Page 1

Instruction manual

Page 2 - 5

IMPORTANT: Read and understand all instructions before

using.

Guide d’utilisation

Page 6 - 9

IMPORTANT: Lire et comprendre toutes les instructions

avant de démarrer les travaux.

Manual de instrucciones

Pagina 10- 13

IMPORTANTE: Lea y comprende todas las instrucciones

antes de usar.

475825_001

KA-KS 120

Page 2

Trimming attachment KA-KS 120

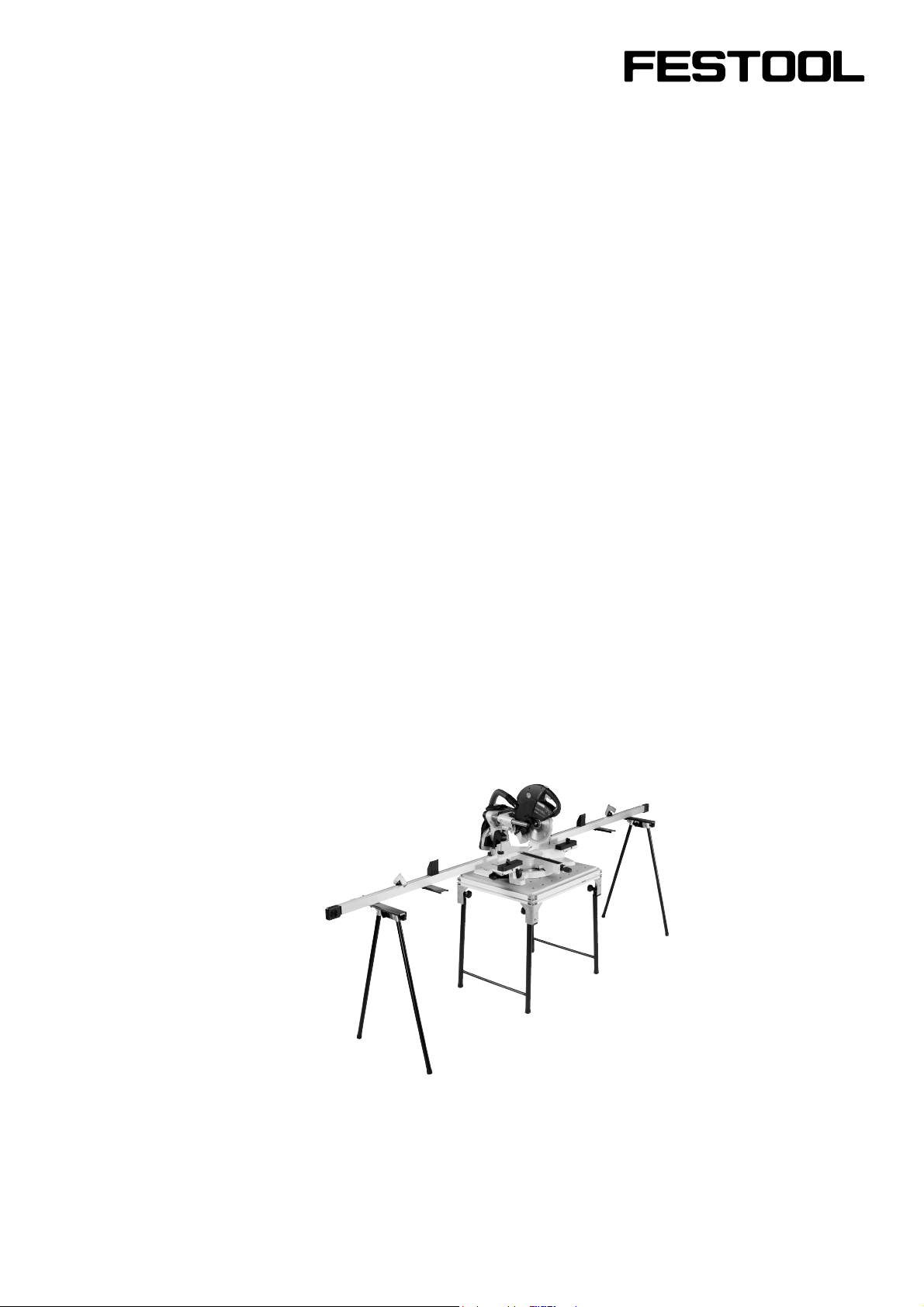

1 Scope of delivery

The trimming attachment consists of the

following main components:

(1.1) Stop profi le

(1.2) Tape measure clamp

(1.3) Support

(1.4) Support plate

(1.5) Stop fl ag

(1.6) Adjustable spacer

(1.7) Extendable end piece

(1.8) Leg support plate

(1.9) Tape measure

(1.13) Cross brace

1.9 1.7

1.6 1.4 1.31.8

1.5 1.2 1.1

2 x KA-KS 120

left

right

2.1 Preparations

– Secure the KS 120 to a Festool multifunc-

tion table (MFT) or a work bench with a

height of 31.1 in./790 mm (see operating

manual KS 120).

