Festo CMSX-...-C-U-F1 series, CMSX-P-S series, CMSX-P-SE series Operating Instructions Manual

Positioner

CMSX-...-C-U-F1-...

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com

Operating instructions

(Translation of the original instructions)

8080775

2017-12b

[8062134]

Positioner CMSX English..............................................

For all available product documentation è www.festo.com/pk

1 Safety

1.1 Intended use

The positioner is intended for controlling the position of the following actuators in

process automation systems:

– pneumatic quarter turn actuators (single- or double-acting)

– pneumatic drives (double-acting) with connected external path/angle sensor

Quarter turn actuators with a mechanical interface in accordance with VDI/VDE

recommendation 3845 are suitable for operation of the positioner CMSX-P-S...

(rotary).

Mounting and commissioning is to be carried out only by qualified personnel,

in accordance with the documentation.

The product may only be used in its original status without unauthorized

modifications.

Only use the product if it is in perfect technical condition.

Observe the product labelling.

Use only compressed air in accordance with the specifications è Technical data.

The cable connector supplied only for cable throughfeed. To achieve the degree

of protection IP65, seal each cable entry tight (cable fitting, blanking plug).

Observe the handling specifications for electrostatically sensitive devices.

1.2 Return to Festo

Hazardous substances can endanger the health and safety of personnel and cause

damage to the environment. To prevent hazards, the product should only be re

turned upon explicit request by Festo.

Consult your regional Festo contact.

Complete the declaration of contamination and attach it to the outside of

the packaging.

Comply with all legal requirements for handling hazardous substances and

transporting dangerous goods.

2 Product overview

2.1 Function

The CMSX digital electropneumatic positioner enables simple and efficient posi

tion control based on the PID control algorithm. The position specification is

provided via an analogue setpoint signal. The current position of the actuator is

detected as follows:

– CMSX-P-S-... (rotary): through an integrated potentiometer

– CMSX-P-SE-... (linear): through an external path/angle sensor

The PID controller compares the measurement value with the analogue-specified

setpoint value and actuates the solenoid valves.

2.2 Configuration

CMSX-P-S-... (rotary)

3

45

7

8

6

6

12 3

9aJaAaB

1 Housing cover

2 Inspection window for LCD display

3 Housing screws

4 Blanking plug

5 Cable entry with cable fitting for

electrical connecting cable

6 Mounting thread for mounting

bridge

7 Shaft

8 Mechanical coupling

9 Base plate

aJ Housing

aA Pneumatic connections (G1/8)

aB Earth terminal

Fig. 1

CMSX-P-SE-...(linear)

6

12 3 4 5

789

6

3

aJ

1 Housing cover

2 Inspection window for LCD display

3 Housing screws

4 Cable entry with cable fitting for

external path/angle sensor

5 Cable entry with cable fitting

for electrical connecting cable

6 Mounting thread

7 Base plate

8 Housing

9 Pneumatic connections (G1/8)

aJ Earth terminal

Fig. 2

Operating elements and connections in the device – example: CMSXPSE...

(linear)

12

4567

8

3

1 LCD display

2 Terminal strip 1 (pin 1 … 14)

3 Terminal strip 2 (pin 1 … 3)

4 Terminal strip 3 (pin 15, 16)

5 Pushbutton Set

6 Pushbutton Sub

7 Pushbutton Add

8 Earth terminal

Fig. 3

2.3 Product variants and type code

Feature Value Description

Type CMSX Positioner for process automation

Product version P Primarily polymers

Design S Positioner, displacement/angle measurement

integrated

SE Positioner, displacement/angle measurement

external

Display type C LCD, backlit

Setpoint value U Configurable (0…10 V, 0…20 mA, 4…20 mA)

Position feedback F1 4…20 mA

Function D Double-acting

S Single-acting

Standard nominal flow rate 50 50 l/min

130 130 l/min

Safety function A Open or close in case of breakdown

1)

C Block in case of breakdown

1)

Generation G1 First generation

Second generation

1) Failure of the operating voltage supply or the setpoint specification

Fig. 4

3 Further information

– Accessories è www.festo.com/catalogue.

– Documents and literature è www.festo.com/sp.

4 Service

Contact your regional Festo contact person if you have technical questions

è www.festo.com.

