Beschneiden:

[729

]

Oben: 61,5 mm

Unten: 61,5 mm

Links: 43,5 mm

Rechts: 43,5 mm

Controller

Description

Assembly and

installation

Type

CMXR-C1

Description

560 322

en 0805NH

232

Edition ____________________________________________________________ en 0805NH

Designation ________________________________________________ GDCP-CMXR-HW-EN

(Festo AG & Co KG., D-73726 Esslingen, Federal Republic of Germany, 2007)

Internet: http://www.festo.com

E-mail: service_international@festo.com

The reproduction, distribution and utilisation of this document, as well as the communication of its contents to others without explicit authorisation, is prohibited. Offenders will

be held liable for compensation of damages. All rights reserved, in particular the right to

carry out patent, utility model or ornamental design registrations.

Festo GDCP-CMXR-HW-EN 0805NH 3

Index of revisions

Author:

Name of manual:

CMXR multi-axis control system

File name:

File saved at:

Consec. no.

Description

Index of revisions

Date of amendment

001 en 0805NH

30.06.08

Trademarks

Microsoft® Windows® Registered trademark of Microsoft Corporation

PROFIBUS, PROFIBUS-DP® Registered trademarks of Profibus International (P.I.)

4 Festo GDCP-CMXR-HW-EN en

Contents and general safety instructions

Table of contents

Table of contents ............................................................................................................ 5

Intended use .................................................................................................................. 7

Areas of application and approval by authorities ............................................................ 8

Important user instructions ............................................................................................ 8

Safety precautions........................................................................................................ 11

Target group ................................................................................................................. 13

Service 13

Contents of this manual ................................................................................................ 13

Documentation on the CMXR-C1 control system ........................................................... 14

Required software versions .......................................................................................... 14

General product-specific terms and abbreviations ........................................................ 15

1. CMXR system overview ....................................................................................... 16

1.1 Product versions ................................................................................................ 16

1.2 Structure of the device ...................................................................................... 18

1.2.1 Central control unit ............................................................................. 18

1.2.2 Optional modules ............................................................................... 19

1.2.3 Peripheral modules ............................................................................ 19

1.3 Operator units for the modular control system ................................................... 21

2. Assembly ............................................................................................................ 22

2.1 General instructions on assembly and dismantling ............................................ 22

2.2 Guidelines on the CMXR device configuration .................................................... 22

2.2.1 Fitting and removing optional modules ............................................... 23

2.2.2 Assembling peripheral modules ......................................................... 25

2.2.3 Dismantling peripheral modules ......................................................... 28

2.3 Guidelines for the installation ............................................................................ 29

2.4 H-rail mounting .................................................................................................. 30

2.5 Dismantling ....................................................................................................... 34

3. Installation of the CMXR-C1 central control unit ................................................. 35

3.1 General instructions on installation ................................................................... 35

3.2 Selecting the power unit .................................................................................... 35

3.3 Instructions on wiring ........................................................................................ 36

3.4 Display, connecting and operating elements on the central control unit ............. 41

3.4.1 Connecting the operating voltage ....................................................... 42

3.4.2 Earthing the CMXR multi-axis control system ...................................... 43

3.4.3 RS 485 A interface (reserved for expansion) ....................................... 44

Festo GDCP-CMXR-HW-EN 0805NH 5

Table of contents

3.4.4 USB interface (for the service technician) ........................................... 44

3.4.5 Rotary switch (reserved for expansion) ............................................... 44

3.4.6 CAN interface X6................................................................................. 44

3.4.7 CAN interface X4 (optional module CECX-F-CO) ................................... 46

3.4.8 Ethernet interface X5 (optional module CECX-C-ET) ............................ 46

3.4.9 Using Compact Flash memory cards ................................................... 46

4. Instructions on commissioning ........................................................................... 50

4.1 General instructions on commissioning ............................................................. 50

4.2 Performance of the central control unit .............................................................. 50

4.2.1 Running up performance .................................................................... 50

4.2.2 Operating states ................................................................................. 52

4.2.3 Behaviour in the event of module errors ............................................. 53

4.2.4 Behaviour in the event of power supply failure ................................... 53

4.2.5 Control key (CTRL key) ........................................................................ 53

5. Diagnostics and error handling ........................................................................... 54

5.1 Summary of diagnostic options ......................................................................... 54

5.2 On-the-spot diagnosis via LED ........................................................................... 54

5.2.1 Power LED .......................................................................................... 54

5.2.2 CAN status LEDs ................................................................................. 54

5.2.3 Ethernet status LEDs .......................................................................... 54

5.2.4 Status LED for the memory card ......................................................... 55

5.3 On-the-spot diagnosis via the 7-segment display ............................................... 55

5.3.1 Error codes ......................................................................................... 56

6. Maintenance and care ......................................................................................... 58

6.1 Changing the battery ......................................................................................... 58

6.2 Cleaning ............................................................................................................ 59

A. Technical appendix ............................................................................................. 61

A.1 Technical data ................................................................................................... 62

A.1.1 General technical data ........................................................................ 62

A.1.2 CMXR-C1, centralcontrol unit .............................................................. 63

A.2 Accessories ....................................................................................................... 64

A.3 Power consumption of components and modules .............................................. 65

A.4 Instructions on EMC-compliant wiring ................................................................ 66

B. Index ................................................................................................................... 68

6 Festo GDCP-CMXR-HW-EN en

Contents and general safety instructions

Product version

Description

CMXR-C1 robot

control

In this product version *), the device's intended use is as a multi-axis control system

with robotic technology functions. In this context, the device takes over the following tasks:

– Controlling selected stepping motor and servo motor controllers from Festo, via

CAN bus (Festo DriveBus), e.g. for constructing a gantry robot, a linear robot or

tripod robot

– Controlling the peripherals (digital, analogue, displacement encoder)

*) Special firmware is included in this product version.

Intended use

The CMXR-C1 multi-axis control system is intended for fitting into a control cabinet.

Table 0.1 Possible product versions

The CMXR multi-axis control system must be used as follows:

- Only in an industrial environment

- As intended

- In the original status without unauthorised alterations. Only the conversions or modi-

fications described in the documentation supplied with the product are permitted.

- In perfect technical condition.

When used together with commercially available components, such as sensors and actuators, the specified limits for pressures, temperatures, electrical data, torques etc. must

be observed. National and local safety regulations must also be observed.

Use only the modules in the CECX series for setting up the modular CMXR multi-axis control system. The use of modules from this series in combination with modules from other

series is impermissible. The products or system components described may only be used

for the applications set out in the technical description and only in combination with the

recommended or permissible external devices.

The products described were developed, manufactured, tested and documented in compliance with the relevant safety standards. If the instructions and safety notes described

in this manual for the designated use are observed, the product will not normally pose a

risk in regard to material damage or people's health.

The following scopes of application are explicitly excluded for the CMXR multi-axis control system:

- Its application in potentially explosive or combustible areas.

- Its application in mining.

- Its application outside.

Festo GDCP-CMXR-HW-EN 0805NH 7

Warning

... means that failure to observe this instruction may result in serious personal injury or damage to property.

The central module is not planned for safety-relevant control tasks (e.g.: shutdown in an

emergency). Additional external protective measures, which ensure the safe operating

status of the system even in the event of a malfunction, must be implemented for safetyrelevant control tasks or safety to persons.

Areas of application and approval by authorities

The product fulfils the requirements of EU directives and bears the CE mark.

Standards and test values, which the product must comply with and fulfil, can be found in

the section "Technical data". The product-relevant EU directive can be found in the declaration of conformance.

Certain configurations of the product have been certified by the Underwriters Laboratories

Inc. (UL) for the USA and Canada. These configurations are marked as follows:

UL Listing Mark for Canada and the United States

Certification conditions / requirements for application for compliance with UL:

Only class 2 power units may be used for the electrical supply ("Only for use in Class 2

circuits").

The modules for the CMXR multi-axis control system described here are "open type

equipment" and must, therefore, be installed into a control cabinet.

All modules with front panel voltage supply must be protected with a back-up fuse. A 10 A

fuse is recommended.

Important user instructions

Danger categories

This manual includes instructions on the possible dangers which can occur if the product

is not used correctly. These instructions are marked (Warning, Caution, etc), printed on a

shaded background and marked additionally with a pictogram. A distinction is made between the following danger warnings:

Notes on the use of this manual

8 Festo GDCP-CMXR-HW-EN en

Contents and general safety instructions

Caution

... means that failure to observe this instruction may result in personal injury or damage to property.

Note

... means that failure to observe this instruction may result in damage to property.

Electrostatically sensitive devices: incorrect handling can result in

damage to components.

The following pictogram marks passages in the text which describe activities using electrostatically sensitive devices.

Festo GDCP-CMXR-HW-EN 0805NH 9

Information:

Recommendations, tips and references to other sources of information.

Accessories:

Information on necessary or useful accessories for the Festo

product.

Environment:

Information on the environmentally-friendly use of Festo products.

