Page 1

Lichfield Road, Branston Industrial Estate, Burton Upon Trent, Staffordshire DE14 3HD

Tel. 08707 282 885 - Fax 08707 282 886

ALL SPECIFICATIONS SUBJECT TO CHANGE

Phone numbers:

Installer

Service Engineer

Serial No.

Read these Instructions thoroughly before

using the appliance

FERROLI HELPLINE

FOR SERVICE INFORMATION OR

HELP TELEPHONE: 08707 282 885

ALWAYS QUOTE YOUR SERIAL NUMBER

FOR IMMEDIATE ASSISTANCE

TECHNICAL

INFORMATION

INSTALLATION

and

SERVICE

INSTRUCTIONS

WALL MOUNTED, ROOM SEALED,

FAN ASSISTED, GAS COMBINATION BOILER,

COMPUTERISED AND SYNTHESIZED VOICE

01/01

Page 2

2

Page 3

3

INDEX

Page

4. Introduction

4. Related documents

5. General description

6. Technical data

7. Appliance dimensions

8. Boiler flow diagram

9. Boiler main parts

10. Installation details

10. Location of boiler

10. Terminal position

10. Air supply

11. Minimum clearance

12. Flue system

12. Gas supply

12. Water system

14. Control heating pump

14. Additional expansion vessel

15. Installation of boiler

17. Preparing flue assembly

18. Connecting the boiler

20. Fitting the flue assembly

20. Electrical installation

21. Wiring diagram

22. External sensor location

23. Gas conversion and adjustments

26. Control panel

28. Programming heating

29. Programming boiler parameters

32. Switching boiler on and off

33. Routine maintenance

34. Diagnosis and troubleshooting

Page 4

4

Introduction

The XIGNAL CE boiler is a high efficiency heat generating appliance of a totally new design. It is

environment friendly, gas fired and prduces hot water for both the central heating system and domestic

hot water.

The new concept of XIGNAL CE is that it is fitted with a microcomputer to regulate the boiler performance

through technically sophisticated controls. This guarantees correct and optimum operation while being

extremely simple to use. The diagnostic information and the operative status of the boiler are constantly

visible on the display and can also be communicated by synthesized voice.

The boiler operation can be easily programmed be setting four daily heating levels. The fuel management

system incorporates an internal and external sensor accurately calculating the heat output required (the

temperature of the water in the radiators is regulated depending on the external temperature).

XIGNAL CE has a new generation gas burner ensuring perfect combustion with high flame efficiency and

low emissions of pulluting gases like NOx and CO

2

. The burner is ignited and monitored electronically

ensuring the burner performance functions completely automatic and safe. This system also isolates the

boiler from the domestic environment, ensuring total safety.

XIGNAL CE heat exchanger is made entirely of copper this ensures high efficiency even when the heating

is low, protection against rust and oxidation makes the heat exchanger both reliable and long lasting.

Related Documents

The appliance must be installed strictly in accordance with these instructions:

The Gas Safety Regulations (Installation & Use) 1984.

The Local Building Regulations.

The Building Regulations.

The Building Standards (Scotland - Consolidated) Regulations.

British Standards Codes of Practice:

B.S. 7593 - 1993 Treatment of water in domestic hot water central heating systems.

B.S. 5546 - 1990 Installation of hot water supplies for domestic purposes

B.S. 5440 - Part 1FLUES

B.S. 5440 - Part 2AIR SUPPLY

B.S. 5449 - 1990 FORCED CIRCULATION HOT WATER SYSTEMS

B.S. 6798 - 1987 INSTALLATION OF GAS FIRED HOT WATER BOILERS

B.S. 6891 - 1989 GAS INSTALLATIONS

B.S. 7671 - 1992 IEE WIRING REGULATIONS

Page 5

5

GENERAL DESCRIPTION

The boiler is able to operate with two types of fuel gas: natural or propane (L.P.G.). The type of gas should

be chosen when the boiler is ordered. Conversions can also be carried out during the installation phase

.The boiler is controlled by an internal microcomputer and all settings to the regulating systems are carried

out on the assembly line by use of software. This ensures that the set values always remain absolutely

accurate throughout plant use

The user may program and select the various options through the control panel. These functions include

summer/winter operation, choice of the sanitary water temperature and that of the plant delivery, daily

program setting and activation, boiler release.

The heating function is only activated when Winter operation is selected (key

). The microcomputer

handles the heating function either according to the set daily program or according to the temperature

set on the knob of the ambient unit. In both cases, the demand for heat will activate the circulation pump,

the fan and the electronic equipment to start the burner. The burner ignites at a power value that will have

been preset according to the fuelling gas. If the pressure in the heating system is less than 0.5 bar or more

than 2.5 bar, the microcomputer will prevent boiler operation for safety reasons.

During operation, the plant delivery temperature is regulated according to the external temperature

(detected by the relative probe). Temperature regulation will be proportional to the compensating curve

set on installation according to the structural characteristics of both the building and system.

When the temperature of the water in the boiler approaches the value established by the computer, the

valve will reduce the amount of gas (modulating) delivered to the main burner in order to keep the water

temperature near to the required value. If the water temperature reaches the preset value, the burner will

go out and will wait 2 minutes until igniting again. Having terminated the demand for heat, the burner

will stop while the circulator will continue to operate for six minutes so that the temperature is evenly

distributed throughout the system.

If hot water is used during the heating system, the microcomputer will detect this by means of the flowmeter

and will disactivate the heating function. This stops the circulator and activates hot water production. Hot

water is constantly maintained at the set value even during different water flow rates. This is due to a

correct establishment of the outlet flow of hot water and adequate modulation of the burner rating. Once

use of hot water ceases, the computer will wait for 2 minutes before re-activating the heating function.

Only hot water production is activated during "Summer" operation. However, the circulating pump of

the heating function will operate for 1 sec. at the end of each demand for water in order to prevent the

pump itself from sticking.

The microcomputer continuously checks that boiler operation is correct. In the event of faults, these are

immediately visualized (the display will flash) and notified by synthesized voice when the relative button

is depressed. Boiler operation will be inhibited until the fault is rectified or, in some cases, until the boiler

is manually reset.

All faults are memorized by the microcomputer together with the other operational parameters. This

enables the technical assistance service to proceed with a correct diagnosis.

Page 6

6

Technical data

NATURAL GAS (G20) PROPANE LPG (G31)

Nominal heat input (gross caloric value) 34.8 kW 34.0 kW

Minimum heat input (gross caloric value) 15.1 kW 14.8 kW

Nominal heat input (net caloric value) 31.3 kW 31.3 kW

Minimum heat input (net caloric value) 13.6 kW 13.6 kW

Nominal heat output 27.9 kW 27.9 kW

Minimum heat output 11.8 kW 11.8 kW

Gas rate 3.27 m

3

S/h 2.40 kg/h

Burner setting pressure 15,0 mbar (max.) 34,5 mbar (max.)

