 tr/min

Course de sablage: - LEX 2 150/3 3 mm

- LEX 2 150/7, LEX 2 185/7 7 mm

Débit dair en charge nominale 14 cfm

Poids: - LEX 2 150 1.3 kg / 2.8 lbs

- LEX 2 185 1.4 kg / 3 lbs

Symboles

n

0

tr/min tours par minute

Vitesse de rotation à vide

Utilisation

Ces outils sont conçus par principe pour le

sablage des matériaux suivants : bois, plastique, métal, pierre, composite, peinture, vernis,

enduit et similaires. Il est interdit de poncer

des matières contenant de l'amiante avec

l'appareil.

L'utilisateur est responsable de tout dommage ou accident dû à

l'utilisation on conforme des machines.

Description fonctionnelle

Branchement et mise en route

Lors du raccordement à

l'air comprimé, veillez à ce que l'outil pneumatique n'est pas sous tension.

Traitement de lair comprimé

Pour assurer le bon fonctionnement des outils

pneumatiques Festool, il faut toujours utili-ser

l'appareil Festool VE. Composé d'un filtre, d'un

régulateur, d'un purgeur de conden-sat et d'un

huileur, l'appareil de conditionnement fournit

un air comprimé propre, sans condensat et

huilé. L'huileur doit être réglé de façon à ajouter

une goutte d'huile à l'air comprimé toutes les

7 à 10 minutes.

Les dommages résultant d'un mauvais

traitement de l'air comprimé sont exclus de la

garantie. En cas d'emploi de deux outils

pneumatiques Festool au maximum, nous recommandons el raccord de 3/8. Pour l'air

comprimé, il faut choisir un compresseur

fournissant au moins 20 cfm à une pression de

service de 87 psi. La canalisation doit avoir un

diamètre suffisamment grand (9 mm / 1/2

mini).

Raccordement Tuyau IAS 2

La sableuse excentrique est un outil pneumatique se raccordant au système Festool IAS 2.

Ce système à flexibles regroupe trois fonctions

dans un seul flexible :

- Air comprimé (1.1)

- Extraction de lair (1.2)

- Aspiration des poussières (1.3)

8

Page 9

Branchement et débranchementvoir figure 2.

Système de raccordement IAS 2voir fiche

technique jointe.

Mise en marche

Appuyez sur le levier (3.1) pour mettre l'outil

pneumatique en marche. Relâchez l'outil pour

arrêter l'outil.

Réglages de loutil

Débranchez toujours l'air

comprimé avant de travailler sur l'outil.

Réglage de la vitesse

Vous pouvez régler la vitesse en continu entre

4 000 et 6 000 tr/min au moyen de la molette

(3.2) pour la meilleure vitesse correspondant

au travail.

Aspiration

La poussière du sablage est aspirée directement à son point de production par les canaux

d'aspiration dans le plateau de sablage. Pour

assurer une aspiration optimale des poussières,

nous recommandons l'emploi d'aspirateurs

Festool dotés d'une commande marche/arrêt

automatique pour outils pneu-matiques.

Pour éviter des dommages

du moteur à air comprimé, ne laissez pas l'outil

pneumatique tourner à vide.

Plateau de sablage

Suivant leur diamètre, les

plateaux sablage sont plus ou moins lourds.

Un tampon de sablage de la mauvaise taille

produit des vibrations excessives.

Nutilisez que des tampons de sablage laissant

une surface uniforme non éraflée.

Selon leur utilisation, les panneaux de sablage

ont trois grains:

- Dur : résistance élevée du bord, pour le

dégrossissage des surfaces et le sablage sur

chant.

- Souple : universel pour sablage grossier et

fin, à structure élastique pour surfaces planes

et bombées.

9

Page 10

- Extra-souple : élasticité élevée, pour sablage

fin soigné sur pièces moulées, bom-bages,

rayons. À ne pas employer sur chant!

Montage - Figure 4. Assurez-vous que le

tampon de sablage (4.1) et l'outil (4.2) sont

bien encliquetés!

Abrasifs

Il est possible d'utiliser des abrasifs autoadhésifs comme le papier sablé Stickfix et des

toiles emery qui peuvent être collés au tampon

de sablage.

Il suffit de poser l'abrasif sur le tampon de

sablage et de le décoller après usage.