1.10

1.12

1.131.11

1

2 Set-up

When setting up the attachment, proceed in

the sequence specifi ed.

Important: you will require a crown moulding stop (AB-KS 120) to make the connection to the KS 120.

Refer to Figure 1 for the arrangement and

positioning of the individual parts.

Fig. 1 shows a rear view of the trimming

attachment.

The following section describes how to attach

the right trimming attachment. Use the

same procedure to attach the left trimming

attachment! Fig. 2 shows the stop mounted

on both sides!

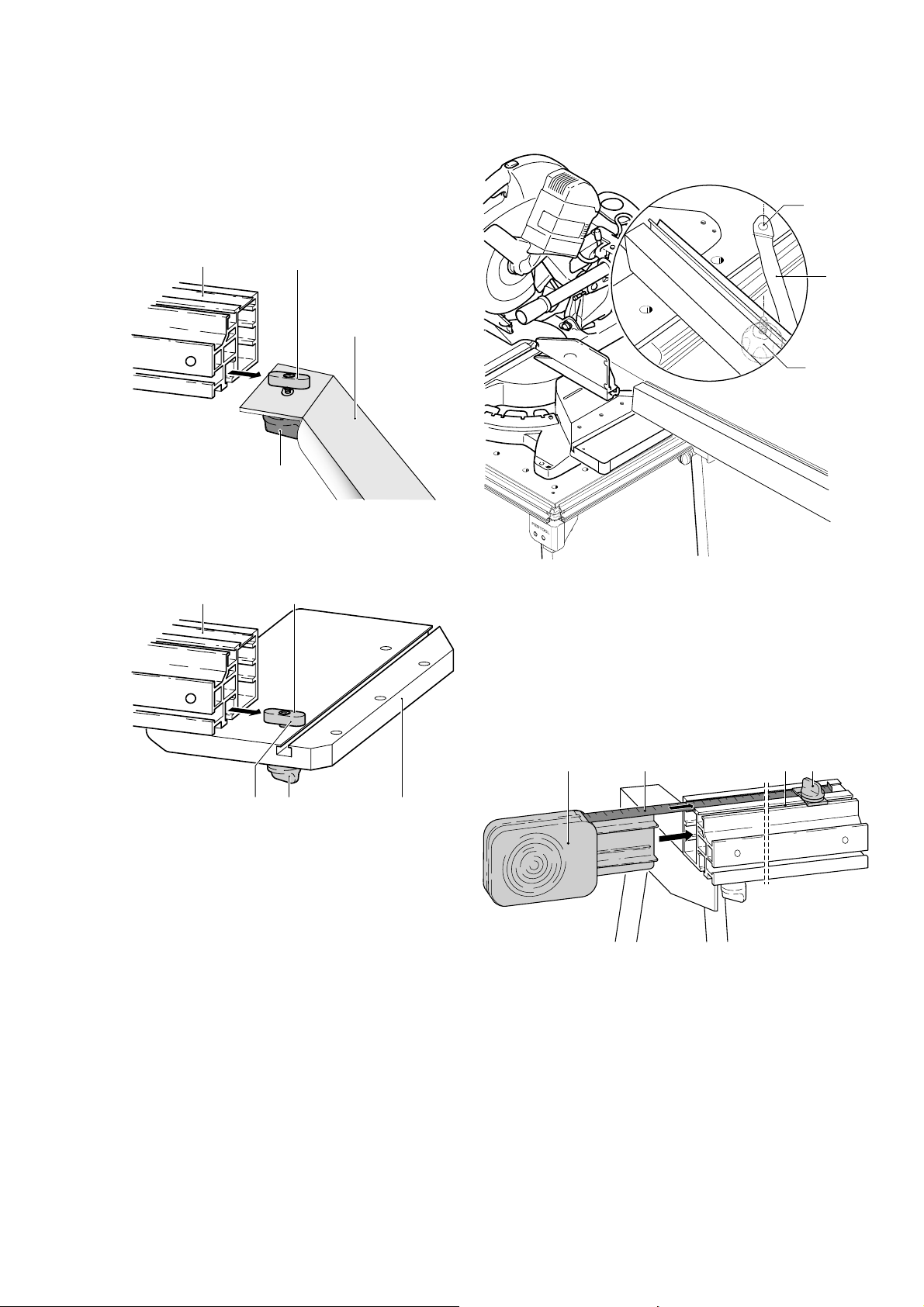

2.2 Leg support plate

The leg support plate (1.8) is designed to

support the trimming attachment and is

fi xed to the extendable end piece (1.7).

