CMMO-ST-C5-1-DIOP/DION

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com

Brief description

Original instructions

8071645

2017-05a

[8071647]

Motor controller CMMO-ST English......................................

For all available product documentation è www.festo.com/sp

This brief description is intended solely for initial information. The full description

of the motor controller CMMO-ST-C5-1-DIOP/DION includes the following docu

ments:

Designation Contents

Brief description

CMMO-ST-...

1)

Brief equipment and functional description of the motor controller

for initial information

Manual

GDCP-CMMO-ST-EA-SY-...

Equipment and functional description of the motor controller for all

product variants

– Mounting

– Commissioning via web server/Festo Configuration Tool (FCT)

– Communication via I/O interface

– Technical data

Help system for the FCT

software

Descriptions of the Festo Configuration Tool (FCT) for

commissioning and parameterisation of:

– Configurable axis/motor combinations

– Positioning systems in Festo's Optimised Motion Series (OMS)

Description

GDCP-CMMO-ST-EA-S1-...

Use of the STO safety function (“Safe Torque Off”)

Parameter lists List with standard settings of the parameter files for positioning

systems in Festo's Optimised Motion Series (OMS)

Special documentation

CMMO-ST_SPU L

1)

Requirements for operating the product in the USA and Canada in

accordance with certification by Underwriters Laboratories Inc. (UL).

1) The documentation is enclosed in printed format.

Fig. 1 Documentation on the CMMO-ST

1 Safety

Observe the safety instructions and warnings in the documentation of the motor

controller and the documentation of the other components used.

Before mounting and installation work: Switch off the supply voltage. Secure

against accidental reactivation. Only switch on the supply voltage again when

mounting and installation work is complete.

Never remove or insert a plug connector when the motor controller is powered.

Observe the handling specifications for electrostatically sensitive devices.

Only enable the controller if the drive has been professionally installed and fully

parameterised.

Do not perform any repairs on the motor controller. In the event of a defect:

Replace the complete motor controller.

Warning

Serious injury or damage to components as a result of collisions.

Make sure that there are no objects in the positioning range while the system

is connected to a source of electric power.

Make sure that nobody is in, or is able to reach into, the operating area of the

connected actuators

Secure the danger zone through suitable safeguarding measures, e.g. guards

and warnings.

Caution

Personal injury and material damage.

Falling loads in the event of a voltage failure or disconnection of the power sup

ply when installing the drive in an inclined or vertical position.

Secure loads through external safety measures (e.g. toothed latches or mov

able bolts).

Caution

High temperatures on the housing surfaces.

Touching the surface may cause a person to be startled and react in an uncon

trolled manner, with subsequent damages.

Protect the motor controller to prevent accidental touching.

Inform operating and maintenance staff about any potential hazards.

Before touching the product, e. g. for mounting or installation: Allow the mo

tor controller to cool down to room temperature.

1.1 Intended use of the CMMO-ST

The motor controller CMMO-ST is intended for controlling the following drives with

2-phase stepper motors from Festo:

– Positioning systems in the Optimised Motion Series (OMS) with axis/motor units

from Festo

– Configured drives (rotary/linear):

– Axes from Festo e.g. EGC, DNCE, DGE

– User-defined axes

Observe the specified standards as well as the regulations of the trade associ

ations, the German Technical Control Board (TÜV), the VDE regulations or the

relevant national regulations.

Observe the limit values for all additional components (e.g. sensors, actuators).

Use the CMMO-ST only as follows

– in perfect technical condition

– in its original condition, without unauthorised modifications

– within the limits of the product defined through the technical data

– within the specified service life of the switching elements for the safety function

– as an installed device in a control cabinet

Use outside the control cabinet is possible if all of the plug connectors are connec

ted and all unused interfaces are sealed with protective caps.

1.2 Intended use of the STO function

The STO function (“Safe Torque Off”) according to EN61800-5-2 is intended to

disconnect the torque from a motor that is connected to the CMMO-ST. The STO

function prevents an unexpected start-up of the connected motor. The STO func

tion should only be used for applications in which the specified safety characterist

ics suffice.

