Page 1

TEMPRA 12 - 18

wall-hung, gas-fi red,

system boiler,

for central heating

INSTALLATION, MAINTENANCE AND USER INSTRUCTIONS

cod. 3543724/6 - 05/2005

TEMPRA 12: G.C. N° 41-267-11

TEMPRA 18: G.C. N° 41-267-12

Page 2

2

Tempra 12 - 18

This symbol indicates “Warning”

and is placed near all warnings

regarding safety. Such provisions

must be strictly adhered to so as

to avoid danger and damage to

persons and property.

This symbol highlights a note or an

important warning.

• Carefully read the warnings in this instruction booklet, as they provide important

indications on the safety of installation,

operation and maintenance.

• The instruction booklet is an integral

and essential part of the product and

must be carefully kept by the user for

future reference.

• If the appliance is sold or transferred to

another owner, or if it is moved, always

check that the booklet accompanies the

boiler for reference by the new owner

and/or installer.

• The installation and maintenance operations must be performed according to the

standards in force, the instructions of the

manufacturer and must be carried out by

professionally qualified personnel.

• Incorrect installation or poor maintenance

may cause a damager to persons or

property. The manufacturer declines all

liability for damage deriving from errors

in the installation and maintenance of the

appliance, and where there is a failure

to observe the instructions provided by

the manufacturer.

• Before performing any cleaning or

maintenance operations, disconnect the

appliance from the mains power supply

using the system switch and/or the

corresponding on-off devices.

• In the event of faults and/or poor

operation of the appliance, it should be

deactivated. Do not attempt to repair

the appliance. Contact professionally

qualified personnel only.

• The products must only be repairedreplaced by professionally qualified

personnel, using original spare parts

only. Failure to heed this warning may

affect the safety of the appliance.

• To ensure the correct operation of the

appliance, annual maintenance must be

performed by qualified personnel.

• This appliance must only be used for the

purposes it has specifically been designed

for. All other uses are considered

improper and thus dangerous.

• After having removed the packaging,

check that the contents are intact.

• The parts of the packaging must not be

left within the reach of children, as they

are potential sources of danger.

• In case of doubt do not use the appliance

and contact your supplier.

Certification

The CE Mark attests that Ferroli gas-fired

appliances conform to the requirements

specified in the corresponding European

directives.

In particular, this appliance conforms to

the following EEC directives:

• Directive 90/396, Gas Appliances,

• Directive 92/42, Efficiency,

• Directive 73/23, Low Voltage, (amended

by no. 93/68)

• Directive 89/336, Electromagnetic

Compatibility (amended by no. 93/68)

IMPORTANT

Your "benchmark" Installation, Commissioning and Service Record Log Book will be enclosed in your

customer information pack. "This record must be completed and left with the end user"

"All CORGI Registered Installers carry a CORGI ID card and have a registration number. Both

should be recorded in your central heating log book. You can check with the CORGI registered

by calling CORGI on 01256 372300".

Page 3

3

Tempra 12 - 18

1. Operating/user instructions ...................................................................4

1.1 Introduction ............................................................................................................4

1.2 Control panel ..........................................................................................................5

1.3 Ignition and shut-down...........................................................................................5

1.4 Settings ...................................................................................................................6

1.5 Maintenance............................................................................................................6

1.6 Troubleshooting......................................................................................................6

2. Installation ..............................................................................................7

2.1 General instructions................................................................................................7

2.2 Place of installation .................................................................................................7

2.3 Water connections ..................................................................................................9

2.4 Gas connection .....................................................................................................10

2.5 Electrical connections ...........................................................................................11

2.6 Flues connections .................................................................................................14

3. Service and maintenance......................................................................22

3.1 Settings .................................................................................................................22

3.2 Commissioning......................................................................................................24

3.3 Maintenance..........................................................................................................25

3.4 Replacement of Parts............................................................................................27

3.5 Troubleshooting....................................................................................................31

4. Characteristics and technical specifi cations..........................................34

4.1 Dimensions and fittings ........................................................................................34

4.2 Overall view and main components .....................................................................35

4.3 Hydraulic diagram.................................................................................................36

4.4 Technical data table..............................................................................................37

4.5 Diagrams ...............................................................................................................38

4.6 Wiring diagram .....................................................................................................39

Benchmark................................................................................................40

Page 4

4

Tempra 12 - 18

1. OPERATING/USER INSTRUCTIONS

1.1 Introduction

Dear Customer,

Thank you for having chosen the Tempra 12/18, an advanced-concept FERROLI wall-hung boiler

featuring cutting-edge technology, high reliability and constructional quality. Please carefully read

this manual and leave it with the end user.

The Tempra 12/18 is a high efficiency heat generator for central heating systems, operating

on natural gas or LPG.

The boiler can be connected to an external hot water cylinder for the production of domestic

hot water.

The boiler body is made up of a copper heat exchanger, the special shape of which guarantees

high heat exchange efficiency in all operating conditions, and an atmospheric burner featuring

electronic ignition with ionisation flame control.

The boiler is completely sealed from the surrounding environment: the air required for combustion

is taken in from the outside, and a fan is used to expel the flue gases. The accessories supplied with

the boiler also include a variable-speed pump, expansion vessel, safety valve, air pressure switch,

temperature sensors and safety thermostat.

The microprocessor-based control system means that the operation of the appliance is almost completely

automatic. The central heating output is automatically regulated by the control system according to

requirements. The domestic hot water output (with external hot water cylinder installed) is automatically

and continuously controlled to ensure both comfort and economical operation.

The user simply has to set the temperature required inside the home (using the optional, yet

recommended room thermostat) or set the system temperature and the required domestic hot

water outlet temperature at the cylinder stat. The regulation and control system will then ensure

optimum operation all year round.

Page 5

5

Tempra 12 - 18

1.2 Control panel

To access the control panel, open the drop down cover.

0

5

1

2

3

4

6

CEAB D

POS. DESCRIPTION

A OFF/ON/RESET switch

B Central heating temperature

setting

C Water pressure gauge

D Domestic hot water storage

temperature setting (with optional kit)

E Clock position (optional)(EIRE only)

bar

Burner on signal

Lock-out warning signal

Stand-by in central heating operation (light flashing)

Central heating request (light on)

Mains power (light on)

ab de

a

b

d

e

LED

Table 1

1.3 Ignition and shut-down

Ignition

• Open the gas isolation valve upstream of the boiler.

• Ensure 230V supply is present at the boiler.

• Place the main switch “A” in the ON position.

• Place knob “B” in the Winter position and set the room thermostat, if fitted, to the required

temperature value. At this point, the burner will ignite and the boiler will start operating automatically,

managed by its control and safety devices.

If, after having correctly performed the ignition operations, the burners do not ignite and the

lock-out warning light is on, wait around 15 seconds, then turn knob A to the RESET position

and release it. The control unit will be reset and will repeat the ignition cycle. If, after a number

of attempts, the burners does not ignite, refer to the paragraph on troubleshooting.

Shut-down

Close the gas isolation valve upstream of the boiler, turn knob “A” to OFF and disconnect the

appliance from the mains power supply.

When the boiler power is off the boiler anti-freeze protection is not active.

For extended periods of inactivity during the winter months, and in order to avoid damage due

to freezing, all the water should be drained from the boiler, both the domestic hot water and

the central heating system; alternatively, drain only the domestic hot water and place approved

antifreeze fluid in the central heating system.

fig. 1

Page 6

6

Tempra 12 - 18

Before calling the service centre, check that the problem is not due to no gas or mains power

supply.

Table 2

Boiler locked-out

LED Problem Solution

Check if the gas isolation valve upstream of the boiler and on the counter are open.

Turn knob “A” Fig. 1 to “Reset” and then release it.

In the event of repeated boiler lock-out, contact the nearest service centre.

1.4 Settings

Summer/Winter setting and system temperature control

With knob “B” Fig. 1 in the position of the symbol (Summer), the central heating function is

deactivated. This is only for use with optional water control kit. With the knob “B” Fig. 1 in the position of

the symbol (Winter), both the central heating function and domestic hot water are active, if used with

an external clock/programmer knob “B” must be kept in the winter position and the clock/programmer

used to control the central heating and hot water. Turning the knob clockwise increases the central heating

water temperature, anticlockwise decreases it. The temperature can be set from a minimum of 35° to a

maximum of 85°. It is not recommended, however, to operate the boiler below 45°.