3.6 3.7

3.5

3.4

3.1

3.3

3.2

3.8

3

– Unscrew both rotary knobs (3.1) until the

two support legs (3.3) can be inserted into

the clamping sleeves (3.4).

– Insert the support legs until the leg sup-

port plate reaches the same height as your

KS 120.

– Tighten the rotary knobs (3.1) to clamp

the support legs in place.

– Screw the rotary knob (3.2) through the

recess (3.5) and into the slot nut (3.8) in

the bottom slot (3.7) on the extendable

2

Page 3

end piece to secure the mounting plate.

Note: The two cams (3.6) must slot into

the groove (3.7).

3.2 Cross brace

Secure the cross member (1.13) to the stop

profi le.

– Slide the slot nut (4.2) into the stop profi le

(4.1).

4.1

4.2

4.3

sembly instructions).

– Insert a clamp (6.3) in the hole (6.1) to

secure the cross brace (6.2) to the MFT.

Do not tighten yet!

6.1

6.2

6.3

4

4.4

2.4 Stop profi le

Secure the stop profi le to the bench for the

bracket support (AB-KS 120):

5.1 5.2

5.4 5.35.5

5

– Insert the rotary knob (5.4) through the

hole (5.5) in the bracket support bench and

secure the slot nut (5.2). Do not tighten

the knob yet – you must be able to lift the

slot nut approx. 0.2 in. above the bracket

support.

– Slide the stop profi le (5.1) onto the slot nut

(5.2) until the stop profi le is fl ush with the

edge of the bench (5.3).

– Fit the bracket support bench to the KS 120

(see bracket support assembly instructions).

– Align the bracket support bench so that

the stop profi le is fl ush with the stop ruler

on the KS 120. Clamp the bracket support

bench in place (see bracket support as-

6

–Use a long workpiece to align the trimming

attachment in relation to the compound

mitre saw.

– Tighten the rotary knob (5.4).

– Now tighten the connections on the cross

braces (4.4) and (6.3).

2.5 Tape measure, tape measure

clamp

7.2 7.3 7.47.1

7

– Insert the tape measure (7.1) into the

extendable end piece.

– Guide the tape measure (7.2) through the

top grooves on the extendable end piece,

the adjustable spacer and the stop profi le

in succession.

– Unscrew the rotary knob (7.4) for the tape

measure clamp.

– Insert the slot nut for the tape measure

clamp into the slot (7.3) on the stop pro-

fi le.

3

Page 4

– Secure the tape measure clamp towards

the end of the tape measure by tightening

the rotary knob (7.4).

2.6 Support plate

The support plate (1.4) is used to support

longer workpieces.

8.38.1 8.2

8.4

8.5

8

(9.2) on the stop profi le or the adjustable

spacer.

–If necessary, extend the telescopic section

of the trimming attachment 4 in. to insert

the support plate into the groove.

– Slide the support to the required positi-

on.

– Tighten the rotary knob (9.1) to secure the

support.

2.8 Stop fl ag

The stop fl ag (1.5) is used to adjust the

distance between the saw blade and the

workpiece so that the workpiece is cut to

the required length.

– Unscrew the rotary knob (1.11) on the

adjustable spacer.

– Move the stop profi le (1.1) and the spacer

(1.6) approx. 3.1 in. apart.

10.1 10.2

– Screw the rotary knob (8.5) through the

recess (8.4) and into the slot nut (8.1) in

the slot (8.2) on the stop profi le to secure

the support plate. Note: The two cams

(8.3) must slot into the groove (8.2).

–If necessary, extend the telescopic section

of the trimming attachment 4 in. to insert

the support plate into the groove.

2.7 Support

The support (1.3) is used to support taller

workpieces.

9.1 9.2

9

9.3

10

10.4

10.3

– Unscrew the rotary knob (10.1) that clamps

the stop fl ag.

– Insert the slot nut (10.3) into the top slot

(10.2) on the stop profi le or the adjustable

spacer.

– Slide the stop fl ag to the required positi-

on.

– Tighten the rotary knob (10.1) to secure

the stop fl ag.

Adjusting play on the stop fl ag

– Turn (tighten or unscrew) the two screws

(10.4) until the stop fl ag moves smoothly

along the slot, but without play.

