Festo CMMP-AS-C5-3A-M0, CMMP-AS-***-M0 Series, CMMP-AS-C2-3A-M0, CMMP-AS-C5-11A-P3-M0, CMMP-AS-C10-11A-P3-M0 Mounting And Installation

Motor controller

CMMP-AS-...-M0

Description

Mounting and

installation

For motor controller

CMMP-AS-...-M0

8049674

1511c

CMMP-AS-...-M0

Translation of the original instructions

GDCP-CMMP-M0-HW-EN

CANopen®, Modbus®, Heidenhain®, EnDat®, PHOENIX®, Windows® are registered trademarks of the

respective trademark owners in certain countries.

Identification of hazards and instructions on how to prevent them:

Danger

Immediate dangers which can lead to death or serious injuries

Warning

Hazards that can cause death or serious injuries

Caution

Hazards that can cause minor injuries or serious material damage

Other symbols:

Note

Material damage or loss of function

Recommendations, tips, references to other documentation

Essential or useful accessories

Information on environmentally sound usage

Text designations:

Activities that may be carried out in any order

1. Activities that should be carried out in the order stated

– General lists

è Result of an action/References to more detailed information

2 Festo – GDCP-CMMP-M0-HW-EN – 1511c –

CMMP-AS-...-M0

Table of Contents – CMMP-AS-...-M0

Instructions on this documentation 6.................................................

Target group 6...................................................................

Product identification, versions 6....................................................

Service 6.......................................................................

Specified standards/directives 6....................................................

Documentation 8................................................................

1 Safety and requirements for product use 9......................................

1.1 Safety 9..................................................................

1.1.1 Safety instructions for commissioning, repair and de-commissioning 9........

1.1.2 Protection against electric shock through protective extra-low voltage (PELV) 10.

1.1.3 Intended use 10.....................................................

1.2 Requirements for product use 11...............................................

1.2.1 Transport and storage conditions 11....................................

1.2.2 Technical requirements 11............................................

1.2.3 Qualification of the specialists (requirements for the personnel) 11............

1.2.4 Range of application and certifications 11................................

2 Product overview 13.........................................................

2.1 The entire system for the CMMP-AS-...-M0 13.....................................

2.2 Scope of delivery 14..........................................................

2.3 Device view 15..............................................................

3 Mechanical installation 19....................................................

3.1 Important notes 19..........................................................

3.2 Mounting 20................................................................

3.2.1 Motor controller 20..................................................

4 Electrical installation 23......................................................

4.1 Safety instructions 23........................................................

4.2 Allocation of the plug connectors 25.............................................

4.3 Connection: I/O communication [X1] 29..........................................

4.3.1 Plug [X1]: 29.......................................................

4.3.2 Pin assignment [X1] 29...............................................

4.3.3 Use analogue inputs as digital inputs 30.................................

4.4 Connection: Resolver [X2A] 32..................................................

4.4.1 Plug [X2A] 32.......................................................

4.4.2 Pin assignment [X2A] 32..............................................

4.5 Connection: Encoder [X2B] 33..................................................

4.5.1 Plug [X2B] 33.......................................................

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 3

CMMP-AS-...-M0

4.5.2 Pin assignment [X2B] 33..............................................

4.6 Connection: CAN bus [X4] 36...................................................

4.6.1 Plug [X4] 36........................................................

4.6.2 Pin assignment [X4] 36...............................................

4.7 Connection: Motor [X6] 37.....................................................

4.7.1 Plug [X6] 37........................................................

4.7.2 Pin assignment [X6] 37...............................................

4.8 Connection: Voltage supply [X9] 39..............................................

4.8.1 Plug 39............................................................

4.8.2 Pin assignment [X9] – single-phase 39...................................

4.8.3 Pin assignment [X9] – triple-phase 40....................................

4.8.4 Mains fuse 41......................................................

4.8.5 AC supply 41.......................................................

4.8.6 Braking resistor 43..................................................

4.9 Connection: Incremental encoder input [X10] 44...................................

4.9.1 Plug [X10] 44.......................................................

4.9.2 Pin assignment [X10] 44..............................................

4.9.3 Type and design of the cable [X10] 45...................................

4.9.4 Connection instructions [X10] 45.......................................

4.10 Connection: Incremental encoder output [X11] 45..................................

4.10.1 Plug [X11] 45.......................................................

4.10.2 Pin assignment [X11] 45..............................................

4.11 FCT interfaces 46............................................................

4.11.1 Overview of interfaces 46.............................................

4.11.2 USB [X19] 46.......................................................

4.11.3 Ethernet TCP/IP [X18] 47..............................................

4.12 Connection: I/O interface for STO [X40] 49........................................

4.12.1 Plug [X40] 49.......................................................

4.12.2 Pin assignment [X40] 49..............................................

4.12.3 Circuitry with use of the STO safety function [X40] 49.......................

4.12.4 Circuitry without use of the STO safety function [X40] 49....................

4.13 Instructions on safe and EMC-compliant installation 51..............................

4.13.1 Explanations and terms 51............................................

4.13.2 General remarks on EMC 51...........................................

4.13.3 EMC areas: First and second environment 52..............................

4.13.4 EMC-compliant wiring 53.............................................

4.13.5 Operation with long motor cables 55....................................

4.13.6 ESD protection 55...................................................

5 Commissioning 56...........................................................

5.1 General connection instructions 56..............................................

5.2 Tools / material 56...........................................................

5.3 Connecting the motor 56......................................................

4 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

CMMP-AS-...-M0

5.4 Connect motor controller CMMP-AS-...-M0 to the power supply 57.....................

5.5 Connecting a PC 57..........................................................

5.6 Check operating status 58.....................................................

6 Service functions and diagnostic messages 59....................................

6.1 Protective and service functions 59..............................................

6.1.1 Overview 59........................................................

6.1.2 Phases and mains failure detection 59...................................

6.1.3 Overload current and short-circuit monitoring 59..........................

6.1.4 Overvoltage monitoring for the intermediate circuit 59......................

6.1.5 Temperature monitoring for the heat sink 59..............................

6.1.6 Monitoring of the motor 60............................................

6.1.7 I2t monitoring 60....................................................

6.1.8 Power monitoring for the brake chopper 60...............................

6.1.9 Commissioning status 61.............................................

6.1.10 Rapid discharge of the intermediate circuit 61.............................

6.1.11 Detection of faults in conjunction with the functional safety engineering 61.....

6.2 Operating mode and diagnostic messages 61.....................................

6.2.1 Operation and display components 61...................................

6.2.2 7-segment display 62................................................

6.2.3 Acknowledgement of error messages 63.................................

6.2.4 Diagnostic messages 63..............................................

7 Maintenance, care, repair and replacement 64....................................

7.1 Maintenance and care 64......................................................

7.2 Repair 64..................................................................

7.3 Replacement and disposal 64..................................................

7.3.1 Dismounting and installation 64........................................

7.3.2 Disposal 64........................................................

A Technical appendix 65........................................................

A.1 Technical data CMMP-AS-...-M0 65..............................................

A.1.1 Interfaces 73.......................................................

A.2 Supported encoders 79.......................................................

B Diagnostic messages 81......................................................

B.1 Explanations of the diagnostic messages 81......................................

B.2 Diagnostic messages with instructions for fault clearance 82.........................

Index 121........................................................................

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 5

CMMP-AS-...-M0

Instructions on this documentation

This documentation is intended to help you safely work with the motor controller CMMP-AS-...-M0 and

describes the mounting and installation processes.

Target group

This documentation is intended exclusively for technicians trained in control and automation techno

logy, who have experience in installation, commissioning, programming and diagnostics of positioning

systems.

Product identification, versions

This description refers to the following versions:

– CMMP-AS-...-M0 from Rev 01

– FCT plug-in CMMP-AS from Version 2.3.x.

Note

Before using a newer firmware version, check whether a newer version of the FCT plugin or user documentation is available for it

Support Portal: è www.festo.com/sp

Rating plate (example) Meaning

CMMP-AS-C2-3A-M0

1622901

XX Rev XX

IND. CONT. EQ.

1UD1

In: 1* (100...230)V AC±10%

(50...60)Hz 3A

Out: 3*(0...270)V AC

(0...1000)Hz 2,5A

Max surround air temp 40°C

D-73734 Esslingen IP10/20

Type designation CMMP-AS-C2-3A-M0

Part number 1622901

Serial number XX

Revision status Rev XX

Input data 100 … 230 V AC ±10%

50 … 60 Hz 3 A

Output data

0 … 270 V AC

0 … 1000 Hz 2.5 A

Degree of protection

IP10/20

Max. ambient temperature 40 °C

Tab. 1 Rating plate example CMMP-AS-C2-3A-M0

Service

Please consult your regional Festo contact if you have any technical problems.