5 Transport and storage

– Store the product in a cool, dry, UV-protected and corrosion-protected environ

ment. Ensure that storage times are kept to a minimum.

6 Mounting

Note

Mounting only by qualified personnel.

Note

Protect the underside of the device against splash water, moisture and humidity

by selecting an appropriate mounting position.

Pay attention to the actuator's direction of motion.

Use only mounting bridges DARQ-K-P-A1-F05-... or DADG-AK-F6-A2

è www.festo.com/sp.

6.1 CMSX-P-S-... (rotary)

4

7

6

3

2

1

5

Fig. 5

1. Determine the direction of rotation of the quarter turn actuator.

2. Close the process valve.

3. Switch off compressed air and power supply.

4. Fasten the mounting bridge 2 to the positioner:

– 4housing screws M44

– Tightening torque 1.5 Nm ±20 %

5. Fasten the mechanical coupling 5 to the shaft of the positioner 1:

– 2 threaded pins 6

– Tightening torque 0.5 Nm ±10 %

6. Place the positioner with the mounting bridge and the coupling on the quarter

turn actuator 7 and align it. The angle of rotation of the actuator must be within

the sensing range of the positioner è Fig. 6.

7. Secure the positioner with mounting bridge to the quarter turn actuator:

– 4mounting screws M53

– Tightening torque 3 Nm ±20 %

3

21

2

1 Flat spot of the shaft

2 Identification of the alignment

of the flat spot

3 Identification for sensing range

Fig. 6

The angle position of the quarter turn actuator is detected by the shaft of

the positioner.

The shaft of the positioner can be freely rotated and does not have a mechanical

stop. The permissible sensing range is 100°.

6.2 CMSX-P-SE-...(linear)

5

4

2

1

6

3

Fig. 7

1. Close the process valve.

2. Switch off compressed air and power supply.

3. Fasten the mounting bridge 1 to the positioner:

– 4 housing screws M4 3

– Tightening torque 1.5 Nm ±20 %

4. Secure the housing (flange socket) 5 to the linear actuator 6:

– 4 mounting screws M54

– Tightening torque 2.7 Nm±10 %

5. Secure the positioner with mounting bridge to the housing (flange socket):

– 4 mounting screws M62

– Tightening torque 3 Nm ±20 %

7 Installation

7.1 Pneumatic

1

2

65

34

1 Supply port (1)

2 Working port (2)

3 Working port (4)

4 QS-1/8-…-I-push-in fitting

(accessories)

5 Silencer (accessory)

6 Exhaust port (3)

Fig. 8

Recommendation: Use push-in fittings of type QS-1/8-…-I and tubes of type PUN.

1. Switch off compressed air and power supply.

2. Connect working port (2) and working port (4) to the working ports of the

pneumatic actuator.

In the case of single-acting actuators, only connect working port (4). Seal

working port (2) with a blanking plug.

– Keep the tubing short.

3. Connect the supply port (1) to the compressed air source.

4. Screw a suitable silencer into the exhaust port (3).

7.2 Electrical

Warning

Electrical voltage.

Injury due to electric shock.

Switch off power supply before opening the device.

Note

The IP65 degree of protection depends on the type of electrical connection.

Inappropriate cables or an incorrect installation will reduce the degree of protec

tion of the positioner.

1. Switch off compressed air and power supply.

2. Loosen the housing screws è Fig. 1,3. Remove the cover of the housing.

3. Guide the electric connecting cable through the cable fitting to the terminal

strips è Fig. 1,5:

– Max. length of the signal line 30 m

– Outside diameter of electric connecting cable: 7…13 mm

– Conductor cross-section: max. 1.5 mm²

– Use wire end sleeves.

4. If different reference potentials are used for the input signals and the operating

voltage supply, stabilise input signals:

– Current input signal: Set wire bridges between pin 4 and pin 6.

– Voltage input signal: Set wire bridges between pin 2 and pin 6.

5. For CMSX-SE-... (linear): Guide the connecting cable for external path/angle

sensor through the cable fitting (è Fig. 2,4) to the terminal strip 2.

– Max. length of the signal line 15 m

– Outside diameter of electric connecting cable: 3…6.5 mm

– Conductor cross-section: max. 1.5 mm²

– Do not use any wire end sleeves.