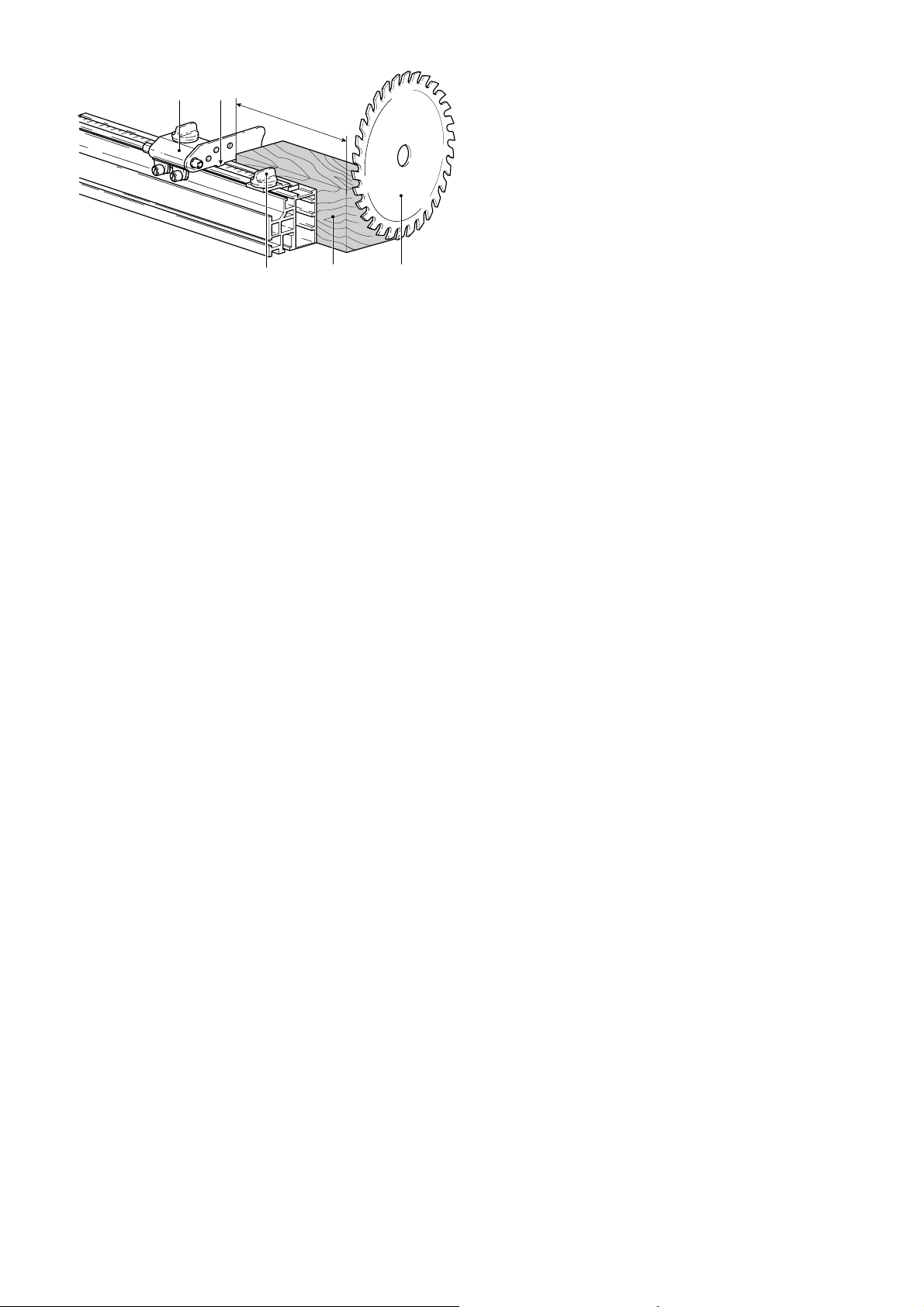

3 Adjustments

3.1 Tape measure

The tape measure starts at 11.81 in./

30 cm so that it does not come into contact with the saw blade. Therefore, make

sure that the distance between the tape

measure and the saw blade is correct:

– Unscrew the rotary knob (9.1) that clamps

the support.

– Insert the slot nut (9.3) into the top slot

4

Page 5

11.1 11.2

11

17.72 in.

11.5

11.4

11.3

– Set both the horizontal and vertical mitre

angles on the KS 120 to 0°.

– Place a workpiece (11.4) with a length

of 18.72 in./450 mm on the KS 120

lengthways against the saw blade (11.3).

– Slide the stop fl ag (11.1) up to the workpi-

ece. Clamp the stop fl ag in this position.

