Page 1

Kapex® KS 120

Miter Saw

Sliding Dual Compound Miter Saw

Supplemental User’s Manual

WARNING To reduce the risk of serious or fatal injury, read and understand

all safety precautions and instructions in this manual before using this tool.

Page 2

Limited Warranty

30 Day Money Back Guarantee

We are so confident that you will thoroughly enjoy our tools, that

we offer a 30 day money back guarantee. If you are not

1+2 Limited Warranty

Festool USA offers a 3-year limited warranty, one of the longest

in the industry. This warranty is valid on the pre-condition that

the tool is used and operated in compliance with the Festool

Conditions of 1+2 Limited Warranty

You are entitled to a free extended limited warranty (1 year + 2

years = 3 Years) for your Festool power tool. Festool USA is

responsible for all shipping costs during the first year of the

warranty. During the second and third year of the warranty, the

customer is responsible for shipping the tool to Festool. Festool

will pay for return shipping to the customer using UPS Ground

Service. All warranty service is valid 3 years from the date of

purchase on your receipt or invoice.

Excluded from the coverage under this warranty are: normal

wear and tear, damages caused by misuse, abuse, or neglect;

damage caused by anything other than defects in material and

workmanship. This warranty does not apply to accessory items

such as circular saw blades, drill bits, router bits, jigsaw blades,

sanding belts, and grinding wheels. Also excluded are "wearing

parts," such as carbon brushes, lamellas of air tools, rubber

collars and seals, sanding discs and pads, batteries, and Festool

gear (hats and t shirts).

The obligations of Festool USA in its sole discretion under this

warranty shall be limited to repair or replacement or a refund of

the purchase price for any Festool portable power tool that is

found to have a defect in materials or workmanship during the

completely satisfied, your full purchase price will be refunded,

excluding all freight charges.

operating instructions. Festool USA warrants that the specified

tool will be free from defects in materials and workmanship for a

term of 3 years from the date of purchase.

warranty period. FESTOOL USA SHALL NOT BE LIABLE FOR ANY

CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES

REGARDLESS OF THE THEORY OF LAW ON WHICH THE CLAIM IS

BASED. ALL WARRANTIES IMPLIED BY STATE LAW, INCLUDING

THE IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE HEREBY LIMITED TO THE

DURATION OF THREE YEARS.

Some states in the U.S. and some Canadian provinces do not

allow the limitations on how long an implied warranty lasts, so

the above limitation may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights that

vary from state to state in the U.S. and from province to province

in Canada.

With the exception of any warranties implied by state or province

law as limited above, the foregoing express limited warranty is

exclusive and in lieu of all other warranties, guarantees,

agreements, and similar obligations of Festool USA. Festool USA

makes no other warranty, express or implied, for Festool portable

power tools. No agent, representative, distributor, dealer, or

employee of Festool USA has the authority to increase or

otherwise change the obligations or limitations of this warranty.

Repairs

If your Festool power tools require repair, you must contact our

Service Department at (800) 554-8741 for authorization and

address details. No collect shipments will be accepted. No Festool

hats, t-shirts or other wearables may be returned. Also contact

our Service Department at the telephone number listed above if

you have any questions about warranty claim procedures.

Returns

If you need to return your Festool tools for any reason, please return it to the dealer from which you originally bought the tool.

Liability Statement

This product has been built to the high standards of Festool.

Please do not attempt to operate or repair this equipment without

adequate training. Any use, operation, or repair in contravention

of this document is at your own risk. By acceptance of this

system you hereby assume all liability consequent to your use or

misuse of this equipment. Festool USA assumes no liability for

incidental, special, or consequential damage of any kind.

Equipment specifications, applications, and options are subject to

change at the sole discretion of Festool USA without notice.

Proprietary Notice

All drawings and information herein are the property of Festool,

TTS Tooltechnic Systems AG & Co. KG. All unauthorized use and

reproduction is prohibited.

Written and Illustrated by Rick Christopherson.

© 2008 TTS Tooltechnic Systems AG & Co. KG

All rights reserved. Printed in the United States of America and

Germany.

2 Kapex KS120 Miter Saw

Festool USA is a division of Tooltechnic Systems, LLC.

Festool is a trademark and service mark of TTS Tooltechnic

Systems AG & Co. KG

Kapex and FastFix are registered trademarks of TTS Tooltechnic

Systems AG & Co. KG

MiterFast is a trademark of TTS Tooltechnic Systems AG & Co. KG

www.festoolusa.com

Page 3

Contents

Limited Warranty .............................................2

30 Day Money Back Guarantee......................... 2

1+2 Limited Warranty..................................... 2

Conditions of 1+2 Limited Warranty.................. 2

Repairs ......................................................... 2

Returns......................................................... 2

Liability Statement ......................................... 2

Proprietary Notice........................................... 2

About This Manual............................................3

Tool Symbols................................................. 3

General Power Tool Safety Warnings ...............4

Work Area Safety........................................ 4

Electrical Safety.......................................... 4

Personal Safety........................................... 4

Power Tool Use and Care.............................. 4

Service...................................................... 5

Specific Safety Rules for Miter Saws.................. 5

Respiratory Exposure Safety Warnings .............. 5

Tool Description ...............................................5

Technical Specifications................................... 5

Intended Use................................................. 6

Functional Description..................................... 6

Setup................................................................8

Setting Up a New Miter Saw............................. 8

Changing Sawblades....................................... 9

Transporting the Saw.....................................10

Dust Extraction .............................................10

Basic Operation..............................................11

Setting the Motor Speed.................................11

Using the Laser Guides...................................11

Power Trigger and Plunge Release................... 11

Using the Hold Down Clamp ........................... 12

Setting the Miter Angle.................................. 12

Setting the Bevel Angle ................................. 13

Using the Auxiliary Fence............................... 13

Setting the Depth Limit.................................. 14

Using the Tall Miter Latch............................... 14

Using the MiterFast Tool ................................ 15

Using the Bed Extensions and Crown Stops ...... 16

Cutting Techniques ........................................17

Miter Cuts.................................................... 18

Bevel Cuts................................................... 18

Depth Limited (Dado/Half-Lap) Cuts................ 19

Compound Miter Cuts.................................... 20

Calculating Compound Angles...................... 21

Compound Angle Calculator ........................ 21

Crown Moulding............................................ 22

Adding Auxiliary Fence Faces.......................... 23

Making a Zero-Clearance Insert...................... 23

Calibration and Adjustment............................24

Calibrating the Miter Angle............................. 24

Calibrating the Bevel Angle ............................ 26

Calibrating the Lasers.................................... 28

Troubleshooting.............................................29

Optional Accessories......................................30

Sawblades................................................... 30

MFT/3-Kapex Table....................................... 31

Bolt Down (Clamping) Kit............................... 31

Crown Stop.................................................. 31

About This Manual

Save These Instructions

It is important for you to read and understand this manual. The

information it contains relates to protecting YOUR SAFETY and

PREVENTING PROBLEMS. The symbols below are used to help you

recognize this information.

Indicates a potentially hazardous

WARNING!

CAUTION!

Laser

Radiation

NOTICE:

Note:

situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury.

This symbol is used on the machine and

in this manual to signify the possibility of

laser radiation.

Indicates a potential situation which, if

not avoided, can result in property

damage or damage to the tool.

Indicates information, notes, or tips for

improving your success using the tool.

Tool Symbols

V Volts

W Watts

Hz Hertz

~ Alternating Current (AC)

no No-load Speed

Ø Diameter

Class II Double Insulated

Designated Danger Zone.

Avoid positioning hands,

fingers, or arms in the area

designated by this symbol.

Supplemental User’s Manual 3

Page 4

General Power Tool Safety Warnings

WARNING! Read all safety warnings and

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire, and

serious or fatal injury.

Work Area Safety

► Keep your work area clean and well lit. Cluttered or

dark work areas invite accidents.

► Do not operate power tools i n expl osi ve atmospheres,

such as in the presence of flammable liquids, gases,

Electrical Safety

► Power tool plugs must match the outlet. Never modify

the plug in any way. Do not use any adapter plugs

with power tools. Unmodified plugs and matching outlets

will reduce risk of electric shock.

► Avoid body contac t wi th earthed or grounded surfac es

such as pipes, radiators, ranges and refrigerators.

There is an increased risk of electric shock if your body is

earthed or grounded.

► Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of electric

shock.

► Do not abuse the cord. Never use the cord for

carrying, pulling, or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving

parts. Damaged or entangled cords increase the risk of

electric shock.

► When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a cord

for outdoor use reduces the risk of electric shock.

Personal Safety

► Stay alert, watch what you are doing, and use

common sense when operating a power tool. Do not

use a power tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inattention

while operating power tools may result in serious personal

injury.

► Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask, nonskid safety shoes, hard hat, or hearing protection used for

appropriate conditions will reduce the risk of personal

injuries. (Eye protection must comply with ANSI Z87.1)

► Prevent unintentional starting. Ensure the switch is in

the off-position before connecting to power source,

picking up, or carrying the tool. Carrying power tools

with your finger on the switch or energizing power tools that

Power Tool Use and Care

► Do not force the power tool. Use the correct power

tool for your application. The correct power tool will do

the job better and safer at the rate for which it is designed.

► Do not use the power tool if the switch does not turn

it on and off. Any power tool that cannot be controlled with

the switch is dangerous and must be repaired.

