Page 1

1

RFA

PACKAGED AIR CONDITIONERS AND HEAT PUMPS

ROOF TOP

FOR OUTDOOR INSTALLATION

INSTALLATION AND OPERATION MANUAL

R

E

F

R

I

G

E

R

A

N

T

G

A

S

E

C

O

-

F

R

I

E

N

D

L

Y

i migliori gradi centigradi

Page 2

2

The manufacturer declines all the responsabilities regarding inaccuracies contained in this manual, if due to printing or typing mistakes.

The manufacturer reserves the right to apply changes and improvements to the products at any time and without notice.

Dear Customer,

thank you for having purchased a FERROLI product. It is the result of many years of experiences and of particular research studies and has been made with top quality materials and advanced technologies. The CE mark guarantees that the products satisfy

all the applicable European Directives.

The qualitative level is kept under constant control and FERROLI products therefore offer Safety, Quality and Reliability.

Due to the continuos improvements in technologies and materials, the product specication as well as performances are subject

to variations without prior notice.

Thank you once again for your preference

FERROLI S.p.A.

Page 3

3

TABLE OF CONTENTS

GENERAL FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unit dataplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unit description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit identification code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Description of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Constructive configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

TECHNICAL DATA AND PERFORMANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

NOMINAL performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Performances with NOT STANDARD air flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

COOLING performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

HEATING performances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hot water coil performances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electrical heater coil performances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Condensing gas heating module performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Plant side aeraulic performances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Available static head - unit without options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Available static head of the return air fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Pressure drops to be added due to condensate generation on the internal coil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Pressure drops - unit with option “Special filters” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pressure drops - unit with option “Heating integration” : "Hot water coil" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Pressure drops - unit with option “Heating integration” : "Condensing gas heating module" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Pressure drops - unit with option “Heating integration” : "Electricl heater coil". . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Pressure drops - unit with option “Droplets separator” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Pressure drops - unit with option “Air flow silencers” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Operating limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Noise levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Unit noise levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Internal fan noise levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Air flow silencers acoustic attenuation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Return air fan noise levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Overall dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Minimum operating area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

CONNECTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Hydraulic connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Aeraulic connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

General standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Condensing gas heating module connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

RECEIVING AND POSITIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

START UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Start up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

CONTROL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Main structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Inputs and outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Controller technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Alarm table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Alarm diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Functions available for the user . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Probe characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Serial communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Maintenace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

SAFETY AND POLLUTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

General considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Refrigerant safety card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Page 4

4

GENERAL FEATURES

General instructions

Declaration of conformity

Unit dataplate

The figure shows the fields reported on the unit dataplate :

A - Trademark

B - Model

B1 - Code

C - Serial number

D - Capacity in cooling

E - Capacity in heating (heat pump)

F - Power input in cooling

G - Power input in heating (heat pump)

H - Reference standard

I - Power supply

L - Maximum absorbed current

M - Refrigerant type and charge weight

N - Unit weight

O - Sound pressure level at 1 metre

P - IP protection level

Q - Maximum pressure - high pressure side

R - Maximum pressure - low pressure side

S - PED certification body

This manual and the wiring diagram supplied with the unit must be kept in a dry place for possible future consultations .

This manual provides information on installation and correct use and maintenance of the unit. Before carrying out installation,

please carefully read all the information contained in this manual, which describes the procedures necessary for correct

installation and use of the unit.

Follow carefully the instructions contained in this manual and respect the safety regulations in force. The unit must be installed

in conformity with the laws in force in the country of use. Unauthorized tampering with the electrical and mechanical equipment

INVALIDATES THE WARRANTY.

Check the electrical specifications given on the dataplate before making the electrical connections. Read the instructions given in

the specific section on electrical connections.

Deactivate the equipment in case of fault or poor operation.

If the unit requires fixings, contact only specialized service centers recognized by the manufacturer and use original spare parts.

The unit must be installed outdoor and connected to a proper air duct distribution system. Any use different from that permitted or

outside the operating limits indicated in this manual is prohibited (unless previously agreed with the firm).

The manufacturer declines any responsability for damage or injury due to non-compliance with the information given in this

manual.

The firm declares that the present unit complies with the requirements of the following directives :

• Machinery directive 2006/42/EC

• Pressure equipment directive (PED) 97/23/EC

• Electromagnetic compatibility directive (EMC) 2004/108/EC

• Low voltage directive (LVD) 2006/95/EC

Codice

Code

B1

Rev

Ferroli Spa

Via Ritonda 78/A

(VR) Italy

Page 5

5

GENERAL FEATURES

Unit description

This series of packaged air conditioners and heat pumps

(roof top) satisfies the cooling and heating requirements of

medium and large buildings (commercial centres, ipermarkets,

cinemas, outlets, offices, canteens, restaurants ...)

All the units are suitable for outdoor installation and can be

applied to plants realized with various type of air ducts.

Each model is available in various constructive configurations

and can be equipped with a large range of accessories in order

to fit the different installation requirements.

The region in contact with the treated air, easily accessible,

is realized with perfectly washable metal surfaces, externally

insulated in order to minimize the thermal losses and to avoid

condensate generation both on the internal part and the

external part of the structure.

The refrigerant circuit, contained in a compartment protected by

the air flow to simplify the maintenance operations, is equipped

with scroll compressors mounted on damper supports. Each

compressor is placed on an independent refrigerant circuit in

order to keep a constant ratio between the sensible cooling

power and total cooling power also at partial loads and to

guarantee a better treatment of the air besides a greater

reliability.

Each refrigerant circuit is equipped with thermostatic expansion

valves, reverse cycle valve, axial fans with safety protection

grilles, finned coils made of copper pipes and aluminium

louvered fins and high and low pressure switches.

All the units are provided with a phase presence and correct

sequence controller device.

All the units are accurately built and individually tested in the

factory. Only electric, aeraulic and hydraulic connections are

required for installation.

Unit identification code

The codes that identify the units and the meaning of the letters used are described below.

RFA PC 90.2 VB AB 0M5

Unit type

PC - Packaged unit operating

as heat pump (reversible on the

refrigerant circuit)

Power supply

5 - 400 V - 3N - 50 Hz

Operating range

M - Medium temperature.

The unit is suitable for temperate climate regions

Refrigerant type

0 - R410A

Acoustic setting up

AB - Base setting up

AS - Low noise seting up

Constructive configuration

VB - Base version

V1 - 1 damper version

V2 - 2 dampers version

V3 - 3 dampers version

N° compressors

Model

Page 6

6

GENERAL FEATURES

Description of components

External structure. Basement, supporting structure and

lateral panels are made of galvanized and painted sheetsteel (colour RAL 7035) to guarantee good resistance to

atmospheric agents.

The inspection panels are all easily removable by means of

¼ turn locks in order to allow total accessibility to the internal

components. The area in contact with the treated air is realized

with galvanized sheet-steel to guarantee proper cleaning and

is externally insulated by means of foam panels and double

panels with interposed an appropriate thermo acoustic

absorber layer in class 1.

External fan section. It is realized by axial fans with alluminium

sickle profiled blades, placed in a galvanized and painted

sheet-steel nozzle, equipped with a safety protection grille and

directly coupled to external rotor motors with intenal thermal

protection. The fans rotational speed is modulated continuosly

by a phase cut device (option) that allow to control the

condensing pressure (in cooling) and the evaporation pressure

(in heating) according to the value read by the temperature

probe placed on the liquid line.

Internal fan section. It is realized by a couple of centrifugal

fans with double aspiration with forward curved blades

balanced both statically and dynamically according to ISO

1940 standards, grade 6.3. The screw, the impeller, and the

frame are realized with galvanized sheet-steel, while the shaft

is made of C40 steel. The fan is coupled by means of belt and

pulleys to a three phase asynchronous 4-poles electrical motor

connected to an appropriate belt tightening slide, with IP55

protection rating, F insulation class, and suitable for continuous

service (S1) with enough heating margins in case of overloads

of limited extent. For powers equal to or greater than 4 kW the

units are equipped as standard with star-delta starter in order

to reduce the starting current and to ensure longer life of the

transmission. The pulley installed on the motor is a variable

diameter type pulley, and allows, within certain limits, to adjust

the rotational speed of the fan to obtain the desired air flow and

available head values.

Return air fan section. It is realized by a couple of centrifugal

fans with double aspiration with forward curved blades

balanced both statically and dynamically according to ISO

1940 standards, grade 6.3. The screw, the impeller, and the

frame are realized with galvanized sheet-steel, while the shaft

is made of C40 steel. For the models of frame 1 and 2 the

fan is directly coupled to a 2 speed electrical motor (star or

delta connection). For the models of frame 3 the fan is coupled

by means of belt and pulleys to an electrical motor connected

to an appropriate belt tightening slide. The pulley installed on

the motor is a variable diameter type pulley, and allows, within

certain limits, to adjust the rotational speed of the fan to obtain

the desired air flow and available head values.