Setting the ambient temperature (using the optional room thermostat)

Set, using the room thermostat or remote control, the temperature required inside the rooms. Based

on the command from the room thermostat, the boiler is ignited and heats the system water to the set

central heating outlet temperature. When the required temperature inside the rooms is reached, the

boiler switches off. If no room thermostat or remote control is available, the boiler will maintain the

system at the set central heating outlet temperature.

Domestic hot water temperature control

Set the hot water cylinder temperature, using knob “D” (supplied in the optional kit).

System water pressure control

Manually filling the central heating system with external connection and cock. The filling pressure when

the system is cold, as read on the boiler water pressure gauge, must be around 1.0 bar (at least 0.5

bar). If the pressure drops during operation to a value lower than the minimum described above, the

User must restore the initial value using the filling loop. Once the operation is completed, always close

the filling loop. This device is fitted to the system by the installer.

1.5 Maintenance

It is recommended to have annual service of the appliance performed by qualified personnel. Please

refer to Chap. 3.3 in this manual for further information.

The casing, the control panel and the aesthetic parts of the boiler can be cleaned using a soft and damp

cloth, dipped in soapy water if necessary. Do not use abrasive detergents or solvents.

1.6 Troubleshooting

Any anomalies or operating faults are signalled by the LEDs on the control panel. The following table lists

the faults that may arise due to simple problems that can be resolved by the user.

Page 7

7

Tempra 12 - 18

2. INSTALLATION

2.1 General instructions

This appliance must only be used for the purposes it has been specifically designed for. This appliance is

used to heat water to below boiling temperature at atmospheric pressure and must be connected

to a central heating and/or hot warm distribution system, according to its characteristics, performance and heating capacity. All other uses are considered improper.

THE BOILER MUST ONLY BE INSTALLED BY SPECIALIST AND QUALIFIED PERSONNEL, IN

COMPLETE COMPLIANCE WITH ALL THE INSTRUCTIONS REPORTED IN THIS TECHNICAL MANUAL,

THE LEGAL STANDARDS IN FORCE, THE PRESCRIPTIONS OF STANDARDS AND ANY LOCAL STANDARDS, AND ACCORDING TO THE RULES OF GOOD PRACTICE.

Incorrect installation may cause damager to persons and property. The manufacturer will not

be held liable in such events.

This appliance must be installed strictly in accordance with these instructions.

The Gas Safety Regulations (Installations & Use).

The Local Building Regulations.

The Building Regulations.

The Buildings Standards (Scotland - Consolidated) Regulations.

British gas publication DM2 - Guide for installation in timber framed housing.

British Standards Codes of Practice:

B.S. 7593 TREATMENT OF WATER IN DOMESTIC HOT WATER CENTRAL HEATING SYSTEMS

B.S. 5546 INSTALLATION OF HOT WATER SUPPLIES FOR DOMESTIC PURPOSES

B.S. 5440 Part 1 FLUES

B.S. 5440 Part 2 AIR SUPPLY

B.S. 5449 FORCED CIRCULATION HOT WATER SYSTEMS

B.S. 6798 INSTALLATION OF GAS FIRED HOT WATER BOILERS

B.S. 6891 GAS INSTALLATIONS

B.S. 7671 IEE WIRING REGULATIONS

B.S. 4814 SPECIFICATION FOR EXPANSION VESSELS

B.S. 5482 INSTALLATION OF LPG

Model Water Bye Laws

For Northern Ireland the rules in force apply

2.2 Place of installation

The appliance’s combustion chamber is sealed from the surrounding environment and as a result the

appliance may be installed in any room without purpose built ventilation. The installation environment

must nonetheless feature sufficient ventilation, to avoid dangerous conditions arising in the event of

even minor gas leaks. These safety standards are imposed by EEC Directive no. 09/396 for all gas

appliances, including the so-called sealed appliances.

The place of installation must in any case be free of dust, inflammable objects or materials and corrosive

gases. The environment must be dry and not prone to freezing.

The boiler is supplied ready for wall-hung installation. The rear frame of the appliance has a series of

slots for fastening it to the wall, using screws with wall plugs. The fastening to the wall must provide

stable and effective support of the appliance.

The boiler must be fastened to a closed part of wall, which is free of apertures or holes behind the frame

of the boiler that may allow the internal components of the boiler to be reached.

If the appliance is enclosed in a cabinet or alongside another appliance, space must be allowed

for normal maintenance operations. Fig. 2 and Tab. 3 show the minimum and recommended space

to be left free around the appliance.

Page 8

8

Tempra 12 - 18

Fixing to the wall

For Top Flue connections.

Select suitable position for boiler, using the template mark

flue outlet and boiler mounting points. Drill two 10 mm holes

70 mm deep to accept the wall plugs. Fix the wall bracket to

the wall using standard lock nut (M8) on both sides. Mount the

boiler on the wall bracket and fix using the special antitheft

nut (M8) as described in the fig. 3a. Mount the boiler on the

wall bracket.

For Back Flue connections.

Select suitable position for boiler, using the plate inserted in

the optional “back flue outlet kit” mark flue hole and plate

fixing points.

Follow procedure in 2.6 for boiler transformation and mounting.

fig. 3b

Boiler

dimensions

100 1802595

165 115

720 13

160

12485

400

36 155

16.5

120

120

A A

B

D

C

> 500 mm

Minimum Recommended

A

B

D

30 mm

150 mm

15 mm

(from opening panels)

150 mm

300 mm

C 150 mm 300 mm

Table 3

fig. 2

16.5

117.5 117.5

Øi 100

290

235

133 16.53831

102.5 177.5

20 260 10

fig. 4

fig. 3a

Page 9

9

Tempra 12 - 18

2.3 Water connections

The heat capacity of the appliance should be established in advance by calculating the heating

requirements of the building according to the standards in force. For correct operation and long-life

of the boiler, the hydraulic system must be suitably proportioned and always fitted with all the

accessories that guarantee regular operation.

In the case where the central heating outlet and inlet pipes follow paths whereby, at some points,

pockets of air may form, air vent valves should be installed at such points.

In addition, a drain device should be installed at the lowest point in the system, to allow

complete draining.

If the boiler is installed at a lower level than the system, a flow-return valve should be fitted to prevent

the natural circulation of water in the system.

The temperature differential between the outlet and the inlet of the boiler should not exceed 20°C.

Do not use the water pipes as the earth for electrical appliances.

Before installation, carefully clean all the pipes in the system to remove any residues or impurities that

may affect the correct operation of the appliance.

Make the connections to the corresponding fittings, as shown in Fig. 5.

Key

1 Central heating outlet, 3/4”

2 Gas inlet, 1/2”

3 Central heating inlet, 3/4”

It is recommended to fit isolation valves between the boiler and the central heating system; these allow

the boiler to be isolated from the heating system, if necessary.

The discharge of any safety valves must be routed to outside dicharging to ground level 100 mm

from the floor so as not to create a danger to anyone passing. The manufacturer of the boiler will

not be held liable if this warning is not heeded, and the discharge valve intervenes and floods

the room.

Make the connections to the boiler in a way that its internal tubing is not subject to stress.

fig. 5

36 12485

98

2

3

1

155

Page 10

10

Tempra 12 - 18

Water treatment

if water treatment is used Ferroli Ltd recommend only the use of Fernox or Sentinel water

treatment products, which must be used in accordance with the manufacturers instructions. For

further information contact:

Fernox Manufacturing Co. LTD. Sentinel Division

Tandern house, Marlowe Way Betz Dearborn LTD

Croydon, surrey, CRO 4YS Widnes, Cheshire WA8 5351

Tel. 02870 5601 5000 Tel. 0151 424 5351

Note - If the boiler is installed in an existing system

any unsuitable additives must be removed by thorough cleansing.

All systems should be cleansed according to B.S.

7593.

Note - In hard water areas treatment to prevent

lime scale may be necessary.

Note - It is important that the correct concentration

of the water treatment product is maintained in accordance with the manufactures instructions.

Filling the boiler and the system

The filling pressure, when the system is cold, must be around 1 bar (at least 0.5 bar). If the pressure

drops during operation to a value lower than the minimum described above, the User must restore

the initial value using the filling loop. For correct boiler operation, the pressure, when hot, must

be around 1,5-2 bar. Once the operation is completed, always close the filling loop. This device

is fitted to the system by the installer.

2.4 Gas connection

Before making the connections, check that the appliance is configured for operation with the

type of fuel available, and carefully clean all the gas pipes in the system, to remove any residues

that may affect the correct operation of the boiler.