► Disconnect the plug from the power source before

making any adjustments, changing accessories,

transporting, or storing the tool. Such preventive safety

measures reduce the risk of starting the tool accidentally.

► Stor e i dl e t ools out of reach of children and do not

allow persons unfamiliar with the power tool or these

instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

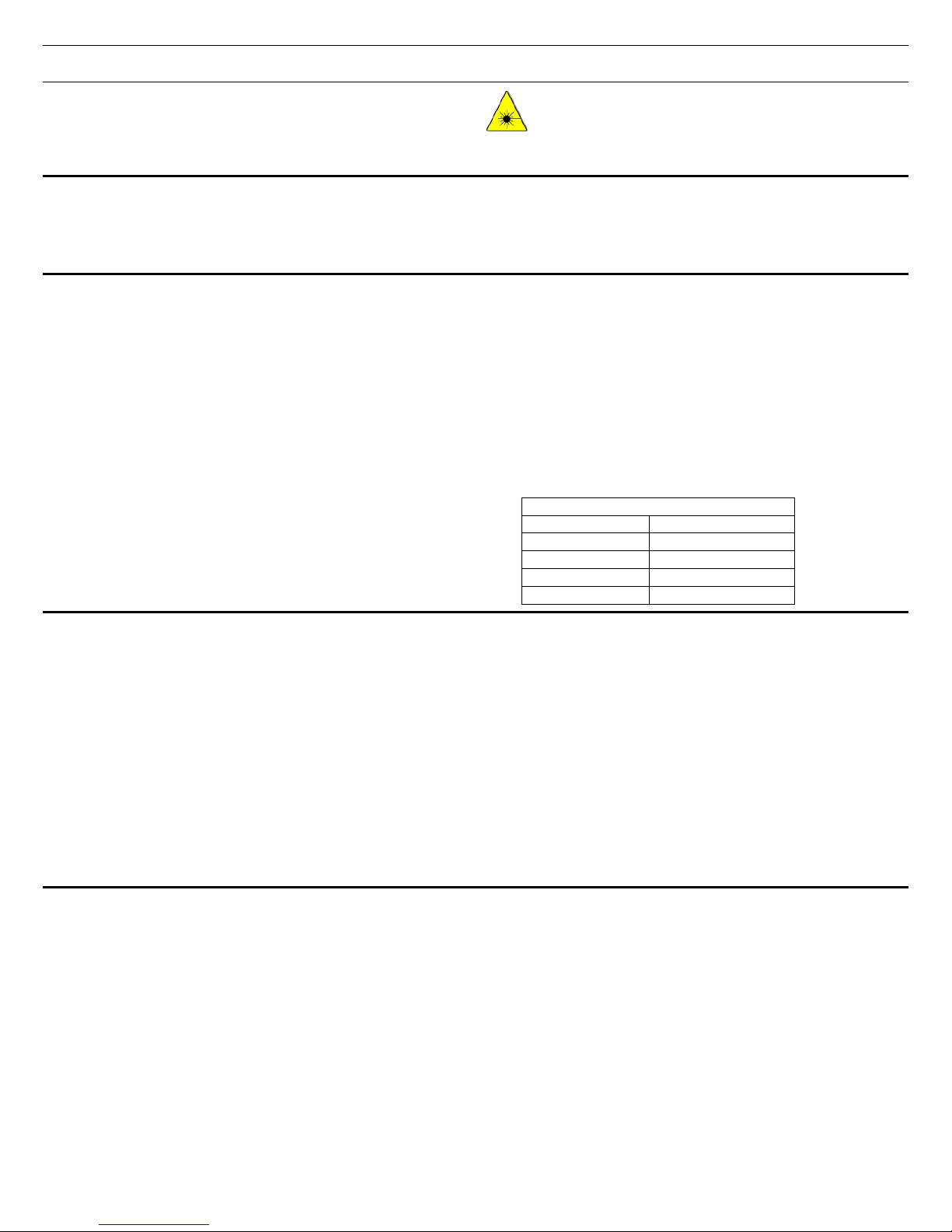

CAUTION! Laser Radiation. This product contains a

Class II laser. Do not look directly into the laser beam.

Power ≤ 1mW, Wavelength: 640 to 660 nm

Save all warnings and instructions for future reference.

or dust. Power tools create sparks which may ignite the

dust or fumes.

► Keep children and bystanders away while operating a

power tool. Distractions can cause you to lose control.

► If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of a GFCI reduces the risk

of electric shock.

► Never use an extension cord that is damaged,

including cuts, exposed wires, or bent/missing

prongs. Damaged extension cords increase the risk of fire

or electric shock.

► Use only extension cords rated for the purpose.

► Use only extension cords rated for the amperage of

this tool and the length of the cord. Using too small of

an extension cord can cause the cord to overheat.

Extension Cord Ratings

Cord Length Size (AWG)

<25 Ft. 14

25-50 Ft. 12

50-100 Ft. 10

>100 Ft. Not recommended

have the switch on invites accidents.

► Remove adjusting key or wrench before turning the

power tool on. A wrench or a key that is left attached to a

rotating part of the tool may result in personal injury.

► Do not overreach. Keep proper footing and balance at

all times. This enables better control of the tool in

unexpected situations.

► Dress properly. Do not wear loose clothi ng or jewelry.

Keep your hair, clothing, and gloves away from

moving parts. Loose clothes, jewelry, or long hair can be

caught in moving parts.

► If devi c es are provi ded for the c onnect ion of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection can

reduce dust-related hazards.

► Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

► Keep cutting tools sharp and clean. Properly maintained

tools with sharp cutting edges are less likely to bind and are

easier to control.

► Use the power tool, ac c essori es, and tool bits etc. in

accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations different

from those intended could result in a hazardous situation.

4 Kapex KS120 Miter Saw

Page 5

Service

► To reduce the risk of serious or fatal injury, never

open the motor housing. Have your power tool

serviced only by a qualified repair person using only

identical replacement parts.

Specific Safety Rules for Miter Saws

► To reduce the risk of serious or fatal injury, never alter

or misuse the power tool.

► Be certain the miter saw is mounted or securely placed

on a level, firm work surface before using. A level and

firm work surface reduces the risk of the miter saw becoming

unstable or tipping.

► Make sure all controls and clamping handles are

secured before starting any operation. Unsecured

clamps or adjustment handles can cause the saw and/or

workpiece to move unexpectedly.

► Always unplug the saw before servicing or changing

the sawblade.

► Never remove or disable the blade guard. Inspect the

blade guard before use. Repair or replace a damaged or

improperly functioning blade guard before further use.

► Keep hands out of the path of the sawblade. Never

cross your hand over intended line of cutting.

Supporting the workpiece “cross handed” e.g. holding the left

side of the workpiece with your right hand, is very

dangerous.

► Do not reach in back of the moving saw blade with

either hand to remove wood scraps, hold down or

support the workpiece, or for any other reason. The

proximity of the spinning saw blade to your hand may not be

obvious and you may be seriously injured.

► Use clamps to support workpiece whenever possible.

Do not use this saw to cut pieces that are too small to

be securely clamped.

► Clamp the offcut side of the workpiece when using a

length stop. An unsecured offcut can bind between the

length stop and the saw blade.

► If securing the workpiece by hand, you must always

keep hands outside of “No Hand” area as marked with

a symbol on the base. Your hand, if placed inside the “No

Hands” region, can easily slip or be pulled into the blade.

► Support long workpiec es to prevent them from tipping.

► Any repairs to the laser must be carried out by the

laser manufacturer or by an authorized agent of the

laser manufacturer. Never attempt to replace the laser on

this tool with a different type of laser.

A tipping workpiece can lift up and contact the spinning

sawblade, or bring the operator’s hand upward into the

blade.

► For proper control, never “pull” the saw through the

cut, always chop or push cut. See page 17 of this manual.

► Cut only one workpiece at a time. Multiple workpieces

cannot be adequately clamped or braced and may bind on

the blade or shift during cutting.

► Keep workpieces firmly against the rear fence when

cutting. Never cut workpieces that do not lay flat or

are curved in any way. A curved workpiece can be grabbed

by the blade and propelled back against the fence.

► Inspect workpieces for nails or foreign objects. Make

sure there are no tools or foreign objects on the saw.

► Do not cut round stock unless it is clamped in such a

way as to prevent rotation. Round stock will tend to roll

while it is being cut.

► Use only sawblades recommended by the

manufacturer and designed for use with the saw, with

a 30mm arbor bore, a 260mm diameter, and a

maximum thickness of 2mm. Be sure that the speed

marked on the saw blade is at least equal to the speed

marked on the saw. Do not use high speed steel saw

blades.

► Select the correct saw blade for the material to be cut.

Do not use the saw to cut materials other than those

recommended by the manufacturer. Never force the tool

or attachment to do a job for which it was not designed.

► Never use this saw for cutting ferrous metals.

► Never use saw blades that are damaged or deformed.

Never use a dull sawblade. A dull sawblade places undue

stress on the saw and the workpiece and can increase the

risk of kickback.

► Make sure the sawblade is securely installed and is not

backward. The arrow on the blade should match the

direction of the arrow marked on the tool.