Filtering section. All the units are equipped with waved type

filter cells realized with a galvanized sheet metal frame, an

electrically welded galvanized steel wire protective screen

and a reusable filter element made of polyester fiber stiffened

with synthetic resins. The filter cells have G4 efficiency

class according to standard CEN-EN 779 (Eurovent EU4

classification - 90% average weighted efficiency) and class 1

flame resistance. The filter cells are easily accessible for the

periodic cleaning and inspection operations. Once the advised

final pressure drop has been reached, the synthetic fiber can be

partially reused after treating with warm water and detergents.

Refrigerant circuit. It is contained inside a compartment

separated from the air flow to simplify maintenance and control

operations.

The ermetic scroll compressors (1) are mounted on damper

supports and are protected against overtemperatures and

overcurrents. They are equipped with an electrical heater,

that is activated when the compressor turns off, to keep the

compressor crankcase oil temperature high enough to prevent

migration of refrigerant during winter stops and to evaporate

any liquid present in the crankcase, in order to prevent possible

liquid rushes on starting (only heat pump models).

Page 7

7

GENERAL FEATURES

The internal side heat exchanger (user side) (2) is a finned

coil realized with grooved copper pipes and aluminium fins

with notched profile to increase the heat exchange coefficient.

To avoid condensate drag, the frontal crossing air velocity

don't exceed 2,7 m/s, also with the maximum air flow rate

configuration and in the least favourable thermohygrometric

conditions. For the condensate drainage there is a stainless

steel drain tray with inclined bottom, equipped with threaded

connector for the discharge.

The external side heat exchanger (source side) (3) is a

finned coil realized with grooved copper pipes and aluminium

fins with notched profile.

The expansion device (4), a thermostatic expansion valve with

external equalizer , allow the unit to adjust itself to the different

operating conditions keeping steady the set superheating.

The presence in each refrigerant circuit of two valves (one

for the cooling mode and one for the heating mode) allow

to optimize the adjustment of each valve and to obtain the

maximum efficiency.

Each refrigerant circuit contains moreover solid core hermetic

filter dryer (5) to restrain impurity and moisture residuals that

could be present in the circuit, liquid separator (6) placed on

the inlet pipe to protect the compressor against liquid returns,

liquid and humidity indicator (7) to detect the presence of

liquid before each thermostatic valve and allow to verify the

presence of humidity inside the refrigerant, shut off valves

(8) upstream and downstream of each external coil to allow to

stock all the refrigerant inside the coils (pump down) and permit

to execute maintenance operations on the refrigerant circuit

without discharging it, high and low pressure switches in

order to assure the compressor to operate inside the permitted

limits, 4 way reverse cycle valve (9) to allow operating

mode change reversing the refrigerant flow (only heat pump

models) and pressure connections SAE 5/16” - UNF 1/2” 20 equipped with pin, gasket and blind nut, as required for the

use of R410A refrigerant (they allow the complete check of

the refrigerant circuit: compressor inlet pressure, compressor

outlet pressure and thermostatic valve upstream pressure).

Electrical panel. It contains all the power, control and security

components necessary to guarantee the unit to work properly.

The unit is managed by a microprocessor controller to which all

the electrical loads and the control devices are connected. The

user interface, accessible removing the protection panel of the

electrical board, allow to view and to modify, if necessary, all

the parameters of the unit.

All the units are supplied with an outdoor temperature sensor,

already installed on the unit.

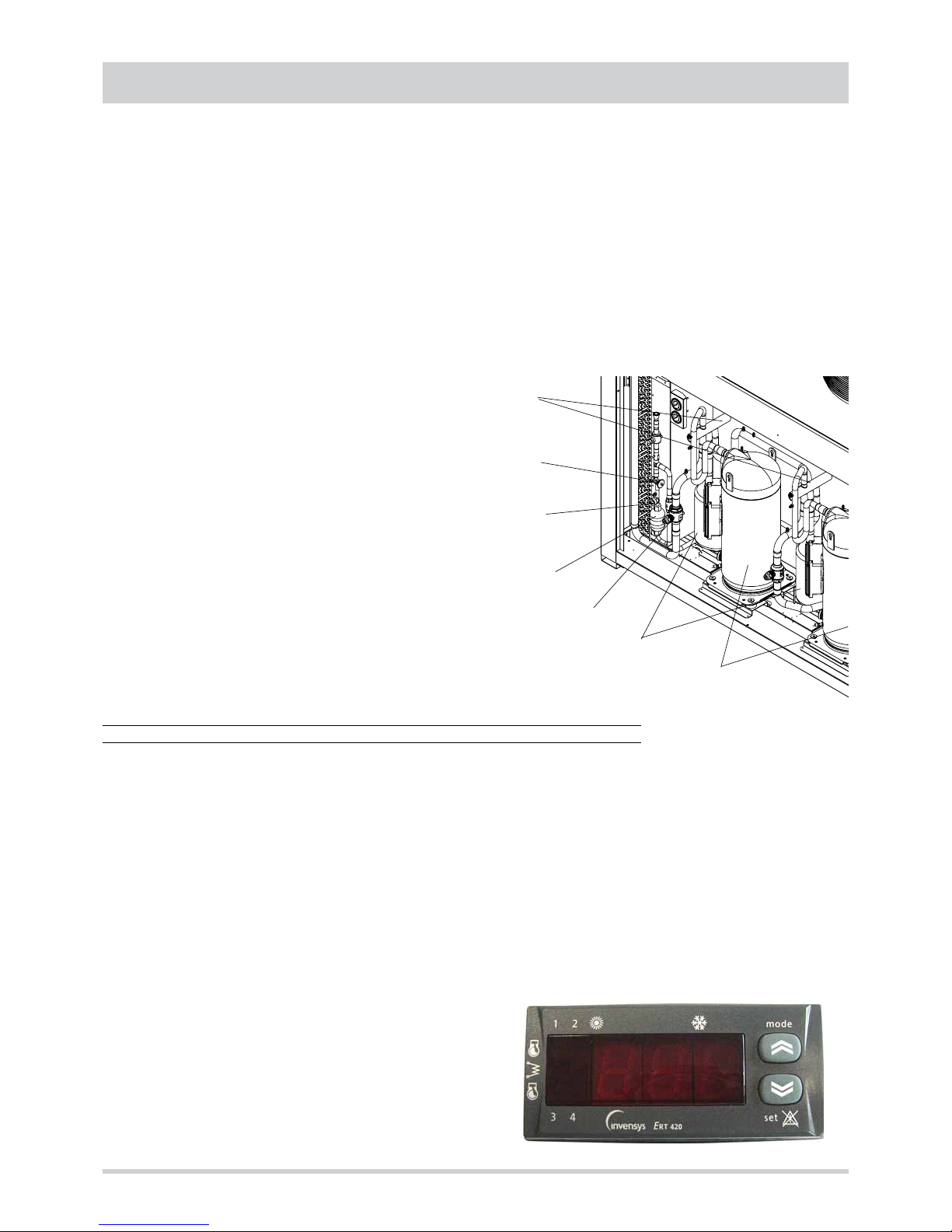

Control system

The unit is managed by a microprocessor controller to which,

through a board placed inside the electrical panel, all the

electrical loads and the control devices are connected. The

user interface, accessible removing the protection panel of

the electrical board, is realized by a display and two buttons

that allow to view and, if necessary, modify all the operating

parameters of the unit.

Are available, as accessories, a remote control, that reports all

the functionalities of the user interface placed on the unit, or a

remote thermostat.

The main functions available are :

- treated air temperature management (through set point

adjustment)

- treated air humidity management (only with enthalpic free

cooling option)

- treated air quality management (CO

2

)

- thermal or enthalpic (option) free cooling

- external fan management by means of continuos rotational

speed control (option)

- internal fan management

- return air fan management

- integrative heating sources management (electrical heater

coil, hot water coil, gas heating module)

- defrost cycle management

- dampers management (outdoor air, return air and expulsion

air)

- compressor and internal fan operating hours recording

- serial communication through Modbus protocol

- remote on-off

- remote cooling-heating

- active alarms visualization

- general alarm digital output

6

8

5

4

7

9

3

1

Page 8

8

Constructive configurations

GENERAL FEATURES

Base version - VB

Each model can be supplied in different constructive

configurations in order to satisfy the application requirements

that can be necessary for the plants. The various versions,

obtained adding to the base version some modules, are always

supplied already assembled, wired and tested in the factory.

All the versions can be arranged with standard air flow position

(frontal for the models of frame 1 and 2 and upwards for the

models of frame 3) or with downwards air flow position.

