Page 1

Motor controller

Description

Fitting and

Installation

Typ CMMD-AS-...

Description

571 734

en 1002NH

[751 593]

Page 2

Page 3

Edition __________________________________________________ 1002NH en

Designation ____________________________________ P.BE-CMMD-AS-HW-EN

Order no. ___________________________________________________ 571 734

Festo AG & Co. KG, D-73726 Esslingen, 2010

Internet: 0Hhttp://www.festo.com

E-mail: service_international@festo.com

The copying, distribution and utilisation of this document as well as the communication

of its contents to others without expressed authorization is prohibited. Offenders will be

held liable for compensation of damages. All rights reserved, in particular the right to

register patents, utility patents or design patents.

Festo P.BE-CMMD-AS-HW-EN 1002NH 3

Page 4

Index of revisions

Author:

Festo AG & Co. KG

Name of manual:

Festo P.BE-CMMD-AS-HW-DE 1002NH

File name:

File saved at:

Consec. no.

Description

Index of revisions

Date of amendment

001

Produced:

1002NH

Trademarks

Microsoft® Windows®, CANopen®, CiA® and PROFIBUS® are registered brands of the

respective trademark owners in certain countries.

4 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 5

Contents

CONTENTS

1. General information .............................................................................................. 10

1.1 Documentation .................................................................................................... 10

1.2 Type code CMMD-AS-C8-3A ................................................................................. 10

1.3 Scope of delivery ................................................................................................. 11

2. Safety instructions for electric drives and controllers .......................................... 12

2.1 Icons used ........................................................................................................... 12

2.2 General Information ............................................................................................ 13

2.3 Hazards due to improper use .............................................................................. 14

2.4 Safety instructions .............................................................................................. 15

2.4.1 General safety information .................................................................. 15

2.4.2 Safety instructions for assembly and maintenance .............................. 17

2.4.3 Protection aganst touching electric components ................................. 18

2.4.4 Protection by low voltage (PELV) against electric shock ...................... 20

2.4.5 Protection against dangerous movements ........................................... 20

2.4.6 Protection aganst touching hot components ....................................... 21

2.4.7 Protection when handling and assembling .......................................... 22

3. Product description ............................................................................................... 23

3.1 General information............................................................................................. 23

3.2 Device description ............................................................................................... 23

3.3 Bus connection .................................................................................................... 24

3.4 Performance characteristics ................................................................................ 24

3.5 Interfaces ............................................................................................................ 27

3.5.1 Overview of the setpoint value interfaces ............................................ 27

3.5.2 Analogue setpoint specification ........................................................... 28

3.5.3 Interfaces for direct synchronous operation ........................................ 28

3.5.4 I/O functions and device control .......................................................... 34

3.5.5 RS232 interface (diagnosis/ parametrisation interface) ...................... 35

3.5.6 Control via RS485 ................................................................................ 40

3.5.7 Multi-firmware strategy ....................................................................... 42

3.5.8 Motor feedback .................................................................................... 42

3.5.9 Brake chopper (Brake control) ............................................................. 42

3.5.10 Feedback from motor (angle encoder) ................................................. 42

Festo P.BE-CMMD-AS-HW-EN 1002NH 5

Page 6

Contents

3.5.11 Control interface [X1] ........................................................................... 43

3.5.12 Increment generator interface [X10] ..................................................... 44

3.5.13 SD card holder [M1] ............................................................................. 44

3.5.14 SD memory card .................................................................................. 44

3.6 Field bus interface ............................................................................................... 45

3.6.1 FHPP (Festo Handling and Positioning Profile) ..................................... 46

3.6.2 CAN bus ............................................................................................... 47

3.6.3 PROFIBUS ............................................................................................ 48

3.6.4 DeviceNet ............................................................................................ 48

3.7 Function overview ............................................................................................... 49

3.7.1 Operating modes ................................................................................. 49

3.7.2 Setpoint value processing ................................................................... 50

3.7.3 I²t function ........................................................................................... 51

3.7.4 Positioning controller ........................................................................... 51

3.7.5 Homing ................................................................................................ 53

3.7.6 Trajectory generator ............................................................................ 57

3.7.7 I/O sequence control ........................................................................... 58

3.7.8 Safety functions, error messages ......................................................... 60

3.7.9 Behaviour when switching off enable .................................................. 60

3.7.10 Oscilloscope function .......................................................................... 62

3.7.11 Jog and teach function I/O ................................................................... 63

3.7.12 Position record linking with positioning/

torque control switching ...................................................................... 68

3.7.13 On-the-fly measurement ...................................................................... 74

3.7.14 Endless positioning .............................................................................. 74

3.7.15 Relative positioning records ................................................................ 76

3.7.16 Adjustment to the axis and motor construction set.............................. 76

4. Functional safety engineering .............................................................................. 77

4.1 General information and intended use ................................................................ 77

4.2 Integrated function "Safe Torque Off" (STO)....................................................... 80

4.2.1 General remarks/description "Safe Torque Off" (STO) ........................ 80

4.2.2 Timing diagram, STO ............................................................................ 81

4.2.3 Switching example STO ....................................................................... 83

4.2.4 EMERGENCY STOP request, monitoring of protective door .................. 85

4.2.5 Testing the safety function STO ........................................................... 86

6 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 7

Contents

4.3 Integrated function "Safe Stop 1" (SS1) ............................................................. 87

4.3.1 General remarks/description "Safe Stop 1" SS1 ................................. 87

4.3.2 Timing diagram, SS1 ............................................................................ 88

4.3.3 Activation of SS1.................................................................................. 90

4.3.4 Setting the switch-off delay ................................................................. 90

4.3.5 Parameterization example FCT ............................................................. 91

4.3.6 Sample circuit SS1 ............................................................................... 92

4.3.7 EMERGENCY STOP request, monitoring of protective door .................. 94

4.3.8 Restoration of normal operation .......................................................... 95

4.3.9 Testing the safety function................................................................... 95

4.3.10 Determination of the brake time .......................................................... 95

4.3.11 Setting the delay time .......................................................................... 96

5. Mechanical installation ........................................................................................ 97

5.1 Important instructions ......................................................................................... 97

5.2 Mounting ............................................................................................................. 98

6. Electrical installation .......................................................................................... 100

6.1 Device view ....................................................................................................... 100

6.2 Interfaces .......................................................................................................... 102

6.3 Entire system CMMD-AS .................................................................................... 103

6.4 Interfaces and plug assignments ....................................................................... 105

6.4.1 I/O interface [X1.1/2] ......................................................................... 105

6.4.2 Shaft encoder motor – EnDat 2.1 and 2.2 [X2.1/2] ............................. 108

6.4.3 Safe stop [X3.1/2] .............................................................................. 109

6.4.4 Field bus CAN [X4] .............................................................................. 109

6.4.5 RS232/RS485 [X5] ............................................................................. 109

6.4.6 Motor connection [X6.1/2]: ................................................................ 110

6.4.7 Power supply [X9] .............................................................................. 110

6.4.8 Synchronisation control [X10.1/2] ..................................................... 111

6.4.9 SD card [M1] ...................................................................................... 111

6.4.10 Field bus settings and boot loader ..................................................... 112

Festo P.BE-CMMD-AS-HW-EN 1002NH 7

Page 8

Contents

6.5 Instructions on safe and EMC-compliant installation ......................................... 113

6.5.1 Explanations and terms ..................................................................... 113

6.5.2 Connection instructions ..................................................................... 113

6.5.3 General information on EMC .............................................................. 113

6.5.4 EMC areas: second environment ........................................................ 114

6.5.5 EMC-compliant wiring ........................................................................ 114

6.5.6 Operation with long motor cables ...................................................... 115

6.5.7 ESD protection ................................................................................... 115

7. Preparations for commissioning ......................................................................... 116

7.1 General connection instructions ........................................................................ 116

7.2 Tools / material ................................................................................................. 116

7.3 Connect the motor to the motor controller ........................................................ 116

7.4 Connecting motor controller to the power supply .............................................. 117

7.5 Connecting a PC ................................................................................................. 117

7.6 Checking readiness for operation ...................................................................... 117

7.7 Timing diagram switch-on sequence ................................................................. 118

8. Service functions and error messages ................................................................ 119

8.1 Protective and service functions ........................................................................ 119

8.1.1 Overview ............................................................................................ 119

8.1.2 Temperatur monitoring for motor and power section,

shaft encoder monitoring ................................................................... 119

8.1.3 Short-circuit monitoring of the output stage/overload current

and short-circuit monitoring .............................................................. 119

