Ferroli PEGASUS F2 51, PEGASUS F2 68, PEGASUS F2 85, PEGASUS F2 102 Instructions For Use, Installation And Maintenance

Page 1

INSTALLATION ANDINSTALLATION AND

INSTALLATION AND

INSTALLATION ANDINSTALLATION AND

MAINTENANCE INSTRUCTIONSMAINTENANCE INSTRUCTIONS

MAINTENANCE INSTRUCTIONS

MAINTENANCE INSTRUCTIONSMAINTENANCE INSTRUCTIONS

PEGASUS F2PEGASUS F2

PEGASUS F2

PEGASUS F2PEGASUS F2

Appr. nr. A 9503 A - 0085 AQ 0765

GAS-FIRED CAST-IRON BOILERSGAS-FIRED CAST-IRON BOILERS

GAS-FIRED CAST-IRON BOILERS

GAS-FIRED CAST-IRON BOILERSGAS-FIRED CAST-IRON BOILERS

WITH ELECTRONIC IGNITIONWITH ELECTRONIC IGNITION

WITH ELECTRONIC IGNITION

WITH ELECTRONIC IGNITIONWITH ELECTRONIC IGNITION

AND FLAME RECTIFICATION MONITORINGAND FLAME RECTIFICATION MONITORING

AND FLAME RECTIFICATION MONITORING

AND FLAME RECTIFICATION MONITORINGAND FLAME RECTIFICATION MONITORING

Models 51 - 68 - 85 - 102Models 51 - 68 - 85 - 102

Models 51 - 68 - 85 - 102

Models 51 - 68 - 85 - 102Models 51 - 68 - 85 - 102

cod. 3543463/0 - 01/01

Page 2

ContentsContents

Contents

ContentsContents

1.1.

1. General technical data .............................................................................................................. 3

1.1.

2.2.

2. Dimensions and technical data ................................................................................................. 3

2.2.

3.3.

3. Boiler installation ...................................................................................................................... 7

3.3.

4.4.

4. Wiring and connection diagrams...............................................................................................8

4.4.

5.5.

5. Startup and shutdown ............................................................................................................. 13

5.5.

6.6.

6. Regulating ............................................................................................................................... 15

6.6.

7.7.

7. Fuel conversion (from natural to l.p.g. Gas) ............................................................................. 19

7.7.

8.8.

8. Maintenance and cleaning ...................................................................................................... 20

8.8.

9.9.

9. Fault finding ............................................................................................................................ 21

9.9.

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

2

Page 3

1. GENERAL TECHNICAL DATA1. GENERAL TECHNICAL DATA

1. GENERAL TECHNICAL DATA

1. GENERAL TECHNICAL DATA1. GENERAL TECHNICAL DATA

1.011.01

IntroductionIntroduction

1.01

Introduction

1.011.01

IntroductionIntroduction

Pegasus F2Pegasus F2

The

Pegasus F2, with CE approval, is designed for use with natural gas (G20) or LPG (G31) for indirect

Pegasus F2Pegasus F2

central heating and hot water.

1.021.02

Installation requirementsInstallation requirements

1.02

Installation requirements

1.021.02

Installation requirementsInstallation requirements

Only CORGI registered installers should fit the Pegasus boilers.

The boiler installation should comply with relevant British Standards Specifications, codes of practice,

and Current Building Regulations, together with any special Regional Requirements of the Local

Authorities, gas supplier and Insurance Companies.