Respiratory Exposure Safety Warnings

Substantial or repeated inhalation of dust and other airborne

contaminants, in particular those with a smaller particle size,

may cause respiratory or other illnesses. Various dusts

created by power sanding, sawing, grinding, drilling and other

construction activities contain chemicals or substances known

(to the State of California and others) to cause cancer, birth

defects or other reproductive harm. Some examples of these

chemicals/substances are:

► lead from lead-based paints;

► crystalline silica from bricks, cement, and other masonry

products;

► arsenic and chromium from chemically-treated lumber; and

► some wood dusts, especially from hardwoods, but also from

some softwoods such as Western Red Cedar.

The risk from these exposures varies, depending on how often

you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area and use a properly

functioning dust extraction system. When the inhalation of

dust cannot be substantially controlled, i.e., kept at or near

the ambient (background) level, the operator and any

bystanders should wear a respirator approved by NIOSH for

the type of dust encountered.

Tool Description

Technical Specifications

Power Consumption 1600 Watts (13 amps @ 120 volts) Max. Depth (tall) 120 mm (4.75”) at 60 mm (2.3”)

Motor Speed 1400 - 3400 RPM (no load) Max. Depth at 45° Bevel 55mm (2.2”)

Arbor Diameter 30 mm Max. Width at 90° Miter 305mm (12”)

Max. Blade Size 260 mm (10.25”) dia., 2mm (5/64”) thick Max. Width at 45° Miter 210mm (8.25”)

Max. Depth (std.) 88 mm (3.46”) Weight 21.5 kg (47.3 lbs)

All metric dimensions are controlling. The arbor diameter is critical for safe operation, and is presented in metric only.

Supplemental User’s Manual 5

Page 6

Intended Use

The Kapex miter saw is intended to cut wood, plastic,

aluminum, and similar materials. All applications beyond

this are regarded as improper use. The tool should not be

altered or used for any other purpose other than as

specified in these operating instructions. Using the tool in

Functional Description

contravention to this manual may lead to injury and will

void your warranty. The user shall be responsible and

liable for accidents, injuries, and property damage

resulting from misuse or abuse of this tool.

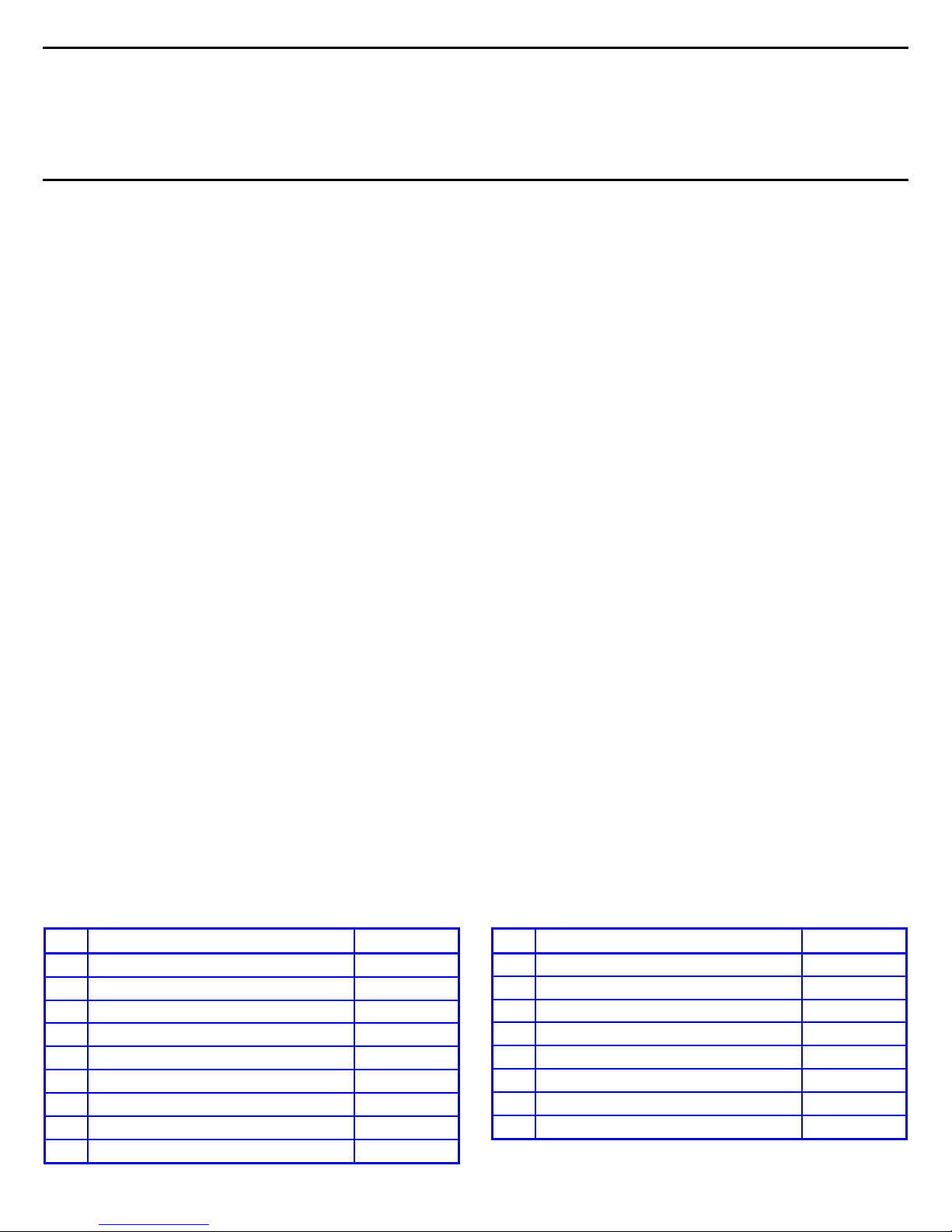

Item Name or Description Ref. Page(s)

A Bevel Gauge and Pointer (both sides) 12, 18

B Power Cord Storage 10

C Tall Miter Latch 14, 22

D Tall Miter Release 14, 22

E Bevel Lock 12, 18

F Bevel Range Selector 12, 18

G Dust Extraction Port 10

H FastFix® Arbor Lock 9

I Trigger Lock 11

Item Name or Description Ref. Page(s)

J Power Switch/Trigger 9, 10, 11

K Main Handle 11, 17

L Laser Dust Lens 28

M Blade Guard 9

N Miter Stop Release Lever 12, 15, 18, 20

O Miter Lock Lever 12, 15, 18, 20

P Miter Gauge and Pointer 12, 15,

Q MiterFast™ Angle Tool and Storage 15

6 Kapex KS120 Miter Saw

Page 7

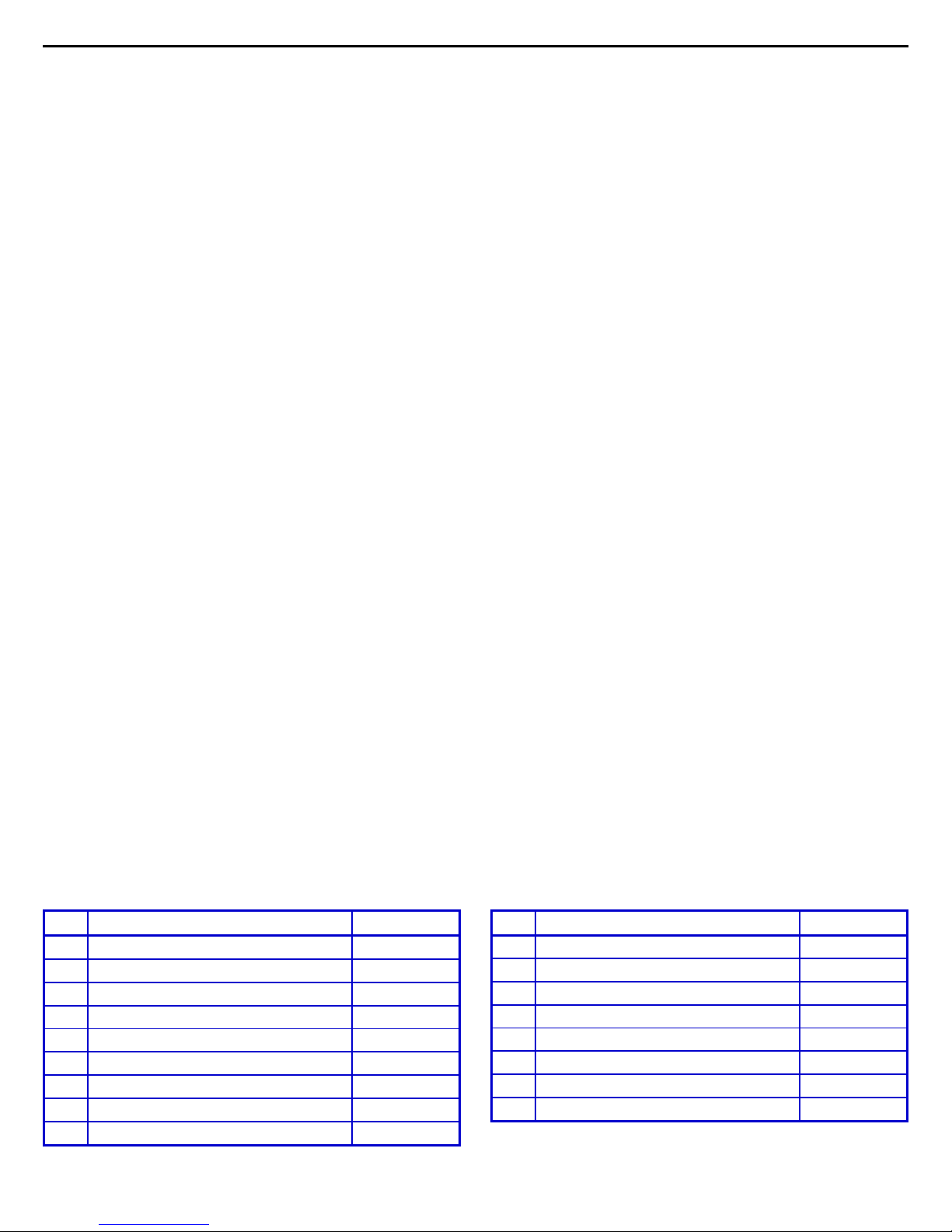

Functional Description (continued)