The dotted components are accessories.

It only allows to operate with all return air.

It contains the standard filtering section and the airrefrigerant exchange coil that allows the heating, cooling and

dehumidification processes to be performed.

It is possible to add a further heating section (hot water coil or

electrical heater coil) and the droplets separator.

Instead of such heating section it is possible to add a gas

heating module, placed between the filtering section and the

air-refrigerant exchange coil.

1 damper version - V1

It allows to operate with a percentage of outdoor fresh air,

adjustable manually setting the damper placed on the adding

module. The outdoor air inlet is equipped with a rain protection

cap and a metal safety grille. The expulsion from the conditioned

ambient of an air flow rate equal to the outdoor fresh air flow

rate must be realized independently from the unit by means of

overpressure openings or other extraction devices.

In the adding module can be placed various type of special

filters in order to complete the standard filtering section.

Also in this version it is possible to add a further heating

section (hot water coil or electrical heater coil) and the droplets

separator.

Instead of such heating section it is possible to add a gas

heating module, placed between the filtering section and the

air-refrigerant exchange coil.

Downstream the internal fans, air flow silencers can be installed

to reduce the noise transmitted to the conditioned ambients

through the air ducts (only for the models of frame 1 and 2).

RETURN AIR AIR FLOW

AIR FLOWRETURN AIR

OUTDOOR AIR

Page 9

9

GENERAL FEATURES

2 dampers version - V2

The presence of two motorized dampers managed by the

controller of the unit allows to operate with a minimum

percentage of outdoor fresh air (adjustable through the user

interface) and to perform thermal free cooling.

The outdoor air inlet, equipped with a rain protection cap and

a metal safety grille, is designed for 100% of the total air flow

rate and allows to operate in free cooling with all outdoor air.

The expulsion from the conditioned ambient of an air flow

rate equal to the outdoor fresh air flow rate must be realized

independently from the unit by means of overpressure

openings or other extraction devices.

In the adding module can be placed various type of special

filters in order to complete the standard filtering section.

It is possible to add a further heating section (hot water coil

or electrical heater coil) and the droplets separator. Instead of

such heating section it is possible to add a gas heating module,

placed between the filtering section and the air-refrigerant

exchange coil.

It is also possible to perform enthalpic free cooling by means of

the installation of the humidity sensors.

Downstream the internal fans, air flow silencers can be installed

to reduce the noise transmitted to the conditioned ambients

through the air ducts (only for the models of frame 1 and 2).

3 dampers version - V3

The presence of three motorized dampers managed by

the controller of the unit allows to operate with a minimum

percentage of outdoor fresh air (adjustable through the user

interface), to perform thermal free cooling and to manage the

air expulsion.

The outdoor air inlet, equipped with a rain protection cap and

a metal safety grille, is designed for 100% of the total air flow

rate and allows to operate in free cooling with all outdoor air.

The expulsion from the conditioned ambient of an air flow rate

equal to the outdoor fresh air flow rate is realized through the

return air fan and the expulsion damper placed inside the unit.

In the adding module can be placed various type of special

filters in order to complete the standard filtering section.

Also in this version it is possible to add a further heating

section (hot water coil or electrical heater coil) and the droplets

separator. Instead of such heating section it is possible to add

a gas heating module, placed between the filtering section and

the air-refrigerant exchange coil.

It is also possible to perform enthalpic free cooling by means of

the installation of the humidity sensors.

Downstream the internal fans, air flow silencers can be installed

to reduce the noise transmitted to the conditioned ambients

through the air ducts (only for the models of frame 1 and 2).

RETURN AIR

EXPULSION AIR

AIR FLOW

AIR FLOW

RETURN AIR

OUTDOOR AIR

OUTDOOR AIR

Page 10

10

GENERAL FEATURES

Options

Constructive

configuration

VB - Base version It only allows to operate with all return air.

V1 - 1 damper version It allows to operate with a fixed percentage of outdoor fresh air, manually set.

V2 - 2 dampers version

It allows to operate with a variable percentage of outdoor fresh air, adjusted by

the unit controller according to free cooling and air quality control algorythms.

V3 - 3 dampers version

It allows to operate with a variable percentage of outdoor fresh air, adjusted by

the unit controller according to free cooling and air quality control algorythms.

Moreover it manages the expulsion of an air flow rate equal to the outdoor fresh

air flow rate.

Air flow

position

Standard

(frontal or upwards)

For the models of frame 1 and 2 the standard position is frontal while for the

models of frame 3 the standard position is upwards.

Downwards It is available for all the models and it allows a more compact installation.

Internal fan

Standard

In order to adjust the performances of the internal fan to the air flow rate and

available head values required, for each model are available three type of internal fan that are different for pulleys used, electrical motor installed power and in

some cases for the kind of fan used.

The pulley installed on the electrical motor is a variable diameter type pulley

and allows, within certain limits, to adjust the performance curve of the fan to

the characteristic curve of the plant.

Upsized

Reduced

Heating

integration

Hot water coil

2 or 3 rows

with pipes

It performs the heating function (as heat pump integration or replacement), the

post heating function (in cooling mode) and the ice protection function. It is

equipped with automatic air vent, drain valve, shut off ball valves at the inlet and

outlet, safety valve (6 bar) and stainless steel condensate tray.

The ball type motorized 3 way valve is managed by the unit controller according

to an on-off logic.

Hot water coil

2 or 3 rows

with 3 way valve

Electrical heater coil

standard or upsized

It performs the heating function (as heat pump integration or replacement), the

post heating function (in cooling mode) and the ice protection function. It is

equipped with safety thermostat and is protected against overcurrents by means of fuses placed inside the electrical panel.

Condensing

gas heating module

standard or upsized

It performs the heating function (as heat pump replacement) and the ice protection function. The stainless steel air-fumes exchanger is coupled with a mo-

dulating premixed burner that allows to adjust the power supplied inside a wide

operating range and to maximize the exploitation of the fumes condensing heat

also at part loads.

Low noise acoustic setting up

It allows to reduce the noise emissions produced by the unit through the insulation of the walls of the compartment that contains the refrigerant circuit and the

use of sound absorbent jackets on the compressors. Such setting up includes

also the modulating control of the external fans.

Air flow silencers

They allow to reduce the noise transmitted to the conditioned ambients through

the air ducts. They are realized by mineral wool acoustic baffles with fiberglass

coating placed downstream the centrifugal internal fan.

They are available only for the models of frame 1 and 2 with standard "Air flow

position" option.

External fans control

The modulating control of the external fans allows to operate with low outdoor

temperatures in cooling and high outdoor temperatures in heating and permits

to reduce noise emissions in such operating conditions.

The fans rotational speed is modulated continuosly by a phase cut device that

allow to control the condensing pressure (in cooling) and the evaporation pressure (in heating) according to the value read by the temperature probe placed

on the liquid line.

Page 11

11

GENERAL FEATURES

Accessories

Spring vibration dampers

Allow to reduce the transmission to the unit support plane of the mechanical vibrations generated by the compressor and by the fans in their normal operating mode.

In order to keep the insulation degree higher than 90%, the number and the features of the dampers are different

according to the model and the constructive configuration.

When this accessory is chosen, flexible connections must be used on all the aeraulic and hydraulic connections.

Moreover the height of the dampers, fitted between the basement of the unit and the support plane, must be

taken into account to design correctly the air ducts.

External coils

protection grilles

Protect the external surface of the finned coils.

High and low

pressure gauges

Each refrigerant circuit is equipped with two analog gauges, placed inside the refrigerant circuit compartment,

that detect the pressure in the compressor inlet and outlet pipes.

Remote control

It is suitable for wall mounting and reports all the functions available on the user interface normally placed on the

unit. It therefore allows the complete remote control of the unit.

Remote thermostat

It is suitable for wall mounting and consists of a simplified remote user interface compared to the standard one

normally placed on the unit. It allows to select the operating mode, set a deviation respect to the active set-point

and visualize the operating status and the presence of active alarms.

Modbus serial interface

on RS485

It allows to communicate with the unit controller and to view the operating conditions of the unit through Modbus

communication protocol. The RS485 serial line ensures the signal quality up to distances of about 1200 metres

(that can be extended by means of proper repeaters).

Programmer clock

It allows the unit to be turned on and off according to a set program, through the digital input available on the unit

wiring board (remote on-off).

Phase sequence and

voltage controller

It checks not only the presence and correct order of the power supply phases but also the voltage level on each

phase and avoid the unit to operate with voltage levels outside the permitted limits.

Roof curb

Metal structure to be applied to the units with downwards air flow in order to facilitate the installation and to

guarantee a perfect tight between the air duct and the unit itself.

The correct positioning of the roof curb requires an accurate finishing of the installation area.