Minimum burner pressure 3,0 mbar (min.) 6,9 mbar (min.)

Main injector Ø 1.15 mm 0.72 mm

Dimensions (o/all)

Height 1020 mm

Width 480 mm

Depth 360 mm

Weight (net) 51 kg

Weight (gross) 53 kg

Electricity supply: 230V - 50 Hz

Fuse rating:

Mains 2 Amp. (main fuse)

on P.C.B. in boiler F2 Amp (Fast)

Electrical input 150 Watt

Domestic Hot Water flow:

(35°C rise) 11.4 l/min.

Minimum Domestic Hot Water Flow 2.5 l/min.

Maximum domestic cold water

Inlet pressure: 10,0 bar

C.H. Safety valve pressure setting 3 bar

C.H. Expansion vessel capacity 7 litre

Min. heating circuit pressure 0,8 bar

Max. heating circuit pressure 3.0 bar

Boiler water capacity:

Heating 1.5 litre

Domestic hot water 0.5 litre

Pipe connections:

Gas 22 mm

Domestic cold water inlet 15 mm

Domestic cold water outlet 15 mm

Central heating flow 22 mm

Central heating return 22 mm

Pressure relief valve drain 15 mm

Min. installation clearances. Sides:

Left hand 5* mm

Right hand 5* mm

Front 50** mm

(plus access for service)

Min. height from worktop to base 200 mm

* If using a side outlet flue then the minimum clearance on the flue outlet side of the appliance is increased to 75 mm (3 in.)

** Access to the front of the boiler must be available for maintenance (min. 600 mm)

The maximum working temperature of the central heating water is 85°C.

The maximum domestic hot water production temperature is 65°C, which can be regulated from 40 to 65°C.

Page 7

7

Key

1. Electricity cable entry

2. Gas supply

3. Domestic Hot Water outlet

4. Domestic Cold Water inlet

5. Central Heating Pressure relief valve

6. Central Heating Flow outlet

7. Central Heating Return inlet

Appliance Dimensions

TOP VIEW

FRONT VIEW LEFT SIDE VIEW REAR VIEW

480

163

900

370

448

66

213

144

77.5507580505097.5

12 3 4 5 67

40

100

60

Page 8

8

S.p.A.

124749

1...4

MAN

AUTO

Model Water Bye Laws.