Item Name or Description Ref. Page(s)

A Bevel Gauge and Pointer (both sides) 12, 18

I Trigger Lock 9, 10, 11

J Power Switch/Trigger 9, 10, 11

K Main Handle 11, 17

L Laser Dust Lens 28

M Blade Guard 9

N Miter Stop Release Lever 12, 15, 18, 20

O Miter Lock Lever 12, 15, 18, 20

R Bevel Adjustment Knob 12, 18

Item Name or Description Ref. Page(s)

S Speed Control Dial (see inset) 11

T Laser On/Off Button (see inset) 11

U Depth Limit Adjustment Knob 13

V Slide Lock Knob 10

W Head Lock Knob 10

X Auxiliary Fence 13

Y Main Fence 13, 23

Z Table Inserts 23

Supplemental User’s Manual 7

Page 8

Setup

Setting Up a New Miter Saw

Congratulations on your purchase of a new Kapex Sliding

Dual Compound Miter Saw. Before using your new miter

saw, make sure you fully read and understand all of the

instructions, precautions, and safety information presented

in this manual.

WARNING! To avoid tipping the miter saw during

use, the miter saw must be placed on a stable

surface.

Note: There is a 2.5 mm hex key needed for

making adjustments located in the Styrofoam

packing material. Take care not to lose it.

Note: You may want to save the original box and

packing material in case you ever need to send in

the saw for service.

The KS120 miter saw is ready to use right out of the box,

but there are several placement options available,

depending on the intended use. These options include:

► For truly portable use, the KS120 may be used directly

on a jobsite floor. The height of the cutting bed was

specifically designed to coincide with the height of a

Festool #1 Systainer, which can be used as an outfeed

support.

► For a more permanent installation, the Kapex saw is

equipped with 4 bolt holes, to be used with ¼-20 (M6)

bolts to securely bolt the saw to a work table.

► The Kapex saw was specif ically designed to be

compatible for operation on a Festool Multi-Function

Table (MFT). The four feet under the saw coincide with

the hole spacing of an MFT tabletop to keep the saw

firmly in position, and the optional bolt kit permits quick

mounting.

► The KS120 can also be used on a level and stable jobsite

work table. The saw must be securely clamped to the

table to help prevent it from tipping or falling off.

Note: When clamping or bolting the Kapex to a

work table, take care not to over tighten the

clamps or bolts, as this may distort the saw base.

8 Kapex KS120 Miter Saw

Page 9

Changing Sawblades

WARNING! To reduce the risk of injury from

contact with a moving part, always unplug the

saw before changing blades.

1. Push in and rotate the FastFix

This prevents the arbor from turning and also disables

the motor.

2. Loosen the clamping screw on the arbor bolt guard,

and rotate the guard away from the arbor bolt. (The

combination hex key is stored on the back of the saw

by the power cord.)

®

arbor lock clockwise.

4. Without pushing down on the trigger lock, pull up on

the trigger to release the blade guard.

5. Raise the blade guard out of the way and remove the

outboard arbor flange and sawblade from the arbor.

6. Inspect the friction lining on the two arbor flanges. If

the lining is damaged, replace the flanges, as this can

cause the sawblade to wobble.

Note: The friction lining on the arbor flanges

grips the blade, but also permits the blade to slip

slightly, in the event of a binding condition.

WARNING! When installing a new blade, make

sure the arbor bolt is properly tightened and the

rotation direction of the sawblade matches the

rotation direction indicated on the saw (see image

below).

7. Make sure the blade is oriented correctly and install

the blade onto the inboard arbor flange.

8. Replace the outboard arbor flange, tighten the arbor

bolt, and then unlock the FastFix arbor lock.

3. Unscrew the arbor bolt by turning it clockwise. The

arbor bolt is a left-hand thread and turns the

opposite of a standard screw.

Supplemental User’s Manual 9

Page 10

Transporting the Saw

When The Kapex miter saw is collapsed for transport, it is

very well balanced and easily carried using the integrated

carrying handles.

1. Unplug the saw and coil the power cord on the reel at

the rear of the saw.

4. Set the miter angle to 60° and push down on the miter

lock lever.

5. Pick up the saw from the rear by grasping the two

handle points as shown below.

WARNING! To reduce the risk of unexpectedly

starting the saw, make sure the saw is

unplugged.

2. Pull the power trigger (without depressing the trigger

lock) and lower the motor head down. When the head

is in the down position, push in on the Head Lock Knob

(see the picture to the upper right).

3. Push the motor head all the way to the rear of the saw

and tighten the Slide Lock Knob.

Dust Extraction

The Kapex saw can be connected to a dust extractor to

substantially reduce dust during operation. The dust port

swivels to either side, and accepts either a 27 or 36 mm

Festool hose. The 27 mm hose fits inside the dust port, or

the 36 mm hose fits over the outside of the dust port.

Note: For optimal dust extraction performance,

Festool recommends using a 36 mm hose.

10 Kapex KS120 Miter Saw

Page 11

Basic Operation

Setting the Motor Speed

The Kapex saw has electronic speed control with soft-start

circuitry. The electronic controller will maintain the motor

speed even as the load changes. The speed control is

infinitely variable from 1400 to 3400 RPM. The optimal

speed of the saw is predominately determined by the type

of material being cut.

Material Speed

Soft wood products and veneer plywoods 6

Hardwood products 3-6

Plastic laminate countertops 6

Hard plastics 3-5

Soft plastics 1-4

Aluminum 4-6

Using the Laser Guides

CAUTION! Laser Radiation. Do not look

directly into the laser beam.

The Kapex saw contains a low-power solidstate laser system

that scans across the path of the sawblade to indicate to the

user where the blade will cut the workpiece. (The laser does

not cut the workpiece.)

The two laser beams shine down on the workpiece on either

side of the sawblade. The sawblade will cut the workpiece

between the two laser lines.

To turn on the laser, press the On/Off button on the rear of

the motor near the speed control dial. Pressing the button a

second time will turn the laser off. The laser will also

automatically shut off if left on for more than approximately

30 minutes.

Turn the speed control dial to the number shown in the

table to the left. The speeds listed in the table are just

rough guidelines, and actual results may vary.

Power Trigger and Plunge Release

The power trigger turns on the saw but also releases the

motor head to plunge downward. To help prevent

accidental starting of the saw, the trigger lock must be

pushed to release the trigger to power the saw.

► To start the saw (activ ate the sawblade), press the

trigger lock and squeeze the trigger. The saw head can

then be plunged downward.

► To plunge the saw head down without starting the saw,

squeeze the power trigger, but do not press the trigger

lock.

Supplemental User’s Manual 11

Page 12

Using the Hold Down Clamp

The hold down clamp fits in a socket on either the left or

right sides of the saw. To insert or remove the clamp,

rotate it to the rear to unlock it from the socket, as shown

in the first image below. To lock the clamp in its socket,

otate it to the forward position, as shown in the center

r

image below. To secure the workpiece, press down on the

green knob and rotate the locking handle down, as shown

in the image on the right, below. To release the clamp,

rotate the locking lever up.

Setting the Miter Angle

A mitered cut is where the saw head is rotated side-toside. The Kapex saw is capable of mitering 50° to the left

and 60° to the right. Positive stops are located at 0, 22½,

30, and 45 degrees. The miter gauge pointer also includes

½ degree vernier indices for accurately setting the miter

angle to half-degree values. Also refer to “Using the

MiterFast Tool

1. Release the miter lock by lifting up on the handle.

“ described on page 15.

12 Kapex KS120 Miter Saw

2. Press down on the miter stop release lever, and rotate

the miter to the desired angle.

► To stop at one of the preset positive lock miter

positions, release the miter stop lever just before

reaching the angle, and the miter stop will click as it

locks into position.

► To set the miter angle to ½ degree between the

primary angles, line up the ½° vernier indices with

the adjacent angle index marks. (The example

shown to the left represents 20½°.)

3. When the desired miter angle is set, engage the miter

lock by pressing down on the miter lock lever.

Note: When setting a miter angle very close to

one of the miter stops (for example, at 45½° ),

keep holding down the miter stop release lever

until you fully engage the miter lock lever, to

prevent the miter angle from jumping to the

nearby miter stop position.

Page 13

Setting the Bevel Angle

A beveled cut is where the saw head is tilted to the left or

right from vertical. The Kapex saw is capable of beveling

up to 47° to the left and right.

The bevel range selector engages a series of angle stops.

The selector has three settings. The first setting, (0-45°)

limits the bevel travel between 0 degrees and 45 degrees

to the left. The second setting (±45°) limits the bevel

travel between 45 degrees to the left and 45 degrees to

the right. The last setting (±47°) limits the bevel travel to

the full extent of the saw, which is 47 degrees to the left

and to the right.

