Page 1

i migliori gradi centigradi

MONITORING SYSTEM

FOR SERIES:

• RHV R134a

• RHV R407C BTZ

• RVW

• RLA

• RHA

INSTRUCTION MANUAL

Page 2

2

The manufacturer declines all responsibility for any inaccuracies in this manual due to printing or typing errors.

The manufacturer reserves the right to make changes and improvements to products in the catalog at any time and without notice.

Page 3

3

TABLE OF CONTENTS

MONITORING SYSTEM - User interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

FUNCTION BUTTONS “F1”, “F2”, “F3”, “F4” AND “ON/OFF” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

JOYSTICK BUTTON: “MENU”

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

LED STATUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

MONITORING SYSTEM - User menù . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

COOLING MODE IR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

HEATING MODE IP (reversible refrigerant side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

HEATING MODE IW (reversible water side) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

HEAT RECOVERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

MONITORING SYSTEM - User setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CONTROL PANEL UNIT ON/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

REMOTE OFF BY DIGITAL INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

CHANGE OPERATING MODE (hot / cooling) BY CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

CHANGE OPERATING MODE (SUMMER / WINTER) BY DIGITAL INPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

SETTING THE OPERATING SET POINT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

TERMOREGULATION TIME PROPORTIONAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

HEAT RECOVERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

IHEAT RECOVERY SETTING THE PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

STATE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

DATE AND TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

TIME SCHEDULING MANAGEMENT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

MONITORING SYSTEM - Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

BIOS ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

USER ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

AUTOMATIC ALARMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

ALARMS HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

DISPLAYING THE ALARMS HISTORY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Page 4

4

Page 5

MONITORING SYSTEM - User interface

CONTROL PANEL

The control panel is composed of the instrument’s front panel, equipped with an LCD display, three indicator LEDs, and one joystick buttons and three function button, it enables viewing and/or checking the operating mode and parameters, resources and

complete alarm diagnostics.

In particular, it enables:

• Managing alarm situations

• Checking the status of resources.

KEY

1.Display

2. Alarms LED

3. LED for communication between the motherboard and the keypad

4. Power supply LED

5. Joystick Menu Buttons

6. Function Buttons

On pressing any of the buttons the display will light up for a few seconds; without pressing any of the buttons, the display will go

out after a few seconds. When switching on, the instrument will go into the state saved at the last machine shutdown or stand-by.

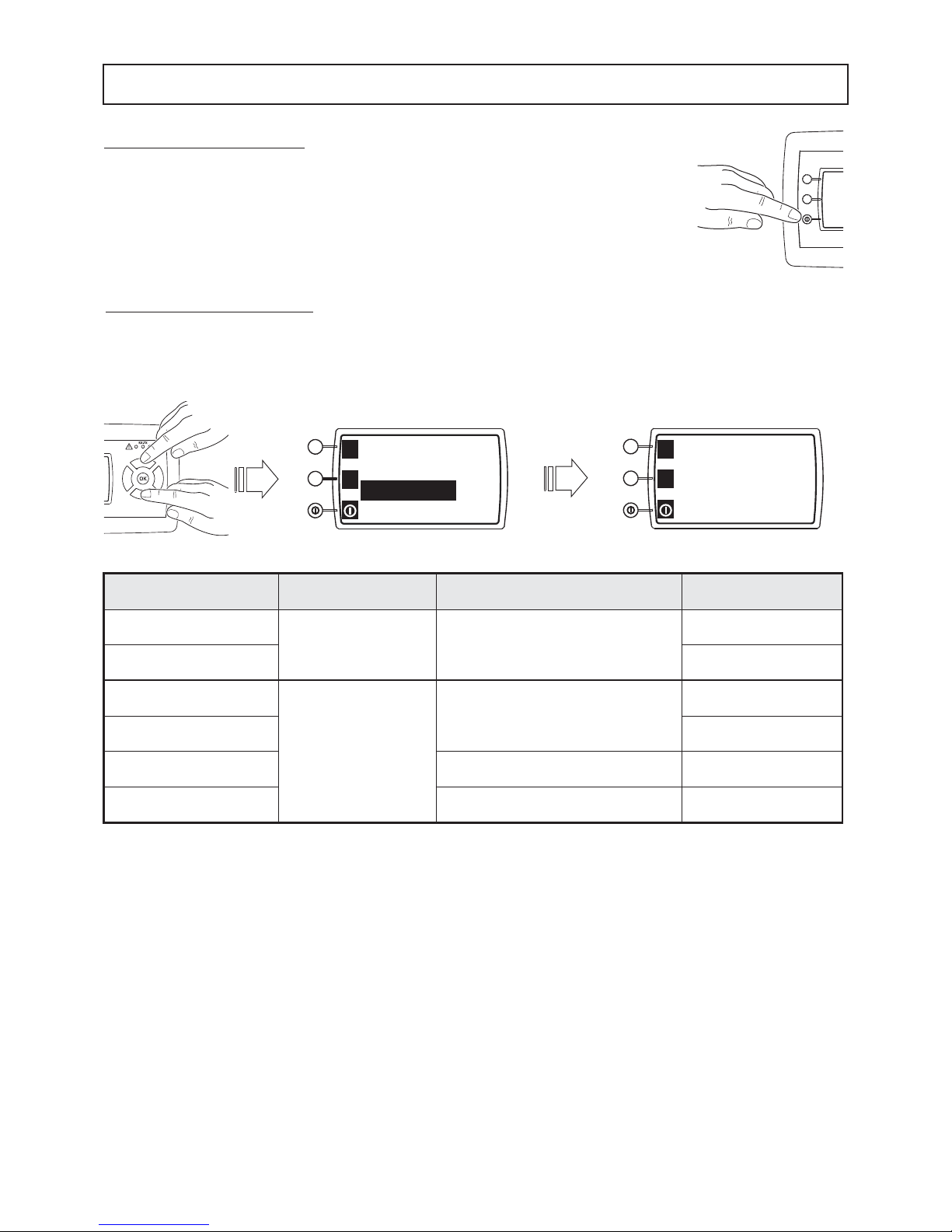

FUNCTION BUTTONS “F1”, “F2”, “F3”, “F4” AND “ON/OFF”

On the left of the keyboard there are 3 buttons whose function is shows on the

left of the LCD.

At POWER ON the LCD display shows the F1 (up), F2 (middle) and ON/OFF

(down) functions.

• By a single pressure of ON/OFF button: the keyboard displaying change:

F1 became F3 (up button) and F2 became F4 (middle button). The ON/OFF

(down) button doesn’t change.

By a new pressure on ON/OFF button, the keyboard displaying change and

show the previous situation:

F1, F2 and ON/OFF.

• BY PUSHING FOR SOME SECONDS THE ON/OFF BUTTON:

THE MACHINE ON-OFF (ON-OFF)

Using the buttons, the function of which is shown on the display, you can directly access main functions:

• Pressing a single time: shows the ma

in menu on the display.

• Pressing for a few seconds: directly access the menu associated with that

particular position.

KEY F1 : show the INPUTS and OUTPUTS resources of system control.

KEY F2 :

show the PARAMETER submenu (for the service only, with password).

KEY F3 : show the ALARMS submenu.

KEY F4 : show the COMPRESSOR submenu.