– Unscrew the rotary knob for the measuring

tape clamp (11.5).

– Move the tape measure until the measure-

ment at the edge (11.2) of the stop fl ag

indicates 18.72 in./450 mm.

– Use the tape measure clamp (11.5) to se-

cure the tape measure in this position. The

tape measure now indicates the exact dis-

tance to the saw blade. The measurement

at the edge (11.2) is the distance between

the stop fl ag and the saw blade.

3.2 Length adjustment

Unscrew the rotary knob (1.12) to extend and

retract the end piece (1.7). The maximum

extension length is 90.55 in./2300 mm.

Unscrew the rotary knob (1.11) to move

the spacer.

4 Working

To trim a workpiece to a certain length, proceed as follows:

– Adjust the stop fl ag to the required dimen-

sion.

– Place the workpiece against the stop

fl ag.

– Cut through the workpiece with the

KS 120.

5

Page 6

Guide butée KA-KS 120

1 Eléments fournis

Le guide butée comprend les éléments principaux suivants :

(1.1) Profi lé de butée

(1.2) Bloque-mètre

(1.3) Support

(1.4) Plaque d'appui

(1.5) Curseur de butée

(1.6) Pièce intermédiaire réglable

(1.7) Embout coulissant

(1.8) Support de pieds

(1.9) Mètre

(1.13) Renfort transversal

1.9 1.7

1.6 1.4 1.31.8

1.5 1.2 1.1

2 x KA-KS 120

gauche

droite

2.1 Opération préparatoire

– Fixez la KS 120 à une table multifonction

Festool (MFT) ou à une table de travail

d'une hauteur de 31.1 in./790 mm (voir

la notice d'utilisation de la KS 120).

1.10

1.12

1.131.11

1

2 Montage

Lors du montage, procédez dans l'ordre

indiqué.

Important : la butée inclinée (AB-KS 120)

est additionnellement nécessaire pour le

raccordement à l'unité KS 120.

Pour l'orientation et le positionnement des

pièces, reportez-vous à l'illustration 1.

La vue de la fi gure 1 correspond à la vue

de derrière.

Le paragraphe suivant décrit le montage du

guide-butée droit. Procédez de la même

manière pour le guide-butée gauche ! A des

fi ns de meilleure orientation, la butée est

représentée montée des deux côtés sur la

fi gure 2 !

2.2 Support de pieds

Le support de pieds (1.8) est fi xé à l'embout

coulissant (1.7) et sert d'appui pour le guide

butée.

3.6 3.7

3.5

3.4

3.1

3.3

3.2

3.8

3

– Dévissez les deux molettes (3.1) jusqu'à

ce que les deux pieds (3.3) puissent être

insérés dans les fi xations (3.4).

– Enfoncez les pieds jusqu'à ce le support

de pieds soit à la même hauteur que la

KS 120.

– Bloquez les pieds à l'aide des molettes

(3.1).

– Solidarisez la plaque de fi xation et l'embout

coulissant à l'aide de la molette (3.2) à

visser au niveau de l'encoche (3.5) et du

6

Page 7

coulisseau (3.8) à insérer dans la gorge

inférieure (3.7) de l'embout coulissant.

Attention : les deux ergots (3.6) doivent

s'enclencher dans la gorge (3.7).

2.3 Renfort transversal

Fixez le renfort transversal (1.13) sur le

profi lé de butée.

– Engagez le coulisseau (4.2) dans le profi lé

de butée (4.1).

4.1

4.2

4.3

la KS 120. Bloquez la tablette du support

d'angle (voir la notice de montage du sup-

port d'angle).

–Fixez le perçage (6.1) du renfort transversal

(6.2) à l'aide du dispositif de serrage (6.3)

de l'unité MFT. Ne pas encore serrer !

6.1

6.2

6.3

4

4.4

2.4 Profi lé de butée

Fixez le profi lé de butée à la tablette du

support d'angle (AB-KS 120) :

5.1 5.2

5.4 5.35.5

5

– Fixez le coulisseau (5.2) à l'aide de la

molette (5.4) au niveau du trou (5.5) de

la tablette du support d'angle. Ne serrez

pas encore ! Le coulisseau doit pouvoir

s'abaisser d'environ 0.2 in. par rapport au

support d'angle.

– Poussez le profi lé de butée (5.1) sur le

coulisseau (5.2) jusqu'à ce que le profi lé

de butée soit au même niveau que le chant

de la tablette (5.3).

– Montez la tablette du support d'angle sur

la KS 120 (voir la notice de montage de la

tablette du support d'angle).