Fig. 2

6

68

98

140

142

141

Page 9

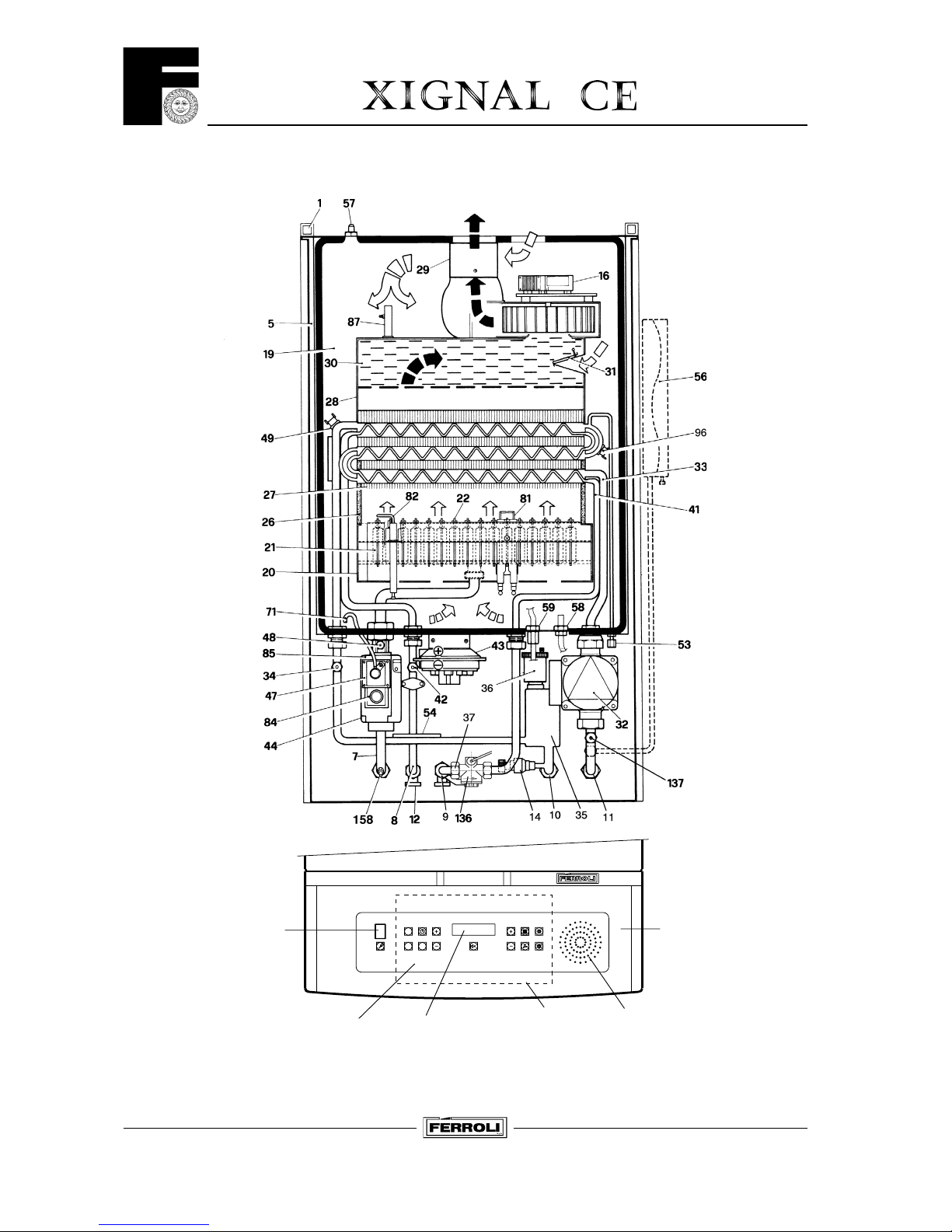

9

Boiler flow diagram

Main parts

1 Fixing point

5 Room sealed compartment

6 Instrument panel

7 Gas inlet

8 Domestic hot water outlet

9 Domestic hot water inlet

10 Central heating flow

11 Central heating return

12 D.H.W. drain point

14 Safety valve

16 Fan

19 Combustion chamber

20 Burner unit

21 Main injector

22 Burner

26 Combustion chamber insulation

27 Copper exchanger for C.H. or D.H.W.

29 Flue outlet manifold

30 Excess air chamber

31 Air pressure control damper

32 C.H. pump

33 Heating water circuit

34 Heating temp. sensor

35 Air separator

36 Automatic air vent

37 Cold water inlet filter

41 Domestic hot water circuit

42 D.H.W. temperature sensor

43 Air pressure switch

44 Gas valve

47 Gas valve modulator

48 Burner pressure test point

49 Overheat thermostat

53 Heat exchanger venting point

54 Temperature sensing phial

56 Expansion tank

57 Fan air inlet pressure test point

58 Fan air outlet pressure test point

59 Flue outlet pressure test point

65 230V line terminal strip and probe connections

68 Control box with P.C.B.

71 Balance tube

81 Ignition electrode

82 Flame sensing electrode

83 Automatic ignition control panel

84 1. gas valve operator 230V

85 2. gas valve operator 230V

87 Venturi test point

96 Control heating limit sensor

98 Main switch

101 P.C.B.

136 Flowmeter

137 Pressure sensor

140 Touch keyboard

141 Loudspeaker

142 Display P.C.B.

158 Gas inlet pressure test point

Page 10

10

Installation Details

Gas Safety (Installation & Use) Regulations: 1984

In the interest of safety, it is the law that all gas appliances are installed by a competent person in accordance with

the above Regulations, Building Regulations/Building Standards Scotland, Codes of Practice, current I.E.E.

Regulations and the byelaws of the Local Water Undertaking. Failure to comply with the Regulations may lead

to prosecution; it is in your interest and that of safety to ensure that the law is complied with.

Important - If the boiler is to be fitted in a timber framed building it should be fitted in accordance with

the British Gas publication; Guide for Gas Installation in Timber Frame Housing: Reference DM2. If in doubt

advice must be sought from the Local Gas Region of British Gas Plc.

Location of Boiler

The installation of the XIGNAL CE must be on a suitable non-combustible load bearing wall which will provide

an adequate fixing for the boiler mounting bracket assembly. The location should be in an area where the water

pipes will not be subjected to frost conditions. In siting the combination boiler the following limitations must be

observed:

The combination boiler may be installed in any room or internal space, although particular attention is

drawn to the requirements of the current, i.e. wiring regulations and in Scotland the electrical provisions of the

building regulations applicable in Scotland, with respect to the installation of the combination boiler in a room or

internal space containing a bath or shower.

Where a room sealed appliance is installed in a room containing a bath or shower any electrical switch or

appliance control utilising mains electricity, should be so situated that it cannot be touched by a person using the

bath or shower.

Terminal Position

POS. MINIMUM SPACING (fig. 3) mm

A Directly below an openable window, air vent, or any other ventilation opening 300

B Below gutters, soil pipes or drainpipes 75

C Below Eaves 100

D Below a Balcony 100

E From vertical drainpipes or soilpipes 75

F From internal or external corners 100

G Above adjacent ground or balcony level 100

H From a surface facing the terminal 600

I Facing another terminal 1,200

J From opening (door/window) in carport into dwelling 1,200

K Vertically from a terminal on the same wall 300

L Horizontally from a terminal on the same wall 300

N Below carport 600

A Quinnel Barrat and Quinnel guard (part. No. C2) should be screwed to the wall centrally over the terminal, when

the distance is less than 2 m from the outside floor.

Air Supply

The room in which the boiler is installed does not require a purpose provided vent. If the boiler is installed in a

cupboard or compartment, permanent air vent are required in the cupboard or compartment, one at high level

one at low level, either direct to the outside air to a room. Both high and low level air vents must communicate with

the same space.

Minimum effective area requirements of compartment air vents (for cooling purposes only) (fig. 4).

Page 11

11

NOTES

* If a side outlet flue is to be used, a clearance of 75 mm will be needed on the flue outlet side of the boiler.

** Access to the front of the boiler must be available for maintenance (min. 600 mm).

Fig. 5

Fig. 4

APPLIANCE

FLUE

SYSTEM

APPLIANCE

LOCATION

ROOM-SEALED AIR VENT AREAS

IN ROOM NIL

IN COMPARTMENT

OPEN TO ROOM

IN COMPARTMENT

OPEN TO OUTSIDE

HIGH LEVEL:

252 cm2 (38 in.2)

LOW LEVEL:

252 cm2 (38 in.2)

HIGH LEVEL:

126 cm2 (19 in.2)

LOW LEVEL:

126 cm2 (19 in.2)

AIR VENT

AIR VENT

Terminal Position Air supply

Minimum Clearance mm

Fig. 3

Page 12

12

Flue system

The boiler allows the flue outlet to be taken from the rear of the boiler or from either side.

A standard flue length of 0.75 metres is provided. Alternative lengths of two or three metres can be supplied

(equivalent to wall thicknesses of up to 565, 1815 and 2815 mm for rear flues and deduct 91 mm plus distance

from side wall for side outlet flues).

It is absolutely essential, to ensure that products of combustion discharging from the terminal cannot re-enter

the building, or enter any adjacent building, through ventilators, windows, doors, natural air infiltration, or forced

ventilation/air conditioning.

Gas Supply

If necessary the local Gas Region should be consulted, at the installation planning stage, in order to establish the

availability of an adequate supply of gas.

An existing service pipe must not be used without prior consultation with the Local Gas Region.

A gas meter can only be connected by the Local Gas Region, or by a Local Gas Region's Contractor.

Installation pipes should be fitted in accordance with BS6891-1988.

Appliance inlet working pressure must be 20 mbar MINIMUM.

Pipework from the meter to the combination boiler must be of an adequate size.

Do not use pipes of a smaller size than the combination boiler inlet gas connection.

The complete installation must be tested for gas soundness and purged as described in BS6981-1988. All pipework

must be adequately supported. An isolating gas valve is provided and should be fitted on the manifold assembly.

Water System

Central Heating

It must be a sealed system. Detailed recommendations are given in BS6798, BS5449, BS6700 and CP342 Part.

2. Pipework not forming part of the useful heating surface should be insulated to prevent any heat losses or

possible freezing (i.e. in roof spaces or ventilated underfloor spaces). Drain taps should be positioned at the

lowest point of the system in accessible locations to permit the whole system to be drained down. The drain

taps should be in accordance with BS2879. Copper tubing to BS2871, Part. 1 is recommended for water carrying

pipework. Pipework in horizontal runs should have a gradient where possible to facilitate the removal of air.

It should be ensured that the boiler heat exchanger is not a natural point for collecting air. A typical heating system

with domestic hot water circuit is illustrated in fig. 6.