6. Wire the electrical connections è Fig. 9.

– Tightening torque: max. 0.6 Nm

7. Connect the earth terminal with low impedance (short cable with large cross

section) to the earth potential è Fig. 3, 8. Leave the cable at pin 9 unchanged.

8. Tighten the union nut of the cable fitting è Fig. 2,4,5.

– Tightening torque: 1.5Nm

9. If commissioning is carried out immediately after installation, leave the cover

dismounted.

10.Place the housing cover in position and tighten the 4 housing screws

è Fig. 2, 3.

– Observe the correct position of the seals.

– Tightening torque: 1.5Nm

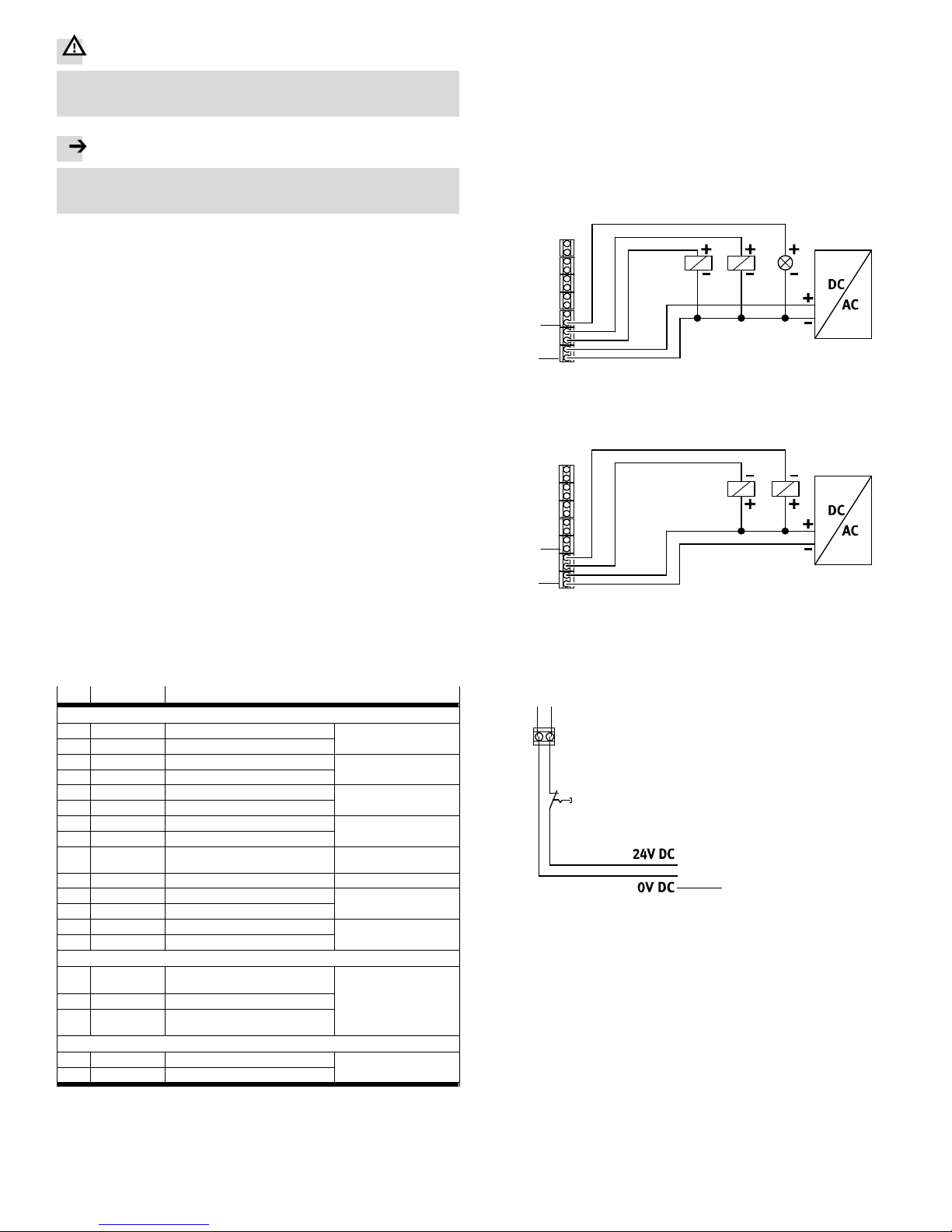

Pin allocation

Pin Designation Description

Terminal strip 1 (pin1…14)