Specified standards/directives

Issue status

2006/42/EC EN 60204-1:2006-06/A1:2009-02

2006/95/EC EN 50178:1997-10

2004/108/EC IEC 61131-2:2007-09

EN 61800-3:2004-12 + A1:2012-3

Tab. 2 Standards/directives specified in the document

6 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

CMMP-AS-...-M0

Production time period

On the type plate, the first 2 characters of the serial number indicate the production period in encryp

ted form (è Tab. 1) The letter specifies the manufacturing year and the character behind it (number or

letter) indicates the month of production.

Manufacturing year

X = 2009 A = 2010 B = 2011 C = 2012 D = 2013 E = 2014

F = 2015 H = 2016 J = 2017 K = 2018 L = 2019 M = 2020

Tab. 3 Manufacturing year (20-year cycle)

Manufacturing month

1 January 2 February

3 March 4 April

5 May 6 June

7 July 8 August

9 September O October

N November D December

Tab. 4 Manufacturing month

Type codes

CMMP

AS C5 11 A P3

– – – – –

M0

Type

CMMP

Motor controller, premium

Motor technology

AS AC synchronous

Nominal current

C2 2.5 A

C5 5 A

C10 10 A

Input voltage

3A

11 A

100 ... 230 V AC

3x 230 ... 480 V AC

Number of phases

– 1-phase

P3 3-phase

Number of slots

M0

Without slot

Fig. 1 Type codes

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 7

CMMP-AS-...-M0

Documentation

You will find additional information on the motor controller in the following documentation:

User documentation on the motor controller CMMP-AS-...-M0

Name, type Table of contents

Hardware description,

GDCP-CMMP-M0-HW-...

Mounting and installation of the motor controller CMMPAS-...-M0 for all variants/output classes (1-phase, 3-phase), pin

assignments, error messages, maintenance.

Function descriptions,

GDCP-CMMP-M0-FW-...

Description FHPP,

GDCP-CMMP-M3/-M0-C-HP-...

Functional description (firmware) CMMP-AS-...-M0, Instructions

on commissioning.

Control and parameterisation of the motor controller via the

FHPP Festo profile.

– Motor controller CMMP-AS-...-M3 with the following field

busses: CANopen, Modbus TCP, PROFINET, PROFIBUS, Ether

Net/IP, DeviceNet, EtherCAT.

– Motor controller CMMP-AS-...-M0 with fieldbus CANopen,

Modbus TCP.

Description CiA 402 (DS 402),

GDCP-CMMP-M3/-M0-C-CO-...

Control and parameterisation of the motor controller via the

device profile CiA 402 (DS 402)

– Motor controller CMMP-AS-...-M3 with the following field

busses: CANopen and EtherCAT.

– Motor controller CMMP-AS-...-M0 with fieldbus CANopen.

Description CAM-Editor,

P.BE-CMMP-CAM-SW-...

Description of the safety function

STO, GDCP-CMMP-AS-M0-S1-...

Cam disc function (CAM) of the motor controller CMMPAS-...-M3/-M0.

Functional safety engineering for the motor controller CMMPAS-...-M0 with the integrated safety function STO.

Help for the FCT plug-in CMMP-AS User interface and functions of the CMMP-AS plug-in for the

Festo Configuration Tool è www.festo.com/sp.

Tab. 5 Documentation on the motor controller CMMP-AS-...-M0

8 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

1 Safety and requirements for product use

1 Safety and requirements for product use

1.1 Safety

1.1.1 Safety instructions for commissioning, repair and de-commissioning

Warning

Danger of electric shock.

– When cables are not mounted to the plugs [X6] and [X9].

– When connecting cables are disconnected when powered.

Touching live parts can result in severe injuries and even death.

The product may only be operated in a built-in status and when all protective measures

have been initiated.

Before touching live parts during maintenance, repair and cleaning work and when there

have been long service interruptions:

1. Switch off power to the electrical equipment via the mains switch and secure it

against being switched on again.

2. After switch-off, wait at least 5 minutes discharge time and check that power is

turned off before accessing the controller.

The safety functions do not protect against electric shock but only against dangerous

movements!

Note

Danger from unexpected movement of the motor or axis.

– Make sure that the movement does not endanger anyone.

– Perform a risk assessment in accordance with the EC machinery directive.

– Based on this risk assessment, design the safety system for the entire machine,

taking into account all integrated components. This also includes the electric drives.

– Bypassing safety equipment is impermissible.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 9

1 Safety and requirements for product use

1.1.2 Protection against electric shock through protective extra-low voltage (PELV)

Warning

Use for the electrical power supply only PELV circuits in accordance with EN 60204-1

(Protective Extra-Low Voltage, PELV).

Also take into account the general requirements for PELV circuits in accordance with

EN60204-1.

Use only power sources which guarantee reliable electrical isolation of the operating

voltage as per EN 60204-1.

Through the use of PELV circuits, protection from electric shock (protection from direct and indirect

contact) in accordance with EN 60204-1 is ensured (Electrical equipment of machines. General require

ments).

1.1.3 Intended use

The CMMP-AS-...-M0 is intended for ...

– Use in control cabinets for power supply to AC servo motors and their regulation of torques (cur

rent), rotational speed and position.

The CMMP-AS-...-M0 is intended for installation in machines or automated systems and may be used

only as follows:

– in excellent technical condition,

– in original status without unauthorised modifications,

– within the limits of the product defined by the technical data

(è Appendix A Technical appendix),

– in an industrial environment.

The product is intended for use in industrial areas. When used outside an industrial environment, e.g. in

commercial and mixed residential areas, measures for radio interference suppression may be ne

cessary.

Note

In the event of damage caused by unauthorised manipulation or other than intended

use, the guarantee is invalidated and the manufacturer is not liable for damages.

10 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

1 Safety and requirements for product use

1.2 Requirements for product use

Make this documentation available to the design engineer, installer and personnel responsible for

commissioning the machine or system in which this product is used.

Make sure that the specifications of the documentation are always complied with. Also consider the

documentation for the other components and modules.

Take into consideration the legal regulations applicable for the destination, as well as:

– regulations and standards,

– regulations of the testing organizations and insurers,

– national specifications.

1.2.1 Transport and storage conditions

Protect the product during transport and storage from impermissible burdens, such as:

– mechanical loads,

– impermissible temperatures,

– moisture,

– aggressive atmospheres.

Store and transport the product in its original packaging. The original packaging offers sufficient

protection from typical stresses.

1.2.2 Technical requirements

General conditions for the correct and safe use of the product, which must be observed at all times:

Comply with the connection and environmental conditions of the product (è Appendix A) and all

connected components specified in the technical data.

Only compliance with the limit values or load limits will enable operation of the product in compli

ance with the relevant safety regulations.

Observe the instructions and warnings in this documentation.

1.2.3 Qualification of the specialists (requirements for the personnel)

The product may only be placed in operation by a qualified electrotechnician who is familiar with:

– the installation and operation of electrical control systems,

– the applicable regulations for operating safety-engineered systems,

– the applicable regulations for accident protection and occupational safety, and

– the documentation for the product.

1.2.4 Range of application and certifications

Standards and test values, which the product complies with and fulfils, can be found in the “Technical

data” section (è Appendix A). The product-relevant EU directives can be found in the declaration of

conformity.

Certificates and declaration of conformity on this product can be found at

è www.festo.com/sp.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 11

1 Safety and requirements for product use

The current revisions and special configurations of earlier revisions (order code ...-C1) of the product

have been certified by Underwriters Laboratories Inc. (UL) for the USA and Canada. These are marked

as follows:

UL Listing Mark for Canada and the United States

Note

Observe the following if the UL requirements are to be complied with in your applica

tion:

– Rules for observing the UL certification can be found in the separate UL special

documentation. The technical data stated therein take priority.

– The technical data in this documentation may show values deviating from this.

Certain configurations of earlier revisions of the product have been certified by Underwriters Laborator

ies Inc. (UL) for the USA. These are marked as follows:

UL Listing Mark for the United States

12 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

2 Product overview

2 Product overview

2.1 The entire system for the CMMP-AS-...-M0

A motor controller CMMP-AS-...-M0 entire system is shown in è Fig. 2.1 è Page 14. For operation of

the motor controller, the following components are required:

– Mains power switch

– FI circuit breaker (RCD), all-current sensitive 300 mA

– Automatic circuit breaker

– Power supply 24 V DC

– Motor controller CMMP-AS-...-M0

– Motor with motor and encoder cables

A Windows PC with USB or Ethernet connection is required for parametrisation.

