Compact performance

Electronics

manual

CP modules

Input module

type

CP−E16...−M...−...

Input module

type

CP−E16−KL−IP20−Z

Output module

type

CP−A08...−M12−...

Manual

165 225

en 0802e

[730 690]

Contents and general instructions

Original de. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edition en 0802e. . . . . . . . . .

Designation P.BE−CPEA−EN. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. .

Orderno. 165 225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E (Festo AG&Co. KG, D73726 Esslingen, Federal Republic of Germany, 2008)

Internet: http://www.festo.com

E−Mail: service_international@festo.com

The copying, distribution

and utilization of this document as well as the

communication of its contents to others without expressed authorization

is prohibited. Offenders will be held liable for the payment of damages.

All rights reserved, in particular the right to carry out patent, utility model

or ornamental design registration.

Festo P.BE−CPEA−EN en 0802e

I

Contents and general instructions

II

Festo P.BE−CPEA−EN en 0802e

Contents and general instructions

Contents

Designated use V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Target group VI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service VI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important user instructions VII . . . . . . . . . . . . . . . . .

Notes on the use of this manual IX . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

1. Input modules type CP−E16...−M...−... 1−1 . . . . . . . . . . . . . . . . . .

1.1 Function of input modules type CP−E16...−M...−... 1−3 . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Display and connecting elements 1−4 . . . . . .

1.2 Fitting 1−6 . . . . . . . . . . . . . . . . . . . . . .

1.3 Installation 1−10 . . . . . . . . . . . . . . .

1.3.1 Determining PNP or NPN operation (only with type CP−E16−M8−Z) 1−11 . . . . .

1.3.2 Connecting the separate power supply for the sensors

(only with type CP−E16−M8−Z) 1−12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Connecting the sensors 1−15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.4 Connecting the input module 1−26

1.4 Instructions on commissioning 1−28 . . . . . . . . . . .

1.5 Technical specifications 1−33 . . . . . . . . . . . . . . . . . . . . . . .

2. Input module type CP−E16−KL−IP20−Z 2−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Method of operation of input module CP−E16−KL−IP20−Z 2−3 . . . . . . . . . . . . . . . .

2.1.1 Display and connecting elements 2−4 . . . . . . . . . . . . . . . . . . . . .

2.2 Fitting 2−5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Installation 2−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Determining PNP or NPN operation 2−9 . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Connecting the separate power supply for the sensors 2−10 . . . . . . . . . . . . . . . . .

2.3.3 Connecting the sensors 2−13 . . . . . . . . . . . . . .

2.3.4 Pin assignment (PNP and NPN inputs) 2−16 . . . . . . . . . . . . . . . . .

2.3.5 Circuitry examples of PNP inputs 2−17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.6 Circuitry examples of NPN inputs 2−20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.7 Connecting the input module 2−23 . . . . . .

2.4 Instructions on commissioning 2−25 . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . .

.

. . . . . . . . . . . . . . . . . . .

. .

. . . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . . .

. .

Festo P.BE−CPEA−EN en 0802e

III

Contents and general instructions

2.5 Technical specifications 2−29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Output modules type CP−A08...−M12−... 3−1 . . .

3.1 Summary 3−3 . . . . . . . . . . . . . . . . . . . . . . .

3.2 Fitting 3−4 . . . . . . . . . . . . . . . . . . .

3.3 Installation 3−5 . . . . . . . . . . . .

3.3.1 Connecting the actuators 3−6 . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3.2 Connecting the output module 3−13 . . . . . . . . . . . . .

3.3.3 Connecting the load voltage 3−14 . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Instructions on commissioning 3−17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . .

3.5 Technical specifications 3−20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A. Index A−1 . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IV

Festo P.BE−CPEA−EN en 0802e

Contents and general instructions

Designated use

The CP modules described in this manual are intended ex

clusively for use on a CP string, an axis interface string or a

CP branch line in conjunction with a CP field bus node, the

Smart Positioning Controller type SPC200 or the Powerbox

type CP−FB−TBOX−SUBD9. CP modules and CP cables are only

be used as follows:

to

in accordance with designated use

in its/their original state

without any modifications by the user

in faultless technical condition.

When used together with commercially available compo

nents, such as sensors and actuators, the specified limits for

pressures, temperatures, electrical data, torques etc. must be

observed. National and local safety regulations must

observed. All CP modules comply with protection class III.

also be

Festo P.BE−CPEA−EN en 0802e

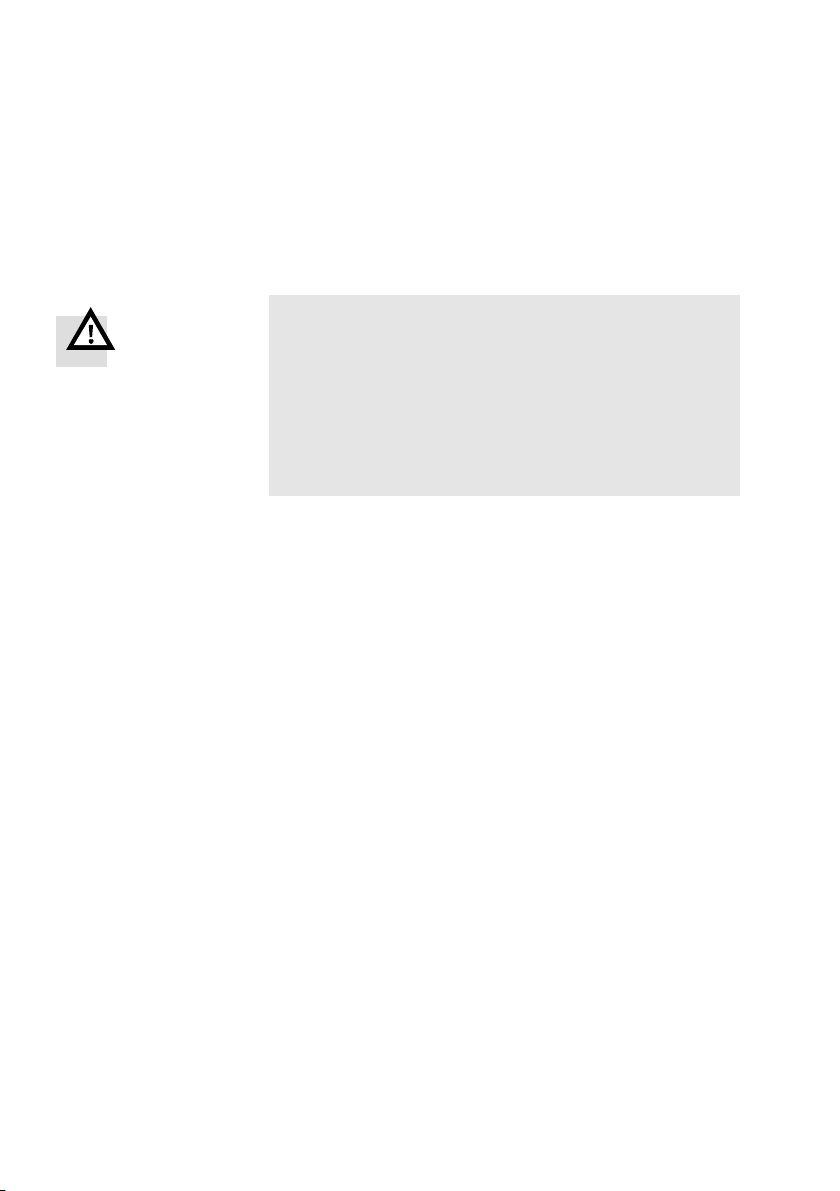

Warning

S Use only PELV circuits as per IEC/DIN EN 60204−1 (Pro

tective Extra−Low Voltage, PELV) for the electrical supply.

Consider also the general requirements for PELV circuits

in accordance with IEC/DIN EN 60204−1.

S Use power supplies which guarantee reliable electrical

isolation of the operating voltage as per IEC/DIN EN

60204−1.

V

Contents and general instructions

Target group

This manual is directed exclusively at technicians trained in

control and automation technology.

Service

Please consult your local Festo repair service if you have any

technical problems.

VI

Festo P.BE−CPEA−EN en 0802e

Contents and general instructions

Important user instructions

Danger categories

This manual contains instructions on the possible dangers

which may occur if the product is not used correctly. These

instructions are marked (Warning, Caution, etc), printed on a

shaded background and marked additionally with a picto

gram. A distinction is made between the following danger

warnings:

Warning

This means that failure to observe this instruction may

result in serious personal injury or damage to property.

Caution

This means that failure to observe this instruction may

result in personal injury or damage to property.

Festo P.BE−CPEA−EN en 0802e

Please note

This means that failure to observe this instruction may

result in damage to property.

The following pictogram marks passages in the text which

describe activities with electrostatically sensitive compo

nents.

Electrostatically sensitive components may be damaged if

they are not handled correctly.

VII

Contents and general instructions

Marking special information

The following pictograms mark passages in the text contain

ing special information.

Pictograms

Information:

Recommendations, tips and references to other sources of

information.

Accessories:

Information on necessary or sensible accessories for the

Festo product.

Environment:

Information on environment−friendly use of Festo products.

VIII

Text markings

S The bullet indicates activities which may be carried out in

any order.

1. Figures

denote activities which must be carried out in the

numerical order specified.

Hyphens indicate general activities.

Festo P.BE−CPEA−EN en 0802e

Contents and general instructions

Notes on the use of this manual

CP I/O modules are available in the designs PNP (positive−

switching) and NPN (negative−switching). The positive−switch

ing modules with M12 connectors are available in 4−pin and

5−pin designs. The 5−pin design offers an earthing connection.

This manual contains general basic information on the

method of operation, and on fitting, installing and commis

sioning CP

This manual refers to:

systems.

Input modules

PNP:

CP−E16−M8

CP−E16−M12x2

CP−E16−M12x2−5POL

NPN:

CP−E16N−M8

CP−E16N−M12x2

PNP or NPN:

CP−E16−M8−Z

CP−E16−KL−IP20−Z

Festo P.BE−CPEA−EN en 0802e

Output modules

PNP:

CP−A08−M12

CP−A08−M12−5POL

NPN:

CP−A08N−M12

Information on further modules, as well as basic information

which must be observed in conjunction with the higher−order

system, can be found in the manuals for the relevant systems.