Safety characteristics

The STO function of the CMMO-ST fulfils the requirements for the following safety

characteristics:

– PL e/Cat. 3 according to ENISO13849-1

– SIL 3 according to EN61800-5-2

– SILCL3 according to EN62061

The achievable safety level depends on the other components used to implement

the safety function.

To protect against unintended motor start-up, the motor controller must be activ

ated via the connection [X3] with the category required for the application accord

ing to EN ISO 13849-1, e.g. via an external safety switching device.

Qualification of specialists (personnel requirements)

The product may only be placed in operation by a qualified electrotechnician who

is familiar with:

– installation and operation of electrical control systems

– the applicable regulations for operating safety-engineered systems

– the applicable regulations for accident prevention and occupational safety

– the documentation for the product

Diagnostic coverage (DC) for the safety function

Diagnostic coverage depends on the interconnection of the motor controller with

the control loop system as well as the implemented diagnostics measures.

If a potentially dangerous malfunction is recognised during the diagnostics, appro

priate measures must be taken to maintain the safety level.

Note

The motor controller cannot detect a cross circuit in the input circuit by itself.

If required, use a safety switching device with cross-circuit detection.

1.3 Possible misuse of the STO function

The following misuses are among those not approved as intended use:

– Bridging of the STO function

– Use in applications where switching off can result in hazardous movements or

conditions.

Note

The STO function must not be used as the sole safety function for drives that are

subject to permanent torque or force (e.g. suspended loads, vertical axes).

The STO function does not provide protection against electric shock, only

against dangerous movements!

2 Requirements for product use

Provide the complete product documentation to the following personnel:

– the design engineer and the installer of the machine or system

– the personnel responsible for commissioning

Keep this documentation safe throughout the entire product lifecycle.

Ensure compliance with the specifications in this documentation. Also comply

with the documentation for the other components and modules (e.g. motor

controller, circuits, etc.).

Take into consideration all of the legal regulations that are applicable for the

installation site, as well as the following documents:

– Regulations and standards

– Regulations of the testing organisations and insurers

– national regulations.

For correct and safe use of the STO function:

Conduct a risk assessment for your machine.

Comply with the specified safety characteristics (è Chapter 7, Technical data).

Range of applications and certifications

The motor controller with integrated STO safety function is a safety-related part of

the control systems. The motor controller carries the CE mark. Certain configura

tions of the product have been certified by Underwriters Laboratories Inc. (UL).

Certificates and the declaration of conformity relating to this product can

be found online è www.festo.com/sp

Specified standards

Version status

ENISO13849-1:2008-06/AC:2009-03

EN 61800-5-2:2007-10

EN62061:2005-04

Fig. 2 Standards specified in the document

2.1 Transport and storage conditions

Protect the product during transport and storage from excessive stress factors,

such as:

– Mechanical loads

– Temperatures that are too high or too low

– Moisture

– Aggressive atmospheres.

Store and transport the product in its original packaging. The original pack

aging offers sufficient protection from typical stresses.

2.2 Technical prerequisites

For correct and safe use of the product:

Conduct a risk assessment for your machine or system.

Comply with the specified safety characteristics è Chapter 7

Comply with the specified connection and operating conditions for all of the

connected components è Chapter 7. Only compliance with the limit values or

load limits will enable operation of the product in compliance with the relevant

safety regulations.

3 Product description

3.1 Product overview

1 [X9] Load/logic voltage

2 [X1] I/O interface for control

system with SPC/IPC

3 Front view with 7-segment display

4 [X18] Parameterisation interface,

Ethernet RJ-45

5 [X1A] Reference switch

6 [X3] STO

7 [X2] Encoder RS422

8 [X6] Motor

9 Functional earth

aJ Surface for reverse side mounting

aA Surface for side mounting

1

2

3

4

56 7 8 9

aA aJ

Fig. 3 Components of the CMMO-ST

3.2 Scope of delivery

Number Component

1 Motor controller CMMO-ST

1 Operator package

– Brief description

– CD-ROM with following contents:

– Parameterisation software “Festo Configuration Tool” (FCT)

– Product documentation

– Parameter lists for suppor ted positioning systems

1 Assortment of plugs NEKM-C-10 with 5 plug connectors for motor, encoder, power

supply, reference switch and for switching signals of the STO function

1 H-rail clip

Fig. 4 Scope of delivery

4 Mounting

Caution

Unexpected and unintended movement of the drive during mounting, installation

and maintenance work.

