Manual

Controller Modular CECX

CECX-X-C1

CECX-X-M1

761886

1112c en

1112c en

Original . . . . . . . . . . . . . . . . . . . . . en

Edition . . . . . . . . . . . . . . . . . . . . . . Rev 01 (1112c en)

Designation . . . . . . . . . . . . . . . . . . GDCC-CECX-SY-EN

© (Festo AG & Co. KG, D-73726 Esslingen, 2011)

Internet: http://www.festo.com

E−Mail: service_international@festo.com

The copying, distribution and utilization of this document

as well as the communication of its contents to others

without expressed authorization is prohibited. Offenders

will be held liable for compensation of damages. All rights

are reserved, in particular the right to carry out patent,

utility model or ornamental design registration.

1112c en

Content

CECX-I: CECX modular control system::

Overview of functions

Network configuration

Control configuration

CECX-II: System ManualCECX

CECX-III: Library: Ethernet.lib

CECX-IV: Library: EventData.lib

CECX-V: Library: IncEnc.lib

CECX-VI: Library: Festo_EasyIP.lib

CECX-VII: Library: PLCService.lib

CECX-VIII: Library: SysLibComEx.lib

CECX-IX: Library: Festo_Motion.lib

CECX-X: Library: Festo_PartDetector.lib

CECX-XI: Interface FED/VipWin

1112c en

1112c en

CECX modular control system

CECX modular control system

CECX modular control system

Table of contents

CECX modular control system..................................................................................................................1

Overview of functions and libraries..........................................................................................................1

Network configuration..............................................................................................................................12

Network Configuration[SLOT]..............................................................................................................12

Control configuration...............................................................................................................................13

Adding / configuring a module .............................................................................................................13

End points and status values of configured modules...........................................................................14

Process map........................................................................................................................................15

Address setting for modules ................................................................................................................15

CECX-D-16E .......................................................................................................................................16

CECX-D-14A-2....................................................................................................................................17

CECX-D-8E8A-NP-2............................................................................................................................18

CECX-D-6E8A-PN-2............................................................................................................................20

CECX-A-4E-V......................................................................................................................................21

CECX-A-4A-V......................................................................................................................................22

CECX-A-4E4A-V..................................................................................................................................23

CECX-A-4E4A-A..................................................................................................................................24

CECX-E-4E-T-P1.................................................................................................................................25

CECX-E-6E-T-P2.................................................................................................................................26

CECX-F-PB-S-V1 (12 Bytes, 32 Bytes, 64 Bytes)............................................................................... 27

CECX-F-PB-V1....................................................................................................................................28

CECX-C-2G2.......................................................................................................................................30

CECX-S-2S1........................................................................................................................................31

CECX-C-2G1.......................................................................................................................................32

CECX-C-S1, CECX-S-S4....................................................................................................................33

CECX-B-CO.........................................................................................................................................33

CAN Master [SLOT].............................................................................................................................35

Bus interface [SLOT] (for Controller CECX-X-M1)...............................................................................36

Unused [SLOT]....................................................................................................................................37

Notes on system behavior .......................................................................................................................37

Watchdog exception............................................................................................................................37

CECX-I ii

CECX modular control system

CECX modular control system

The CECX modular control system contains a complete development environment that is based on the

CoDeSys 2.3.x development environment of the firm 3S. It supports a host of devices of different

manufacturers. These devices each have different characteristics and functions.

To enable a control (target system) to be used under CoDeSys a so-called Target Support

Package is required for the respective target system. This enables the system functions of

the target system to be accessed and contains appropriate information in the form of online

Help. The Target Support Package makes the CoDeSys functions usable for the respective

device or limits them if necessary.

With the corresponding Target Support Package CoDeSys 2.3.x can support all the features and functio ns

of these devices. The development environment therefore contains many functions that ar e only available

on specific controls. Not all these functions are supported by the CECX modular control system.

The functions of CoDeSys provided by Festo that are supported by CECX modular control

system is contained in the Overview of functions further down.

Overview of chapters

Overview of functions and libraries

Network configuration

Control configuration

Additional information on the hardware is contained in the system manual of online Help.

Overview of functions and libraries

CECX function overview

This overview of functions specifies which functions are supported or not supported in CECX and which

pre-settings become effective for this target system when a new project is created.

Functionality / functions Supported

Project options

Loading and storing Yes

User information Yes

Editor Yes

Work area Yes

Colors Yes

Directories Yes

Log book Yes

Compiling options

Debugging Yes

Replacing constants Yes

Nested comments Yes

Creating binary files Yes

CECX-I 1

CECX modular control system

Passwords Yes

Actions shade programs Yes

Compiling LREAL as REAL Yes

Number of data segments Yes

Excluding objects Yes

Compiler version Yes 2)

Macro before compiling Yes

Macro after compiling Yes

Automatic check Yes

Source download

Symbol configuration Yes

Project data base (ENI server) No

Macros Yes

2) If nothing else is specified always use the current compiler version.

Only source code Yes

All files Yes

Implicit during loading Yes

Notes during loading Yes

Creating implicit during boot

project

Only upon request Yes

Yes

Functionality / functions Supported

Managing projects All functions Yes

Managing objects All functions Yes

General editing functions All functions Yes

CECX-I 2

CECX modular control system

Functionality / functions Supported

General online functions

(part 1)

Login Yes

Logout Yes

Loading Yes

Start Yes

Stop Yes

Reset Yes

Reset (cold) Yes

Reset (origin) Yes

Breakpoint on/off Yes

Breakpoint dialog Yes

Single step over Yes

Single step in Yes

Single cycle Yes

Writing values Yes

Forcing values Yes

Cancel forcing Yes

Writing/forcing dialog Yes

Functionality / functions Supported

General online functions

(part 2)

Invocation hierarchy Yes

Sequence control Yes

Simulation Yes

Communication parameters Yes

Load source code Yes

Creating boot project Yes

Writing file into control Yes

Loading file from control Yes 1)

Online change Yes 2)

VAR PERSISTENT Yes

CECX-I 3

CECX modular control system

1) If a project is stored in the control (project options->source download) the name "Source.dat" is always

allocated on the target system. To open the project that has been stored in the control in CoDeSys it must

first be uploaded (online->load file from control, specify "Source.dat" as file name). The file must then be

renamed <projectname>.pro on the PC. The project can then be opened in CoDeSys as usual. 2) If online

Change is used the contents of addresses can be displaced.

Functionality / functions Supported

Windows All functions Yes

Editors (languages)

Control configuration

Alarm configuration All functions Yes

Global variables All functions Yes

Instruction list (IL) Yes

Structured Text (ST) Yes

Sequential Function Chart (SFC) Yes

Ladder Diagram (LD) Yes

Function chart (FUP) Yes

Continuous graphic function chart (CFC) Yes

Configuration options

HW scan No

State No

Diagnosis from target system No

Addresses automatically Yes

Check address overlapping Yes

Storing configuration files in the

project

Yes

Library manager All functions Yes

Log book All functions Yes

CECX-I 4

CECX modular control system

Functionality / functions Supported

Task configuration

1) Longer waiting decides at equal priority

Insert/add task

Insert/add program call-up Yes

Name Yes

Priority (0-31) Yes 1)

Cyclical Yes

Free-running Yes

Event-driven Yes

Externally event-driven Yes

Watchdog

Time

Sensitivity

Yes

Functionality / functions Supported

System events 1) start

stop

before_reset

after_reset

shutdown

excpt_cycletime_overflow

excpt_watchdog

excpt_access_violation

after_reading_inputs

before_writing_outputs

debug_loop

DI_edge

Task configuration

in online mode

Task processing

sequence

All functions Yes

A task with a valid condition is executed, either when the time

specified at "Interval" has expired, or after a rising edge of a condition

variable specified at event.