NOTICE: These settings are not hard-limits, and

turning the bevel adjustment knob into one of the

limit settings will cause the spring loaded limit to

be bypassed. However, it should be noted that

doing so can cause premature wear to the bevel

limits.

1. Release the bevel lock by lifting the lever.

2. As necessary, turn the bevel range selector to the

desired range.

3. Rotate the bevel adjustment knob until the bevel index

pointer is pointing to the desired angle. (There is a

duplicate pointer on either side of the saw.)

4. Lower the bevel lock lever.

Using the Auxiliary Fence

The auxiliary fence provides support for taller workpieces.

The two halves of the fence can be slid toward or away

from the blade, or removed completely. Performing

beveled cuts requires the auxiliary fence to be moved

away from the blade area.

► To move the auxiliary fence, lift the locking lever, slide

the fence, then lower the locking lever.

► To remove the auxiliary fence, lower the limit screw by

turning it clockwise, then slide the fence out of the

retaining slot.

Supplemental User’s Manual 13

Page 14

Setting the Depth Limit

The depth limit is used for making partial cuts that do not

cut all the way through the workpiece, such as making

dados. When the depth limit is engaged, the sawblade’s

vertical travel is limited from going below the preset height.

The height is easily adjustable by turning the depth limit

knob. Turning the knob clockwise ¼-turn raises the

sawblade by

approximately 1

mm (0.040”), and

turning it

counterclockwise

lowers the

sawblade.

To engage the

depth limit, pull the

knob forward. To

disengage the

depth limit, push

the knob back.

Using the Tall Miter Latch

The tall miter latch is used for cutting boards in the vertical

position, such as mitering baseboard material. In this

cutting position, the height of the cut is maximized. The

miter latch holds the saw head slightly forward from its

normal position, and also increases the maximum depth

that the saw can plunge downward.

WARNING! To reduce the risk of injury from loss

of control, never cut tall boards without the

auxiliary fence installed. The workpiece can tip if

not properly supported.

Note: The bevel position must be at zero degrees

before you can engage the tall miter latch. The

latch will not engage if the saw head is tilted.

Releasing the Tall Miter Latch

While pressing down on the release lever (see previous

image), pull the saw head away from the fence. The tall

miter latch will spring to the vertical position when it

releases.

Cutting the Workpiece

Stand the workpiece up against the fence and plunge the

saw head down into the cut.

Engaging the Tall Miter Latch

1. Pull the saw head away from the fence.

2. While holding the latch lever down, push the saw head

back toward the fence until the tall miter latch locks

into the back of the saw head.

14 Kapex KS120 Miter Saw

Page 15

Using the MiterFast Tool

The MiterFast™ angle transfer tool converts a corner angle

measurement into a miter setting. The miter line in the

center of the tool is always at the midpoint of the two

angle arms, and when lined up with the saw’s laser,

provides the proper miter angle for the measured corner.

Measure the Corner

► For measuring an outside corner, extend the extension

arms as shown in the image below.

► For measuring an inside corner, retract the extension

arms as shown in the second image below.

1. Loosen the lock knob on the MiterFast tool.

2. Place the MiterFast tool in (or on) the corner and slide

the lock knob forward to expand the arms.

3. When the arms are lined up with the corner walls,

retighten the lock knob.

4. Place the MiterFast tool on the saw with one of the

arms up against the fence.

5. Turn on the laser for the saw. (Refer to Using the Laser

Guides

on page 11.)

6. Adjust the miter angle of the saw (refer to Setting the

Miter Angle

on page 12) until either of the laser beams

line up with the miter line on the MiterFast tool.

7. Lock the miter setting on the saw.

8. Fold up the MiterFast tool and return it to its storage

position in the base of the saw.

Supplemental User’s Manual 15

Page 16

Using the Bed Extensions and Crown Stops

The optional bed extensions provide a

useful platform for using additional

workpiece control accessories as well as

extending the size of the bed of the Kapex

saw. The optional bed extension accessory

includes the crown stop, as shown to the

upper right.

The extension can be mounted to the left

side or right side of the saw’s bed, or if two

are used, to both sides simultaneously.

The T-channel can also be used to secure

additional clamping elements such as the

Festool Quick Clamp or Screw Clamp shown

to the right. These clamps can be used for

clamping larger workpieces, or used in

conjunction with the Kapex hold down

clamp for multiple clamping needs, such as

the dado example shown on page 19.

Installation

To install the bed extension, place the edge into the Vchannel of the Kapex bed, position the extension forward or

back as needed, and then tighten the clamping knob (see

image to the right).

Setting up the Crown Stop

The crown stop is used for cutting crown moulding and

holds the moulding at the desired angle against the fence of

the saw so that it can be cut using a standard miter cut

(refer to the Crown Moulding

stop slides forward or back depending on the size of the

moulding, and clamps in place to serve as a secondary

fence.

To set up the crown stop, place the moulding against the

fence and bed of the saw, as shown in the lower left image,

slide the crown stop up against the moulding, and tighten

the clamping knob. Use the hold down clamp to secure the

moulding while cutting, as shown in the lower right image.

discussion on page 22). The

16 Kapex KS120 Miter Saw

Page 17

Cutting Techniques

There are three basic cutting techniques for sliding miter

saws, but only two are proper and authorized. These are

Chop-Cut, Push-Cut, and the improper method is a Pull-Cut.

Chop-Cut

A chop-cut is used for cutting narrow or tall stock, where

the front edge of the workpiece is behind the center of the

sawblade. For this type of cut, the saw head is brought

straight down into the cut.

Push-Cut

A push-cut is used for cutting wider boards, but is also

usable in most situations where a chop-cut could be used.

For this type of cut, the saw head is pulled out toward the

operator, plunged downward, and the primary cutting of the

workpiece occurs as the saw head is being pushed back

toward the rear of the saw (as shown in the picture below).

Pull-Cut (Improper Method)

WARNING! To reduce the risk of injury from loss

of control, never use the pull-cut technique.

The third type of cut, called a pull-cut, or climb-cut, should

be avoided for both safety reasons and for cutting

performance reasons. This type of cut is made by plunging

the saw head down, and then pulling it forward. The danger

of this type of cut is that the sawblade wants to self-feed

into the cut (called climb-cutting), and this can cause the

saw head to jump forward unexpectedly. The reason this

type of cut results in a poor quality cut is because it is using

two different actions for the same cut. It starts out with a

lunge-cut, and then finishes with a climb-cut. This means

p

that the sawblade is cutting the wood in two different

manners, and there will frequently be a rough edge at the

transition from one type of cut to the other.

Tips for Successful Cutting

► For more accurate cuts, mark your cutting length with

a thin pencil line. A thick line will result in a less

accurate cut length.

► When fitting one piece to another, it may be helpful to

make the initial cut slightly long, and then trimming

the cut to final length after test-fitting the piece.

► When cutting a new board, cut off the original factory

end to ensure a square, fresh end, before measuring

for your final length.

► When cutting small trim , use a zero clearance fence

and/or insert to prevent small offcuts from being

thrown behind the fence by the windage from the

spinning blade (see page 23).

► When cutting multiple pieces of varying lengths from

a limited supply of stock, always cut the longest

pieces first, and cut the remaining pieces from the

leftovers.

► Do not force the blade through the cut. A cleaner

edge will be achieved with a steady, moderate feed

rate.

► A chop-type of cut yields the lowest tearout on the

front and top edges of the cut, but the most tearout

on the rear side of the cut.

► A push-type cut yields moderate tearout on the top

surface, but the best cut edge.

Diagram of Push-Cut Method

Supplemental User’s Manual 17

Page 18

Miter Cuts

Miter cuts are used when a board needs to be cut at an

angle across its width. The most common application for a

miter cut is for joining two boards to form a corner without

endgrain showing. The miter angle is one-half of the

corner angle. So for a 90° corner, for example, the miter

angle is 45°.