Enthalpic free cooling

It allows to increase the seasonal efficiency of the unit through a more extended

and optimized use of the free cooling function, obtained considering the enthalpies of the outdoor and of the return air instead of the simple temperatures. The

measure of the relative humidity (of the outdoor and of the return air), necessary

for the enthalpy calculation, is realized through two capacitive humidity sensors.

Air quality control (CO

2

)

It manages the motorized dampers opening (in the versions in which they are

present) according to the CO

2

percentage of the ambients to be conditioned,

increasing, if necessary, the outdoor fresh air percentage.

If the (thermal or enthalpic) free cooling function is enabled the dampers opening is obtained by the combination of the two control logics.

Special filters

To complete the standard filtering section it is possible to add rigid pocket filters of various efficiency (from F6 to F9 according to EN 779) or active carbon

filters with F7 filtering class. The filter supporting frame is studied to guarantee

a perfect tight and an easy lateral extraction of the filters for the maintenance

operations.

Available only for the units with V1, V2 or V3 constructive configuration.

Filters differential pressure switch

It detects the pressure difference between upstream and downstream the filtering section. When the pressure drops exceed the maximum permitted value

(factory set according to the type of filters fitted on the unit) the pressure switch

stops the unit avoiding it to work with an air flow rate excessively low compared

to the one required.

Droplets separator

It is reccomended for units that require air flow rates particularly high compared

to the standard air flow rate and when the medium crossing air velocity is higher

than 2,7 m/s.

It avoids the condensate droplets that are generated on the exchange coil during cooling mode operation to be dragged. It is equipped with stainless steel

condensate tray with inclined bottom and threaded connector for the discharge.

It is never required if the hot water coil is mounted.

Page 12

12

TECHNICAL DATA AND PERFORMANCES

Frame

1 2 3

Model

35.1 45.1 55.1 70.2 90.2 110.2 140.2 180.2 220.2

U.M.

Powwer supply

400 - 3N - 50 400 - 3N - 50 400 - 3N - 50 V-ph-Hz

Technical data

Refrigerant

Type

R410A R410A R410A R410A R410A R410A R410A R410A R410A -

Compressor

Type

scroll scroll scroll scroll scroll scroll scroll scroll scroll -

Quantity

1 1 1 2 2 2 2 2 2 n°

Refrigerant circuits

1 1 1 2 2 2 2 2 2 n°

Power steps of the unit

0 - 100 0 - 100 0 - 100 0 - 50 - 100 0 - 50 - 100 0 - 50 - 100 0 - 50 - 100 0 - 50 - 100 0 - 50 - 100

%

Oil charge compressor 1

3,25 3,25 4,70 3,25 3,25 4,70 6,80 6,30 6,30 kg

Oil charge compressor 2

- - - 3,25 3,25 4,70 6,80 6,30 6,30 kg

Internal side heat exchanger (plant)

Type

finned

coil

finned

coil

finned

coil

finned

coil

finned

coil

finned

coil

finned

coil

finned

coil

finned

coil

-

Quantity

1 1 1 1 1 1 1 1 1 n°

Frontal surface

0,84 1,08 1,32 1,26 1,62 1,98 2,52 3,24 3,78 m

2

External side heat exchanger

Type

finned

coil

finned

coil

finned

coil

finned

coil

finned

coil

finned

coil

finned

coil

finned

coil

finned

coil

-

Quantity

1 1 1 2 2 2 2 2 2 n°

Frontal surface

1,96 1,96 1,96 1,96 1,96 1,96 4,00 4,00 4,00 m

2

External section fans

Type

axial axial

axial

axial

axial

axial

axial axial

axial -

Quantity

2 2 2 4 4 4 4 4 4 n°

Diameter

630 630 630 630 630 630 800 800 800 mm

Maximum rotational speed

900 900 900 900 900 900 900 900 900 rpm

Total installed power

1,6 1,6 1,6 3,2 3,2 3,2 8,0 8,0 8,0 kW

Internal section fans

Type

centrifugal centrifuga centrifuga centrifuga centrifuga centrifuga centrifuga centrifuga centrifuga

-

Quantity

2 2 2 2 2 2 2 2 2 n°

MINIMUM air flow rate

5200 6800 8400 9100 12100 14000 18500 23500 28500 m3/h

STANDARD air flow rate

6200 8100 10000 11000 14500 17000 22500 29000 35000 m3/h

MAXIMUM air flow rate

7200 9400 11700 13000 17000 20100 26500 34000 41000 m3/h

STANDARD available static head 200 200 200 200 200 200 200 200 200 Pa

Absorbed power

1,4 1,8 2,2 3,5 4,3 5,1 6,6 8,7 10,5 kW

Installed power

1,5 2,2 2,2 4,0 5,5 5,5 11,0 11,0 18,4 kW

Page 13

13

TECHNICAL DATA AND PERFORMANCES

NOMINAL performances

PC

Cooling A35A27 ( source : air in 35°C d.b. / plant : air in 27°C d.b. 19°C w.b. )

Total cooling capacity 35,5 46,3 57,7 71,0 92,3 113,0 142,0 184,0 226,0

kW

RST* 0,70 0,70 0,70 0,70 0,70 0,70 0,70 0,70 0,70

-

Power input 10,9 14,0 17,7 22,5 28,8 36,6 46,6 59,5 73,7

kW

EER 3,26 3,31 3,26 3,16 3,20 3,09 3,05 3,09 3,07

-

Air flow rate plant side 6200 8100 10000 11000 14500 17000 22500 29000 35000

m3/h

Available static head plant side 200 200 200 200 200 200 200 200 200

Pa

Heating A7A20 ( source : air in 7°C d.b. 6°C w.b. / plant : air in 20°C d.b. )

Heating capacity 36,7 47,8 59,5 73,9 95,9 118,0 148,0 192,0 236,0

kW

Power input 11,2 14,4 18,2 23,0 29,5 37,5 47,7 60,9 75,5

kW

COP 3,28 3,32 3,27 3,21 3,25 3,15 3,10 3,15 3,13

-

Air flow rate plant side 6200 8100 10000 11000 14500 17000 22500 29000 35000

m3/h

Available static head plant side 200 200 200 200 200 200 200 200 200

Pa

Data declared according to EN 14511. The values are referred to units without options and accessories operating with 100% return air.

* RST = ratio between sensible cooling capacity and total cooling capacity.

Frame

1 2 3

Model

35.1 45.1 55.1 70.2 90.2 110.2 140.2 180.2 220.2

U.M.