If several tasks have a valid condition, the task with the highest

priority is executed.

If several tasks have a valid condition and equal priority, then the task

with the longest waiting period is executed.

Yes

Yes

Yes

Yes

The processing of program calls for each task in the online mode is

executed according to their order in the task editor from top to

bottom.

Processing of the PLC_PRG as cyclical task with 10 ms with

watchdog. 2)

Yes

Yes

CECX-I 5

CECX modular control system

Defining Extras->Debug task Yes

Switching Extras->Debug task on/off Yes

Extras-> call hierarchy Yes

1) The control is a preemptive multi-task system in which the tasks with the higher priority can interrupt or

displace those with a lower one. The system events are executed in a highest priority task conte xt and

therefore displace all other tasks. This means that a system event should contain only a very short code and

the execution time should not exceed 50 µs.

If this time factor would not be observed in a system event (e.g. due to long calls or even endless loop) then

the entire control would be blocked.

To prevent this from occurring it is monitored via a hardware watchdog which returns the control to a safe

state by means of a restart.

Functions of long duration in the context of a system event, such as SysResetPlcProgram or file operations,

should therefore not be executed. An IEC task with the highest priority which runs as event-driven task

should be used for debugging. In the context of the event only the event on which the task is waiting is called

up (if necessary, also information that would otherwise be lost is stored, e.g. the precise time stamp,

although this should only be assignments to global variables).

2) With some functions (e.g. SysRTCSetTime) this could cause task monitoring (watchdog) to respond.

Functionality / functions Supported

Watch and recipe

manager

Work area All functions Yes

Offline mode

Online mode

Insert -> new watch list Yes

Extras-> rename watch list Yes

Extras-> save watch list Yes

Extras-> load watch list Yes

Extra -> monitoring active Yes

Extras-> write recipe Yes

Extras-> read recipe Yes

Forcing and writing values in watch

manager

Yes

Functionality / functions Supported/name

Target system settings Target platform

Name Modular controller: CECX-X-

C1

Motion controller: CECX-X-M1

CECX-I 6

Type-adjusted operand

value

Only relevant for X86

CECX modular control system

Functionality / functions Setting

Target system settings Memory partitioning

1) Of these 12 bytes are used by the runtime system, and the rest of 131060 bytes can be used by the

application.

Basis, area Fixed setting

Size (code) 6 MB

Size per segment (global) 14 MB

Size (marker) 8 KB

Size (input) 8 KB

Size (output) 8 KB

Size retain 128 KB 1)

Own retain segment on/off On

Size of the entire data memory 20 MB

Maximum number of global data

segments

Maximum number of modules 4096

1

Functionality / functions Supported

Target system settings General

I/O configuration: configurable Yes

I/O configuration: Download as file No (added to

program code)

I/O configuration: No address check Yes / can be

set

Supporting CANopen configuration Yes

Supporting profibus configuration Yes

Supporting preemptive multi-tasking Yes / fixed

Online change Yes / can be

set

Updating used IOs Yes / can be

set

Single-task in multi-tasking No

Byte addressing Yes / fixed

Zero initialization Yes / fixed

Sending symbol file Yes / can be

set

Symbol configuration from INI file No

PLC browser Yes

Trace recording Yes

VAR_IN_OUT as reference Yes / fixed

CECX-I 7

CECX modular control system

Initializing Inputs Yes / fixed

Automatically loading boot project Yes / can be

set

Softmotion Yes / can be

set

Maintain forcing No / fixed

Save No

Cycle-independent forcing No

Functionality / functions Supported

Target system settings

Network

functions

Visualization

Supporting parameter manager Yes / can be

set

Supporting network variables Yes 1) / can

be set

Names of supported network interfaces Yes

Index areas for parameters Yes

Index areas for variables Yes

Index areas for mappings Yes

Subindex area Yes

Display width in pixel Yes / can be

set

Display height in pixel Yes / can be

set

Use of 8.3 file format Yes 2) / can

be set

Alarm handling within the control No

Trend data recording within the control Yes / can be

set

CECX-I 8

Activating system variable 'CurrentVisu' Yes / can be

set

Supported fonts in the target system No

Simplified input handling Yes / can be

set

Web visualization No (is not

displayed)

Preventing download of the visualization

files

Target visualization No

Using VISU_INPUT_TASK Yes / fixed

Deactivation creation of tasks No

Keyboard operation for table Yes / can be

Yes / can be

set

set

CECX modular control system

1) Network variables are only supported via UDP.

2) MS-DOS file name conventions (8+3 characters).

Functionality / functions Supported

Trace recording All functions Yes

PLC browser All functions Yes

Parameter manager All functions Yes

ENI All functions No

IEC operators and

additional standard

extending functions

Arithmetic operators Yes

Bit string operators Yes

Bit shift operators Yes

Selection operators Yes

Comparative operators Yes

Operands in

CoDeSys

Address operators Yes

Call operators Yes

Type conversion Yes

Numeric operators Yes

Constants

BOOL constants Yes

TIME constants Yes

DATE constants Yes

TIME_OF_DAY constants Yes

DATE_AND_TIME constants Yes

Numbers constants Yes

REAL and LREAL constants Yes

STRING constants Yes

Typed constants Yes

Addresses %+Area prefix + size prefix + number (e.g.

1) to be created in the control.

Variables Yes Variables

System flags (implicitly declared variables) No 1)

Yes

%QX4.7)

CECX-I 9

CECX modular control system

Functionality / functions Supported

Data types in

CoDeSys

Operators in CoDeSys

commands

Standard data

types

Defined data types

Operators Yes

Functions of the library Standard.lib Yes

Functions of the library Util.lib Yes

Command line commands Yes Command line

Command file commands Yes

BOOL Yes

Integer data types Yes

REAL / LREAL Yes

String Yes

Time data types Yes

Array Yes

Pointer Yes

Enumeration type Yes

Structures Yes

References Yes

Sub-range types Yes

Keyboard operation All functions Yes

Siemens import All functions Yes

DDE communication All functions Yes

CoDeSys visualization All functions Yes

CoDeSys HMI All functions Yes 1)

CoDeSys license

management

Tools for calling up

external applications

SoftMotion All functions Yes 2)

1) Not contained in the scope of supply of CoDeSys provided by Festo.

2) Target-dependent

All functions Yes 1)

All functions No

Libraries on CECx

CoDeSys provided by Festo makes available the following libraries for the CECx:

Library Description Source

CECX-I 10

CECX modular control system

Standard.lib Modules that are required by IEC61131-3 as

standard modules for an IEC programming

system.

Util.lib Modules for BCD conversion, bit/byte

functions, mathematical help functions,

controllers, signal generators, function

manipulators and analog value processing

AnalyzationNew.lib Modules for analyzing of terms

3S_CanDrv.lib

3S_CANopenManager.lib

3S_CANopenMaster.lib

SysLibCallback.lib 1)

SysLibCom.lib

SysLibDir.lib

SysLibDirect.lib

SysLibEvent.lib

SysLibFile.lib 2)

SysLibFileAsync.lib

SysLibFileStream.lib

SysLibGetAddress.lib

SysLibIecTask.lib

SysLibInitLibrary.lib

SysLibMem.lib

SysLibPLCConfig.lib

SysLibPlcCtrl.lib

SysLibProjectInfo.lib

SysLibRtc.lib 3)

SysLibSem.lib

SysLibShm.lib

SysLibSockets.lib 4)

SysLibSocketsAsync.lib 4)

SysLibStr.lib

SysLibTask.lib

SysLibTime.lib

SysTaskInfo.lib

BusDiag.lib

Ethernet.lib Modules for network configuration

− CANopen libraries

System libraries that offer access to special

hardware and software functions of a CECx

(e.g. access to real-time clock, file system,

communication interface, etc.).