– Orientez la tablette du support d'angle de

telle sorte que le profi lé de butée soit au

même niveau que la réglette de butée de

6

– Alignez à l'aide d'une pièce à travailler

longue le guide-butée par rapport à la scie

guidée.

– Serrez la molette (5.4).

–Serrez à présent les liaisons du renfort

transversal (4.4) et (6.3).

2.5 Mètre, bloque-mètre

7.2 7.3 7.47.1

7

– Positionnez le mètre (7.1) sur l'embout

coulissant.

– Déroulez le mètre (7.2) dans la gorge

supérieure de l'embout coulissant, de la

pièce intermédiaire réglable et du profi lé

de butée.

– Desserrez la molette (7.4) du bloque-mè-

tre.

– Insérez le coulisseau du bloque-mètre dans

7

Page 8

la gorge (7.3) du profi lé de butée.

– Bloquez le bloque-mètre à proximité de

l'enrouleur du mètre en serrant la molette

(7.4).

2.6 Plaque d'appui

La plaque d'appui (1.4) sert à soutenir les

pièces longues.

8.38.1 8.2

8.4

8.5

8

– Desserrez la molette (9.1) de fi xation du

support.

– Insérez le coulisseau (9.3) dans la gorge

supérieure (9.2) du profi lé de butée ou de

la pièce intermédiaire réglable.

–Ecartez le cas échéant l'élément télescopi-

que du guide-butée de 4 in., afi n de guider

la tôle-support dans la rainure.

– Amenez le support jusqu'à la position sou-

haitée.

– Fixez le support en vissant la molette

(9.1).

2.8 Curseur de butée

Le curseur de butée (1.5) permet de régler

la distance par rapport à la lame de scie et

donc la longueur de la pièce à scier.

– Desserrez la molette (1.11) de la pièce

intermédiaire réglable.

– Ecartez le profi lé de butée (1.1) et la pièce

intermédiaire (1.6) d'environ 3.1 in.

10.1 10.2

– Solidarisez la plaque d'appui et le profi lé de

butée à l'aide de la molette (8.5) à visser

au niveau de l'encoche (8.4) et du coulisseau (8.1) à insérer dans le gorge (8.2)

du profi lé de butée. Attention : les deux

ergots (8.3) doivent s'enclencher dans la

gorge (8.2).

–Ecartez le cas échéant l'élément télescopi-

que du guide-butée de 4 in., afi n de guider

la tôle-support dans la rainure.

2.7 Support

Le support (1.3) sert à soutenir les pièces

hautes.

9.1 9.2

10

10.4

10.3

– Desserrez la molette (10.1) de blocage du

curseur de butée.

– Insérez le coulisseau (10.3) dans la gorge

supérieure (10.2) du profi lé de butée ou

de la pièce intermédiaire réglable.

– Amenez le curseur de butée dans la posi-

tion souhaitée.

– Bloquez le curseur de butée en vissant la

molette (10.1).

Réglage du jeu du curseur de butée

– Vissez ou dévissez les deux vis (10.4) jus-

qu'à ce que le curseur de butée se déplace

sans jeu (mais librement) dans la gorge.

9

3 Réglages

3.1 Mètre

Afi n que le mètre ne puisse pas entrer en

contact avec la lame de scie, il commence

à 11.81 in./30 cm. Il est donc important de

régler correctement la distance par rapport

à la lame de scie :

9.3

8

Page 9

11.1 11.2

11

17.72 in.

11.5

11.4

11.3

– Réglez l'inclinaison de la KS 120 à 0° (ho-

rizontale et verticale).

– Positionnez une pièce (11.4) de 18.72

in./450 mm de long contre la lame de scie

(11.3) de la KS 120.

– Poussez le curseur de butée (11.1) contre

la pièce. Bloquez le curseur de butée dans

cette position.

– Desserrez la molette du bloque-mètre

(11.5).

– Décalez le mètre jusqu'à ce que le bord

(11.2) du curseur de butée indique la graduation 18.72 in./450 mm.

– Bloquez le mètre dans cette position à

l'aide du bloque-mètre (11.5). Le mètre

indique désormais le distance exacte par

rapport à la lame de scie. Le distance du

curseur de butée par rapport à la lame de

scie se lit au niveau du bord (11.2).

3.2 Réglage de la longueur

Une fois la molette (1.12) desserrée, il est

possible de sortir ou de rentrer l'embout

(1.7). La longueur maximale est de 90.55

in./2300 mm.

Une fois la molette (1.11) desserrée, il

est possible de déplacer la pièce intermédiaire.

4 Travail

Pour scier une pièce à la longueur voulue,

procédez comme suit :

– Réglez la longueur voulue à l'aide du cur-

seur de butée.