Les abrasifs doivent être

centrés sur le tampon et les trous doivent être

alignés sur ceux du tampon. appliqués de façon

concentrique et leur perforation doit concorder

avec celle du plateau de ponçage.

Entretien

Débranchez toujours l'air

comprimé avant de travailler sur les outils.

Les travaux d'entretien et de réparation

nécessitant l'ouverture du logement du moteur

ne doivent être effectués que par le personnel

d'un atelier autorisé du service après-vente.

Palettes

Il est recommandé de faire changer les palettes

du moteur après 500 heures de service environ.

Lubrification

Si l'outil n'a pas été utilisé pendant un certain

temps, une fin de semaine, par exemple,

mettez 1 ou 2 gouttes d'huile dans le raccord

d'arrivée de l'air comprimé avant de le mettre

en marche.

Remplacement du silencieux

Pour préserver la performance de loutil

pneumatique, il faut remplacer à intervalles

réguliers le silencieux sur le raccord IAS 2.

Nettoyage des canaux daspiration

Nous recommandons de nettoyer une fois par

semaine (surtout en cas de sablage de mastic

de résine) les canaux d'aspiration dans l'outil

(5.4) avec une petite brosse plate ou avec un

chiffon en tissu.

Accessoires, outils

Pour des raisons de

sécurité, il faut utiliser exclusivement des

accessoires et outils d'origine Festool!

Les références des accessoires et outils figurent

dans le catalogue Festool.

Garantie

Frein du tampon

Le collier (5.1) qui assure le contact avec le

tampon de sablage évite l'accroissement excessif de la vitesse. Il s'use et doit être remplacé

quand le freinage diminue. Pour cela, il faut

enlever le tampon, enlever le collier de la

fixation encliquetable (5.2) et mettre un collier

neuf.

Conditions de la garantie (1+2 ans)

Vous avez droit à une prolongation de garantie

gratuite (1 an + 2 ans = 3 ans) pour votre outil

Festool. Festool assumera tous les coûts

dexpédition pendant la première année de la

garantie alors que les deuxième et troisième

années, les coûts devront être assumés par le

client. Festool paiera les frais de retour de loutil

au client par service de livraison terrestre UPS.

10

Page 11

La garantie est valable pour une période de 3

ans à compter de la date dachat indiquée sur

votre reçu ou votre facture.

Garantie limitée de Festool

Cette garantie est valable à condition que loutil

soit utilisé conformément aux instructions de

Festool. Festool garantit, à lacheteur initial

seulement, que loutil indiqué sera exempt de

tout défaut de matériau et de fabrication

pendant un an à compter de la date dachat.

Festool ne donne aucune garantie

supplémentaire, implicite ou explicite, sur les

outils portables Festool. Aucun agent,

représentant commercial, distributeur, vendeur

ou employé de Festool nest autorisé à

prolonger ou à modifier les obligations ou

restrictions de la présente garantie. Les

obligations de Festool sont, à son entière

discrétion, limitées à la réparation ou à

léchange des outils portables Festool trouvés

défectueux dans le présent emballage, tels que

fournis avec le présent Guide dutilisation.

Cette garantie exclut lusure normale, les

dommages causés par un usage impropre, les

abus ou la négligence, ou tout dommage autre

que ceux attribuables à des défauts de matériau

et de fabrication. Cette garantie ne sapplique

pas aux accessoires tels que lames de scie

circulaire, mèches de perceuse et vilebrequin,

lames de scie sauteuse, bandes abrasives et

meules. Sont également exclues les pièces

dusure, telles que balais de charbon, lamelles

pour outils à air comprimé, joints et manchons

de caoutchouc, disques et patins ponceurs, ainsi

que les piles.

Les outils portables Festool à remplacer ou à

réparer doivent être retournés avec le reçu

dachat à Festool (appelez au 800-554-8741

pour connaître ladresse dexpédition).

FESTOOL NEST EN AUCUN CAS

RESPONSABLE DES DOMMAGES DIRECTS

OU INDIRECTS, IMPLICITES OU

EXPLICITES, DÉCOULANT DE LA RUPTURE

DE CETTE GARANTIE OU DE TOUTE AUTRE

GARANTIE. TOUTES LES GARANTIES

IMPLICITES, Y COMPRIS LES GARANTIES

IMPLICITES DE QUALITÉ MARCHANDE ET

DADÉQUATION À UN USAGE

PARTICULIER, SONT LIMITÉES À UNE

PÉRIODE DE TROIS ANS.

