Page 1

DRRD-08/10

Festo AG & Co. KG

Postfach

73726 Esslingen

Germany

+49 711 347-0

www.festo.com

Operating instructions 8030937

1310NH

[8030939]

Original: de

Semi-rotary drive DRRD-8/10 English....................................

Note

Installation and commissioning may only be performed in accordance with these

instructions by technicians with appropriate qualifications.

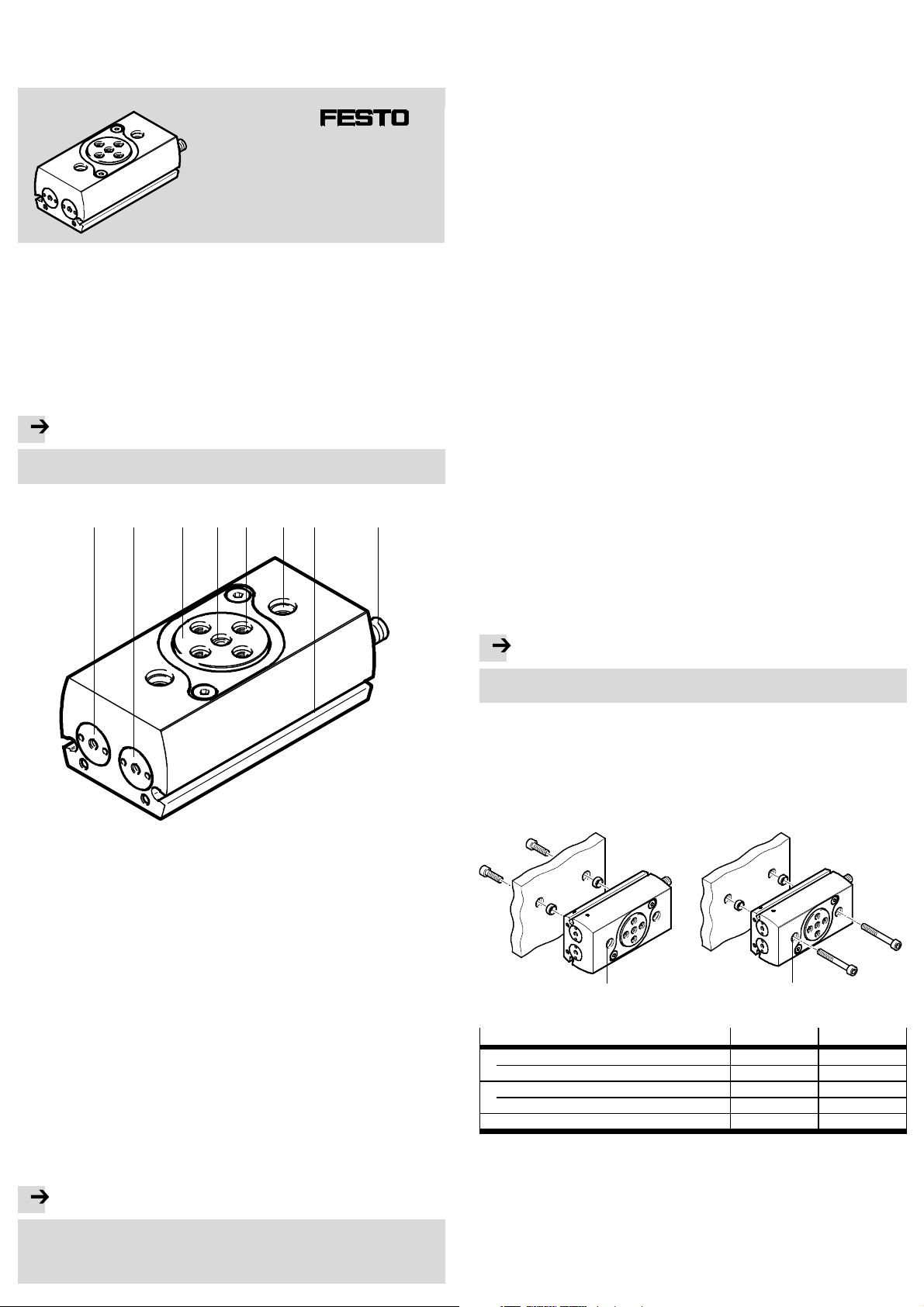

1 Control sections and connections

1 234

67 8

5

• Take into consideration the legal regulations applicable for the destination, as

well as:

– regulations and standards,

– regulations of the testing organizations and insurers,

– national specifications.