IX

Contents and general instructions

Manuals on the CP system Periph

erals

Manual CP system, installation and commissioning"

Contents General basic information on the method of operation, fitting, installation

Manual CP field bus node,

Contents Special information on

type P.BE−CPSYS−...

and commissioning of CP systems.

programming and

diagnosis"

type P.BE−CP−FB...

or P.BE−VIFB...−10...

commissioning, pro

gramming and diag

nosing related to the

node used.

CPV valve terminal,

pneumatics" or CPA

valve terminal, pneu

matics"

type P.BE−CPV−...

or P.BE−CPA−...

Information on fitting,

installing and commis

sioning CPA or CPV

valve terminals

CP modules,

electronics"

type P.BE−CPEA−...

Information on fitting,

installing and commis

sioning CP I/O

modules

Fig.0/1: Manuals on the CP system

X

Festo P.BE−CPEA−EN en 0802e

Contents and general instructions

Manuals on the SPC200 Smart Positioning Controller Peripherals

Manuals SPC200 Smart

Positioning Controller,

User manual

type P.BE−SPC200−...

Contents Installation, commis

sioning and diagnosis

with SPC200;

standard components

and modules

Description CPV valve terminal

pneumatics

type P.BE−CPV−...

Contents Information on the

CPV valve terminals

Manual WinPISA

type P .SW−WIN−PISA−...

Functions of the

WinPISA software

package

CP modules

electronics

type P.BE−CPEA−...

Information on the

CP I/O modules

Manuals on:

proportional directional control

valves

service unit

position measuring system

cylinder or linear drives

Fig.0/2: Manuals on the SPC200

Festo P.BE−CPEA−EN en 0802e

XI

Contents and general instructions

XII

Festo P.BE−CPEA−EN en 0802e

Input modules type CP−E16...−M...−...

Chapter 1

1−1Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

Contents

1. Input modules type CP−E16...−M...−... 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Function of input modules type CP−E16...−M...−... 1−3 . . . . . . . . . . .

1.1.1 Display and connecting elements 1−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Fitting 1−6

1.3 Installation 1−10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Determining PNP or NPN operation (only with type CP−E16−M8−Z) 1−11 . . . . . . . .

1.3.2 Connecting the separate power supply for the sensors (only with type CP−E16−M8−Z)

1.3.3 Connecting the sensors 1−15 . . . . . . . . . .

1.3.4 Connecting the input module 1−26 . . . . . . . . . . . . . . .

1.4 Instructions on commissioning 1−28 . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Technical specifications 1−33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1−12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . .

. . . .

1−2

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

1.1 Function of input modules type CP−E16...−M...−...

CP input modules provide digital inputs for connecting sen

sors and enable e.g. cylinder positions to be scanned. A dis

tinction is made between the following types:

Type

CP−E16−M12x2−...

CP−E16N−M12x2

CP−E16−M8

CP−E16N−M8

CP−E16−M8−Z Provides 16 PNP or 16 NPN inputs and has

Explanation

Provides 16 PNP inputs; sensor connec

tions via 8 sockets with M12 thread

Provides 16 NPN inputs;

sensor connections via 8 sockets with M12

thread

Provides 16 PNP inputs;

sensor connections via 16 sockets with M8

thread

Provides 16 NPN inputs;

sensor connections via 16 sockets with M8

thread

its own connection for supplying the sen

sor voltage

Festo P.BE−CPEA−EN en 0802e

1−3

1. Input modules type CP−E16...−M...−...

1.1.1 Display and connecting elements

The diagram below shows, as an example, the display and

connecting elements on the input module type

CP−E16...−M12x2.

3

2

1

9

8

7

1 Status LED (green)

2 Identification for input type:

INPUT−P for PNP inputs

INPUT−N for NPN inputs

3 Sensor connections

4 Yellow LED for status display

(one LED per input)

Fig.1/1: Display and connecting elements

4

5

6

5 Groove for identification signs

(IBS6x10)

6 Earth/ground connection

7 Type plate

8 Protective cap

9 CP connection

1−4

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

The diagram below shows the additional display and operat

ing elements on the input module type CP−E16−M8−Z.

1 Connection for

the power supply

to the sensors

1

2

2 Red LED for

displaying short

circuits or failure

of the sensor

voltage (one LED

per input group)

2

Fig.1/2: Additional elements of type CP−E16−M8−Z

Festo P.BE−CPEA−EN en 0802e

1−5

1. Input modules type CP−E16...−M...−...

1.2 Fitting

Input modules are intended for fitting onto a wall or a hat rail.

If you are fitting the module onto a wall, you will require the

following space:

Type

CP−E16...−M8 approx. 150 x 66 mm

CP−E16−M8−Z approx. 217 x 66 mm

CP−E16...−M12x2−... approx. 141 x 78 mm

Mounting area

Fitting onto a wall The diagram below shows the dimensions for the four

threaded holes of M4 screw size.

1−6

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

1 Input module,

type

CP−E16...−M12x2−...

1

2 Input module,

type CP−E16...−M8

3 Input module,

type CP−E16−M8−Z

2

3

Fig.1/3: Mounting dimensions for CP−E16...−M...−...

131.9 mm

63 mm

40 mm

139.9 mm

40 mm

207.9 mm

Festo P.BE−CPEA−EN en 0802e

1−7

1. Input modules type CP−E16...−M...−...

In order to fit the module onto a hat rail, you will require

fastening kit CP−TS−HS35. This kit consists of 2 fastenings,

2 M4x12 screws and two washers.

Fitting onto a hat rail Proceed as follows when fitting the modules onto a hat rail:

1. Make sure that the mounting surface can support the

weight

of the node.

2. Fit a hat rail (support rail as per EN50022 − 35x15; width

35 mm, height 15 mm).

3. Fasten the hat rail to the fastening surface at intervals of

at least every 100 mm.

4. Let both fastenings on the hat rail snap into place (see

Fig.1/4).

1−8

5. Fasten the housing to the fastening

with the screws sup

plied, as shown in the diagram below.

6. Tighten the screws. The fastening and the housing will

then be clamped firmly on the hat rail.

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

1 Fastening

2 Housing

3 M4x12 screw

4 Washer

5 Hat rail

Fig.1/4: Fitting onto a hat rail

Proceed with dismantling as follows:

1. Loosen the screws.

2. Remove the housing.

3. Lift the fastening out of the hat rail with a screwdriver.

1 Screwdriver

2 Fastening

5

1

2

3

4

1

2

Fig.1/5: Dismantling the fastening

Festo P.BE−CPEA−EN en 0802e

1−9

1. Input modules type CP−E16...−M...−...

1.3 Installation

Warning

Before carrying out installation and maintenance work,

switch off the following:

the operating and load voltages on the higher−order sys

tem (e.g. CP field bus node)

if necessary, the separate supply voltages.

You can thereby avoid:

unexpected movements of the connected actuators

non−defined switching states of the electronic compo

nents.

Warning

Connect the earth connection on the side of the housing

(see Fig.1/1) with low impedance (short cable with large

cross−sectional area) to the earth potential.

In this way you can avoid faults due to electromagnetic

influences and ensure electromagnetic compatibility in

accordance with EMC guidelines.

1−10

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

1.3.1 Determining PNP or NPN operation (only with type CP−E16−M8−Z)

Input module type CP−E16−M8−Z provides PNP or NPN inputs.

You can determine either PNP or NPN operation by installing

a bridge in the socket of the sensor supply connection. The

following views show the rear of the socket.

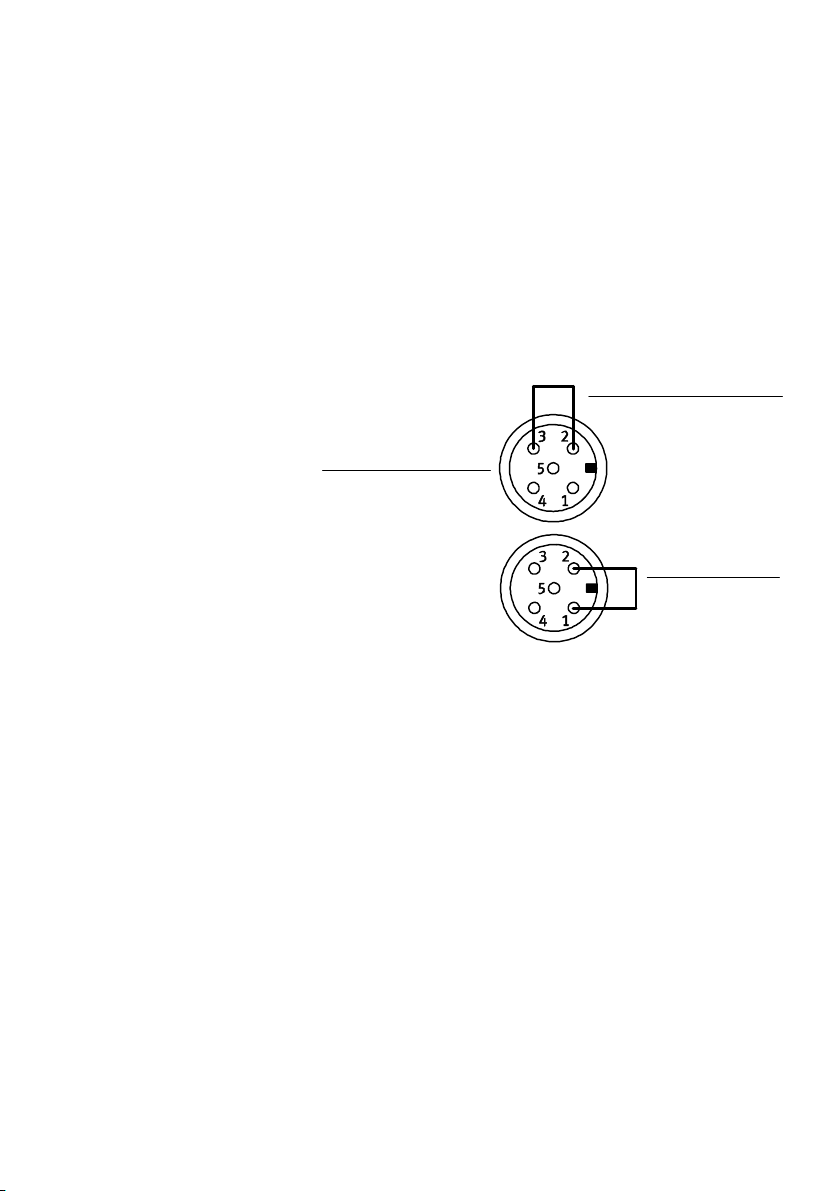

1 Pin assignment

1: + 24 V DC

± 25 %

2: PNP/NPN

3. 0 V

4: not connected

5: earth/ground

connection

1

2 PNP operation

(pins 2 and 3

bridged)

2

3

3 NPN operation

(pins 2 and 1

bridged)

Fig.1/6: Determining PNP or NPN operation (only with type CP−E16−M8−Z)

Festo P.BE−CPEA−EN en 0802e

1−11

1. Input modules type CP−E16...−M...−...

1.3.2 Connecting the separate power supply for the sensors (only with type

CP−E16−M8−Z)

Warning

S Use only PELV circuits as per IEC/DIN EN 60204−1 (Pro

tective Extra−Low Voltage, PELV) for the electrical supply.

