Page 1

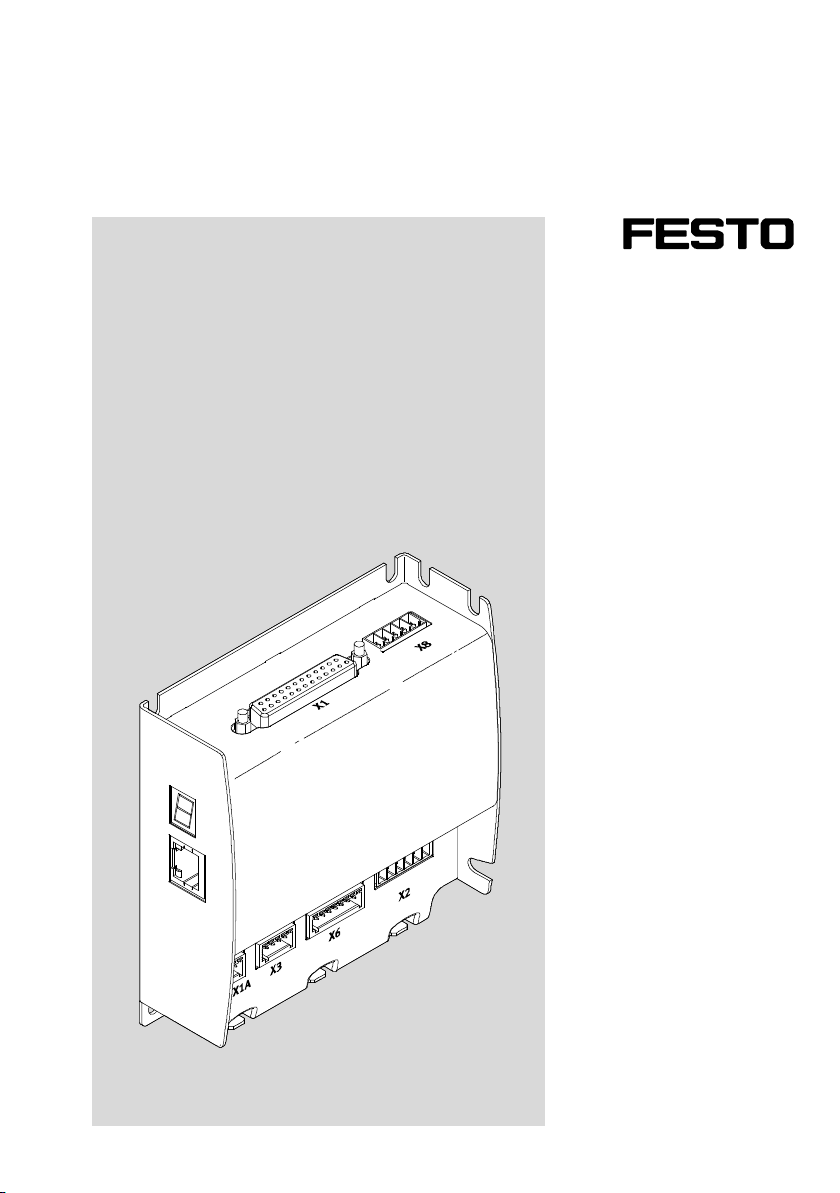

Motor controller

CMMO-ST

Description

Motor controller

CMMO-ST-C5-1-DIO

8022056

1301a

Page 2

CMMO-ST

Translation of the original instructions

GDCP-CMMO-ST-EA-SY-EN

Adobe Reader

®

,CANopen®,CiA®are registered trademarks of the respective trademark owners in

certain countries.

Identificationof hazards and instructions on how to prevent them:

War n ing

Hazards that can cause death or serious injuries.

Caution

Hazards that can cause minor injuries or serious material damage.

Other symbols:

Note

Material damage or loss of function.

Recommendations, tips, references to other documentation.

Essential or useful accessories.

Information on environmentally sound usage.

Text designations:

• Activities that may be carried out in any order.

1. Activities that should be carried out in the order stated.

– General lists.

2 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a –

Page 3

CMMO-ST

Table of Contents – CMMO-ST

1 Safety and requirements for product use 9......................................

1.1 Safety 9..................................................................

1.1.1 General safety instructions 9.........................................

1.1.2 Intended use 10.....................................................

1.2 Requirements for product use 11...............................................

1.2.1 Technical requirements 11............................................

1.2.2 Qualification of the specialists (requirements for the personnel) 11............

1.2.3 Range of application and certifications 12................................

2Overview 13................................................................

2.1 System overview 13..........................................................

2.2 Overview of CMMO-ST 14.....................................................

2.2.1 General properties 14................................................

2.2.2 Commissioning options 14............................................

2.2.3 Control profiles of the I/O interface 14...................................

2.2.4 Closed loop versus open-loop operation 15...............................

2.3 Overview of CMMO-ST operating modes 15.......................................

2.3.1 Positioning mode 15.................................................

2.3.2 Speed mode 15.....................................................

2.3.3 Force mode 15......................................................

2.4 Overview of drive functions 16.................................................

2.4.1 Jogging 16.........................................................

2.4.2 Teac h 16..........................................................

2.4.3 Standstill monitoring 16..............................................

2.4.4 Brake 16..........................................................

2.4.5 Comparators & messages 17..........................................

2.4.6 Record Linking 17...................................................

2.4.7 Record switching by PLC 17............................................

2.4.8 Trace 17...........................................................

2.4.9 Firmware update 17.................................................

2.4.10 Parameter file 17....................................................

2.4.11 Flash memory 18....................................................

2.4.12 Higher-order control 18...............................................

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 3

Page 4

CMMO-ST

2.5 Interfaces and simultaneous connections 18......................................

2.5.1 Number of connections 19............................................

2.6 Measuring reference system 19.................................................

2.6.1 Basic concepts 19...................................................

2.6.2 Calculationrules 20..................................................

2.6.3 Prefix and direction of rotation 21......................................

2.6.4 Units of measurement 21.............................................

2.7 Homing run 21..............................................................

2.7.1 Homing overview 21.................................................

2.7.2 Homing methods to a fixed stop 22.....................................

2.7.3 Homing methods to switch with/without index search 23....................

2.7.4 Homing method “current position” 24...................................

2.7.5 Automatic homing ( valve profile) 24.....................................

2.7.6 Movement to zero 25.................................................

2.8 Monitoring functions 25.......................................................

2.9 Safety aspects 26............................................................

3Mounting 27...............................................................