The gas connections must be made using the relative coupling (see Fig. 5), according to the standards in

force, with a rigid metal pipe, or a stainless steel flexible continuous-wall pipe, fitting a gas cock between

the system and the boiler. Check that all the gas connections for soudness.

The capacity of the gas meter must be sufficient for the simultaneous use of all the connected appliances.

The diameter of the gas pipe, which leaves the boiler, does not necessarily determine the choice of the

diameter of the pipe used between the appliance and the gas meter; this must be chosen according to

its length and the pressure drop, according to the standards in force.

Do not use the gas pipes as the earth for electrical appliances.

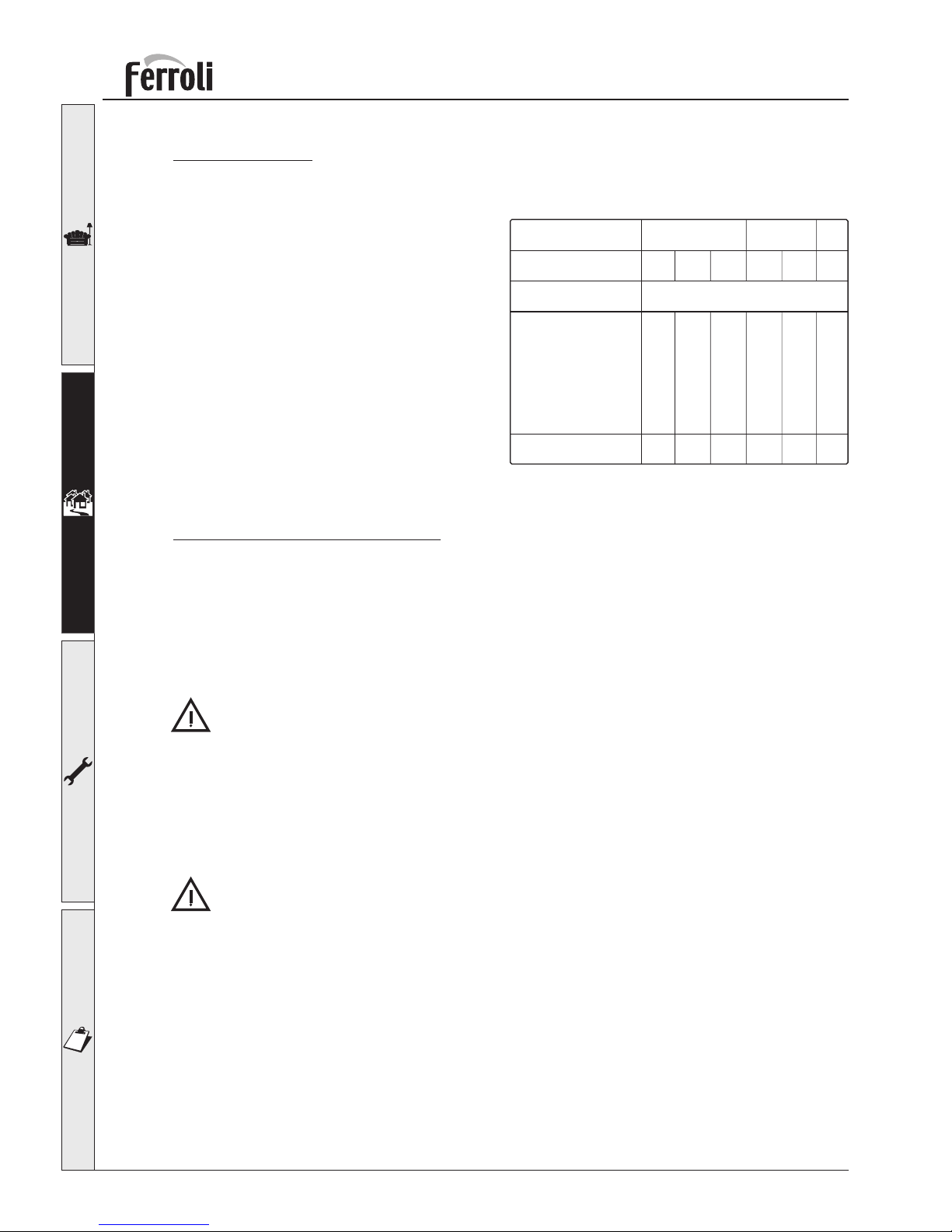

VESSEL CHARGE

PRESSURE (bar)

INITIAL SYSTEM

PRESSURE (bar)

TOTAL WATER

CONTENT of SYSTEM

Litres

25

50

75

100

125

150

175

200

For syst. volumes other than

those given above, must. the syst.

volume by the factor across

0.5 1.0 1.5

1.0 1.5 2.01.5 2.0 2.0

EXPANSION VESSEL VOLUME (litres)

3.5

7.0

10.5

14.0

17.5

21.0

24.5

28.0

6.5

12.9

19.4

25.9

32.4

38.8

45.3

51.8

13.7

27.5

41.3

55.1

68.9

82.6

96.4

110.2

4.7

9.5

14.2

19.0

23.7

28.5

33.2

38.0

10.3

20.6

30.9

41.2

51.5

61.8

72.1

82.4

8.3

16.5

24.8

33.1

41.3

49.6

57.9

66.2

0.140 0.190 0.330.259 0.551 0.412

Page 11

11

Tempra 12 - 18

Room thermostat

WARNING: THE ROOM THERMOSTAT MUST HAVE 230V LIVE CONTACTS.

Standard Systems

For a general pipe layout and wiring diagram on the “S” and “Y” plan systems please see

fig. 6A, 6B, 6C and 6D.

2.5 Electrical connections

Connection to the mains power supply

The boiler should be connected to a single-phase, 230 Volt-50 Hz electrical line.

The electrical safety of the appliance is ensured only when the appliance is correctly connected

to an effective earth system, as prescribed by the safety standards in force. Have professionally

qualified personnel check the efficiency and the rating of the earth system. The manufacturer

is not liable for any damage caused by the appliance not being correctly earthed. In addition,

make sure that the electrical system is adequately rated for the maximum power absorbed by

the appliance, indicated on the boiler rating plate, and in particular that the cross-section of the

wires is suitable for the power absorbed by the appliance.

The boiler is pre-wired and fitted with a cable for connection to the electrical line. The connections

to the mains supply must be made using a fixed connection, featuring a double-pole switch with

a contact opening of at least 3 mm. Max 3A fuses must be installed between the boiler and the

line. The correct polarity must be followed (LINE: brown wire / NEUTRAL: blue wire / EARTH:

yellow-green wire) in the electrical connections.

The appliance’s power cable must not be replaced by the user. In the event where the cable is

damaged, turn off the appliance and contact professionally qualified personnel to replace it. If

replacing the electrical power cable.

All wiring must conform to current I.E.E. Regulations

Accessing the electrical terminal block

Follow the operation shown in Figs. 6a and 6b to access the electrical terminal block. The layout

of the terminals for the various connections is shown in the wiring diagram, in the chapter on

Technical Specifications.

Fig. 6a Fig. 6b

Page 12

12

Tempra 12 - 18

Tempra 12/18 “S” Plan

Pipe layout

Wiring diagram

FERROLI

TEMPRA

BOILER

12/18

D.H.W.

Zone Valve

A.A.V

C.H.

Zone Valve

To ensure a passage of 6ltrs

per minute an Automatic

by-pass must be fitted.

(Building regulation part L)

10987654

321

Tempra 12/18 Junction Box

ENEL

diverter valve

(optional)

9&10

optional

cylinder

sersor

Terminal 8 - SWITCH LINE

12345678910

PROGRAMMER

DHW ON

CH ON

NEUTRAL

LIVE

CH

zone

valve

DHW

zone

valve

Room Thermostat

Cylinder Thermostat

N

E

L

230 Vac

fused at

3 amps

BROWN BLUE

GREY ORANGE

NL

1112

Fig. 6c

Fig. 6d

Page 13

13

Tempra 12 - 18

Tempra 12/18 “Y” Plan

Pipe layout

FERROLI

TEMPRA

12/18

Auto air vent

To ensure a passage of 6ltrs

per minute an Automatic

by-pass must be fitted.

(Building regulation Document L

April 2001)

“Y” Plan valve

Wiring diagram

10987654321

Tempra 12/18 Junction Box

NL

12345678910

PROGRAMMER

NEUTRAL

LIVE

CH ON

DHW ON

DHW OFF

BLUE

WHITE

GREY

ORANGE

Room Thermostat

Cylinder Thermostat

N

E

L

240 Vac

fused at 3 amps

Honeywell V4073H mid position

The heating system must have a bypass capable of

passing 6 litres/minute if TRV are fitted throughout

3 WAY ZONE VALVE

2

1

C

NL

Terminal 8 - SWITCH LINE

1112

Fig. 6e

Fig. 6f

Page 14

14

Tempra 12 - 18

Ø

Replacing the restrictor

To install or change the restrictor, remove the fan unit,

remove the flue gas connecting pipe 1 (as shown in Fig.