CAUTION: IF THE ALARM SIGNAL “RTC” (REAL TIME CLOCK) APPEARS WHEN STARTING FOR THE FIRST TIME, SET

THE DATE AND TIME IN THE RESPECTIVE “DATE AND TIME” MENU.

1234

5

6

17:25 01/03

Cool

Water IN 12.0°C

Water OUT 7.0°C

F1

F2

5

F1

F2

F3

F4

Page 6

LED STATUS

LEDs ( )

The first LED (green) indicates there is supply voltage:

• LED ON means that the controller is powered

• LED OFF means that the controller is not powered

LED (RX-TX)

The second LED (amber) indicates there is communication between the controller and the keypad:

• ON when there is communication

• OFF when there is no communication

LED ( )

The third LED (red) indicates there are alarms:

• ON if there is at least one active alarm

• OFF if there are no active alarms

• BLINKING if there are alarms that have ended but have not yet been manually reset.

• BLINKING without alarms to indicate that:

- function HPP (High Pressure Prevention) is active (RHV - RVW units)

- function ATC (Advanced Temperature Control) is active (RLA - LFL unit)

- function PRE-ALARM HIGH PRESSURE is active (RLA - LFL unit)

- function PRE-ALARM LOW PRESSURE is active (RLA - LFL unit).

The alarm reset procedure is explained in paragraph MONITORING SYSTEM - ALARMS

6

• Position UP: scrolls through the menu

items upwards or increases the value of a

parameter.

• Position DOWN: scrolls through the

menu items downwards or decreases the

value of a parameter.

• Position LEFT (ESC): returns to the

previous menu.

• Position RIGHT: moves into the sub-

menu, confirms an action, enters editing a value or again confirms a changed

value.

N.B. PRESSING THE (ENTER) BUTTON IN THE MIDDLE CONFIRMS THE COMMAND OR

ACCESSES THE DISPLAYED MENU.

JOYSTICK BUTTON: “MENU”

Used to scroll through the menus by acting on the four positions (UP; DOWN; LEFT; RIGHT) pressing a single time; in particular:

MONITORING SYSTEM - User interface

Page 7

7

When the unit switches on, the display shows the first page of the main screen.

On the top line there is the current time (17:25) and the page no. (1/4 comprising

the screen.

-

“Standby” indicate the state of operation of the unit (Standby, cooling, shutdown).

- “Water IN” indicate the temperature of inlet evaporator.

- “Water OUT” indicate the temperature of the outlet evaporator.

Pressing the DOWN button takes you to page 02/04

- “Power” show the power output from the unit.

- “Set Point 1” the set point adjustment.

- “Band 1” the band adjustment

By using the UP/DOWN-ENTER buttons to select the Set point 1 and/or Band 1 line,

it is possible to change the adjustment settings.

17:25 01/04

Standby

Water IN

12.0°C

Water OUT

7.0°C

02/04

Power 70%

Set Point 1

7.0°C

Band 1 1.0°C

03/04

Real Set 7.0°C

REM OFF enable

NO

Menu

04/04

Reserved menu

COOLING MODE IR

Pressing the DOWN button takes you to page 03/04.

- “Real Set” indicate the current point of adjustment.

- “REM OFF enable” enable switch off the unit via digital input. This function has

priority over keypad commands. On the RH side of the display YES/NO appears

depending on the enabling of Remote OFF.

- “Menu” indicate the access point to the user menu. Pressing Enter, with the

UP/DOWN buttons it is possible to access the following pages (see the table).

Pressing the DOWN button takes you to page 04/04.

-“Reserved menu” is reserved for the support service.

DISPLAY DESCRIPTION

Page 1 of 3

Inputs and outputs

Displays the status and values of the digital and analog inputs/outputs

Alarms Used to see and/or reset the status of the alarms

Date and time Used to set the current date and time

Page 2 of 3

Pumps Used to see the activation status of the pumps

Circuits Used to see the activation status of the circuits

Compressors Used to see the activation status of the compressors

Page 3 of 3

Condenser

(water condenser)

Fans

(air condenser)

Used to see the state of condensation control

Used to see the state of fans control

Time scheduling Used to set the operating time scheduling

Language selection Used to select the language (english by default)

MENU 01/03

Inputs and outputs

alarms

Date and time

MENU 02/03

Pumps

Circuits

Compressor

MENU 03/03

Condenser / Fans

Time scheduling

Language selection

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

MONITORING SYSTEM - User menù

Page 8

8

When the unit switches on, the display shows the 4 page of the main screen

On the top line there is the current time (17:25) and the page no. (1/4 comprising the

screen.

- “Standby” indicate the state of operation of the unit (standby, cooling, hot, shutdown).

- “Water IN” indicate the temperature of inlet evaporator.

- “Water OUT” indicate the temperature of the outlet evaporator.

Pressing the DOWN button takes you to page 02/04

- “Power” indicate the power delivered by the unit.

- “Set Point 1” the set point adjustment.

- “Band 1”, the band of

adjustment

.

By using the UP/DOWN-ENTER buttons to select the Set point 1 it is possible to

change the adjustment settings.

17:25 01/04

Standby

Water IN

40.0°C

Water OUT

45.0°C

02/04

Power 70%

Set Point 1

45.0°C

Band 1 1.0°C

03/04

Local mode Hot

Real Set 45.0°C

REM S/W enable NO

04/04

REM OFF enable

NO

Menu

Reserved menu

HEATING MODE IP (reversible refrigerant side)

Pressing the DOWN button takes you to page 03/04.

- “Local mode”, selection of the mode of operation by control panel.

- “Real Set”, indicate the current point of adjustment.

- “

REM S/W enable” enable mode change of the unit via digital input. This func-

tion has priority over keypad commands. On the RH side of the display YES/NO

appears depending on the enabling of REM S/W.

By using the UP/DOWN-ENTER buttons to select the

“Local mode” it is possible

to change the Mode of operation (HOT-COOLING

) of unit.

Pressing the DOWN button takes you to page 04/04.

- “REM OFF enable” enable switch off the unit via digital input. This function has

priority over keypad commands. On the RH side of the display YES/NO appears

depending on the enabling of REM OFF.

- “Menu” indicate the access point to the user menu. Pressing Enter, with the

UP/DOWN buttons it is possible to access the following pages (see the table).

-“Reserved menu” is reserved for the support service.

DISPLAY DESCRIPTION

Page 1 of 3

Inputs and outputs

Displays the status and values of the digital and analog inputs/outputs

Alarms Used to see and/or reset the status of the alarms

Date and time Used to set the current date and time

Page 2 of 3

Pumps Used to see the activation status of the pumps

Circuits Used to see the activation status of the circuits

Compressors Used to see the activation status of the compressors

Page 3 of 3

Fans Used to see the state of fans control

Time scheduling Used to set the operating time scheduling

Language selection Used to select the language (english by default)

MENU 01/03

Inputs and outputs

alarms

Date and time

MENU 02/03

Pumps

Circuits

Compressor

MENU 03/03

Fans

Time scheduling

Language selection

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

MONITORING SYSTEM - User menù

Page 9

9

When the unit switches on, the display shows the first page of the main screen

On the top line there is the current time (17:25) and the page no. (1/5 comprising the

screen.