3.1 General instructions 27.......................................................

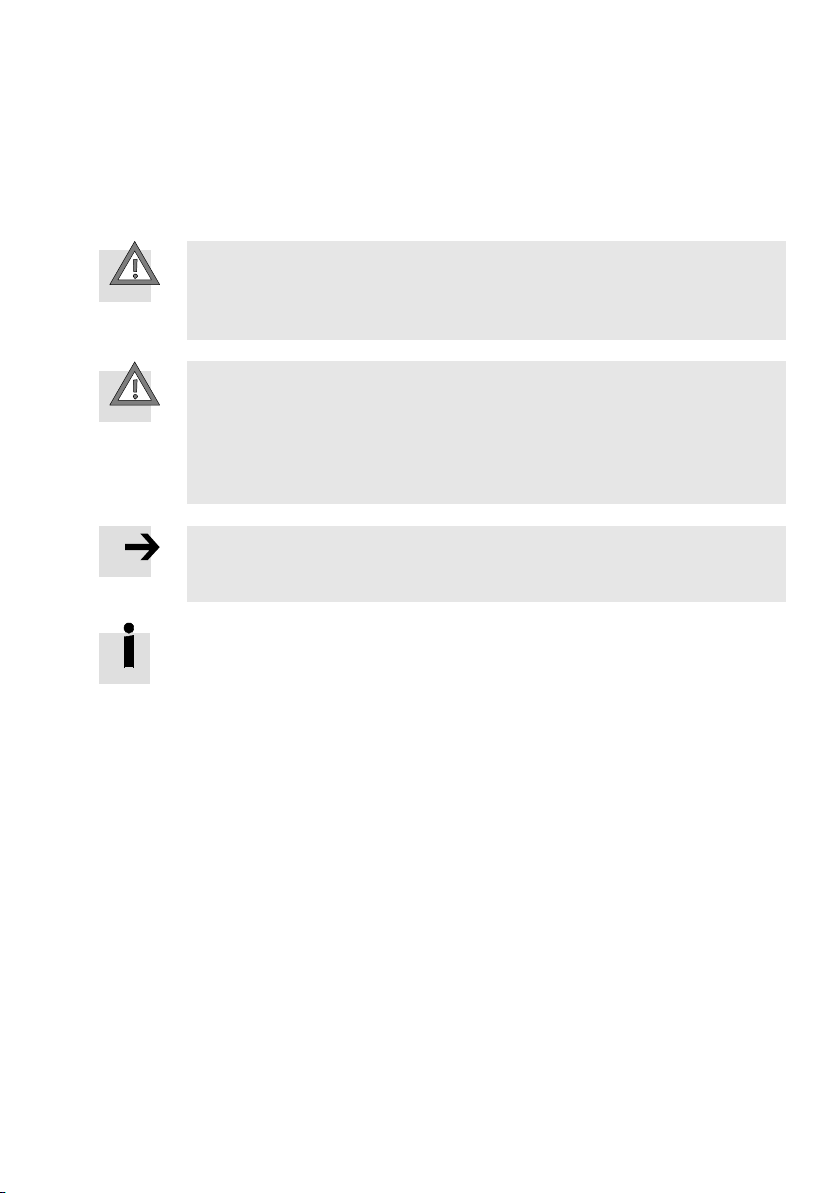

3.2 Dimensions of the controller 28.................................................

3.3 Mountingthe controller 29....................................................

3.3.1 Fitting 29..........................................................

3.3.2 H-rail mounting 30...................................................

4 Electrical installation 31......................................................

4.1 Overview 31................................................................

4.2 Power supply [X9] 33.........................................................

4.3 Functional earth 34..........................................................

4.4 I/O interface [X1] 35..........................................................

4.4.1 Electrical specifications of [X1] 36......................................

4.5 Reference switch [X1A] 36.....................................................

4.6 STO [X3] 37.................................................................

4.7 Encoder [X2] 38.............................................................

4.8 Motor [X6] 38...............................................................

4 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 5

CMMO-ST

5 Commissioning 39...........................................................

5.1 Safety regulations 39.........................................................

5.2 Ethernet interface (RJ-45) 41...................................................

5.2.1 Deliverystatus of the CMMO-ST 41.....................................

5.2.2 DHCP or fixed IP address 41...........................................

5.2.3 Safety in the network 42..............................................

5.2.4 Timeout 42........................................................

5.2.5 Initial start-up via Ethernet 43.........................................

5.3 Commissioning via web server 44...............................................

5.3.1 What does the web server enable? 44...................................

5.3.2 Parameter files 44...................................................

5.3.3 Initial start-up with the web server 46...................................

5.3.4 Creating a parameter backup file 50.....................................

5.4 Commissioning with FCT (Festo Configuration T ool) 51..............................

5.4.1 Installing the FCT 51.................................................

5.4.2 Starting the FCT 52..................................................

5.5 I/O interface 54.............................................................

5.5.1 Profiles for selection 54..............................................

5.5.2 Properties of the valve profile (7) 55....................................

5.5.3 Properties of the binary profile (31) 66..................................

5.6 Structure of the records in the record table 77.....................................

5.6.1 Positioning mode 77.................................................

5.6.2 Speed mode (binary profile only) 79.....................................

5.6.3 Force mode (only in binary profile) 80...................................

5.7 Record switching by PLC (binary profile) 81.......................................

5.8 Record linking (binary profile only) 82............................................

5.9 Comparators 83.............................................................

5.9.1 Position comparators 83..............................................

5.9.2 Speed comparators 84...............................................

5.9.3 Force comparators 84................................................

5.9.4 Time comparators 85................................................

5.10 Instructions on operation 86...................................................

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 5

Page 6

CMMO-ST

6Diagnostics 87..............................................................

6.1 Types of malfunction 87.......................................................

6.2 7-segment display 87.........................................................

6.3 Diagnostic memory 89........................................................

6.4 Malfunctions: Causes and remedy 90............................................

6.4.1 Error responses 90..................................................

6.4.2 Table of error messages 90............................................

6.4.3 Problems with the Ethernet connection 103................................

6.4.4 Other problems and remedies 105.......................................

6.4.5 Malfunction“Index pulse too close on proximitysensor” (2Eh) 106.............

A Technical appendix 107........................................................

A.1 Technical data 107............................................................

B Control via Ethernet (CVE) 109..................................................

B.1 Basic principles 109...........................................................

B.1.1 Communication principle 109...........................................

B.1.2 CVEprotocol 110.....................................................

B.1.3 Controlling the drive 116...............................................

B.2 Explanation of increments 124..................................................

B.3 List of CVE objects 125.........................................................

C Glossary 132................................................................

6 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 7

CMMO-ST

Instructions on this documentation

This documentation is intended to help you safely work with the motor controller CMMO-ST.

Product identification, versions

The hardware version indicates the version status of the CMMO-ST’s electronics. The

firmware version indicates the version status of the operating system.

Youcan find the specifications of the version status as follows:

– Hardware version and firmware version in the Festo Configuration Tool (FCT) with an

active online connection to the CMMO-STon the “Controller” panel.

Firmware version from

V 1.0.x Motor controller CMMO-ST with I/O interface

What’s new? Which FCT plug-in?

CMMO-ST V 1.00

supports the following drives:

–EPCO

– For additional drives: see Festo catalogue

www.festo.com

V 1.1.2 Advancedparameter settings via web browser From CMMO-ST V 1.1.0

Tab. 1 Firmware Version

Service

Please consult your regional Festo contact if you have any technical problems.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 7

Page 8

CMMO-ST

Documentation

You will find more extensive information in the following documentation:

UserdocumentationontheCMMO-ST

Name Type Contents

STO documentation with a

brief overview of the

CMMO-ST.

Enclosed in printed format.

GDCP-CMMO-ST-STO-… Use of the STO safety function

(“Safe Torque Off ”).

Also includes intended use of the

CMMO-ST and a documentation

overview.

Description

(on CD-ROM)

GDCP-CMMO-ST-EA-SY-… Installation, commissioning and

diagnostics of positioning systems with

the CMMO-ST with communication via

I/O interface.

Help system for software

(included in the FCT

software)

Dynamic and static help for

the Festo Configuration Tool

Functional descriptions for the Festo

Configuration Tool configuration

software.

UL documentation CMMO-ST_SPUL Requirements for observing the

certified UL conditions if the product is

operated in the USA or Canada.

Operating instructions e.g. for electric cylinder

Installing and commissioning the drive

type EPCO

Tab. 2 Documentation on the CMMO-ST

8 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 9

1 Safety and requirements for product use

1 Safety and requirements for product use

1.1 Safety

1.1.1 General safety instruc tions

When c ommissioning and programming positioningsystems, the safety regulations in this description

as well as those in the operating instructions for the other components used must be observed.

The user must make sure that nobody is within the sphere of influence of the connected actuators or

axis system. Access to the possible danger area must be prevented by suitable measures such as

shutting them off and warning signs.

War n ing

Electric axes move with high force and at high speed. Collisions can lead to serious

injury to people and damage to components.

• Make sure that nobody c an place body parts in the positioning range of the axes or

other connected actuators and that there are no objects in the positioning path

while the system is still connected to a power supply.

War n ing

Parameterisation errors can cause injury to people and damage to property.

• Only enable the c ontroller if the axis system has been installed and parameterised

by technically qualified staff.

Note

Damage to the product from incorrect handling.

• Switch off the supply voltage before mounting and installation work. Switch on

supply voltage only when mounting and installation work are completely finished.

• Never unplug or plug in a product when powered!

• Observe the handling specifications for electrostatically sensitive devices.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 9

Page 10

1 Safety and requirements for product use

1.1.2 Intended use

The CMMO-ST motor controller is used for controlling stepper motors in accordance with the Festo

catalogue, and is especially intended for use with EPCO electric drives.

This description documents the basic functions of the CMMO-ST and the I/O interface.

EPCO drives and additional components are documented in separate operating instructions.

The CMMO-ST and the connectable modules and c ables may only be used as follows:

–asintended

– only in an industrial environment

– in perfect technical condition

– in original status without unauthorised modifications (only the conversions or modifications

described in the documentation supplied with the product are permitted)

• Observe the safety instructions and intended use in the documentation for all the components and

modules.

• Observe the standards specified in the relevant chapters, as well as the regulations of the trade

associations, the German Technical Control Board (TÜV), the VDE conditions or relevant national

regulations.

• Observe the limit values for all additional components (e.g. sensors, actuators).

Note

In the event of damage caused by unauthorised manipulation or other than intended

use, the guarantee is invalidated and the manufacturer is not liable for damages.

10 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 11

1 Safety and requirements for product use

1.2 Requirements for product use

• Make this documentationavailable to the design engineer, installer and personnel responsible for

commissioning the machine or system in which this product is used.

• Make sure that the specifications of the documentationare always complied with. Also consider the

documentation for the other components and modules.

• Take into co nsiderat io n the legal regulations applicable for the destination as well as:

– regulations and standards

– regulations of the testing organizations and insurers

– national specifications

1.2.1 Technical r equirements

General conditions for the correct and safe use of the product, which must be observed at all times:

• Complywith the connection and environmentalconditions specified in the technical data of the

product ( appendix A.1) and of all connected components.

Only compliance with the limit values or load limits permits operation of the product in accordance

with the relevant safety regulations.

• Observe the instructions and warnings in this documentation.

1.2.2 Qualification of the specialists (requirements for the personnel)

The product may only be placed in operation by a qualified electrotechnician who is familiar with:

– installationand operation of electrical control systems

– the applicable regulations for operating safety-engineered systems

– the applicable regulations for accident protection and industrial safety

– the documentation for the product

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 11

Page 12

1 Safety and requirements for product use

1.2.3 Range of application and certifications

Standards and test values, which the product complies with and fulfils, can be found in the “Technical

data” section ( appendix A.1). The product-relevant EU directives can be found in the declaration of

conformity.

Certificates and the declaration of conformity for this product c an be found at

www.festo.com.

Certain configurationsof the product have been certified by Underwriters Laboratories Inc. (UL) for the

USA and Canada. These configurations bear the following mark:

UL Listing Mark for Canada and the United States

Note

Observe the following if the UL requirements are to be complied with in your application:

– Rules for observing the UL certification can be found in the separate UL special

documentation. The technical data stated therein take priority.

– The technical data in this documentation may show values deviating from this.

12 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 13

2Overview

2Overview

2.1 System overview

1

2

3

4

1 Higher order controller level: PLC

2 Parameterisation and commissioning level:

Festo Configuration Tool (FCT)

-orweb browser

Fig. 2.1 System overview

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 13

3 Controller level: CMMO-ST

4 Drive level:

for example Electric cylinder with stepper

motor

Page 14

2Overview

2.2 Overview of CMMO-ST

2.2.1 General properties

– Rotor-oriented control: stepper motor behaves like a servo motor; force control possible, energy-

optimised operation, low heat generation

– Separate load and logic supply (no new homing run required after emergency stop)

– Control cabinet unit, field use in IP40 environments is also possible (with full pin assignment)

– Ethernet interface with integrated web server

– Backup file: includes all parameterisation settings. It can be stored on separate d ata storage

media. Enables seamless device replacement.

– 7 segment display to indicate device states, errors and warnings

– Internal braking resistor present

– The CMMO is available as an NPN variant (type code CMMO-…-DION) and a PNP variant

(type code CMMO-…-DIOP). This document describes both variants.

– Function “Safe torque off ” (STO):

description GDCP-CMMO-ST-STO-…

2.2.2 Commissioning options

The CMMO-ST can be parameterised and commissioned as follows:

– With the integrated web server, using a mechanical drive of the OMS series (optimised motion

series): diagnostics and parameterisation via standard web browser, s imple positioning

( section 5.3)

–withFCT, the Festo Configuration Tool: convenient, full function range ( section 5.4)

Control via Ethernet (CVE):

It is possible to start records from a PC programme via the Ethernet interface. However,

in-depth knowledge of programming TCP/IP applications is required for this purpose

( appendix B.1).