Observe the instructions regarding mains fuses in è Chapter 4.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 13

2 Product overview

1

2

3

4

5

6

7

1 Power switch

2 Fuse

3 Power pack for logic voltage

4 Optional: external braking resistor

Fig. 2.1 Complete structure CMMP-AS-...-M0 with motor and PC

5 Motor controller CMMP-AS-...-M0

6 PC

7 Motor (e.g. EMMS-AS with encoder)

2.2 Scope of delivery

The delivery includes:

Scope of delivery

Motor controller CMMP-AS-...-M0

Operator package CD

Brief description

Assortment of plugs NEKM-C-7, NEKM-C-8

Tab. 2.1 Scope of delivery

14 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

2 Product overview

2.3 Device view

aJ

9

8

7

6

5

4

3

1

2

1 Digital I/O interface for control of the STO

function [X40]

2 Activation of firmware download [S3]

3 SD-/MMC card slot [M1]

4 Activation of CANopen terminating resistor

[S2]

Fig. 2.2 Motor controller CMMP-AS-...-M0: Front view

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 15

5 CANopen interface [X4]

6 Ethernet interface [X18]

7 USB interface [X19]

8 7-segment display

9 Reset button

aJ LEDs

2 Product overview

5

4

3

1

2

1 PE connection

2 I/O communication [X1]

4 Incremental encoder output [X11]

5 Power supply [X9]

3 Incremental encoder input [X10]

Fig. 2.3 Motor controller CMMP-AS-...-3A-M0: Top view

16 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

2 Product overview

5

4

3

1

2

1 PE connection

2 I/O communication [X1]

4 Incremental encoder output [X11]

5 Power supply [X9]

3 Incremental encoder input [X10]

Fig. 2.4 Motor controller CMMP-AS-...-11A-P3-M0: Top view

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 17

2 Product overview

4

3

1

2

1 Spring-loaded terminal connection for the

outer shield of the motor cable

3 Connection for the resolver [X2A]

4 Connection for the encoder [X2B]

2 Motor connection [X6]

Fig. 2.5 Motor controller CMMP-AS-...-M0: Bottom view

18 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

3 Mechanical installation

3 Mechanical installation

3.1 Important notes

Note

Proceed carefully when mounting. During mounting and subsequent operation of the

drive, ensure that that no metal shavings, metal dust or mounting parts (screws, nuts,

pieces of wire) fall into the motor controller.

Note

The motor controllers CMMP-AS-...-M0

Use only as installed devices for control cabinet mounting.

Mounting orientation with the power supply [X9] on top.

Mount it with the clip on the mounting plate.

Installation clearances:

For sufficient ventilation of the device, a minimum clearance of 100 mm to other

sub-assemblies is required above and below the device.

An installation clearance of 150 mm underneath the device is recommended for

optimum wiring of the motor or encoder cable!

The motor controllers of the CMMP-AS-...-M0 family are designed in such a way that

they can be mounted directly on a heat-dissipating mounting plate if used as inten

ded and installed correctly. We wish to point out that excessive heating can lead to

premature aging and/or damage to the device. With high thermal stress on the mo

tor controller CMMP-AS-...-M0, a mounting distance (è Fig. 3.2) is recommended!

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 19

3 Mechanical installation

3.2 Mounting

Observe the safety instructions è Chapter 1 during mounting and installation work.

Please note

Damage to the motor controller due to incorrect handling.

Switch off the supply voltage before mounting and installation work. Switch on sup

ply voltage only when mounting and installation work are completely finished.

Observe the handling specifications for electrostatically sensitive devices. Do not touch

the printed circuit board and the pins of the manifold rail in the motor controller.

3.2.1 Motor controller

Mounting clips are located at the top and bottom of the motor controller CMMP-AS-...-M0. They are

used to attach the motor controller vertically to a mounting plate. The clips are part of the radiator

profile, ensuring an optimal heat transfer to the mounting plate.

Please use size M5 screws to attach the motor controller CMMP-AS-...-M0.

20 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

3 Mechanical installation

Fig. 3.1 Motor controller CMMP-AS-...-M0: Mounting plate

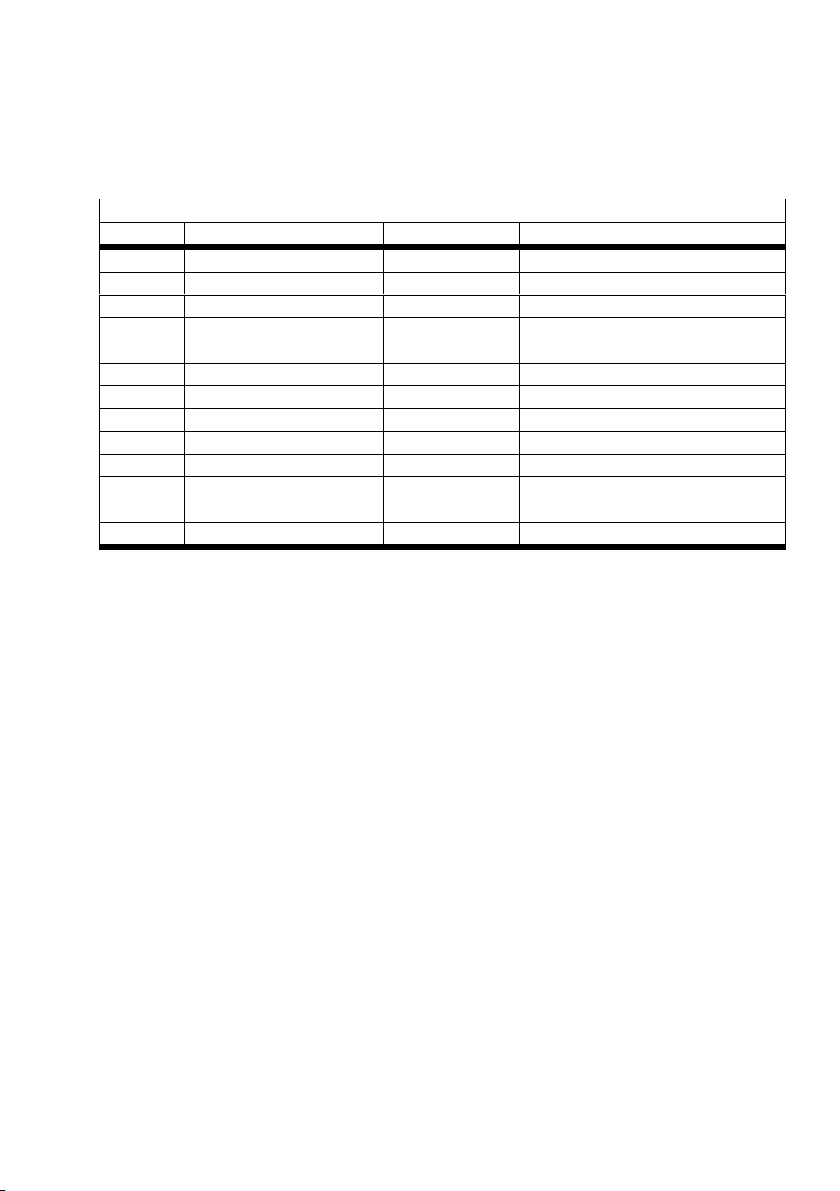

CMMP-AS-... H1 L1 L2 L3 L4 L5 L6 B1 B2 B3 D1 D2

-3A-M0 [mm] 207 248 202 281 12.5 19 10.5 66 61 30.7 10 5.5

-11A-P3-M0 [mm] 247 297 252 330 12.5 19 10.5 79 75 37.5 10 5.5

Tab. 3.1 Motor controller CMMP-AS-...-M0: Dimensions table

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 21

3 Mechanical installation

Fig. 3.2 Motor controller CMMP-AS-...-M0: Mounting distance and installation clearance

Motor controller L1 H11)

CMMP-AS-...-3A-M0 [mm] 71 100

CMMP-AS-...-11A-P3-M0 [mm] 85 100

1) An installation clearance of 150 mm underneath the device is recommended for optimum wiring of the motor or encoder cable!

Tab. 3.2 Motor controller CMMP-AS-...-M0: Mounting distance and installation clearance

22 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4 Electrical installation

4.1 Safety instructions

Warning

Danger of electric shock

Motor controllers are devices with increased leakage current ( 3.5 mA). If wiring is

incorrect or the device is defective, high voltage can occur on the housing, which can

result in serious injury or even death if the housing is touched.

Before commissioning, also for brief measuring and test purposes, connect the PE

protective conductor:

– to the earthing screw of the controller housing

– to pin PE [X9], power supply.

The cross section of the protective conductor at PE [X9] must correspond at least

to the cross section of the external conductor L [X9].

Observe the regulations of EN 60204-1 for the protective earthing.

Warning

Danger of electric shock

– when the module or cover plate is not mounted on the card slot [EXT]

– when cables are not mounted to the plugs [X6] and [X9]

– if connecting cables are disconnected when powered.

Touching live parts causes severe injuries and can lead to death. Before mounting and

installation work:

1. Switch off power to the electrical equipment via the mains switch and secure it

against being switched on again.

2. After switch-off, wait at least 5 minutes discharge time and check that power is

turned off before accessing the controller.

Warning

Danger of electric shock

This product can cause a DC current in the protective ground conductor. In cases where

an error current protection unit (RCD) or an error current monitoring device (RCM) is

used to protect against direct or indirect contact, only the Type B kind of RCD or RCM is

permitted on the power supply side of this product.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 23

4 Electrical installation

Caution

Danger from unexpected movement

Faulty pre-assembled lines may destroy the electronics and trigger unexpected move

ments of the motor.