-

“Standby” indicate the state of operation of the unit (Standby, cooling, hot, shutdown).

- “Water IN” indicate the temperature of inlet evaporator.

- “Water OUT” indicate the temperature of the outlet evaporator.

Pressing the DOWN button takes you to page 02/05

- “Cond. Out” indicate the temperature of the outlet condenser.

- “Power” show the power output from the unit.

- “Set Point 1” the set point adjustment.

By using the UP/DOWN-ENTER buttons to select the Set point 1 it is possible to

change the adjustment settings.

17:25 01/05

Standby

Water IN

12.0°C

Water OUT

7.0°C

02/05

Cond. Out 42.0°C

Power 70%

Set Point 1

7.0°C

03/05

Band 1 1.0°C

Local mode Hot

Real Set 45.0°C

04/05

REM S/W enable NO

REM OFF enable

NO

Menu

05/05

Reserved menu

HEATING MODE IW (reversible water side)

Pressing the DOWN button takes you to page 03/05.

- “Band 1”, the band 1 of adjustment.

- “Local mode”, selection of the mode of operation by control panel.

- “Real Set”, indicate the current point of adjustment.

By using the UP/DOWN-ENTER buttons to select the

“Band 1” it is possible to

change the band regolation.

By using the UP/DOWN-ENTER buttons to select the

“Local mode” it is possible

to change the Mode of operation (HOT-COOLING

) of unit.

Pressing the DOWN button takes you to page 04/05.

- “

REM S/W enable” enable mode change of the unit via digital input. This func-

tion has priority over keypad commands. On the RH side of the display YES/NO

appears depending on the enabling of REM S/W.

- “REM OFF enable” enable switch off the unit via digital input. This function has

priority over keypad commands. On the RH side of the display YES/NO appears

depending on the enabling of REM OFF .

- “Menu” indicate the access point to the user menu. Pressing Enter, with the

UP/DOWN buttons it is possible to access the following pages (see the table).

DISPLAY DESCRIPTION

Page 1 of 3

Inputs and outputs

Displays the status and values of the digital and analog inputs/outputs

Alarms Used to see and/or reset the status of the alarms

Date and time Used to set the current date and time

Page 2 of 3

Pumps Used to see the activation status of the pumps

Circuits Used to see the activation status of the circuits

Compressors Used to see the activation status of the compressors

Page 3 of 3

Condenser Used to see the state of condensation control

Time scheduling Used to set the operating time scheduling

Language selection Used to select the language (english by default)

MENU 01/03

Inputs and outputs

alarms

Date and time

MENU 02/03

Pumps

Circuits

Compressor

MENU 03/03

Condenser

Time scheduling

Language selection

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

MONITORING SYSTEM - User menù

Pressing the DOWN button takes you to page 05/05.

-“Reserved menu” is reserved for the support service.

Page 10

10

DISPLAY DESCRIPTION

Page 1 di 4

Inputs and outputs

Displays the status and values of the digital and analog inputs/outputs

Alarms Used to see and/or reset the status of the alarms

Date and time Used to set the current date and time

Page 2 di 4

Pumps Used to see the activation status of the pumps

Circuits Used to see the activation status of the circuits

Compressors Used to see the activation status of the compressors

Page 3 di 4

Condenser Used to see the state of condensation control

Heat Recovery Used to see the state of heat recovery

Time scheduling Used to set the operating time scheduling

Page 4 di 4

Language selection Used to select the language (english by default)

When the unit switches on, the display shows the first page of the main screen

On the top line there is the current time (17:25) and the page no. (1/4 comprising

the screen.

- “Standby” indicate the state of operation of the unit (standby, cooling, shutdown).

- “Water IN” indicate the temperature of inlet evaporator.

- “Water OUT” indicate the temperature of the outlet evaporator.

Pressing the DOWN button takes you to page 02/04

- “Power” show the power output from the unit.

- “Set Point 1” the set point adjustment.

- “Band 1” the band adjustment.

By using the UP/DOWN-ENTER buttons to select the Set point 1 and/or Band 1

line, it is possible to change the adjustment settings.

17:25 01/04

Standby

Water IN

12.0°C

Water OUT

7.0°C

02/04

Power 70%

Set Point 1

7.0°C

Band 1 1.0°C

03/04

Real Set 7.0°C

Recovery

41.0°C

REM OFF enable

NO

04/04

Menu

Reserved menu

HEAT RECOVERY

Pressing the DOWN button takes you to page 03/04.

- “Real Set” indicate the current point of adjustment.

- “Recovery” indicate the inlet heat recovery temperature.

- “REM OFF enable” enable switch off the unit via digital input. This function has

priority over keypad commands. On the RH side of the display YES/NO appears

depending on the enabling of REM OFF .

Pressing the DOWN button takes you to page 04/04.

- “Menu” indicate the access point to the user menu. Pressing Enter, with the

UP/DOWN buttons it is possible to access the following pages (see the table).

-“Reserved menu” is reserved for the support service.

MENU 01/03

Inputs and outputs

Alarms

Date and time

MENU 02/03

Pumps

Circuits

Compressor

MENU 03/04

Condenser

Heat Recovery

Time scheduling

MENU 04/04

Language selection

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

F1

F2

MONITORING SYSTEM - User menù

Page 11

11

REM. ON/OFF ENABLE

YES

F1

F2

Real Set 7.0°C

REM OFF enable

NO

Menu

F1

F2

REMOTE OFF BY DIGITAL INPUT

To activate this function, select REM OFF enable from the main screen and with the joystick-menu buttons set YES.

NOTE: IF YOU ENABLE REM OFF BY DIGITAL INPUT WHILE THE UNIT IS ON, THE UNIT COULD SWITCH OFF IF THE

1_On/OffRem REMOTE DIGITAL INPUT IS OPEN.

MONITORING SYSTEM - User setting

CONTROL PANEL UNIT ON/OFF

To switch the machine on and off, press the “on/off” function button for a few seconds.

Unit ON-OFF

by control panel

REM OFF enable digital input: 1_On/Off REM Unit status

on

No

The unit status

not depends by digital input

on

off off

on

Yes

CLOSE (off)

on

off off

on OPEN (on) off

off

The unit status

not depends by digital input

off

Page 12

12

MONITORING SYSTEM - User menù

RECOMMENDED SETTINGS : to configure correctly the function ON / OFF from digital input, follow the following guidelines :

CAUTION : THESE OPERATIONS MUST BE PERFORMED BY QUALIFIED PERSONNEL.

- Sure that the parameter REM OFF Enable is set to NO (figura 1).

- Turn off the unit from the control panel and wait until it is displayed the writing Standby.

- Remove power to the electrical panel by bringing the door lock switch in position “0”.

- connect the remote contact to the user terminal within the electrical panel and make sure that contact is closed.

(ref. Electrical schematic of the unit).

- Close the electrical panel.

- Apply power to the electrical panel by bringing the door lock switch in position "1".

- Press the ON / OFF button on the control panel to turn on the machine.

At this point the machine is turned on and is ready to turn the compressors to meet the set-point set.

- Set the parameter REM OFF enable at YES. In this way, digital off contact is enabled.

Opening the contact On/Off REM the unit before shutting down and then in standby.