Important - A bypass must be fitted to ensure a minimum flow rate through the boiler of 6 l/min. The bypass should

be fitted as far as possible from the boiler if thermostatic radiator valves are fitted throughout.

Make up Water

Provision must be made for replacing water lost from sealed system. Reference should be made to BS6798, for

methods of filling and making up sealed systems. There must be no direct connection between the boiler's central heating

system and the mains water supply. The use of mains water to charge and pressurise the system directly, is conditional

upon the Local Water Bye-law. Again any such connection must be disconnected after use (fig. 7).

Domestic Hot Water

Always fit a water softener or descaler in «hard water areas». A 15 mm copper connection point on the boiler

jig bracket for attaching to the main supply is provided. The maximum domestic water pressure for the inlet supply is

10 bar (145 P.S.I.). If the cold mains supply exceeds 5 bar (72 P.S.I.), a water governor or pressure reducing valve must

be fitted by the installer into the mains supply in an inconspicuous but accessible position preferable between 3 and 5

metres (10-16 ft) before the appliance. Such a valve must be approved by the Water Research Council.

Attention - Is drawn to the Model Water Bye-laws.

Fittings manufactured from duplex (alpha-beta) brass are not acceptable for underground use and certain water

undertakings will not accept their use above ground.

Page 13

13

Fig. 7

NOTE: A bypass must be fitted as far as possible from the boiler if thermostatic radiator valves are fitted

throughout.

Fig. 6

Gas

Cold water

Additional expansion vessel C.H.

(if required)

Filling

point C.H.

Bypass

Key

1. Filling point C.H.

2. Temporary connection

3. Cold water supply

Page 14

14

Built-in Central Heating Water Circulating Pump

The pump head available for circulating the water is given in fig. 8.

N.B. - The pump is factory set at position 3. The pump is a Grundfos type 15-50 UPS series.

Grundfos Pump performance graph

Note - Minimum flow through boiler heat exchanger at any time should not fall below 6 litres per minute.

If required an additional expansion vessel may be fitted to the central heating return inlet.

If the total volume of water in the system exceeds 40 litres an additional expansion vessel must

be fitted to the central heating return inlet.

Pump performance curve Grundfos UPS 15-50

SAFETY VALVE

SETTING (bar)

VESSEL CHARGE

PRESSURE (bar)

INITIAL SYSTEM

PRESSURE (bar)

TOTAL WATER

CONTENT of SYSTEM

3.0

0.5 1.0 1.5

1.0 1.5 2.0 1.5 2.0 2.0

EXPANSION VESSEL VOLUME (litres)

LITRES

25 3.5 6.5 13.7 4.7 10.3 8.3

50 7.0 12.9 27.5 9.5 20.6 16.5

75 10.5 19.4 41.3 14.2 30.9 24.8

100 14.0 25.9 55.1 19.0 41.2 33.1

125 17.5 32.4 68.9 23.7 51.5 41.3

150 21.0 38.8 82.6 28.5 61.8 49.6

175 24.5 45.3 96.4 33.2 72.1 57.9

200 28.0 51.8 110.2 38.0 82.4 66.2

0.140 0.259 0.551 0.190 0.412 0.33

For syst. volumes other than

those given above, mult. the syst.

volume by the factor across

1 2 3 Speed settings

A Boiler pressure drop

B Max. available pump head C.H.

Fig. 8

SIZING OF ADDITIONAL EXPANSION VESSELS:

Deduct from the value given in the table the 7 litre vessel

supplied.

Note

1. Fill C.H. installation to min. 1.5 bar.

2. Select by preference the expansion vessel for

increased system pressure of 2.0 bar

3. Expansion vessel must be fitted to Central Heating

Return Inlet

4. The standard 7 litres expansion vessel is charged

to 1 bar

Page 15

15

Installation

Note - To mount the boiler on the wall, a two person lift will be needed.

1.0 UNPACKING

The appliance is delivered in 2 cartons.

1.1 The large carton contains the boiler, the Installation/Servicing and Users Instructions, external and

internal sensors.

1.2 The second carton contains the mounting jig assembly, complete with isolating valves, the assembly

fixing screws and wall plugs (x4), the boiler mounting nuts and washers (x2), drilling template, flue

assembly and turret.

When the cartons are unpacked examine for any signs of damage in transit. All protective plastic should

be left in place until installation is complete.

2.0 FIXING THE MOUNTING JIG ON THE WALL (Rear Wall Flue Applications)

2.1 Select the boiler location carefully ensure that all requirements given in previous text are satisfied.

Fig. 10 will also give guidance to fixing dimensions.

2.2 Locate template on wall, mark the positions of the four jig bracket fixing holes and the flue opening.

2.3 Carefully cut the circular hole (118 mm minimum diameter) for the flue assembly.

2.4 Using a 10 mm drill, drill 70 mm deep holes to accept the wall plugs, and insert wall plugs.

2.5 Fit the mounting jig assembly using the four fixing screws provided (Ensure that all the service

cocks are in the OFF position). Operate valves several times to ensure they are free.

2.6 With the exception of the connection to the pressure relief valve, make all the water and

gas connections to the jig bracket valves. Fully tighten (fig. 11). Water connections can be made

with compression or capillary fittings (before the gas inlet to the boiler there must be at least 100

mm of straight before any bends).

3.0 FIXING THE MOUNTING JIG ON THE WALL (Side Wall Flue Applications)

3.1 Select the boiler location carefully ensuring that all the requirements given in previous text are

satisfied.

Fig. 10 will aso give guidance.

3.2 Locate the template on wall and mark the position of the four jig bracket fixing holes.

3.3 Using a 10 mm drill, drill 70 mm deep holes to accept the wall plugs, and insert wall plugs.

3.4 Fit the mounting jig assembly using the four fixing screws provided.

3.5 Extend a horizontal line from the centre of the rear flue outlet to the side wall.

3.6 Mark the centre line (vertically) for the flue assembly hole, and mark the centre of the hole.

3.7 Carefully cut the circular hole (118 mm minimum diameter) for the flue assembly.

Page 16

16

Fig. 10

1 = Electrical cable entry

2 = Gas supply

3 = Domestic Hot Water outlet

4 = Domestic Cold Water Inlet

5 = Outlet Central Heating safety valve

6 = Central Heating flow outlet

7 = Central Heating return inlet

2 = 22 mm

3-4-5 = 15 mm

6-7 = 22 mm

3 Domestic Hot Water

outlet 15 mm

5 Outlet central heating

safety valve 15 mm

Important Note - Always use two spanners to prevent twisting of soft copper pipework.

Note - The central heating safety valve (5) should be piped 15 mm to discharge safely outside the property.

Fig. 11

2 Gas 22 mm

4 Domestic Cold Water inlet 15 mm

6 Central Heating flow outlet 22 mm

7 Central Heating return inlet 22 mm

Important Note - Always use two spanners to prevent twisting of soft copper pipework on the boiler.