2.2.3 Control profiles of the I/O interface

Valve profile (7)

Simple I/O control: Based on the pneumatic valve pilot, 7 position records can be selected directly

through one input each (7 separate inputs). Upon reaching the target position the output corresponding to the input is set (7 separate outputs). The valve profile exclusively supports simple positioning

operation, optionally with reduced torque.

Binary profile (31)

Flexible I/O control: 31 records (plus record 0 = homing) can be addressed via 5 inputs. The binary

profile also enables jogging and teaching, force mode, speed mode and record linking.

A detailed description of these profiles section 5.5.

14 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 15

2Overview

2.2.4 Closed loop versus open-loop operation

Regulated (with positional feedback), motor with encoder (closed-loop operation)

In closed-loop operation the rotor position of the motor is detected by an incremental encoder/encoder

and reported back to the controller (closed loop).

The force mode is only possible in closed-loop operation. Running or referencing to stop is also only

possible in closed-loop operation.

In closed-loop operation only the energy required to move the load is supplied to the motor, i.e. the

motor operates in an energy-optimised manner with low heat generation.

Controlled (without positional feedback), motor with/without encoder (open-loop operation)

In open-loop operation (without feedback of the rotor position) only the positioning mode and speed

mode, as well as homing to proximity sensor or to “current position” are possible.

When travelling to a stop it can result in step losses and thus to defective position values.

In open-loop operation the motor is always operated with the set driving current when travelling and

with the set holding current when at a standstill.

Operation of motors with an encoder can also be parameterised so that no feedback from the encoder

is required.

2.3 Overview of CMMO-ST operating modes

Records

Orders are stored in a record table in CMMO-ST in the form of parameter records. Each record contains

all of the information required for a specific function depending on the selected mode.

During operation, the higher-order controller (PLC) then makes a successive selection from the records

that are saved in the CMMO-ST (“record selection”).

2.3.1 Positioning mode

During positioning mode the positioning tasks are saved as a “position record” in the record table.

Each position record includes information about the target position, speed, acceleration, etc.

In the binary profile record linking can also be configured.

2.3.2 Speed mode

The drive moves at a specified speed. The corresponding records in the record table are designated

speed records. There are speed records with and without stroke limit.

The speed mode is only available in the binary profile.

2.3.3 Force mode

The motor generates a predetermined torque. Depending on the mechanics this results in a torque or

linear force. The corresponding records in the record table are designated force records. There are

force records with and without stroke limit.

The force mode is only possible with clos ed-loop operation (motor with encoder) and is only available

in the binary profile.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 15

Page 16

2Overview

2.4 Overview of drive functions

2.4.1 Jogging

During the jogging mode the drive moves as long as a corresponding signal is present. This function is

commonly used to approach teaching positions or to move the drive out of the way. If the drive is not

referenced, the software end positions are disabled and the drive can be positioned behind the software end positions by jogging.

This function is only available in the binary profile.

2.4.2 Teach

The teach function enables the current position to be adopted as a parameter:

1st step: The drive is moved to the desired position (e.g through jogging).

2nd step: The user starts the teach command; the current position is transferred to a position record

as the target position.

For additional information sections 2. 4.11 and 5.5.3.

2.4.3 Standstill monitoring

Standstill monitoring is only available during closed-loop operation in the binary profile. If the standstill position window is exited durin g position control, it is indicated by the standstill monitoring function: if this position window is exited for a period longer than that defined in the “standstill monitoring

time”, the controller signals this to the higher-order controller. One of the freely assignable outputs

(no. 6 or no. 7) can be used for this purpose.

The position controller also tries to move the drive back into the position window.

2.4.4 Brake

If the drive is equipped with a brake, it is controlled as follows:

Switch-on delay

When setting the release (ENABLE), the time set for the switch-on delay star ts to run (e.g. 150 ms)

and the position controller of the CMMO-ST assumes control of the connected drive. The brake opens

simultaneously. The CMMO-ST only accepts positioning jobs after expiration of the switch-on delay.

Switch-off delay

When the enable signal is removed, the time set for the switch-off delay starts to run. The brake closes

during this time. The position controller holds the drive in position. The position controller is only

switched off after expiration of the switch-off delay.

If the enable signal is removed while the drive is executing a record, the drive is brought to a standstill

with the quick stop ramp (Quick stop). As soon as the drive has come to a standstill, the brake output

is reset: the brake/clamping unit closes. Simultaneously, the switch-off delay time begins to run. The

CMMO-ST still controls the position. The controller end stage is switched off after the switch-off delay.

A closed brake can be opened via digital input no. 9.

16 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 17

2Overview

2.4.5 Comparators & messages

The following drive conditions can be ascertained via so-called record messages:

– Position comparator active

The drive is located between two defined positions (in the “Position zone”).

Detailed description section 5.9.1.

– Speed comparator active

The speed is within a defined range.

Detailed description section 5.9.2.

– Force comparator active

The actual force (or torque) calculated via the current is within a defined range.

Detailed description section 5.9.3.

– Time comparator active

The time since the start of the position record is within a defined range.

Detailed description section 5.9.4.

In FCT it can be parameterised so that the presence of these states is signaled via digital outputs.

2.4.6 Record Linking

The record linking function allows records to be linked together: the pres ence of a defined step enabling condition after a record has been executed causes another record to be executed automatically.

Only available in the binary profile. Detailed description section 5.8.

2.4.7 Record switching by PLC

The record switching function enables the PLC to start a new record before an active record has been

completed. Detailed description section 5.7.

2.4.8 Trace

The “trace” oscilloscope function in FCT makes it possible to record drive data over a defined period in

real time, e.g. speeds and contouring errors during a movement.

2.4.9 Firmware update

The Festo Configuration Tool (FCT) enables firmware to be updated. This should only be performed in

accordance with the instructions provided by Festo Service.

2.4.10 Parameter file

After completing parametrisation, you can upload a parameter file from the controller to your computer; doing this creates a backup copy of the parameters in case the controller becomes damaged or

before firmware updates. This includes information about the connected motor, the drive and the parameter settings executed. If the CMMO-ST needs to be replaced, you can simply import the parameter

file from the old CMMO-ST into the new CMMO-ST. The new CMMO-ST is then ready for immediate use.

An example of creating a parameter backup file with the web server section 5.3.4.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 17

Page 18

2Overview

2.4.11 Flash memory

The integrated FLASH memory of the CMMO-ST includes the parameter files and the firmware.

In principle, the number of possible write cycles is limited.

Entries are written into the FLASH memory by the following procedures:

– teaching with automatic storage ( section 5.5.3)

– downloading a new parameter file

– a firmware update

–“saving”inFCT

– reconfiguration of malfunction properties/error responses

– recording of movements with the trace function in FCT

Note

Damage to the FLASH memory

The FLASH memory used by the CMMO-ST is designed for 100,000 write cycles.

•Donot use the TEACH function in combination with “automatic storage” in continu-

ous operation, as this will quickly exceed the maximum number of write cycles.

Minimum time between downloading two parameter files: 3 seconds.

2.4.12 Higher-order control

“Higher-order control” is an exclusive access right.

Many motor controllers have multiple interfaces through which they can be controlled (e.g. an I/O

interface and a CAN interface). Simultaneous control by multiple interfaces, however, could result in

uncontrollable behaviour of the drive.

Master control ensures that only one interface controls the drive (i.e. it has sovereignty).

The interface that has higher-order control is specified in CVE object #3. The other interfaces then only

have read access to the motor controller.

2.5 Interfaces and simultaneous connections

Physical interfaces

TheCMMO-SThastwophysicalinterfaces:

– I/O interface

– EtherCat interface

Logical interfaces

Three logical interfaces can be distinguished within the Ethernet interface:

– FCT Interface

– web browser interface

– CVE interface (control via Ethernet)

Interfaces

Physical I/O interface EtherCat interface

Logical I/O interface FCT Web browser CVE

Tab. 2.1 Physical and logical interfaces

18 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 19

2Overview

Together with the I/O interface there are four logical interfaces,ofwhichonly one can have

higher-order control.

When the CMMO is switched on the I/O interface has master control. Any other logical interface can

take higher-order control from the I/O interface.

FCT can take master control from a web browser. This is not possible the other way around. The

change in higher-order control can be blocked by CVE with object #4.

2.5.1 Number of connections

Simultaneously permissible are a maximum of:

– 1 CVE connection

– 1 web browser connection

– 2 FCT connections, of which only one can have master control.

In total a maximum of two Ethernet connections are permissible simultaneously.

2.6 Measuring reference system

2.6.1 Basic concepts

Homing

The position of the reference point REF is ascertained during homing.

Movement to zero

Following the homing run: travel from the homing point to the axis zero point ( section 2.7.6).

Homing m ethod

defines the way in which the reference point REF is ascertained.

Homing point REF

binds the measuring reference system, for example, to a proximity sensor or a fixed stop (depending

on the homing method).

Axis zero point AZ

is shifted by a defined distance from the reference point REF. But this offset can also be = 0.

The software limits and the project zero point refer to the axis zero point.

Project zero point PZ

is a point to which the actual position and the absolute target positions from the position record table

refer.

The project zero point is shifted by a defined distance from the axis zero point AZ. But this offset can

also be = 0.

Software end positions

limit the permitted positioning range (work stroke). If the target position of a positioning command

lies outside the software end positions, the positioning command will not be processed and an error

will be registered.