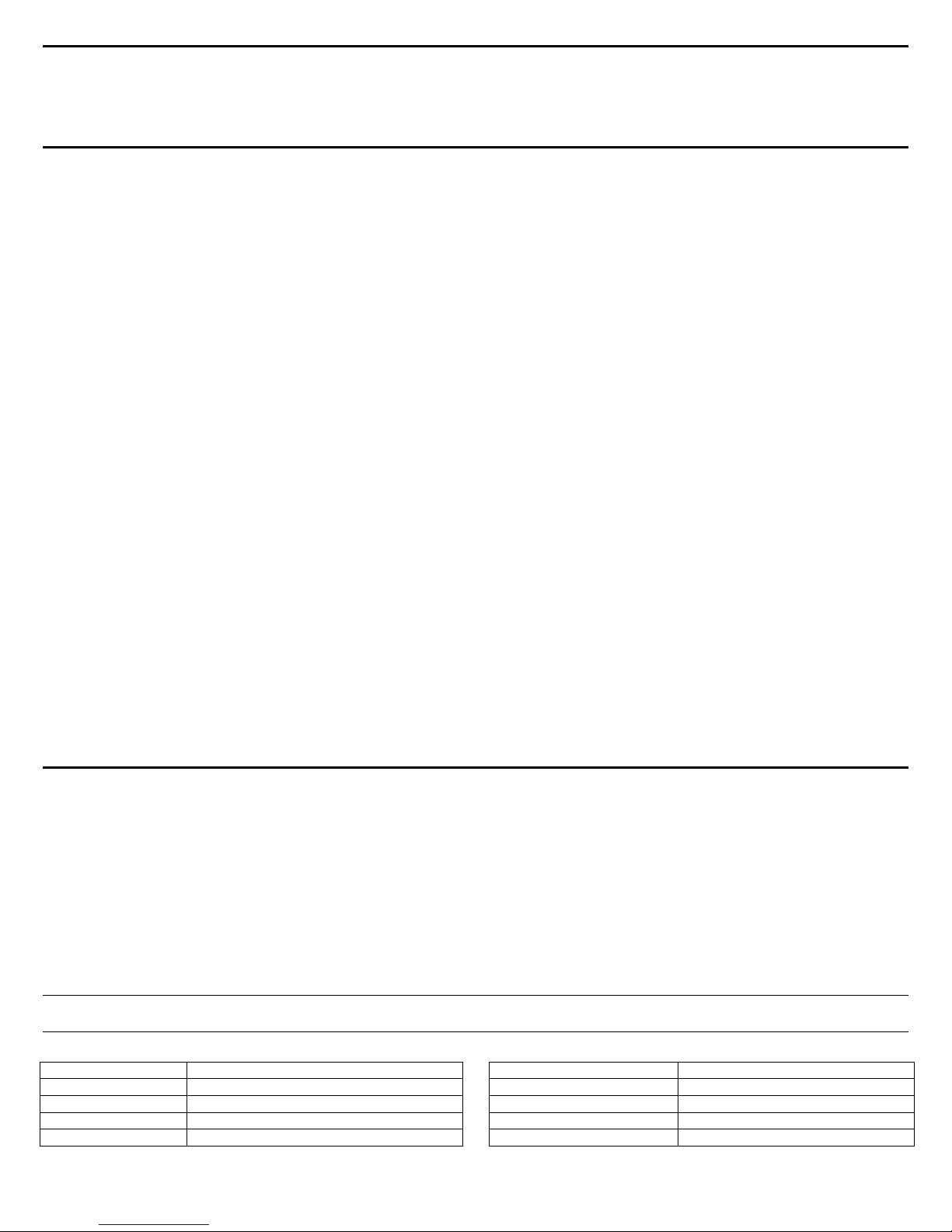

Miter Angles for Polygons

Number of sides Corner Angle Miter Angle

3 – Triangle 120 60

4 – Square 90 45

5 – Pentagon 72 36

6 – Hexagon 60 30

7 – Heptagon 51.4 25.7

8 – Octagon 45 22.5

For even the most experienced woodworkers, cutting

accurate and tight fitting miters can be problematic. The

following are some tips for making accurate miters.

► Clamp the workpiece down. Because the sawblade is

cutting at an angle with the workpiece edge and fence, it

will tend to move the workpiece sideways, in the

direction of the cut, as the cut progresses. This can

result in a cut that is not straight, or the angle of the cut

may be off.

► Cut slowly. Cutting too rapidly can cause the sawblade to

deflect as it encounters varying densities in the

woodgrain.

► Use a chop-cut only for narrow miters. When in doubt,

use a push-cut.

► When marking the length of the workpiece, use a sharp

pencil to draw a thin line. The thicker the line, the more

difficult it will be to cut accurately on the line.

► When marking a workpiece length to match a wall or

other structure, use a utility knife to mark the cut with a

small nick. This is more accurate than a pencil line.

► If a utility knife is used to mark the cut, you can use a

method called “Sneaking up on the cut.” This is where

you make an initial cut longer than needed, and

continually make very small re-cuts until the cut line

splits through the center of the nick you made with the

utility knife.

Bevel Cuts

Bevel cuts are used when a board needs to be cut at

an angle across its thickness. The most common

application for a bevel cut is for constructing a box or

similar structure.

The following are tips for making accurate bevel cuts:

► Clamp the workpiece down. If the workpiece is not

held firmly, the blade will tend to pull the workpiece

into the cut and up the blade.

► For best results, use only a push-cut.

► Take care not to deflect the saw head sideways.

Because the saw head is tilted to the side, it can be

18 Kapex KS120 Miter Saw

easy to inadvertently push the saw head down or pull it up

as you feed the saw into the cut. This will result in a crooked

cut.

► Place the workpiece on the saw with the best-side down.

Because of the angle of the blade teeth exiting the workpiece

on the top side of the cut, there will be slightly more tearout

on the top, especially on the sharper edge.

Page 19

Depth Limited (Dado/Half-Lap) Cuts

WARNING! Never attempt to install or use a

dado blade in the Kapex saw. Using either a

stacked-dado or wobble-dado blade will exceed

the capacity of the arbor, and the blade may

impact the saw’s guards, resulting in personal

injury and damage to the saw.

A dado is a special type of cut where the depth of the cut

does not go all the way through the workpiece. One

common example of this type of cut is for making halflapped joints, which is shown to the right and described

below. In a half-lap joint, material is removed from the

intersection of both workpieces comprising the joint. When

the joint is assembled, the pieces overlap, creating a

strong joint, but unlike a full-lap joint, the thickness of the

joint is equal to just the thickness of the workpieces.

Depth Setting

For making a half-lap joint, it is necessary to set the saw’s

cutting depth to be exactly in the center of the workpiece

thickness. The most accurate way of finding the center of a

board is to trim from both sides until the two cuts meet.

Use a piece of scrap wood that is the same thickness as

the actual workpiece. Starting with a depth setting that

you know to be less than half the workpiece thickness,

make a cut from the top side, and then flip the piece over

and make a second cut, as shown below by the Red color.

Gradually lower the depth of cut and repeat these two cuts

until the two cuts meet, and the spine reaches a zerothickness. This is exactly the center of the workpiece.

Half-Lap Joint

Clamping

It is important that both the fence spacer and workpiece

are securely clamped to the saw for cutting. Use the Kapex

Hold Down Clamp (see page 12) to clamp the fence

spacer, and use an auxiliary clamp, such as a Festool

Quick Clamp or Screw clamp (see page 16) to secure the

workpiece.

Fence Spacer

The center of the sawblade is 50 mm (2”) forward of the

saw’s fence, which results in the curved ramp at the rear

of the cut shown in the image below. To account for this

and remove the radius at the end of the cut, add a 50mm

(2”) spacer in front of the fence, and clamp it in place with

the Kapex hold down clamp as shown to the right.

Cutting the Dado

Before cutting the dado, mark the right and left sides of

the cut to indicate how wide the dado needs to be. Then

make successive kerf-cuts between the lines until all the

material between the lines is removed. The closer together

each of these successive cuts are, the smoother the

bottom of the dado will be. For best results, clean the

bottom of the dado with a sharp chisel.

Supplemental User’s Manual 19

Page 20

Compound Miter Cuts

Compound miter cuts are where the saw is both in a miter

position and a bevel position at the same time. There are

several applications for compound miter cuts, but cutting

crown moulding and sloped miters are common examples.

The example below shows a very simple birdfeeder roof.

The greatest challenge with compound miters is

determining the proper saw settings to achieve the desired

miter angle. These saw settings can be found in look-up

tables for standard mouldings, but for non-standard

angles, determining the proper saw settings requires

mathematical calculation.

Note that there are several methods for

accurately cutting crown moulding depending on

the circumstances. Make sure to review the

methods described in the applicable section on

page 21.

Calculating compound miter settings requires two

parameters from the desired joint: the corner angle and

the slope.

Slope

The Slope angle is the angle that each piece makes with

respect to the base of the corner, such as the ceiling or

floor in the examples provided here. For a roof-like

structure, this would be the pitch of the roof.

For crown moulding, this would be the

compliment of the “Spring Angle” of the

moulding. Common spring angles for

mouldings are 38/52 and 45/45.

Determining the Corner Angle of Polygons

The corner angle for standard polygons is

shown in the table on page 18.

Using the MiterFast Tool to Find a Corner Angle

For non-standard corner angles, such as a

room that is slightly out of square, the

MiterFast tool can be used to determine the

corner angle. To use the MiterFast tool to measure

the corner angle, follow the “Using the MiterFast Tool

procedure on page 15, but instead of making the cut,

record the saw’s miter setting angle. This angle is ½ the

corner angle, so multiplying by 2 will give you the corner

angle. (The compound angle calculator on page 21 also

has an option for letting you enter this angle directly

without needing to double it.)

Determining the Slope of a Pyramid (Polyhedron)

A polyhedron is a pyramid that can have any number of

sides. The easiest method for determining the slope of the

polyhedron is by measuring the Drop and Projection of

one face. These are the distances from the center-to-theedge, and the base-to-the-point of the pyramid. Note that

with a polyhedron with an odd number of sides, the center

is found by drawing bisecting lines as shown in the image

below.

”

Corner Angle

The corner angle is the angle between the two pieces,

when viewed looking straight down on the joint. The

corner angle is relatively easy to determine, but it is also

the value that can cause the greatest amount of confusion

for many woodworkers. That’s because most woodworkers

view angles differently than a mathematician will. A

woodworker typically considers both inside and outside

corners as 90 degrees (with a 45 degree miter) even

though a mathematician would make the distinction that

one corner is 90 degrees and the other is 270 degrees. To

be consistent with miter saw settings, the corner angle is

measured from a straight line between the two pieces, as

shown above.