8a) and insert the diaphragm 2 (as shown in Fig. 8b).

Type

60/100

Length up to:

1 bend + 1 metre

1 bend + 3 metres

1 bend + 3 metres

1 bend + 4 metres

1 bend + 5 metres

Restrictor to be used

80/125

Table 4a

Tempra 12 Tempra 18

37 mm

37 mm

43 mm

47 mm

43 mm

47 mm

Total calculated

flue lenght

Use restrictor

Min

0 m

10 m

15 m

20 m

30 m

35 m

40 m

Max

10 m

15 m

20 m

30 m

35 m

40 m

45 m

Table 4b

Tempra12Tempra

18

43 mm

47 mm

37 mm

Choice of the restrictors using

concentric flue

Choice of the restrictors using 2

pipe system

2.6 Flues connections

This is a “type C” sealed and forced draught appliance, and as such the air inlet and flue gas

outlet must be connected to one of the exhaust/intake systems indicated below. Using the

tables and the methods of calculation described, first verify, before installation, that the flues

do not exceed the maximum allowed length. The standards in force and local legislation must

be adhered to for terminal positions.

Restrictors

For the operation of the boiler, the restrictors supplied with the appliance must be fitted, according to

the indications shown in the tables below.

The Ø37 for Tempra 12 and Ø43 for Tempra

18 restrictor is fitted as standard on the boilers.

Before inserting the flue gas outlet pipe, check

that the correct restrictor is installed (when this

needs to be used) and correctly positioned.

N.B.:

The diameter Ø of the hole is stamped on the restrictor

fig. 7

fig. 8a

8b

2

1

Page 15

15

Tempra 12 - 18

Connection using concentric flue

For side outlet or roof outlet concentric air/flue gas pipe can be connected directly to the top of the

boiler, or a special back flue outlet kit is available for Rear outlet. Numerous accessories are available

upon request for the various different installation requirements. Please refer to the flue accessories

catalogue, or the price list.

Rear Outlet

Front view

Side Outlet

Front view

P = S + 85 mm

Right hand

L = S + D + 225 mm

Left hand

L = S + D + 145 mm

Drill the wall 10, 20 mm

greater than the diameter

of the pipe

Slope

downwards

by 3 mm/m

70

DS50* 125

110

50

L

115

160 240

* = between 10

and 60 mm

Bend 60/100

1KWMR81U

DS

L

125

70

165

720

400

13

160

Slope downwards

by 3 mm/m

70

S 50* 125

P

35

Drill the wall 10, 20 mm

greater than the diameter

of the pipe

240160

Ø60 Ø80

70 min.

Cut the internal pipe

70 mm longer than “L”

50*

50

115

115

80

-3 mm/m

160 240

Top view

fig. 9a fig. 9b

Top view

Page 16

16

Tempra 12 - 18

Sloped tile

1KWMA82U

Concentric

adapter 60/100

1KWMR52A

Max. 4m extension

60/100

1KWMA56U

160 240

950

50

max. 4 mt

Roof terminal

1KWMA83U

950

53

50 950

50

1000 125

10

Vertical outlet

For installation (top flue connection):

1. Define the position for the installation of

the appliance

2. Drill the wall for the passage of the air/flue

gas pipe according to the references

indicated in the figure, considering that

the horizontal sections of pipe must have

a downwards slope of around 3 mm per

metre of length, to prevent any rainwater

from entering the boiler.

3. Make a hole that is 10 - 20 mm greater

in diameter than the rated diameter of

the coaxial pipe used, to simplify its

installation.

4. If necessary, cut the end of the pipes to

measure, remembering that the outside

part of the pipes must protrude from the

wall by between 10 and 60 mm. Eliminate

any burrs from the cut.

5. Connect the pipes to the boiler, placing the

gaskets correctly, and seal the connections to

the wall using the special seal couplings.

For installation (back flue connection):

For direct back flue connection it is necessary

to use the optional kit 1KWMR04A, and it

is required to alter the fan direction inside

the boiler.

Follow carefully next procedure:

fig. 10

The total length in linear metres of the

concentric pipes must not exceed the maximum

length indicated in the table below, considering

that each bend gives rise to the reduction

indicated. For example, a D= 60/100 pipe

with 1 x 90° bend + 1 metre horizontal + 2

x 45° bends + 1 metre horizontal, has a total

equivalent length of 4 metres.

Reduction factors for bends

1 m

0,5 m

0,5 m

0,25 m

Table 5b

Maximum allowed

pipe length

Ø mm

60/100

4 m 5 m

Ø mm

80/125

Table 5a

1,00 m

Rear

outlet

Remove fan by pulling off electrical connections.

Pull off air pressure switch tubes from the air

pressure switch remove 2 screws b. Rotate the

fan downward to disengage it from the securing

pin a.

Fig. 11a

b

b

a

Page 17

17

Tempra 12 - 18

Fig. 11b Fig. 11c Fig. 11d

Take off the four screws which fix the back plate on sealed chamber, remove and

rotate the plate through 90° and fit it to the top of the boiler to cover the original

flue outlet. Secure it in place with the four screws removed previously.

Remove fan mounting plate by undoing the three fixing screws d. Rotate the fan through 90°

so that the fan nozzle points sideways. Secure the fan to the plate in the new position using

screws in position c.

Fig. 11e

c

d

c

d

d

-

c

Common

For rear outlet

For upper outlet

Fig. 11g

For rear

outlet

c

c

c

Fig. 11f

d

d

d

For upper

outlet

Fig. 11h

Fix with the screws (b). Refit wiring connections to fan and air pressure switch tubes ensuring correct

orientation. I.E. red tube to air pressure switch connection with red dot (+) and clear tube to air

pressure switch connection with no paint marking (-).

Fit the fan into the boiler rotating the front to engage with the pin a. Secure with the screws b.

Rear

b

b

Page 18

18

Tempra 12 - 18

Fig. 11m

3. Gently pull back until wall

seal is flush with the wall.

Fig. 11l

2. Push through the outer flue.

Fig. 11i

1. Core drill 127mm hole (5").

Fig. 11n

4. Place wall plate on outer

flue ensuring it is level. Mark

and drill four holes, two top,

for expanding bolts and two

bottom for plugs and screws.

Fix plate to wall with the

square gasket between the

wall and the plate use the

large diameter washers for the

bolts and screws.

Square GasketCircular Gasket

Fig. 11o

5. Through plate into air tube,

drill two holes and fix in place

using two self tapping screws

M4 x 6mm long.

6. Cut the outer flue flush with

the flange on the hanging

plate.

Fig. 1p

7. Inser t the aluminium flue

pipe into white plastic

outer flue, making sure

the aluminium pipe sits

fully and centrally into

the flue terminal. Mark

the aluminium flue pipe

at the point it is flush with

the mounting plate. Add

36mm to this mark and

cut the aluminium inner

flue pipe at this point.

Fig. 11g

35 mm

Page 19

19

Tempra 12 - 18

4

5

6

2 3

Air

Flue

gases

110

160

Ø100

Ø60

Ref.

1

2

3

4

5

6

N° Pieces

1

1

1

1

33

1

Bend Ø80 air pipe

Horizontal Ø80 air pipe

Wind-protection terminal

T adaptor

Vertical Ø80 flue

Stack + connecting pipe

Description

Equivalente

pressure drop

1,5 m

1,0 m

2,0 m

included

33,0 m

4,0 m

41,5 m

Total

Table 6

fig. 12

fig. 13

Connection using two pipe system

The appliance may be connected to a system

of separate air/flue gas pipes with wall or

roof outlet, as shown in drawings 14-15 to the

side. Numerous accessories are available upon

request for the various different installation

requirements. The most frequently-used

components are shown in Tables 7 - 8 - 9 -10.

Please refer to the flue accessories catalogue

or the price list for other components.

To check that the maximum allowed length of

the pipes is not exceeded, a simple calculation

must be performed before installation:

1. For each component, Tables 7 - 8 - 9 list a

pressure drop in “equivalent air-metres”,

depending on the position of installation of

the component itself (air intake or flue gas

outlet, vertical or horizontal).