When wiring the system, use only the supplied plug connectors and preferably the

cables listed in the catalogue as accessories.

è www.festo.com/catalogue

Lay all flexible lines so that they are free of kinks and free of mechanical stress; if

necessary use chain link trunking.

Note

ESD (electrostatic discharge) can cause damage to the device or other system parts at

plug connectors that are not used.

Before installation: Earth the system parts and use appropriate ESD equipment (e.g.

shoes, earthing straps etc.).

After installation: Seal unassigned Sub-D plug connectors with protective caps

(available at authorized dealers).

Observe the handling specifications for electrostatically sensitive devices.

24 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.2 Allocation of the plug connectors

The motor controller CMMP-AS-...-M0 is connected to the supply voltage, the motor, the external brak

ing resistor and the holding brake in accordance with the following circuit diagrams.

min. 100 V AC -10 %

max. 230 V AC +10 %

L

N

Braking resistor

alternative

PE

+24 V

0 V

Power circuit

breakers

external

internal

24 V DC supply

Single-phase

X9

L

N

ZK+

ZKBR-INT

BR-CH

PE

24V+

GND24V

Connection for the outer

screening of the motor cable

X6

T

M

3~

U

V

W

PE

MT+

MTPE

BR+

Encoder/resolver

Br-

X2A/X2B

E

Angle encoder

Encoder

/Resolver

Fig. 4.1 CMMP-AS-...-3A-M0: Single-phase connection to the supply voltage and the motor

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 25

4 Electrical installation

Note

The maximum voltage of 230 V AC +10 % must be present between the external con

ductors è Fig. 4.2.

In typical European low voltage networks that have a nominal star voltage of 230 V, a

mesh voltage of approx. 400 V develops between two external conductors, which could

result in damage to the motor controller!

min. 100 V AC -10%

max. 230 V AC +10%

L1

L2

Braking resistor

alternative

PE

+24 V

0 V

Connection for the outer

screening of the motor cable

T

M

3~

external

Power circuit

breakers

internal

24 V DC supply

2-phase

X9

L

N

ZK+

ZKBR-INT

BR-CH

PE

24V+

GND24V

X6

U

V

W

PE

MT+

MTPE

BR+

Br-

X2A/X2B

E

Angle encoder

Encoder/

Resolver

Fig. 4.2 CMMP-AS-...-3A-M0: Dual-phase connection L1/L2 to the supply voltage and the motor

26 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

min. 230 V AC -10%

max. 480 V AC +10%

L1

L2

L3

PE

Braking resistor

alternative

+24 V

0 V

Connection for the outer

screening of the motor cable

T

M

3~

Power circuit

breakers

external

internal

24 V DC supply

3-phase

X9

L1

L2

L3

ZK+

ZKBR-EXT

BR-CH

BR-INT

PE

24V+

GND24V

X6

U

V

W

PE

MT+

MTPE

BR+

Br-

X2A/X2B

E

Angle encoder

Encoder/

Resolver

Fig. 4.3 CMMP-AS-...-11A-M0: Triple-phase connection to the supply voltage and the motor

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 27

4 Electrical installation

The power supply cables for the power end stage are alternatively connected to the following terminals:

Power end stage supply

Observe instructions in chapter è 4.8.5

AC supply L, N for single-phase motor controllers

L1, L2, L3 for three-phase motor controllers

DC supply ZK+, ZK–

Tab. 4.1 Connection of power supply cables

Motor temperature switch

PTC or N/C contact/

N/O contact1)

MT+, MT–;

[X6]

if this is carried together with the motor phases in

one cable

(e.g. KTY81)

Analogue

temperature sensor

1) EMMS-AS motors have a PTC

1)

MT+, MT–;

[X2A] or [X2B]

Tab. 4.2 Connection of the motor temperature switch

Note

Temperature sensors must be sufficiently isolated from the motor winding.

The connection of the encoder/resolver via the Sub-D plug connector to [X2A] or [X2B] is roughly shown

diagrammatically in è Fig. 4.1,

è Fig. 4.2 and è Fig. 4.3.

Note

If the polarity of the operating voltage connections is reversed, or if the operating

voltage is too high or the operating voltage and motor connections are reversed, the

motor controller CMMP-AS-...-M0 will be damaged.

28 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.3 Connection: I/O communication [X1]

4.3.1 Plug [X1]:

Motor controller Design on the device Counterplug

CMMP-AS-...-M0 Sub-D plug connector, 25-pin, socket Sub-D plug connector, 25-pin, pins

Tab. 4.3 Plug design [X1]

4.3.2 Pin assignment [X1]

See Technical data è section A.1.1 for connected loads of the inputs and outputs.

In the firmware factory setting (delivery status) the control interface for CANopen is parameterised (bus

settings via DIL switch) to enable a device to be replaced without FCT è Tab. 4.4.

[X1] Pin no. Desig

nation

13 DOUT3 Output freely parameterisable, optionally parameterisable as DIN11

25 DOUT2 Output freely parameterisable, optionally parameterisable as DIN10

12 DOUT1 Output freely parameterisable

24 DOUT0 Controller ready, output permanently assigned

11 DIN 9 Fieldbus data profile (CiA 402, FHPP), input freely parameterisable

23 DIN 8 Fieldbus activation communication, input freely parameterisable

10 DIN7 Limit switch 1 (blocks n 0), input permanently assigned

22 DIN6 Limit switch 0 (blocks n 0), input permanently assigned

9 DIN5 Controller enable, input permanently assigned

21 DIN4 End stage enable, input permanently assigned

8 DIN 3 Fieldbus offset node number bit 3, input freely parameterisable

20 DIN 2 Fieldbus offset node number bit 2, input freely parameterisable

7 DIN 1 Fieldbus offset node number bit 1, input freely parameterisable

19 DIN 0 Fieldbus offset node number bit 0, input freely parameterisable

6 GND24 Reference potential for digital I/Os

18 +24 V 24 V output

5 AOUT1 Analogue output freely parameterisable

17 AOUT0 Analogue output freely parameterisable

4 +VREF Reference output for setpoint potentiometer

16 DIN13 Fieldbus transmission rate bit 1, optionally parameterisable as AIN2

3 DIN12 Fieldbus transmission rate bit 0, optionally parameterisable as AIN1

15 #AIN0 Setpoint input 0, differential analogue input

2 AIN0

14 AGND Reference potential for analogue signals

1 AGND Screening for analogue signals, AGND

1) Configuration with FCT. Observe not è Abschnitt 4.3.3.

Tab. 4.4 Pin assignment: I/O communication [X1] (firmware factory setting)

Specification

1)

1)

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 29

4 Electrical installation

The standard assignment of the I/O interface in the FCT corresponds to è Tab. 4.5.

[X1]

Pin no. Desig

Specification

nation

13 DOUT3 Following error, output freely parameterisable, optionally paramet

erisable as DIN11

25 DOUT2 Brake unlocked, output freely parameterisable, optionally paramet

erisable as DIN10

12 DOUT1 Motion Complete, Output freely parameterisable

24 DOUT0 Controller ready, output permanently assigned

11 DIN 9 Flying measurement (sample)/reference switch, input freely para

meterisable

23 DIN 8 Start positioning task, input freely parameterisable

10 DIN7 Limit switch 1 (blocks n 0), input permanently assigned

22 DIN6 Limit switch 0 (blocks n 0), input permanently assigned

9 DIN5 Controller enable, input permanently assigned

21 DIN4 End stage enable, input permanently assigned

8 DIN 3 Position selector bit 3, input freely parameterisable

20 DIN 2 Position selector bit 2, input freely parameterisable

7 DIN 1 Position selector bit 1, input freely parameterisable

19 DIN 0 Position selector bit 0, input freely parameterisable

6 GND24 Reference potential for digital I/Os

18 +24 V 24 V output

5 AOUT1 Position setpoint value, analogue output freely parameterisable

17 AOUT0 Speed setpoint value, analogue output freely parameterisable

4 +VREF Reference output for setpoint potentiometer

16 AIN13 Setpoint input 2, single ended analogue input, optionally paramet

erisable as DIN13

1)

3 AIN12 Setpoint input 1, single ended analogue input, optionally paramet

erisable as DIN12

1)

15 #AIN0 Setpoint input 0, differential analogue input

2 AIN0

14 AGND Reference potential for analogue signals

1 AGND Screening for analogue signals, AGND

1) Configuration with FCT. Observe not è Section 4.3.3.

Tab. 4.5 Pin assignment: I/O communication [X1] (FCT factory setting)

4.3.3 Use analogue inputs as digital inputs

If the digital inputs AIN1 and ANI2 are used as digital inputs, then a ground reference from AGND to

GND24 at plug X1 pins 14 and 6 must be established.

Note

Connecting AGND to GND24 renders the electronics overvoltage protection inoperable.

30 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

Controller CMMP-AS-…-M0

AIN0

#AIN0

Pin no.

x1

AIN0

#AIN0

AIN1

AIN2

+VREF

15

16

2

AIN1/AIN2

3

4

+VREF

AGND

AGND

+15 V DC

AGND

AOUT0

AOUT1

AGND

100 mA

max!