Power supply

400 - 3N - 50 400 - 3N - 50 400 - 3N - 50 V-ph-Hz

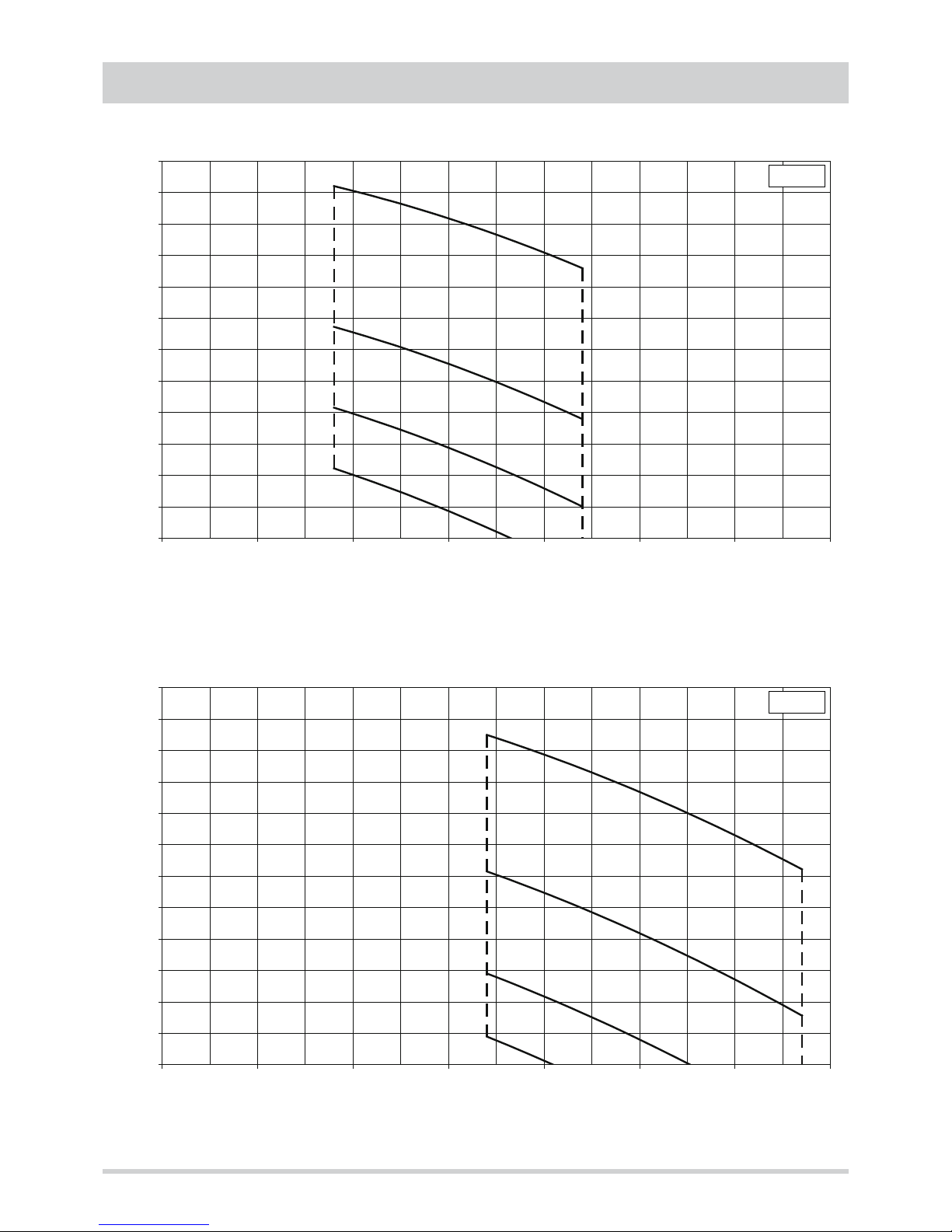

The graphs reported below allow to get the corrective factors to be applied to the performances with standard air flow rate in order

to obtain the real performances with the selected air flow rate.

0,85

0,90

0,95

1,00

1,05

1,10

1,15

0,80 0,85 0,90 0,95 1,00 1,05 1,10 1,15 1,20

COOLING OPERATING MODE

Performances with NOT STANDARD air flow rate

0,85

0,90

0,95

1,00

1,05

1,10

1,15

0,80 0,85 0,90 0, 95 1,00 1,05 1,10 1,15 1,20

HEATING OPERATING MODE

Heating capacity

Total cooling capacity

Power input

RST

Power input

Air flow rate / STANDARD air flow rate Air flow rate / STANDARD air flow rate

Page 14

14

0,4

0,6

0,8

1,0

1,2

1,4

1,6

1,8

2,0

15 20 25 30 35 40 45 50

0,5

0,6

0,7

0,8

0,9

1,0

1,1

1,2

1,3

1,4

1,5

15 20 25 30 35 40 45 50

0,5

0,6

0,7

0,8

0,9

1,0

1,1

1,2

1,3

1,4

1,5

15 20 25 30 35 40 45 50

TECHNICAL DATA AND PERFORMANCES

COOLING performances

The graphs allow to get the corrective factors to be applied to the

nominal performances in order to obtain the real performances in the

selected operating conditions.

The reference nominal condition is : A35A27

source : air in 35°C d.b. / plant : air in 27°C d.b. 19°C w.b.

Inlet w.b. temperature plant side :

Cooling capacity

Inlet air temperature d.b. [°C]

Inlet air temperature d.b. [°C]

Inlet air temperature d.b. [°C]

Power input

EER

A

B

C

D

A

B

C

D

A

B

C

D

0,5

0,6

0,7

0,8

0,9

1,0

1,1

1,2

1,3

1,4

1,5

15 20 25 30 35 40 45 50

RST

Inlet air temperature d.b. [°C]

A

B

C

D

A = 27°C

B = 23°C

C = 19°C

D = 15°C

E = 11°C

E

E

E

E

Page 15

15

TECHNICAL DATA AND PERFORMANCES

0,4

0,6

0,8

1,0

1,2

1,4

1,6

1,8

2,0

-15 -10 -5 0 5 10 15 20

0,5

0,6

0,7

0,8

0,9

1,0

1,1

1,2

1,3

1,4

1,5

-15 -10 -5 0 5 10 15 20

0,5

0,6

0,7

0,8

0,9

1,0

1,1

1,2

1,3

1,4

1,5

-15 -10 -5 0 5 10 15 20

HEATING performances

Heating capacity

Inlet air temperature w.b. [°C]

Inlet air temperature w.b. [°C]

Inlet air temperature w.b. [°C]

Power input

COP

A

B

C

D

A

B

C

D

A

B

C

DEE

E

The graphs allow to get the corrective factors to be applied to the

nominal performances in order to obtain the real performances in the

selected operating conditions.

The reference nominal condition is : A7A20

source : air in 7°C d.b. 6°C w.b. / plant : air in 20°C d.b.

Inlet d.b. temperature plant side :

A = 28°C

B = 24°C

C = 20°C

D = 16°C

E = 12°C

Page 16

16

TECHNICAL DATA AND PERFORMANCES

Hot water coil performances

2 ROWS

Water : 60 - 40 °C

Air flow rate

Minimum Standard Maximum

Model

T

inlet air

Capacity

Water

flow rate

Water

pressure

drops

Capacity

Water

flow rate

Water

pressure

drops

Capacity

Water

flow rate

Water

pressure

drops

[°C] [kW] [l/h] [kPa] [kW] [l/h] [kPa] [kW] [l/h] [kPa]

35.1

10 40,8 1771 4 45,7 1985 5 50,1 2176 6

15 33,3 1448 2 38,3 1664 4 42,7 1855 4

20 25,4 1102 1 29,4 1279 2 33,3 1448 2

45.1

10 52,7 2292 4 59,2 2571 5 64,8 2817 5

15 43,0 1869 2 49,4 2147 4 55,2 2400 4

20 32,6 1417 1 37,8 1644 2 42,8 1861 2

55.1

10 64,7 2812 4 72,7 3157 5 79,6 3457 5

15 52,7 2290 2 60,5 2631 4 67,8 2946 4

20 39,8 1731 1 46,2 2008 2 52,3 2274 2

70.2

10 70,8 3075 14 80,2 3484 18 88,8 3858 20

15 60,8 2641 11 68,8 2991 13 76,2 3309 16

20 50,8 2208 8 57,5 2498 10 63,6 2762 12

90.2

10 92,9 4038 14 104,5 4541 17 115,1 5003 20

15 79,8 3467 11 89,7 3896 13 98,7 4290 16

20 66,7 2898 8 74,9 3253 10 82,4 3579 11

110.2

10 110,2 4788 13 124,4 5404 16 137,4 5969 19

15 94,6 4111 10 106,7 4637 12 117,8 5118 14

20 79,1 3436 7 89,1 3871 8 98,3 4269 11

140.2

10 141,5 6150 14 160,4 6968 18 177,6 7716 20

15 121,5 5282 11 137,6 5982 13 152,3 6618 16

20 101,6 4416 8 115,0 4996 10 127,1 5524 12

180.2

10 185,9 8076 14 209,0 9082 17 230,3 10006 20

15 159,6 6934 11 179,3 7792 13 197,5 8580 16

20 133,4 5796 8 149,7 6506 10 164,7 7158 11

220.2

10 220,4 9576 13 248,7 10808 16 274,7 11938 19

15 189,2 8222 10 213,4 9274 12 235,6 10236 14

20 158,2 6872 7 178,2 7742 8 196,5 8538 11

2 ROWS

Water : 80 - 60 °C

Air flow rate

Minimum Standard Maximum

Model

T

inlet air

Capacity

Water

flow rate

Water

pressure

drops

Capacity

Water

flow rate

Water

pressure

drops

Capacity

Water

flow rate

Water

pressure

drops

[°C] [kW] [l/h] [kPa] [kW] [l/h] [kPa] [kW] [l/h] [kPa]