Certains états américains et certaines provinces

canadiennes ne permettent pas la limitation des

garanties implicites; il se pourrait donc que les

limites indiquées ci-dessus ne sappliquent pas

dans votre cas. À lexception de certaines

garanties implicites des provinces ou des états

indiquées ici, la présente garantie est exclusive

et remplace toute autre garantie, convention

et obligation similaire de Festool.

Cette garantie vous confère des droits légaux

spécifiques, et vous pouvez aussi avoir dautres

droits pouvant varier dun état à lautre, ou

dune province à lautre au Canada.

11

Page 12

NORMAS GENERALES DE

SEGURIDAD

Lea y entienda todas las

instrucciones. El incumplimiento de una sola

de las instrucciones aquí listadas, puede tener

como resultado una descarga eléctrica, fuego y/

o lesiones personales serias.

CONSERVE ESTAS INSTRUCCIONES

Área de trabajo

1 Mantenga su espacio de trabajo limpio

y bien iluminado. Bancos de trabajo

desordenados y áreas oscuras facilitan

accidentes.

2 Mantenga espectadores, niños, y

visitantes fuera del alcance mientras

maneje herramientas. Distraccio-nes pueden

causarle la pérdida del control.

Seguridad personal

3 Manténgase atento, observe lo que está

haciendo y use el sentido común cuando

use una herramienta. No trabaje estando

cansado o bajo influencia de drogas,

alcohol, o medicamentos. Un momento sin

prestar atención mientras maneja una

herramienta puede tener como resultado serias

lesiones personales.

4 Vístase apropiadamente. No lleve ropa

suelta o joyas. Sujete pelo largo. Mantenga

su pelo, ropa y guantes fuera del alcance

de partes movibles. Ropa, joyas y pelo suelto

pueden pillarse en partes movibles.

5 Evite accidentes al iniciar. Asegúrese de

que, al conectar el suministro del aire, la

herramienta está desconectada. Transportar

herramientas con el dedo en el interruptor o

enchufar las herramientas con el interruptor

encendido puede provocar accidentes.

6 Quite llaves de ajuste o conmutadores

antes de encender la herramienta. Una llave

inglesa u otra llave que se deja puesta en partes

rotatorias de la herramienta pueden causar

lesiones personales.

7 No exceda límites. Mantenga

estabilidad y balance apropiado en todo

momento. Estabilidad y balance apropiado

posibilitan el mejor control de la herramienta en

situaciones inesperadas.

8 Use equipo de seguridad. Lleve siempre

gafas protec-toras. Mascarilla de polvo,

zapatos de seguridad antirresbaladizos, casco, o

protección de los oídos deben ser utilizados en

condiciones adecuadas.

Uso y cuidado de la herramienta

9 No abuse de la manguera. No tire de la

herramienta ni la arrastre tomándola por

la manguera. Mantenga la manguera fuera

de calor, filos agudos o partes movibles.

Reemplace las mangueras dañadas

inmediatamente. Las mangueras dañadas

aumentan el riesgo de accidentes.

10 Use abrazaderas u otras formas

prácticas de sujetar y asegurar la pieza de

trabajo en una plataforma estable. Sujetar

la pieza de trabajo con la mano o contra el cuerpo

es inestable y puede causar la pérdida de control.

11 No fuerce la herramienta. Use la

herramienta correcta para su aplicación. La

herramienta correcta hará su trabajo de manera

mejor y más segura al nivel para el cual está

diseñada.

12 No use la herramienta si el interruptor

no la enciende y apaga. Cualquier herramienta

que no se pueda controlar por el interruptor es

peligrosa y debe ser reparada.

13 Desconecte la manguera de aire

comprimido de la herramienta antes de

realizar cualquier ajuste, cambiar

accesorios, o guardar la herramienta. Estas

medidas preventivas de seguridad reducen el

riesgo de poner en funcionamiento la

herramienta accidentalmente.