+24 V DC

DIN 0

DIN9

DOUT0

14

17

5

14

1

AGND

18

19

11

24

100 mA

max!

DOUT3

GND24

13

6

PE PE

Plug housing

Fig. 4.4 Basic circuit diagram of connection [X1]

AMON0/1

+24 V DC

GND24

AGND

AGND

AGNDGND

DINX

GND24

GND

+24 V DC

DOUTX

GND

GND24

Control cable and Sub-D plug connector è www.festo.com/catalogue.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 31

4 Electrical installation

4.4 Connection: Resolver [X2A]

4.4.1 Plug [X2A]

Motor controller Design on the device Counterplug

CMMP-AS-...-M0 Sub-D plug connector, 9-pin, socket Sub-D plug connector, 9-pin, pins

Tab. 4.6 Plug design [X2A]

4.4.2 Pin assignment [X2A]

[X2A] Pin no. Designation Value Specification

1 S2 3.5 V

6 S4

2 S1 3.5 V

7 S3

3 AGND 0 V Screening for signal pairs

8 MT- GND Reference potential for

4 R1 7 V

9 R2 GND

5 MT+ +3.3 V R

Tab. 4.7 Pin assignment [X2A]

5-10 kHz

eff

Ri 5 kΩ

5-10 kHz

eff

R

5 kΩ

i

5-10 kHz

eff

IA 150 mA

= 2 kΩ Temperature sensor, motor

i

SINE tracking signal,

differential

COSINE tracking signal,

differential

(inner screening)

temperature sensor

Carrier signal for resolver

eff

temperature, N/C contact, PTC,

KTY ...

The outer screening must always be connected to the PE (plug housing) of the motor controller.

The inner screenings must be placed on one side on the motor controller CMMP-AS-...-M0 on PIN3 of

[X2A].

32 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.5 Connection: Encoder [X2B]

4.5.1 Plug [X2B]

Motor controller Design on the device Counterplug

CMMP-AS-...-M0 Sub-D plug connector, 15-pin, socketSub-D plug connector, 15-pin, pins

Tab. 4.8 Plug design [X2B]

4.5.2 Pin assignment [X2B]

[X2B] Pin no. Designation Value Specification

1 MT+ +3.3 V R

9 U_SENS+ 5 V … 12 V

2 U_SENS-

RI L 1 kΩ

10 US 5 V/12 V ±10%

I

3 GND 0V Reference potential for en

11 R 0.2 VSS … 0.8 V

4 R#

RI L 120 Ω

12 COS_Z1 1) 1 V

5 COS_Z1# 1)

13 SIN_Z1

1)

6 SIN_Z1# 1)

RI L 120 Ω

1 V

RI L 120 Ω

14 COS_Z0 1) 1 VSS ±10%

7 COS_Z0# 1)

15 SIN_Z0

1)

8 SIN_Z0# 1)

1) Heidenhain encoder: A=SIN_Z0; B=COS_Z0, C=SIN_Z1; D=COS_Z1

RI L 120 Ω

1 VSS ±10%

RI L 120 Ω

Tab. 4.9 Pin assignment: Analogue incremental encoder – optional

= 2 kΩ Temperature sensor, motor

i

temperature, N/C contact, PTC,

KTY ...

Sensor cable for the encoder

supply

Operating voltage for high-res

= 300 mA

max

olution incremental encoder

coder supply and motor tem

perature sensor

Zero impulse tracking signal

SS

(differential) from high-resolu

tion incremental encoder

SS

COSINE commutation signal

(differential) from high-resolu

tion increment generator

SS

SINE commutation signal

(differential) from high-resolu

tion incremental encoder

COSINE tracking signal

(differential) from high-resolu

tion incremental encoder

SINE tracking signal

(differential) from high-resolu

tion incremental encoder

The outer screening must always be connected to the PE (plug housing) of the motor controller.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 33

4 Electrical installation

[X2B] Pin no. Designation Value Specification

1 MT+ +3.3 V R

= 2 kΩ Temperature sensor, motor

i

temperature, N/C contact, PTC,

KTY ...

9 U_SENS+ 5 V … 12 V

2 U_SENS-

RI L 1 kΩ

10 US 5 V/12 V ±10%

I

max

= 300 mA

Sensor cable for the encoder

supply

Operating voltage for high-res

olution incremental encoder

3 GND 0V Reference potential for en

coder supply and motor tem

perature sensor

11 –

4 –

12 DATA 5 V

5 DATA#

13 SCLK 5 V

6 SCLK#

14 COS_Z0 1) 1 VSS ±10%

7 COS_Z0 1)#

15 SIN_Z0

8 SIN_Z0 1)#

1) Heidenhain encoder: A=SIN_Z0; B=COS_Z0

SS

RI L 120 Ω

SS

RI L 120 Ω

RI L 120 Ω

1)

1 VSS ±10%

RI L 120 Ω

Bidirectional RS485 data cable

(differential)

RS485 clock output

(differential)

COSINE tracking signal

(differential) from high-resolu

tion incremental encoder

SINE tracking signal

(differential) from high-resolu

tion incremental encoder

Tab. 4.10 Pin assignment: Incremental encoder with serial interface, e.g. EnDat – optional

The outer screening must always be connected to the PE (plug housing) of the motor controller.

34 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

[X2B] Pin no. Designation Value Specification

1 MT+ +3.3 V R

= 2 kΩ Temperature sensor, motor

i

temperature, N/C contact, PTC,

KTY ...

9 U_SENS+ 5 V … 12 V

2 U_SENS-

RI L 1 kΩ

10 US 5 V/12 V / ±10%

I

max

= 300 mA

Sensor cable for the encoder

supply

Operating voltage for highresolution incremental encoder

3 GND 0V Reference potential for

encoder supply and motor

temperature sensor

11 N 2 VSS … 5 V

4 N#

RI L 120 Ω

SS

12 H_U 0V/5V

L 2 kΩ

R

I

5 H_V Phase V Hall sensor for

at VCC

Zero impulse RS422

(differential) from digital incre

ment generator

Phase U Hall sensor for

commutation

commutation

13 H_W Phase W Hall sensor for

commutation

6 –

14 A 2 VSS … 5 V

7 A#

15 B 2 VSS … 5 V

8 B#

RI L 120 Ω

SS

SS

RI L 120 Ω

A tracking signal RS422

(differential) from digital incre

mental encoder

B tracking signal RS422

(differential) from digital incre

mental encoder

Tab. 4.11 Pin assignment: Digital incremental encoder – optional

The outer screening must always be connected to the PE (plug housing) of the motor controller.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 35

4 Electrical installation

4.6 Connection: CAN bus [X4]

4.6.1 Plug [X4]

Motor controller Design on the device Counterplug

CMMP-AS-...-M0 Sub-D plug connector, 9-pin, pin Sub-D plug connector, 9-pin, socket

Tab. 4.12 Plug design [X4]

4.6.2 Pin assignment [X4]

[X4] Pin no. Designation Value Description

1 – – Not assigned

6 CAN-GND – Galvanically connected to GND in the

motor controller

2 CAN-L – Negative CAN signal (dominant low)

7 CAN-H – Positive CAN signal (dominant high)

3 CAN-GND – Galvanically connected to GND in the

8 – – Not assigned

4 – – Not assigned

9 – – Not assigned

5 CAN shield – Screening

Tab. 4.13 Pin assignment for CAN-interface [X4]

motor controller

36 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.7 Connection: Motor [X6]

4.7.1 Plug [X6]

CMMP-AS-... Design on the device / coding Counterplug / coding

...-C2-3A-M0 PHOENIX Contact

...-C5-3A-M0

MSTBA 2.5/9-G-5.08 BK

...-11A-P3-M0 PHOENIX Power-Combicon

...-C10-11A-P3-M0

PC 5/9-G-7.62 BK

Tab. 4.14 Plug design [X6]

4.7.2 Pin assignment [X6]

[X6]1) Pin no. Designation Value Specification

1 Br- 0 V brake Holding brake (motor), signal

1

2 BR+ 24 V brake

3 PE PE Cable shield for the holding

4 -MTdig GND Motor temperature sensor,

5 +MTdig +3.3 V 5 mA

6 PE PE Protective earth conductor

7 W Technical data

9

8 V

9 U

1) Representation of the plug on the device of the motor controller CMMP-AS-...-3A-M0

Tab. 4.15 Pin assignment [X6] connection: Motor

Pin 1 (BR-) PHOENIX Contact

MSTB 2.5/9-ST-5.08 BK

– PHOENIX Power-Combicon

PC 5/9-ST-7.62 BK

level dependent on switching

status, high-side/low-side

switch

brake and the temperature

sensor (with Festo cables: n.c.)

N/C contact, N/O contact, PTC,

KTY ...

from the motor

Connection of the three motor

è Tab. A.9

phases

Pin 9 (U)

–

The shielding for the motor cable must also be attached to the housing of the motor con

troller (spring clip: Fig. 2.5 è Page 18).