1 Usp+ Voltage input signal + Setpoint input 0…10 V

2 Usp- Voltage input signal -

3 Isp+ Current input signal + Setpoint input

4…20 mA, 0…20 mA

4 Isp- Current input signal 5 +24 VDC Operating voltage supply; 24 VDC Supply to electronics and

valves

6 0 VDC Operating voltage supply; 0 VDC

7 I- Current output signal - Actual value output

4…20 mA

8 I+ Current output signal +

9 – Connected to the ear th terminal

at the factory

Leave the cable unchanged

10 ALARM Alarm digital output Alarm output

11 D-OUT1 Digital output Out 1 Status output

12 D-OUT2 Digital output Out 2

13 +24 VDC Load voltage supply for outputs; 24 V DC Supply to digital outputs

14 0 VDC Load voltage supply for outputs; 0 V DC

Terminal strip 2 (pin1…3)

1 0 VDC Operating voltage-

External path/angle sensor

External potentiometer

path/angle sensor with

max. 20 kΩ

2 U+ Sensor signal actual value

3 +5 VDC Operating voltage+

External path/angle sensor

Terminal strip 3 (pin 15, 16)

15 D-IN- Digital input - Digital input

1)

16 D-IN+ Digital input +

1) Permits separate circuits if separate power supply units are used

Fig. 9

Setpoint inputs è Pin1…4

The setpoint value can be specified as an external voltage or current signal.

With the SIGNAL parameter, the type of setpoint value can be selected è Fig. 14.

Actual position output è Pin 7, 8

The actual position (valve position VP) is output as a current signal and can be

processed in higher-level systems. The OPEN parameter influences the actual

position è Fig. 14.

Digital output ALARM è Pin10 and pin14

The ALARM digital output delivers high level if the maximum positioning time

is exceeded.

The maximum positioning time is determined during initialisation.

Digital outputs D-OUT1 and D-OUT2 è Pin11,12 and pin14

The digital outputs D-OUT1 and D-OUT2 can be connected as PNP or NPN outputs.

10

14

Fig. 10

To connect the digital outputs ALARM, D-OUT1 and D-OUT2 as PNP outputs, con

nect the minus pole of the load to pin 14. The PNP outputs are positive switching,

from plus to minus.

10

14

Fig. 11

To connect the digital outputs D-OUT1 and D-OUT2 as NPN outputs, connect

the plus pole of the load to pin 13. The NPN outputs are negative switching,

from minus to plus.

Digital input è Pin15,16

15 16

1

1 Reference potential

Fig. 12

8 Commissioning

Note

Commissioning should only be carried out by qualified personnel.

For detailed instructions on commissioning è www.festo.com/sp.

Prerequisites

The positioner is fully mounted and connected.

Familiarize yourself with the menu system, the functions of the pushbuttons and

the parameters of the positioner prior to commissioning.

Checking operating conditions

Check operating conditions and limit values è Technical data.

Check the connection points for tightness.

Ensure there is a stable operating voltage supply, particularly during the com

missioning phase.

Factory settings

Menu Display Description

Basic menu level

- OPERAT Auto

Automatic

ACTUAT Stopped

PID controller not active

Main menu

2 CONFIG SIGNAL 4-20mA

Current input active; 4 … 20 mA

OPEN

1)

anti-clk

Active direction of the actuator clockwise

DIRECT increase

The setpoint position is increased with a rising

setpoint value

CHARACTE linear

Linear setpoint characteristic curve

D-OUT1

D-OUT2

power-L

power-L

Low level if load voltage supply is present

for outputs

D-IN stop-H

In the case of high level, block the actuator

in position

3 PARA DEADBAND 1.0%

Deadband of the PID controller: 1.0 %

PID--P 1

P-propor tion of the PID controller: 1

PID--D 4

D-propor tion of the PID controller: 4

MIN 0%

Value for the lower stroke limit: 0 %

MAX 100%

Value for the upper stroke limit: 100 %

SPMIN 0%

Value for the lower setpoint limit or seal-closing

boundary: 0 %

SPMAX 100%

Value for the upper setpoint limit or

seal-closing boundary: 100 %

4 CURVE 0% 0.0

Support point at 0 % setpoint signal: 0 %

5% 5.0

Support point at 5 % setpoint signal: 5 %

... ...