– Positionnez la pièce contre le curseur de

butée.

– Sciez la pièce avec la KS 120.

9

Page 10

Tope para tronzar KA-KS 120

1 Dotación de suministro

El tope para tronzar se compone principalmente de los siguientes elementos:

(1.1) Perfi l de tope

(1.2) Dispositivo de fi jación de la cinta

métrica

(1.3) Apoyo

(1.4) Chapa de apoyo

(1.5) Tope de apoyo

(1.6) Pieza intermedia ajustable

(1.7) Pieza fi nal extensible

(1.8) Soporte

(1.9) Cinta métrica

(1.13) Traviesa

1.9 1.7

1.6 1.4 1.31.8

1.5 1.2 1.1

2 x KA-KS 120

izquierda

derecha

2.1 Trabajos preliminares

– Fije la KS 120 a una mesa multifuncional de

Festool (MFT) o a una mesa de trabajo con

una altura de 31.1 in./790 mm (véase el

manual de instrucciones de la KS 120).

1.10

1.12

1.131.11

1

2 Estructura

Para el montaje de la estructura proceda en

la secuencia descrita a continuación.

Importante: para unir a la sierra de tronzar

KS 120 necesita adicionalmente el soporte

angular (AB-KS 120).

Preste atención a la imagen 1 con objeto

de llevar a cabo la alineación y el posicionamiento de las piezas sueltas.

La vista en la fi gura 1 se corresponde con la

vista desde la parte posterior.

A continuación de describe la estructura

del tope derecho para tronzar. Proceda de

forma análoga para montar el tope izquierdo

para tronzar. Para facilitar la orientación se

representa en la fi gura 2 el tope montado

en ambos lados.

2.2 Soporte

El soporte (1.8) sirve de apoyo para el tope

para tronzar y se sujeta con la pieza fi nal

extensible (1.7).

3.6 3.7

3.5

3.4

3.1

3.3

3.2

3.8

3

– Abra ambos botones giratorios (3.1) hasta

que las patas de apoyo (3.3) puedan introducirse en las abrazaderas de tubo (3.4).

– Introduzca las patas hasta que el soporte

quede a la misma altura que su KS 120.

– Inmovilice las patas de apoyo cerrando los

botones giratorios (3.1).

– Atornille fi rmemente la chapa de sujeción

en la entalladura (3.5) con el botón giratorio (3.2), así como la lengüeta insertada (3.8) en la ranura inferior (3.7) de la

10

Page 11

pieza fi nal extensible. Atención: los dos

salientes (3.6) han de quedar enclavados

en la ranura (3.7).

2.3 Traviesa

Fije la traviesa (1.13) al perfi l de tope.

–Deslice la lengüeta insertada (4.2) sobre

el perfi l de tope (4.1).

4.1

4.2

4.3

–Fije el taladro (6.1) de la traviesa (6.2)

con la sujeción (6.3) a la MFT. ¡No apriete

aún!

6.1

6.2

6.3

4

4.4

2.4 Perfi l de tope

Afi ance el perfi l de tope a la mesa de apoyo

angular (AB-KS 120) :

5.1 5.2

5.4 5.35.5

5

– Sujete la lengüeta insertada (5.2) con el

botón giratorio (5.4) en el taladro (5.5)

de la mesa de apoyo angular. No apriete

el botón hasta su tope: la lengüeta debe

poder separarse 0.2 in. aprox. del apoyo

angular.

– Deslice el perfi l de tope (5.1) por la len-

güeta insertada (5.2) hasta que quede

enrasado con el borde de la mesa (5.3).

– Monte la mesa de apoyo angular en la

KS 120 (véanse las instrucciones de montaje del apoyo angular).

– Regule la mesa de apoyo angular de tal

modo que el perfi l de tope quede enrasado

con la guía de tope de la KS 120. Inmovilice la mesa de apoyo angular (véanse

las instrucciones de montaje del apoyo

angular).

6

–Efectúe la alineación del tope para tronzar

y la sierra tronzadora con la ayuda de una

pieza de trabajo larga.

– Cierre el botón giratorio (5.4).

–Fije ahora las uniones de la traviesa (4.4)

y (6.3).

2.5 Cinta métrica, dispositivo de fi -

jación de la cinta métrica

7.2 7.3 7.47.1

7

– Coloque la cinta métrica (7.1) sobre la

pieza fi nal extensible.

– Desenrolle la cinta métrica (7.2) por las

ranuras superiores de la pieza fi nal exten-

sible, de la pieza intermedia ajustable y del

perfi l de tope.