Identifying special information

The following pictograms mark passages in the text which contain special information.

Pictograms

Text designations

The bullet indicates activities which may be carried out in any order.

1. Digits indicate activities which must be carried out in the specified sequence.

- Hyphens indicate general activities.

10 Festo GDCP-CMXR-HW-EN en

Contents and general safety instructions

Caution

Assemblies and modules may be damaged if they are not handled

correctly.

Do not touch the electrical contacts of the modules.

Observe the handling specifications for electrostatic sensitive

devices.

Protecting the components against discharges of static elec-

tricity: Discharge yourself of static electricity before fitting or

removing the modules.

Caution

Destruction of modules and damage to the CMXR-C1 central processor unit

Switch off the supply voltages before you mount or remove the

modules.

Install the device into a suitable control cabinet (see sec-

tion 2.3).

Caution

Unqualified accessing of the multi-axle control system can trigger a

malfunction in the machine/system and cause injury or material

damage

Make sure that only suitably qualified personnel can access the

modular control system.

Safety precautions

The documentation includes the information required for assembling the CMXR multi-axis

control system and for installing the central module.

Knowing and implementing perfectly the information contained in the documents is a

requirement for the successful planning and safe installation, commissioning and maintenance of control systems. Only qualified personnel have the required specialised knowledge to correctly interpret and implement the instructions contained in these instructions.

The documentation can not take every conceivable application into consideration. Should

you need any more information, then please ask for this at your nearest Festo subsidiary.

During installation, commissioning and maintenance work, please observe the associated

documents of your multi-axis control system.

The documents are intended for qualified personnel. These are persons who have the

relevant knowledge in the field of automation technology matching their field of activity.

Safety instructions on handling

The modules used in the system are sensitive against electrostatic discharge in a dismantled state.

Festo GDCP-CMXR-HW-EN 0805NH 11

Caution

Unqualified accessing of the multi-axle control system can trigger a

malfunction in the machine/system and cause injury or material

damage

Please observe the following instructions:

Safety instructions on planning

- Follow the safety instructions in the continuing documentation of your multi-axis con-

trol system.

- The instructions contained in the documents must always be adhered to. Sources of

danger could otherwise result or safety devices integrated in the multi-axis control

system could be rendered ineffective.

- The safety and accident prevention regulations relevant to each application must be

observed regardless of the safety instructions specified in these manuals.

- Provide the load and operating voltage as a circuit with limited energy as per

IEC/DIN/EN 61131–2 and always make sure there is fuse protection with max. 10 A.

- The 24 V supply for the equipment must be assured by reliable isolation of the low-

voltage of contact-hazardous voltages.

- Put precautionary measures in place that allow an interrupted program to continue to

operate after voltage drops and voltage failure. The occurrence of dangerous operating states must be avoided, however temporary they may be.

- Emergency-stop devices must remain operative in all operating modes of the automa-

tion equipment. Unlocking the emergency-stop device must not initiate an uncontrolled restart.

- Additional external measures, which assure a safe operating status of the overall sys-

tem even in the event of a fault, must be put in place anywhere where faults occurring

in the control system could result in injuries or extensive material damage.

12 Festo GDCP-CMXR-HW-EN en

Contents and general safety instructions

Caution

Unqualified accessing can cause injury or material damage

Please observe that the device may only be opened by qualified

specialists and maintenance work may only be carried out if expressly permitted by Festo (see the "Maintenance instructions"

section).

Installation instructions on the optional and peripheral modules

used by you can be found in the brief description and manual for

the respective module.

Additional information on installation and commissioning the product version used by you can be found in the corresponding system

manual (see the following tables).

Safety instructions on maintenance

Before opening the device:

1. Interrupt the power supply and

2. disconnect interface connections.

Target group

This document is intended exclusively for technicians trained in control and automation

technology who have experience in installing and commissioning programmable logic controllers.

Service

Please consult your local Festo repair service if you have any technical problems.

Contents of this manual

This documentation describes the following:

- Design and assembly of the CMXR-C1 central control unit

- Assembly of optional and peripheral modules

- Installation of the central module and the optional modules

- General measures for adhering to EMC

- General guidelines for installing the modular control system

- Maintenance instructions

- General technical data for the multi-axis control system.

Furthermore, the installation and configuration are described to such an extent so as to

provide a central control unit that will be ready for operation. "Ready for operation"

means the module is ready for loading the firmware and the application.

Festo GDCP-CMXR-HW-EN 0805NH 13

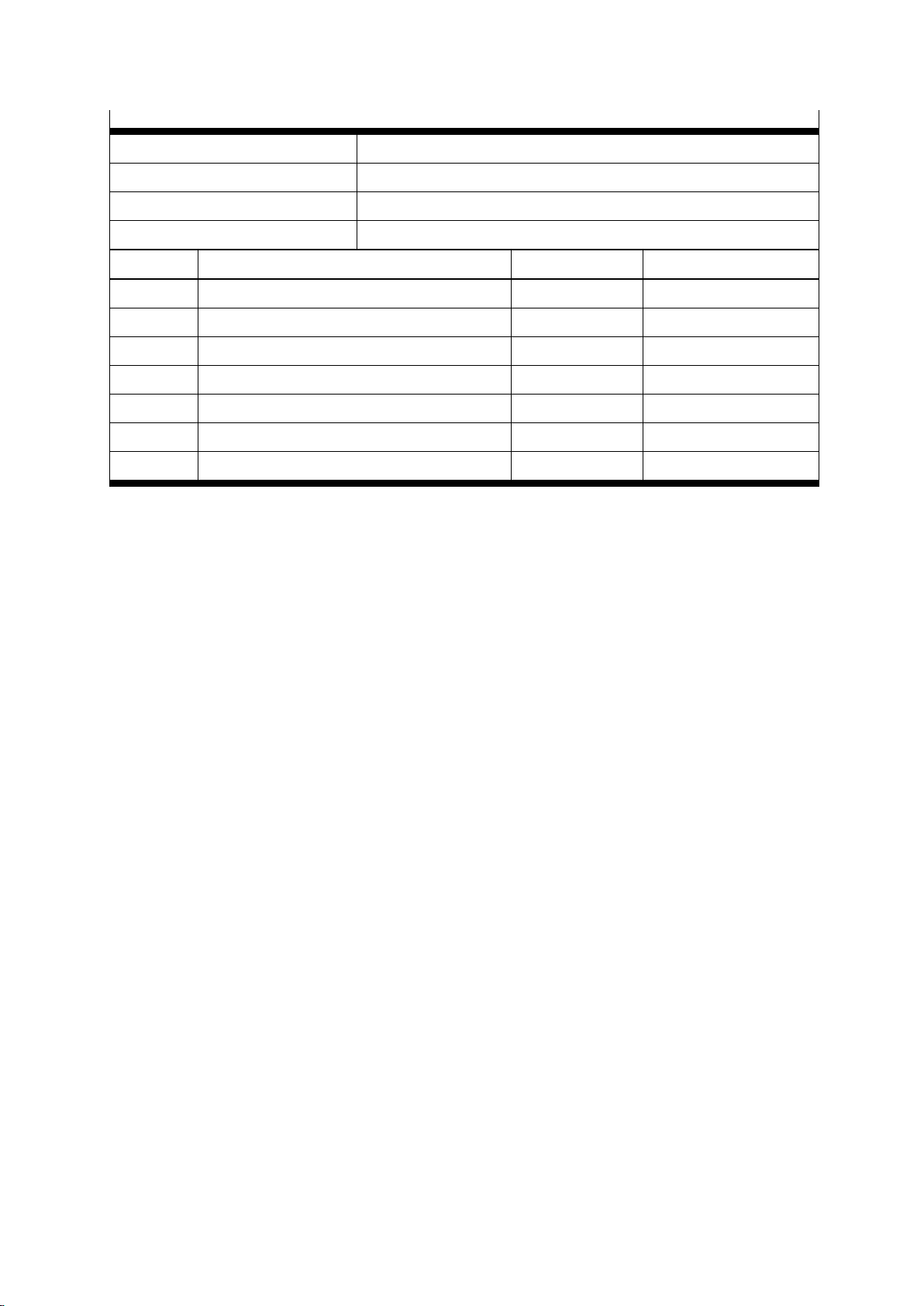

Type *)

Title

Description

Electronics

description

CMXR multi-axis control

system

This manual: provides an overview of the structure,

components and assembly of the CMXR multi-axis controller; installation of the central module and the optional modules

CECX-D-...digital module

Assembly, installation and commissioning instructions

for the corresponding CECX digital input/output module

CECX-A-...analogue module

Assembly, installation and commissioning instructions

for the corresponding CECX analogue input/output

module

CECX-C-2G2 encoder interface

Assembly, installation and commissioning instructions

for the corresponding module

CECX-F-PB-S-V0

fieldbus interface

Assembly, installation and commissioning instructions

for the corresponding PROFIBUS interface

CDSA-D1-VX operator unit

Assembly, installation and operating functions of the

CDSA-D1-VX operator unit

System manual

CMXR multi-axis control

system

Programming instructions

CMXR multi-axis control

system

CDSA manual

CDSA handheld terminal

Software for CDSA

CDSA handheld terminal

Online help for FCT

software package

FCT with CMXR PlugIn

Commissioning the CMXR multi-axis control system

*) The manuals can be found on the supplied CD-ROM as a PDF file.

