1

Assembly instructions (original: de)

8031498

1401NH

[8031400]

†‡

Terminal CPX

CPX, CPX-M

Festo AG & Co. KG

Postfach

73726 Esslingen

Germany

+49 711 347-0

www.festo.com

1. Safety instructions and notes on mounting .............................................. 1

2. Parts list ................................................................................................... 2

3. Intended use ............................................................................................ 2

4. Wall mounting .......................................................................................... 3

4a. Check positions of the mountings ....................................................... 3

4b. Assemble mountings ........................................................................... 3

4c. Overview of the fastening points ......................................................... 4

5. H-rail mounting ........................................................................................ 5

5a. Mount H-rail ........................................................................................ 5

5b. Mount CPX-terminal to H-rail ............................................................... 5

1. Safety instructions and notes on mounting

Warning

Electric voltage.

Injury (death) due to electric shock.

Switch off power supply before assembly work.

Caution

Unexpected movement of components.

Injury due to electric shock, impact, squeezing.

Switch off compressed air before assembly work.

Note

Electrostatic charge.

Damage to the internal electronics.

Electrostatically discharge assembly personnel prior to assembly work.

Note

Malfunction due to incorrect earthing.

Earth in accordance with regulations

CPX-system description: Potential equalisation.

Note

Malfunction and material damage due to incorrect assembly.

Plan sufficient space:

– permit heat dissipation through air circulation

CPX-system description.

– permit access to the connections.

Requirements of the mounting surface:

– torsion-free operation of the product

– acceptance of the weight and other forces that occur.

Observe assembly conditions ( following tables).

Resistance to vibration/ resistance to

shock

in accordance with

EN 60068

Wall H-rail

Vibration Part 2-6 SL21) SL1

Shock Part 2-27 SL2 SL1

Continuous shock Part 2-27 SL1 SL1

Vibration load

Frequency range [Hz] Acceleration [m/s

2

] Displacement [mm]

SL1 SL2 SL1 SL2 SL1 SL2

2 … 8 2 … 8 − − ±3.5 ±7

8 … 27 8 … 27 10 10 − −

27 … 58 27 … 60 − − ±0.15 ±0.7

58 … 160 60 … 160 20 50 − −

160 … 200 160 … 200 10 10 − −

Shock load

Acceleration [m/s

2

] Duration [ms] Shocks per direction

SL1 SL2 SL1 SL2 SL1 SL2

±150 ±300 11 11 5 5

Continuous shock load

Acceleration [m/s

2

] Duration [ms] Shocks per direction

±150 6 1000

1)

1)

SL1 = Severity level 1

SL2 = Severity level 2

2

2. Parts list

18375d_10

1 Terminal

CPX

(1x)

Wall mounting

18373d_2

Attachment for

CPX-modules (plastic):

2 Mounting

CPX-BG-RW-...

18373d_3

Mounting for

CPX-modules (metal):

3 Mounting bracket

CPX-M-BG-RW-...

4 Screw M3

(thread-cutting)

H-rail mounting

18373d_6

Not included in delivery:

5 H-rail

(EN 60715 - 35x7.5 or

35x15)

(1x)

18373d_7

Mounting

CPX-CPA-BG-NRH:

6 Screw

7 Clamping component

(3x)

(3x)

3. Intended use

Product Usage

CPX-terminal 1 Control of electric actuators.

Interrogation of the sensors.

Mounting 2/3 Additional wall mounting of the CPX-terminal 1.