Diagnosis for CAN bus systems and

PROFIBUS DP systems

From 3S: − standard

libraries on CoDeSys

− Modbus libraries on

CoDeSys

From 3S − target system

specific libraries that are

adjusted specially to a

CECx system

From KEBA: − target

system specific library

EventData.lib Modules for evaluating interruptible inputs

IncEnc.lib Modules for latch functions of incremental

encoders

PLCService.lib Modu les for control services (e.g. operating

hours counter, version information, etc.)

SysLibComEx.lib Modules for switching the mode between

RS485/422

KSys.lib

TestFunctions.lib

Internal modules

CECX-I 11

CECX modular control system

ModbusTCPSrv.lib 5) Modules for ModuBus TCP-Server 3S additional libraries

1) The SysLibCallback.lib supports the system events listed under "System events".

2) Example for accessing a USB stick:

sFileName := '/usbmassstorage.0.0/testdatei.txt';

dwFilePointer := SysFileOpen(sFileName, 'a');

3) SysRtcCheckBattery and SysRtcGetHourMode are not supported. When a date is set before 1990-12 27-00:00:00 with function SysRtcSetTime, this is lost after a system restart.

4) The ports between 10 000 and 20 000 should be used exclusively for the application.

5) Additional descriptions on the application, please see: Library\Docu

Network configuration

The settings of the control are described in the network configuration, to make it accessible via Ethernet.

When the development PC is connected to a network there is an automatic search for controls on this

network. The controls found are displayed under Network Configuration[SLOT].

Network Configuration[SLOT]

Tab Find PLC lists the controls that have been found in the network.

The following actions can be activated with buttons:

Search Network

Add PLC

Net Config

Set as active PLC

Search Network

By pressing button Search Network the search for controls in the network will be repeated.

Prerequisite is that Multicast has been enabled by the network administrator and "Answer on find

requests" has been selected in Net Config, for the relevant control.

Add PLC

When this button is pressed the window Add PLC opens. After entering the name or the IP address of the

control and OK, CoDeSys searches for the control.

This function can also be used to find controls for which Answer on find requests" has not been selected

in Net Config,.

Net Config

After selecting a control (PLC) and pressing button Net Config, a window opens for entering the

configuration of the network parameters for the selected control.

The following parameters can be entered:

Name Description

PLC name Name of the control in the network

IP IP address *)

Subnet Subnet mask *)

Gateway Gateway entry *)

Enable DHCP When selected, the IP address is automatically requested

CECX-I 12

CECX modular control system

from the DHCP server.

Answer on find requests When selected: the control answers to search requests.

See Search Network and Add PLC.

Synchronize RTC with PC When selected: After confirmation with OK the selected

control takes over the date and time from the PC.

Reboot on OK When selected: A reboot is carried out after OK, to take

over the settings.

*) Examples and information on different network configurations: See system manual of the control (startup, establishing Ethernet connection to PC/control).

Set as active PLC

Takes over the network settings of the selected control (PLC) in the communication settings of CoDeSys.

Control configuration

The settings of the target system are described in the control configuration. Entered here are the control

components used and how they are configured.

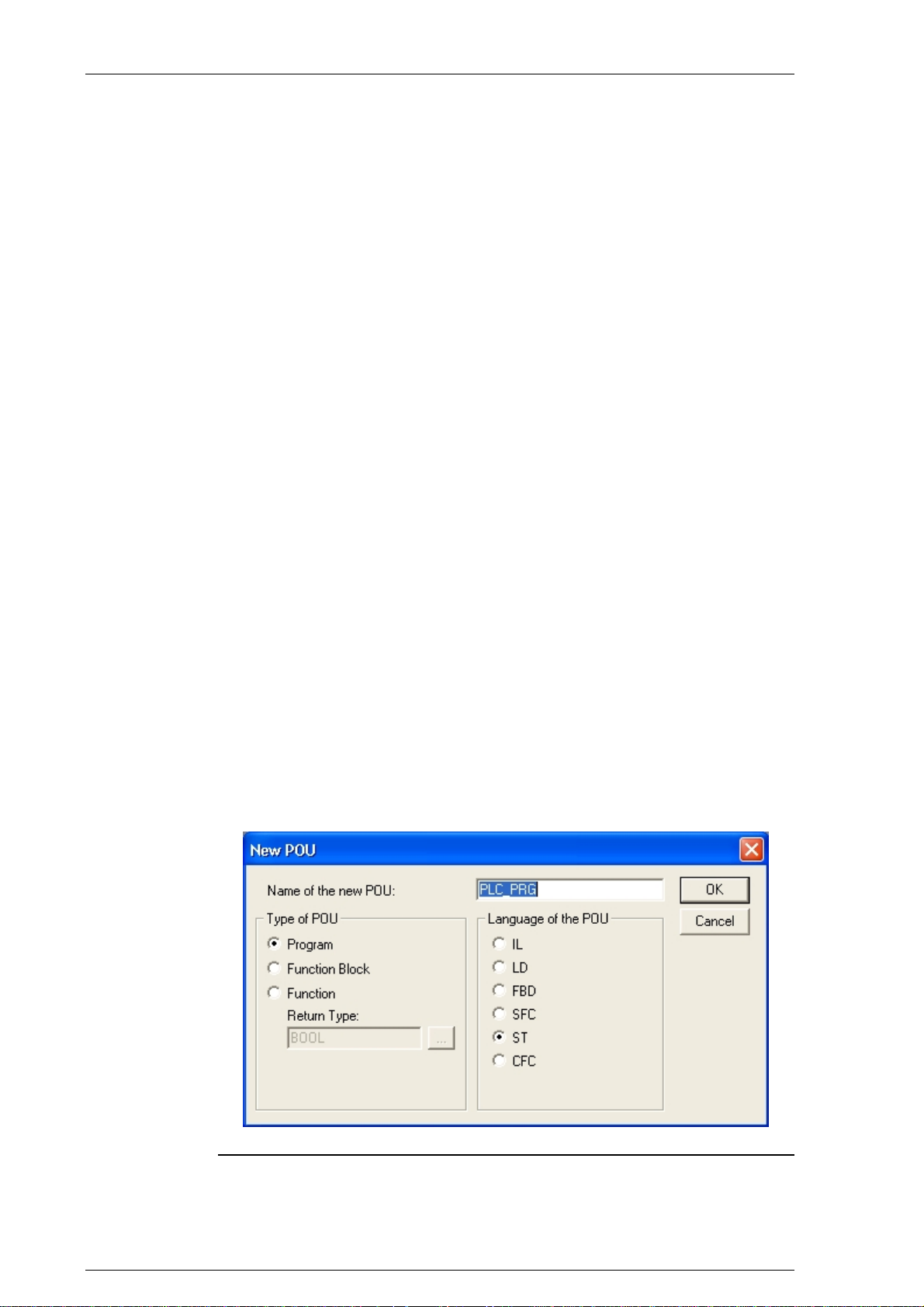

Prerequisites

A target system of the CECX series must be installed with Install Target.

When creating a new project the target system must be selected in Target system settings under

configuration.

The settings for Target platform, Memory partioning, General, Network functions and Visualization

are preset and must not be changed.

That makes the target system available under resources -> control configuration for the configuration

entries.