Usable Stroke

The distance between the two software limits. Maximum stroke by which the axis can move with the

set parameterisation.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 19

Page 20

2Overview

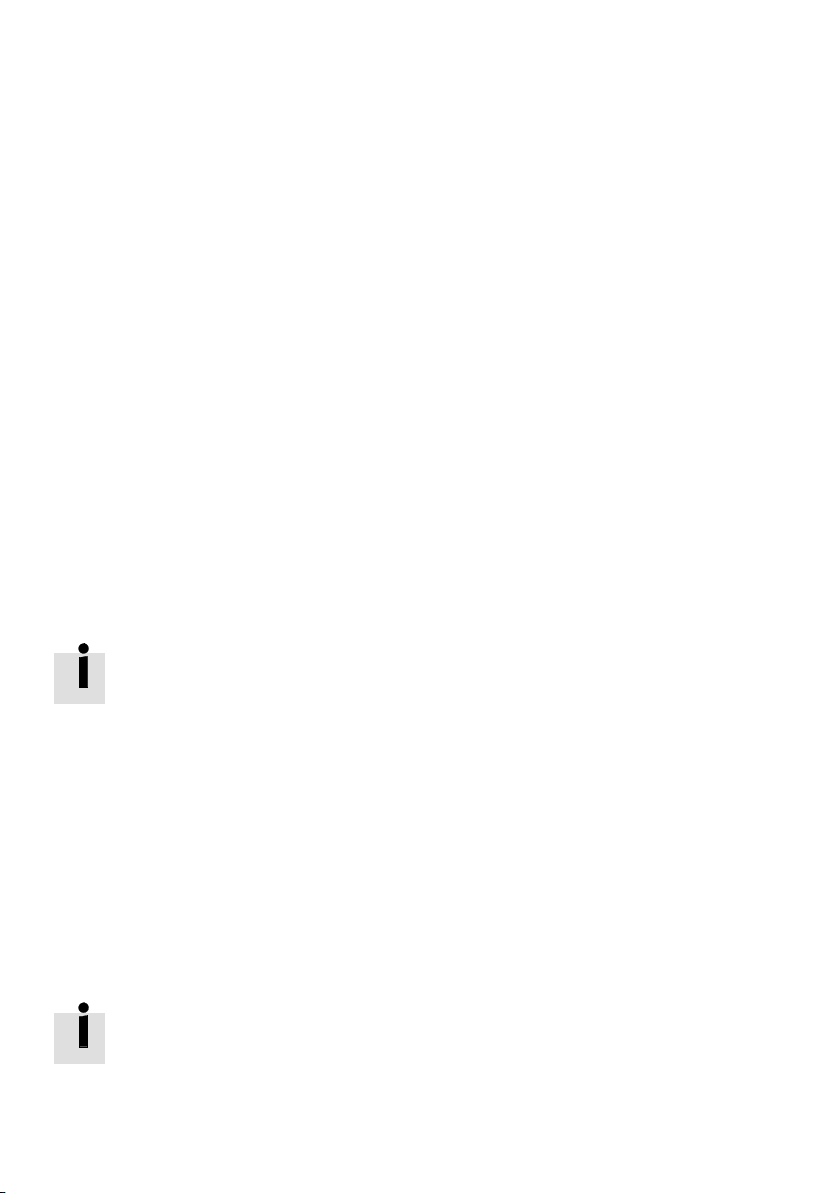

Measuring reference system

SLN SLP

e

bc

REF

a

AZ

1230

d

PZ

g

TP/AP

AZ

REF

PZ

a

d

b

SLN

c

SLP

REF Homing point (reference point) a Offset axis zero point

AZ Axis zero point b, c Offset software end

positions

PZ Project zero point d Offset project zero point

SLN Negative software end position (software limit negative) e Usable stroke

SLP Positive software end position (software limit positive)

TP/AP Target position/actual position g Offset TP/AP to PZ

Tab. 2.2 Measuring reference system

2.6.2 Calculation rules

Dot

Calculation rule

Axis zero point AZ =REF+a

Project zero point PZ =AZ+d =REF+a+d

Negative software end position SLN =AZ+b =REF+a+b

Positive software end position SLP =AZ+c =REF+a+c

Target position/actual position TP, AP =PZ+g =AZ+d+g

=REF+a+d+g

20 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 21

2Overview

2.6.3 Prefix and direction of rotation

All points and offsets have a sign prefix. The following applies for EPCO type drives (unless reversal of

direction has been activated):

Value

+ Positive values face from the basis point in the direction of the extended end position.

– Negative values face from the basis point in the direction of the retracted end position.

2.6.4 Units of measurement

During parameterisation via a web browser or FCT you can use commonly used units for length

specifications, such as millimetres or inches.

If you are using CVE objects, you will need the so-called interface increments SINC ( appendix B.2).

Direction

2.7 Homing run

A homing run must be performed every time the logic voltage supply is switched on in order to anchor

the reference point and the measuring reference system in the positioning range of the axis. A drive

function cannot be started without a successful homing run (exception: jogging).

2.7.1 Homing overview

– Homing methods to a fixed stop

( section 2.7.2)

– Homing methods to reference switch with/without index

( section 2.7.3)

– Homing method “current position”

( section 2.7.4)

– Automatic homing (valve profile)

( section 2.7.5)

– Movement to zero

( section 2.7.6)

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 21

Page 22

2Overview

2.7.2 Homing methods to a fixed stop

Homing to a fixed stop is only possible in closed-loop operation ( section 2.2.4).

The stop is detected by a motor shutdown in combination with a sharp rise in the motor current. The

parameters for stop detection can be set in FCT.

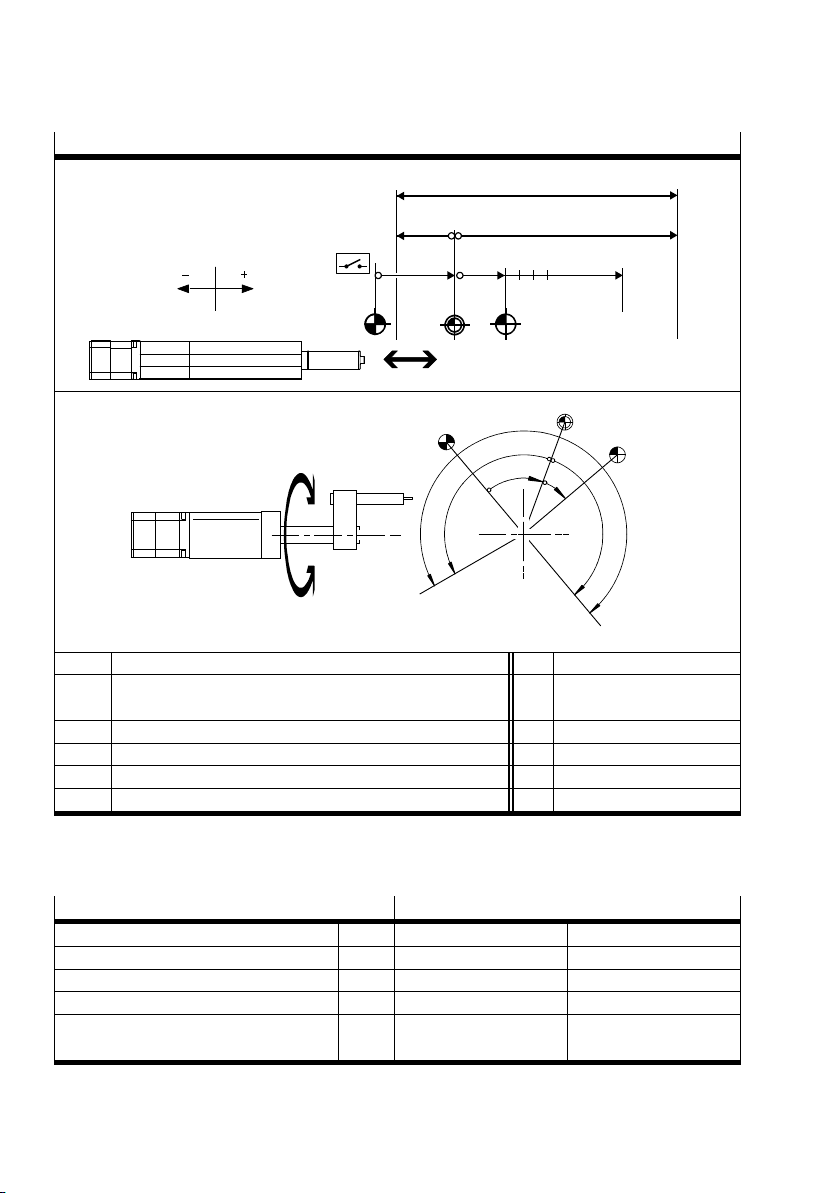

Homing m ethods to the stop

– Negative fixed stop (retracted end position)

REF

2

REF

+

AZ

1

– Positive fixed stop (extended end position)

REF

1

AZ

2

–

1 Homing: The drive moves to the fixed stop at the search speed (= reference point RE F).

2 Movement to zero: the drive moves from the reference point REF to the axis zero point AZ.

Tab. 2.3 Homing to the stop

Note

Material damage due to moved measuring reference system

In the event of greatly reduced dynamic values (low maximum motor current) combined

with high travelling resistance (e.g. due to frictional grip), there is a danger that the

drive will come to a standstill and the controller will recognise a stop incorrectly.

A movement to zero should be executed when homing to a fixed stop ( section 2.7.6)

in order to exit the stop position. Otherwise the drive could be driven continuously

against an elastic stop, which would result in a strong temperature increase and eventually lead to the controller shutting down.

If the system does not have a stop (axis of rotation), the homing run will never be completed, i.e. the drive will run continuously at the parameterised search speed.