35.1

10 65,3 2867 8 73,1 3212 10 80,4 3532 12

15 59,2 2599 7 66,3 2912 8 72,9 3202 10

20 53,2 2335 6 59,5 2616 7 65,5 2875 8

45.1

10 84,7 3722 8 94,9 4167 10 104,2 4578 11

15 76,8 3374 6 86,0 3777 8 94,5 4150 10

20 69,0 3031 6 77,2 3392 7 84,8 3726 8

55.1

10 104,2 4577 7 116,6 5121 10 128,1 5625 11

15 94,5 4149 6 105,7 4642 8 116,1 5099 10

20 84,8 3727 5 94,9 4169 6 104,2 4578 7

70.2

10 110,7 4864 29 125,9 5531 36 139,8 6141 43

15 100,6 4419 24 114,4 5025 30 127,0 5579 36

20 90,6 3979 20 103,0 4524 25 114,3 5023 30

90.2

10 145,6 6396 29 164,3 7217 35 181,5 7972 42

15 132,3 5811 24 149,3 6556 30 164,9 7242 35

20 119,1 5231 20 134,4 5902 25 148,4 6518 30

110.2

10 172,6 7581 26 195,5 8587 32 216,5 9510 38

15 156,8 6887 22 177,6 7800 28 196,7 8638 32

20 141,2 6200 18 159,8 7021 23 177,0 7775 28

140.2

10 221,4 9728 29 251,8 11062 36 279,6 12282 43

15 201,2 8838 24 228,8 10050 30 254,0 11158 36

20 181,1 7958 20 206,0 9048 25 228,7 10046 30

180.2

10 291,2 12792 29 328,6 14434 35 363,0 15944 42

15 264,5 11622 24 298,5 13112 30 329,7 14484 35

20 238,2 10462 20 268,7 11804 25 296,8 13036 30

220.2

10 345,2 15162 26 390,9 17174 32 433,0 19020 38

15 313,6 13774 22 355,1 15600 28 393,3 17276 32

20 282,3 12400 18 319,7 14042 23 354,0 15550 28

Page 17

17

TECHNICAL DATA AND PERFORMANCES

3 ROWS

Water : 80 - 60 °C

Air flow rate

Minimum Standard Maximum

Model

T

inlet air

Capacity

Water

flow rate

Water

pressure

drops

Capacity

Water

flow rate

Water

pressure

drops

Capacity

Water

flow rate

Water

pressure

drops

[°C] [kW] [l/h] [kPa] [kW] [l/h] [kPa] [kW] [l/h] [kPa]

35.1

10 85,7 3765 19 97,7 4293 24 109,1 4791 30

15 77,8 3419 17 88,8 3899 20 99,1 4351 25

20 70,1 3080 13 79,9 3511 17 89,2 3918 20

45.1

10 111,5 4899 19 127,1 5581 24 141,7 6224 29

15 101,3 4449 16 115,4 5068 20 128,7 5652 24

20 91,2 4007 13 103,9 4564 17 115,8 5088 20

55.1

10 137,3 6032 19 156,4 6868 24 174,3 7656 29

15 124,7 5478 16 142,0 6237 19 158,3 6952 24

20 112,3 4934 13 127,8 5616 17 142,5 6259 20

70.2

10 146,0 6413 70 169,4 7440 90 191,2 8399 112

15 132,8 5833 59 154,0 6766 77 173,9 7638 95

20 119,8 5261 49 138,9 6102 64 156,8 6888 79

90.2

10 192,8 8468 70 221,6 9736 89 248,7 10924 109

15 175,3 7701 59 201,6 8854 76 226,1 9934 92

20 158,1 6945 49 181,8 7984 62 203,9 8957 77

110.2

10 227,5 9992 64 262,7 11538 82 295,6 12984 101

15 206,9 9087 54 238,9 10492 70 268,8 11807 85

20 186,6 8196 46 215,4 9462 58 242,4 10646 71

140.2

10 292,0 12826 70 338,7 14880 90 382,4 16798 112

15 265,6 11666 59 308,1 13532 77 347,8 15276 95

20 239,5 10522 49 277,8 12204 64 313,6 13776 79

180.2

10 385,5 16936 70 443,3 19472 89 497,3 21848 109

15 350,6 15402 59 403,1 17708 76 452,3 19868 92

20 316,2 13890 49 363,5 15968 62 407,8 17914 77

220.2

10 455,0 19984 64 525,3 23076 82 591,2 25968 101

15 413,7 18174 54 477,7 20984 70 537,6 23614 85

20 373,1 16392 46 430,8 18924 58 484,7 21292 71

3 ROWS

Water : 60 - 40 °C

Air flow rate

Minimum Standard Maximum

Model

T

inlet air

Capacity

Water

flow rate

Water

pressure

drops

Capacity

Water

flow rate

Water

pressure

drops

Capacity

Water

flow rate

Water

pressure

drops

[°C] [kW] [l/h] [kPa] [kW] [l/h] [kPa] [kW] [l/h] [kPa]

35.1

10 55,6 2417 10 63,2 2745 12 70,3 3054 14

15 47,9 2081 7 54,4 2362 10 60,4 2626 11

20 40,0 1737 6 45,6 1982 7 50,6 2201 8

45.1

10 72,3 3141 10 82,0 3564 12 91,2 3962 14

15 62,2 2705 7 70,6 3067 10 78,4 3407 11

20 51,9 2253 5 59,2 2572 7 65,7 2854 8

55.1

10 88,9 3865 10 100,9 4384 12 112,1 4871 14

15 76,6 3328 7 86,8 3771 8 96,4 4187 11

20 63,7 2769 5 72,8 3161 7 80,7 3506 8

70.2

10 95,8 4164 36 110,7 4812 47 124,6 5416 56

15 82,8 3599 28 95,7 4156 36 107,6 4675 44

20 69,9 3039 20 80,6 3504 26 90,6 3937 32

90.2

10 126,4 5491 36 144,8 6291 46 162,0 7038 55

15 109,2 4745 28 125,0 5432 35 139,8 6074 43

20 92,1 4004 20 105,4 4578 26 117,7 5114 31

110.2

10 149,2 6484 32 171,7 7458 42 192,6 8369 52

15 129,0 5603 25 148,2 6441 32 166,2 7223 40

20 108,8 4729 19 124,9 5429 24 140,0 6082 29

140.2

10 191,7 8328 36 221,5 9624 47 249,3 10832 56

15 165,7 7198 28 191,3 8312 36 215,2 9350 44

20 139,8 6078 20 161,3 7008 26 181,2 7874 32

180.2

10 252,7 10982 36 289,5 12582 46 323,9 14076 55

15 218,4 9490 28 250,0 10864 35 279,6 12148 43

20 184,3 8008 20 210,7 9156 26 235,4 10228 31

220.2

10 298,4 12968 32 343,3 14916 42 385,2 16738 52

15 257,9 11206 25 296,5 12882 32 332,4 14446 40

20 217,7 9458 19 249,9 10858 24 279,9 12164 29

Page 18

18

0

50

100

150

200

250

300

350

400

450

500

550

600

5000 6000 7000 8000 9000 10000 11000 12000

TECHNICAL DATA AND PERFORMANCES

Plant side aeraulic performances

Available static head - unit without options

The graphs are referred to units operating with air at the temperature of 20°C (density 1,20 kg/m

3

).

Air flow rate [ m

3

/h ]

Available static head [ Pa ]

Upsized

35.1

Standard

Reduced

The internal fan must be selected according to the required air ow rate and to the required total head.

The required total head must be calculated as sum of the required available head and of the pressure drops of the options or

accessories applied to the unit. Such pressure drops must be calculated according to the required air ow rate using the graphs

reported in the present manual.

The graphs reported below show the characteristic aeraulic curves of each model. Such curves are obtained subtracting to the

head supplied by the fan the pressure drops of the standard lters (G4), the pressure drops of the internal coil and the pressure

drops of the internal structure of the unit.

N.B. The curves are referred to units with BASE constructive conguration (VB) without options or accessories and with

dry internal coil.

Model

35.1 - 45.1 - 55.1 70.2 - 90.2 - 110.2 140.2 - 180.2 - 220.2

U.M.

Standard Upsized Standard Upsized Standard Upsized

Nominal heating capacity

max 44,8 54,0 93,4 145,0 186,8 290,0 kW

min 15,5 16,3 31,5 46,3 63,0 92,6 kW

Efciency

max 94,3 93,1 95,3 93,5 95,3 93,5 %

min 105,0 105,0 105,0 105,2 105,0 105,2 %

Gas input

(15°C – 1013 mbar)

max 5,03 6,14 10,37 16,40 20,74 32,8 m

3

/h

min 1,57 1,64 3,17 4,66 6,34 9,32 m

3

/h

Condensate generated 1,45 1,45 2,60 3,87 5,20 7,74 l/h

Available static head exhaust fumes 120 120 120 100 120 100 Pa

Model 35.1 - 45.1 - 55.1 70.2 - 90.2 - 110.2 140.2 - 180.2 - 220.2 U.M.

Standard coil 9,0 18,0 36,0 kW

Upsized coil 18,0 31,5 63,0 kW

The reported data are referred to the module operating with natural gas G20 at 20 mbar supply pressure.

Electrical heater coil performances

Condensing gas heating module performances

Page 19

19

0

50

100

150

200

250

300

350

400

450

500

550

600

5000 6000 7000 8000 9000 10000 11000 12000

TECHNICAL DATA AND PERFORMANCES

Air flow rate [ m3/h ]

Available static head [ Pa ]

Upsized

55.1

Standard

Reduced

The graphs are referred to units operating with air at the temperature of 20°C (density 1,20 kg/m

3

).