This drop is called “equivalent air-metres”

as it relates to the pressure drop of one

metre of air intake pipe (defined as being

equal to 1). For example, a 90° bend in a

Ø80 flue gas outlet has a pressure drop

equivalent to 2.5 air-metres, that is, equal to

2.5 linear metres of air intake pipe.

2. Once having completely defined the layout

of the double flue system, add the pressure

drops in equivalent-metres, according to the

position of installation of all the components

and accessories in the system.

3. Check that the total pressure drop calculated

is less than or equal to 45 equivalent

metres, that is, the maximum allowable for

this model of boiler.

If the flue system chosen exceeds maximum allowable limit, some sections of

the pipes should be larger in diameter.

Page 20

20

Tempra 12 - 18

Pipes and fittings reduction table

Air Flue

Vertical

Horizontal

Vertical

Horizontal

Description

Male

-fem

ale

flue Ø80

Male

-fem

ale

bend 45° Ø80

Male

-fem

ale

bend 90° Ø80

Air terminal of

inlet protection

Ø80

Outlet flue air inlet for

connection with split end

Ø80

1112

1,2 2,2

1,5 2,5

Reduction

2

3

12

Condensate flue

outlet

A

c

c

e

s

s

o

r

i

e

s

Ø

8

0

Airwall terminal

products

of combustion Ø80

5

Table 7

The pressure drop values described refer to original Ferroli pipes and accessories.

Page 21

21

Tempra 12 - 18

P

D, E

Q

Q

l

B

C

A

G

F

L

J

H

H

K

N

N

MM

Q

Flue terminal positions

Directly below an opening, air brick opening windows, etc.

Above an opening, air brick, opening windows, etc

Horizontally to an opening, air brick, opening windows, etc.)

Below gutters, soil pipes or drain pipes

Below eaves

Below balconies or car port roof

From a vertical drain pipe or soil pipe

From an internal or external corner

Above ground roof or balcony level

From a surface facing the terminal

(also see 6.1.2)

From a terminal facing the terminal

From an opening in the car port ( e.g. door,

window) into the dwelling

Vertically from a terminal on the same wall

Horizontally from a terminal on the same wall

From the wall on which the terminal is mounted

From a vertical structure on the roof

Above intersection with roof

Dimensions Terminal position

(kW input expressed in net)

Balanced flues room

sealed

Fanned

draught

A 300 mm

B 300 mm

C 300 mm

D 75 mm

E 200 mm

F 200 mm

G 150 mm

b

H 300 mm

I 300 mm

J 600 mm

K 1200 mm

L 1200 mm

M 1500 mm

N 300 mm

O N/A

P N/A

Q N/A

NOTE N/A = Not applicable

a

In addition, the terminal should not be nearer than 150 mm (fanned draucht) or 300 mm (natural draught) to an opening in the building fabric

formed for the purpose of accommodating a built-in element such as a window frame.

Tab. 8

Minimum dimensions of flue terminal positions (alltypes)(see fig. 14)

Fig. 14

Page 22

22

Tempra 12 - 18

IN OUT

C

F

EB A D

Key

A Pressure test point upstream

B Pressure test point downstream

C Protection screw

D Minimum pressure adjustment screws

E Maximum pressure adjustment screws

F Pressure compensation pipe

3. SERVICE AND MAINTENANCE

3.1 Settings

All the adjustment and conversion operations must be performed by Qualified Personnel, such as

personnel from the Local Customer Service Centre.

FERROLI Ltd. declines all liability for damage to persons and/or things deriving from tampering with

the appliance by non-authorised persons

Conversion of supply gas

The appliance can operate on Natural Gas or LPG as the supply gas, and is factory configured for

use with one of the two gases, as is clearly marked on the packaging and on the rating plate on the

appliance itself. If the appliance has to be used with a gas other than the one it has been set for, the

special conversion kit must be used, as shown below:

1 Replace the nozzles in the main burner, installing the nozzles indicated in technical data table in

Chap. 4.4, according to the type of gas used

2 Adjust the minimum and maximum pressures in the burner (ref. corresponding paragraph), setting

the values indicated in technical data table for the type of gas used.

3 Change the position of Jumper 02 on the electronic board (ref. corresponding paragraph).

4 Apply the adhesive label in the conversion kit next to the rating plate, to confirm the

conversion operation.

Adjusting the burner pressure

This appliance, featuring flame modulation, has two set pressure values: the minimum and maximum,

which must be the values indicated in technical data table, according to the type of gas.

• Connect a suitable pressure gauge to the pressure test point “B”, located downstream of

the gas valve.

• Disconnect the pressure compensation pipe “F”.

• Remove the protection cap “C”.

• Turn the potentiometer P3 (located on the control board)

to the minimum position (clockwise).

• Operate the boiler in central heating mode.

• Adjust the minimum pressure using the screw “D”,

clockwise to decrease it and anticlockwise to increase.

• Turn the potentiometer P3 to the maximum position

(anticlockwise).

• Adjust the maximum pressure using the screw “E”, clockwise to increase it and anticlockwise to decrease it.

• Reconnect the pressure compensation pipe “F”.

• Replace the protection screw “C”.

fig. 15

Page 23

23

Tempra 12 - 18

fig. 16a

Adjustments on the electronic board

Follow the indications shown in the figure to access the electronic board.

Potentiometer position and functions

P1 = Central heating temperature adjustment

P2 = Factory set - Do not adjustment

P3 = Heating output adjustment

P4 = Gas pressure adjustment for ignition

P5 = Factory set - Do not adjustment

X6

X1 X2 X3 X4

12121312345678910 123

45

678910

111213

21

X5

L1

L2

L3

L4

L5

+- +-

Transformer

P2

DHW

X12

12

+

-

P3

+

-

P5

+

-

P4

JP02

JP01

JP03

123456789

X10

Nat/LPG

P1

CH

X11

RY100

RY101

PC PNO L N HL HL MV1 MV2 MV3 MV4

FAN

LN

X8

X7

RY1

RY2

PMF03F

JP01 inserted = Diverting valve System

JP01 not inserted = Not able

JP02:

Jumper inserted for

natural gas operation

Jumper inserted for LPG operation

Jumper adjustment

fig. 16b

fig. 17

Page 24

24

Tempra 12 - 18

Adjusting the maximum heating output (not normally required)

This adjustment may only be performed electronically using the adjustment potentiometer “P3”,

starting with cold heating system.

Connect a suitable pressure gauge to the pressure test point B located on the gas valve; turn the

temperature control knob to the maximum value, then adjust the pressure to the value required, using

the pressure-output diagram in the chapter on technical specifications. Once this operation has been

completed, turn the burner on and off 2 or 3 times using the thermostat and check that the pressure

remains stable at the set value. If not, a further fine adjustment must be performed, until the pressure

remains stable at the set value. When the burner is ignited to check the calibration pressure, turn the

setting thermostat knob to the maximum value, otherwise the procedure will be incorrect.

Adjusting the heating ∆t by varying the flow-rate/discharge head of the pump

The thermal head, ∆t (difference between the central heating outlet and inlet temperature) must

be less than 20°C. This is checked by varying the flow-rate and discharge head of the pump, using

the speed control (or switch) on the pump itself. Note that increasing the speed of the pump

decreases the ∆t, and vice-versa.

3.2 Commissioning

The appliance must only be commissioned for use by Qualified Personnel,

Before igniting the boiler:

• Open any on-off valves between the boiler and systems.

• Check the gas system for soundness, proceeding with care and using a leak detection water solution

to find any leaks from the connections.

• Fill the system with water and ensure that the air contained in the boiler and the system

has been completely vented, by opening the air vent valve on the boiler and any vent valves

in the system.

• Check that there are no water leaks in the heating system, in the domestic hot water circuits,

in the connections or in the boiler.

• Check the correct connection of the electrical system.

• Check that the appliance is properly earthed.

• Check that the pressure value and gas rate for the heating system are correct.

• Check that there are no flammable liquids or materials in the immediate vicinity of the boiler.

Igniting the boiler

• Open the gas isolation valve upstream of the boiler.

• Vent the air in the pipe upstream from the gas valve.

• Close any switches or insert any plugs upstream of the boiler

• Place the main switch in the ON position.

• Place knob “B” in the Winter position to a value higher than 50°C and set the room thermostat, if

fitted, to the required temperature value. At this point, the burner will ignite and the boiler will start

operating automatically, managed by its control and safety devices.