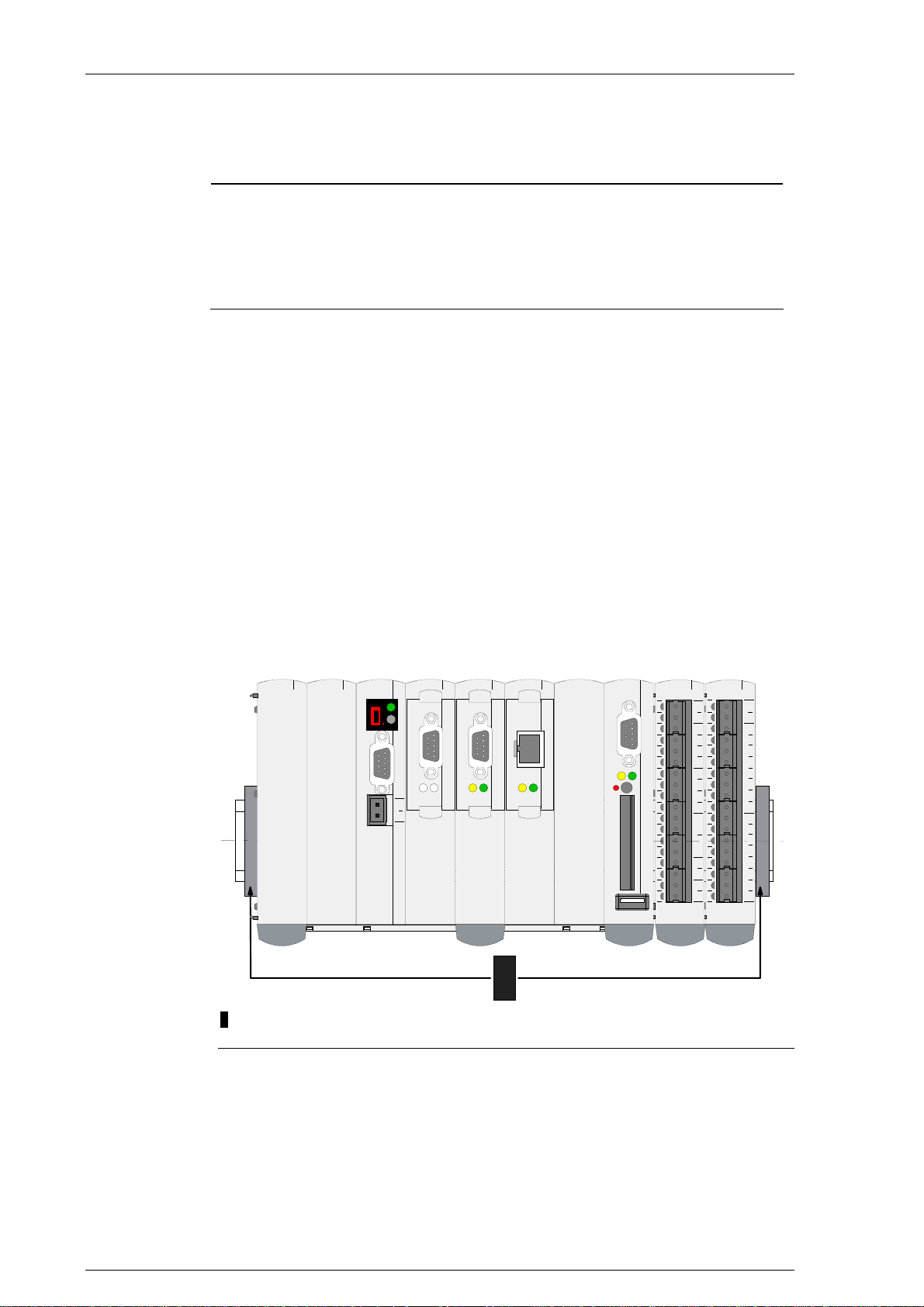

Adding / configuring a module

Further modules can be added by plugging in at the side on the bus connection of the central processor

module. Each hardware module that is added must be entered in the control configuration of CoDeSys.

Select Control configuration under Resources..

For production versions CECX-C1 and CECX-M1 different windows are displayed for the PLC

configurations.

CECX-I 13

CECX modular control system

In both cases a module is added by clicking on ExtModules[SLOT] with the right mouse button, selecting

Add subelement and clicking on the desired module in the menu offered.

The parameters that can be configured are listed in tab Module parameter s.

See also online Help of the CoDeSys programming system, Resources, chapter Export/import of modules.

End points and status values of configured modules

When a module has been configured, CoDeSys creates end points which can be access ed in the IEC

program.

The following end points will be created:

One end point per input or output containing the measured value (e.g. the value V for an analog,

electrical signal).

A status value as diagnosis information for each module (module error: If this value is TRUE, an

error exists, otherwise not)

A status value for each end point (end-point error: If this value is TRUE, an error exists, otherwise

not)

Example for the end point and status values that have been created. The actual addresses are specified

by the concrete project and need not agree with the example shown here.

CECX-I 14

CECX modular control system

For a description of the stored status values: See the description of the configuration of modules in the

following chapters.

Process map

Input

Input

Treiber

physikalische

Inputs (Sensoren)

Output

Merker

Output

Treiber

physikalische

Outputs (Aktoren)

Byte addressing is used.

%IX0.0

-

%IX0.7

%IX1.0

-

%IX1.7

%IX2.0

-

%IX2.7

%IX3.0

-

%IX3.7

%IX4.0

-

%IX4.7

%IX5.0

-

%IX5.7

%IX6.0

-

%IX6.7

%IX7.0

-

%IX7.7

%IX8.0

-

%IX8.7

%IX9.0

-

%IX9.7

%IB0 %IB1 %IB2 %IB3 %IB4 %IB5 %IB6 %IB7 %IB8 %IB9

%IW0 %IW2 %IW4 %IW6 %IW8

%ID0 %ID4 %ID8

Attention:

In the system CECX the access of direct adressed BOOL-variables (%IX0.0, %QX0.0, %MX0.0) is not

possible. The access to bits must be always byte wise.

Address setting for modules

Die station address is set on the module via rotary switches (hexswitch).

The following rules apply for assigning addresses:

Modules of the same type (e.g. several CECX-D-16E modules), that have been added to the

In the CoDeSys configuration there are two options for specifying addresses:

1. Auto

2. Pre-defined value between 0 and F (Hex).

The "auto" setting is intended for those instances where the control does not contain several modules of

the same type. Here it is not necessary to inform the programming system of a fixed, pre-defined address.

A pre-defined value must be specified when several modules of the same type are used in the control a nd

the modules must be differentiated. The "address" module parameter specified in the configuration entry

must then agree with the switch position set on the module.

same CPU module, must have different addresses.

If this instruction is not adhered to and address conflicts result, it is possible that

modules are not recognized and that inputs/output settings are duplicated, set

incorrectly or not set at all.

Different type modules (e.g. a CECX-D-16E module and a CECX-A-4E4A-V module on a CPU

module) can use the same address settings.

CECX-I 15

CECX modular control system

The "auto" setting and the specific assignment of addresses should not be mixed in an

control system.

CECX-D-16E

Digital input module

16 digital inputs of type 1

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically. See

chapter "Address setting for modules".

0 - F The address set here (specified in hexcode) must be

brought into agreement with the position of the

address switch on the module.

DI0 - DI15: despike None No input signal debouncing.

100 ms Debouncing time 100 ms.

DI0 - DI1: Interrupt None No edge evaluation.

Rising edge Signal change at rising edge. *)

Falling edge Signal change at falling edge. *)

Both Signal change at every signal edge. *)

*) The two inputs DI0 and DI1 can be interrupted. i.e. they can trigger system events when corresponding

module parameters have been set. They can be evaluated with the functions of the 'EventData.lib" library.