Hardware/software

Firmware version

CMXR multi-axis control system

from V 1.0

Documentation on the CMXR-C1 control system

Table 0.2 Documentation on the CMXR multi-axis control system

Required software versions

This documentation refers to the following versions:

Table 0.3 Hardware and software states

14 Festo GDCP-CMXR-HW-EN en

Contents and general safety instructions

Term / abbreviation

Meaning

A

Digital output

Address switch

Used to set the internal module address.

Analogue input/outputs

Analogue inputs and outputs

Application

Sum of user programs

CANopen

Fieldbus protocol base on CAN, which is standardised as a European standard.

E

Digital input

Ethernet

Physical protocol and network for connecting various devices.

Functional earth

Earthing whose sole purpose it is to safeguard the intended function of the electrical equipment. The functional earth is used to discharge interference voltage,

which otherwise could lead to impermissible influences on the device.

I/O module

Common term for those modules that provide digital or analogue inputs and/or

outputs.

Logic 0

0 V applied at input, or output supplies 0 V.

Logic 1

24 V applied at input, or output supplies 24 V.

Optional modules

Are plugged into slots (max. 3) on the central module and provide special interfaces for the central module.

Peripheral modules

For expanding the range of functions, peripheral modules can be plugged into the

central module on the right-hand side. Signal generators and actuators are connected, for example, via input/output modules.

Retain data

Data which are written into the memory of the control system by the application.

Normally these are quantities, information on time or similar. Retain data keep

their value after the device has been switched off and on. If the program is restarted, you can continue to work with the saved data. The data are not saved on

the Compact Flash memory card.

Runtime system

Operating system attachment

Status report

Files which the device can save for error analysis. These include important information about the state of the device at the time the error occurred. They can be

read out for service purposes.

Terminating resistor

Resistor for minimizing signal reflections at the fieldbus. Terminating resistors

must be installed or switched in at the end of bus segment cables.

General product-specific terms and abbreviations

The following product-specific abbreviations are used in this documentation:

Table 0.4 Product-specific terms and abbreviations

Festo GDCP-CMXR-HW-EN 0805NH 15

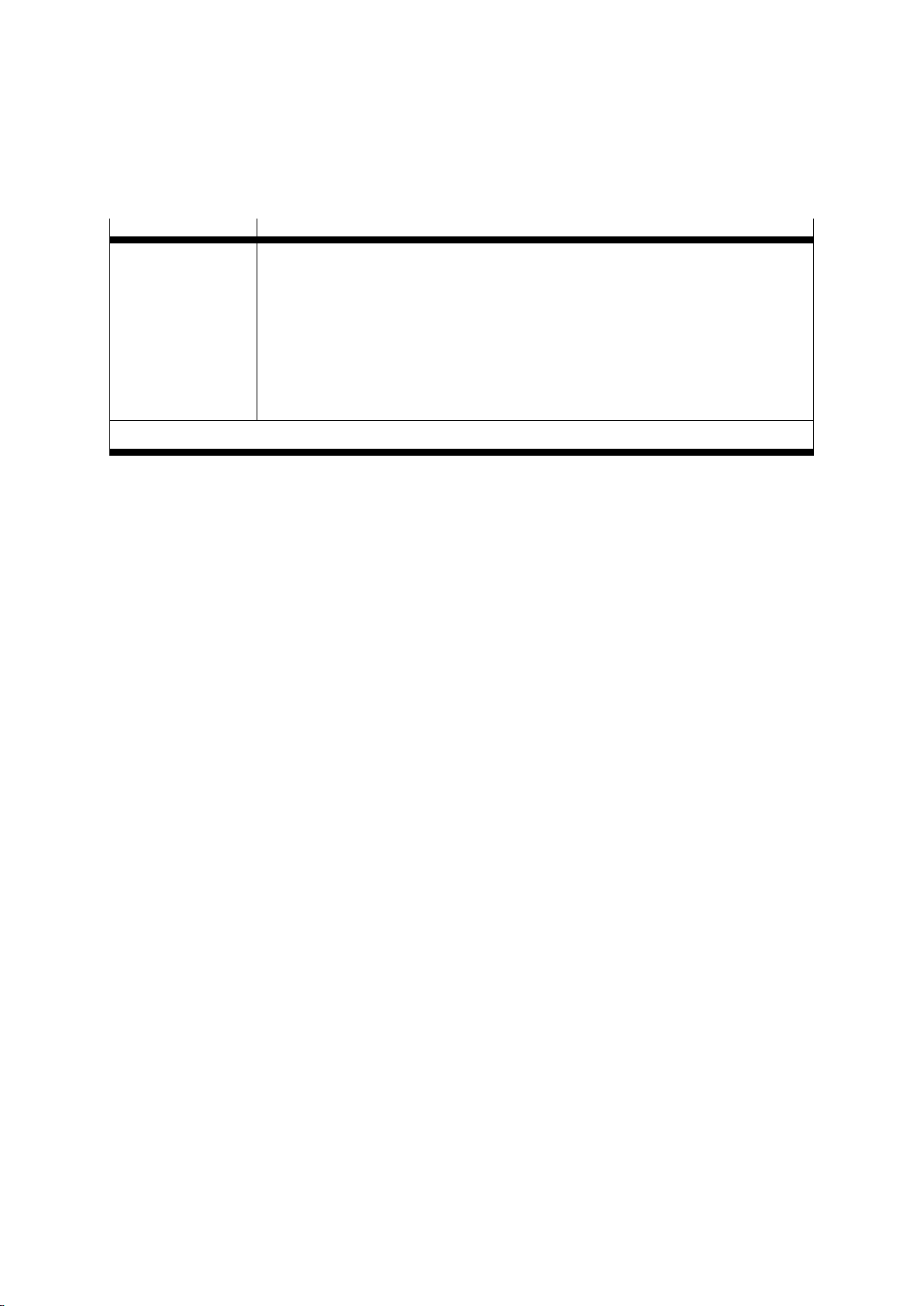

Product version

Description

Central control unit

CMXR-C1

Multi-axis control system 1)

Used for constructing a gantry robot, a linear or tripod

robot. In this context, the device takes over the following tasks:

– The control of selected Festo stepping motor and

servo motor controllers, via CAN bus X6 (Festo DriveBus)

– The control of the peripherals (digital, analogue,

displacement encoder)

Expanding the device with further modules is permissible.

1) Shown here is the standard configuration

The device configurations shown in this manual can thus deviate

from your device configuration.

1. CMXR system overview

1.1 Product versions

The device is available in the following versions:

Table 1.1 Product versions of the modular control system

16 Festo GDCP-CMXR-HW-EN en

1. CMXR system overview

1 Wall bracket

CAFM-D1-W

2 Operator unit

CDSA-D1-VX

3 Interface unit

for operator unit

CAMI-C

4 Motor controller

(connected here via

Festo DriveBus X6)

5 Motor

6 Peripheral

equipment (here

CPV valve cluster)

connected via

CAN (X4)

7 CMXR multi-axis

control system

1 2 4 6 3 7 5

Product version of CMXR multi-axis control system

The device has two CAN interfaces in this version. Drives - Festo stepper motors or servo

motors - can be connected via CAN interface (X6). Communication with the drives occurs

on the basis of CANopen profile DS402 via Festo DriveBus.

The peripherals can be controlled using the CANopen protocol via the second CAN interface (X4), e.g. Festo CPV valve clusters.

Furthermore, you can adapt the structure of the CMXR multi-axis control system to your

requirements, because the device can be equipped in this product version with further

digital, analogue and fieldbus modules (see section 1.2.3).

Fig. 1.1 Structure of a multi-axis system with CMXR multi-axis control system (example)

Display and control unit CDSA-D1-VX is used for operating, observing and programming

the multi-axis control system.

Festo GDCP-CMXR-HW-EN 0805NH 17

Central control unit

Description

– Motorola Power PC 400 MHz

– 64 MB RAM

– Slots for optional modules (CAN, Ethernet and RS-232-C inter-

face)

– CAN interface X6 for servo axes

– Bus connection for peripheral modules

– Slot for Compact Flash memory card

– USB interface

1.2 Structure of the device

The device is constructed on a modular basis. It essentially consists of:

- One central module

- Optional modules (are inserted into a slot in the central module)

- Peripheral modules (are connected in series on the right of the central module)

- If necessary, display and operating devices.

1.2.1 Central control unit

The central control unit is the centrepiece of the CMXR multi-axis control system. It provides the required resources for processing the user programs (processor, RAM, etc.).