Consider also the general requirements for PELV circuits

in accordance with IEC/DIN EN 60204−1.

S Use power supplies which guarantee reliable electrical

isolation of the operating voltage as per IEC/DIN EN

60204−1.

By the use of

(protection against direct and indirect contact) is guaranteed

in accordance with IEC/EN 60204−1 (Electrical equipment for

machines, General requirements).

The CP input module must be earthed to ensure that it func

tions correctly (e.g. EMC).

The connected sensors are supplied with + 24 V DC via the

connection

sors with high current consumption to be connected (max.

125 mA per sensor).

PELV circuits, protection against electric shock

for the sensor supply. The module enables sen

1−12

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

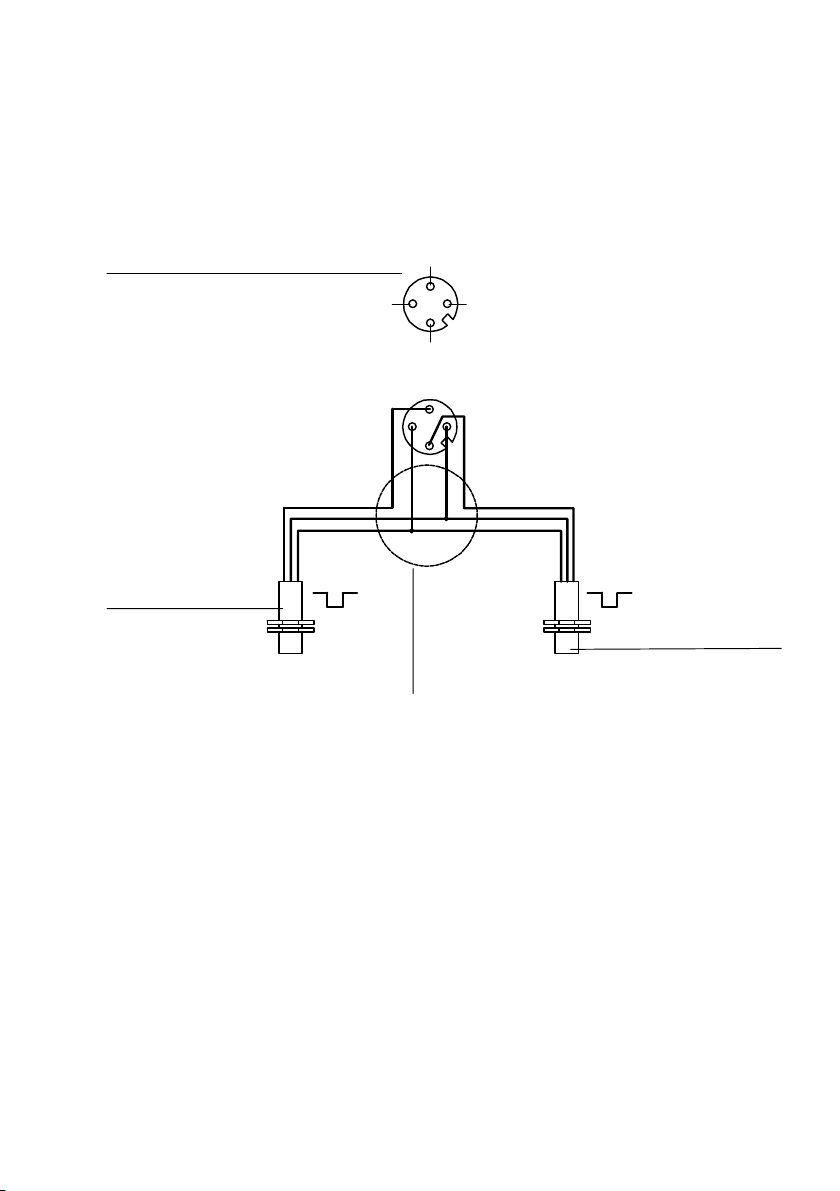

The following diagram shows the pin assignment of the con

nection as well as an example of a connection for PNP oper

ation (bridge between pins 2 and 3). See Determining PNP

or NPN operation", section 1.3.1.

1 Pin assignment

1: + 24 V DC

± 25 %

2: PNP/NPN

3. 0 V

4: not connected

5: earth/ground

connection

2

3

4

1

5

2 The sensor

voltage can be

switched off sep

arately; the oper

ating voltage is

supplied via the

CP connection

AC

230V

DC

24V

0V

24V

Fig.1/7: Pin assignment and connection example of the sensor supply (PNP operation)

23

145

1

2

Festo P.BE−CPEA−EN en 0802e

1−13

1. Input modules type CP−E16...−M...−...

Potential equalization

The CP module has two earthing connections for potential

equalization:

on the connection for the sensor voltage supply (pin 5).

on the housing (earthing connection see Fig.1/7).

Please note

S Always connect the earth potential to pin 5 of the sensor

supply voltage.

S Connect the earth connection on the left−hand side of the

housing with low impedance (short cable with large

cross−sectional area) to the earth potential.

S With low−impedance connections you can ensure that

the housing of the module and the

pin 5 have the same potential and that there are no

equalizing currents.

In this way you can avoid faults due to electromagnetic

influences and ensure electromagnetic compatibility in

accordance with EMC guidelines.

earth connection at

1−14

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

1.3.3 Connecting the sensors

Caution

If you are using input module type CP−E16−M8−Z, make

sure that pin 2 of the sensor supply connection is bridged

in accordance with the operating method of your system

(either PNP or NPN operation, see section 1.3.1).

Use the following cables or plugs for connecting the sensors:

Type

CP−E16...−M12x2 SEA−GS−7 (PG7)

CP−E16−M12x2−5P OL Use plugs with union nuts

CP−E16...−M8

and

CP−E16−M8−Z

Plugs Cable

SEA−WS−7 (PG7)

with M12x1 thread.

Use plugs with union nuts

with M8x1 thread (outer

diameter max. 12mm).

KM12−DUO−...

KM8−M8−GSGD−...

Fasten the plugs with the aid of the union nut in order to pre

vent unintentional loosening, e.g. due to shock. Seal the un

used sensor connections with the protective caps supplied.

Only in this way can you comply with protection class IP 65.

Festo P.BE−CPEA−EN en 0802e

1−15

1. Input modules type CP−E16...−M...−...

Pin assignment (PNP and NPN inputs)

The diagrams below show, as an example, the pin assignment

of the sensor connections of the various CP input modules.

Pin assignment

1 1: 24V

4: Ex+1

1 3

3. 0V

2 1: 24V

4: Ex

3. 0V

Ex = Input x

3 1

Fig.1/8: Pin assignment of type CP−E16...−M8 and CP−E16−M8−Z

Pin assignment

4

1 1: 24V

2: Ex+1

3. 0V

4: Ex + 2

2 1: 24V

2: Ex+1

3. 0V

4: Ex

3

Ex+2 Ex+3

Ex

2

2

1 3

1

4

Ex+1

Ex

4

2

1

1

Ex+1

Ex = Input x

Fig.1/9: Pin assignment of type CP−E16...−M12x2

1−16

4

Festo P.BE−CPEA−EN en 0802e

2

1. Input modules type CP−E16...−M...−...

Pin assignment

1 1: 24V

2: Ex+3

3. 0V

4: Ex+2

5: earth/ground

connection

Ex+2

2 1: 24V

2: Ex+1

3. 0V

4: Ex

5: earth/ground

connection

Ex = Input x

Fig.1/10: Pin assignment of type CP−E16−M12x2−5POL

4

5

3 1

2

2

1 3

5

4

1

Ex+3

Ex+1Ex

2

Festo P.BE−CPEA−EN en 0802e

1−17

1. Input modules type CP−E16...−M...−...

Internal structure of CP−E16−M8 (PNP inputs) and

CP−E16−M8−Z with PNP operation

24V + 10/− 15 %

23

0V

1 Pin assignment

1: 24V + 10/− 15 %

4: Ex

3. 0V

Ex = Input x

Fig.1/11: Internal structure

1

Pin 1

Pin 4

4

Pin 3

2 PLC/IPC Ex (e.g. via field bus)

3 Logic identifier Ex

4 Green LED Ex

1−18

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

4

3

Circuitry examples of CP−E16−M8 (PNP inputs) and

CP−E16−M8−Z with PNP operation

Pin assignment

1

3. 24V

4: Ex

3. 0V

1

2 Three−wire sensor

(positive−

switching)

2

3 Two−wire sensor

(positive−

switching)

4 Contact

Ex = Input x

1

3

4

Fig.1/12: Circuitry examples

Festo P.BE−CPEA−EN en 0802e

1−19

1. Input modules type CP−E16...−M...−...

Internal structure of CP−E16−M12x2−... (PNP inputs)

24V + 10/− 15 %

3

2

4

0V

1 Pin assignment

1: +24V + 10/− 15 %

2: Ex+1

3. 0 V

4: Ex

5: Earth connection only with

type CP−E16−M12x2−5POL

2 PLC/IPC Ex+1 (e.g. via field bus)

Ex = Input x

5

6

7

3 Logic identifier Ex+1

4 Green LED Ex+1

5 PLC/IPC Ex (e.g. via field bus)

6 Logic identifier Ex

7 Green LED Ex

1

Pin 1

Pin 5

Pin 2

Pin 4

Pin 3

Fig.1/13: Internal structure

1−20

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

Circuitry examples of CP−E16−M12x2... (PNP inputs)