• Observe the warnings and notes on the product and in the relevant operating

instructions.

• Remove all transport packaging, such as transparencies, caps and cartons

(with the exception of any covers in the pneumatic ports).

The packaging is intended for recycling

(exception: oil paper = residual waste).

• Take into account the materialspecifications ( 11 Technical data).

• Use the product in its original status, without any unauthorised product modifications.

• Take into consideration the ambient conditions at the location of use.

Corrosive elements in the environment (e.g. ozone) will reduce the service life of

the product.

• Compare the limit values specified in these operating instructions with your

actual application (e.g. pressures, forces, torques, temperatures, masses,

speeds, etc.).

Operation of the product in compliance with the relevant safety regulations is

contingent on adherence to the load limits.

• Take the tolerance of the tightening torques into account. Unless otherwise

specified, the tolerance is ± 20 %.

• Do not modify any screws or threaded pins unless this is requested in these

instructions. For safety reasons, they are fixed with a screw locking agent.

For vertical installation:

• Make sure that the drive has reached a stable position when it comes to a stop

(e.g. the lowest point or secured with external stops).

• Make sure there is a supply of correctly prepared compressed air

( 11 Technical data).

• Having selected a medium, stick with it for the entire life of the product

(e.g. always use unlubricated compressed air).

• Pressurize your entire system slowly.

There will then be no uncontrolled movements. For slow start-up pressurisation,

use on-off valve HEL.

1 Supply port

(swivel clockwise)

2 Supply port

(swivel anti-clockwise)

3 Flanged shaft

4 Shaft opening with centring recess

5 Payload mounting interface (4x)

6 Mounting interface DRRD (2x)

7 Slot for cylinder switch (2x)

8 Shock absorber for swivel angle

adjustment, secured with lock nut

(2x)

for through-feed of

cables/compressed

Fig. 1

2 Function and application

The DRRD semi-rotary drive is a double-acting twin-piston drive. Whe n the compressed air supply ports are pressurised reciprocally, two pistons arranged in parallel move in the opposite direction backwards and forwards. This linear motion is

converted through pinions into a swivel motion of the flanged shaft. The DRRD has

an elastic end-position c ushioning.

The DRRD semi-rotary drive is intended for swivelling payloads which have to execute a defined angular movement.