...

100% 100

Support point at 100 % setpoint signal: 100 %

1) Only CMSX-P-S-... (rotary)

Fig. 13

8.1 Switch on positioner

1. Switch on the operating voltage supply.

2. Switch on the setpoint specification.

3. Switch on the compressed air.

è When the operating voltage supply is switched on for the first time, the fact

ory settings are effective. The positioner behaves as follows:

– Positioner is in the automatic mode

– PID controller is not active and does not react to setpoint specifications.

If the operating voltage supply is switched back on, the last operating

status is immediately effective. If the PID controller is activated, the current

setpoint value is immediately valid.

è The initial position is displayed (example).

--- 0.0%

VP: 0.0%

8.2 Initialisation

The following values are determined during initialisation:

– Permitted stroke range

– Maximum positioning time

During initialisation, movement takes place into both end positions in succession,

independently of the present setpoint value.

Perform initialisation in the following cases:

– During commissioning

– After changes in the system structure

Initialisation can be carried out manually or automatically (recommendation:

Automatically).

Menu 2 CONFIG

Display Description

MENU 2 CONFIG

SIGNAL

Signal type

0-10V Voltage input (pin 1, 2); 0 … 10 V

4-20mA

Current input (pin3,4); 4 … 20 mA (presetting)

0-20mA

Current input (pin 3, 4); 0 … 20 mA

OPEN

Active direction of the actuator - only CMSX-P-S-...(rotary)

clockwis

Clockwise

anti-clk

Anti-clockwise (presetting)

DIRECT

Direction of action of the setpoint value signal

increase

The setpoint position is increased with a rising setpoint value

(presetting)

decrease

The setpoint position is increased with a falling setpoint value

CHARACTE

Type of setpoint characteristic curve

linear

Linear setpoint characteristic curve (presetting)

1:25

Equal-percentage setpoint characteristic curve

1:33

1:50

user-def

User-defined setpoint characteristic curve

D-OUT1

D-OUT2

Function of the digital outputs D-OUT1, D-OUT2

power-H

High level if load voltage supply is present for outputs

power-L

Low level, if load voltage supply is present for outputs (preset)

limit1-H

High level, if end position 1 is reached

limit1-L

Low level, if end position 1 is reached

limit2-H

High level, if end position 2 is reached

limit2-L

Low level, if end position 2 is reached

limits-H

High level, if end position 1 or end position 2 is reached

limits-L

Low level, if end position 1 or end position 2 is reached

stop-H

High level in the operating status, PID controller not active

stop-L

Low level in the operating status, PID controller not active

D-IN

Function of the digital input

(PID controller not active)

stop-H

In the case of high level, block actuator (presetting)