1

Pin assignment

3. 24V

2: Ex +1

3. 0V

4: Ex

5: *)

1

2 Sensor 2 (Ex+1)

positive switching

3 2−way distributor

(T−piece)

4 Sensor 1 (Ex)

positive switching

4

5

3

1

2

*) Only with type

CP−16−M12x2−5POL

earth/ground

connection

Ex = Input x

Fig.1/14: Circuitry examples

Festo P.BE−CPEA−EN en 0802e

4

2

3

1−21

1. Input modules type CP−E16...−M...−...

Internal structure of CP−E16N−M8 (NPN inputs) and

CP−E16−M8−Z with NPN operation

0V

23

24V + 10/− 15 %

1 Pin assignment

1: 24V + 10/− 15 %

4: Ex

3. 0V

Ex = Input x

Fig.1/15: Internal structure

1

Pin 3

Pin 4

4

Pin 1

2 PLC/IPC Ex (e.g. via field bus)

3 Logic identifier Ex

4 Green LED Ex

1−22

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

Circuitry examples of CP−E16N−M8 (NPN inputs) and

CP−E16−M8−Z with NPN operation

Pin assignment

1

3. 24V

4: Ex

3. 0V

2 Three−wire sensor

(negative−

switching)

1

2

3 Two−wire sensor

(negative−

switching)

4 Contact

Ex = Input x

1

3

4

3

4

Fig.1/16: Circuitry examples

Festo P.BE−CPEA−EN en 0802e

1−23

1. Input modules type CP−E16...−M...−...

Internal structure of CP−E16N−M12x2 (NPN inputs)

0V

3

2

4

24V + 10/− 15 %

1 Pin assignment

1: +24 V + 10/− 15 %

2: Ex+1

3. 0 V

4: Ex

2 PLC/IPC Ex+1 (e.g. via field bus)

Ex = Input x

Fig.1/17: Internal structure

5

6

7

3 Logic identifier Ex+1

4 Green LED Ex+1

5 PLC/IPC Ex (via field bus)

6 Logic identifier Ex

7 Green LED Ex

1

Pin 3

Pin 2

Pin 4

Pin 1

1−24

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

Circuitry examples of CP−E16N−M12x2 (NPN inputs)

1

3

4

1

2

2

1 Pin assignment

1. 24V

2: Ex+1

3. 0V

4: Ex

Ex = Input x

Fig.1/18: Circuitry examples

Festo P.BE−CPEA−EN en 0802e

4

3

2 Sensor 2 (Ex+1) (negative logic)

3 2−way distributor (T−piece, e.g. Festo

Duo cable; only 4−pin)

4 Sensor 1 (Ex) (negative logic)

1−25

1. Input modules type CP−E16...−M...−...

1.3.4 Connecting the input module

Caution

Please observe the maximum permitted string lengths. You

can thereby avoid errors in data exchange between the

input module and the higher−order system (e.g. field bus

node).

Use only the following original cables for connecting the

modules:

For connection

to:

Field bus node

with CP connection

Axis interface

typeSPC−AIF−...

Powerbox type

CP−FB−TBOX−...

max. permitted string

Cable type

length

10 m KVI−CP−1−...

See manual for the

SPC200

type P.BE−SPC200−...

See manual for the

higher−order system

or

KVI−CP−2−...

(suitable for

drag chain)

The following functions are provided for the module via the

CP cable:

Operating voltage for the internal electronics

Connection for data exchange

in the case of input modules without connection for sup

plying the sensors:

Operating voltage for the connected sensors.

1−26

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

Input modules should be connected to one of the following:

to the CP connection of the higher−order system (field bus

node or axis interface or Powerbox)

to the CP connection of a CP output module

to the CP connection of a valve terminal.

Further information can be found in the relevant system manual.

Festo P.BE−CPEA−EN en 0802e

1−27

1. Input modules type CP−E16...−M...−...

1.4 Instructions on commissioning

Warning

Please be careful if the string assignment is modified at a

later stage.

After saving the string assignment/hardware configur

ation, check the address assignments of your higher−order

system before starting user programs.

You can thereby avoid:

addressing errors with unintentionally incorrectly fitted

CP modules.

When the string assignment on CP field bus nodes has

been

modified (CP modules added or removed), you must save the

new string assignment by pressing the SAVE button on the

node. Proceed here as described in the manual CP system,

installation and commissioning".

When the string assignment has been modified on the

SPC200, the new hardware configuration must also be saved.

Proceed here

as described in the manual for the SPC200 or in

the WinPISA manual.

Status LED The operating status of the input module is indicated by the

status LED on the CP connection (see table below).

1−28

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

Status LED Sequence Operating status Error treatment

ON

OFF

Operating voltage applied None

LED lights up

ON

OFF

LED is out

Operating voltage not ap

plied or no connection to

the higher−order system

or

S Check the CP cable and the

operating voltage connection

on the higher−order system

or

In conjunction with the CP node:

incorrect string assignment

S correct string assignment

ascertained during oper

ation

In conjunction with the

SPC200:

LED flashes

see user manual for the

SPC200

ON

OFF

Test phase when power sup

ply has been switched on

or

short circuit in sensor

supply 3)

or

S see user manual type

P.BE−SPC200

S None

or

S eliminate shor t circuit and,

if applicable, delete error

or

With type CP−E16−M8−Z:

undervoltage in sensor

S eliminate undervoltage

supply (< 17 V)

or

In conjunction with the CP

node:

incorrect string assignment

S check string assignment

when operating voltage is

switched on

In conjunction with the

SPC200:

see user manual for the

SPC200

1)

With type CP−E16−M8−Z the error will be deleted automatically With other modules the error will

S see user manual type

P.BE−SPC200

be deleted when the input module is disconnected from the string or when the power supply is

switched on again on the higher−order system.

2)

When the string assignment on CP field bus nodes has been modified (CP modules added or

removed), you must save the new string assignment by pressing the SAVE button on the node

(see Manual for the CP system, installation und commissioning").

3)

With type CP−E16−M8−Z the short circuit LED on the relevant input group will light up.

1)

2)

Festo P.BE−CPEA−EN en 0802e

1−29

1. Input modules type CP−E16...−M...−...

Short circuit in the sensor supply on input module

type CP−E16−M8−Z

If there is a short circuit, the input module will switch off the

power supply for the relevant input group and pass the error

on to the higher−order system. The short circuit LED of the

relevant input group lights up.

1 Input group 1

(upper row)

3

2 Input group 2

(lower row)

3 Red LED for

displaying short

circuits or failure

of the sensor

voltage (one LED

per input group)

Fig.1/19: Short circuit displays with type CP−E16−M8−Z

The status LEDs of the relevant input group are switched off

and the relevant inputs supply a 0−signal. The other input

group remains ready to operate. When the short circuit is

eliminated, the error will be deleted automatically.

3

1

2

1−30

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

Short circuit in the sensor supply on input modules

without sensor supply connection

If there is a short circuit, the input module will switch off the

power supply for the sensors self−holding and pass the error

on to the higher−order system. The status LEDs will be

switched off and the inputs of the module supply a 0−signal.

When the short circuit has been eliminated, delete this

as follows:

In conjunction with the CP node:

S Disconnect the input module briefly from the string or

S switch the operating voltage off and then on again.

In conjunction with the SPC200:

S For procedure see user manual type P.BE−SPC200

error

Replacing CP modules If a fault occurs on a CP module during operation, you

replace the module during operation by another module of

the same type.

Please note

Please note here the instructions in the manual for the

higher−order system (e.g. CP system, CP field bus node,

SPC200).

Festo P.BE−CPEA−EN en 0802e

can

1−31

1. Input modules type CP−E16...−M...−...

Status display There are one or two green LEDs next to the sensor connec

tions. These indicate the status of the signal at the relevant

output. The LEDs indicate the following:

Status LED

Sequence Status

ON

OFF

logical 1 (signal present)

LED lights up

logical 0 (no signal)

Only in the start−up phase when:

there is a 1−signal and

there is a string assignment

error

LED is out

LED flashes

ON

OFF

ON

OFF

Please note

in conjunction with the CP field bus node:

If there is a string assignment error during the start−up

phase, the CP node will switch the power supply for the

input module, and thereby also for the connected sensors,

cyclically on and off. In this case, therefore, the status LEDs

and the LEDs

of the connected sensors will flash, providing

there is a signal (logical 1).

1−32

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

1.5 Technical specifications

General technical specifications Type CP−E16...−...

Temperature range:

Operation

Storage/transport

Relative humidity 95% non−condensing

− 5 °C ... + 50 °C

− 20 °C ... + 70 °C

Protection class as per EN 60529; plug con

nector inserted or provided with protective cap

Protection against electric shock as per

EN 60204−1 / IEC 204

Electromagnetic compatibility

Interference emitted

Immunity against interference

Vibration and shock

Vibration

Shock

IP65

(protection against direct and indirect contact) by

connection to a PELV power unit (Protected Extra

Low Voltage)

Tested as per EN 55011, limit class B

Tested as per EN 50082−2

Tested as per DIN/IEC 68/E N60068 part 2−6;

severity class 2

Tested as per DIN/IEC 68/E N 60068 part 2−27;

severity class 2

Festo P.BE−CPEA−EN en 0802e

1−33

1. Input modules type CP−E16...−M...−...

Special technical data Type CP−E16−M8−Z; positive switching

(PNP) or negative switching (NPN)

operation

Digital inputs

Design

Logic level, positive switching

ON

OFF

Logic level negative switching

ON

OFF

Current consumption (at 24V) (input current

from sensor to input)

Response delay (at 24 V) Typ. 3 ms

Sensor supply VD 24 V ±25 % Max. 1 A per input group (electronic short−circuit

Electrical isolation None

Internal current consumption of electronics <40 mA

16 inputs as per IEC 1131−2 type 2 inputs

24 V DC, positive or negative switching

PNP (reference 0 V):

≥ 8.6 V

≤ 6 V

PNP (reference 24 V):