Before starting work: Switch off power supplies.

Secure the power supplies against accidental reactivation.

4.1 Mounting the controller

The controller can be mounted with an H-rail or on a flat surface.

max. 5mm

41mm

61.35mm

Fig. 5 Mounting on an H-rail

Mount the CMMO-ST on the H-rail as follows:

1. Hang the CMMO-ST over the hook of the H-rail clip and into the H-rail from

above.

2. Press the lower part of the CMMO-ST onto the H-rail until it clicks into place.

Mount the CMMO-ST on a flat surface as follows:

1 Remove the H-rail

clip

2 Reverse side

mounting surface

3 Notches (x3) for

reverse side

mounting

4 Side mounting

surface

5 Recesses (x4) for

side mounting

3

4

5

1

2

Fig. 6 Mounting on a side or reverse side mounting surface

5 Electrical installation

Caution

Unexpected and unintended movement of the drive during mounting, installation

and maintenance work.

Before starting work: Switch off power supplies. Cancelling the enable signal

on the controller is not sufficient.

Secure the power supplies against accidental reactivation.

5.1 Connections and cables

Caution

Unexpected and unintended movement of the drive as a result of incorrectly

assembled cables.

Only use the plug connectors provided and preferably the cables listed in the

specified accessories è www.festo.com/catalogue.

Lay all flexible cables so that they are free of kinks and mechanical stress; if

necessary in a drag chain. Observe the instructions for the axis and the addi

tional components.

ESD protection

At unassigned plug connectors, damage can occur to the device or to

other system parts as a result of ESD (electrostatic discharge).

Observe the handling specifications for electrostatically sensitive

devices.

Seal unassigned plug connectors with protective caps.

Earth system parts prior to installation.

Use appropriate ESD equipment (e.g. shoes, earthing straps, etc.).

The plug connectors used for connecting the motor controller are included in the

scope of delivery (assortment of plugs NEKM-C-10).

Additional accessories:

Control cable for the higher-order controller (I/O interface)