8.1.4 Voltage monitoring for the intermediate circuit ................................. 120

8.1.5 I²t monitoring ..................................................................................... 120

8.1.6 Temperature monitoring for the heat sink ......................................... 120

8.1.7 Power monitoring for the brake chopper ........................................... 120

8.2 Operating mode and error messages ................................................................ 121

8.2.1 Operating mode and error display ..................................................... 121

8.2.2 Error messages .................................................................................. 121

A. Technical data ..................................................................................................... 125

A.1 General .............................................................................................................. 125

A.2 Operation and display components ................................................................... 126

A.2.1 Status display .................................................................................... 126

A.2.2 Control elements ............................................................................... 126

8 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 9

Contents

A.3 Interfaces .......................................................................................................... 127

A.3.1 I/O interface [X1.1/2] ......................................................................... 127

A.3.2 Shaft encoder motor [X2.1/2] ............................................................ 128

A.3.3 CAN bus [X4] ...................................................................................... 128

A.3.4 RS232/RS485 [X5] ............................................................................. 128

A.3.5 Motor connection [X6.1/2] ................................................................. 129

A.3.6 Power supply [X9] .............................................................................. 130

A.3.7 Increment generator interface [X10.1/2] ............................................ 130

B. Index ................................................................................................................... 131

Festo P.BE-CMMD-AS-HW-EN 1002NH 9

Page 10

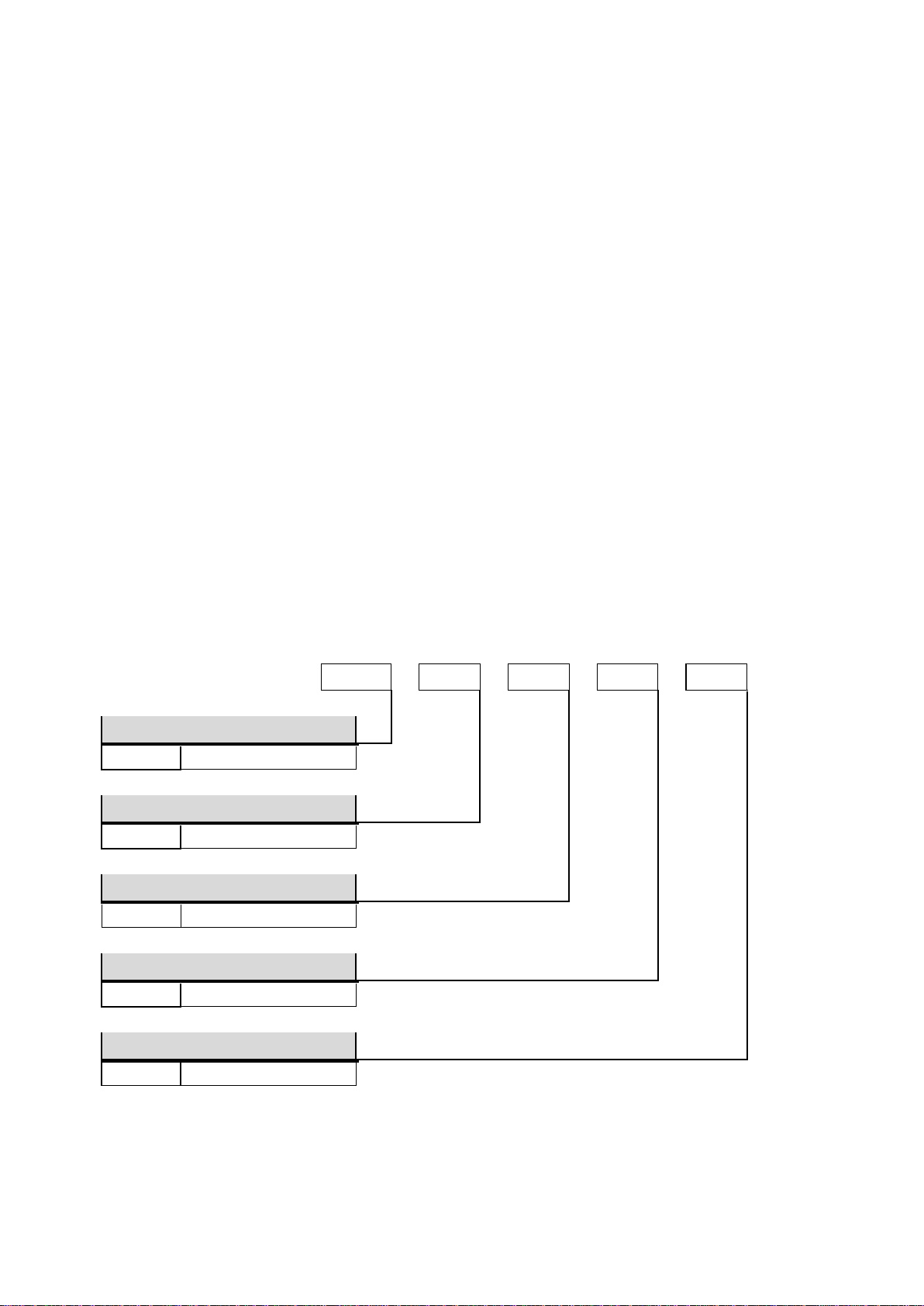

1. General information

CMM

— D —

AS — C8 — 3A

Series

CMM

Motor controller

Version

D

Dual converter

Motor technology

AS

AC-Servo

Rated motor current

C8

8 O

Input voltage

3A

230 V AC power section

1. General information

1.1 Documentation

This product manual is intended to help you safely work with the servo motor controller of

the CMMD-AS series. It contains safety instructions which must be followed.

This document provides information on:

- mechanical mounting

- electrical installation

See the following manuals on the CMMS product family for further information:

- and an overview of the range of functions.

- CANopen manual "P.BE-CMMS-CO-…":

Description of the implemented CANopen protocol as per DSP402.

- PROFIBUS manual "P.BE-CMMS-FHPP-PB-…":

Description of the implemented PROFIBUS-DP protocol.

- DeviceNet manual "P.BE-CMMS-FHPP-DN-…":

Description of the implemented DeviceNet protocol.

- FHPP manual "P.BE-CMM-FHPP-…":

Description of the implemented Festo profiles for handling and positioning.

1.2 Type code CMMD-AS-C8-3A

Motor controller for servo motors, 8 A nominal current, 230 V AC

10 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 11

1. General information

Number

Delivery

1

Servo motor controller CMMD-AS-C8-3A

1

CD (parametrisation software, documentation, S7 module, GSD, EDS, firmware)

1

Plug range

1.3 Scope of delivery

The delivery includes:

Table 1.1 Scope of delivery

Festo P.BE-CMMD-AS-HW-EN 1002NH 11

Page 12

2. Safety instructions for electric drives and controllers

Information

Note

Important information and remarks.

Caution

Failure to comply can result in severe property damage.

Warning

Failure to comply can result in property damage and personal

injury.

Warning

DANGER!

Considerable property damage and personal injury can occur if

these instructions are not observed.

Warning

Dangerous voltage

The safety instructions contain reference to dangerous voltages

which may occur.

Accessories

Environment

2. Safety instructions for electric drives and

controllers

2.1 Icons used

12 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 13

2. Safety instructions for electric drives and controllers

Note

Prior to commissioning, read through the "211HSafety instructions for

electric drives and controllers" (starting on page 212H12) and the

chapter 213H6.5 214H"Instructions on safe and EMC-compliant installation"

(page 215H113).

Note

Only trained and qualified personnel should be allowed to handle

the electric systems.

These safety instructions must be observed at all times.

Do not try to install or commission the motor controller before

you have carefully read through all safety instructions for

electric drives and controllers in this documentation.

You must read through these safety instructions and all other user

instructions before working with the motor controller.

2.2 General Information

Festo AG & Co.KG is not liable for damage caused by failure to observe the warning

instructions in these operating instructions.

If the documentation in the language in question cannot be understood fully, please

contact your vendor and inform them.

Proper and safe operation of the motor controller requires correct transport, storage,

mounting and installation as well as project planning that takes into account the risks,

protection and emergency measures, as well as careful operation and maintenance.

Trained and qualified personnel

For the purpose of this manual and the warning instructions on the product itself,

technicians working with this product must be adequately familiar with the erection,

mounting, setting-up and operation of the product as well as with all warnings and

precautionary measures in accordance with the operating instructions in this product

manual, and must be sufficiently qualified for this task:

- Training and instructions on or authorization to switch on and switch off

devices/systems in accordance with technical safety standards, and to earth

and mark them appropriately in accordance with the application requirements.

- Training or instructions in using and maintaining suitable safety equipment in

accordance with technical safety standards.

- Training in first aid.

The following instructions must be read before the system is commissioned for the first

time to prevent injury and/or material damage:

Festo P.BE-CMMD-AS-HW-EN 1002NH 13

Page 14

2. Safety instructions for electric drives and controllers

If you do not have any user instructions for the motor controller,

please contact your relevant sales representative.