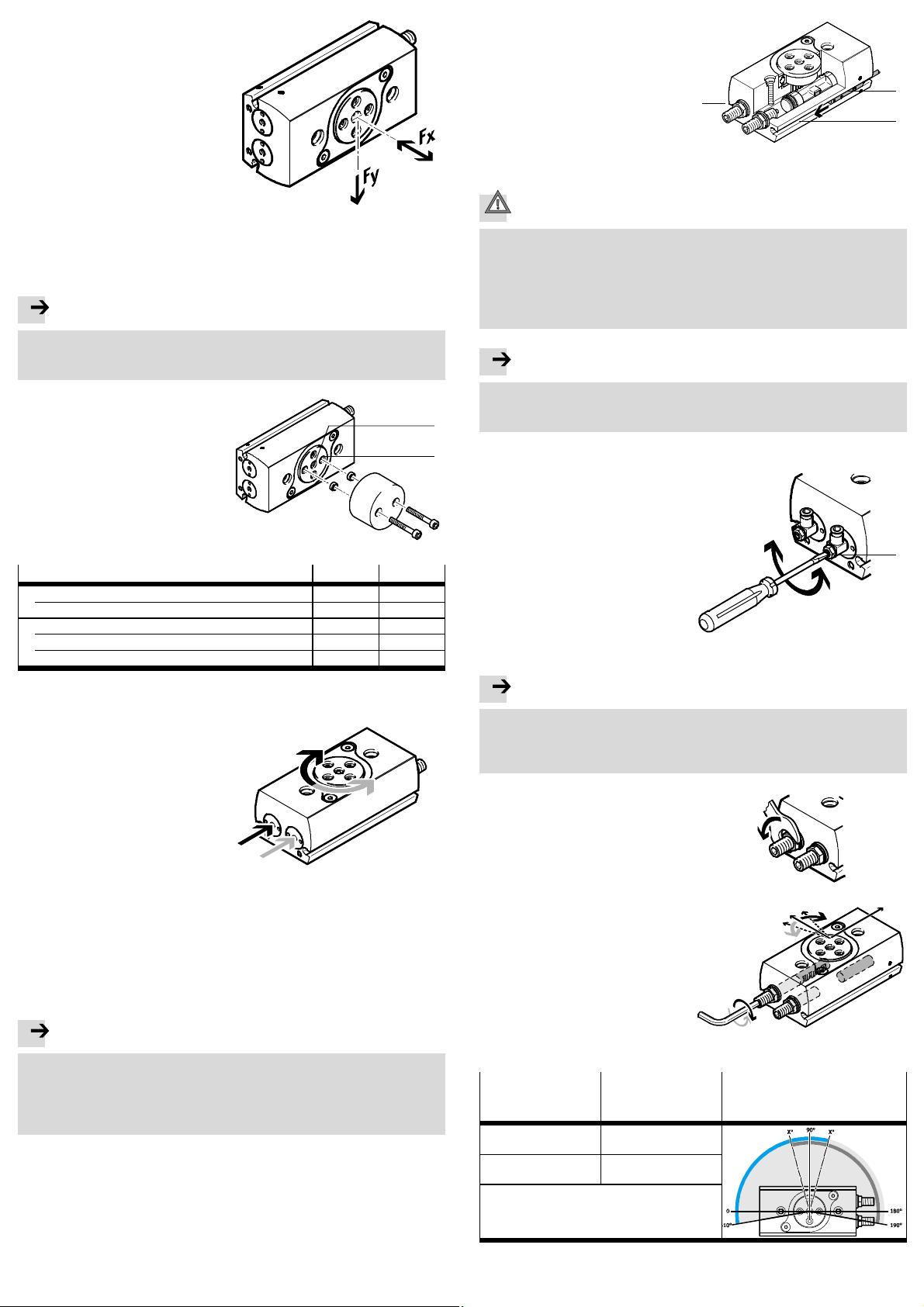

4 Installation

4.1 Mechanical installation

Note

• Handle the DRRD with care to prevent damage to the flanged shaft. This applies in particular to the following points:

1. Position the DRRD so that you can easily reach the control sections and connections.

2. Secure the DRRD at the mounting interface 6 by using two screws and two

centring sleeves each.

Observe the tightening torque ( Fig. 3).

Direct mounting Through-hole fastening

6 6

Fig. 2

Size

Screw (direct mounting) M4 M4

Tightening torque [Nm] 3 3

Screw (through-hole fastening) M3 M3

Tightening torque [Nm] 1.2 1.2

Centring sleeve ZBH [mm] 7 7

8 10

Fig. 3

3 Requirements for product use

Note

Malfunction and material damage due to incorrect handling.

• Always comply with the specifications of this c hapter.

Only in this way can you ensure that the product functions correctly and

safely.

Page 2

3. Pull tubing and cables through the

hollow flanged shaft, if necessary.

Diameter for wiring ( Fig. 6).

4. When mounting the payload, observe the following specifications:

– installation without tilting

– permissible radial force Fy

– permissible axial force Fx

– permissible mass moment of

inertia

– a structure that is as rotationally

symmetrical as possible.

Fig. 4

The mass moment of inertia of the payload should be calculated. Lever arms,

cantilevers and masses should be considered in the calculation (maximum permissible values www.festo.com/catalogue).

Note

If there are demanding requirements for concentricity of the components on the

flanged shaft:

• Use the middle centring hole 4 as well as one of the 4 existing centring holes.

5. Secure the payload to the drive

flange at the mounting interface 5

by using at least two screws positioned opposite one another and

centring sleeves.

Observe the tightening torque

( Fig. 6).