– Control cable

– 25-pin Sub-D plug

NEBC-S1G25-K-3.2-N-LE25

NEFC-S1G25-C2W25-S6

Connecting the I/O interface via a connection block

– Connection block

– Cable CMMO-ST/connection block

S1G25-C2W25-S7

NEBC-S1G25-K-...-N-S1G25

Motor and encoder cables

NEBM according to the drive configuration in various connector types and lengths

è www.festo.com/catalogue

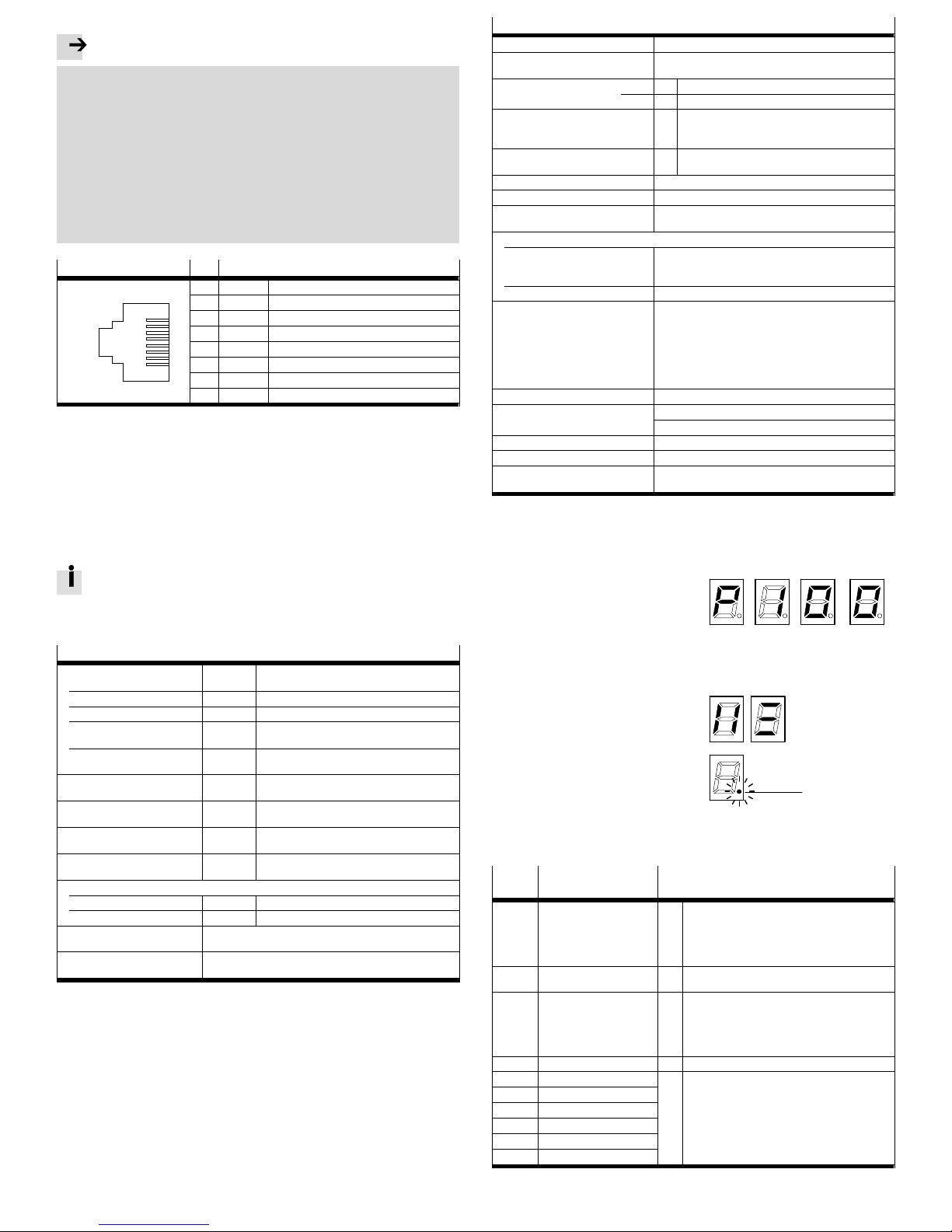

5.2 [X1] I/O interface

Communication with the higher-order controller (PLC/IPC) occurs via the I/O inter

face.

The switching logic of the inputs and outputs is dependent on the interface variant

of the controller:

– CMMO-ST-...-DIOP: Positive logic PNP

– CMMO-ST-...-DION: Negative logic NPN

Connection

1

114

25

13

X1

Pin 1 2 … 11 12 13 ... 22 23 24 25

Input (I) Output (A) – LOG IC

OUT

1)

GND

01 02 … 11 01 02 ... 11 – +24 V 0 V

1) Not overload-proof! Max. 100 mA permissible.

Fig. 7 I/O interface connection [X1]

5.3 [X1A] Reference switch

Connection Pin Function

13

13

X1A

1 +24 V

LOGI C

OUT

Voltage output for supplying the reference switch.

Not overload-proof! Max. 100 mA permissible.