Ask them to send the documents to the person responsible for

safe operation of the stepping motor controller immediately.

If the motor controller is sold, rented and/or passed on in any other

way, these safety instructions must also be passed on with it.

For safety and guarantee reasons it is not permitted for the motor

controller to be opened by the user.

Correct project planning is required for the motor controller to

function properly.

Warning

DANGER!

Incorrect handling of the motor controller and failure to observe the

specified warning instructions as well as incorrect manipulation of

the safety devices can lead to damage to property, bodily injury,

electric shock or in extreme cases death.

Warning

DANGER!

High electric voltage and high working current!

Danger of death or serious bodily injury due to electric shock!

Warning

DANGER!

High electric voltage due to incorrect connection!

Danger of death or bodily injury due to electric shock!

Warning

DANGER!

Surfaces of the device housing may be hot!

Danger of injury! Danger of burning!

2.3 Hazards due to improper use

14 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 15

2. Safety instructions for electric drives and controllers

Warning

DANGER!

Dangerous movements!

Danger of death, serious bodily injury or damage to property due to

unintentional movement of the motors!

Warning

The motor controller corresponds to protection class IP20 as well

as degree of contamination 2.

The environment must conform to this protection class or the

degree of contamination (see chapter 5.1).

Warning

Use only accessories and spare parts which are approved of by

the manufacturer.

Warning

The motor controllers must be connected to the mains network

in accordance with EN standards and VDE or appropriate

national regulations, so that they can be disconnected with

suitable de-energising devices (e.g. power switch, fuse, circuit

breaker).

Warning

For switching the control contacts, gold contacts or contacts with

high contact pressure should be used.

Precautionary measures must be taken for preventing interference

to switching systems, e.g. wiring fuses and relays with RC elements

or diodes.

You must observe the safety regulations and directives of the

country in which the device is to be used.

2.4 Safety instructions

2.4.1 General safety information

Festo P.BE-CMMD-AS-HW-EN 1002NH 15

Page 16

2. Safety instructions for electric drives and controllers

Warning

The environmental conditions specified in the product

documentation must be observed.

Safety-critical applications are not permitted if they are not

explicitly approved by the manufacturer.

For instructions on safe and EMC-compliant installation,

see chapter 216H6.5 "Instructions on safe and EMC-compliant

installation" (page 218H113).

The manufacturer of the system or machine is responsible for

ensuring that the limit values required by the national regulations

are observed.

Warning

The technical data and connection and installation conditions for

the motor controller must be taken from this product manual and

complied with.

Warning

DANGER!

The general installation and safety regulations for working on

high-voltage systems (e.g. DIN, VDE, EN, IEC or other national

and international regulations) must be observed.

Failure to observe these regulations can lead to bodily injury, death

or considerable damage to property.

The following precautionary measures also apply without claim to

completeness:

VDE 0100

Regulations for setting up high-voltage systems

up to 1,000 volts

EN 60204-1

Electrical equipment for machines

EN 50178

Equipping high-voltage systems with electronic

devices

EN ISO 12100

Safety of machines – basic concepts,

general guidelines

EN ISO 14121-1

Safety of machines – guidelines for risk

evaluation

EN 1037

Safety of machines – avoiding unintentional

starting up

EN ISO 13849-1

Safety-related parts of controllers

16 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 17

2. Safety instructions for electric drives and controllers

Warning

The motor controller may only be operated, maintained and/or

serviced by persons qualified and trained to work on or with

electrical devices.

Warning

The series-supplied motor holding brake or an external motorholding brake controlled by the drive controller alone is not

suitable for protecting human beings.

Vertical axes must be additionally secured against falling or

sliding down when the motor is switched off with, for example,

- mechanical locking of the vertical axis,

- external braking, safety catch or clamping devices or

- sufficient weight compensation of the axis.

Warning

The internal brake resistance can cause dangerous intermediate

circuit voltage during operation and up to several minutes after the

motor controller is switched off. If touched, this can lead to fatal or

serious injuries.

Before carrying out maintenance work, make sure that the

power supply is switched off and locked and that the

intermediate circuit is discharged.

Switch off power to the electrical equipment and secure it

against being switched on again. Wait until the intermediate

circuit is discharged in the case of:

- maintenance and repair

- cleaning

- long service interruptions.

Warning

Proceed carefully with mounting. Make sure that , during mounting

as well as later during the operation of the drive, no drilling

shavings, metal dust or mounting parts (screws, nuts, pieces of

wire) can fall into the motor controller.

Ensure that the external power supply of the controller (mains

voltage 230 V) is switched off.

2.4.2 Safety instructions for assembly and maintenance

For assembling and maintaining the system, the relevant DIN,

VDE, EN and IEC regulations as well as all national and local safety and accident

prevention regulations must always be observed. The system manufacturer or the user is

responsible for ensuring that these regulations are observed.

Avoiding accidents, bodily injury and/or material damage:

Festo P.BE-CMMD-AS-HW-EN 1002NH 17

Page 18

2. Safety instructions for electric drives and controllers

The intermediate circuit or the 230 V mains voltage must always be

switched off before the 24 V logic power supply is switched off.

Warning

Work in the vicinity of the machine must only be carried out

when the AC or DC power supply is switched off and locked.

Switched-off final stage or switched-off controller enable are not

suitable locking conditions. In the event of a fault, this could lead

to unintentional movement of the drive.

Warning

Carry out commissioning with a free-running motor in order to

avoid mechanical damage, e.g. due to incorrect direction of

rotation.

Warning

Electronic devices are never fail-proof.

The user is responsible for ensuring that his system is brought into

a safe state if the electric device fails.

Warning

DANGER!

The motor controller and, in particular, the brake resistance can

take on high temperatures, which can cause severe bodily burns on

contact.

Warning

Dangerous voltage

High voltage!

Danger of death or serious bodily injury due to electric shock!

2.4.3 Protection aganst touching electric components

This section concerns only devices and drive components with voltages over 50 V. It is

dangerous to touch components with voltages of more than 50 V, as this can cause an

electric shock. When electric devices are operated, certain components in these devices

are always under dangerous tension.

For operation, the relevant DIN, VDE, EN und IEC regulations, as well as all national and

local safety and accident prevention regulations must always be observed. The system

manufacturer or the user is responsible for ensuring that these regulations are observed.

18 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 19

2. Safety instructions for electric drives and controllers

Warning

Before switching the device on, attach the intended covers and

protective screens so that the device cannot be touched.

For built-in devices, make sure that there is an external housing,

such as a control cabinet, to ensure that the electric components

cannot be touched.

The standards EN 60204-1 and EN 50178 must be observed.

Warning

Ensure that the minimum copper cross section is used for the entire

length of the protective earth conductor in accordance with

standard EN 60204.

Warning

Before commissioning, also for brief measuring and test

purposes, always connect the protective conductor to all

electric devices or connect to an earth cable in accordance with

the connection diagram.

Otherwise, high voltages may occur on the housing. These could

cause an electric shock.

Warning

Do not touch the electrical connection points of the components

when the device is switched on.

Warning

Before touching electric components with voltages over 50 V,

disconnect the device from the mains or voltage source.

Protect the device against being switched on again.

Warning

During installation note the amount of intermediate circuit

voltage, especially with regard to insulation and protective

measures.

Make sure that the earthing, the cross section size of the conductor

and the corresponding short-circuit protection are correct.

Festo P.BE-CMMD-AS-HW-EN 1002NH 19

Page 20

2. Safety instructions for electric drives and controllers

Standards

- International: IEC 60364-4-41

- European: EN 50178

Warning

DANGER!

High electric voltage due to incorrect connection!

Mortal danger, danger of injury from electric shock.

Causes

- Unsafe or faulty circuitry or cabling

- Faults in operating the components

- Faults in the measured value and signal generators

- Faults or non-EMC-compliant components

- Errors in the software in the higher-order control system

2.4.4 Protection by low voltage (PELV) against electric shock

Voltages from 5 to 50 V on the connections and terminals of the motor controller are

protective small voltages which can be touched without danger in accordance with the

following standards:

Devices, electrical components and cables may only be connected to connections and

terminals from 0 to 50 V, providing they have protective low voltage (PELV = Protective

Extra Low Voltage).

Connect only voltages and current circuits which have reliable separation of dangerous

voltages. Such separation is achieved e.g. with isolating transformers, reliable

optocouplers or battery operation separate from the mains network.

2.4.5 Protection against dangerous movements

During startup, the safety functions used, e.g. "Safe halt", must be checked for proper

functioning.

The user shall establish a regular inspection of the safety function.