F1

F2

Real set 7.0°C

REM S/W enable

NO

REM OFF enable

NO

17:25 01/04

Standby

Water IN 12.0°C

Water OUT 7.0°C

F1

F2

17:25 01/04

Standby

Water IN 12.0°C

Water OUT 7.0°C

F1

F2

17:25 01/04

Cooling

Water IN 12.0°C

Water OUT 7.0°C

F1

F2

REM ON/OFF ENABLE

YES

F1

F2

Real Set 7.0°C

REM OFF enable

NO

Menu

F1

F2

Page 13

13

MONITORING SYSTEM - User setting

REMOTE S/W ENABLE

YES

F1

F2

Real Set 7.0°C

REM

S/W enable

NO

REM OFF enable

NO

F1

F2

CHANGE OPERATING MODE (SUMMER / WINTER) BY DIGITAL INPUT

To activate this function, select REM S/W enable from the main screen and with the joystick-menu buttons set YES.

NOTE: IF YOU ENABLE REM S/W WHILE THE UNIT IS TURNED ON, THE UNIT COULD SWITCH OFF AND CHANGE THE

MODE OF OPERATION IF THE DIGITAL INPUT REM S/W IS OPEN.

LOCAL S/W MODE

COOLING

F1

F2

Set point 1 7.0°C

Band 1

1.0°C

Local mode

COOLING

F1

F2

CHANGE OPERATING MODE (hot / cooling) BY CONTROL PANEL

To change the operation mode (hot / cooling) by control panel, select LOCAL MODE from the main screen.

NOTE: THE CHANGE, OF THE OPERATION MODE BY CONTROL PANEL HAS A PRIORITY MORE LOW COMPARED TO

CHANGE THE OPERATION MODE BY DIGITAL INPUT: IF THE DIGITAL INPUTS S/W REM IS OPEN THE UNIT WORK IN

HEAT PUMP REGARDLESS TO CHANGE OPERATING MODE BY CONTROL PANEL.

THE CHANGE OPERATING MODE FROM DIGITAL INPUT HAS PRIORITIES IN RELATION TO CHANGE OPERATING

MODE FROM KEYBOARD: IF THE DIGITAL INPUTS S/W REM IS OPEN THE UNIT WORK IN HEAT PUMP REGARDLESS

TO CHANGE OPERATING MODE FROM KEYBOARD.

Local mode

by control panel

REM S/W enable digital input: 14_S/W REM

Mode of operation

of unit

Cooling

NO

the mode of operation of unit,

not depends by digital input

Cooling

Hot Hot

Cooling

YES CLOSE (off) Cooling

Hot

Cooling

YES OPEN (on) Hot

Hot

Page 14

14

MONITORING SYSTEM - User menù

RECOMMENDED SETTINGS : to properly configure the change mode of operation by digital input, try the following:

CAUTION: THESE OPERATIONS MUST BE PERFORMED BY QUALIFIED PERSONNEL

-Sure that the parameter REM S/W Enable is set to NO.

-Turn off the unit from the control panel and wait until it is displayed the writing Standby.

-Remove power to the board by bringing the door lock switch in position "0".

- Connect the remote contact (summer / winter) to the user terminal within the electrical panel and make sure that contact

is close. (Electrical schematic of the unit).

- Close the electrical panel.

- Apply power to the electrical panel by bringing the door lock switch in position "1"

- Wait for the main page on the control panel.

- Set the local mode of operation at Cooling.

-Set the parameter REM S/W Enable at YES.

(Note: If you set REM S/W Enable = YES and the remote contact Summer / Winter is

- CLOSED (off): the unit is ready for operation at cooling mode

- OPEN (on): 4-way valves immediately reverse cycle-switching

and the unit will be ready for operation at heat-pump mode)

TO PRESS THE ON/OFF BUTTON ON THE CONTROL PANEL, THE UNIT AUTOMATICALLY BEGINS TO OPERATE IN A

MODE ESTABLISHED BY REM S/W DIGITAL CONTACT.

F1

F2

Real set 7.0°C

REM S/W enable

NO

REM OFF enable

NO

17:25 01/04

Standby

Water IN 12.0°C

Water OUT 7.0°C

F1

F2

F1

F2

03/04

Local mode

Cooling

Real set

45.0°C

REM S/W enable

NO

F1

F2

03/04

Local mode

Cooling

Real set

45.0°C

REM S/W enable

YES

Page 15

15

MONITORING SYSTEM - User setting

SETTING THE OPERATING SET POINT

From the main screen, press the “Up” and “Down” buttons to access Set Point 1 and press ENTER: the “Setpoint 1 chiller

mode” screen will appear. Press ENTER to make the temperature value 7.0°C blink and change it with the “Up” and “Down”

buttons as required. Press ENTER to confirm.

To return to the main screen, press the

LEFT (ESC)

LEFT (ESC) button several times:

Power 70%

Set Point 1 7.0°C

Band 1 1.0°C

CH SET 1 01/01

Setpoint 1

chiller mode

7.0°C

F1

F2

F1

F2

To modify the Band 1 proceed in a similar manner to the one described for setting the operating SET POINT.

IMPORTANT NOTE:

In “time proportional regulation” is reccomended to keep the band=1°C.

Page 16

16

TICP: Chiller INC power time (TIME INCREASING COOLING POWER)

TDCP:

Chiller DEC power time (TIME DECREASING COOLING POWER)

CB: COOLING BAND

SET POINT: SET POINT TEMPERATURE IN COOLING

The function of the regulator consists in activating a number of resources (power step) in proportion to the time that the evaporator water outlet by spends beyond the threshold given by CHILLER SETPOINT + (BAND / 2). The band is symmetric with

respect to the value of CHILLER SETPOINT.

When the temperature has exceeded the threshold value for the duration of the parameter CHILLER INC POWER TIME, activate a power step. If the temperature of evaporator water outlet by remains above the threshold value for further TEMPO

POWER INCREASE IN COLD, is another power step.

If the temperature of evaporator water outlet by remain within the temperature range determined by CHILLER SETPOINT +

(BAND / 2) and CHILLER SETPOINT - (BAND / 2) the power output from the machine remains constant.

If the temperature of evaporator water outlet by remains below the threshold CHILLER SETPOINT - (BAND / 2) for the time

given by the parameter CHILLER DEC POWER TIME is a step off power.

In this algorithm there is no hysteresis.

TERMOREGULATION TIME PROPORTIONAL

COOLING MODE (IR)

MONITORING SYSTEM - User setting

TEMPERATURE

WATER OUTLET

TIPF TIPF

+1 +1 +1-1 -1 -1

TDPF TDPF TDPF

TIME

Set

Point

CB

TEMPERATURE READ BY

EVAPORATOR

WATER OUTLET PROBE

CHILLER setpoint

+(BAND / 2).

CHILLER setpoint

- (BAND / 2).

TICP

TDCP

TDCP

TDCP

TICP

Page 17

17

HEATING MODE (IP / IW)

MONITORING SYSTEM - User setting

The function of the regulator consists in activating a number of resources (power step) in proportion to the time that the evaporator water outlet by spends below the threshold given by HEAT PUMP SETPOINT - (BAND / 2). The band is symmetric with

respect to the value of HEAT PUMP SETPOINT.