2 SIG NAL

REF

CMMO-ST-...-DIOP:

– Input for PNP switch

– switches to +24 V

– NO/NC version

CMMO-ST-...-DION:

– Input for NPN switch

– switches to GND

– NO/NC version

3 GND Reference potential (ground)

Fig. 8 Reference switch connection [X1A]

5.4 [X2] Encoder

Connection Pin Function

X2

18

1

8

1 A

1)

Incremental encoder signal A+

2 A/ 1)Incremental encoder signal A–

3 B

1)

Incremental encoder signal B+

4 B/ 1)Incremental encoder signal B–

5 N

1)

Incremental encoder signal zero pulse N+

6 N/ 1)Incremental encoder signal zero pulse N7 5 V

(± 10 %)

Supply of the encoder.

Not overload-proof! Max. 100 mA

permissible.

8 0 V Reference potential

1) At each pin: 5 V and Ri = approx. 120 Ω

Fig. 9 Encoder connection [X2]

5.5 [X3] STO

The STO safety function (“Safe Torque Off”) is described in detail in the document

GDCP-CMMO-ST-STO-…. The STO function should only be used in the manner de

scribed in this document.

Recommendation for initial motor start-up without safety equipment:

– The setup must at least include an emergency stop switching device

– Two-channel switch-off via control ports STO1 [X3.2] andSTO2[X3.3]

Connection Pin Function

X3

15

15

1 +24 V

LOGI C

OUT

Logic voltage output [X9]

Not overload-proof! Max. 100 mA

permissible.

2 STO1 Control port for STO function: Channel 1

3 STO2 Control port for STO function: Channel 2

4 DIAG1 The acknowledgment contact is closed (low

impedance) when the STO function is

active.

5 DIAG2

Fig. 10 STO connection [X3]

5.6 [X6] Motor

Connection Pin Function

X6

16

16

1 String A Connection of the two motor strings

2 String A/

3 String B

4 String B/

5 BR+ Connection of the holding brake

Short-circuit- and overload-proof. 24 V,

max. 1.4 A è 33 W. BR– = GND,

BR+ is switched (24 V load)

6 BR–

Fig. 11 Motor connection [X6]

5.7 [X9] Power supply

War ni ng

Electric shock

Injury to people, damage to the machine and system.

For the electrical power supply, use only PELV circuits in accordance with

IEC 602041 (Protective Extra-Low Voltage, PELV).

Also observe the general requirements for PELV circuits IEC60204-1.

Use only voltage sources which guarantee reliable electrical isolation of the

operating and load voltage in accordance with IEC60204-1.

Connection Pin Function

X9

51

51

1 Do not connect!

2 Do not connect!

3 Supply of the control electronics (logic

supply)

4 Reference potential (0 V) for operating

voltage, logic voltage, STO and

controller interface

5 Supply of the power output stage and

the motor (load voltage)

Fig. 12 Connection [X9] with plug connector (assortment of plugs NEKM-C-10)

5.8 [X18] Ethernet interface

Note

Unauthorised access to the device can cause damage or malfunctions. When

connecting the device to a network:

Protect the network from unauthorised access.

Measures for protecting the network include:

– Firewall

– Intrusion Prevention System (IPS)

– Network segmentation

– Virtual LAN (VLAN)

– Virtual Private Network (VPN)

– Security at a physical access level (Port Security).

Additional information è Guidelines and standards for security in information

technology, e.g. IEC 62443, ISO/IEC 27001.

Connection Pin Function

X18

8

1

1 TD+ Transmitted data +

2 TD– Transmitted data –

3 RD+ Received data +

4 – not connected

5 – not connected

6 RD– Received data +

7 – not connected

8 – not connected

Fig. 13 Ethernet interface connection [X18]

6 Commissioning

Connect the CMMO-ST directly to the computer/notebook via an Ethernet cable

(point-to-point connection).

Simplified commissioning for positioning systems (OMS) via integrated web

server with English-language parameterisation and diagnostics website

(http://192.168.178.1)

Complete commissioning of configured motor/axis combinations with FCT

(Festo Configuration Tool)

The complete commissioning process for the motor controller is described

in the manual GDCP-CMMO-ST-EA-SY-… and in the Online Help for the

CMMO-ST plug-in of the FCT software.