Dangerous movements can be caused by incorrect control of connected motors. There are

various causes:

These faults can occur immediately after the device is switched on or after an uncertain

period of operation.

The monitoring functions in the drive components exclude to a large extent the possibility

of incorrect operation of the connected drives. WIth regard to the protection of people,

especially the danger of bodily injury and/or material damage, one must not rely on these

circumstances alone. Until the installed monitoring functions become effective, you must

reckon with at least one faulty drive movement, the extent of which depends on the type

of control and on the operating state.

20 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 21

2. Safety instructions for electric drives and controllers

Warning

DANGER!

Dangerous movements!

Danger of injury or death, serious bodily injury or material damage.

Warning

DANGER!

Surfaces of the device housing may be hot (up to approx. 85 °C,

see chapter 8)!

Danger of injury! Danger of burning!

Warning

Danger of burning!

Do not touch the surface of the housing in the vicinity of heat

sources.

After switching devices off, leave them for 10 minutes to cool

down before touching them.

If you touch hot parts of the device such as the housing, which

contains the heat sink and resistors, you may burn yourself.

For the above-mentioned reasons, the protection of human beings must be ensured with

the aid of monitoring systems or by measures which are of higher order than the system.

These measures are foreseen depending on the specific features of a danger and error

analysis by the system manufacturer. The safety regulations applicable to the system

must be observed here as well. Undesired movements of the machine or other incorrect

functions can occur as a result of switching off, avoiding or failing to activate safety

devices.

2.4.6 Protection aganst touching hot components

Festo P.BE-CMMD-AS-HW-EN 1002NH 21

Page 22

2. Safety instructions for electric drives and controllers

Warning

DANGER!

Danger of injury as a result of incorrect handling

Bodily injury caused by squeezing, cutting, impact!

Warning

Observe the general regulations on setting up and safety when

handling and mounting.

Use suitable mounting and transport devices.

Take suitable measures to prevent clamping and squashing

of fingers.

Use only suitable tools. If specified, use special tools.

Use lifting devices and tools in a correct manner.

If necessary, use suitable protective equipment

(e.g. protective glasses, safety shoes, safety gloves).

Do not stand under hanging loads.

Wipe up spilled liquids on the floor to avoid slipping.

2.4.7 Protection when handling and assembling

Handling and assembling certain components in an unsuitable manner can cause injury

under unfavourable circumstances.

The following safety measures apply here:

22 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 23

3. Product description

3. Product description

3.1 General information

The CMMD-AS series of servo positioning controllers are intelligent AC servo dual

converters with extensive parametrisation possibilities and expansion options. This allows

flexible use in a wide range of different applications.

The servo positioning controller CMMD-AS is intended for operation of the EMMS-AS

motor series with digital absolute angle encoders in single-turn and multi-turn design.

Point-to-point positioning or master-slave applications are easily possible as is multipleaxis synchronised path drive. With a higher-level multiple axis controller, communication

can take place via the integrated CAN interface.

The parametrisation tool FCT (Festo Configuration Tool) makes possible simple operation

and startup of the servo positioning controller. Graphic depictions and pictograms make

intuitive parameterization possible.

3.2 Device description

With the CMMD-AS double position controller, two almost identically constructed CMMSAS boards, each containing a DSP Motion Control, are installed next to each other in a

housing. Since the two boards in the CMMD-AS share some interfaces, the second board

is equipped only partially.

There are some connections between the boards in the CMMD-AS to exchange power

between the two boards and also permit communication between the axis controllers.

Both axes use both the same mains connection and the same 24V connection. These

connections are connected in the device.

The intermediate circuits are connected internally.

The braking resistors are wired parallel internally so that double sustained brake

performance is available.

A very fast serial synchronous interface (SSIO) is implemented between axis 1 (master)

and axis 2 (slave). The master passes on fieldbus telegrams meant for the slave over

this interface.

Communication through the RS232/RS485 interface runs over axis 1 (master).

It converts telegrams for axis 2 (slave) to corresponding SSIO telegrams.

Axis 1 (master) can reset (RESET) axis 2 (slave).

The SD card is also addressed via the SSIO interface.

For firmware download, the boot program of axis 1 (master) first accesses the SD card;

axis 2 (slave) is held by axis 1 (master) in RESET for so long. After that, axis 1 (master)

frees the SSIO so that axis 2 (slave) can also read firmware from the SD card.

After the start of the application, access to the SD card and data exchange between

axis 1 (master) and axis 2 (slave) are synchronised. Two additional pilot lines are

available between axis 1 (master) can axis 2 (slave) for this purpose.

Telegram exchange between axis 1 (master) and axis 2 (slave) takes place is

a synchronised way and at a fixed time interval.

Axis 1 (master) and axis 2 (slave) use the same firmware.

Festo P.BE-CMMD-AS-HW-EN 1002NH 23

Page 24

3. Product description

Note

For DeviceNet and PROFIBUS, the fieldbus data for axis 2 are read

from axis 1, passed on to axis 2 and evaluated there. The answer is

returned to axis 1 with the next communication task (every 1.6 ms)

at the earliest. Only then can the answer be returned over the

fieldbus.

This means that the processing time of the fieldbus protocols –

depending on the fieldbus – can be twice as long as with the

CMMS-AS.

Example:

Processing time for 8 bytes of control data + 8 bytes of parameter

data = 16 bytes of data per axis and data direction.

CMMS-AS 1.6 ms

CMMD-AS 2 x 1.6 ms = 3.2 ms

3.3 Bus connection

Both axes are controlled over a shared fieldbus interface. If a bus connection is activated,

this control interface always applies for both axes.

With CAN and RS485, the second axis gets the address of the first axis +1

Node number

Bus modules (PROFIBUS or DeviceNet) must be plugged into the extension slot [Ext1].

The bus modules are automatically recognised when the controller is switched on.

For PROFIBUS and DeviceNet, only the bus address specified on the DIP switches is

assigned; the data for two controllers are send in a shared telegram.

= node number

Slave

Master

+1

3.4 Performance characteristics

Flexible power management

The nominal current of both axes together is 8 A. These 8 A can be distributed flexibly

between axes 1 and 2. The maximum nominal current for axis 1 is thereby 7 A.

With a distribution of 7 A : 1 A for axes 1/2, the specified total rated output of the

double output stage in S1 operation must be reduced. An increase in the maximum

nominal current is permissible only for axis 1 due to the cooling profile.

The maximum peak current per axis is 10 A. Unlike the nominal current, a distribution

of the maximum peak current is not possible.

The motor nominal and peak currents are set fixed in the FCT user software.

An increase in the motor nominal current can result in impermissible temperature

rises.

24 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 25

3. Product description

Compactness

Smallest dimensions

Can be connected directly to each other in series

Full integration of all components for motor controller and power section, including

RS232 and CANopen interface

Integrated brake chopper

Integrated EMC filters

Automatic actuation for a holding brake integrated in the motor

Adheres to the current CE and EN standards without additional external measures

(motor cable length of up to 15 m)

Encoder interface

High-resolution Heidenhain increment generator, absolute encoder (multiturn and

singleturn) with EnDat.

Input / Output

Freely programmable I/Os

High-resolution 12-bit analogue input

Jog/Teach operation

Simple coupling to a higher-level controller via I/O

Synchronous operation

Master/slave operation

Extension and field bus module

PROFIBUS DP

DeviceNet

Integrated CANopen interface

Open interface in accordance with CANopen

Festo Handling and Positioning Profile (FHPP)

Protocol in accordance with the CANopen standards DS 301 and DSP 402

Contains "Interpolated position mode" for multiple-axis applications

Motion control

Can be operated as a torque, speed or position controller

Integrated positioning controller

Time-optimised (trapezoidal) or jerk-free (S-shaped) positioning

Absolute and relative movements

Point-to-point positioning with and without smooth transitions

Position synchronisation

Electronic gear unit

2 x 64 position sets (position sets 0 ... 63, whereby position set 0 is reserved for

homing)

Festo P.BE-CMMD-AS-HW-EN 1002NH 25

Page 26

3. Product description

Integrated sequence control

Automatic sequence of position sets without a higher-level controller

Linear and cyclic position sequences

Adjustable delay times

Branches and wait positions

Definable stop positions for uncritical standstill points

Integrated safety functions in accordance with EN ISO 13849-1 safety category 3 in the basic unit (see chapter 4)

Integrated "Safe halt" in accordance with EN 13849-1 safety category 3 in the

basic unit

Protection against unexpected start-up

Two-channel disconnection of the output stage

Certification of BG (in preparation)

Less external circuitry

Shorter response times in the event of an error

Faster restart, intermediate circuit remains charged

Interpolating multi-axis movement

With a suitable controller, the CMMD-AS can perform path movements with interpolation

via CANopen.