14 Guarde herramientas desocupadas

fuera del alcance de niños u otras personas

sin experiencias. Las herramientas son

peligrosas en manos de personas inexpertas.

15 Mantenga las herramientas con

cuidado. Mantenga herramientas para

cortar afiladas y limpias. Herramientas

mantenidas correctamente, con filos afilados,

difícilmente se traban y se controlan con mayor

facilidad.

16 Compruebe si hay alineación incorrecta

o trabadura de partes movibles, rotura de

partes, o cualquier otra condición que

puedan afectar el funcionamiento de la

herramienta. En caso de daños, arregle la

herramienta antes de usarla. Muchos

accidentes son causados por herramientas con

mal mantenimiento.

17 Use solo accesorios que recomiende el

fabricante para su modelo. Accesorios que

funcionen en una herramienta pueden ser

peligrosos al usarlos en otra.

Mantenimiento

18 El mantenimiento de la herramienta

solo se podrá realizar por personal de

mantenimiento calificado. Revisión o

mantenimiento realizado por personal no

calificado puede resultar en el riesgo de lesión

19 Cuando se revise una herramienta, use

solo repuestos idénticos. Siga las instrucciones en la sección de mantenimiento

12

Page 13

de este manual. El uso de repuestos no

autorizados o el incumplimiento de las

instrucciones de mantenimiento pueden

conllevar el riesgo de lesión.

Algunos polvos creados por lijadoras mecánicas, aserraderos, trituradores, perforadoras y

otras actividades de construcción contienen

sustancias químicas que se sabe (en el Estado

de California) causan cáncer, defectos de

nacimiento u otros daños al sistema reproductivo. Algunos ejemplos de estas sustancias

químicas son:

Plomo de las pinturas con base de plomo

Sílice cristalino de los ladrillos y cemento y

otros productos de mampostería, y

Arsénico y cromo de madera tratada con

sustancias químicas

El riesgo de exposición a estas sustancias varía,

dependiendo de cuantas veces se hace este tipo

de trabajo.

Para reducir el contacto con

estas sustancias químicas:

trabaje en un área con buena

ventilación y trabaje con equipo

de seguridad aprobado, como

mascarillas para el polvo

diseñadas específicamente para

filtrar partículas microscópicas.

Datos técnicos

Diámetro del plato lijador: - LEX 2 150 150 mm / 6

- LEX 2 185 185 mm / 7

Accionamiento Motor de paletas de aire comprimido

Presión de servicio (presión de flujo) 87 psi

Velocidad sin carga 4,000 - 8,000 rpm.

Órbitas por minuto 8,000 - 16,000 opm.

Carrera de lijado: - LEX 2 150/3 3 mm

- LEX 2 150/7, LEX 2 185/7 7 mm

Consumo de aire con carga nominal 14 cfm

Peso: - LEX 2 150 1.3 kg / 2.8 lbs

- LEX 2 185 1.4 kg / 3 lbs

Símbolos

n

0

rpm revoluciones por minuto

opm orbitas por minuto

revoluciones sin carga

Uso conforme a la destinación

Conforme a las especificaciones, las máquinas

están diseñadas para lijar madera, plástico,

metal, piedra, material compuesto,

recubrimientos de pintura, emplaste y

materiales similares. No se deberá procesar

material que contenga asbesto.

¡El usuario es responsable

por cualquier daño o lesión que resulte del uso

incorrecto de esta herramienta!

Descripción del funcionamiento

Conexión y puesta en servicio

Asegúrese de que la

herramienta neumática está apagada cuando

conecta al suministro de aire comprimido.

Preparación del aire comprimido

Siempre se deberá utilizar una unidad de

servicio Festool para asegurar que las

herramientas neumáticas Festool funcionan

correctamente. Esta unidad consta de un filtro,

una unidad de control, un drenaje de

condensados y un lubricador, y sirve para

limpiar y lubricar el aire comprimido así como

para mantenerlo libre de condensados. Para

ello, el lubricador deberá ajustarse de tal modo

que cada 7-10 minutos aprox. añada una gota

de aceite al aire comprimido.

Los daños que puedan ocasionarse por un

tratamiento deficiente del aire comprimido

quedarán excluidos del derecho de garantía.