• Checking gas inlet pressure

- Connect a pressure gauge to inlet tet point;

- Fire the Boiler and set at full gas rate by turning P3 to maximum (anticlockwise);

- Check the pressure gauge is reading 20 mbar (+/-1 mbar);

- Check that this pressure remains as above with any other gas appliances in the house turned on;

- If the pressure is below this reading it should be investigated before continuing as this is a sign

of an incorrect or partially blocked gas supply;

- Turn-off appliance;

- Remove pressure gauge, tihten test point and test with leak detection fluid.

Page 25

25

Tempra 12 - 18

If, after correctly having performed the ignition operations, the burners do not ignite and the shutdown warning light is on, wait around 15 seconds and then turn knob “A” (Fig. 1) to the RESET position and release it. The control unit will be reset and will repeat the ignition cycle. If, after a number

of attempts, the burners do not ignite, refer to the paragraph “Troubleshooting”.

In the case of power failures while the boiler is in operation, the burners will switch off. When

mains power returns, the burners will automatically re-ignite.

Checks during operation

• Check the gas supply and the water system for tightness.

• Check the efficiency of the flues and air-flue gas pipes during the operation of the boiler.

• Check that the water circulation between the boiler and the systems is correct.

• Ensure that the gas valve modulates correctly both in the central heating phase and the

production of domestic hot water.

• Check the correct ignition of the boiler, by performing a series of ignition and shut-down tests using

the room thermostat or the remote control.

• Ensure that the consumption of gas indicated by the counter corresponds to the values shown

in the technical data table in Chap. 4.

Shut-down

Close the gas isolation valve upstream of the boiler and disconnect the appliance from the

mains power supply.

For extended periods of inactivity during the winter months, in order to avoid damage due to

freezing, all the water should be drained from the boiler, both the domestic hot water and the

central heating system; alternatively, drain only the domestic hot water and place the special

antifreeze fluid in the central heating system.

3.3 Maintenance

The following operations must only be performed by Qualified Personnel

S

easonal checks on the boiler and the stack

The following checks should be made on the appliance at least once a year:

• The control and safety devices (gas valve, flow-meter, thermostats, etc.) must be working properly.

• The pipes and the air-flue gas terminals must be free of obstacles and not have any leaks.

• The water systems must be perfectly tight and the gas supply sound.

• The burner and the heat exchanger must be clean. Follow the instructions in the next paragraph.

• The electrodes must be free of deposits and positioned correctly.

• The pressure of the water in the system when cold must be around 1 bar; if not, restore this value.

• The expansion vessel must be full.

• The gas rate and the pressure must correspond to the values indicated in the corresponding tables.

• The circulation pumps must not be blocked.

Page 26

26

Tempra 12 - 18

Opening the casing

To open the boiler casing:

1 Using a screwdriver, completely remove the 2

screws, “A”

2 Open the control panel “B” by pulling down

3 Unscrew the 2 screws “C”

4 Remove the casing “D”.

fig. 19

C

D

B

fig. 18

A

D

Air

Flue

gases

Cleaning the boiler and the burner

The body and the burner must not be cleaned using chemical products or steel brushes. Special care

must be taken to ensure all the systems relating to the sealed compartment are tight (gaskets, cable

glands, etc..), to avoid air leaks which, causing a drop in the pressure inside in chamber, may activate the

differential pressure switch and thus shut-down the boiler. Special attention must also be paid, after all

the operations have been completed, to checking and performing all the ignition phases and operation

of the thermostats, gas valve and circulation pump.

After these checks, ensure that there are no gas leaks.

Analysis of combustion

Two test points are installed inside the boiler, one for the flue gases and the other for the intake air.

To make the measurements, proceed as follows:

1) Remove the boiler casing

2) Open the air and flue gas sample points in the

sealed compartment;

3) Insert the probes as far as possible;

4) Open a hot water tap;

5) Adjust the domestic hot water temperature to the

maximum setting.

6) Wait 10-15 minutes to allow the boiler to reach

stable operating conditions*

7) Take a reading with your flue gas analyser.

8) CO/CO2 ratio should be 0.004 or below. If above

a full service is required to find the cause and then

RE-TEST.

9) Following a full service the permissible reading is

now 0.008 or below.

Testing before thermal equilibrium has been reached will give incorrect readings.

fig. 20

Page 27

27

Tempra 12 - 18

3.4 Replacement of Parts

Initial procedure

a) The boiler is cold, electricity supply is isolated, and the gas supply is turned off at the inlet

of the boiler

b) For replacement of parts where water connections are broken, it will be necessary to isolate and drain

either or both the central heating or domestic hot water circuits of the boiler only. The cold water mains

inlet is isolated at the inlet isolation valve. The D.H.W. is drained by opening a hot tap.

The C.H. flow and return cocks are turned off at the isolation valve.

c) Remove components following special notice below and replace in reverse order.

d) Ensure water and gas washers are in good condition.

Final procedure

• Re-open valve and re-charge the system to about 1 bar, and vent boiler and radiators.

Re-charge to 1 bar if necessary.

• Upon completion of the work the following. Should be checked:

I) Gas soundness of all joints

II) Water soundness of all joints

III) The electricity supply.

IV) The pressure of the sealed system and top up

where necessary.

To lower the control panel (fig. 21)

• Remove the two fixing screw (fig. 21) "A"

• Lift the two metal brackets "B"

• Rotate down the front panel "C"

Fig. 21

Remove and re-presurising of C.H. expansion

vessel (fig. 22)

• Refer to initial procedure a, b

• Isolate electricity and water supplies

• Remove outer case (two screws bottom rear corners)

• Loosen the "A" connections to expansion vessel

• Remove "B" screw

• Remove the expansion vessel

• Re-assemble in reverse order

• Re-pressure expansion vessel

(charge pressure 0,8-1 bar)

• Re-fill system to 1 - 1.5 bar

• Check for leaves

Fig. 22

B

C

A

A

B

Page 28

28

Tempra 12 - 18

Gas valve (fig. 23)

• Isolate gas and electricity supplies

• Remove outer case (two screws bottom rear corners)

• Remove the two securing screws and lower control panel

• Disconnect electrical connections from valve ("A")

• Disconnect plastic tube "C"

• Loosen the connection "D" on gas pipe and the gas inlet

connection of the boiler "E"

• Remove the two fixing screw "E" below gas valve

• Slide out gas valve

• Remove four fixing screw "F" on top of the valve and disconnect

the gas pipe

• Remove bottom connection from gas valve.

• Fit top + bottom gas connections to the new gas valve and

replace in reverse order

• Check operation and gas pressures

Central Heating Temperature Sensor (fig. 25)

• Isolate electricity and water supplies

• Remove outer case (two screws bottom rear corners)

• Remove the two securing screws and lower control panel

• Identify the sensor from figure 24

• Disconnect electrical connection to the sensor

• Drain the affected service either D.H.W. or C.H.

• Unscrew the sensor, do not leak water onto P.C.B.

• Replace in reverse order

Safety Valve (fig. 25)

• Isolate electricity and water supplies

• Remove outer case (two screws bottom rear corners)

• Remove the two securing screws and lower control panel

• Identify valve from fig. 25

• Drain the boiler

• Release the outlet union to the valve and undo the valve

union connection

• Remove the valve outlet fitting

• Replace in reverse order

• Refill to 1 - 1.5 bar and TEST

Air pressure switch (fig. 24)

• Isolate electricity

• Remove outer case (two screws bottom rear corners)

• Open room sealed compartment

• Remove the two screw "A" fixing air pressure switch

• Disconnect electrical leads "B"

• Remove pressure sensing tubes (white=D; Red=C)

• Note relevant positions of all connections and replace in reverse order.