To do this, position setpoints are specified by the controller in a fixed time slot pattern.

In between, the servo positioning controller independently interpolates the data values

between two support points.

Parametrisation program "Festo Configuration Tool FCT"

Simplest start-up and diagnosis

Confiuration of motor controller, motor and axis

Automatic adjustment of all controller parameters with use of Festo Mechanics

2-channel oscilloscope function

English and German

26 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 27

3. Product description

Note

If the following does not differentiate between axis 1 and axis 2,

the statements apply automatically for both axes.

For example, [X1] stands for both [X1.1] and [X1.2].

Interface

Setpoint specification via

Function

Operating mode

Reference

Analogue

inputs

[X1.1] (+ 10 V, axis 1)

[X1.2] (+ 10 V, axis 2)

Analogue setpoint

specification with 12-bit

resolution

Regulating torque

Speed control

Chapter

3.5.2

(page 28)

Pulse/dire

ction

interface

[X1.1] (24 V, axis 1)

[X1.2] (24 V, axis 2)

or

[X10.1] (5 V, axis 1)

[X10.2] (5 V, axis 2)

CW/CCW

(pulse CW / pulse CCW)

CLK / DIR

(Pulse/Direction)

Synchronisation

Chapter

3.5.3

(page 28)

A/B track

signals

[X10.1] (5 V RS422, axis 1)

[X10.2] (5 V RS422, axis 1)

Encoder

- Input (slave)

- Emulation (master)

Synchronisation

Chapter

3.5.3

(page 28)

Digital

inputs/out

puts

[X1.1] (24 V DC, axis 1)

[X1.1] (24 V DC, axis 2)

Record selection

Jog/Teach operation

Linked position records

Start and stop functions

Positioning controller

Chapter

3.5.4

(page 34)

RS485

[X5]

Record selection

Linked position records

Start and stop functions

Homing

Regulating torque

Speed control

Positioning controller

Chapter

3.5.6

(page 40)

CANopen

field bus

[X4] (CAN)

Direct mode

Homing

Jog mode

Record selection

Interpolated Position

Mode

Regulating torque

Speed control

Position control

Positioning controller

Chapter

3.6.1

(page 46)