The central control unit offers 3 slots for optional modules, which offer further ports for

interfaces of the central control unit. To expand functions, the peripheral modules can be

connected to the central control unit, on the right-hand side.

Table 1.2 Central control unit

18 Festo GDCP-CMXR-HW-EN en

1. CMXR system overview

Optional modules

Description

ELECTRICAL INTERFACE

CECX-C-ET

Ethernet connection X5 for the Ethernet controller integrated in the central

module

Baud rate: 10 Mbit

FIELDBUS INTERFACE

CECX-F-CO

CAN connection X4 for the CAN controller integrated in the central module

Baud rate: up to 1 Mbit

Peripheral modules

Brief description

INPUT MODULE

CECX-D-16E

Digital input module

16 digital inputs

1.2.2 Optional modules

Optional modules can be used to increase the communication ability of the central control

unit. The optional modules are components of the CMXR-C1 central control unit:

Table 1.3 Optional modules

1.2.3 Peripheral modules

The central control unit can be adapted to the wide range of requirements by means of

peripheral modules. Peripheral modules establish the connection for the process. Sensors

and actuators are, for example, connected via digital modules and analogue modules.

Fieldbus modules establish the connection to control systems. The following peripheral

modules are supported:

Festo GDCP-CMXR-HW-EN 0805NH 19

Peripheral modules

Brief description

INPUT/OUTPUT MODULE

CECX-D-8E8A-NP-2

Digital input/output module

8 digital inputs and

8 digital outputs 2 A at 50% concurrence, short-circuit proof and overload proof

OUTPUT MODULE

CECX-D-14A-2

Digital output module

14 digital outputs, 2 A at 50% concurrence per group, short-circuit proof and

overload proof

INPUT/OUTPUT MODULE

CECX-A-4E4A-A

Analogue input/output module

– 4 analogue current inputs

differential 0 … 20 mA, resolution: 14 bit

4 analogue current outputs 0 … 20 mA, resolution: 12 bit

INPUT/OUTPUT MODULE

CECX-A-4E4A-V

Analogue input/output module

– 4 analogue voltage inputs differential

+/-10 V or 0 V - Uref, resolution: 14 bit

4 analogue voltage inputs +/-10 V, resolution: 12 bit

20 Festo GDCP-CMXR-HW-EN en

1. CMXR system overview

Peripheral modules

Brief description

ENCODER INTERFACE

CECX-C-2G2

Increment generator interface module

2 encoder interfaces

FIELDBUS INTERFACE

CECX-F-PB-S-V0

PROFIBUS slave interface

PROFIBUS DP-V0 slave

Operation and display

Description

OPERATOR UNIT

CDSA-D1-VX

Used for operating, observing and programming the CMXR-C1 multi-axis control system.

Table 1.4 Peripheral modules

1.3 Operator units for the modular control system

The CDSA-D1-VX handheld control is available for the CMXR multi-axis control system for

programming and monitoring:

Table 1.5 Operator unit

Festo GDCP-CMXR-HW-EN 0805NH 21

Caution

Assemblies, modules and control systems may be damaged if they

are not handled correctly.

Before carrying out assembly, installation and maintenance

work, always switch off the operating and load voltage supplies.

Note

Damage to components

Handle all modules and components with great care.

Note especially the following:

- Contact surfaces must be clean (avoid contact errors).

- The contacts for the bus plugs must not be bent.

- Make sure that no bits of wire, filling material or chips fall into

the device when you drill holes or connect wires.

2. Assembly

2.1 General instructions on assembly and dismantling

2.2 Guidelines on the CMXR device configuration

Guidelines on the CMXR multi-axis controller device configuration

The CMXR multi-axis control system is supplied pre-assembled from the factory. You may

adapt the device to your requirements by adding or removing modules.

Rules for assembly

- A maximum of 8 peripheral modules may be connected in series on the right of the

central module.

- The layout of the peripheral modules is freely selectable.

- The central control unit provides 7 W to supply the peripheral modules with power. To

ensure the stable functioning of the multi-axis control system, the power requirement

of the modules connected in series must not exceed 7 W (see section A.3).

- Peripheral modules of the same type must be set to different module addresses (see

section 2.2.2).

- Peripheral modules with varying type designation (e.g. CECX-D-16E and CECX-D-14A-2)

can have the same module addresses.

22 Festo GDCP-CMXR-HW-EN en

2. Assembly

Recommendation: Assign the module addresses in an ascending

order for peripheral modules of the same type.

1 Central control unit

2 CECX-F-CO optional

module

3 CECX-C-ET optional

module

Caution

Damage to components

Switch off the operating voltage supply for the central module

before inserting or disconnecting optional modules.

Caution

Assemblies and modules may be damaged if they are not handled

correctly

Do not touch the electrical contacts of the modules.

Observe the handling specifications for electrostatic sensitive

devices.

Protecting the components against discharges of static elec-

tricity: Discharge yourself of static electricity before fitting or

removing the modules.

1

2

3

The central control unit and peripheral modules are connected together via an internal

bus. Peripheral modules of the same type are differentiated on the basis of varying module addresses. The module address can be set with an address selector switch on the peripheral module (see section 2.2.1). You can calculate the total power consumption of

all assembled peripheral modules by adding up the power consumption of all the single

modules. The standard configuration of devices for the CMXR multi-axis control system

is shown by the following illustration:

Fig. 2.1 Standard configuration of devices for the CMXR multi-axis control system

2.2.1 Fitting and removing optional modules

Festo GDCP-CMXR-HW-EN 0805NH 23

Slot

Identification on the

central control unit

Permissible optional module

Description

Left slot

-

-

not used

Middle slot

X4 CAN

CECX-F-CO

CAN connection

Right slot

X5 Ethernet

CECX-C-ET

Ethernet connection

Detailed information on optional modules can be found in the respective, associated manual.

1 Blind plate

2 Optional

module (here

CECX-C-ET)

1

2

The slots in the central control unit are intended for the following optional modules; the

modules only fit exactly in these slots:

Table 2.1 Assignment of slots

Installation of an optional module

1. Switch off the operating and load voltage supplies.

2. Remove blind plate on the corresponding slot.

3. Carefully push the module the right way up (right-hand side interface designation) into

the permissible slot, until the mounting levers engage.

Fig. 2.2 Inserting an optional module (CECX-C-ET as example)

Removing an optional module

1. Switch off the operating and load voltage supplies.

2. Carefully press in the mounting lever and pull the module out of the slot.

3. Close off the free slots using the blind plate. This ensures the protection (against acci-

dental contact) of ESD-sensitive parts.

24 Festo GDCP-CMXR-HW-EN en

2. Assembly

1 Blind plate

2 Mounting lever

Caution

Assemblies and modules may be damaged if they are not handled

correctly

Switch off the supply voltages before you mount or remove the

peripheral modules.

Do not touch the electrical contacts of the modules.

Observe the handling specifications for electrostatic sensitive

devices.

Protecting the components against discharges of static elec-

tricity: Discharge yourself of static electricity before fitting or

removing the modules.

1

2

Fig. 2.3 Disassembly of an optional module (example)

2.2.2 Assembling peripheral modules

Peripheral modules are normally supplied ex factory with the address setting 0. The address setting must be checked, or changed, before assembling the peripheral modules.

Setting the module address

The address switch is normally located on the right-hand side of the peripheral modules,

under the bottom cover. The address must be set before prior to the device being assembled. The bus plug is located under the top cover (also see description of peripheral module).

Festo GDCP-CMXR-HW-EN 0805NH 25

1 Bus plug (rear

cover)

2 Recess for H-rail

3 Address switch

(module address)

4 H-rail locking

clip

Additional information can be found in the manual for the respective periphery module.

Caution

Damage to components

Make sure that when setting the module address with the

screwdriver you do not damage any neighbouring components.

4

1

2

Fig. 2.4 Address switch and bus plug for a peripheral module (example)

This is how you set the module address for the periphery modules:

1. Remove the side plate of the address selector switch.

2. Check the address setting and, if necessary, set it using a suitable screwdriver (mod-

3. Reattach the side plate (to protect against contamination and damage caused by elec-

ules with the same type designation need different module addresses).

trostatic discharge when touched).

26 Festo GDCP-CMXR-HW-EN en

2. Assembly

Caution

If handled incorrectly the pins on the bus plug can bend

Proceed with care when assembling the peripheral modules.

1 Cover (on the

right side)

2 Bus plug

3 Upper mechani-

cal locking mechanism

4 Lower mechanical locking mechanism

3 2 4

1

Fitting the peripheral modules

The central control unit always takes up the outer left position within the CMXR multi-axis

control system. Peripheral modules are arranged to the right of this and connected with

one another via bus plugs. The overall assembly can then be snapped onto an H-rail

(TS 35x7.5) (see section 2.4).

To protect against contamination and damage caused by electrostatic discharge, both

side plates (for bus plug and address switch) must be closed on the last module of one

row.