• Re-instate power and test - P/D 1.15 mb

Fig. 24

Fig. 23

Fig. 25

A

B

C

D

D

C

A

F

E

C.H. sensor Safety valve

Page 29

29

Tempra 12 - 18

Removal of burner (fig. 26)

• Isolate gas and electricity supplies

• Remove outer case (two screws bottom rear

corners)

• Remove room sealed cover

• Disconnect ignition and flame rectification

leads "A"

• undo gas rail union "B"

• Undo two screws securing the burner assembly

to the boiler combustion chamber "D"

• Withdraw the burner assembly

Injectors (fig. 26)

• Isolate gas and electricity supplies

• Remove outer case (two screws bottom rear

corners)

• Remove room sealed cover

• Remove fixing screw "C" on both sides of gas

collector

• Remove gas collector

• Unscrew and remove injectors;

• Clear or change injectors

Removal of fan (fig. 27)

• Isolate gas and electricity supplies

• Remove outer case (two screws bottom rear

corners)

• Remove room sealed cover

• Disconnect fan electrical leads "A"and note

positions

• Disconnect air pressure tubes from air pressure

switch "B" + note positions

• Undo two screws securing fan assembly "C"

• Remove fan from boiler

• Swap mounting plate over to new fan + replace

in reverse order

Limit thermostat, or overheat cut off

thermostat (fig. 27)

• Isolate electricity

• Remove outer case (two screws bottom rear

corners)

• Remove room sealed cover

• Identify the location of thermostat from fig. 27

• Pull out thermostat from tube, with its spring

• Remove electrical connections from thermostat

• Remove spring from thermostat

• Replace in reverse order using heat paste on

face of new stat

Fig. 27

C

A

B

D

D

Overheat cut off

thermostat

Limit

thermostat

C

A

B

fig. 26

Page 30

30

Tempra 12 - 18

Spark or flame detect electrode (fig. 28)

• Isolate gas and electricity supply

• Remove outer case (two screws bottom rear

corners)

• Open room sealed compartment and combustion

chamber

• Identify electrode from fig. 28

• Unplug electrical connection "A" from sensing

electrode

• Remove fixing screw and remove flame detect

electrode

• Remove the two fixing screw from spark electrode

plate and remove it.

• Replace in reverse order, spark gap 3.5 mm

Fig. 28

SparkA

Flame detect

Pump (fig. 29)

Replacement of pump head

• Isolate electricity and flow and return pipes

• Remove casing (two screws bottom rear corners).

• Remove the two securing screws and lower control

panel

• Release pressure from boiler via suitable drain point

• Unplug the pump lead "A" from the pump

head

• Place a piece of cloth or other absorbent material over

the rear of the control panel to catch any drops of water

that may fall when the pump head is removed.

• Using a 4mm allen wrench undo the four allen

screws "B" in the pump head, lift away pump

head from the pump body

• fit new head into pump body and secure with the

allen screws tightening evenly.

• Replace electrical connection.

• Refill system and vent pump

Replacement of pump body (fig. 29)

• Proceed as for removal of pump head

• Disconnect the expansion vessel connecting pipe "E" from the rear of the pump body by removing

the U clip from the left hand side

• Disconnect the boiler return pipe and disengage the pump lower connection by removing the U clip "C"

• Disconnect the pump to heat exchanger connection by removing the U clip "F"

• Unscrew the two screws on bottom of pump "D"

• Turn the pump body through 90°, pull the bottom forward and withdraw the pump body

• Reassemble in reverse order taking care to ensure the O-rings are in place and undamaged.

• Refill system and vent pump

Fig. 29

Removal of heat exchanger

• Isolate gas, water and electricity supplies

• Remove casing (2 screws bottom corners)

• Remove the two securing screws and lower control panel

• Drain the boiler

• Remove sealed compartment front panel

• Disconnect the overheat thermostat and central heating limit thermostat

• Remove the main burner, fan, flue hood as described previously

• Remove the pump to heat exchanger flow connection and locknut

• Lift out heat exchanger

• Re-assemble in reverse order

• Refill and TEST

B

D

C

A

F

E

Page 31

31

Tempra 12 - 18

Is LED5 on?

Put main switch to on

CH Selector to

Summer “

” position

Is 230V present across

terminals X1-1 X1-2?

Check and if necessary

replace 2A fuse

YES

Is LED5 ON now?

Repair external

wiring fault

NO NO

Replace

main board

NO

YES

Does fan run at full speed?

Go to CHART 2

NO

YES

Does CH Pump run?

If the boiler temperature

is less than 5°C

frost protection is activated

Disconnect

CH flowtemp sensor

Has fan speed stopped?

Check and if necessary

replace main board

NO

YES

Chek the following carefully before starting

• Gas supply is turned on, is adequate and purged

• Electricity supply is turned on

• Polarity is correct

• CH pressure is set between 1 - 1,5 bar

• CH pump spins freely

• CH system flushed correctly

• CH bypass adquate

NO

Is Relay RY101 switch on?

Check and if

necessary

replace pump

YES

NO

Check pump

wiring

connection

YES

Go to CHART 2

YES

3.5 Troubleshooting

Flow Diagram 1

Checking Power Supply-System Pressure and Anti-freeze Protection

Page 32

32

Tempra 12 - 18

Flow diagram 2

Checking Central Heating Operation

Wait 2 minutes

Put CH temperature selector

to maximum

Ensure external controls

are calling for heat

Is LED4 flashing?

Does CH pump run?

YES

YES

Go to chart 4

Is relay RY101

switch on

Check and if

necessary replace

main board

NO

Is LED4 flashing?

Check HT4 and DH sensors

before replace main board

YES

NO

Is relay RY100

switch on

NO

YES

Go to chart 3

NO

Check

limit thermostat

YES

Check pump

wiring

connection

NO

Check and if

necessary

replace pump

Check and if is necessary

replace man board

Does fan run?

Is relay RY100 switch ON?

NO

Go to charts 2-3

NO

Is 230V present across

fan terminals?

YES

Check air pressure

switch wiring connection N.O.

NO

Check and if

necessary replace

air pressure switch

NO

Check and if

necessary replace fan

YES

Is air pressure switch

activated?

YES

NO

Check and if

necessary replace

air pressure switch

YES

Differential air pressure

across the air pressure

switch is greater than

1.65 mbar?

Go to chart 6

YES

NO

Check and clean fan

Check flue and air

intake are correct

and clean

Check Venturi and

air pressure switch

tubes are clean

Check restrictor

is correct

Flow diagram 3

Checking the Fan/Flue Gas Circuit

Page 33

33

Tempra 12 - 18

Is LED1 light on?

Does sparking start

at burner?

Does burner light?

YES

Is LED2 on

after 10 seconds?

NO

YES

Go to chart 4

Reset lockout

YES

Does burner light now?

Is flame present before

lockout condition?

NO

YES

NO

Check and if necessary

replace safety thermostat

Check electrodes and

leads for damage

and correct connection

Check and if necessary

replace P.C.B.

Adjust with P4 ignition

burner pressure

Check and if necessary

clean burner

Check and if necessary

clean injectors

Check and if necessary

clean flame electrode

Check right position

of spark electrode

Check wires

Check gas supply

is live and purged

Check and if necessary

replace gas valve

NO

YES

Check and if necessary

replace P.C.B.

NO

Is LED2 on

without

the boiler sparking

YES NO

Re-check

air pressure switch

Does burner

flame modulate?

Normal operation

carry out

YES

NO

Boiler operated

on central heating mode

Check CH sensor

and replace it if necessary

Flow diagram 5

Checking Domestic Hot Water Modulation

Flow diagram 4

Checking Ignition

Page 34

34

Tempra 12 - 18

105 1752595

165

720

12485

400

115

13

36

160

155

36

98

3

5

1

155

12485

110

160

Ø100

Ø60

TOP VIEW

BOTTOM VIEW

16.5

270

98

4. CHARACTERISTICS AND TECHNICAL SPECIFICATIONS

4.1 Dimensions and fittings

fig. 30

Key

1 Central heating outlet

2 Gas inlet

3 Central heating inlet

Page 35

35

Tempra 12 - 18

4.2 Overall view and main components

Key

5 Sealed compartment

7 Gas inlet

10 Central heating outlet

11 Central heating inlet

14 Safety valve

16 Fan

19 Combustion chamber

20 Burner assembly

21 Main nozzle

22 Burner

26 Combustion chamber

insulation

27 Copper heat exchanger

29 Flue gas outlet manifold

32 Central heating pump

34 Central heating

temperature sensor

36 Automatic air vent

43 Air pressure switch

44 Gas valve

49 Safety thermostat

50 Central heating limit

thermostat

56 Expansion vessel

63 Central heating

temperature adjustment

74 Filling cock

81 Ignition electrode

82 Detection electrode

84 1st gas valve operator

85 2nd gas valve operator

98 Off –On - Reset switch

145 Water pressure gauge

0

5

1

2

3

4

6

98 63 145

1177 14 84 8544

32

36

26

19

50

27

16

56

4329

49

28

5

82

8122

20

21

34

fig. 31

Page 36

36

Tempra 12 - 18

0

5

1

2

3

4

6

98 63 145

8

14

81

9

32

56

20

44

7

82

49

34

5

87

27

22

19

29

16

31

50

43

fig. 32

4.3 Hydraulic diagram

Key

5 - Room sealed compartment

7 - Gas supply

8 - Central Heating flow outlet

9 - Central Heating return inlet

14 - Safety valve

16 - Fan

19 - Combustion chamber

20 - Burner box

22 - Burner

27 - Copper heat exchanger

29 - Tube flue outlet

31 - Flue collector

32 - Pump

34 - C.H. flow temperature sensor

43 - Air pressure switch

44 - Gas valve

49 - Overheat cu-off thermostat

50 - Central heating limit thermostat

56 - Expansion vessel

63 - C.H. boiler thermostat

81 - Spark electrode

82 - Rectification electrode

87 - Gas pressure test point

98 - Main switch

145 - Pressure gauges

Page 37

37

Tempra 12 - 18

4.4 Technical data table

Gas supply

Pmax Pmin

Nominal Heat Input (Net)