≤ 6 V

≥ 8.6 V

At logical 1"

typ. 8 mA

protection per group)

1−34

Festo P.BE−CPEA−EN en 0802e

1. Input modules type CP−E16...−M...−...

Special technical data

Positive−switching input modules (PNP) without

separate sensor supply connection

TypeCP−E16−M8 and

typeCP−E16−M12x2

Digital inputs

Design

Logic level

ON

OFF

Current consumption (at 24V) (input

current from sensor to input)

Response delay (at 24 V) Typ. 5 ms Typ. 3 ms

Sensor supply VD 24 V ± 25 % Max. 0.5 A (electronic short−circuit protection)

Electrical isolation None

Internal current consumption of

electronics

16 inputs

as per IEC 1131−2

Type 2 inputs

24 V DC positive−switching

> 11 V

< 5 V

At logical 1"

typ. 8 mA

<40 mA Max. 90 mA

TypeCP−E16−M12x2−5POL

16 inputs

as per IEC 1131−2

Type 2 inputs

24 V DC negative−switching

≥ 8.6 V

≤ 6 V

At "logical 1"

typ. 6 mA

Festo P.BE−CPEA−EN en 0802e

1−35

1. Input modules type CP−E16...−M...−...

Special technical data

Digital inputs

Design

Logic level

ON

OFF

Current consumption (at 24V) (input current

from sensor to input)

Response delay (at 24 V) Typ. 5 ms

Sensor supply VD 24 V ± 25 % Max. 0.5 A (electronic short−circuit protection)

Electrical isolation None

Internal current consumption of electronics Max. 90 mA

Negative−switching input modules (NPN)

Type CP−E16N−M8 and type CP−E16N−M12x2

16 inputs as per IEC 1131−2 type 2 inputs

24 V DC negative−switching

< VD − 11 V

> VD − 5 V

At logical 0"

typ. 8 mA

1−36

Festo P.BE−CPEA−EN en 0802e

Input module type CP−E16−KL−IP20−Z

Chapter 2

2−1Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

Contents

2. Input module type CP−E16−KL−IP20−Z 1−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Method of operation of input module CP−E16−KL−IP20−Z 2−3 . . . . . . . . . .

2.1.1 Display and connecting elements 2−4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Fitting 2−5 . . . . .

2.3 Installation 2−8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 Determining PNP or NPN operation 2−9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Connecting the separate power supply for the sensors 2−10 . . .

2.3.3 Connecting the sensors 2−13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.4 Pin assignment (PNP and NPN inputs) 2−16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.5 Circuitry examples of PNP inputs 2−17 .

2.3.6 Circuitry examples of NPN inputs 2−20 . . . . . . . . . . . .

2.3.7 Connecting the input module 2−23 . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Instructions on commissioning 2−25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Technical specifications 2−29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . .

. . .

. . . . . . . . .

. . . . . . . . . . . .

.

2−2

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

2.1 Method of operation of input module CP−E16−KL−IP20−Z

CP input modules provide digital inputs for connecting sen

sors and enable e.g. cylinder positions to be scanned.

Type

CP−E16−KL−IP20−Z Input module type CP−E16−KL−IP20−Z

Explanation

provides 16 PNP or 16 NPN inputs and has

its own connection for the power supply to

the sensors.

It has three 10−pin optional connecting

sockets in screw or tension spring design

and is therefore particularly suited for

fitting into a control cabinet (IP20).

Festo P.BE−CPEA−EN en 0802e

2−3

2. Input module type CP−E16−KL−IP20−Z

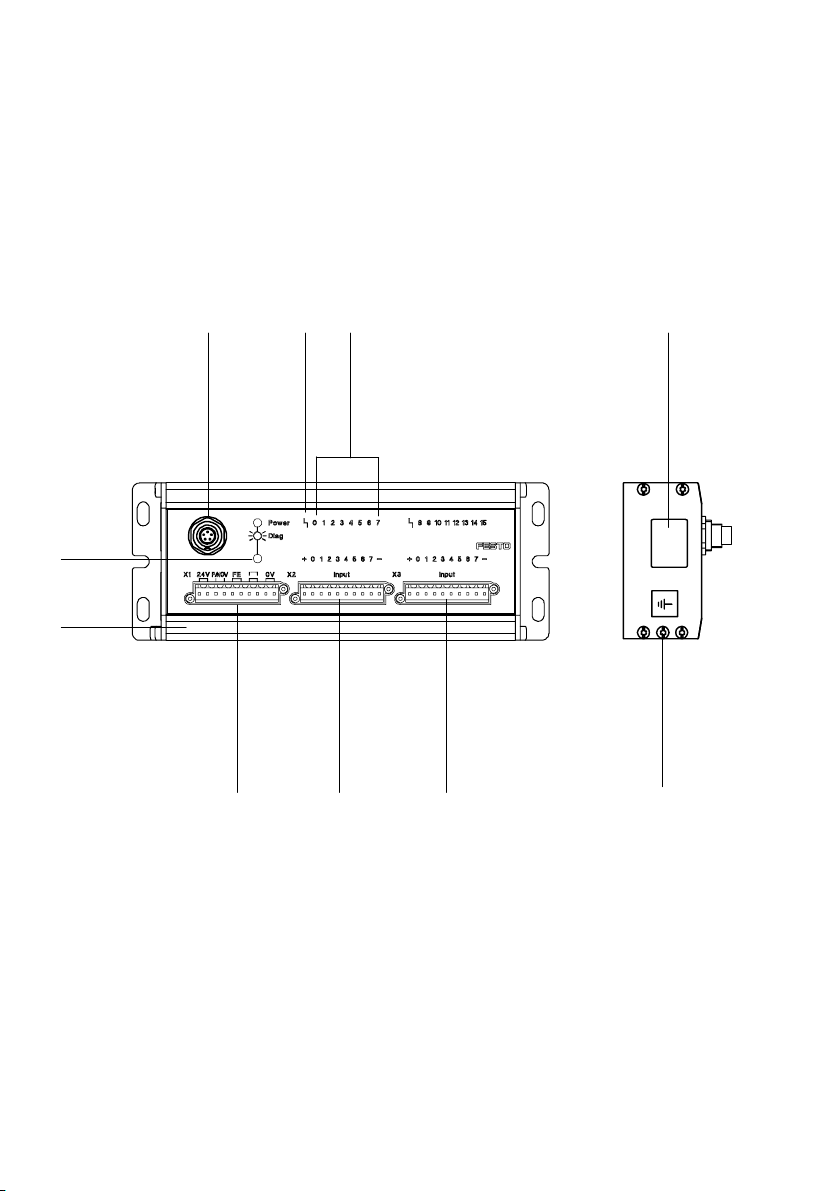

2.1.1 Display and connecting elements

The diagram below shows the display and operating elements

on input module type CP−E16−KL−IP20−Z.

123 4

9

8

CP connection

4

5 Red LED for short circuit/overload

display (one LED per input module)

6 Green LED for status display

(one LED per input)

7 Type plate

Fig.2/1: Display and connecting elements

2−4

5667

8 Earth/ground connection

9 Sensor connections

(8 inputs per input module)

10 Connection for sensor power sup

ply

11 Groove for identification signs

(IBS6x10)

12 Status LED (green)

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

2.2 Fitting

The input module is intended for fitting onto a wall or a hat

rail. If you are fitting the module onto a wall, you will require

the following space:

Type

CP−E16−KL−IP20−Z Approx. 175 x 66 mm

Mounting surface

Fitting onto a wall The diagram below shows the dimensions for the four

threaded holes of M4 screw size. You should fasten the

module with at least 3 screws.

1 Input module,

type

CP−E16−KL−IP20−Z

1

166 mm

Fig.2/2: Mounting dimensions for CP−E16...−M...−...

40 mm

Festo P.BE−CPEA−EN en 0802e

2−5

2. Input module type CP−E16−KL−IP20−Z

Hat rail fitting You will require the following accessories for fitting the mod

ule onto a hat rail:

In order to fit the module onto a hat rail, you will require

fastening kit CP−TS−HS35. This kit consists of 2 fastenings,

2 M4x12 screws and two washers.

Proceed as follows when fitting the modules onto

a hat rail:

1. Make sure that the mounting surface can support the

weight of the module.

2. Fit a hat rail (support rail as per EN50022 − 35x15; width

35 mm, height 15 mm).

3. Fasten the hat rail to the fastening surface at intervals of

at least every 100 mm.

4. Let both fastenings snap into

place on the hat rail (see

Fig.1/4).

5. Fasten the housing to the fastening with the screws sup

plied, as shown in the diagram below.

6. Tighten the screws. The fastening and the housing will

then be clamped firmly on the hat rail.

2−6

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

1 Fastening

2 Housing

3 M4x12 screw

4 Washer

5 Hat rail

Fig.2/3: Fitting onto a hat rail

Proceed with dismantling as follows:

1. Loosen the screws.

2. Remove the housing.

3. Lift the fastening out of the hat rail with a screwdriver.

1 Screwdriver

2 Fastening

2

5

1

2

3

4

1

Fig.2/4: Dismantling the fastening

Festo P.BE−CPEA−EN en 0802e

2−7

2. Input module type CP−E16−KL−IP20−Z

2.3 Installation

Warning

Undesired movement of the connected actuators and non−

defined switching states of the electronics can cause injury

to human beings or damage to property.

Before carrying out installation and maintenance work,

switch off the following:

the operating and load voltages on the higher−order

system (e. g. CP field bus node)

separate power supplies.

Warning

Incorrect or missing earthing can cause interference due to

electromagnetic influences.

Connect the earth connection on the side of the housing

(see Fig.1/1) with low impedance (short cable with large

cross−sectional area) to the earth potential.

2−8

You can then guarantee electromagentic compatibility in ac

cordance with the EMC guidelines.

Caution

Only connection X1 is used for the power supply to the

sensors. Do not connect any external supply to terminals

+ and of X2 and X3. Otherwise the input module may be

damaged.

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

2.3.1 Determining PNP or NPN operation

Input module type CP−E16−KL−IP20−Z provides PNP or NPN

inputs. You can determine either PNP or NPN operation by

installing an external bridge in the sensor supply connection.