– Abra el botón giratorio (7.4) del dispositivo

de fi jación de la cinta.

– Inserte la lengüeta del dispositivo de fi ja-

ción de la cinta en la ranura (7.3) del perfi l

de tope.

– Fije el dispositivo en la zona anterior a la

11

Page 12

cinta métrica cerrando el botón giratorio

(7.4).

2.6 Chapa de apoyo

La chapa de apoyo (1.4) actúa como apoyo

para piezas de trabajo de mayor longitud.

8.38.1 8.2

8.4

8.5

8

– Atornille fi rmemente la chapa de apoyo a

la entalladura (8.4) con el botón giratorio

(8.5) y el muelle de ajuste (8.1) a la ranura

(8.2) del perfi l de tope. Atención: los dos

salientes (8.3) han de quedar enclavados

en la ranura (8.2).

–En caso necesario, saque el telescopio del

tope para tronzar 4 in. para introducir la

chapa de apoyo en la ranura.

2.7 Apoyo

El apoyo (1.3) sirve, como su propio nombre indica, de apoyo para piezas de trabajo

más altas.

9.1 9.2

– Introduzca la lengüeta (9.3) en la ranura

superior (9.2) del perfi l de tope o de la

pieza intermedia ajustable.

–En caso necesario, saque el telescopio del

tope para tronzar 4 in. para introducir la

chapa de apoyo en la ranura.

– Desplace el apoyo hasta la posición desea-

da.

– Fije el apoyo cerrando el botón giratorio

(9.1).

2.8 Tope de apoyo

El tope de apoyo (1.5) permite ajustar la

distancia de separación con respecto a la

hoja de sierra y, por consiguiente, la longitud

de la pieza que vaya a serrarse.

– Abra el botón giratorio (1.11) de la pieza

intermedia ajustable.

– Desplace el perfi l de tope (1.1) y la pieza

intermedia (1.6) hasta dejar entre ellos

una separación de 3.1 in. aprox.

10.1 10.2

10

10.4

10.3

– Abra el botón giratorio (10.1) para la su-

jeción del tope de apoyo.

– Introduzca la lengüeta (10.3) en la ranura

superior (10.2) del perfi l de tope o de la

pieza intermedia ajustable.

– Desplace el tope de apoyo hasta la posición

deseada.

– Fije el tope de apoyo cerrando el botón

giratorio (10.1).

9

9.3

– Abra el botón giratorio (9.1) para la suje-

ción del apoyo.

Ajuste del juego del tope de apoyo

– Gire (abriendo o cerrando) ambos tornillos

(10.4) hasta que el tope de apoyo esté

exento de juego pero se pueda seguir moviendo con facilidad.

12

Page 13

3 Ajustes

3.1 Cinta métrica

11.1 11.2

11

17.72 in.

11.5

11.4

11.3

La cinta métrica parte de una medida de

11.81 in./30 cm para impedir que entre en

contacto con la hoja de sierra. Debe, por

tanto, ajustarse la distancia correcta entre

la cinta métrica y la hoja de sierra:

– Utilice para la KS 120 una escuadra de

inglete que forme un ángulo de 0° con los

planos horizontal y vertical.

– Coloque la pieza de trabajo (11.4) de una

longitud de 18.72 in./450 mm transversal

con respecto a la hoja de sierra (11.3) de

la KS 120.

– Aproxime el tope de apoyo (11.1) hasta

la pieza de trabajo. Inmovilice el tope de

apoyo en esta posición.

– Abra el botón giratorio (11.5) del disposi-

tivo de fi jación de la cinta métrica.

– Desplace la cinta métrica hasta que el

borde (11.2) del tope de apoyo coincida

con la marca de medida de 18.72 in./

450 mm.

– Sujete la cinta métrica en esta posición

con el dispositivo de fi jación (11.5). La

cinta métrica marca ahora la distancia ex-

acta con respecto a la hoja de sierra. En

el borde (11.2) podrá ver la distancia de

separación entre el tope de apoyo y la hoja

de sierra.

3.2 Ajuste de longitud

Con el botón giratorio (1.12) abierto es posible extender y retraer la pieza fi nal (1.7).

La máxima extensión que alcanza es de

90.55 in./2300 mm.

Con el botón giratorio (1.11) abierto es posible desplazar la pieza intermedia.

4 Trabajos

Para tronzar una pieza de trabajo a una

longitud determinada, proceda como se

describe a continuación:

– Ajuste la medida deseada en el tope de

apoyo.

– Coloque la pieza de trabajo pegada al tope

de apoyo.

– Sierre la pieza con la KS 120.

13

Page 14

Page 15

Page 16

Loading...

Loading...