REF

22 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 23

2Overview

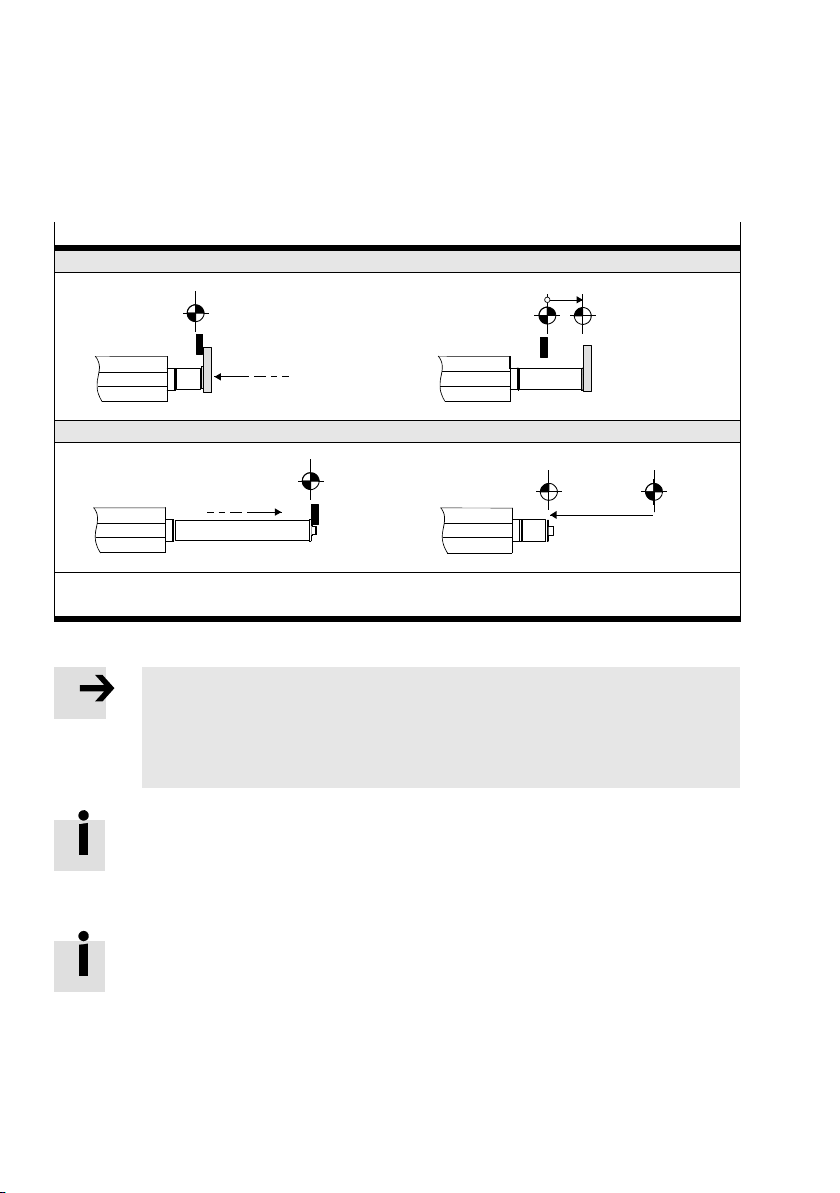

2.7.3 Homing methods to switch with/without index search

Homing methods to switch

– Direction: negative

1

2

+

REF

AZ

– Direction: positive

1

2

AZ

REF

1 The drive runs to the switch at the search speed, turns around and moves slowly at creep speed

in the reverse direction. The reference point REF is at the switch-off point of the switch or on the

following index pulse (depending on parameterisation).

2 Optional movement to zero: The drive runs from the reference point REF at positioning speed to

the axis zero point AZ.

Tab. 2.4 Homing to switch

For closed-loop operation ( section 2.2.4):

A distinction is made between the following options:

1. At the start of the homing run th e switch is already actuated.

In this case, the drive runs counter to the parameterised homing direction.

2. The switch is only found after the start of the movement.

In this case, the drive initially runs in the parameterised homing direction, turns after locating the

switch edge and moves in the reverse direction.

3. The drive moves against a stop before a switch is found.

In this case, the drive reverses and searches for the switch in the reverse direction. If a switch is

found, the drive moves through the complete switching range.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 23

Page 24

2Overview

In all cases the reference point is either at the switch-off point or on the following index

pulse (dependent on the homing m ethod selected).

For the last case: If a switch is not found in the reverse direction before a stop is

reached, the homing run is aborted with an error message.

If no switch is found at all and no stop is available, the homing run will never be completed, i.e. the drive will run continuously at the parameterised search speed.

For a homing run with index search: If no index pulse is found during the index search

over more than one motor rotation, the homing run is aborted with an error message.

For open-loop operation ( section 2.2.4):

The homing run in open-loop operation is generally executed in the same way as in closed-loop operation. However, the following special features apply:

– Stops are not detected

– An index search is not possible

– If a switch has not been found after a certain period of time, the homing run is aborted with an

error message. This timeout time can be set in FCT (“Homing” panel, “Settings” tab). The drive

therefore must always be positioned before the start of a homing run so that it can find the switch.

2.7.4 Homing method “current position”

The current position becomes the reference position. Apart from an optional movement to zero

( section 2.7.6), no positioning motion is executed.

In open-loop operation ( section 2.2.4) without a reference switch, this is the only possible homing

method.

2.7.5 Automatic homing (valve profile)

An “automatic homing run“ can be parameterised in the valve profile (FCT: “Homing” panel,

“Settings” tab).

This is executed automatically if the drive is not referenced at the start of a position record. The

started position record is then executed.

The automatic homing run is aborted if the position record input is reset again before the automatic

homing run has been executed completely.

24 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 25

2Overview

2.7.6 Movement to zero

A movement to zero is possible after a homing run. This is where the drive moves to the parameterised

axis zero point after finding the reference point.

Whether or not a movement to zero is executed can be defined as a homing run parameter in FCT. The

movement to zero is required when homing to the stop; the minimum offset to the axis zero point is

1 mm.

If a movement to zero is not executed, the drive remains at position (-1) * offset axis zero point. Make

sure that this position is not outside the software end positions.

If a movement to zero is to follow a homing run, “Motion complete” will only appear after

completion of the movement to zero. Motion Complete remains inactive between the

homing run and movement to zero.

A movement to zero should be executed when homing to the stop in order to exit the

stop position. Otherwise the drive could be driven continuously against an elastic stop,

which would result in a strong temperature increase and eventually lead to the controller

shutting down.

2.8 Monitoring functions

A complex system of sensors and monitoring functions ensures operational reliability:

– Voltage monitoring: detection of undervoltages and overvoltages in the logic and load voltage

supply.

– Temperature monitoring: output stage and CPU temperature in the CMMO-ST.

2

–I

t monitoring/overload protection

– Software end position recognition

– In the binary profile: contouring error monitoring (e.g.in the event of sluggishness or overloading of

the drive).

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 25

Page 26

2Overview

2.9 Safety aspects

Note

Check within the framework of your EMERGENCY STOP procedures to ascertain the

measures that are necessary for switching your machine/system into a safe state in the

event of an EMERGENC Y STOP.

• If an EMERGENCY STOP circuit is necessary for your application, use additional, separate safety

limit switches (e.g. as normally closed limit switches wired in series).

• Use hardware limit switches or, if required, mechanical safety limit switches and fixed stops or

shock absorbers as appropriate in order to make sure that the axis always lies within the permitted

positioning range.

• Note the following points:

Action

Cancellation of

the ENABLE signal

on the I/O

interface

Switching off the

load voltage

Behaviour

– Without brake/clamping unit:

The drive brakes with the quick stop ramp (Quick stop). The controller

output stage is then switched off. The effective load could possibly slide

down if mounted in a vertical/incline d position.

– When using a brake/clamping unit:

If the drive moves when ENABLE is cancelled, then it will initially be brought

to rest using Quick Stop deceleration. As soon as the drive has come to a

standstill, the brake output is reset: the brake/clamping unit closes.

Simultaneously, the switch-off delay time begins to run. The CMMO-ST still

controls the position. The controller end stage is switched off after the

switch-off delay.

The load voltage is switched off. The effective load on the drive may continue to

move due to inertia, or it will fall if mounted in a vertical or sloping position.

For STO function: separate document GDCP-CMMO-ST-STO-…

26 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 27

3Mounting

3 Mounting

3.1 General instructions

Caution

Uncontrolled drive motion may cause personal injury and material damage.

• Switch off the power supplies prior to any assembly, installation or maintenance

work and prevent them from being restarted accidentally.

Caution

If a drive is mounted in a sloping or vertical position, loads may fall and cause personal

injury.

• Check whether external safety measures are necessary (e.g. toothed latches or

moveable bolts).

This will prevent the work load from sliding suddenly if there is a voltage failure.

Note

When mounting the controller on the machine:

• Observe the IP protection class of the controller and the connectors/cables.

Also observe the operating instruction(s) for the drive and the instructions provided with

any additional components (e.g. assembly instructions for t he cables concerning bending

radii or suitability for use with energy chains).