Flush out the water system.

Note - The maximum inlet cold water pressure must not exceed 10 bar (145 P.S.I.) and a water governor or a pressure

reducing valve will be required if the pressure is in excess of 5 bar (72 P.S.I.).

Ensure all pipework is adequately supported.

Drilling template

Note - Min 91 for side flue outlet

Fixing stud

boiler

Upper bracket

Note - Min 75 for

side flue outlet

Rear flue outlet

Diam. min. 118 mm

Boiler = 480 mm

Lower bracket

Side flue outlet

Diam. min.

118 mm

Page 17

17

Rear flue Outlet

Fig. 12

Aluminium flue pipe length = Plastic air inlet pipe

length plus 50 mm (2") longer.

4.2.1 Accurately measure the Wall thickness (P2).

4.2.2 Accurately measure the distance from the centre of the stud

fixing of the mounting jig assembly to the side wall (Q2).

4.2.3 From the end opposite to the terminal, cut the plastic air duct

(dimension A2) to length (P2 + Q2 + 125 mm).

Note - That the terminal is not included in length A2.

4.2.4 Cut the metal flue duct to length (P2 + Q2 + 175 mm)

(dimension F2).

Note - The metal flue pipe must be 50 mm (2 inches) longer

than the plastic air inlet pipe.

4.2.5 Drill a 3 mm hole 15 mm from the plain end of plastic air duct.

4.2.6 Place flue components to one side to be used later.

Side Flue Outlet

Fig. 13

4.1.1 Accurately measure the Wall thickness (P1)

4.1.2 From the end opposite to the terminal, cut the plastic

air duct (dimension A1) to length (P1 + 105 mm).

Note - That the terminal is not included in A1.

4.1.3 Cut the metal flue duct to length (P1 + 155 mm)

(dimensions F1).

Note - The metal flue pipe must be 50 mm (2 inches)

longer than the plastic air inlet pipe.

4.1.4 Drill a 3 mm hole 15 mm from the plain end of plastic

air duct.

4.1.5 Place flue components to one side to be used later.

4.2

Side Flue Outlet (fig. 13).

Important - The aluminium flue pipe must protrude

into the outside grill by 2 in (50 mm), never cut it to the

same length as the plastic air pipe.

4.0 PREPARING THE FLUE ASSEMBLY

4.1

Rear Flue Outlet (fig. 12)

Important - The aluminium flue pipe must protrude into the outside grill by 2 in (50 mm), never cut it to the same length

as the plastic air pipe (aluminium flue pipe = plastic air inlet pipe + 50 mm !).

Aluminium flue pipe length = Plastic air inlet pipe length plus 50 mm (2") longer.

F1 (Flue outlet)

Fixing

screwAir sealing sleeve

Fixing screw

A1 (Air intake)

Page 18

18

5.0 CONNECTING THE BOILER

5.1 Place the boiler on its back.

5.2 Remove the boiler base plate, four screws (fig. 16). Remove the plugs fitted to the boiler water

connections.

Remove the bag of sealing washers from the boiler pipework. Remove the front panel by sliding

up and pulling away from the main boiler.

5.3 Lift boiler as shown in fig. 15 onto the top studs and fit supplied nuts and washers hand tight.

5.4 Lift at bottom to engage the water and gas connections. Tighten central heating flow and return,

and the domestic hot water inlet and outlet, using appropriate sealing washers. Tighten the gas

union.

5.5 Screw the pressure relief valve adaptor provided, through the jig bracket into the valve, using

the remaining washer (fig. 17).

5.6 Connect the pressure relief valve discharge pipe (15 mm) to the outside of the building, where

possible over a drain. The discharge must be such that it will not be hazardous to occupants or

passers-by cause damage to external electric components or wiring. The pipe should be directed

towards the wall.

It must not discharge above an entrance or window, or any type of public access. The installer must

consider that the overflow could discharge boiling water.

Fig. 14

Fixing

screws

Flue sealing gasket

Air sealing gasket

TOP VIEW BOILER SIDE OUTLET

Page 19

19

Fixing points

Lift here

Fig. 15

Fixing screws

Fig. 16 Fig. 17

Page 20

20

6.0 FITTING THE FLUE ASSEMBLY

6.1 With Sufficient Clearance To Insert Assembly From Inside

6.1.1 Push the air duct seal onto the air duct at the cut end.

6.1.2 Insert the flue assembly into the wall.

6.1.3 Make good internal wall face.

6.1.4 Fully insert the flue assembly into the turret spigot. Insert the self tapping screw supplied. Fully tighten.

6.1.5 Secure the turret.

6.1.6 Slide the air duct seal over the joint.

6.1.7 Check the terminal relationship with the wall as shown in fig. 12.

6.1.8 Make good the outside wall face, re-weatherproof.

6.2 With insufficient Clearance To Insert Assembly From Inside

6.2.1 From outside, push flue duct, then the air duct through the wall.

6.2.2 Push the air duct seal over the air duct.

6.2.3 Fully insert the flue duct into the turret, then the air duct. Slide, back the seal and secure the air duct with the

self tapping screw provided.

6.2.4 Slide the seal over the joint and secure the turret.

6.2.5 Continue as detailed in 6.1.8 above.

7.0 ELECTRICAL INSTALLATION

Electrical installation must be carried out by a competent electrician. The appliance is to be connected to a 230 V

~ 50 Hz supply (see fig. 18). The supply fuse rating is 3A. The terminals are accessible after removing the white base

plate (see fig. 18).

7.1 Procedure

7.1.1 The supply cable must be no less than 0.75 mm (24x0.2 mm) to BS6500 table 16.

7.1.2 The earth conductor must be cut longer than the live and neutral (fig. 19).

Connect the Supply Cable to the terminal block marked 230 V ~ 50 Hz, L, N, the supply cable is to be connected as follows:

i) Connect the brown wire to the L (live) terminal).

ii) The blue wire to the N (neutral) terminal.

iii) The green/yellow wire to the (earth) terminal.

7.1.3 Secure the cable with the cable clamp. The supply cable can be connected to the mains supply by the use of an unswitched

shuttered socket-outlet in conjunction with the 3A fused 3 pin plug both in accordance with BS 1363. This provides

complete isolation. Alternatively, a fused double pole switch having a contact separation of at least 3 mm, in all poles

and provided just for the boiler and its external controls can be used. A wiring diagram is provided on the appliance,

attached to the rear of the front panel. In addition, there is one in this manual (fig. 25). Attention is drawn to the

requirements of the current I.E.E. Regulation and in Scotland, the electrical provisions of the Building regulations.