Status values as diagnosis information

The following status values are created for this module (example):

CECX-I 16

CECX modular control system

Possible error states (when status = TRUE)

Module status: module is defective or missing.

DI status: no error message

CECX-D-14A-2

Digital output module

14 digital output modules 2A at 50%

coincidence, divided into 2 groups (6 and 8

outputs), short-circuit protected, overload

protection, short-circuit detection, group cut-off.

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically. See chapter

"Address setting for modules".

0 - F The address set here (specified in he xcode) must be

brought into agreement with the position of the address

switch on the module.

DO0..DO7: short

circuit scan,

DO8..DO13: short

circuit scan

Scan The short-circuit detection reactivates the outputs not

None This module has two output groups with separate

voltage supply. The short-circuit detection switches off

all active outputs of the output group in which the short

circuit occurred.

CECX-I 17

CECX modular control system

affected by the short circuit.

Status values as diagnosis information

The following status values are created for this module (example):

Possible error states (when status = TRUE)

Module status: module is defective or missing.

DO status: Short circuit of the outputs.

CECX-D-8E8A-NP-2

Digital input/output module

8 digital inputs sink, of which 2 are interruptible

8 digital outputs 2A source at 50% coincidence,

short-circuit protected, overload protection,

short-circuit detection, group cut-off

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically. See chapter

"Address setting for modules".

0 - F The address set here (specified in hexcode) must be

brought into agreement with the position of the address

switch on the module.

short circuit scan None The short-circuit detection deactivates all active outputs

of the output group.

CECX-I 18

CECX modular control system

scan The short-circuit detection reactivates the outputs not

affected by the short circuit.

DI0 - DI7: despike Non e No input signal debouncing.

100 ms Debouncing time 100 ms.

DI0 - DI1: Interrupt None No edge evaluation.

Rising

edge

Falling

edge

Both Signal change at every signal edge. *)

*) The two inputs DI0 and DI1 can be interrupted. i.e. they can trigger system events when corresponding

module parameters have been set. They can be evaluated with the functions of the 'EventData.lib" library.

Status values as diagnosis information

The following status values are created for this module (example):

Signal change at rising edge. *)

Signal change at falling edge. *)

Possible error states (when status = TRUE)

Module status: module is defective or missing.

DI status: no error message

DO status: short circuit of the outputs.

CECX-I 19

CECX modular control system

CECX-D-6E8A-PN-2

Digital input/output module

6 digital inputs source, of which 2 are

interruptible

8 digital outputs 2A sink at 50% coincidence,

short-circuit protected, overload protection,

short-circuit detection, group cut-off

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically. See chapter

"Address setting for modules".

0 - F The address set here (specified in hexcode) must be

brought into agreement with the position of the address

switch on the module.

short circuit scan None The short-circuit detection deactivates all active outputs

of the output group.

scan The short-circuit detection reactivates the outputs not

affected by the short circuit.

DI0 – DI5: despike None Debouncing time 1 ms.

100 ms Debouncing time 100 ms.

DI0 - DI1: Interrupt None No edge evaluation.

Rising

edge

Falling

edge

Both Signal change at every signal edge. *)

*) The two inputs DI0 and DI1 can be interrupted. i.e. they can trigger system events when corresponding

module parameters have been set. They can be evaluated with the functions of the 'EventData.lib" library.

Signal change at rising edge. *)

Signal change at falling edge. *)

CECX-I 20

Status values as diagnosis information

The following status values are created for this module (example):

CECX modular control system

Possible error states (when status = TRUE)

Module status: module is defective or missing.

DI status: no error message

DO status: short circuit of the outputs.

CECX-A-4E-V

Analog input/output module

Analog inputs +/- 10V or 0-10V, resolution 14-

bit, sensor failure detection

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically.

See chapter "Address setting for modules".

0 - F The address set here (specified in hexcode) must be

brought into agreement with the position of the address

switch on the module.

AI0 - AI3: operating

mode

-10..+10V Operating mode with differential input circuit.

CECX-I 21

CECX modular control system

0..URef Single-ended input circuit, calibration standardized to

URef.

Status values as diagnosis information

The following status values are created for this module (example):

Possible error states (when status = TRUE)

Module status: module is defective or missing.

AI status: sensor failure detection

CECX-A-4A-V

Analog input/output module

4 analog outputs +/- 10V, resolution: 12 Bit

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically.

See chapter "Address setting for modules".

0 - F The address set here (specified in hexcode) must be

brought into agreement with the position of the address

switch on the module.

CECX-I 22

Status values as diagnosis information

The following status values are created for this module (example):

Possible error states (when status = TRUE)

Module status: module is defective or missing.

AO status: no error mess age

CECX-A-4E4A-V

Analog input/output module

4 analog inputs universal +/- 10V, resolution: 14

Bit, sensor failure detection

4 analog outputs +/- 10V, resolution: 12 Bit

CECX modular control system

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically. See chapter

"Address setting for modules".

0 - F The address set here (specified in he xcode) must be

brought into agreement with the position of the address

switch on the module.

AI0 - AI3:

operating mode

0...URef Single-ended input circuit, calibration standardized to

Status values as diagnosis information

The following status values are created for this module (example):

-10 ... +10 V Operating mode with differential input circuit.

URef.

CECX-I 23

CECX modular control system

Possible error states (when status = TRUE)

Module status: module is defective or missing.

AI status: sensor failure detection

AO status: no error mess age

CECX-A-4E4A-A

Analog input/output module

4 analog inputs 0-20mA/4-20mA, resolution: 14

Bit

4 analog outputs 0-20mA/4-20mA, resolution:

12 Bit

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically. See chapter

"Address setting for modules".

0 - F The address set here (specified in he xcode) must be

brought into agreement with the position of the address

switch on the module.

AI0 - AI3:

operating mode

4...20 mA Input current range 4 to 20 mA, for detecting cable

Status values as diagnosis information

The following status values are created for this module (example):

0 ... 20 mA Operating mode with input current range 0 to 20 mA.

breakage.

CECX-I 24

Possible error states (when status = TRUE)

Module status: module is defective or missing.

AI status: sensor failure detection at 4...20 mA

AO status: no error mess age

CECX modular control system

CECX-E-4E-T-P1

Temperature measurement module

4 temperature inputs for PT 100 temperature

sensor

2 or 4 conductor technique

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically. See chapter

"Address setting for modules".

0 - F The address set here (specified in he xcode) must be

brought into agreement with the position of the address

switch on the module.

Status values as diagnosis information

The following status values are created for this module (example):

CECX-I 25

CECX modular control system

Possible error states (when status = TRUE)

Module status: module is defective or missing.

TI status: sensor failure detectio n

CECX-E-6E-T-P2

Temperature measurement module

6 temperature inputs for thermocouple type J, K,

L.

Cold junction compensation internal

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically. See chapter

"Address setting for modules".

0 - F The address set here (specified in hexcode) must be

brought into agreement with the position of the address

switch on the module.

operation mode internal

reference

microvolt is applied if the terminal temperature is measured with

TI0 - TI5: sensor

type

K For thermocouple type K (NiCr-Ni) according to IEC

L For thermocouple type L (Fe-CuNi) according to DIN

*) See online help section titled Target system - Festo CECX (hardware configuring,module CECX-E-6E-TP2, chapter Functional description).

Status values as diagnosis information

J For thermocouple type J (Fe-CuNi) according to IEC

The compensation of the terminal temperature is

achieved with an internal temperature measurement

sensor. *)

a semi-conductor temperature sensor (KTY type) with a

nominal resistance of 2,000 W. This semi-conductor

temperature sensor is connected to an analog input.

The cold junction compensation and the linearization

must be realized in the user program. *)

548-1 (-100 °C to 700 °C).