7 Technical data

Safety reference data and safety specifications

Safety function STO Safe Torque Off

(Safe torque off)

Category 3 according to EN ISO 13849-1

Performance Level PLe according to EN ISO 13849-1

Safety Integrity Level SIL3 according to EN 61800-5-2

(Safety integrity level)

SIL Claim Limit SILCL3 according to EN 62061

(SIL Claim Limit)

DCavg [%] 90 Average Diagnostic Coverage

(Average diagnostic coverage)

MTTF

d

[Years] 4500 Mean Time To dangerous Failure

(Mean time to dangerous failure)

HFT 1 Hardware Failure Tolerance

(Hardware fault tolerance)

PFH [1/hr.] 1.3 x 10

-10

Probability of dangerous failure per hour

(Probability of dangerous failure per hour)

T

Proof Test Interval [Years] 20 Test interval

Duration of use [Years] 20 according to EN ISO 13849-1

Type test The STO function has been certified by an independent testing

body. CMMO-ST certificate è www.festo.com/sp

Component/function Suitable for use in category-1 systems and above according

to ENISO138491

Fig. 14 Safety reference data and safety specifications

General technical data

Power supply [VDC] 24 ± 15 %

Protection against electric shock PE LV circuit

(Protected Extra Low Voltage)

Current load voltage (pin 5) [A] 5.7 Nominal current

[A] 8 Peak current

Current logic supply (pin 3) [A] 0.3 Nominal current (without power supply for outputs)

Supply of the outputs for the I/O interface: Max.

0.1 A for each output: i.e. up to 1.1 A.

Max. total current

consumption

[A] 9.4 Depending on system configuration

Fault signal LED

Parameterisation interface Ethernet interface

Parameterisation software – Festo Configuration Tool (FCT)

– Web server

Control interfaces

Digital I/O

– Valve profile

– Binary profile

– DIN1 … DIN4, DOUT1 … DOUT2

– DIN1 … DIN11, DOUT1 … DOUT11

Optional: Ethernet – Control via Ethernet (CVE)

Protective functions –I2t monitoring

– Power section temperature monitoring

– Current monitoring

– Voltage failure detection

– Undervoltage monitoring

– Following error monitoring

– Software end-position detection

Degree of protection IP40 (with full pin allocation)

CE marking (declaration of conformity

è www.festo.com/sp)

according to EU EMC Directive 2014/30/EU

1)

according to EU Machinery Directive 2006/42/EC

Max. cable length [m] 30

Additional certifications UL/RCM Mark

Type of mounting – H-rail

– Mounting plate

1) The component is intended for industrial use.

Fig. 15 General technical data

8 Diagnostics

8.1 7-segment display

The 7-segment display on the CMMO-ST

provides information about the current

operating mode, errors and warnings.

4 characters are always displayed in

succession, followed by a space.

The numbers of diagnostic messages for the error or warning categories are coded

in hexadecimal format.

During a firmware update the display

alternates between vertical and horizontal

segments.

The wave function enables a motor

controller to be identified within a

network that has multiple motor

controllers.

The point flashes in the display of the

selected motor controller; the motor

controller “nods”.

1

1 Point for wave function

(Identification in the network)

Display Operating mode/

event

Priority

B L E Bootloader error 1 Error during the firmware update.

Switch the device off and back on again (reset).

Restart the firmware download process.

If the error occurs repeatedly, please contact your

local Festo Service.

Exxx1)Error 2 Error messages interrupt messages with a lower

priority and must be acknowledged.

Axxx1)Warning 3 Warnings have a lower priority than errors and are

not displayed if they occur when an error is

already displayed. Otherwise they are displayed

twice in succession. Warnings do not have to be

confirmed (acknowledged).

HHHH STO – Safe torque off 4 The STO function has been requested.

P000 Homing 5 Normal operation

P070 Inch positive

P071 Inch negative

P1xx2)Positioning mode

P2xx2)High-power mode

P3xx2)High-speed mode

1) xxx =Fault number, hexadecimal

2) xx =Record number, decimal

Fig. 16 Messages on the 7-segment display

Loading...

Loading...