This is how you assemble the peripheral modules:

1. Switch off the operating and load voltage supplies.

2. Remove the bus plug's right-hand side plate on the device (see Fig.).

3. Carefully insert the peripheral modules until the upper and lower mechanical locking

4. To assemble more peripheral modules, repeat points 2 and 3.

mechanisms engage.

Fig. 2.5 Assembling a peripheral module

Festo GDCP-CMXR-HW-EN 0805NH 27

Caution

If handled incorrectly the pins on the bus plug can bend

Proceed with care when disassembling the peripheral modules.

1 Upper mechanical locking mechanism

2 Lower mechanical locking mechanism

1

2

2.2.3 Dismantling peripheral modules

This is how you disassemble the peripheral modules:

1. Switch off the operating and load voltage supplies.

2. If necessary, remove the device from the H-rail (for disassembling the device, see sec-

tion 2.5).

3. Carefully press (unlock) the upper and lower mechanical locking mechanisms on the

left (see Fig.).

4. Carefully pull the peripheral module from the device.

5. Reattach the bus plug's right side plate to the device (to protect against contamination

and damage caused by electrostatic discharge when touched).

Fig. 2.6 Dismantling a peripheral module

28 Festo GDCP-CMXR-HW-EN en

2. Assembly

2.3 Guidelines for the installation

The device is designated for installing into a control cabinet and can be installed horizontally. Take the wiring for the device into consideration prior to assembly. Keep the device

away from cables with high levels of interference. Leave sufficient distance for the wiring

and cooling system.

Mounting dimensions and clearances

A clearance of 30 mm, above and below the modules, must be maintained for the air circulation.

Fig. 2.7 Dimensions and mounting clearances

Festo GDCP-CMXR-HW-EN 0805NH 29

Caution

Damage or malfunctions can occur if the permissible operating

temperature is exceeded

Please observe the following instructions:

Caution

Incorrect fitting causes operative malfunctions

Prior to fitting the device, check whether the peripheral mod-

ules are correctly mounted and all locking clips have snapped

into place.

To safeguard the modules from slipping or shaking loose due to

vibrations: Attach an end support on the H-rail, both to the left

and right side.

Air-conditioning and venting

The upper and lower sides of the module are equipped with ventilation slots for heat dissipation. When the permissible ambient temperature is maintained there is no need of an

external ventilator. It is, however, absolutely vital that the ventilation slots are kept clear.

Do not mount the device directly above a source of heat, e.g. a heating appliance,

a current transformer or a high-wattage resistor.

To make sure heat dissipation can be ensured, maintain a clearance, above and below

the modules, of at least 30 mm.

Make sure that the operating temperature within the control cabinet is not higher than

the modules' permissible ambient temperature. Air conditioning has to be provided for

the control cabinet if sufficient cooling can not be guaranteed by natural heat dissipation.

When deciding on the configuration in the control cabinet, make certain that the area

around the ventilation slots is not subjected to temperature fluctuations. For example,

do not use air-conditioning units with intermittent operation.

Additional information on calculating the total heat dissipation loss in the control cabinet

can be found in the chapter Power consumption of the modules (see section A.3).

Using air filters

Avoid using contaminated air filters. Clean the air filter regularly.

Recommendation: Install the device into a dust-free, closed control cabinet. If the control

cabinet has vents, these must be equipped with air filters. Make sure that the filter elements are cleaned or exchanged at regular intervals.

2.4 H-rail mounting

The device is intended for fitting on an H-rail (mounting rail to EN 60715).

30 Festo GDCP-CMXR-HW-EN en

2. Assembly

1 Min. screw

spacing

2 H-rail

1

2

When mounting the H-rail, maintain the max. permissible screw spacing. For reasons of

stability, the screw spacing must not exceed 120 mm, as shown in the graphic.

Fig. 2.8 Maximum permissible screw spacing for H-rail mounting

Festo GDCP-CMXR-HW-EN 0805NH 31

1 H-rail retainer

2 H-rail locking

lever

3 H-rail

3 1 2

The CMXR multi-axis control system is attached onto a DIN mounting rail (TS 35 x 7.5 hat

rail). Mount the device in such a way that there is still sufficient space for heat dissipation

and the permissible temperature range is maintained.

Fig. 2.9 H-rail mounting

This is how you attach the device to the H-rail:

1. Pull out all H-rail locking levers (unlock).

2. Slightly tilt the device and place it onto the H-rail, on the H-rail retainer.

3. Press the lower half of the device onto the H-rail.

4. Lock all H-rail locking levers one after the other (see Fig.).

5. Secure the device with end supports (device end terminals) (see the following sec-

tion).

32 Festo GDCP-CMXR-HW-EN en

2. Assembly

1 End supports

1

1

Securing with end supports (device end terminals)

To safeguard the modules from slipping or shaking loose due to vibrations, attach an

end support on the H-rail, both on the right and left.

Fig. 2.10 Securing the device with end supports

Festo GDCP-CMXR-HW-EN 0805NH 33

Caution

Damage to components.

Switch off the power supply before the dismantling work and

remove all cable connections.

2.5 Dismantling

This is how you dismantle the device:

1. Switch off the operating and load voltage supplies.

2. Disconnect all cable connections on the device.

3. Pull out all H-rail locking levers (unlock).

4. Remove the device from the H-rail.

34 Festo GDCP-CMXR-HW-EN en

3. Installation of the CMXR-C1 central control unit

Caution

Sudden unexpected movements of the connected actuators can

cause injury to human beings and damage to property.

Before undertaking installation or maintenance work, switch off

the operating voltage supply.

Caution

Damage to components

Note the specified ambient conditions (see Technical data).

Do not install the device:

- in areas subjected to excessive dust, oil mist, conductive dust

or corrosive gas

- directly in areas subjected to shock or vibrations

- in areas subjected to high temperatures, direct sunlight, mois-

ture or rain

- in the proximity of high-voltage equipment or high-voltage

lines.

Warning

Use only PELV circuits as per IEC/DIN EN 60204-1 (protective

extra-low voltage, PELV) for the electric power supply.

Also comply with the general requirements for PELV circuits laid

down in IEC/DIN EN 60204-1.

Use only power sources that guarantee safe electrical isolation

of the operating voltage as per IEC/DIN EN 60204-1.

Provide the load voltage as a circuit with limited energy as per

IEC/DIN EN61131-2 or make sure there is appropriate fusing.

3. Installation of the CMXR-C1 central control

unit

3.1 General instructions on installation

Check within the framework of your EMERGENCY STOP circuit, to ascertain the measures

necessary for putting your machine/system into a safe state in the event of an EMERGENCY STOP (e.g. switching off sources of energy; load voltage supply, compressed air,

shutdown of moving parts etc.).

3.2 Selecting the power unit

Festo GDCP-CMXR-HW-EN 0805NH 35

With the CMXR multi-axis control system, you do not have to observe any type of special wiring. Instructions on EMC-compliant

wiring can be found in Appendix A.4.

Only use the appropriate plugs that guarantee a secure push-in

connection. Plugs from the Festo range are appropriate (see

Appendix A.2).

By the use of PELV power units, protection against electric shock (protection against direct and indirect contact) is guaranteed in accordance with IEC/DIN EN 60204-1 (electrical

equipment of machines, general requirements).

The current requirement of the device depends on the amount and type of integrated

modules (see Technical data for the used module).

Recommendation: Use closed-loop power units. When selecting the power units, check

that they have sufficient output.

3.3 Instructions on wiring

The device or certain modules are equipped with pin strips attached on the front-side. The

appropriate plugs, with a grid dimension of 5.08 mm, are required for the connection.

Cable specifications for Festo plugs (see Appendix A.2):

Cable cross section min: 0.2 mm² (AWG 24)

Cable cross section max: 2.5 mm² (AWG 13)

Strip length: 10 mm

Permitted copper conductors

- Single wire, multi-wire, fine wire, also with tin-plated individual cores

- Fine wire compressed

- Fine wire with core end sleeves *)

- Fine wire with pin cable socket *)

*) If necessary, use next smaller cross-sectional area

36 Festo GDCP-CMXR-HW-EN en

3. Installation of the CMXR-C1 central control unit

Supply cable

Description

Cable type

Unscreened cable. The cable cross section must be adapted to the module's

power consumption.

Plug type

Plug with grid dimension 5.08 mm (see Appendix A.2).

I/O cables, digital

Description

Cable type

Unscreened cable

Plug type

Plug with grid dimension 5.08 mm (see Appendix A.2).

Recommendation: Split the plug blocks in such a way that associated signals are present on each plug.

I/O cables, analogue

Description

Cable type

Twisted pair cable with screen against low-frequency 50 Hz fields

Plug type

Plug with grid dimension 5.08 mm (see Appendix A.2).

Recommendation: Split the plug blocks in such a way that associated signals are present on each plug.