1 Internal

connection

2 Pin assignment

1: + 24 V *)

2: Bridged with 1

3: PNP/NPN

4: 0 V

5: FE

6: FE

7: Not assigned, but

bridged with 8

8: Not assigned, but

bridged with 7

9: Bridged with 10

10: 0 V

*) Sensor supply

for the inputs

+ 24 V DC ± 25 %

3 PNP operation

(pins 3 and 4

bridged)

24V 0V

P/N 0V

12345678910

24V 0V

P/N 0V

24V 0V

P/N 0 V

FE

1

2

FE

FE

3

4

4 NPN operation

(pins 3 and 2

bridged)

Fig.2/5: Determining PNP or NPN operation

Internal bridges A separate load supply for the valves/outputs can be looped

through via pins 7 and 8. By means of the other internal

bridges (24 V, FE, 0 V), the relevant potential can be passed

on to the next CP module.

Festo P.BE−CPEA−EN en 0802e

2−9

2. Input module type CP−E16−KL−IP20−Z

2.3.2 Connecting the separate power supply for the sensors

Warning

S Use only PELV circuits as per IEC/DIN EN 60204−1 (Pro

tective Extra−Low Voltage, PELV) for the electrical supply.

Consider also the general requirements for PELV circuits

in accordance with IEC/DIN EN 60204−1.

S Use power supplies which guarantee reliable electrical

isolation of the operating voltage as per IEC/DIN EN

60204−1.

By the use of

PELV circuits, protection against electric shock

(protection against direct and indirect contact) is guaranteed

in accordance with IEC/EN 60204−1 (Electrical equipment for

machines, General requirements).

The CP input module must be earthed to ensure that it func

tions correctly (e.g. EMC).

The sensors are supplied with + 24 V DC via the connection

the sensor supply. The module enables sensors with high

for

current consumption to be connected (max. 1 A per input

module).

2−10

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

The following diagram shows the pin assignment of the con

nection as well as an example of a connection for PNP oper

ation (bridge between pins 3 and 4). See also Determining

PNP or NPN operation", section 1.3.1.

1 Pin assignment

1: + 24 V *)

2: Bridged with 1

3: PNP/NPN

4: 0 V

5: FE

6: FE

7: Bridged with 8

8: Bridged with 7

9: Bridged with 10

10: 0 V

*) Sensor supply

for the inputs

+ 24 V DC ± 25 %

P/N

P/N 0 V

FE

0V

FE

24V 0V

12345678 910

24V 0V

1

DC

AC

Fig.2/6: Pin assignment and connection example of the sensor supply (PNP operation)

Festo P.BE−CPEA−EN en 0802e

2−11

2. Input module type CP−E16−KL−IP20−Z

Potential equalization

The CP module has two earthing connections for potential

equalization:

on the connection for the sensor voltage supply

(pin 5 or 6)

on the housing (earthing connection see Fig.1/7).

Please note

S Always connect the earth potential to pin 5 or 6 of the

sensor supply voltage.

S Connect the earth connection (FE) on the left−hand side

of the housing with low impedance (short cable with

large cross−sectional area) to the earth potential.

S With low−impedance connections you can ensure that

the housing of the

pin 5 or 6 have the same potential and that there are no

equalizing currents.

In this way you can avoid faults due to electromagnetic

influences and ensure electromagnetic compatibility in

accordance with EMC guidelines.

module and the earth connection at

2−12

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

2.3.3 Connecting the sensors

Caution

Long signal cables reduce the immunity to interference.

Do not exceed the maximum permitted signal cable length

of 30 m.

Caution

Make sure that pin 3 of the sensor supply connection is

bridged in accordance with the operating mode of your

system (PNP or NPN operation, see section 1.3.1).

Recommendation: Use the connector sockets from connecter

set type SEA−KL−SAC10/30.

Sockets in the connector set

type SEA−KL−SAC10/30

Tension spring socket, 1−row 1 See leaflet

Tension spring socket, 3−rows 2 See leaflet

Number Connection

cross−sec

tional area

with product

with product

Two rows of the three−row connector socket are intended as

distributor boards for the sensor supply. These rows are each

connected internally (see Fig.2/9).

S Fasten these sockets with the aid of the fitted screws. The

maximum tightening torque is 0.2 Nm.

Festo P.BE−CPEA−EN en 0802e

Recommended

for connection

X1

X2, X3

2−13

2. Input module type CP−E16−KL−IP20−Z

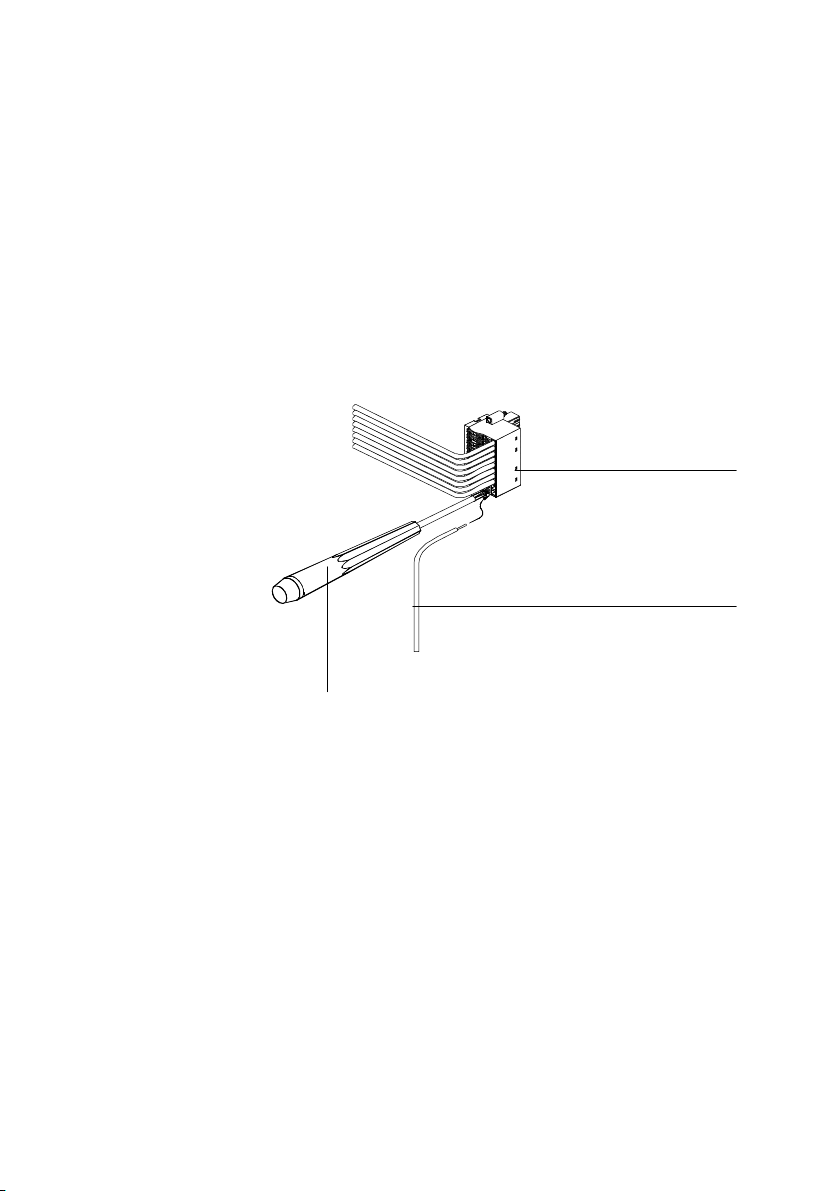

Instructions on wiring the connector sockets from connecter

set type SEA−KL−SAC10/30

Solid wires and wires with core end sleeves can easily be in

serted into the desired tension spring terminal. In order to

insert flexible wires, you must use a tool (e.g. a screwdriver)

to press down the coloured push button assigned to

sion spring terminal.

1 Tension spring

socket from con

nector set type

SEA−KL−SAC10/30

2 Cables

3 Screwdriver

the ten

1

2

3

Fig.2/7: Wiring the connector sockets

2−14

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

The following connector sets contain further possible con

nector sockets.

Further possible connector sets Number Connector

cross section

Type PSI ZC13−Z

(tension spring sockets, 1−row)

Type PSI ZC13−S

(screw−terminal sockets, 1−row)

4 See leaflet

with product

4 See leaflet

with product

Possible for

connection

X1, X2, X3

X1, X2, X3

Festo P.BE−CPEA−EN en 0802e

2−15

2. Input module type CP−E16−KL−IP20−Z

2.3.4 Pin assignment (PNP and NPN inputs)

8 sensors can be connected to each of the connections X2

and X3. The voltage supplied externally via pins 1/2 and 9/10

of plug X1 is provided at terminals + and of X2 and X3 for

supplying the sensors.

Caution

Do not connect any external supply to terminals + and of

X2 and X3. Otherwise the input module may be damaged.

Pin assignment

1 Plug X2

+: 24 V DC

0: I0

1: I1

2: I2

3: I3

4: I4

5: I5

6: I6

7: I7

−: 0 V DC

+01234567−

2 Plug X3

+: 24 V DC

0: I8

1: I9

2: I10

3: I11

4: I12

5: I13

6: I14

7: I15

−: 0 V DC

12

Fig.2/8: Pin assignment of plugs X2 and X3

2−16

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

2.3.5 Circuitry examples of PNP inputs

Three−row connector socket from connector set type

SEA−KL−SAC10/30

Two rows of the three−row connector socket are intended as

distributor boards for the sensor supply. These rows are each

connected internally. The upper row (blue push buttons) is

intended for the 0 V distributor, the centre row (red push but

tons) is intended for the 24 V distributor. The relevant voltage

must

be supplied with the aid of an external bridge from ter

minals + and (lower row).