stop-L

In the case of low level, block actuator in position

lmt1-H

In the case of high level, travel to stop 1

lmt1-L

In the case of low level, travel to stop 1

lmt2-H

In the case of high level, travel to stop 2

lmt2-L

In the case of low level, travel to stop 2

Fig. 14

8.3 Menu structure

3

3

333

SIGNAL

0-10V

SIGNAL

4-20 mA

SIGNAL

0-20 mA

*CONFIG*

signal

33

OPEN

anti-clk

OPEN

clockwis

*CONFIG*

open

33

DIRECT

increase

DIRECT

decrease

*CONFIG*

direct

3

D-OUT1

power-H

D-OUT1

power-L

D-OUT1

stop-L

D-OUT1

stop-H

D-OUT1

limits-L

D-OUT1

limits-H

D-OUT1

limit2-L

D-OUT1

limit2-H

D-OUT1

limit1-L

D-OUT1

limit1-H

*CONFIG*

d-out1

33

D-IN

stop-H

D-IN

stop-L

D-IN

lmt2-L

D-IN

lmt2-H

D-IN

lmt1-L

D-IN

lmt1-H

*CONFIG*

d-in

33

CHARACTE

linear

CHARACTE

1:25

CHARACTE

user-def

CHARACTE

1:50

CHARACTE

1:33

*CONFIG*

characte

33

D-OUT2

power-H

D-OUT2

power-L

D-OUT2

stop-L

D-OUT2

stop-H

D-OUT2

limits-H

D-OUT2

limits-H

D-OUT2

limit2-L

D-OUT2

limit2-H

D-OUT2

limit1-L

D-OUT2

limit1-H

*CONFIG*

D-OUT2

33

--MENU-2 CONFIG

--MENU-3 PARA

--MENU-4 CURVE

--MENU-5 INFORM

--MENU-6 INIT

36

SP:50.0%

VP:50.1%

--> 50.0%

VP:50.1%

--- 50.0%

VP:50.1%

***50.0%

VP:50.1%

•ACTUAT•

Stopped

•ACTUAT•

Running

•OPERAT•

Manual

•OPERAT•

Auto

1/2

1: +

2: 4: ++

5: --

1/2

*SENSOR*

-----+--

*SENSOR*

------+-

*SENSOR*

----+---

*SENSOR*

+-------

*SENSOR*

-+------

NEEDSTOP

FIRST!

*SENSOR*

--+-----

*SENSOR*

---+----

*SENSOR*

ERROR

*SENSOR*

-------+

--MENU-1 SENSOR

1/2 1/2 1/2

3

1/2 1/2 1/2

66

1/2 1/2 1/2

1/2

1/2

1/2

1/2

1/2

1/2

1/2

1/2

1/2 1/2

1/2

1

2

4

OPEN

anti-clk

OPEN

clockwis

*CONFIG*

open

33

3

1 Basic menu level

2 Main menu level

3 1 = Press Add

2 = Press Sub

3 = Press Set

4 = Press and hold Add for 3seconds

5 = Press and hold Sub for 3seconds

6 = Press and hold Set for 3seconds

7 = Press and hold Add and Set for 3seconds

4 Submenu only available for CMSX-P-S-... (rotary)

Fig. 15

DEADBAND

1.0%

*PARA*

deadband

33

PID--P

1

*PARA*

pid--p

33

PID--D

4

*PARA*

pid--d

3

MAX

100%

*PARA*

max

33

SPMAX

100%

*PARA*

spmax

33

MIN

0%

*PARA*

min

33

SPMIN

0%

*PARA*

spmin

33

--MENU-3 PARA

36

1/2 1/2 1/2

3

1/2 1/2 1/2

1/2

1/2 1/2 1/2 1/2 1/2 1/2 1/2

*CURDEF*

0%

3

*CURDEF*

5%

*CURDEF*

10%

*CURDEF*

90%

*CURDEF*

100%

*CURDEF*

95%

--MENU-4 CURVE

36

3

3

3

3 3

1/2

1/2

1/2

1/2

1/21/2

*INFORM*

L1 0°

*INFORM*

L2 90°

*INFORM*

V1 ...k

*INFORM*

Ver ....

*INFORM*

V2 ...k

--MENU-5 INFORM

33

1/2 1/2 1/2 1/2

1/2

AutoInit

24-1

*INITIA*

Autoinit

3

7

Fcty Rst

ok

*INITIA*

Fcty Rst

37

--MENU-6 INIT

36

1/2

1/2

1/2

Sytm Rst

ok

*INITIA*

Sytm Rst

37

SetAsDef

Saved

*INITIA*

SetAsDef

37

1/2

1/2

AutoInit

24-2

AutoInit

24-n

AutoInit

OK

*SENSOR*

ERROR

AutoInit

failed

3

UserInit

11-0

*INITIA*

Userinit

3

7

UserInit

11-1

UserInit

11-n

UserInit

ok

*SENSOR*

ERROR

UserInit

failed

3

1

*INFORM*

L1 IN

*INFORM*

L2 OUT

1/2

3

2

1 Main menu level

2 1 = Press Add

2 = Press Sub

3 = Press Set

4 = Press and hold Add for 3seconds

5 = Press and hold Sub for 3seconds

6 = Press and hold Set for 3seconds

7 = Press and hold Add and Set for 3seconds

3 Submenu only available for CMSX-P-SE-... (linear)

Fig. 16

9 Operation

Observe the operating conditions.

Observe limit values.

After the supply voltage is switched on, the positioner is in the same operating

status and the same operating mode as was valid before the supply voltage was

switched off.

10 Maintenance

With intended use, the product is maintenance-free.

Clean the outside of the product with a soft cloth and soap suds.

11 Fault clearance

Note

For detailed instructions on fault clearance è www.festo.com/sp.