A motor holding brake can be connected to terminals BR+ and BR-. The locking brake is supplied from

the logic supply of the motor controller. The maximum output current provided by the CMMP-AS-...-M0

motor controller must be observed.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 37

4 Electrical installation

To release the holding brake, care must be taken to maintain the voltage tolerances at the

holding brake connection terminals.

Also observe the specifications in Tab. A.4 è Page 66.

It may be necessary to insert a relay between the device and the holding brake, as shown in

Fig. 4.5è Page 38:

BR+

Br-

CMMP-AS-...-M0

Resistor and

Capacitor for

+24V power pack

Spark arresting

GND power pack

+24V brake

Free-wheeling diode

GND brake

Motor

Fig. 4.5 Connecting a high-current holding brake to the device

High voltages with spark formation are created when inductive direct currents are con

nected via relays. For interference suppression, we recommend integrated RC interfer

ence suppressors, e.g. from Evox RIFA, designation: PMR205AC6470M022 (RC element

with 22 Ω in series with 0.47 μF).

38 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.8 Connection: Voltage supply [X9]

The motor controller CMMP-AS-...-M0 receives its 24 V DC power supply for the control electronics via

the plug connector [X9].

The main power supply for the motor controllers CMMP-AS-…-3A-M0 is 1-phase and for the motor con

trollers CMMP-AS-…-11A-P3-M0 3-phase.

4.8.1 Plug

CMMP-AS-... Design on the device / coding Counterplug / coding

...-C2-3A-M0 PHOENIX Contact

...-C5-3A-M0

MSTBA 2.5/9-G-5.08-BK

...-C5-11A-P3-M0 PHOENIX Power-COMBICON

...-C10-11A-P3-M0

PC 5/11-G-7.62-BK

Tab. 4.16 Plug design [X9]

4.8.2 Pin assignment [X9] – single-phase

[X9]1) Pin no. Designation Value Specification

1 L 100 … 230 V AC

2 N Mains neutral conductor (refer

3 ZK+ 60 … 380 V DC Alternative supply:

1

4 ZK- GND_ZK Alternative supply:

5 BR-INT 460 V DC Internal braking resistor connec

6 BR-CH 460 V DC Brake chopper connection for

9

7 PE PE Connection for protective

8 +24 V +24 V DC ±20% Supply for control section, holding

9 GND24 V GND24 V DC Reference potential for supply 0V

1) Representation of the contact strip on the motor controller CMMP-AS-...-3A-M0

Tab. 4.17 Pin assignment [X9] – single-phase

Pin 9

(GND24V)

PHOENIX Contact

MSTB 2.5/9-ST-5.08-BK

– PHOENIX Power-COMBICON

PC 5/11-ST-7.62-BK

Mains phase

±10%

50 … 60 Hz

ence potential)

Positive intermediate circuit

voltage

Negative intermediate circuit

voltage

tion (bridge after BR-CH when

using the internal resistor).

– internal braking resistor to

ward BR-INT – or –

– external braking resistor

against ZK+

conductor from the mains

brake and I/O

Pin 1

(L)

–

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 39

4 Electrical installation

4.8.3 Pin assignment [X9] – triple-phase

[X9]1)

Pin no. Designation Value Specification

1 L1 230 … 480 V AC

2 L2 Mains phase 2

3 L3 Mains phase 3

1

4 ZK+ … 700 V DC Alternative supply: Positive in

±10%

50 … 60 Hz

5 ZK- GND_ZK Alternative supply: Negative in

6 BR-EXT 800 V DC Connection of the external

7 BR-CH 800 V DC Brake chopper connection for

8 BR-INT 800 V DC Internal braking resistor connec

9 PE PE Connection for protective con

10 +24V +24 V DC ±20 % Supply for control section,

11

11 GND24 V GND24 V DC Reference potential for supply

1) Representation of the contact strip on the motor controller CMMP-AS-...-11A-P3-M0

Tab. 4.18 Pin assignment [X9] – triple-phase

Mains phase 1

termediate circuit voltage

termediate circuit voltage

braking resistor

– internal braking resistor

against BR-INT – or –

– external braking resistor

against BR-EXT

tion (bridge after BR-CH with use

of the internal resistor)

ductor from the mains

holding brake and I/O

Note

The DC power supply must be generated from a max. 230/400 V or a max. 277/480 V

grid.

40 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.8.4 Mains fuse

In the mains power supply cable, an automatic circuit breaker is installed for protection of the line:

Motor controller

Phases Mains fuse

1)

CMMP-AS-C2-3A-M0 1 B10

CMMP-AS-C5-3A-M0 1 B16

CMMP-AS-C5-11A-P3-M0 3 B16

CMMP-AS-C10-11A-P3-M0 3 B16

1) The required fuse is dependent, among other things, on the cable cross section, ambient temperature and laying procedure.

Observe the following instructions!

Tab. 4.19 Required mains fuses

In designing the fuses, also observe the following standards:

EN 60204-1 “Safety of machinery – Electrical equipment of machines – Part 1:

General requirements”

Take into consideration the legal regulations applicable for the destination as well as:

– Regulations and standards,

– Regulations of the testing organisations and insurers,

– national specifications.

4.8.5 AC supply

Switch-on behaviour:

– As soon as the motor controller CMMP-AS-...-M0 is provided with mains voltage, the intermediate

circuit is charged ( 1 s) via the braking resistors, with the intermediate circuit relay deactivated.

– After the intermediate circuit has been pre-charged, the relay engages and the intermediate circuit

without resistors is connected directly to the mains supply.

AC supply with active PFC

The PFC step is available only for 1-phase motor controllers (CMMP-AS-...-3A-M0).

Note

Operation with mains line choke is not permissible, since the control circuit could be

stimulated to oscillate.

Note

Operation with isolating transformer is not permissible as no reference potential (N) is

available.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 41

4 Electrical installation

Note

When the load voltage is switched on, ensure that the reference potential (N) is

switched before the phase (L1). This can be achieved through:

– unswitched reference potential (N)

– use of fuses with leading N when switching of the reference potential is specified.

DC supply - intermediate circuit coupling

A direct DC power supply can be used for the intermediate circuit as an alternative to AC power or for

achieving intermediate circuit coupling.

The intermediate circuits of several identically constructed motor controllers (CMMP-AS-...-3A-M0/-M3

or CMMP-AS-...-11A-P3-M0/-M3) can be connected via the terminals ZK+ and ZK- at plug connector

[X9]. Coupling of the intermediate circuits is useful in applications where high braking energies occur or

where motion must still be performed when the power supply fails.

Note

For 1-phase motor controllers (CMMP-AS-...-3A-M0), the PFC step must be deactivated

when the motor controller is coupled through the intermediate circuit.

Note

If the intermediate circuits are coupled, it is imperative that all of the motor controllers

are supplied via the same phase (e.g. L1) è Example Fig. 4.6.

Otherwise, the motor controllers will be damaged due to the resulting voltage at the

rectifiers.

The maximum number of coupled motor controllers is limited by the power of the sup

ply. Pay attention to a symmetrical load of the network here.

42 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

L

N

PE

+24 V

0 V

Power circuit

breakers

Single-phase

X9

Power circuit

breakers

L

N

ZK+

ZK

-

BR-INT

BR-CH

PE

24V+

GND24V

Fig. 4.6 Example of intermediate circuit coupling with common supply, single-phase

Fig. 4.6 is a schematic representation; note the information for mains fuses in

è Section 4.8.4.

4.8.6 Braking resistor

If no external braking resistor is used, a bridge to the internal braking resistor must be

connected in order for the intermediate circuit quick discharge to function! è Tab. 4.17 or

Tab. 4.18.

For larger braking power an external braking resistor must be connected [X9]

è Section 4.7.2 and Fig. 4.5.

Single-phase

X9

L

N

ZK+

ZK

-

BR-INT

BR-CH

PE

24V+

GND24V

The motor controller detects the external brake resistance automatically as soon as the intermediate

circuit voltage rises above the response threshold (è A.1, Tab. A.6).

After that, a connected external brake resistance can also be displayed in the configuration software.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 43

4 Electrical installation

4.9 Connection: Incremental encoder input [X10]

4.9.1 Plug [X10]

Motor controller Design on the device Counterplug

CMMP-AS-...-M0 Sub-D plug connector, 9-pin, socket Sub-D plug connector, 9-pin, pins

Tab. 4.20 Plug design [X10]

4.9.2 Pin assignment [X10]

[X10] Pin no. Designation Value Specification

1 A/CLK/CW 5 V RI L 120 Ω Incremental encoder signal A

Stepper motor signal CLK

Pulses clockwise CW

pos. polarity in accordance with

RS422

6 A#/CLK#/CW# 5 V RI L 120 Ω Incremental encoder signal A

Step motor signal CLK

Pulses clockwise CW

neg. polarity in accordance with

RS422

2 B/DIR/CCW 5 V RI L 120 Ω Incremental encoder signal B

Step motor signal DIR

Pulses counterclockwise CCW

pos. polarity in accordance with

RS422

7 B#/DIR#/CCW# 5 V RI L 120 Ω Incremental encoder signal B

Step motor signal DIR

Pulses counterclockwise CCW

neg. polarity in accordance with

RS422

3 N 5 V RI L 120 Ω Incremental encoder zero pulse N

pos. polarity in accordance with

RS422

8 N# 5 V RI L 120 Ω Incremental encoder zero pulse N

neg. polarity in accordance with

RS422

4 GND – Reference GND for encoder

9 GND – Screening for the connecting cable

5 VCC +5 V ±5%

100 mA

Tab. 4.21 Pin assignment X10: Incremental encoder input

Auxiliary supply, maximum load

100 mA, short-circuit proof!