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 27

Page 28

3Mounting

3.2 Dimensions of the controller

108 mm

113 mm

39 mm

Fig. 3.1 Dimensions of the controller

28 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 29

3Mounting

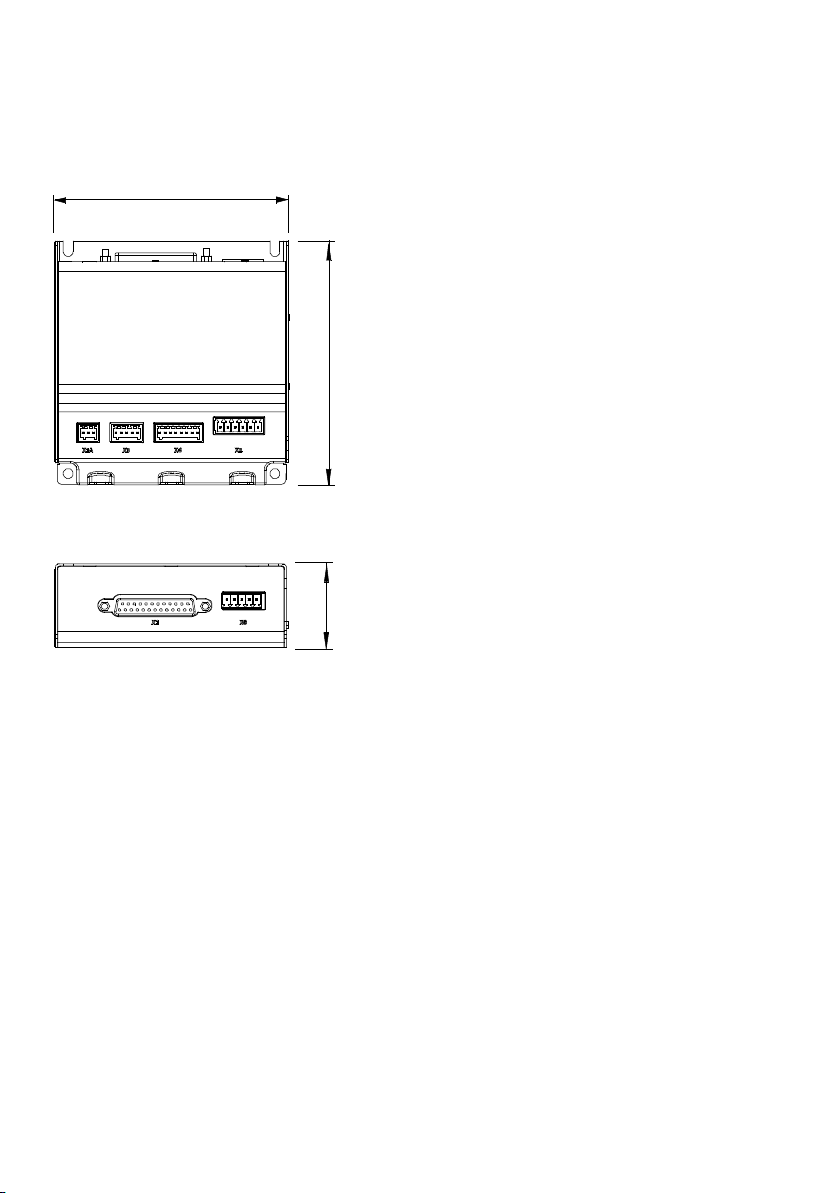

3.3 Mounting the controller

You can mount the controller in one of two ways:

1. Threaded c onnection on a flat surface

2. H-rail mounting

3.3.1 Fitting

You will need 3 or 4 M4 screws, with washers/spring washers if necessary. If a H-rail clip is mounted,

you can remove it.

The following figure shows the location of the holes and recesses that can be used for mountingthe

controller:

12

1

1 Mounting with 4 screws to the base

(lying flat)

2 Mounting on the side with 3 screws

(vertical)

Fig. 3.2 Mounting with screws

When mounting on the side ( 2 ): To exchange the controller, you only need to loosen the

3 screws by a few rotations, after which the controller can be tilted out.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 29

Page 30

3Mounting

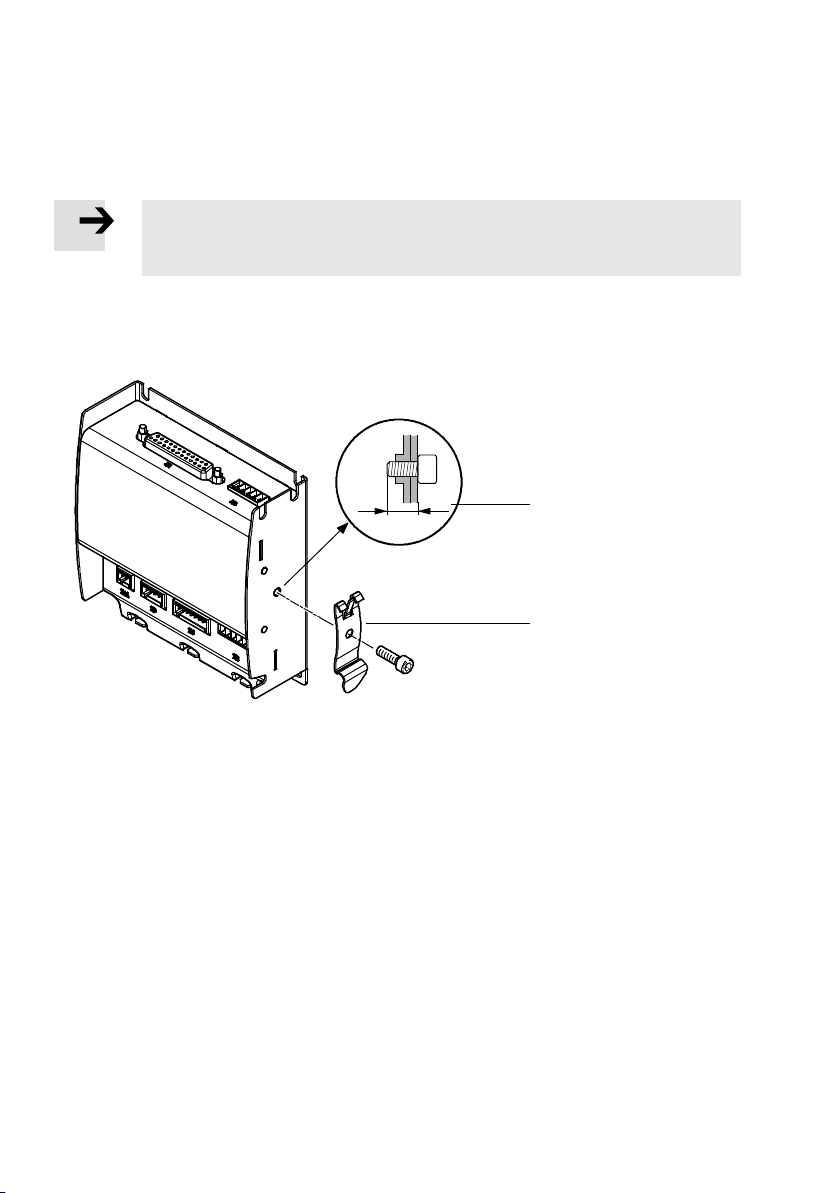

3.3.2 H-rail mounting

1. Mount an H-rail (mounting rail in accordance with IEC/EN 60715: TH 35– 7.5 or TH 35– 15).

2. If not already mounted: Screw the H-rail clip 1 to the side of the controller ( Fig. 3.3).

Note

When using another screw: Please observe the maximum permitted screw-in depth of

5 mm.

3. Hang the CMMO on the H-rail as follows:

• by inserting the top into the hooks in the clip first, then

• press the H-rail downwards until the CMMO clicks into place.

2

max. 5 mm

1

1 H-rail clip 2 Maximum screw-in depth

Fig. 3.3 H-railmounting

30 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 31

4 Electrical installation

4 Electrical installation

4.1 Overview

Caution

Uncontrolled drive motion may cause personal injury and material damage

• Switch off the power supplies prior to any assembly, installation or maintenance

work and prevent them from being restarted accidentally.

Caution

Faulty pre-assembled lines may destroy the electronics and trigger unexpected movements of the motor.

• When wiring the system only use t he supplied connectors and pref erably the cables

that are listed as ac c essories ( Tab. 4.1 ) .

• Lay all flexible lines so that they are free of kinks and free of mechanical stress; if

necessary use chain link trunking.

If unused plug connectors are touched, there is a danger that damage may occur to the

CMMO or to other parts of the system as a result of electrostatic discharge (E S D). Place

protective caps on unused terminals to prevent such discharges.

Note

To ensure compliance with EMC safety:

The maximum length of the individual cables should not exceed 30 m.

The project engineeringperformance data relates to a maximum cable length of 10 m.

To ensure compliance with the IP protection class (if required):

• Please note that the specified IP protection class is only achieved with a full plug

and cable assignment.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 31

Page 32

4 Electrical installation

1

2

3

45 6

1 Power supply (X9)

2 Higher-order controller (PLC/IPC) (X1)

3 Ethernet (X18)

7

5 STO ( X3)

6 Encoder (X2)

7 Motor (X6)

4 Reference switch (X1A)

Fig. 4.1 Connections on the CMMO-ST

)

Port

Cable and Festo type code

1

1 Power (X9) To be prepared by the customer

2 PLC/IPC (X1) Connecting cable: NEBC-S1G25-K-…-N-S1G25

Control cable: NEBC-S1G25-K-3.2-N-LE25

Connection block: NEBC-S1G25-C2W25-S7

Plug: N EBC-S1G25-C2W25-S6

3 Ethernet (X18) Standard network c able, RJ45 plug connector; c ategory 5 or higher

4 Reference switch (X1A) See Festo catalogue

5 STO (X3) To be prepared by the customer

6 Encoder (X2) Encoder cable

– NEBM-M12G8/W8-E-…-LE (G = straight; W = angled)

7 Motor (X6) Motor cable

– NEBM-S1W15-E-…-Q7: for motors with 15-pin plug

– NEBM-S1W9-E-…-Q5: for motors with 9-pin plug

– NEBM-M12G8-E-…-Q5: for size 28 motors

1) Specifications status August 2012. Only the current specifications in the Festo catalogue are relevant: www.festo.com

Tab. 4.1 Overview of cables (accessories)

32 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 33

4 Electrical installation

Observe the tightening torques specified in the documentation for the cables and plugs

used. The assortment of plugs supplied with the CMMO-ST is also available under the

type code NEKM-C-10.

4.2 Power supply [X9]

Port Pin Function

1 – Do not connect!

51

2 – Do not connect!

X9

51

Tab. 4.2 Port X9 “Power” (power supply)

Caution

Damage to the device

With port X9, always pay attention to the correct pin number corresponding to the plug

location on the device.

• Make sure that Pin 1 and Pin 2 are not connected.

3 Logic voltage +24 V supply of the control

electronics

4 Reference

potential

5 Load voltage +24 V supply of the power

0 V reference potential for load

voltage, logic voltage, STO and

controller interface

output stage and the motor

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 33

Page 34

4 Electrical installation

Protection against electric shock (protection against direct and indirect contact) is guaranteed in

accordance with IEC/DIN EN 60204-1 by using PELV circuits (Electrical equipment of machines, general

requirements).

War n ing

• Use only PELV circuits in accordance with IEC/DIN EN 60204-1 (protective extra-low

voltage, PELV) for the electrical power supply.

Also comply with the general requirements for PELV circuits laid down in

IEC/DIN EN 60204-1.

• Use only power units which guarantee reliable electrical isolation of the operating

voltage as per IEC/DIN EN 60204-1.

Caution

Damage to the device

The power supply inputs have no special protection against overvoltage.

• Make sure the permissible voltage tolerance is never exceeded.

Technical data of the voltage supply: ( appendix A.1).