12 Dismantling

Note

Dismounting only by qualified personnel.

Caution

Despite switched-off compressed air, the working ports of the positioner remain

under pressure.

Exhaust working ports before removal of the tubing lines.

12.1 CMSX-P-S-... (rotary)

1. Switch off compressed air.

2. Activate the manual setpoint position mode in the basic menu level

(OPERAT Manual).

3. Move actuator until the working ports are completely exhausted.

4. Switch off power supply.

5. Loosen the housing screws è Fig. 1,3. Remove the cover of the housing.

6. Disconnect electrical and pneumatic connection.

7. Loosen 4 mounting screws (è Fig. 5, 3 ) from the actuator and remove

the positioner with mounting bridge.

12.2 CMSX-P-SE-... (linear)

1. Switch off compressed air.

2. Activate the manual setpoint position mode in the basic menu level

(OPERAT Manual).

3. Move actuator until the working ports are completely exhausted.

4. Switch off power supply.

5. Loosen the housing screws è Fig. 2,3. Remove the cover of the housing.

6. Disconnect electrical and pneumatic connection.

7. Loosen 4 mounting screws (è Fig. 7,2 ) from the housing (flange socket)

and remove the positioner with mounting bridge.

13 Disposal

Observe the local regulations for environmentally friendly disposal.

Dispose of the product in an environmentally friendly manner.

14 Technical data

CMSX-P-...-C-U-F1-...

Sensing range [°] 0…100

Conforms to standard VDI/VDE3845 (NAMUR)

Protection against short circuit Yes

Measured variable

– CMSX-P-S Rotation angle

– CMSX-P-SE Rotation angle or stroke through external

path/angle sensor

Reverse polarity protection – For setpoint value

– For operating voltage connection

Display type Backlit LCD

Setting options Via display and keys

Type of setpoint value characteristic curves – Linear

– Equal percentage (1:25, 1:33, 1:50)

– Freely adjustable over 21 support points

Leakproof characteristics Adjustable via SPMIN and SPMAX

Control range adaptation Adjustable

Alarm for exceeding limit value None

Active direction Adjustable, rising/falling

Operating pressure [bar] 3…8

Setpoint value [mA] 4…20; 0…20

[V] 0…10

Pneumatic initial position in case of breakdown

– CSMX-...-A Regulating effect opening/closing, adjustable

through pneumatic tubing connection

– CMSX-...-C Regulating effect blocking

Operating voltage range DC [V] 21.6…26.4

Max. load resistance of current output [Ω] 500

Idle current

– CSMX-...-G1 [mA] 100…300

– CSMX-... (2. generation) [mA] 90…300

Max. current consumption [A] 1

Max. output current [mA] 500

Switching level [V] Signal 0: 5; signal 1: 10

Max. current consumption

of the digital inputs at 24 V

[mA] 6

Deadband size

– CSMX-...-G1 [%] 0.1…10

– CSMX-... (2. generation) [%] 0.5…10

Operating medium Compressed air according to ISO8573-1:2010

[7:4:4]

Note on the operating medium Lubricated operation not possible

CE marking,

(Declaration of conformity

è www.festo.com/sp)

In accordance with EU EMC Directive

Protection class - in mounted state I P65

Ambient temperature [°C] -5…60

Storage temperature [°C] -20…60

UV resistance Ye s

Vibration resistance according to DIN/IEC 60068,

part 2-6

0.15 mm path at 10 … 58Hz1);

2 g acceleration at 58…150Hz

1)

Shock resistance according to

DIN/IEC60068par t 2‐29

±15 g with 11 ms duration; 5 shocks per

direction

1)

Cable connector – M20 for device connection

– M12 for connection of external path/angle

sensor – only CMSX-P-SE-... (linear)

Type of mounting With accessories, on flange according

to ISO 5211

Max. product weight [g] 970

Pneumatic port G1/8

Standard nominal flow rate

– CMSX-...-50 [l/min.] 50

– CMSX-...-130 [l/min.] 130

Materials

– Housing PC

– Threaded coupling (coupling) High-alloy stainless steel

– Seals NBR

– Adapter plate Aluminium,

– Plate (back plate) Aluminium,

– Cable connection PA

1) Only in combination with a mounting bridge as indicated in the accessories è www.festo.com/catalogue.

Fig. 17

Loading...

Loading...