3.5 Interfaces

3.5.1 Overview of the setpoint value interfaces

Table 3.1 Setpoint value interfaces

Festo P.BE-CMMD-AS-HW-EN 1002NH 27

Page 28

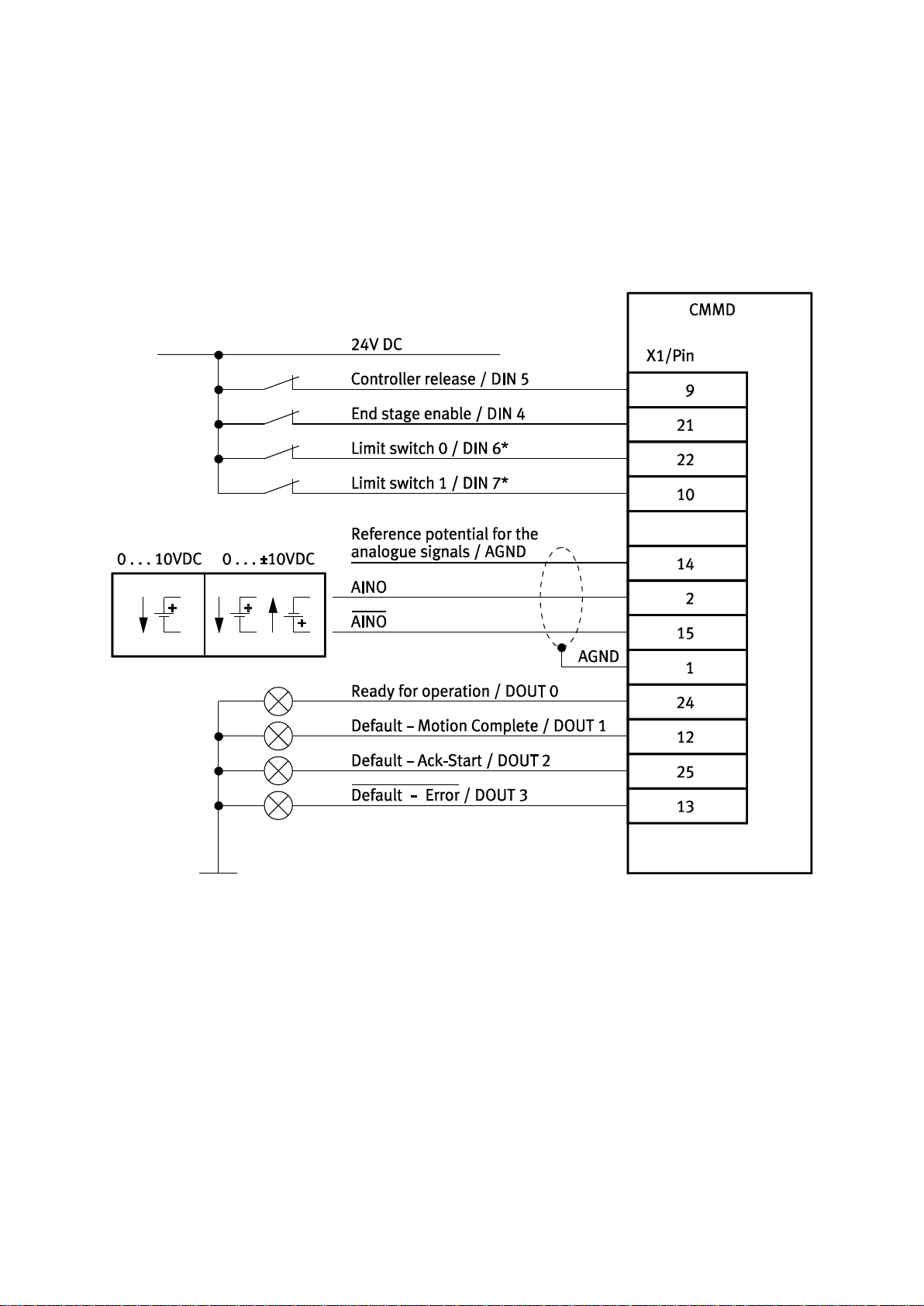

3. Product description

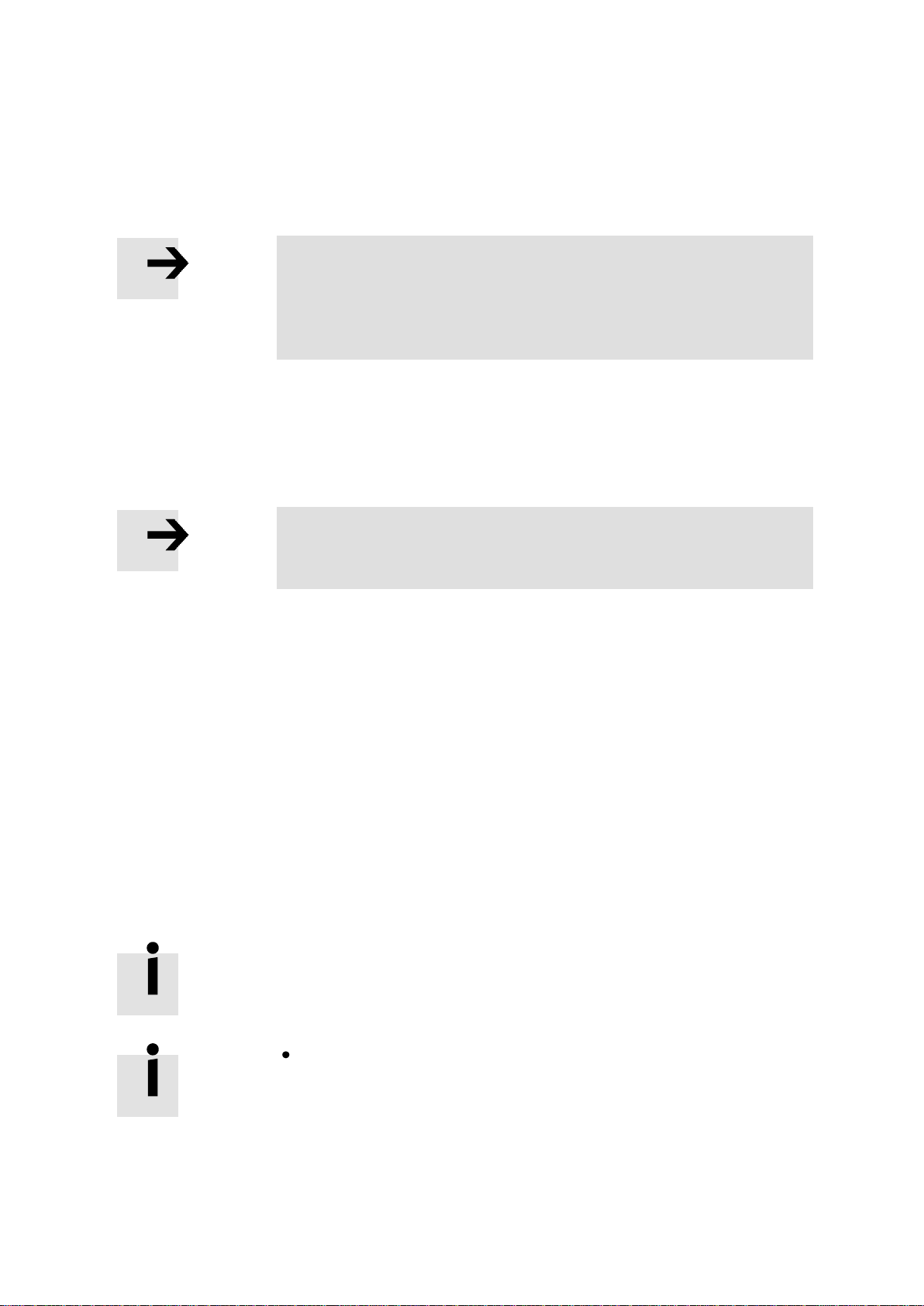

The connection plan shows the switch position in the active operating state.

*) The limit switches are set by default to opener (configuration over FCT)

3.5.2 Analogue setpoint specification

The analogue setpoint specification +/- 10V DC can be configured as

- speed setpoint value

- torque setpoint value.

Required activation with analogue setpoint specification

14533d_1

3.5.3 Interfaces for direct synchronous operation

The motor controller permits a master-slave operation, which hereafter is designated

synchronisation. The controller can function either as a master or slave.

If the motor controller works as master, it can provide (RS422) A/B signals to the

increment generator output (X10).

When the motor controller is to operate as a slave, various inputs and signal forms are

available for synchronisation.

[X10] (5 V RS422) A/B, CW/CCW, CLK/DIR

[X1] (24 V) CW/CCW, CLK/DIR)

28 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 29

3. Product description

Note

5 V DC Pulse-direction signals over [X10], max. 150 kHz

24 V DC Pulse-direction signals over [X1], max. 20 kHz

Voltage

Input

Cycle rate

5 V

[X10]

150 kHz

24 V

[X1]

up to 20 kHz

Using software, the increment generator interface can be configured as both output and

input (master or slave). Additionally, two inputs for the connection of 5V pulse-direction

signals (CLK/DIR), (CW/CCW) are planned on the plug connector.

24V DC pulse-direction signals are carried out via [X1] DIN2 and DIN3.

Output: Generation of increment generator signals [X10]

Based on the encoder data, the motor controller generates the tracking signals A/B as

well as the zero pulse of an increment generator. The number of lines can be set in the FCT

with values between 32 … 2048.

Changes to this interface only become effective after a Reset. (download, secure, reset)

An RS422 power driver provides the signals to [X10] differentially.

Input: Processing of frequency signals [X10]

The signals are evaluated optionally as A/B track signals of an increment generator or as

pulse/direction signals (CW/CCW or CLK/DIR) of a stepping motor control. The signal form

is selected in the FCT. The number of steps per revolution can be parameterized. Beyond

that, an additional electronic gear can be parameterized.

The following signals can be selected:

A/B tracking signals

CLK/DIR – pulse/direction

CW/CCW – pulse

Input: Processing of pulse-direction signals 24 V DC [X1]

CLK/DIR – pulse/direction

CW/CCW – pulse

24V DC pulse-direction signals are carried out via [X1] DIN2 and DIN3.

Clock frequency of pulse-direction signals

Table 3.2 Maximum input frequency

Festo P.BE-CMMD-AS-HW-EN 1002NH 29

Page 30

3. Product description

Note

With setting of synchronisation via FCT, the controller only reacts

via the synchronisation interface. All other functions of the

"Positioning" operating mode are no longer available.

Note

After the change of configuration with FCT with the "Download"

buttons, load the changed configurations into the motor controller

and save them permanently with the "Save" button.

With a Reset (or switching off and back on) of the motor controller,

the new configuration is activated.

Activation of synchronization

Synchronization can be set in various ways.

With the FCT parametrisation software on the "Application Data" page in

the "Operating Modes Settings" tab through selection of the "Synchronisation"

control interface

Via [X1] (digital I/O interface) through selection of mode 3.

To ensure flexibility of the controller, synchronization should be switched on over the

I/O interface.

Required I/O activation during synchronisation via FCT

- DIN4 Output stage enable

- DIN5 Controller enable

- DIN6 Limit switch 0

- DIN7 Limit switch 1

30 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 31

3. Product description

The connection plan shows the switch position in the active operating state.

*) The limit switches are set by default to N/C contact (configuration over FCT)

Required I/O triggering during synchronisation via mode switchover with 24 VDC frequency signals

14530d_1

Festo P.BE-CMMD-AS-HW-EN 1002NH 31

Page 32

3. Product description

The connection plan shows the switch position in the active operating state.

*) The limit switches are set by default to N/C contact (configuration over FCT)

Required I/O triggering during synchronisation via mode switchover with 5 VDC frequency signals

14531d_1

32 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 33

3. Product description

ENABLE

START

STOP

Drive is moving

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

DOUT0: READY

DOUT1: MC

DOUT3: ERROR

DOUT2:

Position synchronous

t1 t1 txtx

t

mc

0

1

DOUT2:

Setpoint reached

t1 = 1.6 ms

tx = x ms (dependent on ramps)

tmc = x ms (dependent on MC window (drive stopped))

Note

The acknowledgment of Dout2 is firmly preset to

"Position synchronous".

I/O Timing Diagram

Fig. 3.1 Signal curve during "catch up" of a leading master (MC) and during

desynchronising

The signal MC is set as long as the drive is at a standstill during active synchronisation

(DIN8: START set). That is, the MC signal is set as long as the window for "DZ = 0" has not

been left.

The signal "Position synchronous" during activation of synchronisation (DIN8: START on

high) is not set until the "Target Reached" window has been left. But since

synchronisation is switched onto a "running" master and the drive first has to be

accelerated, the "Position synchronous" message first goes off until the position

difference has been closed.

Festo P.BE-CMMD-AS-HW-EN 1002NH 33

Page 34

3. Product description

For the "Position synchronous" feedback message, the comparison speed is set to zero

and only a message range is placed in the message window.

General Information

The general limitations and settings via FCT are also valid during synchronisation (axis

movements, velocities, message window, etc.). When catching up to a leading master,

the motor accelerates to the power limit.

The message "Position synchronized" is output at Dout2. The deviation is configured

via the tolerance window for "Motion Complete" in the FCT.

3.5.4 I/O functions and device control

Digital inputs

The digital inputs provide the elementary control functions.

To allow positioning targets to be saved, the CMMD-AS motor controller has a target

table, in which positioning targets can be saved and called up later. Six digital inputs

allow you to select the targets; another input is used as the start input. Two inputs are

used to enable the hardware-side output stage and the regulator.

Digital outputs

Through the CAMC-8E8A option card, additional parametrisable outputs can be added to

the digital outputs available in the basic unit. Can be plugged into the technology slot

Ext1 and Ext2. Depending on the option card, 8 additional outputs for status signals are

available.

34 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 35

3. Product description

Mode

Function

Mode 0

Positioning

Mode 1

Jog function

Mode 2

Travel program

Mode 3

Synchronisation

Parameter

Signal level

In accordance with RS232 specification or RS485 specification

Baud rate

9600 baud to 115 kBaud

ESD protection

ESD-protected (16 kV) driver

Connection

Null modem standard [X5]

Connector socket

over [X5] / D-Sub 9 pin / pin

Limit switch

The limit switches serve to limit the range of motion for safety reasons. During homing,

one of the two limit switches can serve as reference points for positioning control.

Sample input

If a fieldbus is used for activation, a high-speed sampling input is available for time-critical

tasks for various applications (position sensing, special applications, ...).

Analogue input

The CMMD-AS motor controller has an analogue input for input levels ranging from

+10 VDC to –10 VDC. The input is a differential input (12 bit), ensuring a high degree of

protection against interference. The analogue signals are quantified and digitalised by

the analogue-digital converter at a resolution of 12 bits. These analogue signals serve to

specify setpoints (speed or torque) for the control.

Basic functions

The existing digital inputs are already allocated to the basic functions in standard

applications. The analogue input AIN0 is also available as a digital input for use of further

functions, such as the jog function, route program and synchronisation.