Supply cables

Table 3.1 Specification for supply cable

I/O cables, digital

Table 3.2 Specification for I/O cables (digital)

I/O cables, analogue (current or voltage input/output)

Table 3.3 Specification for I/O cables (analogue)

Wiring instructions for analogue cables

- The screened rail must be connected to the GND terminal.

- Cables must be screened (screening connection to GND potential at both ends).

- To achieve the best possible resistance to interference, the analogue cables should

not be laid parallel to high-interference cables (e.g. cables from converters to motors).

The screen is used only to screen electrically low-frequency 50 Hz fields and is not an HF

screen. The type of shield support is, therefore, not quite as important as it is for highspeed data interfaces.

Festo GDCP-CMXR-HW-EN 0805NH 37

1 Twisted pair

cables

2 Screened rail

3 0 V connector

against 50 Hz field,

max. length 1m-+

Ethernet cable

Description

Cable type

Screened connection

Plug type

RJ45

Minimum bending radius

Minimum bending radius during the installation: 60 mm

Minimum bending radius for an installed cable: 50 mm

1 3 2

Fig. 3.1 Example: connecting the analogue inputs/analogue outputs

Short-circuiting unused, prewired inputs

For already prewired but unused inputs, the wires must be short-circuited at the cable end

to prevent transmission of interference.

Ethernet cable

Table 3.4 Ethernet cable specifications

The screened connection was tested with the following cable type:

A cable with the following features must be used for the connection:

- Data cables twisted in pairs and screened

- Surge impedance of 100 Ohm +/- 15%).

An additional screening and earthing connection is not necessary.

38 Festo GDCP-CMXR-HW-EN en

3. Installation of the CMXR-C1 central control unit

CAN cable

Description

Cable type

Twisted, screened two-wire cable with signal earth.

The CAN connection must be made using a suitable cable. We recommend a data

cable as set out in ISO/DIS 11898 (CAN standard). A multi-wire, twisted cable can

also be used. Please not that the CAN+ and the CAN- cables are twisted together

to form a wire pair.

– Surge impedance: min. 108 Ω, typ. 120 Ω, max. 132 Ω

– Line resistance: typ. 70 mΩ/m

– Signal running time: typ. 5 ns/m

Cable length

Depends on the bit rate of the CAN bus transmission

Minimum bending radius

Minimum bending radius during the installation: 48 mm

Minimum bending radius for an installed cable: 24 mm

Plug type

9-pin D-SUB socket plug with completely conductive housing

1 Twisted 2-wire

cable (CAN+, CAN-)

2 Signal earth

(SGND)

3 Screen with

screen earthing

1

2

3

CAN cable

In CMXR, the central control unit can be connected to other bus slaves via a CAN cable.

Table 3.5 CAN cable specification

Fig. 3.2 CAN cable

The cable screening must be connected flush with the plug's screen housing. An additional screening and earthing connection is not necessary.

Externally produced signal and data cables and not connected to the device must not be

part of a cable with self-produced signal and data cables. All screened signal, data and

low-voltage supply lines with screening connected to both sides must be laid parallel to

one another and also parallel to the power supply lines.

Festo GDCP-CMXR-HW-EN 0805NH 39

Bit rate [kbit/s]

Maximum cable length, typical [m]

125

500

250

250

500

100

1000

40

The CAN interface X6 is set permanently to 1000 kbit/s.

Encoder supply and

reference voltage

output

Description

Cable type

Twisted pair cables, with screen against low-frequency 50 Hz fields (see also "I/O

cables, analogue (current or voltage input/output)").

Plug type

Plug with grid dimension 5.08 mm

Incremental encoder

input

Cable type

Standard screened cable

Plug type

9-pin D-SUB plug with completely conductive housing

CAN module connection with modules (without optocoupler)

Table 3.6 Cable lengths of CAN cable

The length specifications shown in the table are maximum values in ideal conditions. The

cable length possible in practice is reduced with poor screen contact, strong interference,

branch lines and poor cable quality.

Furthermore, the cable length is dependent on the properties of the other CAN bus participants and on the optocouplers (if equipped) used.

We recommend the CAN cable be sized only for as long as is really necessary.

Cable for encoder supply output and reference voltage output

Table 3.7 Cable for encoder supply output and reference voltage output

Incremental encoder input

Table 3.8 Specification Cable for incremental encoder input

The cable screening must be connected flush with the plug's screen housing. An additional screening and earthing connection is not necessary.

40 Festo GDCP-CMXR-HW-EN en

3. Installation of the CMXR-C1 central control unit

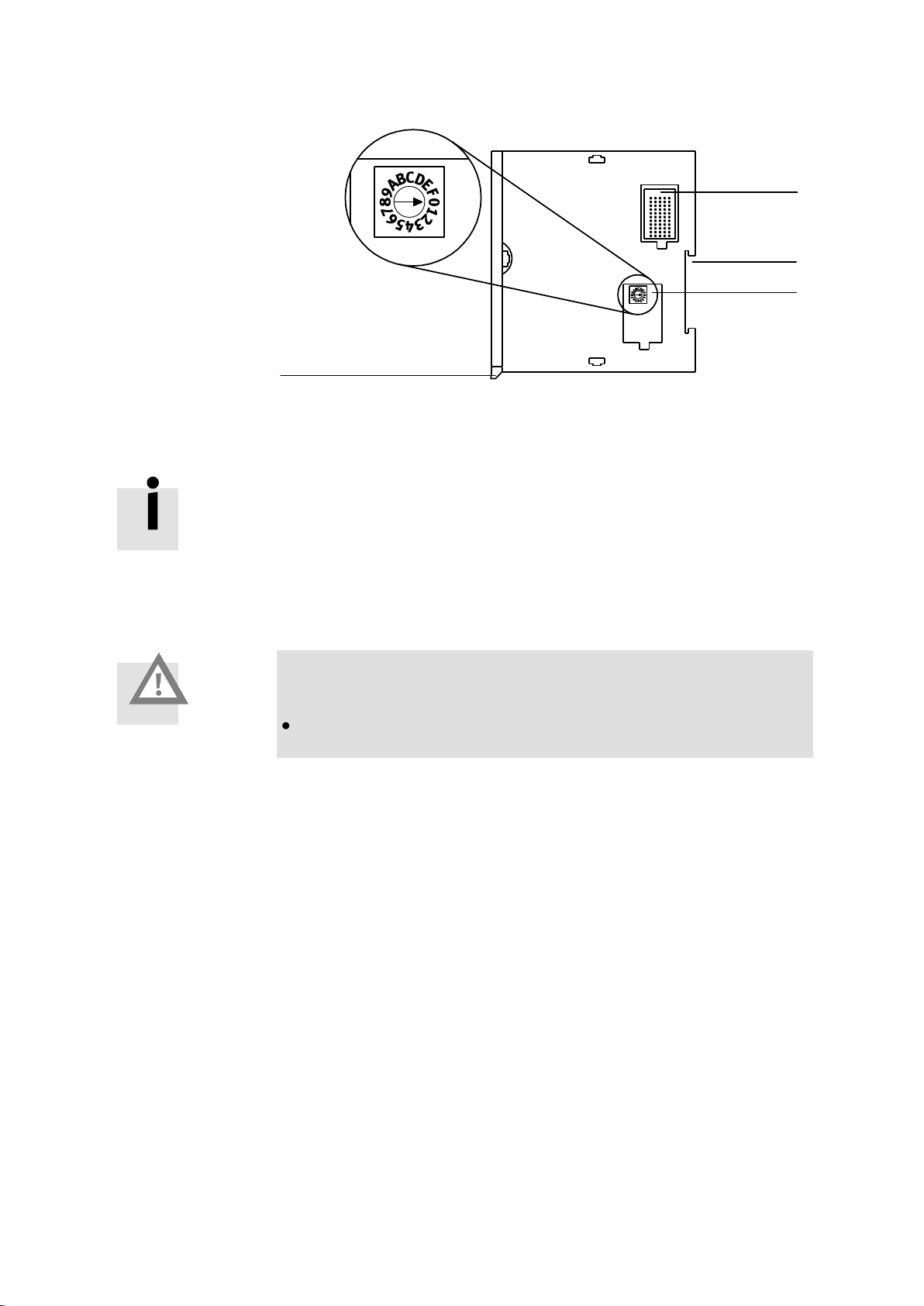

1 7-segment display

2 Power LED (top)

and CTRL key (below)

3 Plug-in cards for

optional modules

4 CAN connection

for servo controller

(X6)

5 Status LEDs

6 Ejection button

for Compact Flash

card

7 Slot for memory

card

8 USB port (X7)

9 Status LED for

the memory card

aJ Operating volt-

age connection (X2)

aA RS-485-A inter-

face (X1)

Information on the peripheral modules can be found in the manual

for the relevant peripheral module.

3 4 1 2 6

7

8

aJ

aA 9 5

3.4 Display, connecting and operating elements on the

central control unit

The following display, connecting and operating elements can be found on the central

control unit:

Fig. 3.3 Display, connecting and operating elements of the central control unit

The following sections describe the elements of the central control unit.