When the temperature remains below the threshold value for the duration of the parameter HEAT PUMP INC POWER TIME,

activate a power step. If the temperature of evaporator water outlet by remains below the threshold value for further HEAT PUMP

INC POWER TIME, is another power step.

If the temperature of evaporator water outlet by remain within the temperature range determined by HEAT PUMP SETPOINT +

(BAND / 2) and HEAT PUMP SETPOINT - (BAND / 2) the power output from the machine remains constant.

If the temperature of evaporator water outlet by remains above the threshold HEAT PUMP SETPOINT + (BAND / 2) for the time

given by the parameter HEAT PUMP DEC POWER TIME is a step off power.

In this algorithm there is no hysteresis.

+1 +1 +1-1 -1 -1

TIHP: Chiller INC power time (TIME INCREASING HEATING POWER)

TDHP:

Chiller DEC power time (TIME DECREASING HEATING POWER)

HB: HEATING BAND

SET POINT: SET POINT TEMPERATURE IN HEATING

TEMPERATURE

WATER OUTLET

TIME

Set

Point

HB

HEATPUMP setpoint

+ (BAND / 2).

HEATPUMP setpoint

- (BAND / 2).

TEMPERATURE READ BY

CONDENSER

WATER OUTLET PROBE

TDHP

TIHP

TIHP TIHP

TDHP

Page 18

18

HEAT RECOVERY

The recovery function heats water using heat from the condenser that otherwise would be dispersed in the environment:

- In air (air-water units)

- In water (water-water units)

When the machine is in cooling mode (compressors on), if the water in the recovery circuit is of a sufficiently low temperature

to require heat, the machine switches from normal to recovery mode.

When the water temperature reaches the recovery set point, the machine switches back to normal operating mode.

Switching from normal operation to heat recovery and vice versa, takes place:

- respecting the minimum time of operation set for the two modes

- minimize compressor power (screw compressor).

MONITORING SYSTEM - User setting

- AIR-WATER UNIT WATER-WATER UNIT

PARTIAL HEAT

RECOVERY

VP

Units in water-water condensation is unique

for all circuits refrigerator and heat recovery

is always TOTAL.

TOTAL HEAT

RECOVERY

VR

OFF

ON

T

BANDA PROP.

SET

SET - recovery set-point PROP. BAND - proportional band T: Temperature measured by sensor at recovery water inlet

OFF

ON2

ON1

BANDA PROP.

SET

T

OFF

ON

T

BANDA PROP.

SET

PROP. BAND

PROP. BAND

PROP. BAND

Page 19

19

ENABLE

Serves to enable the Recovery function.

Using the MENU joystick buttons, select ENABLE .

RECOVERY

01/02

ENABLE YES

SETPOINT

41.0°C

PROP BAND

2.0°C

F1

F2

RECOVERY ENABLE

YES

F1

F2

To change the YES/NO status, press “Enter” twice:

the value YES will start flashing

- change the value as required using the “Up/Down”buttons.

After changing the value, press “Enter” to confirm and then press “Left” to exit.

SET-POINT

Using the MENU joystick buttons, select the SET POINT parameter.

This parameter is set by default to 41.0 °C.

RECOVERY

01/02

ENABLE YES

SETPOINT

41.0°C

PROP BAND

2.0°C

F1

F2

RECOVERY SETPOINT

41.0°C

F1

F2

To change this set-point value, press “Enter” twice:

the value 41.0 ºC will start flashing

- change the set-point value as required using the “Up/Down” buttons.

After changing the value, press “Enter” to confirm and then press “Left” to exit.

MONITORING SYSTEM - User setting

HEAT RECOVERY SETTING THE PARAMETERS

To access the operating parameters for heat Recovery mode, bring on the start screen, scroll through the pages to select the

"Recovery" and press ENTER.

The following items will appear on the display:

•

ENABLE

•

SET-POINT

• PROP. BAND

•

REMOTE

17:25

Off

Water IN 12.0°C

Water OUT 7.0°C

Working Set 7.0°C

Recovery

40.0°C

REM ON-OFF

YES

F1

F2

RECOVERY

01/02

ENABLE YES

SETPOINT

41.0°C

PROP BAND

2.0°C

F1

F2

RECOVERY

02/02

REMOTE YES

F1

F2

F1

F2

Page 20

20

PROP. BAND

Using the MENU joystick buttons, select the PROP. BAND parameter.

This parameter is set by default to 2.0 °C.

RECOVERY

02/02

REMOTE YES

F1

F2

RECOVERY

01/02

ENABLE YES

SETPOINT

41.0°C

PROP BAND

2.0°C

F1

F2

RECOVERY

01/02

ENABLE YES

SETPOINT

41.0°C

PROP BAND

2.0°C

F1

F2

RECOVERY PROP BAND

2.0°C

F1

F2

REM RECOVERY ENABLE

YES

F1

F2

To change this set-point value, press “Enter” twice:

the value 2.0 °C will start flashing

- change the value as required using the “Up/Down”buttons.

After changing the value, press “Enter” to confirm and then press “Left” to exit.

REMOTE

Allows the Recovery function to be enabled from a remote digital input.

Using the MENU joystick buttons, select the REMOTE parameter.

To change the YES/NO status press “Enter”twice:

the value will start flashing

- change the value as required using the “Up/Down”buttons.

After changing the value, press “Enter” to confirm and then press “Left” to exit.

MONITORING SYSTEM - User setting

Page 21

21

STATE OF OPERATION

To know the machine’s operating status, scroll through the main menu down to the bottom and select “menu”, then press “Enter”.

03/04

Real Set 7.0°C

REM OFF enable

NO

Menu

F1

F2

Use the Up and Down buttons to scroll through the menu to display the items:

Under “Inputs and outputs”, there will be the state of the physical inputs of the control

system:

• Analog inputs (temperature probes, pressure transducers)

• Digital inputs (thermal protection, protection water flow, input of control)

• Analog outputs (signals to control fans)

• Digital outputs (relay control)

Under “alarms”, there will be the information needed to verify alarms and reset the unit:

• bios alarms

• user alarms

• automatic alarms

• history

• reset alarms

Under “date and time”,there will be the information for setting the time and date.

Under “Pumps”, there will be a list of the machine’s pumps and for each one of them:

• Operating status

• Days of operation

• Hours of operation

• Pump enable

Under “Circuits” there will be a list of the machine’s circuits and, for each one of them, there will be displayed:

• The compressor suction pressure read by the low-pressure transducer (if present)

• The compressor discharge pressure read by the high-pressure transducer (if present)

• The current operating status (alarm or power)

• The power of the circuits

• Condensation temperature

• The HPP’s status - High Pressure Prevention (only RHV / WSH / RVW unit)

• The ATC’s status - Advanced Temperature Control (only RLA / LFL / WRL unit)

MONITORING SYSTEM - User setting

MENU

Inputs and outputs

Alarms

Date and time

MENU

Pumps

Circuits

Compressors

MENU

Condenser

Fans

Heat recovery

F1

F2

F1

F2

F1

F2

MENU

Time scheduling

Language selection

F1

F2

Page 22

22

MONITORING SYSTEM - User setting

Under “Compressor” there will be a list of the machine’s compressors and, for each one of them, there will be displayed:

• The current state of operation (power or alarm)

• Power output expressed as a %

• Compressor discharge temperature

• Hours of operation

• Days of operation

• Compressor enable

Under “Condenser” there will be the percente of condensing control (water-water unit).