548-1 (-100 °C to 1000 °C).

43710/1977 (-100 °C to +700 °C).

CECX-I 26

The following status values are created for this module (example):

Possible error states (when status = TRUE)

Module status: module is defective or missing.

TI status: sensor failure detectio n

CECX-F-PB-S-V1 (12 Bytes, 32 Bytes, 64 Bytes)

PROFIBUS Slave interface module

PROFIBUS Slave DPV1, each with 32-byte or

64-byte data.

CECX modular control system

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically. See chapter

"Address setting for modules".

0 Only two modules of this type may be operated on one

CPU. An address setting is therefore

not required.

The required GSD file (CECX_F_FB_S_V1_6008.gsd) for the configuration of the PROFIBUS slave

module is stored in the IOCONFIG directory of the Target Support Packages.

Data

The data transmitted over the PROFIBUS are made available in the application in Bytes (Input byte 0 to

31, or 0 to 63 and Output byte 0 to 31, or 0 to 63).

With the configuration of a PROFIBUS slave, the first two data module must be kept

free with 'empty placeholders'! See image.

CECX-I 27

CECX modular control system

You can find more detailed information in the specification of the protocol PROFIBUS-DP (Decentralized

Peripherals) in the relevant field bus literature.

Status values as diagnosis information

The following status values are created for this module (example for 32-byte module):

Possible error states (when status = TRUE)

Module status: module is defective or missing.

BAI status: none.

BAO status: none.

CECX-F-PB-V1

PROFIBUS Master interface module

PROFIBUS Master DPV1.

The module is configurable in the PLC configuration at the lower-most "unused[SLOT]" (see image).

CECX-I 28

CECX modular control system

by selecting CECX-F-PB-V1.

For the use of Profibus DP-V1 services, set the module parameter DPV1Support of the

appropriate slave to "Enabled".

Please consider, that the behaviour of not all Profibus DP-V1-slaves conforms with the

standard. If the DP-V1 communication does not work with the "Enabled" setting, set it to

"Disabled".

Module parameters

A description of the parameters and data can be found in the CoDeSys online help under "Configuring

PROFIBUS modules".

Bus diagnosis

The library BusDag.lib is used for bus diagnosis.

The device number must be set for this as follows:

DEVICENUMBER = 2

Application example for usage of library „BusDiag_Lib“:

Declaration of variables:

PROGRAMM BusDiag_Lib_Profibus

VAR

DiagGBS : DiagGetBusState;

DiagGS : DiagGetState;

Diag : BOOL:=FALSE;

Stationsadress:DWORD; (*Stationsadress of the profibus slave*)

END_VAR

Program code:

DiagGBS(ENABLE := TRUE, DRIVERNAME := 0, DEVICENUMBER := 2);

// Initial situation: In the case of an error the bus has the state 7

// (DiagGBS.EXTENDEDINFO[Stationsadress]:= 7).

// In the following it is described, how to reset the bus state and how to

// get diagnosis information.

// 1. At the first ascending edge of the variable diag in case of an error

// the state of DiagGBS.EXTENDEDINFO[Stationsadress] is set from 7 (bus

// member reports an error) to 3 (bus member is active).

// 2. After the second ascending edge of the variable diag the diagnosis

// information is displayed in DiagGS.EXTENDEDINFO

DiagGS(ENABLE := Diag, DRIVERNAME := 0, DEVICENUMBER := 2,

BUSMEMBERID := Stationsadresse);

CECX-I 29

CECX modular control system

CECX-C-2G2

Motion extension module

Incremental encoder (500 kHz))

2 channels

Module parameters

Name Value Description

Address Auto The address set on the hex switch on the module is

recognized and taken over automatically. See chapter

"Address setting for modules".

0 - 7 The address set here (specified in hexcode) must be

brought into agreement with the position of the address

switch on the module.

Latch input type Sink Latch input DI0, DI1 (sink: switched to 24 V *)

Source Latch input DI0, DI1 (source: switched to 0 V). *)

INC0 - INC1:

encoder-type

RS-422 For encoders with RS-422output (5 V differential).

INC0 - INC1:

edge count

2x Encoder counter pulse 2-fold.

4x Encoder counter pulse 4-fold.

Counter Counter with track A, without direction detection.

Signed

INC0: DI0 - INC1:

DI1 latch edge

Rising edge Latch function activated at rising edge. *)

Falling edge Latch function activated at falling edge. *)

INC0 - INC1:

increments per

revolution

*) Additional latch functions can be used via the IncEnc.lib library.

**) With 24 V encoders no sensor failure and short circuit can be detected.

Status values as diagnosis information

The following status values are created for this module (example):

24 V Encoder interfaces INC0, INC1, incremental input, for

encoder wit 24V output (single ended). **)

1x Encoder counter pulse single.

Counter with track A and B, (with direction detection).

counter

None No latch function (= data storage at change of latch

input signal).

Number of impulses of transducer per rotation.

CECX-I 30

Possible error states (when status = TRUE)

Module status: module is defective or missing.

INC status: sensor failure, short circuit.

DI status: no error message

When parameter INC0 - encoder type (or INC1 - encoder type) is set on RS-422 and no

incremental encoder has been connected to the encoder input, the error state "INC Status"

switches to TRUE. Encoder inputs not used should therefore be configured as 24 V type.

CECX-S-2S1

CECX modular control system

Serial interface module

2 RS-232-C

Modul parameters

Name Value Description

address auto The address set on the hex switch on the module is

recognized and taken over automatically. See chapter

"Address setting for modules".

0 - F The address set here (specified in he xcode) must be

brought into agreement with the position of the address

switch on the module.

Status values as diagnosis information

The following status values are created for this module (example):

Possible error states (when status = TRUE)

Module status: module is defective or missing.

Additional information: See online help section titled Target system - Festo CECX (CECX- S-2S1).

CECX-I 31

CECX modular control system

CECX-C-2G1

Serial interface module

SSI Interface

4 interfaces

Modul parameters

Name Value Description

address auto The address set on the hex switch on the module is

recognized and taken over automatically. See chapter

"Address setting for modules".

0 - F The address set here (specified in he xcode) must be

brought into agreement with the position of the address

switch on the module..

baud rate 125, 250,

500 kBaud,

1 Mbaud.

data bits 16 – 24 Number of data bits

data code Binary oder

gray code

bit oder most

significant bit

first oder

least

significant bit

first

Status values as diagnosis information

The following status values are created for this module (example):

Data transmission rate.

Coding of the sensor. Gray code = after Frank Gray

coding process for robust transmission of digital values.

Specification of sequence in which the bits are

transmitted in the data stream.

Possible error states (when status = TRUE)

Module status: module is defective or missing.

Channel status: Sensor failure detection, sensor shows fault in SSI telegram.

CECX-I 32

CECX modular control system

CECX-C-S1, CECX-S-S4

Serial option module:

CECX-C-S1: RS-232-C,

CECX-S-S4: RS-485/422

Modul parameters

These modules are configured as CoDeSys interface in the PLC configuration via Communication

Parameters, SIO Config. For the application, these interfaces are useable via the functions from the

CoDeSys SysLib Com.

Name Values Description

Port COM2 to

COM8

baud rate Fr om 4800

to 115000

Baud

parity None, odd,

even

data bits 8 Number of data bits.

stop bits 0, 1 oder 2 Number of stop bits.

See also online help to the target system CECX under: Start-up of CoDeSys and control -> Establishing

PC/Control connection -> Serial connection.

See chapter "Operation of interfaces, Serial interfaces".

Data transmission rate.

Parity

CECX-B-CO

CANOpen bus link module:

for up to 12 add-on modules.