Mode switching allows you to switch between the following default settings:

Table 3.3 Mode switching

3.5.5 RS232 interface (diagnosis/ parametrisation interface)

The RS232 interface is intended as a configuration interface.

Table 3.4 Parameters of the RS232 interface

Festo P.BE-CMMD-AS-HW-EN 1002NH 35

Page 36

3. Product description

Parameter

Value

Baud rate

9600 Baud

Data bits

8

Parity

None

Stop bits

1

Parameter

Value

Flow control

None

Emulation

VT100

ASCII configuration

- Sent characters finish with line feed

- Output entered characters locally (local echo)

- During reception, attach line feed to the end of the line

Command

Syntax

Response

New initialisation of the servo positioning controller

RESET!

None (bootup message)

Save the current parameter set and all position sets in the

non-volatile flash memory.

SAVE!

DONE

Setting the baud rate for serial communication

BAUD9600

BAUD19200

BAUD38400

BAUD57600

BAUD115200

Unknown command

as desired

ERROR!

Read the version number of the CM (Configuration

Management) release of the firmware

VERSION?

2300:VERSION:MMMM.SSSS*)

*)MMMM: Main version of the CM release (hexadecimal format)

SSSS: Subversion of the CM release (hexadecimal format)

After reset, the serial interface always has the following basic settings:

Table 3.5 Default parameter

To be able to operate an interface with a terminal program, such as for test purposes, the

following settings are required (recommendations):

Table 3.6 Setting for terminal program

Please note that, immediately after a reset, the motor controller independently issues a

bootup message via the serial interface. A reception program on the controller must either

process or reject these received characters.

General commands

Table 3.7 General commands

36 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 37

3. Product description

Note

To address the communication objects (CO) of axis 2, the character

# is set before the syntax command.

Answers of axis 2 begin with the character #.

The same applies for simulated CAN accesses.

Command

Syntax

Response

Reading a CO

OR:nnnn

nnnn:HHHHHHHH or OR:EEEEEEEE

Writing a CO

OW:nnnn:HHHHHHHH

OK! or OW:EEEEEEEE

Reading a lower limit of a CO

ON:nnnn

nnnn:HHHHHHHH or ON:EEEEEEEE

Reading an upper limit of a CO

OX:nnnn

nnnn:HHHHHHHH or OX:EEEEEEEE

Reading an actual value of a CO

OI:nnnn

nnnn:HHHHHHHH or OI:EEEEEEEE

*)nnnn: Number of the communication object (CO), 16 bit (hexadecimal format)

HHHHHHHH: 32 bit data / values (hexadecimal format)

EEEEEEEE: Return value in case of an access fault

Return value

Significance

0x0000 0002

Data are less than the lower limit, data were not written

0x0000 0003

Data are greater than the upper limit, data were not written

0x0000 0004

Data are less than the lower limit, the data were limited to the lower limit

and then accepted

0x0000 0005

Data are greater than the upper limit, the data were limited to the upper limit

and then accepted

0x0000 0008

Data are outside the valid value range and were not written

0x0000 0009

Data are currently outside the valid value range and were not written

Parameter commands

The exchange of parameters and data takes place over "communication objects" (CO).

They are used in a fixed syntax. Special return values are defined for errors in a write or

read access.

Examples

Acknowledge error axis 1 OW:0030:0001 0000 Answer: OK!

Acknowledge error axis 2 #OW 0030:0001 0000 Answer: #OK!

Homing mode axis 1 Command: =606000:06

Homing mode axis 2 Command: #=606000:06

Table 3.8 Parameter commands

The meaning of the return values is the following:

Table 3.9 Return values

Festo P.BE-CMMD-AS-HW-EN 1002NH 37

Page 38

3. Product description

Command

Syntax

Response

Activate controller enable. To do this, the controller

enable logic must be set to "DIN5 and RS232".

OW:0061:00000001

OK! or OW:EEEEEEEE

1)

Deactivate controller enable. To do this, the controller

enable logic must be set to "DIN5 and RS232".

OW:0061:00000002

OK! or OW:EEEEEEEE1)

Deactivate end stage. To do this, the controller enable

logic must be set to "DIN5 and RS232".

OW:0061:00000003

OK! or OW:EEEEEEEE1)

Acknowledge error

OW:0030:00010000

OK!

1) Faulty return values can be called up due to an inappropriately set controller enable logic,

an intermediate circuit that is not loaded, etc.

Operating mode

Syntax

Response

Regulating torque

OW:0030:00000004

OK! or OW:EEEEEEEE

Speed control

OW:0030:00000008

Positioning

OW:0030:00000002

Note

If you want to perform a positioning, a homing must be performed

once each time the controller is switched on. You can do this via

FCT or as described in chapter "Example "Homing Mode" via

RS232".

Function commands

Table 3.10 Function commands

Setting the operating mode

Due to a necessary synchronization of internal processes, the change of operation mode

can require some cycle times of the controller. We therefore recommend that you always

verify and wait for reception of the desired operation mode.

Table 3.11 Operating mode

Faulty return values can be called up due to invalid values that do not come from the

above-named group. The current operation mode can be read by using the "OR"

command.

Example "Profile position mode" via RS232

With the CAN access simulated via RS232, the motor controller can also be operated in the

CAN "Profile Position Mode". The following describes the sequence in principle.

1. Conversion of the controller enable logic

The controller enable logic can be converted via the COB 6510_10. Since the

simulation of the CAN interface over RS232 can be completely taken over, the enable

logic can also be converted to DINs + CAN.

Command: =651010:0002

As a result, the release can be granted via the CAN control word (COB 60040_00).

Command: =604000:0006 Command "Shutdown"

Command: =604000:0007 Command "Switch on / Disable Operation"

Command: =604000:000F Command "Enable Operation"

38 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 39

3. Product description

2. Activation of the "Profile Position Mode"

The positioning mode is activated via the COB 6060_00 (Mode of Operation). This

must be written once, since all internal sectors must be set correctly thereby.

Command: =606000:01 Profile Position Mode

3. Write position parameters

The target position can be written over the COB 607A_00 (target position). The

target position is thereby written in "position units". That means, it depends on the

set CAN factor group.

The default setting here is 1 / 2

16

revolutions (16 bit portion before the decimal, 16

bit portion after the decimal).

Command: =607A00:00058000 Target position 5.5 revolutions

The travel speed can be written via the COB 6081_00 (profile velocity),

the final speed via the COB 6082_00 (end velocity).

The speeds are thereby written in "speed units". That means, they depend on the

set CAN factor group.

The default setting here is 1 / 2

12

revolutions/min (20 bit portion before the decimal,

12 bit portion after the decimal).

Command: =608100:03E80000 Speed of travel 1000 RPM

The acceleration can be written via the COB 6083_00 (profile acceleration),

the deceleration via the COB 6084_00 (profile deceleration) and

the quick stop ramp via the COB 6085 (quick stop deceleration).

The accelerations are thereby written in "acceleration units". That means, they

depend on the set CAN factor group.

The default setting here is 1 / 28 revolutions/min/s (24 bit portion before the

decimal, 8 bit portion after the decimal).

Command: =608300:00138800 Acceleration 5000 RPM/s

4. Start positioning

Positioning is started via the CAN control word (COB 6040_00):

- Controller enable is controlled via bit 0 ... 3 (see above).

- The positioning is started over a rising edge at bit 4.

The following settings are taken over thereby.

- Bit 5 establishes whether an ongoing positioning is ended first before the

new positioning task is taken over (0), or whether the ongoing positioning

should be cancelled (1)

- Bit 6 establishes whether the positioning should be carried out absolutely (0)

or relatively (1).

Command: =604000:001F Start absolute positioning or

Command: =604000:005F Start relative positioning

5. After positioning has been ended, the condition of the controller is reset so a new

positioning can be started.

Command: =604000:000F Bring motor controller into "Ready" status

Festo P.BE-CMMD-AS-HW-EN 1002NH 39

Page 40

3. Product description

Example "Homing Mode" via RS232

With the CAN access simulated via RS232, the CMMD-AS can also be operated in the CAN

"Homing Mode". The following describes the sequence in principle.

1. Changing of the controller enable logic

2. The controller enable logic can be converted via the COB 6010_10. Since the

simulation of the CAN interface over RS232 can be completely taken over, the enable

logic can also be converted to DINs + CAN.