1 External bridge

for potential dis

tribution (24 V)

2 External bridge

for potential dis

tribution (0 V)

1

blue = −

red = +

+

+01234567−

3 Pin assignment

+: 24V

0...7: Ix + n

−: 0V

4 Contact

5 Two−wire sensor

(positive−switch

ing)

6 Three−wire sensor

(positive−switch

ing)

Ix = Input x

Fig.2/9: PNP inputs (3−row connector socket set SEA−KL−SAC10/30)

56

−

2

3

4

Festo P.BE−CPEA−EN en 0802e

2−17

2. Input module type CP−E16−KL−IP20−Z

Single−row connector socket

1

External potential

distribution

(24 V)

1

+01234567−

2

2 Pin assignment

+: 24V

0...7: Ix + n

−: 0V

3 External potential

distribution (0 V)

4 Contact

5 Two−wire sensor

(positive−switch

ing)

6 Three−wire sensor

(positive−switch

ing)

Ix = Input x

Fig.2/10: PNP inputs (1 row, connector socket)

6

5

3

4

2−18

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

Internal structure (PNP operation)

24V ± 25 %

23

0V

1 Pin assignment

+: 24V ± 25 %

0...7: Ix + n

−: 0V

Ix = Input x

Fig.2/11: Internal structure (PNP operation)

1

+

0...7

4

−

2 PLC/IPC Ix (e.g. via field bus)

3 Logic recognition Ix + n

4 Green LED Ix + n

Festo P.BE−CPEA−EN en 0802e

2−19

2. Input module type CP−E16−KL−IP20−Z

2.3.6 Circuitry examples of NPN inputs

Three−row connector socket from connector set type

SEA−KL−SAC10/30

Two rows of the three−row connector socket are intended as

distributor boards for the sensor supply. These rows are each

connected internally. The upper row (blue push buttons) is

intended for the 0 V distributor, the centre row (red push but

tons) is intended for the 24 V distributor. The relevant voltage

must

be supplied with the aid of an external bridge from ter

minals + and (lower row).

1 External bridge

for potential dis

tribution (24 V)

2 External bridge

for potential dis

tribution (0 V)

1

blue = −

red = +

+

+01234567−

3 Pin assignment

+: 24V

0...7: Ix + n

−: 0V

4 Contact

5 Two−wire sensor

(negative−switch

ing)

6 Three−wire sensor

(negative−switch

ing)

Ix = Input x

Fig.2/12: NPN inputs (3−row connector socket set SEA−KL−SAC10/30)

56

−

2

3

4

2−20

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

Single−row connector socket

1

Pin assignment

+: 24V

0...7: Ix + n

−: 0V

2 External potential

distribution (0 V)

1

6

3 Three−wire sensor

(negative−switch

ing)

4 Two−wire sensor

(negative−switch

ing)

2

+ 0 1234567−

3

5 Contact

5

6 External potential

distribution

(24 V)

Ix = Input x

Fig.2/13: NPN inputs (1 row, connector socket)

Festo P.BE−CPEA−EN en 0802e

4

2−21

2. Input module type CP−E16−KL−IP20−Z

Internal structure (PNP operation)

0V

23

24V ± 25 %

1 Pin assignment

+: 24V ± 25 %

0...7: Ix + n

− : 0V

Ix = Input x

Fig.2/14: Internal structure (NPN operation)

1

−

0...7

4

+

2 PLC/IPC Ix (e.g. via field bus)

3 Logic recognition Ix + n

4 Green LED Ix + n

2−22

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

2.3.7 Connecting the input module

Caution

Please observe the maximum permitted string lengths. You

can thereby avoid errors in data exchange between the

input module and the higher−order system (e.g. field bus

node).

Use only the following original cables for connecting the

modules:

For connection

to:

Field bus node

with CP connection

or CPV valve ter

minal with direct

connection

Axis interface

typeSPC−AIF−...

Powerbox type

CP−FB−TBOX−...

Max. permitted

Cable type

string length

10 m KVI−CP−1−...

See manual for the

SPC200

type P.BE−SPC200−...

See manual for the

higher−order system

or

KVI−CP−2−...

(suitable for

drag chain)

The following functions are provided for the module via the

CP cable:

Operating voltage for the internal electronics

Connection for data exchange

Festo P.BE−CPEA−EN en 0802e

2−23

2. Input module type CP−E16−KL−IP20−Z

Input modules should be connected to one of the following:

to the CP connection of the higher−order system (field bus

node or axis interface or Powerbox)

to the CP connection of a CP output module

to the CP connection of a valve terminal.

Further information can be found in the relevant system

manual.

2−24

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

2.4 Instructions on commissioning

Warning

Please be careful if the string assignment is modified at a

later stage. After saving the string assignment/hardware

configuration, check the address assignments of your

higher−order system before starting user programs.

You can thereby avoid:

addressing errors with unintentionally incorrectly fitted

CP modules.

If, in the case of CP field bus nodes and CP

valve terminals

with direct connection, the string assignment is modified (CP

modules added or removed), the new string assignment must

be saved or configured.

Depending on the design of the node or CP valve terminal,

this is accomplished as follows:

press the SAVE button or

configure with the DIL switch.

Proceed here as described

in the manual CP system, installa

tion and commissioning" or in the manual for your CP valve

terminal with direct connection".

When the string assignment has been modified on the

SPC200, the new hardware configuration must also be saved.

Proceed here as described in the manual for the SPC200 or in

the WinPISA manual.

Status LED The operating status of the input module is indicated by the

status LED on the CP connection (see table below).

Festo P.BE−CPEA−EN en 0802e

2−25

2. Input module type CP−E16−KL−IP20−Z

Status LED Sequence Operating status Error treatment

ON

OFF

Operating voltage applied None

LED lights up

ON

OFF

LED is out

Operating voltage not

applied or no connection

to the higher−order system

S Check the CP cable and the

operating voltage connec

tion on the higher−order

system

or

or

In conjunction with the CP

node:

Incorrect string assignment

S Correct string assignment

ascertained during oper

ation

In conjunction with the

SPC200:

LED flashes

See user manual for the

SPC200

ON

OFF

Test phase when power

supply has been switched

on or

Short circuit in sensor

supply 2) or

Undervoltage in sensor

S See user manual

type P.BE−SPC200

S None

or

S Eliminate short circuit

or

S Eliminate undervoltage

supply (< 17 V)

or

In conjunction with the CP

node:

Incorrect string assignment

S Check string assignment

when operating voltage is

switched on

In conjunction with the

SPC200:

See user manual for the

SPC200

1)

When the string assignment has been modified (CP modules added or removed), the new

S See user manual

type P.BE−SPC200

string assignment must be saved or configured (see manual CP system, installation and com−

missioning" or CP valve terminal with direct connection").

2)

The short circuit LED of the relevant input module lights up.

1)

2−26

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

Short circuit in sensor supply

If there is a short circuit, the input module will switch off the

power supply for the relevant input module and pass the

error on to the higher−order system. The short circuit LED of

the relevant input module lights up.

1 Red LED for short

circuit/overload

display (one LED

per input

module)

2 Input module

(plug X3)

3 Input module 1

(plug X2)

Fig.2/15: Short circuit displays

Reaction with PNP

operation (positive logic)

Reaction with NPN

operation (negative logic)

All status LEDs of the relevant input module are switched

off. The status LEDs of the non−affected input module con

tinue to show the status. However, the inputs are no longer

processed in respect of software. For all 16 inputs, the mod

ule supplies a

short circuit is eliminated, the error will be deleted auto

matically.

All status LEDs of the relevant input module are switched

on. The status LEDs of the non−affected input module con

tinue to show the status. However, the inputs are

processed in respect of software. For all 16 inputs, the mod

ule supplies a 0−signal to the higher−order system. When the

short circuit is eliminated, the error will be deleted auto

matically.

1

1

23

0−signal to the higher−order system. When the

no longer

Festo P.BE−CPEA−EN en 0802e

2−27

2. Input module type CP−E16−KL−IP20−Z

Replacing CP modules If a fault occurs on a CP module during operation, you can

replace the module during operation by another module of

the same type.

Please note

Please note here the instructions in the manual for the

higher−order system (e.g. CP system, CP field bus node,

SPC200).

Status display There are green LEDs above the sensor connections. These

indicate the status of the signal at the relevant input. The

LEDs indicate the following:

Status LED

LED lights up

LED is out

Sequence Status

ON

OFF

ON

OFF

Logical 1 (signal present)

Logical 0 (no signal)

2−28

Festo P.BE−CPEA−EN en 0802e

2. Input module type CP−E16−KL−IP20−Z

2.5 Technical specifications

Technical specifications Type CP−E16−...−...

Temperature range:

Operation

Storage/transport

Relative humidity 95% non−condensing

− 5 °C ... + 50 °C

− 20 °C ... + 70 °C

Protection against electric shock

as per EN 60204−1 / IEC 204

Electromagnetic compatibility

Interference emitted

Immunity against interference

Vibration and shock

Vibration

Shock

1) The maximum permitted signal cable length is 30 m.

(Protection against direct and indirect contact) by

connection to a PELV power unit (Protected Extra

Low Voltage)

Tested as per EN 55011, limit class B

Tested as per EN 61000−6−2

Tested as per DIN/IEC 68/E N60068 part 2−6;

Severity class 2

Tested as per DIN/IEC 68/E N 60068 part 2−27;

Severity class 2

1)

Festo P.BE−CPEA−EN en 0802e

2−29

2. Input module type CP−E16−KL−IP20−Z

Special technical data Type CP−E16−KL−IP20−Z; positive

switching (PNP) or negative switching

(NPN) operation

Protection class as per DIN 60529 IP20

Digital inputs

Design

Logical level, positive switching

ON

OFF

Logical level, negative switching

ON

OFF

Current consumption (at 24V) (input current

from sensor to input)

Response delay (at 24 V) typ. 3 ms

Sensor supply VD 24 V ±25 % Max. 1 A per input group (electronic short−circuit

Electrical isolation of the power supply for the

sensors/inputs from the power supply for the

electronics and the CP bus

Internal current consumption of electronics <40 mA

16 inputs as per IEC 1131−2 type 2 inputs

24 V DC, positive or negative switching

PNP (reference 0 V):

≥ 8.6 V

≤ 6 V

NPN (reference 24 V):

≤ 6 V

≥ 8.6 V

at logical 1"

typ. 8 mA

protection per group)

Yes

2−30

Festo P.BE−CPEA−EN en 0802e

Output modules type CP−A08...−M12−...

Chapter 3

3−1Festo P.BE−CPEA−EN en 0802e

3. Output modules type CP−A08...−M12−...

Contents

3. Output modules type CP−A08...−M12−... 3−1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 Summary 3−3 . . . . . . . . . . . . . . . . .