20 Kapex KS120 Miter Saw

Page 21

Determining the Slope of Crown Moulding

As was mentioned previously, the slope of a crown

moulding is the compliment of its ”Spring Angle” (the

spring angle is measured relative to the wall, and the slope

is measured relative to the ceiling). The two common

spring/slope angles of crown moulding are 38/52 and

45/45. The reason why these angles are represented by

dual numbers is because the actual angle depends on

which direction the moulding is oriented. For example,

turned one way, the slope is 38 degrees, but turned the

other way, the slope is 52 degrees. Note that the sum of

these two angles is always 90 degrees.

For mouldings that are not the standard 38/52 or 45/45,

you will need to measure the moulding to determine its

slope. This is very similar to measuring the Drop and

Projection of a pyramid, but more care needs to be taken

to ensure the measurements are taken from the correct

locations. Important: The slope of a moulding does not

Calculating Compound Angles

necessarily coincide with the “points” or “Tails” of the

moulding. The slope is measured from the back-side of

the moulding, regardless how long the tails of the

moulding may extend (see image below).

There are two separate equations for calculating a

compound angle. One equation is for calculating the miter

setting of the saw, and the other equation is for calculating

the bevel setting of the saw.

⎡

⎛

= Slope

= Slope

⎜

TanArcTanMiter

⎢

⎜

⎢

⎝

⎣

⎡

⎛

⎜

SinArcSinBevel

⎢

⎜

⎢

⎝

⎣

2

2

eCornerAngl

⎞

⎟

⎟

()

Cos

×

⎠

eCornerAngl

⎞

⎟

⎟

()

×

Sin

⎠

If you don’t know the slope angle, but you know the Drop

and Projection, then use the following to calculate the

slope:

Drop

⎤

=

ArcTanSlope

⎥

⎥

⎦

⎤

⎥

⎥

⎦

The most common error in calculating compound

angles is using the wrong Corner Angle. As a

double-check to your calculations, for nearly all

cases, the Corner Angle should be less than 100°.

The only time the angle should be significantly

larger than 90° is either for a 3-sided box, or a

wall corner with a sharp edge.

⎡

⎢

Projection

⎣

⎤

⎥

⎦

Compound Angle Calculator

A compound angle calculator has been built into this Adobe® Acrobat® PDF file. If you do not have an original electronic

version of this manual, visit the

http://www.festoolusa.com/ website to download a copy.

Slope Angle Options

Note: If you are unsure

about the corner angle

you have entered, check

the calculated “MiterFast

Tool Angle” value. This

number should be no

more than 60 degrees for

sharp corners, but

otherwise, it should

always be less than 45

degrees for most corners.

If it is significantly

greater than 45 degrees,

then you probably have

the wrong “Corner

Angle.”

Slope Angle

Corner Angle Options

Corner Angle

Results

Miter Setting

Bevel Setting

Drop

Projection

MiterFast

Tool Angle

Supplemental User’s Manual 21

Page 22

Crown Moulding

There are several methods for cutting crown

moulding, and each method has its benefits

depending on the specific application. The most

common method for cutting crown moulding is to use

a standard miter cut, where the moulding is tilted

against the fence of the saw. For unusual situations,

or when the moulding is too large to fit against the

fence, compound miters are used. In some

applications, inside corners are made using a method

called “coping.” Each of these methods will be

described briefly.

Standard Miter

A standard miter cut is the easiest and most common

method for cutting crown moulding. The Kapex miter

saw has an optional auxiliary crown moulding fence

(also called the Crown Stop) specifically for making

this type of cut. The fence holds the moulding at the

correct angle so it can be cut with a normal miter cut.

For this type of cut, you place the moulding on the

saw as it would normally rest in the installed position.

The edge that normally faces the ceiling is the edge

that should be on the base of the saw.

curves), but the initial cut is made with a miter saw. The first

piece of moulding does not get a miter, and butts into the

adjacent wall. The second piece of moulding gets a coped cut to

match the profile of the first piece.

To make a coped cut, cut the second piece of moulding with a

miter, just as though it was going to be a mitered joint. Then

use a coping saw to cut along the edge of the resulting miter.

Compound Miter

A compound miter cut is used when the moulding is

too tall to use the standard miter method. This can

also be used for a higher level of accuracy when the

tails of the moulding are not perfectly perpendicular

with each other (a common problem with most

mouldings). Place the moulding on the saw with the

flat back face on the base.

General Notes

► If you are mitering both ends of a piece of moulding, make

the more difficult cut first, because it does not need to be

at the exact length. For example, a right-handed operator

may want to cut the left-hand miter first. This makes it

easier cutting the second miter to exact length.

► When installing crown moulding around a room with walls

that may not be square, use a piece of off-cut scrap

moulding to test-fit the miters and lengths.

► It is mathematically impossible to make a mitered joint that

changes two directions at the same time, such as putting

crown moulding around a vaulted ceiling. You must either

make a double miter joint, or use a corner block.

Coped Cut

A coped cut is sometimes used for making inside

corners so there is no visible gap between the two

pieces of moulding. A coped cut requires the use of a

coping saw (a thin bladed handsaw for cutting

22 Kapex KS120 Miter Saw

Page 23

Adding Auxiliary Fence Faces

Auxiliary fence faces can be added to the Kapex fence. One of

the primary benefits of adding fence faces is to create a zeroclearance fence opening for cutting smaller workpieces. The

term, “zero-clearance” means that there is no gap between the

sawblade and the fence. This is achieved by cutting the auxiliary

fence to final length after it is installed.

Making the Auxiliary Fences

The auxiliary fences can be made from solid wood, composite

wood (such as particle board), or soft (non-brittle) plastic.

► Option 1: Place a washer on the back of each

mounting screw.

► Option 2: Using a tablesaw or chisel, back-cut the

lower rear of the fence to clear the fixed portion of

the factory fence.

1. Cut your fence blanks to basic size. They can be wider or

narrower; taller or shorter than the actual fence. Size them

to best suit your needs.

2. Drill and countersink two 11/64” holes for #10 mounting

screws.

3. If desired, trace the shape of the factory fence onto the

auxiliary fence, and then cut the auxiliary fence with a band

saw or coping saw.

4. To permit the fence to slide left or right, it is necessary to

have a space between the auxiliary fence and the fixed

portion of the factory fence. Use one of the options listed.

Making a Zero-Clearance Insert

A zero-clearance insert is helpful when cutting small pieces

to prevent the offcuts from falling under the standard pair

of inserts. The insert can be made from any hard wood.

For best results, the insert should be custom fit to your

saw, so use the dimensions shown below as a starting

guideline. Adjust the thickness to be flush with the saw’s

5. After mounting the auxiliary fence faces to the

saw, use the saw to trim the ends for a zeroclearance fit. Trim one side at a time.

table. To make the countersunk holes for the mounting

screws, first use a small forstner bit to drill the

countersunk holes, and then a regular drill bit to drill a

through-hole for the screw’s shank. After the insert is

installed and screwed down to the saw’s table, cut the kerf

opening with the saw using a standard push-cut.

Supplemental User’s Manual 23

Page 24

Calibration and Adjustment

The Festool Kapex miter saw comes fully calibrated from

the factory and should not require further calibration out of

the box or after normal use. The following calibration

techniques should only be necessary in the event that your

Calibrating the Miter Angle

The calibration method described here is

based on compounding an error by a factor

of four. This makes it easier to detect

extremely small calibration errors. However,

care should be taken in over-using this

calibration procedure because it has such a

fine accuracy that it could be easy to get

carried away and try to over-calibrate the

saw. The factory calibration threshold is

±0.16°, but this calibration procedure is

capable of measuring errors as low as

±0.001°, which is nearly impossible to

obtain in actual practice.

The basis for this procedure is to make four

successive cuts, where each new cut

references from the previous cut. As a r

any angular error in the miter angle will

propagate and be compounded with each

cut. The final cutting error will have 4-times

the actual error of the saw. In the diagram

to the right, you can see that each

successive offcut has a slightly larger angle

than the previous offcut.

You may have heard of this method referred

to as the “5-cut Calibration Method”, but as

long as you start out with a straight edge on

the board, only 4-cuts are required.

Furthermore, any additional cuts made after

the fourth cut will not increase the accuracy,

and it will remain at 4-times the original

error.

esult,

saw is knocked out of alignment, such as can happen

during frequent, or unsecured transport. Use these

procedures only when your saw needs service.

Getting Started

You will need a piece of scrap wood that is between 6 and

12 inches on a side. The scrap does not need to be

perfectly square, but at least the first edge must be

straight. The larger the piece, the more accurate your final

measurement will be.

The material can be anything, but Medium Density

Fiberboard (MDF) will give you the cleanest cuts, and

therefore, the easiest to measure.

► High density plywood, such as Baltic birch, will also give

You will need a ruler to measure the length of the final

offcut, and optionally, a dial caliper to accurately measure

the difference in the width of the offcut at both ends. This

width measurement is the most critical, so a dial caliper is

recommended.

It does not matter whether your measurements

are in metric units or imperial units.

very accurate results.

► Low-grade plywood may have rough edges, depending

on the quality, and therefore, may provide the lowest

accuracy.

► Solid wood can also be used, but you may experience

burning on the rip-cuts if you are using a fine-tooth

blade.

24 Kapex KS120 Miter Saw

Page 25

Measuring the Error

Before adjusting the saw, you first need to measure

whether it is accurately calibrated to begin with. If you

attempt to exceed the factory calibration threshold, you

may end up actually making the saw less accurate.