When connecting two motor controllers in the master-slave mode via [X11] and [X10], the

pins 5 (+5 V - auxiliary supply) must not be connected to each other.

44 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.9.3 Type and design of the cable [X10]

We recommend use of the encoder connection lines in which the incremental encoder signal is twisted

by pairs and the individual pairs are screened.

4.9.4 Connection instructions [X10]

Input [X10] can be used for processing incremental encoder signals and also for pulse direction signals

as generated by stepper motor controller cards.

The input amplifier at the signal input is designed for processing differential signals as per the RS422

interface standard.

4.10 Connection: Incremental encoder output [X11]

4.10.1 Plug [X11]

Motor controller Design on the device Counterplug

CMMP-AS-...-M0 Sub-D plug connector, 9-pin, socket Sub-D plug connector, 9-pin, pins

Tab. 4.22 Plug design [X11]

4.10.2 Pin assignment [X11]

[X11] Pin no. Designation Value Specification

1 A 5 V RA L 66 Ω1) Incremental encoder signal A

6 A# 5 V RA L 66 Ω1) Incremental encoder signal A#

2 B 5 V RA L 66 Ω1) Incremental encoder signal B

7 B# 5 V RA L 66 Ω1) Incremental encoder signal B#

3 N 5 V RA L 66 Ω1) Incremental encoder zero

pulse N

8 N# 5 V RA L 66 Ω1) Incremental encoder zero

pulse N#

4 GND - Reference GND for encoder

9 GND - Screening for connecting

cable

5 VCC +5 V ±5% 100 mA Auxiliary supply, maximum

load 100 mA, short-circuit

proof!

1) The specification for RA designates the differential output resistance

Tab. 4.23 Pin assignment [X11]: Incremental encoder output

The output driver at the signal output provides differential signals (5 V) as per the RS422 interface standard.

Up to 32 other controllers can be addressed by one device.

When connecting two motor controllers in the master-slave mode via [X11] and [X10], the

pins 5 (+5 V - auxiliary supply) must not be connected to each other.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 45

4 Electrical installation

4.11 FCT interfaces

4.11.1 Overview of interfaces

1

2

1 [X19]: USB 2 [X18]: Ethernet

Fig. 4.7 FCT interfaces

4.11.2 USB [X19]

The equipment of the series CMMP-AS-...-M0 have a USB interface for parametrisation. The USB inter

face is used as a configuration interface for the FCT configuration.

The following functions are supported:

– Complete parametrisation of theCMMP-AS-...-M0 via FCT

– Firmware download via FCT

Interface design

The plug connector is designed as a Type B terminal socket. All standard terminal cables up to a length

of 5m can be used. If longer cables are required, the corresponding USB repeaters must be used.

The USB interface is designed as a pure slave interface (the CMMP-AS…-M0 is the slave, the PC is the

host). It meets the USB specification Rev. USB 1.1.

USB driver for the PC

The USB driver package is a component of the FCT installation.

The following operating systems are supported through this:

– Windows XP from Service Pack 2

– Windows Vista

– Windows 7

46 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.11.3 Ethernet TCP/IP [X18]

The equipment of the series CMMP-AS-...-M0 have a USB interface for parametrisation.

The following functions are supported:

– Point-to-point communication between PC and motor controller for parametrisation

– Complete parametrisation of theCMMP-AS-...-M0 via FCT

– Communication from one PC or one PLC to several CMMP-AS-...-M0 that are located in the same

local network for the purpose of monitoring, adaptation of the parametrisation or also process con

trol of the controller via Modbus TCP.

Note

Unauthorised access to the device can cause damage or malfunctions.

When connecting the device to a network:

Protect the network from unauthorised access.

Measures for protecting the network include:

– Firewall

– Intrusion Prevention System (IPS)

– Network segmentation

– Virtual LAN (VLAN)

– Virtual private network (VPN)

– Security at physical access level (Port Security).

For further information è Guidelines and standards for security in information techno

logy, e.g. IEC 62443, ISO/IEC 27001.

Interface design

The interface in the device is designed as an 8P8C socket (RJ45).

The connection has two LEDs with the following function:

– Yellow Physical Link Detect (network connection available)

– Green Data Connection (data connection / data exchange)

The interface is designed to conform to the IEEE 802.3u specification. Cables of type FTP5 or high-order

must be used with 100Base-TX. The interface supports the autosensing function for automatic identi

fication of the connected cable. Both standard patch cables (1:1) and Crosslink (crossed) cables can be

used.

Supported services

The following services are supported by the Ethernet interface:

– TCP/IP

– UDP/IP

– DNS (ARP and BOOTP)

– DHCP

– AutoIP

–TFTP

TFTP must be activated separately in Windows if necessary and a pass rule defined in the

Firewall.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 47

4 Electrical installation

Address allocation

The network settings (IP address, subnetwork mask, gateway) can either be automatically obtained or

manually specified:

– Automatically via DHCP (the automatically obtained IP address lies in the IP range specified by the

DHCP server)

– Automatically via Auto IP (if no DHCP server was found, an address between 169.254.1.0 and

169.254.254.255 is selected pseudorandomly)

– Manual IP assignment (manual setting of the network parameters via FCT)

The following sequence applies for connection set-up:

1. DHCP

2. AutoIP

3. Static IP address

If no IP address can be obtained via the higher-level service, the following service is used. Thus if no

address can be obtained via DHCP, first an AutoIP and then a static address is used.

48 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.12 Connection: I/O interface for STO [X40]

4.12.1 Plug [X40]

Motor controller Design on the device Counterplug

CMMP-AS-...-M0 PHOENIX MINICOMBICON MC

1.5/8-GF-3.81 BK

Tab. 4.24 Plug design [X40]

4.12.2 Pin assignment [X40]

[X40]1) Pin no. Designation Value Specification

8 0 V 0 V Reference potential for auxiliary power

7 24 V +24 V DC Output for auxiliary power supply (24 V DC

6 C2 – Feedback contact for the status “STO” on

5 C1

4 0V-B 0V Reference potential for STO-B.

3 STO-B 0 V / 24 V Control port B for the function STO.

2 0V-A 0 V Reference potential for STO-A.

1 STO-A 0V / 24V Control port A for the function STO.

1) Representation of the plug on the device of the motor controller CMMP-AS-...-M0

Tab. 4.25 Pin assignment [X40]: I/O interface for STO

PHOENIX MINICOMBICON MC

1.5/8-STF-3.81 BK

supply.

logic supply of the motor controller

brought out).

an external controller.

4.12.3 Circuitry with use of the STO safety function [X40]

To work safely with the safety function STO – “Safe Torque Off”, please observe the in

formation in the documentation è GDCP-CMMP-AS-M0-S1-... .

4.12.4 Circuitry without use of the STO safety function [X40]

If you do not need the integrated safety function STO in your application, to operate the

motor controller you must connect the X40 interface, as depicted in Fig. 4.8.

This deactivates the integrated safety function!

When using this circuitry for the CMMP-AS-...-M0, safety in the application must be en

sured through other appropriate measures.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 49

4 Electrical installation

Note

Loss of the safety function!

Lack of the safety function can result in serious, irreversible injuries, e.g. due to uncon

trolled movements of the connected actuator technology.

Bypassing of safety equipment is impermissible.

Make sure that no jumpers or the like can be used parallel to safety wiring, e.g. through use of

maximum wire cross sections or appropriate wire end sleeves with insulating collars.

Use twin wire end sleeves for looping through lines between neighbouring equipment.

1

STO-A

0V-A

STO-B

0V-B

24V

DC

DC

DC

DC

2

5

0V

1 Integrated safety function STO

2 Power output stage in CMMP-AS-…-M0

(only one phase shown)

3 Driver supply

4 Motor connection

5 Voltage supply

Fig. 4.8 Circuitry without use of the safety function – functional principle

3

3

+V DC

3x

U, V, W

4

+VDC

50 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.13 Instructions on safe and EMC-compliant installation

4.13.1 Explanations and terms

Electromagnetic compatibility (EMC) or electromagnetic interference (EMI) involves the following re

quirements:

Resistance to interference

Sufficient interference immunity of an electrical system or electrical device against external electrical,

magnetic or electromagnetic noise via lines or space.