Festo GDCP-CMXR-HW-EN 0805NH 41

Caution

Damage to components

Provide the load voltage and the operating voltage supply as

a circuit with limited energy as per IEC/DIN/EN 61131-2, or

always make sure there is fuse protection with a maximum of

10 A (see graphics in "Connection diagram for supplying +24 V

supply").

1 Power supply

unit

2 External fuse

3 Operating volt-

age connection (X2)

Detailed instructions on this can be found in the manual for the

relevant module.

1 3 2

2

3.4.1 Connecting the operating voltage

The operating voltage for supplying the internal electronics of the installed modules (peripheral and optional modules) is supplied via the central control unit. The central control

unit converts the supplied operating voltage into the required internal operating voltages.

These are forwarded to the installed modules via the bus plug.

The operating voltage connection is designed with reverse polarity protection within the

permissible operating voltage range.

Fig. 3.4 Connection diagram for supplying +24 V supply (example)

Power supply for the peripheral modules

42 Festo GDCP-CMXR-HW-EN en

3. Installation of the CMXR-C1 central control unit

1 Earth terminal

(M4 threaded

socket)

1

3.4.2 Earthing the CMXR multi-axis control system

The correct earthing for the device is important for faultless operation and electrical

safety. For earthing, you must produce a low-impedance connection between the

device's earth terminal and the earth potential. A low-impedance connection can be

achieved by using a, where possible, short, low-impedance cable and a large surface

area contacting. The earth terminal is located underneath the housing.

Fig. 3.5 Earth terminal for the device

Festo GDCP-CMXR-HW-EN 0805NH 43

1 RS 485 A interface (X1)

2 Rotary switches

3 USB interface

(X8)

2 1 3

3.4.3 RS 485 A interface (reserved for expansion)

This interface is reserved for later expansions.

Fig. 3.6 Rotary switch on the central module (reserved for later expansions)

3.4.4 USB interface (for the service technician)

The CMXR modular control system includes one USB Master.

The USB connection (X8) is used solely for diagnostic purposes. Using the appropriate

software, diagnostic data (status reports) and program data generated by the device can

be copied onto a USB stick via the USB interface.

3.4.5 Rotary switch (reserved for expansion)

Two rotary switches are located on the top right side of the housing for the central module. These rotary switches are planned for later expansions (factory setting = 0).

3.4.6 CAN interface X6

For the servo controller connection, a 9-pin CAN connection is located on the central control module (Sub-D plug). This connection is used as an incoming and continuing field bus

cable.

44 Festo GDCP-CMXR-HW-EN en

3. Installation of the CMXR-C1 central control unit

Only use the appropriate sockets that guarantee a secure push-in

connection. Sockets from the Festo range are appropriate (see

Appendix A.2).

CAN (X6) connection

Pin

Signal

Meaning

5

1

9

6

1

2

3

4

5

6

7

8

9

Housing

n.c.

CAN–L

SGND

TERM1

TERM1

GND

CAN–H

TERM2

TERM2

(screening)

Not connected

CAN Bus Low

Signal ground

TERM1 *)

TERM1 *)

optional GND

CAN Bus High

TERM2 *)

TERM2 *)

*) Connection for activating the internal terminating resistor (refer to CAN bus terminal)

1 CAN connection

2 Jumper 1 (CAN+)

3 Jumper 2 (CAN-)

4 Integrated ter-

minating resistor

4

3

Table 3.9 Pin assignment for CAN connection (X6)

CAN bus terminal

Install a bus terminal at both ends of the field bus (first and last slave).

A terminating resistor for the bus terminal is integrated in the device. If you install the device onto the end of the field bus, you can activate the integrated terminating resistor by

connecting pins 4 and 5 (TERM1) and pins 8 and 9 (TERM2) (see the following picture).

Fig. 3.7 CAN interface with activated bus terminal

The two jumpers "Term1" and "Term2" are used to connect the terminating resistor (R) to

the CAN data cables.

The CAN connection must be made using a suitable cable.

Festo GDCP-CMXR-HW-EN 0805NH 45

We recommend a data cable as set out in ISO/DIS 11898 (CAN

standard).

RJ45 socket (X5)

Pin

Signal

Explanation

1

2

3

4

5

6

7

8

Metal covering

TD+

TD-

RD+

n.c.

n.c.

RD-

n.c.

n.c.

Screened

Transmitted data+

Transmitted data

Received data+

Not connected

Not connected

Received data

Not connected

Not connected

Screened

Instructions on wiring can be found in section 3.3.

3.4.7 CAN interface X4 (optional module CECX-F-CO)

CAN interface X6 (see section 3.4.6).

3.4.8 Ethernet interface X5 (optional module CECX-C-ET)

The central control unit is equipped at the factory with the CECX-C-ET optional module

as standard. This module provides an Ethernet connection for the Ethernet controller

built into the central control unit. An RJ-45 connection is available on the front panel for

connecting to an Ethernet network. This means the device can be integrated into both a

10 Mbit/s and a 100 Mbit/s Ethernet.

Table 3.10 Pin allocation for the Ethernet interface (X5)

3.4.9 Using Compact Flash memory cards

To operate the CMXR multi-axis control system, a Compact Flash memory card must be

inserted in the slot with the corresponding firmware and, if necessary, application. The

memory card is used for storing machine data (e.g. tool data and recipes), dependent on

the application used. The memory card can not be used as a removable medium, because

system programs are also stored on it. It is recommended that the Festo memory card,

CAMC-CMXR-C1-CF-256M, be used. The following memory cards are compatible:

46 Festo GDCP-CMXR-HW-EN en

3. Installation of the CMXR-C1 central control unit

Memory capacity

Type (manufactured by Toshiba)

Type (manufactured by Simple Tech)

128 MB

THNCF128MDGI

SLCF128JU

256 MB

THNCF256MDGI

SLCF256JU

512 MB

THNCF512MDGI

SLCF512JU

1 GB

THNCF1G02DGI

SLCF1GBJU

Caution

Memory cards can be damaged if handled incorrectly

Do not remove or insert the memory card during operation.

Do not switch off the device whilst it is writing onto the memory

card.

Do not insert the memory card with too much force into the slot.

Do not drop the memory and do not bend it.

Keep the memory card away from moisture, heat and direct

sunlight.

Keep the memory card away from electrostatic sources or mag-

netic fields.

Note

Only approved memory cards may be used.

Table 3.11 Compatible memory cards

Precautionary measures to be taken when handling memory cards

The memory card is designed in such a way that it can only be inserted into the device in

one direction. The card should simply slip with ease into the slot. The status LED next to

the ejection button lights up if the device has reading or writing access to the card.

Festo GDCP-CMXR-HW-EN 0805NH 47

1 Status LED for

the memory card

2 Memory card

2

1

Inserting the memory card

This is how you insert the memory card:

1. Switch off the supply voltage.

2. Using only slight pressure, carefully insert the memory card in the direction of the

arrow until it engages.

Fig. 3.8 Inserting the memory card

48 Festo GDCP-CMXR-HW-EN en

3. Installation of the CMXR-C1 central control unit

Additional instructions on handling the memory card can be found

in the system manual for the CMXR multi-axis control system.

1 Ejection button

2 Object for

pressing the

ejection button

2

1

Removing the memory card

1. Switch off the supply voltage.

2. Carefully press the ejection button using a suitable object (e.g. blunt pencil). The card

will then be ejected by a few millimetres.

3. Carefully pull the card out of the slot.

Fig. 3.9 Removing the memory card

Festo GDCP-CMXR-HW-EN 0805NH 49

Information on this can be found in the online help for the software

as well as in the associated system manual.

4. Instructions on commissioning

4.1 General instructions on commissioning

The CMXR multi-axis control system is configured and commissioned using the appropriate software.

The firmware and the respective applications are stored on a memory card, which must be

inserted in the slot of the central control unit.

4.2 Performance of the central control unit

4.2.1 Running up performance

The running up performance is divided into the following three main sections:

- Running up the boot block

- Running up the firmware

- Running up the application.

The running up progress is shown in the 7-segment display.

- Numbers > 0 signal the progress during the running up of the boot system and the con-

trol system firmware.

- Special characters and letters (e.g. L, II, ...) describe the running up of the application

or various operating states of the device.

- An error display will be activated if errors are detected during the running up. Errors

are displayed parallel to the states. Here, the status is initially displayed and then the

two- or three-digit error number (e.g. "-,0,-,E,1,0") alternately. Every character is displayed for one second.

50 Festo GDCP-CMXR-HW-EN en

4. Instructions on commissioning

7-segment display

Step

1

The power supply is present (Power on), the module's hardware is initialized.

2

The consistency of the boot block is tested.

3

Power on self-test, consistency of the boot block is tested.

4

The firmware is loaded from the memory card into the DRAM.

5

The firmware is started.

6

Running up of the boot block is completed. The operating system is initialized and started.

7

Various firmware components (services, I/O system, communication) are

started.