3.2 Fitting 3−4 . . . . . . . . . . . .

3.3 Installation 3−5 . . . . . .

3.3.1 Connecting the actuators 3−6 .

3.3.2 Connecting the output module 3−13 . . . . . . .

3.3.3 Connecting the load voltage 3−14 . . . . . . . . . . . . . . . . .

3.4 Instructions on commissioning 3−17 . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Technical specifications 3−20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . .

3−2

Festo P.BE−CPEA−EN en 0802e

3. Output modules type CP−A08...−M12−...

3.1 Summary

Output module CP−A08...−M12−... provides 8 universally usu

able digital outputs for controlling low−current consuming

devices (bulbs, further valves etc.). The diagram below shows

the display and connecting elements on the output module.

12 3

aJ

1 Status LED (green)

2 Connections for actuators

3 Protective cap

4 Groove for identification signs

(IBS6x10)

5 Earth/ground connection

Fig.3/1: Display and connecting elements

4

5

6789

6 Type plate

7 Yellow LED for status display

(one LED per output)

8 CP connection

9 Load voltage connection

aJ Identifier for output type

OUTPUT−P for PNP outputs

OUTPUT−N for NPN outputs

Festo P.BE−CPEA−EN en 0802e

3−3

3. Output modules type CP−A08...−M12−...

3.2 Fitting

The output module is intended for fitting onto a wall and a

hat rail. It requires a mounting area of approx. 173 x 78 mm.

Fitting onto a wall The diagram below shows the dimensions for the four

threaded holes of M4 screw size.

63 mm

163.9 mm

Fig.3/2: Fitting dimensions for output module

CP−A08...−M12−...

Fitting onto a hat rail The procedure for fitting onto a hat rail is the same as with

the input modules type CP−E16...−M... (see section 1.2).

3−4

Festo P.BE−CPEA−EN en 0802e

3. Output modules type CP−A08...−M12−...

3.3 Installation

Warning

Before carrying out installation and maintenance work,

switch off the following:

S the load voltage on the relevant output module.

Also switch off the following when carrying out installation

work:

S the operating voltage supply for the higher−order system

S the load voltage supply for all the output modules

You can thereby avoid:

unexpected movements of

the connected actuators

non−defined switching states of the electronic compo

nents.

Warning

Connect the earth connection on the side of the housing

(see fig. 2/1) with low impedance (short cable with large

cross−sectional area) to the earth potential.

In this way you can avoid faults due to electromagnetic

influences and ensure electromagnetic compatibility in

accordance with EMC guidelines.

Festo P.BE−CPEA−EN en 0802e

3−5

3. Output modules type CP−A08...−M12−...

3.3.1 Connecting the actuators

Use plugs with union nuts with M12 thread for connecting the

actuators. Fasten the plugs with the aid of the union nut in

order to prevent unintentional loosening, e.g. due to shock.

Seal the unused connections with the protective caps sup

plied. Only in this way can you comply with protection class

IP65.

Pin assignment of the actuator connections on the

CP−A08−M12−... (PNP outputs)

Pin assignment

1

1: n.c.

2: n.c.

3. 0V

4: Ax+1

2 Pin assignment

1: n.c.

2: n.c.

3. 0V

4: Ax

n.c. = not connected

(not connected)

Ax = Output x

Fig.3/3: Pin assignment of output module CP−A08...−M12−...

4

3

1

1

2

Ax+1

Ax

2

3

4

1

2

3−6

Festo P.BE−CPEA−EN en 0802e

3. Output modules type CP−A08...−M12−...

By means of internal connections, two outputs can be con

nected on each of the output sockets 0, 2, 4 and 6 on the CP

output module type CP−A08−M12−5POL.

1 Pin assignment

1: n.c.

2: n.c.

3. 0V

4: Ax+1

5: earth/ground

connection

2 Internal connec

tion in the

module

3 Pin assignment

1: n.c.

2: Ax+1

3. 0V

4: Ax

5: earth/ground

connection

n.c.= not connected

(not connected)

Ax = Output x

Fig.3/4: Pin assignment of output module CP−A08−M12−5POL

4

5

3 1

2

Ax+1

Ax

2

1 3

5

4

1

2

3

Festo P.BE−CPEA−EN en 0802e

3−7

3. Output modules type CP−A08...−M12−...

Internal structure of CP−A08...−M12−... (PNP outputs)

1

24V + /− 25%

Pin 2

8

Pin 1

Pin 4

Pin 3

3

0V

1 Load voltage connection

2 Actuator connection

3 On type CP−A08...−M12−...

n.c. = not connected on type

CP−A08−M12−5POL

connections 0, 2, 4, 6: Ax+1

connections 1, 3, 5, 7:

n.c. = not connected

9

3

3

67

4

5 Pin 5 on type CP−A08−M12−5POL

earth/ground connection

6 Green LED

7 Diagnosis

short circuit/overload

load voltage failure

8 PLC/IPC Ax (e.g. via field bus)

2

Pin 1

Pin 2

Pin 4

Pin 3

5

4 Yellow LED

Fig.3/5: Internal structure of output module CP−A08...−M12−...

3−8

9 Electrical isolation

Festo P.BE−CPEA−EN en 0802e

3. Output modules type CP−A08...−M12−...

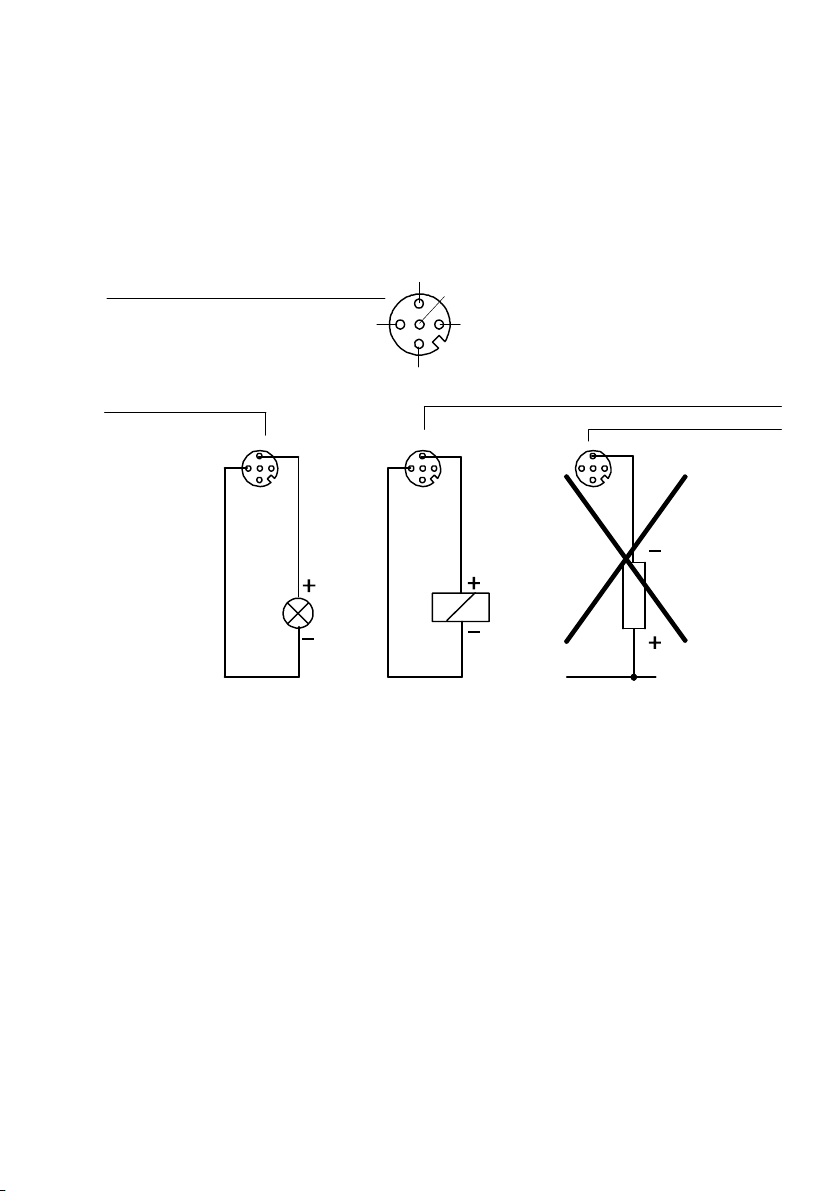

Internal structure of CP−A08...−M12−... (PNP outputs)

1

3 1

4

5

2

1 Pin assignment

1: n.c.

2: *)

3. 0V

4: Ax+1

5: only with type CP−A08−M12−5POL

earth/ground connection

*) On type CP−A08...−M12−...

n.c. = not connected on type

CP−A08−M12−5POL

connections 0, 2, 4, 6: Ax+1

connections 1, 3, 5, 7:

n.c. = not connected

2

2 Example 1:

3 Example 2:

4 Not permitted

Ax = Output x

n.c.= not connected

3

4

Fig.3/6: Examples of circuitry for output module CP−A08...−M12−...

Festo P.BE−CPEA−EN en 0802e

3−9

3. Output modules type CP−A08...−M12−...

Pin assignment of the actuator connections on the

CP−A08N−M12−... (NPN outputs)

Pin assignment

1

1: 24V

2: earth/ground

3: n.c.

4: Ax+1

2 Pin assignment

1: 24V

2: earth/ground

3: n.c.

4: Ax

1)

connection

1)

connection

4

3

1

1

2

Ax+1

Ax

2

3

4

1

2

1)

Current consumer/load must be supplied via this 24 V connection

n.c.= not connected

Ax = output x

Fig.3/7: Pin assignment of output module CP−A08N−M12−...

3−10

Festo P.BE−CPEA−EN en 0802e

3. Output modules type CP−A08...−M12−...

Internal structure of CP−A08N−M12 (NPN outputs)

1

0V

Pin 3

7

Pin 1

Pin 4

24V +/− 25 %

Pin 2

1 Load voltage connection

2 Actuator connection

3 n.c. = not connected

4 Yellow LED

5 Green LED

8

3

56

4

6 Diagnosis

short circuit/overload

load voltage failure

7 PLC/IPC Ax (e.g. via field bus)

8 Electrical isolation

2

Pin 3

Pin 2

Pin 4

Pin 1

Fig.3/8: Internal structure of output module CP−A08N−M12