Remote sensors

The XIGNAL CE is supplied with an internal and external sensor to ensure maximum fuel savings.

Room Sensor

To be in a position within the property normally used for a room thermostat.

Ensure connections complies with the polarity shown in Figure 18 wired to terminals No. 5 and No. 6.

External Sensor

To be wired to terminals No. 7 and No. 8.

Location of sensor see Figure 21 and 22.

L

N

EXTERNAL

SENSOR

ROOM

SENSOR

3015

20 25

S.p.A.

230 V ~

50Hz

1

2

1

2

3

4

5

6

7

8

9

10

Fig. 18

Fig. 19

Blue

Brown

Screw

Page 21

21

1

2

3

P7

P8

RL1

RL2

RL3

RL4

RL5

P6

12 34

P5

P4

P3

P2

P1

OUT

L

N

140

137

136

65

138

139

2

1

96

141

98

N

L

P12

P9

P10

P11

1

2

3

1

2

3

4

5

6

7

8

9

10

1

2

3

4

HDR1

voice

volume

142

101

123456712

43

47

42

16

32

AUTO

MAN

1...4

49

84

85

8 9

X6

X1

83

X2

312145

X3

X4

X5

67

12

13

1715

16

81

82

34

123 4567

1

2

1

2

1

2

1

2

3

4

5

6

7

8

9

10

X

LOW

VOLTAGE

brown

blue

brown

brown

red

black

grey

black

brown

blue

white

yellow

green

orange

S

S

red

green

black

white

white

red

red

blue

black

grey

white

brown

red

white

green

Wiring diagram

Fig. 20

Ohm value

of the sensors

°C Ohm

25 10 K

40 5,4 K

60 2,5 K

80 1,3 K

KEY

16 Fan

32 C.H. pump

34 Heating temperature sensor

42 D.H.W. temperature sensor

43 Air pressure switch

47 Gas valve modulator

49 Overheat thermostat

65 230V line and probe connection terminal strip

81 Ignition electrode

82 Flame sensing electrode

83 Automatic ignition control panel

84 1. operator 230V gas valve

85 2. operator 230V gas valve

96 C.H. limit sensor

98 Main switch

101 Main P.C.B.

136 Flowmeter

137 Pressure sensor

138 External sensor

139 Room sensor

140 Touch keyboard

141 Loudspeaker

142 Display P.C.B.

x possible connection for standard

room thermostat

Note:

strictly comply with the neutral, line

connection polarities and those of the room sensor.

Page 22

22

External sensor location

The external sensor should preferably be installed

on the North, North-East wall or on the one facing

the majority of the main living rooms in the building.

The sensor must never be exposed to the first

morning sunlight. Where possible, it must never be

subjected to direct sunlight and should be protected

if necessary.

In no case may the sensor be mounted near windows,

doors, ventilation openings, stacks or heat sources

which could alter its reading.

Fig. 22

Fig. 21

Page 23

23

8 Gas conversion

Only Qualified Personnel may carry out the following regulating and conversion operations. Ferroli

S.p.A. declines all responsibility for damage to persons and/or property caused by unauthorized persons

having tampered with the appliance. Proceed with the following conversions if the appliance must be used

with a different type of gas.

To switch from Natural gas to L.P.G. and vice versa, it will be necessary to change the main injectors and

to fit the delayer union to the gas valve (part F. fig. 23). Now adjust the minimum and maximum gas

pressure values on the gas valve (see relative paragraph).

9 Adjustments

Adjusting the pressure and flow rate to the main burner

Being the flame modulating type, this appliance has two fixed pressure values: the minimum and

maximum rate. These must be those indicated in the chart for each type of gas.

Attention - The minimum pressure must be regulated first. This will ensure correct burner

ignition. Following this, regulate the maximum pressure value. Each minimum pressure

adjustment involves a variation to the maximum setting value. Since they are particularly

delicate, the following regulating operations must only be carried out by Specialized

Personnel.

Adjusting the minimum and maximum pressure values

Connect a suitable pressure gauge to the pressure test point above the gas valve.

Keep button

depressed for more than 5 seconds. The following message will appear on the display:

TEST NOT ACTIVATED

CURRENT: 165 mA

Remove protective cap "b" from the top of the coil.

Adjust the minimum pressure value using nut "c". Turn this screw anticlockwise to decrease the pressure

or in a clockwise direction to increase it.

Switch the burner off and on three or four times, depressing keys

and , checking each time that the

pressure remains regulated and that the burner regularly ignites. Further adjustment is required if this fails

to occur.

Having terminated this operation, check the maximum pressure value.

TEST ACTIVATED

CURRENT 0 mA

Use buttons on the right to adjust the current to 0 mA.

Press button

. The boiler will operate in TEST mode.

Page 24

24

Delicately depress pin "d" and keep it fully pressed down. If the maximum pressure value must be

adjusted, slowly turn adjuster nut “e” in a clockwise direction to increase the pressure and in an

anticlockwise direction to lower the pressure value.

Having regulated the minimum and maximum pressure values, reset compensating tap "b". The current

value should now be reset to 165 mA.

Disactivate the TEST function by depressing button

. The boiler will now be ready to operate

automatically.

NOTE - The above listed adjustments establish the mechanical travel of the plunger of the “Modureg”

modulator between a minimum and maximum setting.

NOTE - The complete “Modureg” unit must be replaced if the "Modureg" coil fails to operate. Any attempts

to replace the coil alone would irreparably jeopardize the "Modureg" setting.

Anyone carrying out adjustments with these nut should proceed very delicately.

HONEYWELL valve VR 4605 NA 2007 (fig. 18)

Fig. 23

TEST ACTIVATED

CURRENT 165 mA

2

b

a

g

1

f

d

e

c

Key

1. Inlet pressure test point

2. Outlet pressure test point

a. Electrical coil connection

b. Balance cap

c. Minimum pressure regulating nut

d. Maximum pressure pin

e. Maximum pressure regulating nut

f. "Adapter" fitting (only on L.P.G. versions)

g. Protective cap

Page 25

25

Adjustment of the heating ∆t by varying the circulator flow rate-head

Heat variation ∆t (temperature difference in the heating water between the supply and return points of

the system) must be less than 20°C. This is obtained by varying the flow rate head of the circulator using

the multi-speed variator (or switch) of the same. The ∆t value decreases when the speed of the circulator

is increased, and vice versa.

Boiler pressure adjustment

The pressure of the water in the heating plant, indicated by the control panel display, must be regulated

as described in the relative paragraph.