8

Autostart query: Factory setting = Autostart is switched on (if the

Autostart function was deactivated, then at this point a press of the key

(CTRL-key) is expected).

9

Running up of the firmware is completed. The CP module is now ready to

operate. If an application is already present on the memory card, then this

will now be loaded.

Display during the running up of the boot system and the firmware

Table 4.1 Display during the running up of the firmware

Festo GDCP-CMXR-HW-EN 0805NH 51

7-segment display

Step

9

The application is unloaded and the memory is enabled.

10

The application is loaded into the memory.

11

STOP: The application is loaded, but will not yet be processed.

12

The application is started.

13

The application is running.

More detailed information on the performance of the CMXR multiaxis control system can be found in the corresponding system

manual.

7-segment

display

Main operating states

Description

Init

In this operating status:

– the user application is unloaded and the memory enabled (CAUTION:

some configuration changes are only applied after Power on or Reset).

– the transmitting of process data is stopped.

– the visualisation is unloaded.

Stop

In this operating status:

– all global objects, system variables, motion modules etc. are created.

– the interpolator is stopped (no path data available).

– the exchange of process data is started, the output data are set to zero

(digital and analogue outputs: 0V, drives in the "Switch-on lock" status).

The inputs from other I/O modules are not applied.

Run

In this operating status:

– the application programs are processed, the process data is exchanged

according to the configuration.

– the process output data are updated (Unfreeze IO).

– the visualisation application is loaded.

Display during the running up of the application

After the firmware is booted, the system goes into the Init. state

Table 4.2 Display during the running up of the application

4.2.2 Operating states

The control system recognizes the following operating states:

Table 4.3 Operating states

52 Festo GDCP-CMXR-HW-EN en

4. Instructions on commissioning

Caution

Operational errors in conjunction with the CTRL key can cause system faults and lead to loss of data.

Only press the CTRL key upon being instructed to do so by Festo

service staff.

You can switch between the operating states by using the CTRL key.

4.2.3 Behaviour in the event of module errors

Should an error occur, then this will be displayed on the 7-segment display on the central

module. For more information, see section 5.3.1.

4.2.4 Behaviour in the event of power supply failure

A reset is triggered in the event that the complete supply fails. All modules connected in

series are also put into the Reset status and all outputs are reset.

The data in the battery-buffered SRAM are retained.

4.2.5 Control key (CTRL key)

The CTRL key is located next to the 7-segment display on the central modules. This key

can be used by the service technician, for example, to delete data from the memory card,

create Report files or delete Retain data.

Festo GDCP-CMXR-HW-EN 0805NH 53

Diagnostics

options

Brief description

On-the-spot diagnosis via LED

LEDs on the modules indicate signal states, hardware errors, bus errors etc. (see the

manual for the relevant module).

On-the-spot diagnosis via the

7-segment display

The 7-segment display indicates the corresponding error codes in the event of a fault

(see section 5.3.1). These errors can be acknowledged by pressing briefly on the CTRL

key on the central module.

Diagnosis via

software tools

Information on this can be found in the online help for your configuration software.

LED

Description

Power (green)

Lighting up green: power supply present.

Dark: no power supply.

LED

Description

RX (green)

Lights up briefly when a CAN message is received.

TX (yellow)

Lights up briefly when a CAN message is sent.

5. Diagnostics and error handling

5.1 Summary of diagnostic options

The CMXR multi-axis control system offers comprehensive options for diagnostics and

error handling. The following options are available:

Table 5.1 Diagnostics options

5.2 On-the-spot diagnosis via LED

5.2.1 Power LED

The green Power LED is located above the CTRL key on the central modules.

Table 5.2 Power LED

5.2.2 CAN status LEDs

The central control unit has the following two CAN status LEDs on the front panel.

Table 5.3 CAN status LEDs

5.2.3 Ethernet status LEDs

A Link status LED (green) and an Activity LED (yellow) are located on the Ethernet socket

(RJ-45). They light up when telegrams are sent or received.

54 Festo GDCP-CMXR-HW-EN en

5. Diagnostics and error handling

LED

Description

Link status (green)

Lights up as soon as an Ethernet connection is present.

Activity (yellow)

Lights up when data are sent and received.

LED

Description

Status LED (red)

Lights up red during write/read access to the memory card.

Is dark if there is no write/read access to the memory card.

Table 5.4 Ethernet status LEDs

5.2.4 Status LED for the memory card

A status LED is located next to the ejection key for the memory card. It lights up when the

system accesses the memory card.

Table 5.5 Status LED for the memory card

5.3 On-the-spot diagnosis via the 7-segment display

Errors can occur or be present in or during the transitions of the control system's respective operating states (e.g. STOP to RUN). These errors are indicated in the 7-segment display as a sequence of characters together with the current status. Every single character in

the sequence is shown one after the other at 1 second intervals.

The error display can be acknowledged by briefly pressing the CTRL key. After this, the

normal status is displayed.

Example: display during the running up of the firmware

The following sequence of characters signals error 51 in the "Load Firmware" status (no

firmware found):

Status Error

, , , , ,

Example: display during the running up of the application:

The following sequence of characters signals error 203 in the Init status (installation of the

application failed):

Status Error

, , , , , ,

Festo GDCP-CMXR-HW-EN 0805NH 55

Error displays not listed are intended for the support team at Festo.

Error status

Cause

Action

2 – E 401

Extended boot system was not found

Re-initialise the memory card with FCT

2 – E 402

CRC error in extended boot system

Re-initialise the memory card with FCT

2 – E 403

Boot system not suited for HW revision

Re-initialise the memory card with FCT

5.3.1 Error codes

Possible error codes are dependent on the current operating status of the device and

summarised accordingly in the following tables. This means that a first diagnosis is possible without reading out the status report files.

Running-up errors: Error during Power-on self-test

56 Festo GDCP-CMXR-HW-EN en

5. Diagnostics and error handling

Error status

Cause

Action

3 – E 501

Firmware package was not found

Re-initialise the memory card with FCT

3 – E 502

CRC error in firmware package

Re-initialise the memory card with FCT

3 – E 503

Firmware package not suited to HW

Re-initialise the memory card with FCT

3 – E 504

Not enough memory for the firmware

package

Re-initialise the memory card with FCT

Error status

Cause

Action

5 – E 101

Operating system error

Re-initialise the memory card with FCT

5 – E 205

Too many peripheral modules connected

in series

Reduce the number of modules connected

in series

More detailed information on handling the errors in your CMXR

multi-axis control system can be found in the system manual.

Running-up errors: Error loading the firmware

Running-up errors: Error when initialising and starting the operating system

Error handling

Festo GDCP-CMXR-HW-EN 0805NH 57

The device may only be opened by qualified specialists and maintenance work may only be carried out if expressly permitted by

Festo. Other manipulations on the device result in the guarantee

being invalidated.

Recommendation: Change the battery every 3 years.

The battery may only be replaced by a battery of the same type.

Only the following battery type is permissible:

- Battery type: CR2032 (Lithium-Mn, 3 V/220 mAh).

Caution

Short-circuits can cause flammable materials to ignite

Although batteries have a low voltage, they can give off enough

current in a short circuit to cause flammable materials to ignite.

Please note that the regulations for special waste must be ob-

served when disposing of the batteries.

6. Maintenance and care

6.1 Changing the battery

The central control unit is equipped with a real-time clock (RTC). When the power supply is

switched off, the real-time clock is boosted with a battery. The service life of the battery is

at least 3 years.

The battery is located on the right side of the housing, under the lower cover (see Fig. 6.1

Position of the battery).

58 Festo GDCP-CMXR-HW-EN en

6. Maintenance and care

Caution

Bent contact springs can lead to the battery short circuiting

Proceed carefully when changing the battery. Do not use exces-

sive force.

1 Position 1

(insert battery)

2 Position 2

(battery engages)

3 Battery (behind

the cover)

4 Right-hand side

of housing of central control unit

4 3 2

1

Changing the battery

This is how you change the battery:

1. Remove the lower cover on the right side of the housing.

2. Remove old battery by using an antistatic plastic tweezers. In doing so, place the

tweezers in the position marked by the arrow (see Fig. 6.1 Position of the battery).

3. Insert the new battery, as shown above, in position 1 and allow it to engage in posi-

tion 2. Please make sure here that the battery engages in the upper and lower holding

claw.

4. Close the battery cover.

Fig. 6.1 Position of the battery

6.2 Cleaning

Clean the device, if required, with a soft cloth.

Festo GDCP-CMXR-HW-EN 0805NH 59

60 Festo GDCP-CMXR-HW-EN en

A.1. Technical data

A. Technical appendix

Festo GDCP-CMXR-HW-EN 0805NH 61

General information

Short type code

CMXR-C1

Nominal operating voltage

[VDC]

24

Operating voltage range

[VDC]

19,2 ... 30

Total power consumption

[W]

25

Ambient temperature

[°C]

5 ... 55

Storage temperature

(without visualisation)

[°C]