Under "Fans" will list the bench and fans for each of them, will be displayed:

• speed of operation, expressed in %

Under the heading "Heat Recovery" will list the condensers for the heat recovery and for each of them, will be displayed:

• recovery enable

• the power expressed in %

• input temperature

Under "time scheduling", will be settings for configuring the time scheduling.

Under "Language Selection", gives us the opportunity to change the user menu language:

- 0 = italian

- 1 = english

Page 23

23

TIME SCHEDULING MANAGEMENT

The control panel allows you to program the time scheduling of the unit.

PREMISE:

For the correct working of the time scheduling is necessary to set up current day and hour

Time scheduling setup can be done by logging on to the submenu. :

DATE AND TIME

The “Date and time” menu is used to set the date and time on the instrument.

To set the date and time, go to the “Date and time” menu with the joystick-Menu buttons.

MONITORING SYSTEM - User setting

03/04

Real Set

7.0°C

REM OFF enable

NO

Menu

F1

F2

MENU 01/03

Inputs and outputs

Alarms

Date and time

F1

F2

DATE & TIME 01/01

12/02/09 15:35

Date Modify

Hour Modify

F1

F2

TIMER TYPE = 0: “Time scheduling Daily”: With this timer type you can select a different time scheduling for each day of the

week. Under SETUP line you can set up max 4 time bands- singularly activable- for each different day of the week.

TIMER TYPE = 1: “Time scheduling Weekly” : With this timer type for all days the unit will work with the same time scheduling. Under SETUP line you can set up max 4 time bands- singularly activable- for all the days of the week.

TIMER TYPE = 2: “Time scheduling Week end (5+2)” : With this timer type you can select 2 different time scheduling: one for

working days and one for weekend. Under SETUP line you can set up max 4 time bands- singularly activable- for the working

days (from Monday to Friday) and for the weekend days (Saturday and Sunday).

Real Set

7.0°C

REM OFF enable

NO

Menu

F1

F2

MENU

Condenser

Time scheduling

Language selection

F1

F2

MONDAY TUESDAY

WEDNESDAY

THURSDAY FRIDAY SATURDAY SUNDAY

Time band 1

Time band 2

Time band 3

Time band 4

WEEKLY

Time band 1

Time band 2

Time band 3

Time band 4

MONDAY - FRIDAY SATURDAY- SUNDAY

Time band 1

Time band 2

Time band 3

Time band 4

TIME SCHEDULING

01/01

Timer NO

Time type

0

Setup

F1

F2

NO time scheduling disable

YES time scheduling enable

0

Time scheduling

Daily

1

Time scheduling

Weekly

2

Time scheduling

Week end

(5+2)

Page 24

24

After timer type set you have to go to SETUP line to actually setup the start, the end, the unit mode and water temp setup for

each time band.

SETUP: according to the different timer type selected on the display there will be different lines:

IMPORTANT NOTE

For the chiller working, the time scheduling setup is always priority on the setup done by keyboard control, except the

remote ON/OFF by digital input

The digital input remote ON/OFF -IF ENABLED

- is always priority on time scheduling:

If the unit is in OFF mode by remote (remote ON/OFF) and the time scheduling are enabled the unit remains OFF. When

you switch ON the unit by remote ON/OFF the unit starts to work following the time scheduling setup.

Time scheduling management is disabled even if the configuration mode is activated.

For instance for TIMER TYPE = 0 (daily) in submenu SETUP you have to move on MONDAY line then press ENTER and so

setup for each time band the parameters showed:

TIME BAND 1 ENABLE FLAG: this parameter enable/disables the first time band

TIME BAND 1 HOUR: this parameter allows the setting of the start hour of the first time band

TIME BAND 1 MINUTES: this parameter allows the setting of the start minutes

(from 0 to 59 inside the time band hour) of the first time band.

TIMER TYPE = 0 (Daily)

TIMER TYPE = 1 (Weekly)

TIMER TYPE = 3 (Week-end 5+2)

SETUP 01/03

Monday

Twesday

Wednesday

SETUP 02/03

Thursday

Friday

Saturday

SETUP 03/03

Sunday

F1

F2

F1

F2

SETUP 01/01

Weekly

F1

F2

SETUP 01/01

Monday - Friday

Saturday - Sunday

F1

F2

MONDAY 01/24

Time band 1

enable flag

SI

F1

F2

MONDAY 02/24

Time band 1

HOUR

15 h

F1

F2

MONDAY 03/24

Time band 1

MINUTES

25 Min

F1

F2

F1

F2

MONITORING SYSTEM - User setting

Page 25

25

TIME BAND 1 MODE: this parameter allows the setting of the unit operation mode in

the first time band:

1 = OFF

Enabling this mode the unit is off and it is not possible to switch on neither by display

user interface nor by digital input (for instance by remote)

2 = COOLING

Enabling this mode the unit is on and in cooling mode. The water set point is the value fixed

on TIME BAND 1 CH TEMP SETPOINT It is not possible to switch off the unit by dis-

play user interface, but only by digital input (Remote ON/OFF) - if activated -

3 = MANUAL MODE (not used)

4 = LOCAL SET (only cool)

Enabling this mode the unit is on and in cooling mode.

The water set point is the value fixed by display user interface (we can define standard

set point). It is not possible to switch off the unit by display user interface, but

only by digital input (Remote ON/OFF) - if activated -.

TIME BAND 1 CH TEMP SETPOINT:

This parameter allows the setting on chiller mode (CH) of the water temperature set

point.

TIME BAND 1 HP TEMP SETPOINT: not used for only cooling units.

This parameter can be used only for heat pump (HP) units: it allows the setting on

heat pump mode of the water temperature set point.

For each operating mode the standard set point is stored in a non volatile memory of the control board and it will be

used again by the unit when the time scheduling are disabled.

MONDAY 04/24

Time band 1

MODE

1

F1

F2

MONDAY 05/24

Time band 1

CH TEMP SETPOINT

7.0°C

F1

F2

MONDAY 05/24

Time band 1

HP TEMP SETPOINT

45.0°C

F1

F2

MONITORING SYSTEM - User setting

Page 26

26

ALARMS

The alarms menu is used to display and reset any active alarms and display the alarm log.

There are 2 different ways of accessing the alarms menu:

Mode 1: Scroll through the main menu down to the bottom and select “Menu”, then press “Enter”, then select “Alarms” and press

“Enter”.

ALARMS 01/02

BIOS Alarms

USER Alarms

Alarms Reset

F1

F2

ALARMS 02/02

History

Automatic Alarms

F1

F2

Mode 2: Press and hold down button F3 for a few seconds.

The alarm menu is displayed as follow

1° VIEW 2° VIEW

Select the relevant item and press “Enter”.

•

When an alarm is present, the red led is ON.

•

When an alarm is resettable, the red led is blinking.

• In order to reset an alarm, select “alarm reset” and press ENTER.