Recomendamos que se utilicen hasta dos

herramientas Festool con una unidad de servicio

con un conector de 3/8. Para el suministro de

aire comprimido, deberá elegirse un compresor

capaz de suministrar como mínimo 20 cfm con

una presión de servicio de 87 psi. El sistema

de conductos debe disponer de un diámetro lo

suficientemente grande (al menos 9mm / 1/2).

Conexión de la manguera IAS 2

La lijadora excéntrica es una herramienta

neumática que va conectada al sistema Festool

IAS 2. Este sistema combina tres funciones en

una sola manguera:

13

Page 14

- Suministro de aire comprimido (1.1)

- Extracción de aire de escape (1.2)

- Extracción de polvo (1.3)

Conexión y desconexión ver figura 2.

Sistema de conexión IAS 2 ver hoja de

indicaciones adjunta.

Puesta en marcha

La herramienta neumática se pone en marcha

al ejercer presión en la palanca (3.1). Si se

suelta la palanca, la máquina se apaga.

Ajustes de la máquina

Antes de realizar cualquier

trabajo en la máquina, ésta deberá

desconectarse siempre del suministro de aire

comprimido.

Regulación del número de revoluciones

Las revoluciones pueden regularse de modo

continuo con la rueda de ajuste (3.2) entre

4,000 y 8,000 rpm.

De esta forma, la velocidad se puede adaptar

de forma óptima a cada material.

Aspiración

El polvo resultante del lijado se aspira

directamente en el plato de lijado a través de

los canales de aspiración del plato lijador. Para

garantizar una aspiración óptima del polvo,

recomendamos emplear los aspiradores Festool

con dispositivo automático de arranque / paro

para máquinas neumáticas.

Para evitar posibles daños al

motor de aire comprimido, no se deberá

permitir la aspiración a través de la herramienta

neumática cuando está detenida.

Platos lijadores

Los platos lijadores tienen

diferente peso en función de su diámetro. El

uso de un plato lijador de tamaño incorrecto

provocará un nivel de vibración excesivo para

la herramienta.

Utilice sólo platos lijadores con el revestimiento

intacto.

Los platos lijadores están disponibles en tres

niveles de dureza en función del tipo de uso:

14

Page 15

- Duro: gran solidez en cantos, para la remoción

de material grueso de las superficies y al lijar

sobre cantos.

- Blando: universal para lijado grueso y fino,

con estructura elástica para superficies planas

y curvas.

- Superblando: gran elasticidad, para lijado

fino de piezas pre-formadas, formas convexas

y radios. ¡No lo aplique en cantos!

Ensamble - ver figura 4. Asegúrese de que los

soportes de arrastre positivo en la forma del

plato lijador (4.1) y la máquina están alineados

(4.2).

Freno del plato de lijado

El collarín (5.1) hace contacto con el plato

lijador e impide con ello una vibración

incontrolable del plato de lijado. En

consecuencia, el collarín se desgasta con el

tiempo y debe sustituirse por uno nuevo cuando

su efecto de frenado empieza a disminuir. Para

ello, deberá retirarse el plato lijador. Entonces

podrá desmontar el collarín de la conexión

rápida (5.2) y sustituirlo por uno nuevo.

Abrasivos

Los abrasivos autoadheribles, como la lija

Stickfix, y los vellones de lija se pueden fijar a

los platos de lijado Stickfix.

Los abrasivos se adhieren fácilmente al plato

lijador y se despegan después de usarlos.

Los abrasivos deben

colocarse concéntri-camente y sus

perforaciones deben coincidir con las del plato

lijador.

Mantenimiento y cuidado

Antes de realizar cualquier

trabajo en la máquina, ésta deberá

desconectarse siempre del suministro de aire

comprimido.

Todos los trabajos de mantenimiento y de

reparación, para los que se tiene que abrir la

carcasa del motor, sólo deben ser llevados a

cabo por un taller de servicio de asistencia

técnica autorizado.

Paletas

Recomenda-mos sustituir las lamas del motor

después de aprox. 500 horas de servicio.

Lubricación

Tras un largo período de inactividad, por

ejemplo, después de un fin de semana, deberán

aplicarse antes de su puesta en marcha 1 ó 2

gotas de aceite lubricante en la conexión de

aire comprimido (5.3) de la máquina.