Nominal Heat Input (Gross)

Nominal Heat Output

Output

Pmax Pmin

kW 12,0 5,0

kW 14,8 6,4

kW 13,3 5,8

Dimensions, weights, fittings

Depth mm 270

Width mm 400

Height mm 720

Hot water capacity litres 0,8

Expansion vessel pre-fill pressure bar 1

Expansion vessel capacity litres 7

Minimum central heating operating pressure bar 0,8

Maximum central heating operating pressure bar 3

Maximum central heating operating temperature °C90

Index of protection IP 44

Power supply

Power supply voltage/frequency V/Hz 230/50

Max Power Absorbed W 125

C.H. return (with isolation valve fitted) 22

C.H. flow (with isolation valve fitted) 22

Gas system fittings (with isolation valve fitted) 22

Weight with packaging kg 30

Central heating

Natural gas rate (G20) nm3/h 1,4 0,6

Table 9

Main injectors, Natural Gas (G20) mm 6 x 1.3

Burner pressure, Natural Gas (G20) mbar 12,5 2,5

Supply pressure, Natural Gas (G20) mbar 20,0

LPG gas rate (G31) kg/h 1,04 0,45

Main injectors, LPG (G31) mm 6 x 0.77

Burner pressure, LPG (G31) mbar 36,0 7,0

Supply pressure, LPG (G31) mbar 37,0

Safety valve bar 3

Pmax Pmin

Pmax Pmin

18,0 7,5

22,1 9,6

19,9 8,6

270

400

720

0,8

1

7

0,8

3

90

44

230/50

125

22

22

22

30

2,1 0,9

9 x 1.3

11,8 2,5

20,0

1,6 0,7

9 x 0.77

36,0 7,0

37,0

3

Tempra 12 Tempra 18

mm

mm

mm

Page 38

38

Tempra 12 - 18

4.5 Diagrams

Pressure - output diagrams

Tempra 12

Tempra 18

kW

mbar

15

16 17 18 19 20

5

10

15

20

25

30

35

678

9 1011121314

5

21 22 23 24 25

G31

(LPG)

G31

(LPG)

G20

(Natural Gas)

G20

(Natural Gas)

Legenda

1 - 2 - 3 = Pump switch positions

A = Boiler pressure drop

Discharge head available to system

fig. 33

m

C.A.

m3/h

0

0,5

1

1,5

2

2,5

3

3,5

4

0,6 0,8 1 1,2 1,4 1,6 1,8 2 2,2 2,4 2,6

4,5

5

5,5

6

2,8 3 3,2 3,4 3,6 3,8 40,40,20

3

2

1

Tempra 12

Tempra 18

fig. 32

Page 39

39

Tempra 12 - 18

4.6 Wiring diagram

fig. 34

X6

X1

X2 X3

X4

12121312345678910 12345678910111213

21

X5

TEST

X12

12

123456789

X10

W

O

V

R

X8

X7

81 82

PMF03F

JP02

JP01

JP03

Nat/LPG

X11

230V 24V

230V

24V

BR

Blue

BR

Blue

BR

Blue

MV1

MV2

MV3

MV4

Blue

BR

Blue

BR

BR

Blue

R

R

BL

BL

Blue

BR

BL

Y/G

Y/G

BL

10 9 8 7 6 5 4 3 2 1

X9

123

LN

Blue

BR

W

W

1112

BL

98

5034

32

44491643

230V24V

103

4

8

12

14

159

13

72

95

155

Key

16 Fan

32 Central heating pump

34 Central heating flow temperature sensor

43 Air pressure switch

44 Gas valve

49 Safety thermostat

50 Central heating limit thermostat

72 External controls (optional)

81 Ignition electrode

82 Sensor electrode

95 Diverting valve (option)

98 Off/On/Reset switch

103 Relay

155 Storage tank sensor

Key

BR Brown

BLUE Blue

BL Black

W White

O Orange

G Green

R Red

V Violet

Y Yellow

IMPORTANT

Heat demand is generated by the closing of the “External Controls”

contact (reference key 72).

If “External Controls” works with a free contact, remove the jumper

between 8 and 11 terminals on the connector block (reference key 72) and

connected the contacts on these terminals.

If “External Controls” fitted 230Vac, remove the jumper between 8 and

11 terminals on the connector block (reference key 72) and connected the

supply line to terminal 8.

Page 40

BENCHMARK

CONTROLS To comply with the Building Regulations, each section must have a tick in one or other of the boxes

TIME & TEMPERATURE CONTROL TO HEATING ROOM T/STAT & PROGRAMMER/TIMER PROGRAMMABLE ROOMSTAT

TIME & TEMPERATURE CONTROL TO HOT WATER CYLINDER T/STAT & PROGRAMMER/TIMER

COMBI BOILER

HEATING ZONE VALVES FITTED NOT REQUIRED

HOT WATER ZONE VALVES FITTED NOT REQUIRED

THERMOSTATIC RADIATOR VALVES FITTED

AUTOMATIC BYPASS TO SYSTEM FITTED NOT REQUIRED

FOR ALL BOILERS CONFIRM THE FOLLOWING

THE SYSTEM HAS BEEN FLUSHED IN ACCORDANCE WITH THE BOILER MANUFACTURER’S INSTRUCTIONS?

THE SYSTEM CLEANER USED

THE INHIBITOR USED

FOR THE CENTRAL HEATING MODE, MEASURE & RECORD

GAS RATE ft3/hr

BURNER OPERATING PRESSURE (IF APPLICABLE) mbar

CENTRAL HEATING FLOW TEMPERATURE °C

CENTRAL HEATING RETURN TEMPERATURE °C

FOR COMBINATION BOILERS ONLY

HAS A WATER SCALE REDUCER BEEN FITTED? YES NO

WHAT TYPE OF SCALE REDUCER HAS BEEN FITTED?

FOR THE DOMESTIC HOT WATER MODE, MEASURE & RECORD

GAS RATE ft3/hr

MAXIMUM BURNER OPERATING PRESSURE (IF APPLICABLE) mbar

COLD WATER INLET TEMPERATURE °C

HOT WATER OUTLET TEMPERATURE °C

WATER FLOW RATE

lts/min

FOR CONDENSING BOILERS ONLY CONFIRM THE FOLLOWING

THE CONDENSATE DRAIN HAS BEEN INSTALLED IN ACCORDANCE WITH

THE MANUFACTURER’S INSTRUCTIONS? YES

FOR ALL INSTALLATIONS CONFIRM THE FOLLOWING

THE HEATING AND HOT WATER SYSTEM COMPLIES

WITH CURRENT BUILDING REGULATIONS

THE APPLIANCE AND ASSOCIATED EQUIPMENT HAS BEEN INSTALLED AND COMMISSIONED

IN ACCORDANCE WITH THE MANUFACTURER’S INSTRUCTIONS

IF REQUIRED BY THE MANUFACTURER, HAVE YOU RECORDED A CO/CO2 RATIO READING? N/A YES CO/CO2 RATIO

THE OPERATION OF THE APPLIANCE AND SYSTEM

CONTROLS HAVE BEEN DEMONSTRATED TO THE CUSTOMER

THE MANUFACTURER’S LITERATURE HAS BEEN LEFT WITH THE CUSTOMER

m3/hr

m3/hr

COMMISSIONING ENG’S NAME PRINT CORGI ID No.

SIGN DATE

BOILER SERIAL No. NOTIFICATION No.

BENCHMARK No.

GAS BOILER COMMISSIONING CHECKLIST

COLLECTIVE MARK

N/A

N/A

267

Please add the first 4 digits of the Boiler serial No to complete the BENCHMARK No.

Page 41

SERVICE INTERVAL RECORD

It is recommended that your heating system is serviced regularly

and that you complete the appropriate Service Interval Record Below.

Service Provider. Before completing the appropriate Service Interval Record below, please ensure you have carried out the service