4.3 Functional earth

The metal sub-base of the CMMO-ST is used as a functional earth. It is galvanically isolated from the

power supply and, among other things, ensures EMC safety.

Note

• Connect the metal sub-base of the CMMO-ST to the earth potential with low

impedance (short cable with large cross section).

This prevents interference from electromagnetic sources and ensures electromagnetic

compatibility in accordance with EMC directives.

34 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 35

4 Electrical installation

4.4 I/O interface [X1]

Communicationwith the higher-order controller (PLC/IPC) occurs via the I/O interface.

Connection to the CMMO

14 25

1

PNP

Pin 1 2 … 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

I/O 1 2 … 11 1 2 3 4 5 6 7 8 9 10 11 – +24 V 0V

Inputs Outputs – Out GND

Tab. 4.3 Por t X1

Pin 24 and pin 25 can be used to switch an input ( illustration in Tab. 4.3):

– PNP version: Pin 24 at input

– NPN version: Pin 25 at input

Caution

Damage to the device

Pin 24 and pin 25 are not short circuit proof.

The functional description of the I/O interface, dependent on the selected profile, can be

found in the Commissioning chapter.

24

X1

NPN

13

25

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 35

Page 36

4 Electrical installation

4.4.1 Electrical specifications of [X1]

The following specifications apply to both the PN P and NPN variants of the CMMO-ST.

Specifications for the I/O controller interface

Signallevel Based on EN 61131-2, type 1

Inputs

Scanning rate 1ms

Input current at nominal input voltage Typically 2 mA per input

Max. permissible input voltage 29 V

Galvanic isolation No

Outputs

Maximum Current 0.1 A per output

Overload protection Protected against short circuits

Pin 24 (24 V carried out)

Overload protection No (not protected aga inst short circuits). Only use for

switching inputs. Max. 0.1 A.

Tab. 4.4 Specificationsfor the I/O controller interface

4.5 Reference switch [X1A]

Port Pin Function

1 +24 V logic Voltage output for supplying the

13

reference switch (from X9). Not

protected against short circuits.

X1A

2 Signal Voltage input: +24 V with closed or

open reference switch contact

(depending on switch type).

3 0V Reference potential

13

T ab. 4.5 Connection X1A reference switch

The types listed in the Festo catalogue for the respective drive are suitable for use as

reference switches ( www.festo.com).

36 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 37

4 Electrical installation

4.6 STO [X3]

The STO safety function (“Safe Torque Off ”) is described in detail in the document

GDCP-CMMO-ST-STO-…

The STO function should only be used in the manner described in this document.

Port

1

5

X3

15

T ab. 4.6 Connection X3 STO

Pin Function

1 +24 V logic Logic voltage output (from X9)

2 STO 1 Channel 1: switch off the supply

voltage

3 STO 2 Channel 2: switch off the supply

voltage

4 Diagnostics 1 The diagnostic contacts are

potential-free.

The diagnostic contact is low

5 Diagnostics 2

impedance if the STO function has

been requested and activated via

two channels.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 37

Page 38

4 Electrical installation

4.7 Encoder [X2]

An incremental encoder with signals in accordance with RS422 can be connected at connection X2.

Port

18

X2

18

1) Each 5 V and Ri = approx. 120 Ω

T ab. 4.7 Connection X2 encoder

Pin Function

1)

1 A/

1)

2 A/

1)

3 B/

1)

4 B/

1)

5 N/

1)

6 N/

7 5V(±10%) Supply of the encoder.

8 0V Reference potential

Incremental encoder signal A+,

Positive polarity

Incremental encoder signal A–,

Negative polarity

Incremental encoder signal B+,

Positive polarity

Incremental encoder signal B–,

Negative polarity

Increment encoder signal zero pulse,

positive polarity

Increment encoder signal zero pulse,

negative polarity

Max. 100 mA permissible.

Not protected against short circuits.

4.8 Motor [X6]

Port Pin Function

1 String A Connection of the two motor strings

1

X6

1

Tab. 4.8 Connection X6 motor

38 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

6

2 String A/

3 String B

4 String B/

5 BR+ Connection of the holding brake

Short circuit and overload-proof.

24 V, max. 1.4 A 33 W.

BR– = GND,

BR+ is switched (24 V load)

6

6 BR–

Page 39

5 Commissioning

5 Commissioning

5.1 Safety regulations

War n ing

Risk of injury.

Electric axes move with high force and at high speed. Collisions can lead to serious

injury to people and damage to components.

• Make sure that nobody c an reach into the operating range of the axes or other

connected ac tuators – e.g. with a protective grille – and that no objects lie in the

positioning range while the system is still connected to a power supply.

Caution

Unexpected movement of the drive due to incorrect or incomplete parametrisation!

When the CMMO-ST is switched on, the I/O control interface is activated as standard.

• Make sure that there is no ac tive ENABLE signal when switching on the CMMO-ST on

the I/O control interface.

• Parameterise the entire system completely before activating the output stage with

ENABLE.

Caution

When c ontrol via the web browser or FCT is activated, the drive cannot be stopped with

the PAUSE/STOP input or the ENABLE input of the I/O control interface.

Caution

The CMMO-ST cannot detect if the connection to the web browser has been interrupted.

Movements that have been started via the web browser c an no longer be stopped by

using the web browser if the Ethernet connection is interrupt ed during the movement.

• Only use the web browser if you are sure that accidental movements will not result in

any damage.

Caution

Housing surfaces can reach high temperatures. Contact with the surface may result in

shock and uncontrolled reactions wit h subsequent damages.

• Make sure that the surface cannot be touched accidentally and inform your operating and maintenance staff of the possible hazards.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 39

Page 40

5 Commissioning

Note

The CMMO-ST does not carry out any positioningjobs/records if it is not referenced.

• Carry out a homing run in the following cases to anchor the measuring reference

system to the reference point:

– every time the logic voltage supply is switched on or after every failure

– after changing the homing method, the axis zero point, the direction of rotation

Note

If the axis zero point is modified:

Existing software end positions and the target positions in the record table will be

shifted together with the axis zero point.

• Adjust the software end positions and the target positions if necessary.

Note

Damage to components when the permissible impact pulse is exceeded.

• Operate the drive only with the permissibleload ( operating instructions for the

drive).

• If necessary, limit the maximum current (motor force) when travelling to the stop.

Note

Interruption of ongoing tasks due to inadequate load voltage supply.

• Make sure that the tolerance of the load voltage supply can be maintained at full

load directly on the voltage terminal of the CMMO-ST ( section 4.2).

or the encoder resolution

40 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 41

5 Commissioning

5.2 Ethernet interface (RJ-45)

5.2.1 Delivery status of the CMMO-ST

Note

The CMMO-ST is equipped during production with a active DHCP server (Dynamic Host

Configuration Protocol).

• Before adding the CMMO-ST to an existing network, please observe the instructions

in section 5.2.5 “Initial start-up”, as these will enable you to prevent network malfunctions.

Computers with an active DHCP client ac c ept all DHCP servers. If two DHCP servers are activated in a

network by mistake, the functionality of the network may be impaired.

CMMO-ST network settings

Parameters Val u e

IP 192.168.178.1

DHCP server Active

Port Web browser: 8 0

FCT: 7508

CVE (= Control via Ethernet): 49700

Subnet mask 255.255.255.0

Gateway 0.0.0.0 (none)

Tab. 5.1 Network settings: delivery status

5.2.2 DHCP or fixed IP address

Behaviour of the DHCP server

The DHCP server of the CMMO-ST is intended to establish a direct connectionbetween the CMMO-ST

and an individual computer. It is not intended to supply larger networks with IP addresse s.

It assigns IP addresses in a range of 192.168.178.110 … 192.168.178.209 and the subnet mask

255.255.255.0. A gateway is not assigned.

Additional configuration options

DHCP client

The CMMO-ST can also be configured as a DHCP c lient. It then obtains its IP address from a DHCP

server in your network.

Specifying a fixed IP address

Alternatively you can also assign a fixed IP address to the CMMO-ST.

These settings can be adjusted, if required, in FCT ( section 6.4.3).

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 41

Page 42

5 Commissioning

After making changes to the network configuration of the CMMO-ST, it will need to be

restarted in order for the changes to take effect.

5.2.3 Safety in the network

Caution

When c onnecting the CMMO-ST to existing networks (e.g. the Internet): any unauthorised or accidental access to the CMMO-ST c ould result in unforeseeable behaviour.

• Only use the CMMO-ST in subnets that are protected from external unauthorised

access, e.g. by using net w ork security components (special gateways/firewalls).

Use a password if you want to prevent ac c idental access to the CMMO-ST (in FCT: menu

option “Component” / Online / Password).

5.2.4 Timeout

The CMMO-ST detects if the connection to the FCT software has been interrupted and it behaves in

accordance with the settings parameterised in FCT under “Error management” (error number 0x32).

The timeout period is typically 1 s, but it can be longer in slow networks, as the timeout period is

dynamically adapted to the transmission rate.

Caution

The CMMO-ST cannot detect if the connection to the web browser has been interrupted.

Movements that have been started via the web browser c an no longer be stopped by

using the web browser if the Ethernet connection is interrupt ed during the movement.

• Only use the web browser if you are sure that accidental movements will not result in

any damage.

42 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 43

5 Commissioning

5.2.5 Initial start-up via Ethernet

The CMMO-ST will need to be connected directly to a computer/laptop for the initialstart-up phase.

The CMMO-ST cannot be connected immediately to a network during the initial start-up phase, as its

active DHCP server could result in network malfunctions.

1. Switch on the CMMO-ST and connect it to your computer/notebook by using a standard Ethernet

cable (connector: RJ-45). The cable type, i.e. whether it has a straight or crossed connection, is

detected automatically. The DHCP server in the CMMO-ST will now assign an IP address to your

computer, enabling you to access the CMMO-ST (requirement: a DHCP client is active on your computer = default setting for most computers).

Fig. 5.1 Initialstart-up via direct connection

2. Launch your web browser (activate Internet Explorer >6; Firefox >3; JavaScript) and type the IP

address of the CMMO-ST into the address bar (default setting: 192.168.178.1). The CMMO-ST

website will now appear ( section 5.3).