Real Set 7.0°C

REM OFF enable

NO

Menu

F1

F2

MENU

Inputs and outputs

alarms

Date and time

F1

F2

MONITORING SYSTEM - Alarms

F1

F2

F3

F4

F3

F4

Page 27

27

BIOS ALARMS

They solely concern HW and SW operation of the micro-controller and do not involve the machine components (compressors,

pumps, sensors, etc.)

After selecting the bios alarms menu, all active bios alarms are displayed.

The bios alarms can end automatically or can last until operator intervention.

For example: The RTC battery alarm (RTC= Real Time Clock), while not being a cause of failure, shuts down the

machine until the current date and time are set correctly.

Bios alarms list

View display description recovery action

TIMEOUT INTERNAL EXP

Communication error

with the expansion boards

Turn off the unit from switch

control panel

Check the connection between

the motherboard and expansions

Turn on the unit and verify the

adsens of the alarm

If the problem persists contact

the service support

TIMEOUT EXP.1

TIMEOUT EXP.2

TIMEOUT EXP.3

TIMEOUT EXP.4

BIOS AREA CRC ERR EXTERNAL EEPROM Sw error

Turn off the unit from switch

control panel

Turn on the unit and verify the

adsens of the alarm

If the problem persists contact

the service support

USER AREA CRC ERR EXTERNAL EEPROM Sw error

Communication RTC ERR Sw error

Registers RTC ERROR Sw error

Modem connection ERR Sw error

Hardware modem ERR Sw error

Software modem ERR Sw error

Low battery RTC data and time are lost date and time must be setted

If there is no bios alarm the “EMPTY” string is displayed for 2 seconds.

MONITORING SYSTEM - Alarms

Page 28

28

If there are no active user alarms, the “EMPTY” string is displayed for 2 seconds.

Alarms shown on display Components involved Alarm effect Cause of alarm

high temperature water evaporator

evaporator water inlet probe

Stop compressor and fan

The pump stays on

Values outside limit

evaporator 1 antifreeze evaporator water outlet probe

circuit 1 high press auto/man circuit 1 high press transducer

Stop compressor and fan

The evaporator pump stays on

Stop condenser pump

-Values outside limit

circuit 2 high press auto/man circuit 2 high press transducer

Circuit 1 low pressure circuit 1 low press transducer

Circuit 2 low pressure circuit 2 low press transducer

compressor 1 thermal protection

Compressor electronic protector

Discharge pipe compressor switch (if installed)

-current value outside limit

-electronic thermal protector

damaged

compressor 2 thermal protection

compressor 1A thermal protection

compressor 1B thermal protection

compressor 1C thermal protection

compressor 2A thermal protection

compressor 2B thermal protection

compressor 2C thermal protection

Compressor 1 discharge temp Discharge pipe compressor 1 sensor

- Values outside limit

Compressor 2 discharge temp Discharge pipe compressor 2 sensor

evaporator pump A unavailable

evaporator pump A Stop evaporator pump A

-Pump not available from the controller

evaporator pump B unavailable

evaporator pump B Stop evaporator pump B

evaporator pump A thermal protection

evaporator pump A Stop evaporator pump A

-current value outside limit

evaporator pump B thermal protection

evaporator pump B Stop evaporator pump B

evaporator water flow

evaporator 1 water flow

evaporator water differential pressure

switch and/or flowswitch.

Stop unit with only 1 pump present.

Swap to the other pump if two

pump are present If the alarm

persist, stop the unit.

-no water circulation or insufficent

water flow rate

-defective sensors switch not correct

fans 1 thermal protections thermal protection Fans 1

Stop compressor and fan

The evaporator pump stays on

-current value outside limit

fans 2 thermal protections thermal protection Fans 2

Heat recovery pump A thermal protections

Heat recovery pump A Stop heat recovery pump A

-current value outside limit

Heat recovery pump B thermal protections

Heat recovery pump B Stop heat recovery pump B

heat recovery pump A unavailable

Heat recovery pump A Stop heat recovery pump A

-Pump not available from the controller

heat recovery pump B unavailable

Heat recovery pump B Stop heat recovery pump B

heat recovery water flow

differential pressure switch and/or flow

switch, recovery water heat exchanger

immediate exit

from recovery mode

-no water circulation or insufficent

water flow rate

-defective sensors switch not correct

Circuit 1 EEV alarm electronic expansion valv 1 error

Stop compressor and fan

The pump stays on

- value outside limit

Circuit 2 EEV alarm electronic expansion valv 2 error

Immediate stop chiller

Electrical panel temperature switch

(high temperature version)

Stop the unit

- too high temperature inside the

electrical panel

- electrical panel fans damaged

- fans filters dirty

(high temperature version)

User alarms table

USER ALARMS

They are only manual reset alarms and concern solely the machine’s components (compressors, fans, pumps, sensors, pressure switches, etc.) and do not involve the HW and SW operation of the micro-controller.

in order to restart the system it is necessary:

- removing the cause of alarm

- to reset manually the alarm from the alarm submenu

MONITORING SYSTEM - Alarms

Page 29

29

MONITORING SYSTEM - Alarms

Alarms shown on display Components involved Alarm effect Cause of alarm

High temperature water condenser

Water outlet probe condenser 1

Water outlet probe condenser 2

Stop the unit - value outside limit

Low temperature water condenser

Condenser water flow

Condenser water differential pressure

switch and/or flowswitch.

Stop the unit

-no water circulation or insufficent water

flow rate

-defective sensors switch not correct

Condenser pump A thermal protections

Condenser Pump A Condenser Pump A stop

-current value outside limit

Condenser pump B thermal protections

Condenser Pump B Condenser Pump B stop

Condenser pump A unavailable

Condenser Pump A Condenser Pump A stop

-Pump not available from the controller

Condenser pump B unavailable

Condenser Pump B Condenser Pump B stop

High temperature plant return

Evaporator water inlet probe

Stop compressor and fans

of all circuits

Evaporator pumps remain

active

- value outside limit

Low temperature plant return

Page 30

30

AUTOMATIC ALARMS

In case of these alarms the unit start automatically after removing the cause. Manual reset is not required.

Alarms shown on display Components involved Alarm effect Cause of alarm

Dinamic set point sens ERR Dinamic setpoint probe Stop dinamic setpoint function

Sensor faulty, Interrupted or

in short circuit

Sens ERR evaporator water inlet Evaporator water inlet probe

Stop compressors and fans

The evaporator pump stays on.

Stop condenser pump

Sens ERR evaporator water outlet Evaporator water outlet probe

circuit 1 High press sens ERR High pressure transducer circuit 1

Stop compressors 1 and fans circuit 1

The evaporator pump stays on.