The CECX-B-CO is a CANOpen bus link module, and may be connected as slave module to each CAN

master module.

Set the values of the CAN parameters as desired (baudrate according to length of data line, other

parameters adequate to the settings at the CAN modules).

When configuring the CAN master, consider that the parameter „Support DSP301,V4.01 and

DSP306“ is selected. If this option is set, then the CAN module selection is available.

CECX-I 33

CECX modular control system

CAN module selection

Select the add-on modules of the bus link module via CAN-module selection.

At the bus the CECX-B-CO sorts the modules in the following sequence:

1. CECX-E-6E-T-P2 2. CECX-A-4E4A-V 3. CECX-A-4E4A-A

4. CECX-A-4E-V 5. CECX-A-4A-V 6. CECX-E-4E-T-P1

7. CECX-D-16E 8. CECX-D-14A-2 9. CECX-D-8E8A-NP-2

10. CECX-D-6E8A-PN-2 11. CECX-C-2G2 12. CECX-C-2G1

When adding modules take care that the modules selected are inserted in the sequence

described above. Otherwise data could be written onto the wrong modules.

When adding modules, they are inserted above the actual selected module. Do not start

selection with module of CECX-E-6E-T-P2 type.

PDO-Mapping

To ensure that data are transmitted between CAN-Master and CAN-Slave, the 'Receive PDO-Mapping'

and the 'Send PDO-Mapping' must be set right and complete.

In the left window select a data entry (in the example: Write Output 8-Bit_CECX-D-8E8A)

and a PDO (in the example: PDO 0x1400) and add it with the

not used here.

key. The StandardDataTypes must

CECX-I 34

CECX modular control system

The system configuration will be added with an entry.

If the message appears "Caution! The following PDOs are currently not active: ...", it can be ignored.

These are PDOs, which are created but not used in the system.

In the system configuration any name can be entered for the created system variable (e.g. out).

In principal the PDO mapping can be done arbitrary. If a PDO is filled, then a message will be shown, and

the next PDO has to be used.

Digital in-/output values are mapped to unsigned system variables (UINT for 16 bit transmission,

USINT for 8 bit). Bit 0 corresponds to the flirst in-/output, bit 1 to the second in-/output, and so

on. E.g. if the outputs 1, 2 and 4 should be set, then the variable out must be set to the value 11

(= 1+2+8).

For more detailed information to PDO mapping please refer to the system manual, chapter 34 - bus link

module CECX-B-CO.

CAN Master [SLOT]

Configuration entry for a CAN Master for operating CAN slaves.

If the CAN master is set on "unused" or on "Businterface", then the libraries "3S_CANDrv.lib",

"3S_CANOpenManager.lib" and "3S_CANOpenMaster.lib" that have been inserted

automatically must be removed manually, otherwise conflicts could arise during the

compilation of the project.

Bus diagnosis

The library BusDag.lib is used for bus diagnosis (see BusDiag.lib).

For this the DEVICENUMBER must be set as follows.

CAN Master that is used first: DEVICENUMBER = 3,

CAN Master that is used second: DEVICENUMBER = 4.

Information on application

A Start telegram is sent to each CAN participant as standard.

However, a "Start All Nodes" telegram, NodeID = 0, can be sent from the IEC application. For

the second CAN master the NodeID = 1.

This requires that at the start-up of the control the application always sets the flag

bUseStartAllNodes of the master once, e.g. as follows (bInit is defined by the application):

IF NOT bInit THEN

pCanOpenMaster[0].bUseStartAllNodes := TRUE;

bInit := TRUE;

CECX-I 35

CECX modular control system

END_IF

Attention:

This flag must not be set cyclically, since the individual nodes ca no longer be started after a

failure.

Application example for usage of library „BusDiag_Lib“:

Declaration of variables:

PROGRAM BusDiag_Lib_CAN

VAR

DiagGBS : DiagGetBusState;

DiagGS : DiagGetState;

Diag : BOOL:= FALSE;

NodeID: DWORD; //node number of the CAN slaves

CANMaster: INT; //First used CAN master: DEVICENUMBER = 3,

//Second used CAN master: DEVICENUMBER = 4

END_VAR

Program code:

DiagGBS(ENABLE := TRUE, DRIVERNAME := 0, DEVICENUMBER := CANMaster);

// Initial situation: In the case of an error the bus has the state 7.

// (DiagGBS.EXTENDEDINFO[NodeID] := 7).

// For requesting the diagnosis information in the case of an error

// (DiagGBS.EXTENDEDINFO[NodeID] := 7) the variable Diag must be set manually

// to TRUE.

// The emergency telegram is displayed in DiagGS.EXTENDEDINFO

IF Diag THEN

DiagGS(ENABLE := TRUE, DRIVERNAME := 0, DEVICENUMBER := CANMaster,

BUSMEMBERID := NodeID);

Diag := FALSE;

END_IF;

Bus interface [SLOT] (for Controller CECX-X-M1)

Configuration entry of a bus interface for SoftMotion drives.

When the bus interface and CAN master are operated simultaneously the f ollowing information must be

adhered to:

The bus interface must always be configured first in CoDeSys.

As soon as a CAN master is configured it occupies the first CAN circuit (Onboard CAN) and the bus

interface then occupies the plug-in module CECX-F-CO. The controller number at the AxisGroup

parameterization must in this case be set on 1 (see illustration).

CECX-I 36

CECX modular control system

Information on application

The cycle time for the motion task is configured depending on the used drives. If you use

CMMS-AS, CMMS-ST, SFC-LAC oder SFC-LACI the minimal cycle time is 8 ms.

For more information see the systemdescription of the drives.

Unused [SLOT]

Not used at the moment.

Notes on system behavior

The system behavior can, in certain cases, be influenced via application programming e.g. for:

Watchdog exception

Watchdog exception

A watchdog exception occurs when during a task in CoDeSys it is determined that the current cycle of the

maximum allowed time according to task configuration has been exceeded. This leads to the watchdog

exception callback of the Iec application being executed.

The system stops the task in which the exception has occured and the execution of al assigned

programms. The tasks subsequently execute no further cycle until an application reset was performed.

Other tasks of the taskconfiguration are not stopped. When the whole application is stopped, a start is only

possible after an application reset.

If a reaction is desired from the user, a watchdog exception handler must be added (Task configuration>System events):

The system behavior can be influenced as desired in this e.g. by call of a callback function. The name of

the called function must begin with "callback".

The behavior for a watchdog exception must be considered with the application design, e.g.:

switching from automatic to manual mode or reboot of the control. It is dependent on the

device function and the effects which the failure of the affected task can trigger.

The called callback function may not contain long continuing procedures (e .g. writing of files,

etc.) since otherwise the control will be totally blocked.

If a task with assigned programmcall is not defined in the project, a default task (realtime,

priority 10) with 10 ms cyle-time and active watchdog (time: t#11ms / sensitivity: 1) is used.