1 3 4 2 5 7

6

3

4. Wall mounting

4a. Check positions of the mountings

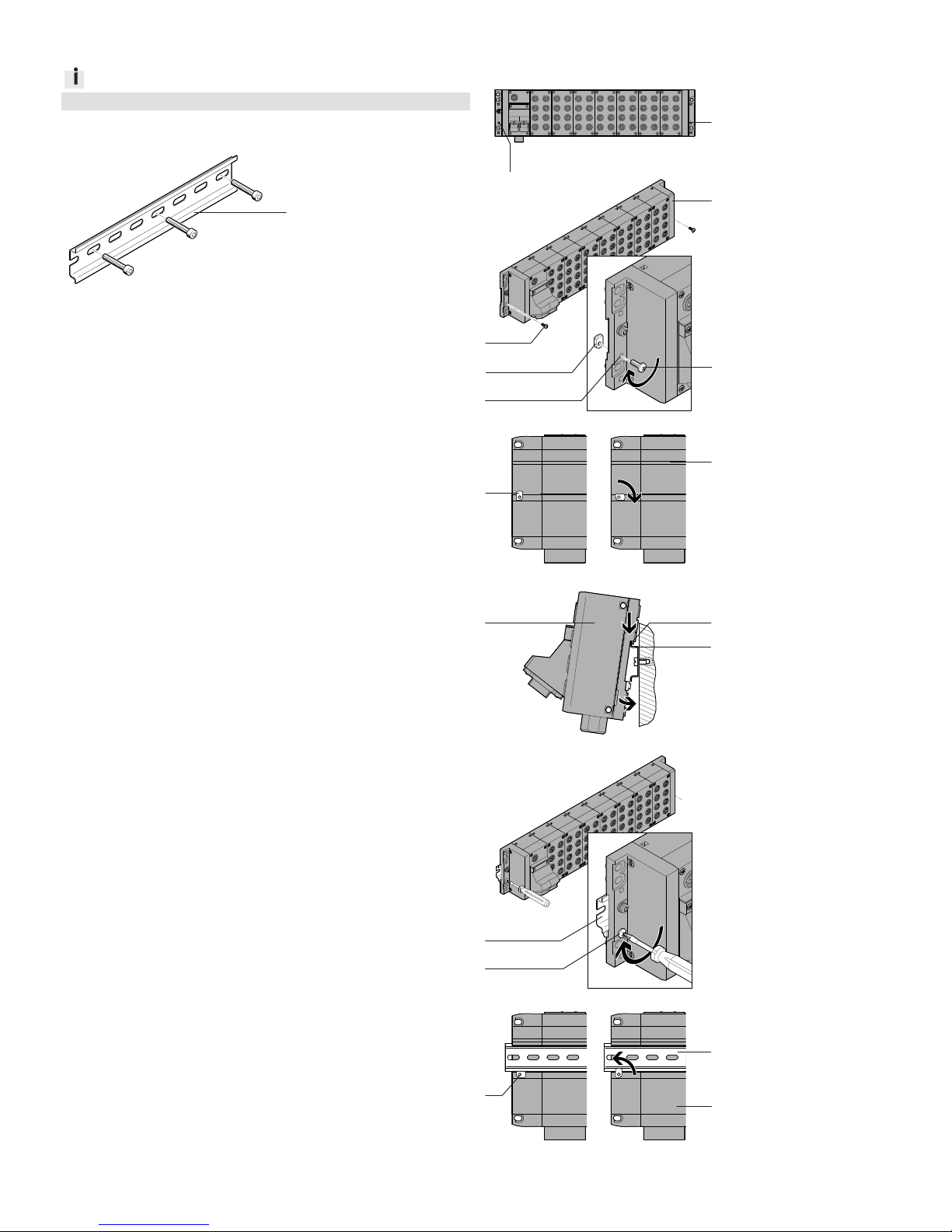

Information

Counting direction of the mod-

ules:

– from end plate (U).

18373d_16

Information

Mountings are pre-assembled, dependent on the configuration.

Check positions of the pre-assembled mountings ( tables) and correct,

if required ( section 4b).

Mounting 2 with CPX-modules (plastic)

Number of modules Mounting between the modules

2/3 5/6 8/9

1 … 3 −

4 … 5 •

6 … 8 • •

9 … 10 • • •

Mounting 3 for CPX-modules (metal)

Number of modules Mounting to the modules

2 3 4 6 7

1 … 3 −

4 •

5 … 6 •

7 •

8 • •

9 … 10 • •

4b. Assemble mountings

Mounting 2 to CPX-modules (plastic)

18375d_4

Press mounting 2 inclined

into the modules (A).

Tilt mounting 2 until it

catches.

Assemble additional mount-

ing 2 opposite.

Mounting 3 to CPX-modules (metal)

Information

For CPX-modules (metal) without system supply, the mounting 3 can be assembled on both sides of the module.

18375d_14

Place mounting 3 aligned

on the module (B).

Tighten screws 4. If you

screw it in again, use the

threads already present.

Observe tightening torque.

2 2

A

3

B

1.5 Nm ± 10 %

4

U

4

4c. Overview of the fastening points

Note

Material damage due to incorrect assembly.

Select screws suitable for the installation situation.

CPX-terminal (plastic)

18375d_7

Mounting point Screw size Number

(C) M6 2x

(D) M4 1x every 2

(E) M6 2x

CPX-terminal (metal)

18375d_15

Mounting point Screw size Number

(C) M6 2x

(F) M6 1x every 3

(E) M6 2x

E

E

D

D

C

D

D

C

E

E

C

F F

C

2

3

5

5. H-rail mounting

Information

A screw 6 and a clamping component 7 are left over.

5a. Mount H-rail

18373d_20

Mount H-rail 5 horizon-

tally.

5b. Mount CPX-terminal to H-rail

18375d_6

Remove pre-assembled

mountings 2/3.

18375d_9

On the reverse side of the

modules:

Place clamping compo-

nents 7 at the mounting

points (G).

Fix clamping components 7

with screws 6.

18373d_22

Align clamping compo-

nents 7 parallel to the

slot (H).

18373d_24

Hang CPX-terminal 1 onto

the H-rail 5 at the slot (H).

Swivel CPX-terminal 1 onto

the H-rail 5.

18375d_8

Tighten screws 6. Observe

the tightening torque.

18373d_23

Tightening the screws 6 turns

the clamping components 7

by 90°. CPX-terminal 1 is secured against tilting and slipping.

H

1

1 6

6

7

G

G

G

7

5 1 5

1.3 Nm ± 10 %

5

H

5

6

7

Loading...

Loading...