0

50

100

150

200

250

300

350

400

450

500

550

600

5000 6000 7000 8000 9000 10000 11000 12000

Air flow rate [ m3/h ]

Available static head [ Pa ]

Upsized

45.1

Standard

Reduced

Page 20

20

0

50

100

150

200

250

300

350

400

450

500

550

600

8000 9000 10000 11000 12000 13000 14000 15000 16000 17000 18000 19000 20000 21000

Air flow rate [ m3/h ]

Available static head [ Pa ]

Upsized

70.2

Standard

Reduced

0

50

100

150

200

250

300

350

400

450

500

550

600

8000 9000 10000 11000 12000 13000 14000 15000 16000 17000 18000 19000 20000 21000

TECHNICAL DATA AND PERFORMANCES

Air flow rate [ m3/h ]

Available static head [ Pa ]

Upsized

90.2

Standard

Reduced

The graphs are referred to units operating with air at the temperature of 20°C (density 1,20 kg/m

3

).

Page 21

21

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

16000 18000 20000 22000 24000 26000 28000 30000 32000 34000 36000 38000 40000 42000

TECHNICAL DATA AND PERFORMANCES

Air flow rate [ m3/h ]

Available static head [ Pa ]

Upsized

140.2

Standard

Reduced

The graphs are referred to units operating with air at the temperature of 20°C (density 1,20 kg/m

3

).

0

50

100

150

200

250

300

350

400

450

500

550

600

8000 9000 10000 11000 12000 13000 14000 15000 16000 17000 18000 19000 20000 21000

Air flow rate [ m3/h ]

Available static head [ Pa ]

Upsized

110.2

Standard

Reduced

Page 22

22

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

16000 18000 20000 22000 24000 26000 28000 30000 32000 34000 36000 38000 40000 42000

Air flow rate [ m3/h ]

Available static head [ Pa ]

Upsized

180.2

Standard

Reduced

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

16000 18000 20000 22000 24000 26000 28000 30000 32000 34000 36000 38000 40000 42000

TECHNICAL DATA AND PERFORMANCES

Air flow rate [ m3/h ]

Available static head [ Pa ]

Upsized

220.2

Standard

Reduced

The graphs are referred to units operating with air at the temperature of 20°C (density 1,20 kg/m

3

).

Page 23

23

TECHNICAL DATA AND PERFORMANCES

The graphs are referred to units operating with air at the temperature of 20°C (density 1,20 kg/m3).

Available static head of the return air fan

When the return air fan is present, verify that the available head, corresponding to an air ow rate equal to the 70% of the air ow

rate dened for the internal fan, is not higher than the pressure drops in the return duct.

If necessary modify the fan speed in order to reduce the available head.

In such way it is possible to guarantee a correct air extraction, keeping a little over pressure in the room to be conditioned also

when the unit is working with all external air.

Air flow rate [ m

3

/h ]

Available static head [ Pa ]

0

50

100

150

200

250

300

350

400

450

500

4000 8000 12000 16000 20000 24000 28000 32000 36000 40000

35.1

45.1

55.1

70.2

90.2

110.2

140.2

180.2

220.2

0

10

20

30

40

5000 10000 15000 20000 25000 30000 35000 40000

Pressure drops to be added due to condensate generation on the internal coil

Air flow rate [ m

3

/h ]

Pressure drops [ Pa ]

35.1 45.1 55.1 70.2 90.2 110.2 140.2 180.2 220.2

Page 24

24

0

30

60

90

120

150

180

5000 6000 7000 8000 9000 10000 11000 12000

Pressure drops - unit with option “Special filters”

Air flow rate [ m

3

/h ]

Pressure drops [ Pa ]

TECHNICAL DATA AND PERFORMANCES

4

5

3

2

1

0

35.1

45.1

55.1

The graphs are referred to units operating with air at the temperature of 20°C (density 1,20 kg/m3).

Type of filter

Efficiency

EN 779

Medium efficiency

Em [%]

(on 0,4 µm parts)

Eurovent

classification

0 STANDARD waved filter G 4 - EU 4

1 Rigid pocket filter F 6 60 ≤ Em < 80 EU 6

2 Rigid pocket filter F 7 80 ≤ Em < 90 EU 7

3 Rigid pocket filter F 8 90 ≤ Em < 95 EU 8

4 Rigid pocket filter F 9 95 ≤ Em EU 9

5

Rigid pocket filter

with active carbons

F 7 80 ≤ Em < 90 EU 7

Page 25

25

TECHNICAL DATA AND PERFORMANCES

The graphs are referred to units operating with air at the temperature of 20°C (density 1,20 kg/m3).

0

30

60

90

120

150

180

18000 20000 22000 24000 26000 28000 30000 32000 34000 36000 38000 40000 42000

Air flow rate [ m3/h ]

Pressure drops [ Pa ]

4

5

3

2

1

0

140.2

180.2

220.2

0

30

60

90

120

150

180

9000 10000 11000 12000 13000 14000 15000 16000 17000 18000 19000 20000

Air flow rate [ m3/h ]

Pressure drops [ Pa ]

4

5

3

2

1

0

70.2

90.2

110.2

Page 26

26

TECHNICAL DATA AND PERFORMANCES

0

20

40

60

80

100

5000 10000 15000 20000 25000 30000 35000 40000

Pressure drops - unit with option “Heating integration” : "Hot water coil"

Air flow rate [ m

3

/h ]

Pressure drops [ Pa ]

0

20

40

60

80

100

120

5000 10000 15000 20000 25000 30000 35000 40000

Pressure drops - unit with option “Heating integration” : "Condensing gas heating module"

Air flow rate [ m

3

/h ]

Pressure drops [ Pa ]

The graphs are referred to units operating with air at the temperature of 20°C (density 1,20 kg/m3).

35.1 - 3R 45.1 - 3R 55.1 - 3R 70.2 - 3R 90.2 - 3R 110.2 - 3R 140.2 - 3R 180.2 - 3R 220.2 - 3R

35.1 - 2R 45.1 - 2R 55.1 - 2R 70.2 - 2R 90.2 - 2R 140.2 - 2R 180.2 - 2R 220.2 - 2R110.2 - 2R

70.2

90.2

110.2

35.1

45.1

55.1

140.2

180.2

220.2

Standard

and upsized

Standard

Upsized

Standard

Upsized

Page 27

27

TECHNICAL DATA AND PERFORMANCES

0

5

10

15

20

25

5000 10000 15000 20000 25000 30000 35000 40000

Pressure drops - unit with option “Heating integration” : "Electricl heater coil"

Air flow rate [ m

3

/h ]

Pressure drops [ Pa ]

0

10

20

30

40

50

5000 10000 15000 20000 25000 30000 35000 40000

Pressure drops - unit with option “Droplets separator”

Air flow rate [ m

3

/h ]

Pressure drops [ Pa ]

The graphs are referred to units operating with air at the temperature of 20°C (density 1,20 kg/m3).

70.2

90.2

110.2

35.1

45.1

55.1

140.2

180.2

220.2

Standard

Upsized

Standard

Upsized

Upsized

Standard

70.2

90.2

110.2

35.1

45.1

55.1

140.2

180.2

220.2

Page 28

28

TECHNICAL DATA AND PERFORMANCES

0

20

40

60

80

100

120

140

160

5000 7000 9000 11000 13000 15000 17000 19000 21000

Pressure drops - unit with option “Air flow silencers”

Air flow rate [ m

3

/h ]

Pressure drops [ Pa ]

The graphs are referred to units operating with air at the temperature of 20°C (density 1,20 kg/m3).

70.2

90.2

110.2

35.1

45.1

55.1

Page 29

29

TECHNICAL DATA AND PERFORMANCES

Operating limits

The graphs reported below show the operating area inside which the correct working of the unit is guaranteed.

10

15

20

25

30

35

40

5 10 15 20 25 30 35 40 45 50 55

COOLING

Inlet air temperature d.b - source side [°C]

Inlet air temperature d.b. - plant side [°C]

0

5

10

15

20

25

30

-15 -10 -5 0 5 10 15 20 25

HEATING

Inlet air temperature d.b - source side [°C]

Inlet air temperature d.b. - plant side [°C]

The limits are approximate and are referred to STANDARD air flow rate.

Page 30

30

TECHNICAL DATA AND PERFORMANCES

Electrical data

Model 35.1 45.1 55.1 70.2 90.2 110.2 140.2 180.2 220.2 U.M.