Honeywell VR 4600 N 4002 valve with V7335A4014 Modureg

Gas pressure Adjustment

1 - With the burner lit:

2 - Connect suitable pressure gauge to burner test point "B", and then:

3 - Disconnect air pressure compensation tube "H";

4 - Disconnect the wires from coil "C" of the Modureg;

5 - Remove protective cover "D";

6 - Remove coil "C" by opening the coupling spring "I";

7 - Screw the minimum adjustment screw "E" up tightly. (clockwise)

8 - Unscrew lock nut "F" on sleeve "G";

9 - Adjust maximum pressure by rotating sleeve "G" clockwise to increase

pressure and anticlockwise to reduce pressure;

10 - Tighten sleeve lock but "F" then check that the pressure

is still at the required value;

11 - Adjust minimum pressure by rotating screw "E" anti-

clockwise until the required value is reached;

12 - Fit coil "C" by sliding it into the sleeve, pushing and

rotating it lightly until the coupling spring "I" clicks into

place;

13 - Shut down and ignite the burner, checking that the

minimum pressure value is stable;

14 - Reconnect the wires to coil "C" of the Modureg;

15 - Reconnect air pressure compensation tube "H";

16 - Replace protective cover "D";

17 - Turn burner off, remove pressure gauge, close and test,

test point;

Key

A Test point inlet pressure - B Burner test point - C Coil -

D Protective cover - E Minimum adjustment screw - F Lock nut

- 0G Sleeve - H Pressure compensation tube - I Coupling

spring - L Adapter (for only L.P.G. version)

D

C

E

G

F

H

A

B

I

L

Page 26

26

FIGURE 24: KEYBOARD

The button that activates the vocal messages is situated on its own, in the middle of the control panel. The

reset button is installed under the lighted main switch.

Each button possesses a single distinct function:

10. Control panel

Open the hinged door for access to the programming keyboard and combined display.

The instructions enabling the user to program the system are affixed to the inner part of the

door.

KEYBOARD

The touch keyboard has been designed for immediate and simple programming. The buttons are logically

grouped according to the function in question.

The six buttons on the left of the display are used to program the daily heating function while the six buttons

on the right are used to set the boiler parameters.

MAN

AUTO

1...6

Main switch:

powers the boiler

Boiler release: resets operation after a

boiler block

Activates daily programming

Disactivates daily programming

Time setting:

used to set the time

Programming of the 6 daily heating

levels

Vocal communication

Heating temperature adjustment and selection

of external probe compensating curve

Hot water temperature adjustment and

delivered temperature display

Summer selection

Winter selection

AUTO

MAN

1...6

Page 27

27

The following symbols may appear in the middle of the display:

- - : indicates that daily programming has been activated

W-: indicates the hold status (2 minutes) after the maximum heating temperature has been reached, or

after hot water has been used.

At the beginning of a demand for heating or hot water, the display will indicate the type of demand for

8 sec. and, if hot water has been used, the relative flow rate.

17:00

W 1,5 BAR70 °C

WINTER

Heating flow

temperature

time

system pressure

Summer Winter

selection

HEATING

DEMAND

D.H.W. DEMAND

FLOW RATE 13 L./MM.

END OF HEATING

DURATION 8 MIN.

END OF D.H.W.

DURATION 30 SEC.

DISPLAY

The alphanumerical display with 2 lines of 16 characters allows the user to check the operational

parameters of the boiler at any moment and to check the duration at the end of sanitary water production

or heating mode. The programmed values can also be displayed, plus the relative flow rate and

temperature during the production of sanitary water. Any faults are immediately indicated by the display

which starts to flash.

Indications during operation:

During operation, the display showes the time, the temperature of the water in the radiators, the pressure

in the plumbing circuit, the choice of summer or winter operation and timed or manual programming.

The type and length of the demand will be displayed for 8 sec. at the end of the demand for heating or

hot water.

SPEAKING FUNCTION

Press key

and the computer will communicate the operative status of the boiler, the ambient

temperature and any faults by synthesized voice.

Page 28

28

10.1 Programming the daily heating function

Clock adjustment

Press key

Adjust the time using the left-hand keys .

Use the left-hand keys

to regulate the time at which the Level is to begin.

Set the required Level temperature (between 5 and 30° C) using the right-hand keys

.

Note: If a temperature of >30°C is set in one of the 6 Levels, the room sensor will control the heating

function throughout the entire duration of that Level, as in manual operation.

Activating and disactivating daily programming

Press the key

AUTO

to activate the daily heating program (symbol will appear on the display ).

Press key

MAN

to disactivate the daily program (symbol will disappear from the display and heating

will be controlled by the room sensor).

LEVEL 3

12:00 20.0 °C

LEVEL 2

9:00 18.0 °C

LEVEL 1

7:00 20.0 °C

LEVEL 4

14:00 18.0 °C

LEVEL 6

23:00 16.0 °C

LEVEL 5

17:00 20.0 °C

Programming the 4 daily heating levels

Press the key once or several

1...4

times to set the programming level (respectively Levels 1-2-

3-4-5-6).

SET TIME

18:10

Page 29

29

10.2 Programming the boiler parameters

General information

For access to the boiler programming parameters, just depress the relative function keys. The

display indications will consequently change. Note that each key correspond to a single

function.

After having selected a function, it will be possible to quit data entry mode in two ways:

- automatically after 8 sec. if no key has been pressed

- by pressing the same function key again.

Boiler flow temperature

Digit key

. The following display message will appear

The delivery temperature may be regulated between 30° C and 85° C by means of the right-hand keys

NOTE: When the external sensor is connected, set the temperature to 85°C and choose the compensation

curve.

Setting the compensation curve of the external probe

Compensation curves must be set according to the characteristics of the heating system and the structural

features of the building. This function is only activated when the external probe is connected.

Press key

twice for access to the programming mode. The following message will appear on the

CONTROL TEMP.

C.H.: 85 °C

display:

Set the desired curve (from 1 to 10) using the right-hand keys . Consult the table on the following

page in order to choose the most suitable curve.

The external sensor will be disactivated if 0 is entered for the compensation curve.

C.H.: 7

SELECT OTC CURVE

Page 30

30

Graph of plant delivery temperatures according to the external temperature and the set compensation

curve.

+20 +10

0 -10 -20

40

30

50

60

70

80

85

35

45

55

65

75

+15 +5 -5 -15

10

9

8

7

6

5

4

3

2

1

TEMPERATURA ESTERNA (°C)

TEMPERATURA MANDATA IMPIANTO (°C)

Fig. 25

EXTERNAL TEMPERATURE (°C)

CENTRAL HEATING FLOW TEMPERATURE (

°

C)

Page 31

31

Regulating the hot water temperature

Press key

once.

Set the temperature of the hot water to the required value between 40 and 65°C using the right-hand keys

. It is unadvisable to exceed a temperature of 50°C.