Stop condenser pump

comp 1 temp disch sens ERR Discharge pipe compressor 1 probe

circuit 1 Low press sens ERR Low pressure transducer circuit 1

condenser 1 temp sens ERR Condenser 1 water outlet probe

circuit 2 High press sens ERR High pressure transducer circuit 2

Stop compressors 2 and fans circuit 2

The evaporator pump stays on

Stop condenser pump

comp 2 temp disch sens ERR Discharge pipe compressor 2 probe

circuit 2 Low press sens ERR Low pressure transducer circuit 2

condenser 2 temp sens ERR Condenser 2 water outlet probe

Power supply control alarm Phase sequence monitor Stop unit

Incorrect sequence or no

power supply phases

Heat recovery H2OIN sens ERR Heat recovery water inlet probe

immediate exit

from heat recovery mode

Sensor faulty, Interrupted or

in short circuit

Sens ERR outdoor air probe Outdoor air probe

The settings depend on the probe

not be executed

Sensor faulty, Interrupted or

in short circuit

DEMAND LIMIT sens ERR DEMAND LIMIT analog input DEMAND LIMIT function ignored

Sensor faulty, Interrupted or

in short circuit

Circuit 1 liquid probe sens ERR Circuit 1 coil probe

Stop compressors and fans circuit 1

The evaporator pump stays on

Sensor faulty, Interrupted or

in short circuit

Circuit 2 liquid probe sens ERR Circuit 2 coil probe

Stop compressors and fans circuit 2

The evaporator pump stays on

Circuit 1 high press pre-all High pressure transducer circuit 1

Red LED blinking

Stores in the historic alarm

The unit stay on

-current value outside limit

Circuit 2 high press pre-all High pressure transducer circuit 2

Circuit 1 low press pre-all Low pressure transducer circuit 1

Circuit 2 low press pre-all Low pressure transducer circuit 2

Circuit 1 gas leakage

Low pressure transducer / switch circuit 1

Stop unit

possible leakage of gas

from the circuit

Circuit 2 gas leakage

Low pressure transducer / switch circuit 2

ERR open file black-box

Black-box file Nothing SW errorERR write file black-box

ERR close file black-box

MONITORING SYSTEM - Alarms

If there are no active AUTOMATIC alarms, the “EMPTY” string is displayed for 2 seconds.

Automatic alarms table

Page 31

31

MONITORING SYSTEM - Alarms

ALARMS HISTORY

The control board has the ability to store in code the last 50 alarm entries that occurred in the unit.

-01/05

-E0701-11-12/06/07-02

total number of alarms in the log

number of alarm displayed (index list)

number of times that the alarm occurred in the same hour

activation date alarm

activation hour alarm

index of the system alarm

alarm code

low pressure alarm

circuit 1

F1

F2

-01/05

E0701-11-12/06/07-02

NEXT

}

DISPLAYING THE ALARMS HISTORY

The alarms log can be displayed from the specific menu using the keys on the keypad. When first opened, the oldest alarm in

the log (number 1 in the list) is shown. Press ENTER on the keypad to scroll through the stored alarms to the most recent.

The last alarm is stored as an index list the greatest number.

If you access the alarms log display menu after having browsed through the alarms log, the display will show the last alarm to

be displayed instead of the the last alarm to be activated.

pressing ENTER on the MENU joystick, displays the next alarm in the list; the alarm list number will therefore be increased. When

you arrive at the end of the list, pressing ENTER will return you to the first alarm in the alarms log.

Page 32

32

Alarms history table for RHV - RVW units

MONITORING SYSTEM - Alarms

Alarm

code

Alarm

E0000 Error probe evaporator water inlet

E0100 Error probe evaporator water outlet

E0200 Error probe dynamic setpoint

E0300 Alarm evaporator high temperature

E0400 Alarm condenser low temperature

E0501 Error transducer high pressure circuit 1

E0502 Error transducer high pressure circuit 2

E0601 Alarm high pressure circuit 1

E0602 Alarm high pressure circuit 2

E0701 Alarm low pressure circuit 1

E0702 Alarm low pressure circuit 2

E0801 Error probe compressor 1 delivery

E0802 Error probe compressor 2 delivery

E0901 Alarm thermal protection compressor 1

E0902 Alarm thermal protection compressor 2

E1001 Alarm compressor 1 delivery temperature

E1002 Alarm compressor 2 delivery temperature

E1101 Alarm thermal protection evaporator pump A

E1102 Alarm thermal protection evaporator pump B

E1200 Alarm evaporator water flow

E1301 Alarm thermal protection fans circuit 1

E1302 Alarm thermal protection fans circuit 2

E1401 Error probe evaporator water outlet

E1501 Alarm antifreeze evaporator

E1601 Error probe condenser

E1701 Error transducer oil compressor 1

E1702 Error transducer oil compressor 2

E1801 Error transducer low pressure circuit 1

E1802 Error transducer low pressure circuit 2

E1901 Alarm compressor 1 oil pressure

E1902 Alarm compressor 2 oil pressure

E2000 Alarm power supply check

E2101 Alarm Electronic Expansion Valve 1 (EEV)

E2102 Alarm Electronic Expansion Valve 2 (EEV)

E2201 Error probe suction compressor 1

E2202 Error probe suction compressor 2

E2301 Alarm thermal protection heat recovery pump A

E2302 Alarm thermal protection heat recovery pump B

E2400 Alarm heat recovery water flow

E2500 Error probe heat recovery water inlet

E2601 Error probe heat recovery 1 water outlet

E2602 Error probe heat recovery 2 water outlet

E2700 Immediate stop chiller

E2801 Alarm thermal protection pump A condenser

E2802 Alarm thermal protection pump B condenser

E2900 Alarm condenser water flow

E3000 Alarm condenser high temperature

E3100 Error probe outdoor air

E3200 Alarm DEMAND LIMIT analog input

Page 33

33

MONITORING SYSTEM - Alarms

Alarm

code

Alarm

E0000 sens err evaporator water inlet

E0300 high temperature plant return

E0400 low temperature plant return

E0501 circuit 1 high press sens err

E0502 circuit 2 high press sens err

E0601 circuit 1 high press auto/man

E0602 circuit 2 high press auto/man

E0701 circuit 1 low pressure

E0702 circuit 2 low pressure

E0901 compressor 1a thermal protection

E0902 compressor 1b thermal protection

E0903 compressor 1c thermal protection

E0904 compressor 2a thermal protection

E0905 compressor 2b thermal protection

E0906 compressor 2c thermal protection

E1101 evaporator pump a thermal protection

E1102 evaporator pump b thermal protection

E1200 evaporator 1 water flow

E1301 fans circuit 1 thermal protection

E1302 fans circuit 2 thermal protection

E1401 evap 1 water out sens err

E1501 evaporator 1 antifreeze

E1601 circuit 1 liquid probe sens err

E1602 circuit 2 liquid probe sens err

E1801 circuit 1 low press sens err

E1802 circuit 2 low press sens err

E2000 power supply control alarm

E2101 circuit 1 eev alarm

E2102 circuit 2 eev alarm

E3100 outdoor air probe sens err

E3301 circuit 1 high press pre-all

E3302 circuit 2 high press pre-all

E3401 circuit 1 low press pre-all

E3402 circuit 2 low press pre-all

E3601 circuit 1 gas leakage

E3602 circuit 2 gas leakage

Alarms history table for RLA - LFL - RHA units

Page 34

NOTE

Page 35

35

The manufacturer declines all responsibility for any inaccuracies in this manual due to printing or typing errors.

The manufacturer reserves the right to make changes and improvements to products in the catalog at any time and without notice.

Page 36

Cod. 3QE26762

Ferroli spa ¬ 37047 San Bonifacio (Verona) Italy ¬ Via Ritonda 78/A

tel. +39.045.6139411 ¬ fax +39.045.6100933 ¬ www.ferroli.it

Loading...

Loading...