3. Alternatively to the web browser, you can also install the FCT software fromtheCD.TheFCTsoftware makes more complex configurations possible than the web browser does ( section 5.4).

If you cannot establish a connection to the CMMO-ST: section 6.4.3.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 43

Page 44

5 Commissioning

5.3 Commissioning via web server

The web server integrated in the CMMO-ST provides access to an English-language parameterisation

and commissioning website, which you can call up with a web browser. Commissioning via the web

server is possible for selected products, i.e. axis mechanisms optimised by Festo.

5.3.1 What does the web server enable?

Parameter files

Uploading and downloading parameter files for initial start-up or for use as backup files.

Homing

Starting a homing run in accordance with the homing method parameterised in the CMMO-ST (default

settings: Tab. 5.2).

The homing run can only be started; a c hange of the homing method must take place in FCT.

Jogging

Jog mode in both directions.

Teaching

Teaching of up to 7 absolute target positions; parametrisation of speed and acceleration of the resulting position records.

Relative target positionscannot be taught. Corresponding position records, however, c an be entered by

hand.

Positioning

Starting and stopping the 7 position records.

I/O

Display of the electro-physical status of the inputs and outputs of the I/O interface.

Diagnostics

Read-out of the diagnost ic memory and display of the most important controller statuses.

Identification

Wave function: Activating a radio button (“Identify this CMMO”, Fig. 5.2) causes the decimal point in

the 7-segment display of the currently connected CMMO-ST to start flashing.

5.3.2 Parameter files

The parameter files support the initial start-up of your drive. The parameter files corresponding to the

respective drive type can be found:

– on the supplied CD

– on the Festo Support Portal fo r download

– as “Cloud” parameter on the Festo Internet Server

44 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 45

5 Commissioning

The parameter files for EPCO drives include the following settings, for example:

Parameters

Default setting

Control Profile Valve profile (7), i.e. 7 position records can be

parameterised via web ser vers, for example:

– target position (absolute/relative)

– travel speed

– acceleration (start up/braking)

– reductionofthefeedforce(forcelimit)

Reference travel method (controlled operation) – negative stop (motor-side) with movement to

zero

– force limit for stop detection

– movement to zero 3 mm

Reference travel speeds:

– Search speed

– 2.5 % of the maximum speed

1)

(travel to the switch/stop)

– Creep speed

– 1.25 % of the maximum speed

1)

(travel to the switch edge/index pulse)

– Positioning speed

– 5 % of the maximum speed

1)

(travel to the axis zero point)

Dimensional reference system:

– Position of the axis zero point

– Software limit switch (negative)

– Software limit switch (positive)

– +3mmfromthemechanicalstop

––3mm

– (stroke length – 3 mm)

Jogging

– Speed phase 1 (slow travel)

– Duration of phase 1

– Speed phase 2 (fast travel)

– 1.25 % of the maximum speed

–2s

– 5 % of the maximum speed

1)

1)

Condition for the “Position reached” message

(Motion complete)

–Targetwindow

– Message Delay

– +/- 0.2 mm

– 100 ms

STOPbuttoninthewebbrowser Deceleration ramp of t he current function

(e.g. of the current record)

Quick Stop (triggered by the controller,

70 % of the maximum deceleration

1)

e.g. in the event of a serious error)

1) The maximum values for speed, acceleration, force, etc. depend on the mechanical system used and can be read via FCT if

required.

Tab. 5.2 Valve profile: default values (EPCO)

All other settings of the parameter files can be read in FCT as needed.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 45

Page 46

5 Commissioning

5.3.3 Initial start-up with the web server

If you have accessed the CMMO-ST website in accordance with section 5.2.5, you will initially be

presented with the diagnostics page:

Fig. 5.2 Website: diagnostics

46 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 47

5 Commissioning

1. Switch to the parameterisationpage by clicking <Parameters> at the far right.

2. Enter the type code of your EPCO drive in the uppermost text box in accordance with the rating

plate, and click <Search> to download a suitable parameter file from the Festo website (Internet

access required). Caution: Incomplete entry of the code may result in malfunctions, uncontrolled

behaviour and damage.

If you do not have a second network connection (e.g. WLAN/WiFi), you can continue to step 4 and

use the parameter file on the CD.

Fig. 5.3 Website: parameters

3. Click <Save> in the Windows dialogue window “Download file” to save the file to your computer.

4. Click <Browse> and select the downloaded parameter file in the dialogue window.

Fig. 5.4 Selecting a parameter file

5. Click the box next to “Device Control” to assume higher-order control.

Fig. 5.5 Assuming higher-order control

6. Click on <Download parameter set to CMMO>.

Fig. 5.6 Transferring a parameter file to the CMMO-ST

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 47

Page 48

5 Commissioning

7. The following screen confirms the successful transmission. The parameter file is automatically

saved in the CMMO-ST.

Fig. 5.7 Download completed successfully

8. To teach position records: Switch to the parameter side again by clicking <Parameters> at the far

right. Then set the enable signal for the output stage by clicking the box next to “Control Enable”.

Fig. 5.8 Setting enable

9. First, start a homing run by c licking the <Start Homing> button (default setting: negative stop

(motor-side) with movement to zero Tab. 5.2).

Then click the <Jog neg.> or <Jog pos.> buttons to move the drive in a negative or positive direction

(in this example: to position 10.00 mm).

Fig. 5.9 Jogging

10. Select “Positioning to absolute position” from the first drop-down menu in the position record table

and then click <Teach Pos>.

Fig. 5.10 Teach

11.Move to a different position and teach this position to position record no. 2.

12. Enter the additional positions. Relative target positions can be entered by hand, but they cannot be

taught.

48 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 49

5 Commissioning

Fig. 5.11 Website: Parameters – Record Sets (1)

13.Adjust the valuesfor travel speed, acceleration and force limit.

Fig. 5.12 Website: Parameters – Record Sets (2)

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 49

Page 50

5 Commissioning

Through the digital output “Force limit reached” (DOUT 11), reaching the parameterised

maximum force (“Torque”) can be displayed. In this way, with corresponding parameterisation, a load limit can be displayed at which the motor can no longer follow the

position sequence (following error). An additional following error message is not activated with these parameter records.

14.Click the <Download> button underneath the position record table in order to transfer the new

position records to the CMMO-ST.

15.To t e s t the taught position records: click the <Move to Pos.> button next to the desired position

record. The drive moves to the respective position.

Fig. 5.13 Executing position records

16.To permanently store the new position records in the CMMO-ST: remove the check mark next to

“Control Enable” and then click the <Store> button underneath the position record table.

Fig. 5.14 Saving position records in the CMMO-ST

5.3.4 Creating a parameter backup file

When parameterisation is complete you can c reate a backup copy of your parameters by using the web

browser. If you ever need to replace the CMMO-ST, you can import this paramete r file into the new

CMMO-ST. Re-parameterisationis therefore no longer required.

1. Establish a connection to the CMMO-ST and launch your web browser as described in section 5.2.5.

2. Click <Upload parameter set to PC>.

Fig. 5.15 Creating a backup copy

3. Click <Save> in the Windows dialogue window “Download file” to save the file to your computer. Give

the file a unique name (*.fpf = Festo Parameter File).

4. To import the parameter backup file into a new CMMO-ST: proceed as described in section 5.3.3

under points 4 ... 7.

The backup copy can also be created by using FCT (“Component / Online / Administer

recoveryfile...”).

50 Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English

Page 51

5 Commissioning

5.4 Commissioning with FCT (Festo Configuration Tool)

The Festo Configuration Tool (FCT) is the software platform for configuring and c ommissioning different

components and devices from Festo.

The FCT consists of the following components:

– A framework as program start and entry point with uniform project and data management for all

supported device types.

– A plug-in for the special requirements of each device type (e.g. CMMO-ST) with the necessary

descriptionsand dialogues. The plug-ins are managed and star ted from the framework.

The FCT software provides more extensive configuration options than the web browser. The binary profile can be used in particular, which also enables jogging and teaching via the I/O interface, force mode,

speed mode and record linking.

The following pages only describe the first few steps in FCT. Implement all other steps in

accordance with the instructions in the integrated FCT help system.

5.4.1 Installing the FCT

Note

FCT plug-in CMMO-ST V 1.0.0 supports the motor controller CMMO-ST-…-IO with firmware version V 1.0.x

For later versions of th e CMMO-ST chec k whether an updated plug-in is available. If

necessary, consult Festo.

Note

Windows administrator rights are required for installing the FCT.

The FCT is installed on your PC with an installation program.

1. Close all programs.

2. Insert the “Festo Configuration Tool” CD into your CD-ROM drive. If Auto-Run is activated on your

system, the installation starts automatically and you can skip steps 3 and 4.

3. Select [Execute] in the Start menu (for Windows 7: see “Accessories” menu).

4. Enter D:\Start (if necessary replace D by the letter of your CD ROM drive).

5. Follow the instructions on the screen.

Festo – GDCP-CMMO-ST-EA-SY-EN – 1301a – English 51

Page 52

5 Commissioning

5.4.2 Starting the FCT

1. Connect the CMMO-ST to your PC via the Ethernet interface ( section 5.2.5).

2. Start the FCT:

double click the FCT ic on on the Desktop

–or–

In the Windows menu [Start], select the entry [Festo Software] [Festo ConfigurationTool].

3. Create a project in the FCT or open an existing project. Add a CMMO-ST to the project:

menu [Components] [Insert].

Instructions on parameterising and commissioning

FCT framework

Information on working with projects and on inserting a device in a project can be found in the help for

the FCT framework with the c ommand [Help] [Contents FCT general].

Plug-in CMMO-ST

The plug-in CMMO-ST fo r the FCT supports processing of all the steps necessary for commissioning a

CMMO-ST. The necessary parameterisation settings can be performed offline, i.e. without the CMMO-ST

being connected to the PC. This enables preparation for the actual c ommissioning process, e.g. in the

design office when a new system is being planned.

Additional information can be found in the plug-in help: command [Help] [Contents of

installed plug-ins] [ Festo (manufacturer name)] [CMMO-ST (plug-in name)].