CECX-I 37

CECX modular control system

CECX-I 38

System manual CECX

CECX-II

Content System Manual CECX

Product design....................................................................................................................1-1

1 Introduction ..................................................................................................................1-1

1.1 Purpose of the document....................................................................................1-1

1.2 Target groups, preconditions..............................................................................1-1

1.3 Intended use of the CECX modular control system............................................1-2

1.4 Notes on this document......................................................................................1-3

1.5 General product-specific terms and abbreviation...............................................1-3

1.6 Application and registrations...............................................................................1-4

2 Safety notes..................................................................................................................2-1

2.1 Representation ...................................................................................................2-1

2.2 General safety instructions.................................................................................2-2

2.3 Safety instructions for programming...................................................................2-4

2.4 Safety instructions for maintenance work...........................................................2-5

2.5 Requirement for UL508 and use conforming to EN 61131.................................2-5

3 System overview ..........................................................................................................3-1

3.1 Structure of the modular control .........................................................................3-1

3.2 Working mode of the control...............................................................................3-4

3.3 Start-up and programming (overview) ................................................................3-5

4 General assembly and installation instructions........................................................4-1

4.1 General instructions on assembly and removal..................................................4-1

4.2 Mounting rail.......................................................................................................4-1

4.3 Footprint..............................................................................................................4-2

4.4 Adding modules..................................................................................................4-2

4.5 Mounting/dismounting the boards and modules.................................................4-3

4.6 Air conditioning, ventilation.................................................................................4-7

5 Power supply of modules............................................................................................5-1

5.1 Connection..........................................................................................................5-1

5.2 Power consumption of modules..........................................................................5-2

5.3 Example power calculation.................................................................................5-3

6 Operation and displays................................................................................................6-1

6.1 Setting the module address................................................................................6-1

6.2 Control key (Ctrl).................................................................................................6-1

6.3 Power LED (Power)............................................................................................6-1

6.4 Diagnosis display (Diagnostics)..........................................................................6-2

6.5 Compact Flash Card...........................................................................................6-2

7 Commissioning of CoDeSys and control...................................................................7-1

7.1 Installing CoDeSys and starting development environment ...............................7-1

7.2 Installation of a Target Support Package (TSP).................................................7-1

I

Content System Manual CECX

7.3 Switch-on control................................................................................................7-4

7.4 Creating a CoDeSys project...............................................................................7-4

7.5 Establishing the connection to the PC/control....................................................7-5

7.6 Configuring modules.........................................................................................7-15

7.7 Connecting an FED ..........................................................................................7-16

7.8 First programming steps...................................................................................7-20

8 Operating behavior ......................................................................................................8-1

8.1 Button and display, general information .............................................................8-1

8.2 Start-up...............................................................................................................8-2

8.3 Operating states ................................................................................................. 8-3

9 Diagnosis......................................................................................................................9-1

9.1 Display of errors in the 7-segment display..........................................................9-1

9.2 Touch control at error display during operations: ...............................................9-1

9.3 Error codes.........................................................................................................9-2

10 Disposal ......................................................................................................................10-1

10.1 Disposal of the module.....................................................................................10-1

10.2 Disposal of the battery......................................................................................10-1

11 Technical data ............................................................................................................11-1

12 EC directives and standards.....................................................................................12-1

12.1 Why EMC-compatible wiring?...........................................................................12-2

13 Connections and wiring.............................................................................................13-1

13.1 General information on interfaces.....................................................................13-1

13.2 General information on inputs / outputs ............................................................13-7

13.3 General limits for wire cross sections.............................................................13-11

13.4 Test of interference immunity .........................................................................13-12

14 CPU module................................................................................................................14-1

14.1 Introduction.......................................................................................................14-1

14.2 Safety notes......................................................................................................14-1

14.3 Description of the module.................................................................................14-4

14.4 Operating elements and displays .....................................................................14-6

14.5 Mounting and installation instructions...............................................................14-7

14.6 Air conditioning and ventilation.......................................................................14-10

14.7 Connections and wiring ..................................................................................14-11

14.8 Configuration ..................................................................................................14-19

14.9 Operating behavior of the CPU module..........................................................14-20

14.10 Diagnosis........................................................................................................14-20

14.11 Maintenance...................................................................................................14-21

14.12 Disposal..........................................................................................................14-23

14.13 Technical data ................................................................................................14-24

14.14 EC directives and standards...........................................................................14-25

15 Digital input module CECX-D-16E ............................................................................15-1

II

Content System Manual CECX

15.1 Introduction.......................................................................................................15-1

15.2 Safety notes......................................................................................................15-1

15.3 Description of the module.................................................................................15-3

15.4 Connections and wiring ....................................................................................15-4

15.5 Configuration ....................................................................................................15-9

15.6 Operating behavior.........................................................................................15-11

15.7 Disposal..........................................................................................................15-11

15.8 Technical data ................................................................................................15-12

15.9 EC directives and standards ...........................................................................15-13

16 Digital output module CECX-D-14A-2.......................................................................16-1

16.1 Introduction.......................................................................................................16-1

16.2 Safety notes......................................................................................................16-1

16.3 Description of the module.................................................................................16-3

16.4 Connections and wiring ....................................................................................16-5

16.5 Configuration ....................................................................................................16-8

16.6 Operating behavior...........................................................................................16-9

16.7 Disposal..........................................................................................................16-12

16.8 Technical data ................................................................................................16-13

16.9 EC directives and standards ...........................................................................16-14

17 Digital input/output module CECX-D-8E8A-NP-2 ....................................................17-1

17.1 Introduction.......................................................................................................17-1

17.2 Safety notes......................................................................................................17-1

17.3 Description of the module.................................................................................17-3

17.4 Connections and wiring ....................................................................................17-4

17.5 Configuration ..................................................................................................17-11

17.6 Operating behavior.........................................................................................17-12

17.7 Disposal..........................................................................................................17-14

17.8 Technical data ................................................................................................17-15

17.9 EC directives and standards ...........................................................................17-17

18 Digital input/output module CECX-D-6E8A-PN-2 ....................................................18-1

18.1 Introduction.......................................................................................................18-1

18.2 Safety notes......................................................................................................18-1

18.3 Description of the module.................................................................................18-3

18.4 Connections and wiring ....................................................................................18-5

18.5 Configuration ..................................................................................................18-12

18.6 Operating behavior.........................................................................................18-14

18.7 Disposal..........................................................................................................18-16

18.8 Technical data ................................................................................................18-17

18.9 EC directives and standards ...........................................................................18-19

19 Analog input module CECX-A-4E-V..........................................................................19-1

19.1 Introduction.......................................................................................................19-1

19.2 Safety notes......................................................................................................19-1

19.3 Description of the module.................................................................................19-3

19.4 Connections and wiring ....................................................................................19-5

19.5 Configuration ..................................................................................................19-10

19.6 Operating behavior.........................................................................................19-11

III

Content System Manual CECX

19.7 Disposal..........................................................................................................19-12

19.8 Technical data ................................................................................................19-13

19.9 EC directives and standards ...........................................................................19-15

20 Analog output module CECX-A-4A-V.......................................................................20-1

20.1 Introduction.......................................................................................................20-1

20.2 Safety notes......................................................................................................20-1

20.3 Description of the module.................................................................................20-3

20.4 Connections and wiring ....................................................................................20-5

20.5 Configuration ....................................................................................................20-8

20.6 Operating behavior...........................................................................................20-9

20.7 Disposal............................................................................................................20-9

20.8 Technical data ................................................................................................20-10

20.9 EC directives and standards ...........................................................................20-11

21 Analog input/output module CECX-A-4E4A-V.........................................................21-1

21.1 Introduction.......................................................................................................21-1

21.2 Safety notes......................................................................................................21-1

21.3 Description of the module.................................................................................21-3

21.4 Connections and wiring ....................................................................................21-5

21.5 Configuration ..................................................................................................21-12

21.6 Operating behavior.........................................................................................21-13

21.7 Disposal..........................................................................................................21-14

21.8 Technical data ................................................................................................21-15

21.9 EC directives and standards ...........................................................................21-17

22 Analog input/output module CECX-A-4E4A-A.........................................................22-1

22.1 Introduction.......................................................................................................22-1

22.2 Safety notes......................................................................................................22-1

22.3 Description of the module.................................................................................22-3

22.4 Connections and wiring ....................................................................................22-5

22.5 Configuration ..................................................................................................22-10