Power supply 400V - 3ph+N - 50Hz V-ph-Hz

F.L.A. - Maximum current input

Compressor 1 23,0 28,0 37,0 23,0 28,0 37,0 45,0 60,0 76,0 A

Compressor 2 - - - 23,0 28,0 37,0 45,0 60,0 76,0 A

Single external fan 3,5 3,5 3,5 3,5 3,5 3,5 4,3 4,3 4,3 A

Internal fan

reduced 2,7 3,6 4,2 6,4 6,4 8,6 17,1 22,9 30,4 A

standard 3,6 4,2 4,9 8,6 11,4 11,4 22,9 22,9 35,6 A

upsized 4,9 6,4 6,4 11,4 17,1 17,1 30,4 35,6 35,6 A

Return air fan 3,5 3,5 3,5 7,0 7,0 7,0 17,1 17,1 17,1 A

Electrical heater coil

standard 13,0 13,0 13,0 26,0 26,0 26,0 52,0 52,0 52,0 A

upsized 26,0 26,0 26,0 45,5 45,5 45,5 90,9 90,9 90,9 A

F.L.I. - Maximum power input

Compressor 1 13,4 16,9 22,6 13,4 16,9 22,6 27,4 36,6 46,3 kW

Compressor 2 - - - 13,4 16,9 22,6 27,4 36,6 46,3 kW

Single external fan 0,8 0,8 0,8 0,8 0,8 0,8 2,0 2,0 2,0 kW

Internal fan

reduced 1,4 1,9 2,3 3,6 3,6 4,8 9,5 12,8 17,1 kW

standard 1,9 2,3 2,7 4,8 6,4 6,4 12,8 12,8 20,5 kW

upsized 2,7 3,6 3,6 6,4 9,5 9,5 17,1 20,5 20,5 kW

Return air fan 1,1 1,1 1,1 2,2 2,2 2,2 9,5 9,5 9,5 A

Electrical heater coil

standard 9,0 9,0 9,0 18,0 18,0 18,0 36,0 36,0 36,0 kW

upsized 18,0 18,0 18,0 31,5 31,5 31,5 63,0 63,0 63,0 kW

L.R.A. - Start current

Compressor 1 118,0 198,0 225,0 118,0 198,0 225,0 272,0 310,0 394,0 A

Compressor 2 - - - 118,0 198,0 225,0 272,0 310,0 394,0 A

Single external fan 7,5 7,5 7,5 7,5 7,5 7,5 11,0 11,0 11,0 A

Internal fan

reduced 11,1 16,6 20,2 33,3 33,3 33,7 67,4 99,0 143,5 A

standard 16,6 20,2 25,0 33,7 49,5 49,5 99,0 99,0 184,4 A

upsized 25,0 33,3 33,3 49,5 67,4 67,4 143,5 184,4 184,4 A

Return air fan 5,5 5,5 5,5 11,0 11,0 11,0 67,4 67,4 67,4 A

TOTAL *

F.L.A. - Maximum total current input 34 39 49 69 81 99 130 160 205 A

F.L.I. - Maximum total power input 17 21 27 35 43 55 76 94 121 kW

M.I.C. - Maximum total start current 129 209 237 164 251 287 357 410 523 A

* BASE version with STANDARD internal fan and without accessories.

Page 31

31

TECHNICAL DATA AND PERFORMANCES

Noise levels

BASE acoustic setting up (AB)

Model

Sound power levels [dB]

by octave bands [Hz]

Sound power

level

Sound pressure level

at 1 metre at 5 metres at 10 metres

63 125 250 500 1000 2000 4000 8000 [dB] [dB(A)] [dB(A)] [dB(A)] [dB(A)]

35.1 83,6 82,7 84,7 79,9 80,6 76,5 69,7 62,4 90 84 67 58 53

45.1 86,6 83,4 85,2 80,4 80,9 76,9 70,6 63,4 91 85 67 58 53

55.1 88,2 84,2 85,7 81,0 81,2 77,4 71,6 64,3 92 85 68 59 54

70.2 86,2 85,4 87,6 82,7 83,5 79,3 72,3 65,2 93 87 69 60 55

90.2 89,0 85,8 87,8 83,0 83,5 79,4 73,0 65,9 94 87 69 61 56

110.2 91,0 86,7 88,5 83,8 84,0 80,2 74,1 67,0 95 88 70 61 56

140.2 93,2 88,9 90,7 86,0 86,2 82,4 76,3 69,2 97 90 71 63 58

180.2 95,2 90,9 92,7 88,0 88,2 84,4 78,3 71,2 99 92 73 65 60

220.2 96,2 91,9 93,7 89,0 89,2 85,4 79,3 72,2 100 93 74 66 61

Model

Sound power levels [dB] by octave bands [Hz]

Sound power

level

63 125 250 500 1000 2000 4000 8000 [dB] [dB(A)]

35.1 84,4 82,8 83,0 76,2 76,0 75,1 72,0 65,9 89 82

45.1 84,5 82,7 83,6 78,1 78,4 78,3 76,0 70,9 90 85

55.1 86,6 83,4 85,5 80,2 81,1 81,0 79,4 75,1 92 87

70.2 84,9 86,4 80,7 78,6 75,2 75,3 73,2 67,4 90 82

90.2 83,8 86,7 82,8 82,5 78,7 78,7 76,9 71,5 91 86

110.2 84,3 88,4 84,2 85,2 80,7 80,9 79,5 74,7 93 88

140.2 75,0 73,0 72,0 74,0 74,0 72,0 70,0 65,0 82 79

180.2 79,0 77,0 76,0 78,0 78,0 76,0 74,0 69,0 86 83

220.2 83,0 81,0 80,0 82,0 82,0 80,0 78,0 73,0 90 87

Unit noise levels

Internal fan noise levels

Reference conditions

Performances referred to units with VB constructive configuration (base version) operating in cooling mode at NOMINAL conditions A35A27 with

STANDARD air flow rate and available static head.

Unit placed in free field on reflecting surface (directional factor equal to 2) with air inlet and outlet connections ducted for 2 metres.

The sound power level is measured according to ISO 3744 standard.

The sound pressure level is calculated according to ISO 3744 and is referred to a distance of 1/5/10 metres from the external surface of the unit.

LOW NOISE acoustic setting up (AS)

Model

Sound power levels [dB]

by octave bands [Hz]

Sound power

level

Sound pressure level

at 1 metre at 5 metres at 10 metres

63 125 250 500 1000 2000 4000 8000 [dB] [dB(A)] [dB(A)] [dB(A)] [dB(A)]

35.1 77,2 78,1 80,8 76,5 77,7 74,1 67,6 60,5 86 81 64 55 50

45.1 80,3 78,9 81,4 77,1 78,1 74,6 68,6 61,6 87 82 64 55 50

55.1 81,9 79,7 81,9 77,7 78,4 75,1 69,6 62,5 88 82 65 56 51

70.2 79,9 80,9 83,8 79,4 80,7 77,0 70,3 63,4 89 84 66 58 53

90.2 82,6 81,2 83,9 79,6 80,6 77,0 70,9 64,0 89 84 66 58 53

110.2 84,9 82,4 84,9 80,7 81,4 78,1 72,3 65,4 91 85 67 59 54

140.2 86,9 84,4 86,9 82,7 83,4 80,1 74,3 67,4 93 87 68 60 55

180.2 88,9 86,4 88,9 84,7 85,4 82,1 76,3 69,4 95 89 70 62 57

220.2 89,9 87,4 89,9 85,7 86,4 83,1 77,3 70,4 96 90 71 63 58

Reference conditions

Performances referred to units with VB constructive configuration (base version) operating in cooling mode at NOMINAL conditions A35A27 with

STANDARD air flow rate and available static head.

The sound power level is obtained starting from the data declared by the manufacturer of the fans.

Page 32

32

TECHNICAL DATA AND PERFORMANCES

Weights

Model 35.1 45.1 55.1 70.2 90.2 110.2 140.2 180.2 220.2 U.M.

Constructive configuration

Base version VB 724 807 874 1052 1220 1345 1820 1940 2010 kg

1 damper version V1 916 999 1066 1316 1484 1609 2148 2268 2338 kg

2 dampers version V2 927 1010 1077 1327 1495 1620 2170 2290 2360 kg

3 dampers version V3 1130 1213 1280 1577 1745 1870 2810 2930 3000 kg

Options and accessories

Internal fan

Reduced -3 -6 -2 -6 -17 -11 -22 0 -12 kg

Upsized 9 7 7 11 49 49 20 32 0 kg

Hot water coil

2 rows with pipes 31 35 38 39 44 49 70 80 90 kg

2 rows with 3 way valve 36 40 43 47 52 57 82 92 102 kg

3 rows with pipes 36 41 46 46 53 61 84 98 114 kg

3 rows with 3 way valve 41 46 51 54 61 69 96 110 126 kg

Electrical heater coil

Standard 21 21 21 37 37 37 74 74 74 kg

Upsized 34 34 34 52 52 52 104 104 104 kg

Condensing

gas heating module

Standard 270 270 270 402 402 402 720 720 720 kg

Upsized 275 275 275 442 442 442 800 800 800 kg