Command: =651010:0002

3. As a result, the release can be granted via the CAN control word (COB 6040_00).

Command: =604000:0006 Command "Shutdown"

Command: =604000:0007 Command "Switch on / Disable Operation"

Command: =604000:000F Command “Enable Operation”

4. Activation of the "Homing mode"

5. The homing mode is activated via the COB 6060_00 (Mode of Operation).

Command: =606000:06 Homing mode

6. Start reference travel

7. Homing is started via the CAN control word (COB 6040_00):

8. Controller enable is controlled via bit 0 ... 3.

9. The homing is started via a rising edge at bit 4.

Command: =604000:001F

10. After homing has been ended, the status of the motor controller must be reset.

Command: =604000:000F Bring motor controller into "Ready" status

3.5.6 Control via RS485

The RS485 interface is on the same plug connector as the RS232 interface.

Communication must be activated separately by the user. RS232 messages can also be

received when RS485 communication is activated, which means that the device can be

accessed for configuration at all times.

Configuration in the FCT

For configuration, the following settings are required in the "Work station" window:

- On the "Application Data" page in the "Operating Mode Settings" tab, set the

control interface to "RS485".

- On the page "Controller, Control Interface, Digital I/O", do not activate the

"active" mode selection

40 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 41

3. Product description

Note

The reply sends the following characters to the first five

positions: "XRnn:" with nn = node number of the device

All devices react to the node number 00 as "Broadcast". In this

way, each device can be addressed without knowing the node

number.

The commands of type "OW", "OR" etc. support an optional

check sum. This check sum is formed without the first five

characters.

The bootup message of the boot loader as well as the bootup

message of the firmware are sent in the RS232 mode.

Then, with the "Download" buttons, load the changed configurations into the motor

controller and save them permanently with the "Save" button.

With a Reset (or switching off and back on) of the motor controller, the new configuration

is activated.

Command syntax under RS485

Control of the motor controller via RS485 takes place with the same objects as with

RS232. Only the syntax of the commands to read/write the objects is expanded in

comparison to the RS232.

Syntax: XTnn:HH……HH:CC

Meanings:

XT: Fixed constants

nn: Node number, identical to the CANopen node number

(setting via DIP switch)

HH……HH: Data (normal command syntax)

Example "Profile position mode" via RS232

If the CMMD-AS is operated over RS485, control can take place just as with

operation over RS232; see chapter "RS232 interface (diagnosis/ parametrisation

interface)" (page 35). If required, the node number is simply written in front of the

command. The node number is set via the DIP switches.

Command: XT07:=607100:000A0000 Target position 10 revolutions send to

node 7

Festo P.BE-CMMD-AS-HW-EN 1002NH 41

Page 42

3. Product description

Parameter

Value

Communication protocol

Heidenhain EnDat 2.1 (without analogue track) and 2.2

Signal level DATA, SCLK

5 V differential / RS422 / RS485

Angle resolution /

number of lines increment

generator

controller-internal up to 16 bit / revolution

Cable length

L 25 m

Cable design in accordance with Heidenhain specification

Limit frequency SCLK

1 MHz

Generator supply

from the controller, 5 V –0% / +5%

IA = 200 mA max.

Sense lines for power supply

not supported

The second axis gets the address of the first axis +1

Node number

= node number

Slave

Master

+1

3.5.7 Multi-firmware strategy

A firmware update can be achieved using any desired customer firmware through the

built-in SD card reader. Automatic bootloader.

3.5.8 Motor feedback

Position return takes place purely digitally via EnDat.

EnDat interface V2.x for single and multiturn encoders

Table 3.12 Signal description of shaft encoder motor EnDat 2.1 and 2.2 [X2]

3.5.9 Brake chopper (Brake control)

A brake chopper with a braking resistor is integrated into the output stage. If the

permitted load capacity of the intermediate circuit is exceeded during the energy

recovery, the braking energy may be converted to heat by the internal braking resistor.

The brake chopper is actuated with software control. The internal braking resistor is

protected against overloading via software and hardware.

3.5.10 Feedback from motor (angle encoder)

The CMMD-AS has a connection for an angle encoder mounted on the motor shaft. This

encoder is used for commutation of a 3-phase synchronous motor and as an actual-value

recorder for the built-in speed and position controller.

The controller supports the following encoders:

EnDat 2.1 encoder – exclusively digital angle information

EnDat 2.2 encoder – digital angle information and service parameters (temperature)

42 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 43

3. Product description

Signal:

Description

AMON

AIN0 / #AIN0

Analogue output for monitor purposes

Differential analogue input with 12-bit resolution.

Alternatively, the differential analogue input can be parameterized with the function

Mode and Stop (DIN12 and DIN13, dependent on the parametrised controller interface).

DOUT0 ... DOUT3

Digital outputs with 24 V level,

DOUT0 is permanently occupied with the function "Ready for operation".

Additional outputs can be configured (Motion complete (Target Reached), Axis in

motion, Target speed achieved, ...)

DIN0 ... DIN13

Digital inputs for 24 V level with following functions:

(The inputs are occupied in their function, dependent on the mode selection)

Mode 0

1 x output stage enable (DIN4)

1 x controller enable / acknowledge error (DIN5)

2 x limit switch (DIN6, DIN7)

6 x position selection (DIN0 ... DIN3, DIN10, DIN11)

1 x start positioning (DIN8)

2 x mode shift (DIN9, DIN12)

1 x stop (DIN13)

Mode 1

2 x jog mode (DIN10, DIN11)

1 x teach (DIN8)

Mode 2

1 x halt route program (DIN3)

1 x start route program (DIN8)

2 x next for route program step enabling condition (DIN 2, 11)

Mode 3

2 x pulse/direction (CLK/DIR or CW/CCW on DIN2, DIN3)

1 x start sync (DIN8)

3.5.11 Control interface [X1]

The control interface [X1] is planned as D-Sub 25-pin. The following signals are available:

Table 3.13 Control interface [X1]

The digital inputs are designed to be configurable:

Mode 0: Standard assignment

Mode 1: Special assignment for jog/teach operation

Mode 2: Special assignment for the route program

Mode 3: Special assignment for synchronisation

To be able to switch between different I/O configurations, DIN12 and DIN9 can also be

configured as selector signals.

As a result, a maximum of four different I/O assignments can be selected. These are

described in the following tables:

Table 6.2 Pin allocation: I/O interface [X1] mode 0

Table 6.3 Pin allocation: I/O interface [X1] mode 1

Table 6.4 Pin allocation: I/O interface [X1] mode 2

Table 6.5 Pin allocation: I/O interface [X1] mode 3.

Festo P.BE-CMMD-AS-HW-EN 1002NH 43

Page 44

3. Product description

Note

When a parameter set is loaded from the memory card, the newest

parameter set is always loaded.

3.5.12 Increment generator interface [X10]

Using software, the increment generator interface can be configured both as input and as

output. Additionally, two inputs for the connection of 5V pulse-direction signals (CLK/DIR,

CW/CCW) are planned on the plug connector.

Encoder emulation of the increment generator – [X10] is output:

From the rotational angle determined via the encoder at the motor, the controller

generates the track signals A and B as well as the zero pulse of an increment generator.

The signals A, B, and N equal those of an increment generator.

Angle resolution / Number of lines Output

The number of lines is continuously switchable.

The following numbers of lines are supported: 2048 – 32 lines per revolution.

The switch only becomes effective after a Reset of the controller. An RS422 power driver

provides the signals to [X10] differentially.

Synchronisation – [X10] is input

Using software, the [X10] interface can be configured as an input for processing of

incremental encoder or pulse-direction signals.

The signals are evaluated optionally as A/B track signals of an increment generator or as

pulse/direction signals (CW/CCW, CLK/DIR) of a stepping motor control. The signal form is

selected via software. The number of steps per revolution can be parametrised. Beyond

that, an additional electronic gear can be parameterized.

3.5.13 SD card holder [M1]

To permit saving of control parameters as well as the complete controller firmware,

a connection possibility for an SD memory card (popular storage medium for digital

cameras) has been incorporated. The connection has been designed as a "push-push"

holder for reasons of quality perception.

3.5.14 SD memory card

Via the SD memory card, parameter sets can be loaded or firmware can be downloaded.

A menu in the parametrisation software allows you to specify a set of parameters on the

memory card and load it or save it.

Also, a configuration word in the parameter record can be used to specify whether

firmware and/or a parameter record is to be loaded from the memory card automatically

on activation.

44 Festo P.BE-CMMD-AS-HW-EN 1002NH

Page 45

3. Product description

If automatic firmware download (dip switch 8 = 1) is activated or there is no valid firmware

in the controller, a check is performed on initialisation whether an SD memory card is

inserted, and if so, it is initialised. If there is a firmware file on the card, it is checked first

(checksum test). If no fault is found, the firmware is transferred from the card to the

controller and saved in the FLASH program.

If the automatic loading of the parameter set is activated via the commissioning software,

the system checks whether a card is inserted when the firmware is started and it is