Cambio del silenciador

El silenciador en la pieza de conexión IAS 2

deberá reemplazarse en intervalos regulares

para mantener la potencia de la herramienta

neumática.

Limpieza de los canales de aspiración

Recomendamos limpiar una vez por semana

(en especial al lijar emplastes de resina

sintética) los canales de aspiración de la

máquina (5.4) con un pequeño cepillo

limpiatubos o con un trapo.

Accesorios, herramientas

¡Por razones de seguridad,

solamente deben emplearse accesorios y

herramientas originales de Festool!

15

Page 16

Los números de pedido para los respectivos

accesorios y herramientas se encuentran en su

catálogo Festool.

Garantía

Condiciones de la Garantía 1 + 2

Usted tiene derecho a una garantía extendida

gratuita (1 año + 2 años = 3 años) para su

herramienta mecánica Festool. Festool se hará

responsable por los costos de envío durante el

primer año de garantía. Durante el segundo y

tercer año de garantía el cliente es responsable

por el costo del envío de la herramienta a

Festool. Festool pagará el embarque de regreso

al cliente usando UPS Ground Service. Todo el

servicio de garantía es válido por 3 años desde

la fecha de la compra de acuerdo a la fecha de

su recibo o factura de compra.

Garantía limitada de Festool

Esta garantía es válida con la condición previa

de que la herramienta se usa y opera de

conformidad con las instrucciones de operación

de Festool. Festool garantiza, sólo al comprador

original, que la herramienta especificada estará

libre de defectos de fabricación y materiales

durante un periodo de un año a partir de la

fecha de compra. Festool no otorga otras

garantías, ni explícitas ni implícitas para

ninguna de las herramientas mecánicas

portátiles Festool. Ningún agente,

representante, distribuidor, comerciante o

empleado de Festool está autorizado para

extender o modificar de cualquier manera las

obligaciones o limitaciones de esta garantía.

Las obligaciones de Festool, a su propia entera

discreción, están limitadas a la reparación o

sustitución de cualquier herramienta portátil

Festool que se encuentre estar defectuosa en

el momento de ser embalada junto con el

manual de usuario.

Quedan excluidos de la cobertura en esta

garantía: el desgaste normal; los daños

causados por uso indebido, el abuso o

negligencia; los daños causados por cualquier

otra causa que no sean defectos del material o

de la fabricación. Esta garantía no aplica a

accesorios como cuchillas de sierras circulares,

brocas de taladro, barrenas de buriladora,

cuchillas de sierra, cuchillas para sierras de

calado, correas de lijadoras y ruedas de esmeril.

También se excluyen las partes que se

desgastan como cepillos de carbón, laminillas

de herramientas de aire, collarines de hule y

sellos, discos y cojines de lijado, y baterías.

Las herramientas mecánicas portátiles Festool

que requieran de reemplazo o reparación deben

devolverse con el recibo de compra a Festool

(llame al 800-554-8741 para los detalles de la

dirección).

EN NINGÚN CASO FESTOOL SE HARÁ

RESPONSABLE POR LOS DAÑOS SECUNDARIOS O CONSECUENTES OCASIONADOS

POR LA VIOLACIÓN DE ESTA O

CUALUQUIER OTRA GARANTÍA, SEA

EXPLÍCITA O IMPLÍCITA. TODAS LAS

GARANTÍAS IMPLICADAS POR LEYES

ESTATALES, INCLUYENDO LAS GARANTÍAS

IMPLICADAS DE COMERCIALIZACIÓN Y

ADECUACIÓN A UN PROPÓSITO PARTICULAR, QUEDAN LIMITADAS A TRES AÑOS

DE DURACIÓN.

Algunos estados de EE.UU. y algunas provincias

de Canadá no permiten las limitaciones en

cuanto a la duración de las garantías implícitas,

de modo que la limitación arriba indicada puede

que no le afecte. A excepción de algunas

garantías implicadas por leyes estatales o

provinciales, limitadas por la presente, la

anteriormente citada garantía, expresamente

limitada, es exclusiva y sustituye a cualquier

otra garantía, acuerdo u obligación similar de

Festool.

Esta garantía le concede derechos legales

específicos y usted podría tener otros derechos

legales que varían de estado a estado en EE.UU.

y de provincia a provincia en Canadá.

16

Loading...

Loading...