1. Number the sides of the scrap piece of wood from 1 to

4, starting with the best edge.

► If you cut the wood on the left side of the blade (as

shown in this example), then number the sides in a

clockwise direction (as shown below).

► If you cut the wood on the right side of the blade,

then number the sides in a counterclockwise

direction.

2. On the #1 side, which will eventually become the final

calibration offcut, label it “Left” and “Right” as shown.

Do this regardless whether the cut is made on the left

or right side of the sawblade.

3. Place the scrap on the saw with the number “1”

against the fence.

10. Measure the width of the fourth offcut at both ends (as

labeled “Right” and “Left”). These two measurements

are critical, so use the best method you can.

Calculating the Error

The equation for calculating the error is shown below,

however, the electronic version of this manual also

contains a built-in calculator. To use the calculator, enter

your measurements (in either mm or inches) in the boxes

and click on the “Calc Error” button. The calculated error

(angle) is displayed to the right of the button.

WARNING! This procedure involves cutting small

workpieces. To reduce the risk of injury, always

clamp the workpiece to the saw.

4. Cut approximately 1/4-inch off the board, so that there

is at least a 1/8-inch offcut. This offcut ensures that

the sawblade will be stable because there is wood on

both sides of the blade during the entire cut.

5. Rotate the board with side #2 against the fence and

repeat the same cut. Note that the side previously cut

is now against the fence for each of the four cuts

described below.

6. Rotate the board to side #3 against the fence and

repeat the same cut.

7. Rotate the board to side #4 against the fence, but this

time, make the cut a little wider, so that the offcut is

large enough to handle without breaking it

(approximately 1/4 to 1/2 inch wide).

8. Discard the first three offcuts, but the fourth offcut is

the calibration offcut.

9. Measure the length of the fourth offcut. The accuracy

of this measurement is not critical, so a standard tape

measure or ruler will suffice.

1

×=

ArcError sin

4

Built-in Electronic Calculator

Width Left Width Right

Length

If the answer is a negative number (Right side wider than

Left side), then your saw is cutting too much to the left of

center. If the answer is a positive number, your saw is

cutting too much to the right of center.

Adjusting the Saw

1. With the miter handle out of the way, loosen only the

middle screw on the miter gauge, and then move the

miter handle back to zero.

2. Engage the miter lock by pressing down on the lock

handle (see page 12). This locks the miter gauge to

the miter handle, and prevents the gauge from moving

until you are ready to move it.

3. Loosen the remaining two screws on the miter gauge,

and gently tap sideways on the miter handle to move

the gauge as needed.

4. Retighten all three screws.

5. Repeat the calibration procedure to verify the results.

⎡

⎢

⎣

−

WidthRightWidthLeft

Length

⎤

⎥

⎦

Supplemental User’s Manual 25

Page 26

Calibrating the Bevel Angle

Calibrating the bevel angle uses the same 4-cut method

described in the Calibrating the Miter Angle

page 24. Refer to the discussion on page 24 for an

explanation of the method.

Except for cutting tall miters, the bevel setting accuracy is

generally less critical than the miter setting accuracy. Take

care not to attempt to over-calibrate this setting.

Getting Started

You will need a piece of scrap wood that is between 4 and

4-3/4 inches on a side. The scrap does not need to be

perfectly square, but at least the first edge must be

straight. The larger the piece, the more accurate your final

measurement will be, but 4-3/4” is the maximum size that

can be cut using the Tall Miter Setting (see page 14).

The material can be anything, but Medium Density

Fiberboard (MDF) will give you the cleanest cuts, and

therefore, the easiest to measure.

► High density plywood, such as Baltic birch, will also give

very accurate results.

► Low-grade plywood may have rough edges, depending

on the quality, and therefore, may provide the lowest

accuracy.

► Solid wood can also be used, but you may experience

burning on the rip-cuts if you are using a fine-tooth

blade.

You will need a ruler to measure the length of the final

offcut, and optionally, a dial caliper to accurately measure

the difference in the width of the offcut at both ends. This

width measurement is the most critical, so a dial caliper is

recommended.

It does not matter whether your measurements

are in metric units or imperial units.

procedure on

2. On the #1 side, which will eventually become the final

calibration offcut, label it “Left” and “Right” as shown.

Do this regardless whether the cut is made on the left

or right side of the sawblade.

3. Lock the saw in the Tall Miter position. Refer to page

14.

4. Make sure that both auxiliary fences are in place and

supporting the workpiece. Refer to page 13.

5. Place the scrap on the saw with the number “1” facing

down against the base of the saw.

WARNING! This procedure involves cutting small

workpieces. To reduce the risk of injury, always

clamp the workpiece to the saw.

6. Cut approximately 1/4-inch off the board, so that there

is at least a 1/8-inch offcut. This offcut ensures that

the sawblade will be stable because there is wood on

both sides of the blade during the entire cut.

7. Rotate the board with side #2 against the base and

repeat the same cut. Note that the side previously cut

is now against the base for each of the four cuts

Measuring the Error

Before adjusting the saw, you first need to measure

whether it is accurately calibrated to begin with. The

factory calibration threshold is ±0.5°. If you attempt to

exceed this calibration threshold, you may end up actually

making the saw less accurate.

1. Number the sides of the scrap piece of wood from 1 to

4, starting with the best edge.

► If you cut the wood on the left side of the blade (as

described below.

8. Rotate the board to side #3 against the base and

repeat the same cut.

9. Rotate the board to side #4 against the base, but this

time, make the cut a little wider, so that the offcut is

large enough to handle without breaking it

(approximately 1/4 to 1/2 inch wide).

10. Discard the first three offcuts, but the fourth offcut is

the calibration offcut.

shown in this example), then number the sides in a

counterclockwise direction (as shown).

► If you cut the wood on the right side of the blade,

then number the sides in a clockwise direction.

► Note that this is the opposite from the miter

calibration numbering.

26 Kapex KS120 Miter Saw

Page 27

11. Measure the length of the fourth offcut. The accuracy

of this measurement is not critical, so a standard tape

measure or ruler will suffice.

12. Measure the width of the fourth offcut at both ends (as

labeled “Right” and “Left”). These two measurements

are critical, so use the best method you can.

Calculating the Error

The equation for calculating the error is shown below,

however, the electronic version of this manual also

contains a built-in calculator. To use the calculator, enter

your measurements (in either mm or inches) in the boxes

and click on the “Calc Error” button. The calculated error

(angle) is displayed to the right of the button.

Adjusting the Saw

1. Using the hex key stored on the cord reel, slightly

loosen the two adjusting screws located behind the

cord reel shown below.

2. You may find it easier to move the entire saw head

instead of just the bevel plate. To move the entire saw

head, leave the bevel lock lever (see page 13) in the

locked position. To move just the bevel plate, move

the bevel lock lever to the unlocked position.

3. Carefully adjust the bevel angle to account for the

error calculated previously.

4. Retighten the two screws, and repeat the procedure to

verify the results.

5. When the calibration is correct, torque the two screws

to 18 ft. lbs. (25 Nm).

1

×=

ArcError sin

4

Built-in Electronic Calculator

Width Left Width Right

Length

► If the answer is a negative number (Right side wider

than Left side), then your saw is cutting too much to

the left of center.

► If the answer is a positive number, your saw is cutting

too much to the right of center.

⎡

⎢

⎣

−

WidthRightWidthLeft

Length

⎤

⎥

⎦

Supplemental User’s Manual 27

Page 28

Calibrating the Lasers

In order to calibrate the lasers, you will need to puncture the

decal on the side of the saw. The 2.5mm adjustment screw

openings are identified by the small circles on the decal.

The 2.5 mm hex key is shipped with the saw and

is located in the Styrofoam packing material.

► The Tilt adjustment is used to ensure the lasers are

pointing parallel to the sawblade, so they trace out the

same line regardless whether the saw is raised or lowered.

► The Yaw adjustment rotates the laser (as viewed from

above the saw) so it remains parallel with the path of the

saw cut (front-to-rear).

► The lateral adjustment moves the laser toward or away

from the saw cut (sawblade).

Setup

1. Before beginning, remove the laser dust lens and clean

it. To remove the lens, loosen the retaining screw,

push in and down on the ribbed surface to release the

locking tabs, and then slide the lens out of the saw.

► You can use any wood that has a relatively smooth

surface. The white melamine board shown below

provides a good contrast between the board surface

and the kerf cut.

5. Turn on the laser.

6. Begin by adjusting the yaw settings so both lasers are

parallel with the saw cut.

Make sure to remove the hex key from the screw

before gauging your progress. The pressure of

2. Wipe off any dust and debris from the lens with a soft

cotton cloth, or rinse it with water and mild soap.

3. Reinstall the lens before making adjustments to the

lasers.

the hex key is enough to deflect the laser.

7. Next, lower the sawblade down into the kerf (touching

the wood) and temporarily adjust the lateral setting

until the laser is against the edge of the kerf.

8. Raise the saw back to the top, and adjust the tilt

setting so the laser remains against the edge of the

kerf (at the same position as the previous setp).

9. Verify the tilt adjustment by raising and lowering the

saw and check that the laser remains the same

distance away from the kerf.

10. Finally, adjust the lateral position to line up wi th the

4. Clamp a smooth piece of scrap wood to the saw and

using the depth limit (see page 14), make a shallow

kerf cut across the board.