Fig. 5

Size 8 10

Shaft opening 4 [mm] ∅ 3 ∅ 3

Centring sleeve ZBH for middle centring hole [mm] 5 5

Screw for thread at 5 M3 M3

Centring sleeve ZBH [mm] 5 5

Tightening torque [Nm] 1.2 1.2

Fig. 6

4.2 Pneumatic installation

• If necessary, remove the covers in the

pneumatic ports.

To adjust the swivel speed:

• Use the GRLA one-way flow control

valves.

These are screwed directly into the

compressed air supply ports.

Fig. 7

4

5

• Place the proximitysensors for

sensing the end positions into the

slots 7.

7

Fig. 8

5 Commissioning

Caution

Danger of injury from rotating loads.

• Make sure the DRRD is only set into motion with protective devices.

• Make sure that in the swivel angle of the DRRD

– nobody can reach in

– no foreign objects can enter

(e.g. by means of an individual protective guard).

Note

• Comply with the following prerequisites:

– the sh ock absorbers are secured with lock nuts

– the o perating conditions are within the permissible ranges.

5.1 Commissioning end-position adjustment

1. Rotate both upstream one-way flow

control valves (B):

– at first completely closed

– thenopenthemagain

approximately one turn.

2. Pressurize the drive optionally in one

of the following ways:

– slow pressurisation of one side

– simultaneous pressurisation of

both sides with subsequent

exhausting of one side.

Fig. 9

Note

Risk of damage!

If the shock absorber is unscrewed too far, it will result in the piston colliding

with the end cap with insufficient cushioning.

• Observe the permissible shock absorber settings ( Fig. 13).

3. Pressurize the corresponding port to

swivel the DRRD into the desired end

position.

4. Loosen the lock nut on the shock

absorber.

Fig. 10

(A)

7

(B)

For vertical installation and eccentric loads:

• Use the controlled check valve HGL or a compressed air spacer compensation

reservoir VZS.

In this way you can prevent the effective load from sliding down suddenly if

there is a sudden pressure drop.

4.3 Electrical installation

Note

Multiple switching cycles of proximity sensors are possible, dependent on the

design.

• Make sure the proximity sensors are always set to the first switching point.

To do this, push the cylinder switch (A Fig. 8) in from the slot end where the

piston to be sensed is located until the first switching occurs.

5. Turn the corresponding shock

absorber until the desired end

position adjustment has been

reached.

Fig. 11

Angle setting Reaction Setting range related to the

basic factory setting (example

DRRD-...-180)

Turn the shock absorber

clockwise

Turn the shock absorber

anti-clockwise

Reduce the swivel angle

Increase the swivel angle

Fig. 12

Page 3

The following settings are possible:

Size

Angle adjustment per rotation [°] 8.2 6.8

Max. shock absorber setting XPmax [mm] 11.9 13.8

Min. shock absorber setting XPmin [mm] 5 5

8 10

Fig. 13

6. Tighten the locking nut of the shock absorber. Observe the tightening torque:

Size

ß Internal hexagon socket [mm] 3 3

ß Lock nut [mm] 8 8

Tightening torque [Nm] 1 1

8 10

Fig. 14

7. Repeat the procedure to set the second end position.

5.2 Carrying out commissioning

1. Start a test run at low swivel speed.

2. When conductingthe test run, check whether the DRRD settings need to be

corrected. These could be:

– swivel angle of the payload ( Fig. 12)

– swivel speed of the payload.

3. Unscrew the one-way flow control valves (B) slowly again up to the desired swivel speed.

4. Interrupt the test run if the piston can be heard to strike ha r d.

Causes of metallic striking may be:

– mass moment of inertia of the payload too high

– swivel speed of the payload too high

– no compressed air cushion on the exhaust side

– Shock absorber unscrewed too far (maximum values Fig. 13).

5. Make sure you remedy the above-named causes.

6. End the test run when all of the necessary corrections have been detected.

7 Maintenance and care

To check functioning of cushioning:

• Carry out the following steps:

DRRD-...

Tes t in t e r va l 2 million switching cycles

Procedure 1. Check the function of the shock absorbers.

Replacement interval

P

In case of audible bottoming out or rebounding:

2. Replace th e cushioning componentsand seals (lubricate the cushioning

components before installation with, for example, LUB-KC1).