Emitted interference

Sufficiently low emitted interference of electrical, magnetic or electromagnetic interference of an elec

trical system or an electrical device on other devices in the environment via cables and space.

Warning

All PE protective earth conductors must always be connected prior to commissioning for

reasons of safety.

The mains-side PE connection is made to the PE connection points (device rear wall) and

[X9] of the CMMP-AS-...-M0.

Make sure that the earth connections between devices and the mounting plate are of

sufficiently large dimensions in order to be able to discharge HF interference.

4.13.2 General remarks on EMC

Interference emission and resistance to interference of a motor controller always depend on the com

plete design of the drive, which consists of the following components:

– Voltage supply

– Motor controller

– Motor

– Electromechanical components

– Design and type of wiring

– Connection to the higher-order controller

Mains filter

Motor controllers and mains filters are provided to increase the interference immunity and to reduce

the level of emitted interference.

Motor controller Mains filter

CMMP-AS-C2-3A-M0 In order to increase the interference immunity and decrease the

CMMP-AS-C5-3A-M0

CMMP-AS-C5-11A-P3-M0

CMMP-AS-C10-11A-P3-M0

Tab. 4.26 Mains filter

level of emitted interference, the motor controller already has

integrated motor chokes and mains filters, which means that it can

be operated without additional shielding and filters in most appli

cations.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 51

4 Electrical installation

The motor controllers CMMP-AS-...-M0 have been checked in accordance with EMC

product standard EN 61800-3 that is applicable to electric drives. The standard compon

ents from the Festo accessories were used for qualification. EMC can only be guaranteed

if the motor and encoder or resolver cables from Festo are used and not extended or

changed in any other form.

In the majority of cases, no external filter measures are required (è Section 4.13.3,

Tab. 4.27).

The declaration of conformity is available at è www.festo.com.

4.13.3 EMC areas: First and second environment

If installed correctly and if all connecting cables are wired correctly, the CMMP-AS-...-M0 motor control

lers fulfil the specifications of the related product standard EN 61800-3. This standard no longer refers

to limit value classes, but to so-called environments.

Note

The first environment (C2) includes electricity grids connected to residential housing;

the second environment (C3) includes grids connected only to industrial plants.

The device may generate high frequency interference, which may make it necessary to

implement interference suppression measures in residential areas.

Applicable for the motor controller CMMP-AS-...-M0:

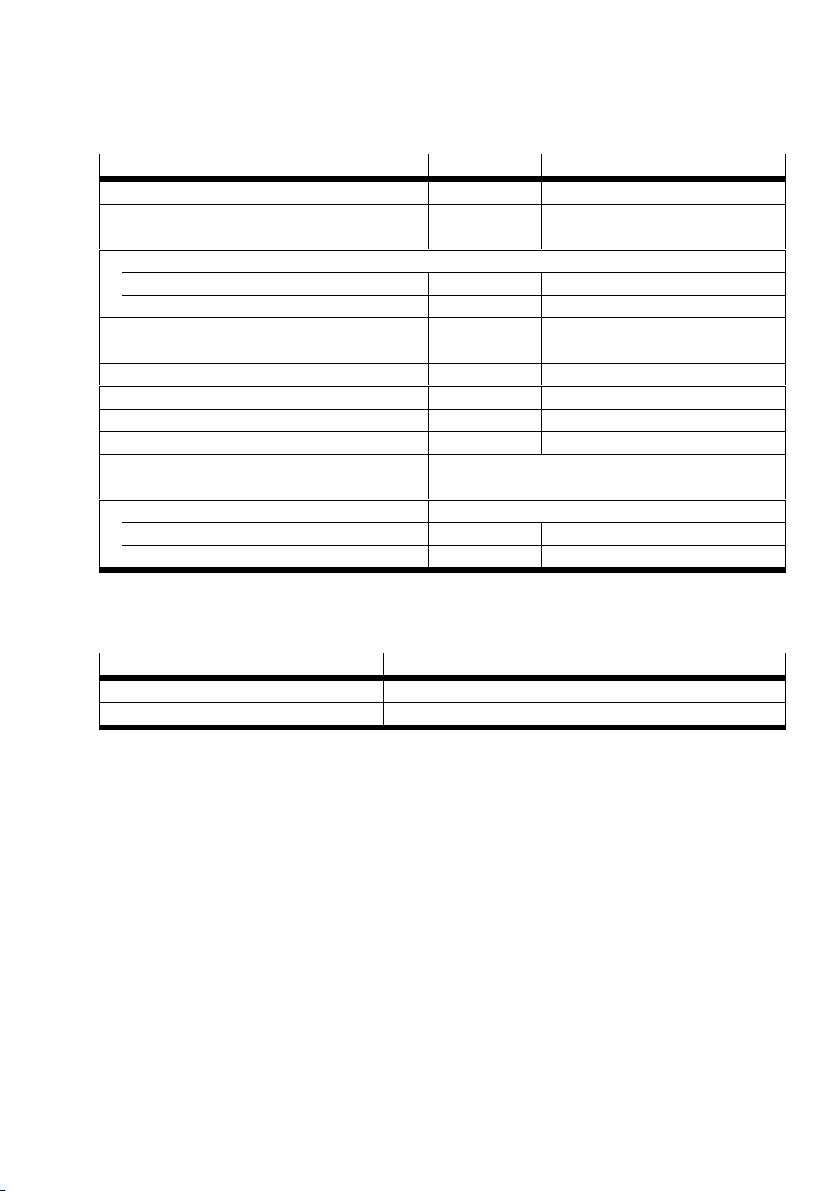

EMC class Area Compliance with EMC requirements

Emitted

interference

Second environ

ment (industrial)

Motor cable lengths up to 25 m without external filters.

A suitable mains filter must be installed when longer mo

tor cables of 25 … 50 m are used.

Resistance to

interference

Second environ

ment (industrial)

Independent of the motor cable length.

Tab. 4.27 EMC requirements

52 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.13.4 EMC-compliant wiring

The following must be observed for EMC-compliant design of the drive system

(see also chapter 4.2 è Page 25):

Cable interfaces on the CMMP-AS-...-M0

Port Interface Cable length [m] Comment

X1 I/O communication 5 Recommendation: Screened

X2A Resolver 50 screened

X2B Encoder 50 screened

X4 CAN 40 at 1 Mbit/s (permissible line length

dependent on the bit rate)

X6 Motor 25 screened (è Tab. 4.27)

X9 Power supply 2 –

X10 Increment generator input 30 screened

X11 Increment generator output 5 screened

X18 Ethernet 10 at least CAT-5

X19 USB 5 in accordance with USB specification

Rev. USB 1.1

X40 Safety function ST0 30 –

Tab. 4.28 Permissible cable lengths on the CMMP-AS-...-M0

1. To keep leaked current and losses in the motor cable as low as possible, the motor controller

CMMP-AS-...-M0 should be placed as close to the motor as possible (è Chapter 4.13.5 è Page 55).

2. Motor and encoder cable must be screened.

3. The screening of the motor cable is attached to the housing of the motor controller CMMP-AS-...-M0

(screened connection terminals, spring clips). The cable screening is also always attached to the

corresponding motor controller to prevent leaked current flowing back to the controller which

caused it.

4. The mains-side PE connection is connected to the PE connection point of the power supply [X9] and

to the PE connection of the housing.

5. The PE internal conductor of the motor cable is connected to the PE connection point of the motor

connection [X6].

6. Signal lines must be separated as far as possible from the power cables. They should not be routed

parallel to one another. If crossovers are unavoidable, they should be made as close to vertical (i.e.

at a 90° angle) as possible.

7. For unscreened signal and control lines, safe/reliable operation cannot be guaranteed. If they must

be used, they should at least be twisted.

8. Even screened cables always have short unscreened parts at both ends (unless a screened plug

housing is used).

In general:

– Connect the inner screenings to the pins of the plug connectors provided for the purpose; length

maximum 40 mm.

– Length of the unscreened wires with self-made cables, maximum 35 mm.

– Connect entire screening on the controller side flush to the PE terminal; maximum length 40 mm.

Festo – GDCP-CMMP-M0-HW-EN – 1511c – English 53

4 Electrical installation

– Connect entire screening flush at the motor to the plug or motor housing; length maximum 40 mm

(guaranteed with NEBM-...).

Danger

All PE protective earth conductors must always be connected prior to commissioning for

reasons of safety.

The regulations of EN 50178 and EN 60204-1 for protective grounding must always be

observed during installation!

54 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

4 Electrical installation

4.13.5 Operation with long motor cables

For applications in combination with long motor cables and/or if the wrong motor cables are selected

with excessive cable capacity, the filters may be subjected to thermal overload. To avoid this, it is ne

cessary to enter the cable length used in the application in the FCT parametrisation software. By using

this information the FCT plug-in then automatically calculates the optimal cycle time for the current

regulator and PWM control. The following restrictions are taken into consideration:

Cable length

Restrictions in the FCT plug-in CMMP