Also remember that, when multiplied by the water flow rate per minute and for 60 minutes, the product

of the temperature difference between the D.H.W. output and input in the boiler cannot exceed the

effective rating of the boiler itself.

CONTROL TEMP.

D.H.W.: 50 °C

Hot water temperature and flow rate display

Press key twice. The flow rate will appear on the lower left-hand side of the display with the temperature

on the right.

FLOW D.H.W. TEMP.

13 L./M. 50 °C

Page 32

32

10.3 Switching the boiler on and off

Inspections to make when switching on for the first time

When the boiler is being switched on for the first time, it is advisable to check that:

the on-off valves between the boiler and systems are open;

the entire system is well charged and vented;

there are no gas or water leaks from the system or boiler;

the electric connection is correct and that the earth wire is connected to an efficient earthing system;

there are no inflammable liquids or materials in the immediate vicinity of the boiler;

the gas pressure and flow rate values are those required for heating.

Switching on the boiler

• Open the gas cock prior to the boiler.

• Purge gas supply.

• Power the boiler by means of the main switch.

• Select summer or winter operation by means of the relative buttons.

• Adjust the knob of the room sensor to the desired value (if winter mode is selected) or open a hot water

tap.

Switching off

Close the gas cock prior to the boiler and turn off the main switch.

Warnings - If the boiler is to remain inactive during the winter period, it is advisable to drain off all the

water in order to prevent damage due to freezing. Failing this, just drain off the hot water and put a special

antifreeze product into the heating system.

Inspections and monitoring after ignition

When switching on for the first time:

Check that the gas and plumbing systems are sound.

Check that the boiler ignites correctly. Test this by switching it on and off a few times by means of the

regulating thermostat.

Check the efficiency of the air-flue pipe during boiler operation.

Check that the fuel consumption indicated by the meter corresponds to that indicated in the technical data.

Check that water correctly circulates between the boiler and systems.

Check that when a hot water tap opens during "Winter" mode, the circulator stops and regular production

of hot water occurs.

Check that the burner switches on and off in the correct way when the hot water tap opens and closes

in "Summer" mode.

Check that the gas valve modulates correctly during both the heating and hot water production phases.

Page 33

33

11 Maintenance and troubleshooting

11.1 Routine maintenance

Only Qualified Personnel must carry out the following operations.

Seasonal inspections of the boiler

It is advisable to have Qualified Personnel check the appliance at least once a year:

The pressure of the water in the cold plant must be between 0.5 and 1 bar. Check that it does not exceed

1.5 bar when hot;

The control and safety devices (gas valve, flow switches, thermostats, etc.) must operate correctly;

The burner and exchanger must be clean. Use soft brushes or compressed air to prevent the parts from

being damaged. never use chemical products;

The expansion tank must be full;

The gas and water systems must be sound;

The end part of the air-flue duct must be free from obstructions and must not leak;

The electrodes must be free from deposits and correctly positioned;

The gas flow rate and pressure must correspond to the indications in the relative tables;

The circulation pump must spin free.

Cleaning the boiler and burner

The boiler needs no particular maintenance. Just clean it once a year. Never use chemical products or

steel brushes to clean the casing or the burner.

Particular care must be taken of all retention systems pertaining to the hermetic chamber (seals, cable

clamps, etc.). This will prevent air leaks which, causing a pressure drop in the chamber itself, could activate

the differential pressure switch which would block the boiler.

After all these operations have been carried out, particular care must also be taken to check

and carry out all ignition and operation phases of the thermostats, gas valve and circulation

pump.

Check that there are no gas leaks after these inspections.

Page 34

34

11.2 Diagnosis and troubleshooting

The microcomputer will make a complete diagnosis during boiler operation. When a fault is detected,

the display will flash and give an error message. Boiler operation will be inhibited and reset at the end

of the fault. Manual reset is sometimes necessary (digit key

).

List of diagnostic messages

The display and vocal message clearly indicate all types of fault. The following table lists the most common

causes that may have generated the faults. Symbol

in the right-hand column indicates that manual

reset is necessary.

Causes and remedies Reset

(Display off)

No 230V power supply

Wait until 230V power returns

Check 230V power supply and fuse

No gas

Check gas system

Defective gas valve

Repair or replace the valve

Clogged injectors

Thoroughly clean the injectors

Gas pressure too low

Check pressure

No spark between electrodes during ignition phase

Check that the boiler is connected to the main

with a good ground connection

Check safety thermostat

Check that the electrodes are correctly positioned

and without incrustations

Check electrical power supply

Check that the Phase-Neutral are not inverted

Check ignition P.C.B. and

electrical connections

Check ignition P.C.B.and

electrical connections

Leaks from the gas valve

Display message

ER 1 IGNITION

PROBLEM

ER 2 IGNITION

PROBLEM

ER 3 FLAME LOST

EXTINGUISHED

ER 4 FLAME NOT

DURING OPERATION

Page 35

35

ER 7 FAULT

C.H. SENSOR

ER 8 FAULT

S.H.W. SENSOR

PROTECT SENSOR

ER 9 FAULT

ER 6 BROKEN

PROTECT SENSOR

ER 5 FAULT

AIR PRESS SWITCH

Defective pressure switch or clogged tubes

Check connections

Replace pressure switch or clean tubes

Water temperature too high

Defective heating temperature sensor

Check connections or replace the sensor

Defective hot water temperature sensor

Check connections or replace the sensor

Defective temperature limit sensor

Check connections or replace the sensor

Plumbing system empty

Check plumbing system

Expansion tank defective

Check expansion tank

Leaks from supply cock

Check plumbing system

Expansion tank defective

Check expansion tank

The plant has been filled when cold at

an excessively high pressure

Reset the plant to an adequate pressure

Defective gas valve modulator

Check the coil

No power to Modureg

Check electrical connection

Blocked circulation pump

Release circulator by removing the plug,

then turn the shaft with a screwdriver

Check or replace the condenser or circulator

The water temperature has reached

the safety limit.

ER 10 WATER PESSURE

TOO LOW

ER 11 WATER PRESSURE

TOO HIGH

ER 12 FAULT

ER 14 BAD WATER

CIRCULATION

ER 15 BROKEN

ABOVE LIMIT

MODUREG

Page 36

Lichfield Road, Branston Industrial Estate, Burton Upon Trent, Staffordshire DE14 3HD

Tel. 08707 282 885 - Fax 08707 282 886

ALL SPECIFICATIONS SUBJECT TO CHANGE

Cod. 3540243/0 - 01/01

Phone numbers:

Installer

Service Engineer

BECAUSE OF OUR CONSTANT ENDEAVOUR FOR IMPROVEMENT DETAILS

MAY VARY SLIGHTLY FROM THOSE QUOTED IN THESE INSTRUCTIONS.

Loading...

Loading...