If there is evidence of wear (bottoming out)

Fig. 16

If the piston can be heard to strike hard in the end position:

• In case of wear, replace the internal cushioning components of the DRRD

( 8 Disassemblyand repair).

• If the DRRD is c ontaminated, clean it with a soft cloth.

Permissible cleaning agents include:

– warm soap suds up to + 60 °C

– petroleum ether

– all non-abrasive cleaning agents.

8 Disassembly and repair

For eccentric masses on the lever arm:

Caution

Danger of injury from masses dropping suddenly.

• Make sure the payload has reached a stable position before venting (e.g. the

lowest point).

• Make sure that the semi-rotary drive is exhausted for disassembly.

• Recommendation: Send the product to o ur re pair service.

This way, the required fine tuning and tests will be taken into special consideration.

• Information about spare parts and accessories can be found at:

www.festo.com/spareparts.

6Operation

Caution

Danger of injury from moving masses.

• Make sure that in the swivel angle of the DRRD

– nobody can reach in

– no foreign objects can enter

(e.g. by means of an individual protective guard).

In the case of several uninterrupted swivel cycles:

Note

Operational reliability can be impaired by an excessive temperature rise.

• Make sure that the following maximum swivel frequencyis not exceeded.

Size

Maximum swivel frequency [Hz] 2.2 2.1

8 10

Fig. 15

To replace the integrated cushioning components

( 9 Accessories):

• Carry out the following steps:

1. Vent the DRRD.

2. Measure the positionof the shock absorber

(dimensionXP) and loosen the lock nut on the

shock absorber 8.

3. Unscrew the shock absorber, lubricate the new

cushioning component (e.g. with LUB-KC1) and

assemble. Use new sealing discs (C Fig. 17) if

required.

4. Screw in shock absorbers up to dimension XP

( point 2).

5. Check the angle adjustment and c orrect,

if necessary.

6. Tighten the lock nut on the shock absorber 8

(tightening torque Fig. 14).

9 Accessories

Note

• Select the corresponding accessories from our catalogue

www.festo.com/catalogue.

(C)

Fig. 17

Page 4

10 Fault clearance

Malfunction

Uneven movement of the

payload

Hard metal impact at the end

position

Flanged shaft does not remain

in th e end position

(rebounding)

Possible cause Remedy

Flow control valves inserted

incorrectly

Asymmetric angle setting Symmetric setting preferred

DRRD defective Return to Festo

Residual energy too high Select a lower swivel speed

Semi-rotary drive moves

against an unpressurized

chamber

Shock absorber unscrewed

too far

Cushioning component

defective/worn

Check the flow control

function (supply or exhaust air

flow control)

Move only against residual air

cushionontheexhaustside

Select a lighter load

Pressurize semi-rotary drive

on both sides

Observe the maximum

permissible unscrewing length

Replace cushioning component

( 8 Disassembly and repair)

Fig. 18

11 Technical data

Size

Design Semi-rotary drive with twin pistons

Cushioning Elastic cushioning rings/plates at both ends

Pneumatic por t M3

Operating medium Compressed air to ISO 8573-1:2010 [7:4:4]

Note on the operating medium Lubricated operation possible (in which case

Operating pressure [bar] 3…8

Mounting position any

Swivel angle [°] 180

Setting range on both sides [°] infinitely adjustable between –100 … +10

Cushioning angle (Z minimum swivel

angle)

Repetition accuracy [°] ≤ 0.03

Ambient temperature [°C] –10 … +60

Theoretical to rque at 6 bar [Nm] 0.2 0.4

Max. axial load (static)

Ten s ion [kN] 0.26

Pressure [kN] 0.7 1.1

Max. permissible axial and radial

force on flanged shaft

Max. permissible mass moment of

inertia

End-position adjustment by turning the cushioning components

Note on materials Contains paint-wetting impairment substances

Materials

Housing Anodised aluminum

Flanged shaft, plug, shock absorber

retaining plate, screws

Seals TPE-U (PU), NBR

Product weight [kg] 0.16 0.25

8 10

lubricated o peration will always be required)

[°] 38 37

dependent on the distance of the force

application point ( www.festo.com/catalogue)

[kgcm2] 15 20

(PWIS)

Steel

Fig. 19

Loading...

Loading...