2. DIMENSIONS AND TECHNICAL DATA2. DIMENSIONS AND TECHNICAL DATA

2. DIMENSIONS AND TECHNICAL DATA

2. DIMENSIONS AND TECHNICAL DATA2. DIMENSIONS AND TECHNICAL DATA

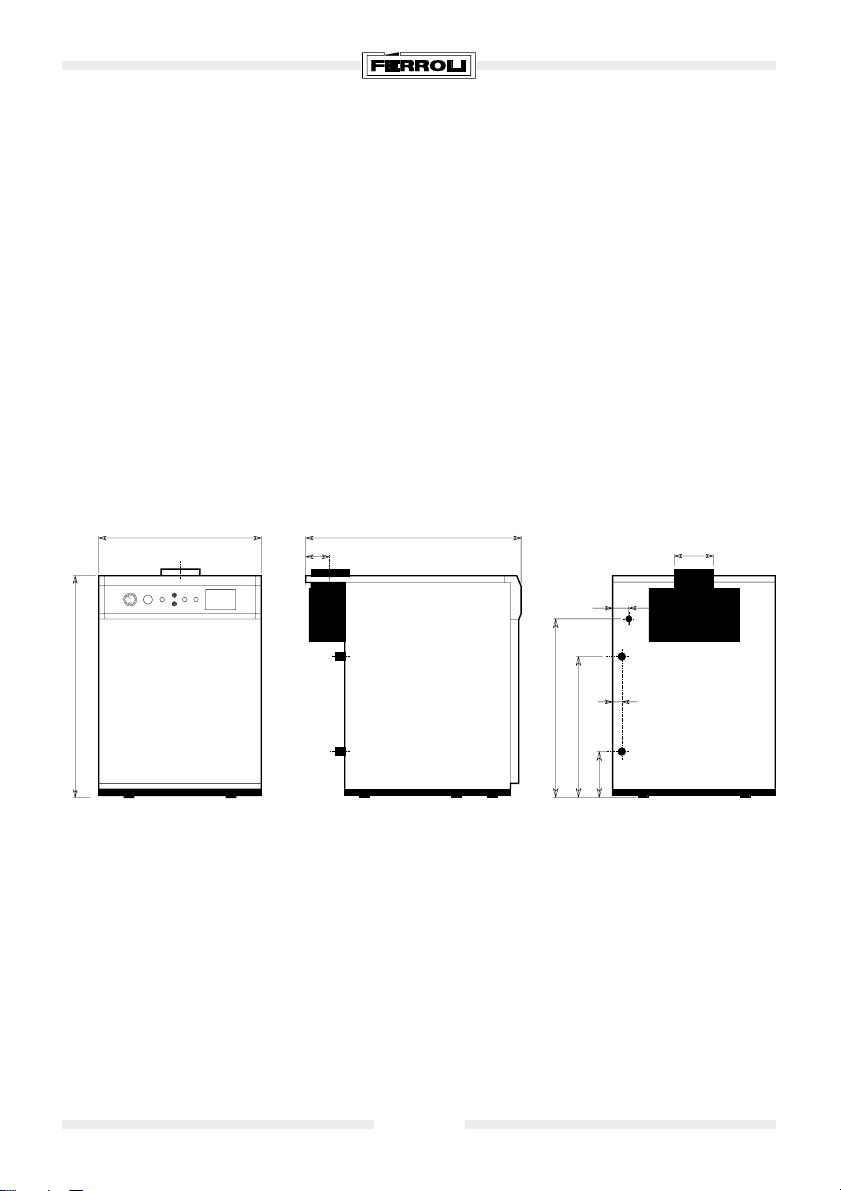

2.012.01

Dimensional data (see fig. 1 and table 2)Dimensional data (see fig. 1 and table 2)

2.01

Dimensional data (see fig. 1 and table 2)

2.012.01

Dimensional data (see fig. 1 and table 2)Dimensional data (see fig. 1 and table 2)

A

1000

a1a1

a1 - Return 1" 1/2

a1a1

a2a2

a2 - flow 1" 1/2

a2a2

a3a3

a3 - Gas inlet 3/4"

a3a3

B

900

D

762

672

222

C

a3

a2

E

a1

Fig. 1

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

3

Page 4

2.022.02

Technical dataTechnical data

2.02

Technical data

2.022.02

Technical dataTechnical data

The standard cast-iron

PEGASUS F2PEGASUS F2

PEGASUS F2 boiler is set to operate on natural gas (G20).

PEGASUS F2PEGASUS F2

The boiler is designed to operate with a flow temperature of 82°C and a maximum ∆t of 20°C.

Pegasus F2 51

Pegasus F2 68

Table 1

Pegasus F2 85

Pegasus F2 102

Pegasus F2 51

Pegasus F2 68

Table 2

Pegasus F2 85

Pegasus F2 102

Pegasus F2 51

Pegasus F2 68

Table 3

Pegasus F2 85

Pegasus F2 102

MODEL

MODEL

MODEL

A

mm

550

640

720

800

No.

OF MAIN

BURNERS

3

4

5

6

C

2,15

2,15

2,15

2,15

HEAT

OUTPUT

D

mm

43

46

44

42

INJECTORS

Nat. G20

0,4

0,4

0,4

0,4

kW

102

51

68

85

PILOT

Ø mm

mm

E

35

38

36

34

RETURN

G.P.L. G31

0,24

0,24

0,24

0,24

NUMBER OF

SECTIONS

4

5

6

7

DIMENSIONS CONNECTIONS

B

mm

Ø mm

96,5

180

96,5

180

106,5

200

106,5

200

PRINCIPALES

INJECTORS

Ø mm

G.P.L. G31

Nat. G20

3,5

3,5

3,5

3,5

a1 Ø

1 1/2"

1 1/2"

1 1/2"

1 1/2"

FLOW

a2 Ø

1 1/2"

1 1/2"

1 1/2"

1 1/2"

GAS SUPPLY

PRESSURE

(mbars)

Nat. G20

15 to 23

15 to 23

15 to 23

15 to 23

HEAT INPUT

(NETT)

kW

56

74,8

93,5

112

GAS

a3 Ø

3/4"

3/4"

3/4"

3/4"

LPG G31

37

37

37

37

WEIGHT

INCLUDING

PACKAGE

GAS PRESS. AT

BURNER MANIFOLD

Nat. G20

13,3

13,3

13,3

13,3

CONTENT

Kg.

260

300

350

400

(mbars)

LPG G31

36

36

36

36

HEAT INPUT

(GROSS)

kW

62,2

83

103,8

124,3

WATER

(liter)

22

26

30

34

GAS FLOW RATE

Nat. G20

m

5,9

7,9

9,9

11,8

MAX

OPERATING

PRESSURE

(bars)

3

/h

4

4

4

4

LPG G31

kg/h

4,34

5,79

7,24

8,68

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

4

Page 5

2.032.03

Main componentsMain components

2.03

Main components

2.032.03

Main componentsMain components

816

75

14

1 2

4

6 3

10

15

11

13

Front view of the boiler without front casing Front view of the boiler without front casing

Front view of the boiler without front casing

Front view of the boiler without front casing Front view of the boiler without front casing

Fig. 2a

5

9

12

KeyKey

Key

KeyKey

11

1 Temperature-pressure gauge

11

22

2 Boiler control thermostat

22

33

3 Ignition lockout re-set botton

33

44

4 Boiler on/off switch

44

55

5 Flue gas safety thermostat

55

66

6 Limit thermostat reset botton

66

77

7 Ignition PCB

77

88

8 Electronic panel (not available UK)

88

6

4

2

1

Control panel Control panel

Control panel

Control panel Control panel

Fig. 2b

99

9 Control panel

99

1010

10 Gas valve

1010

1111

11 Pilot burner assembly

1111

1212

12 Gas burner manifold

1212

1313

13 Gas pressure test point

1313

1414

14 Automatic air vent

1414

1515

15 Drain cock

1515

1616

16 Flue gas sampling point

1616

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

9

8

7

3

5

Page 6

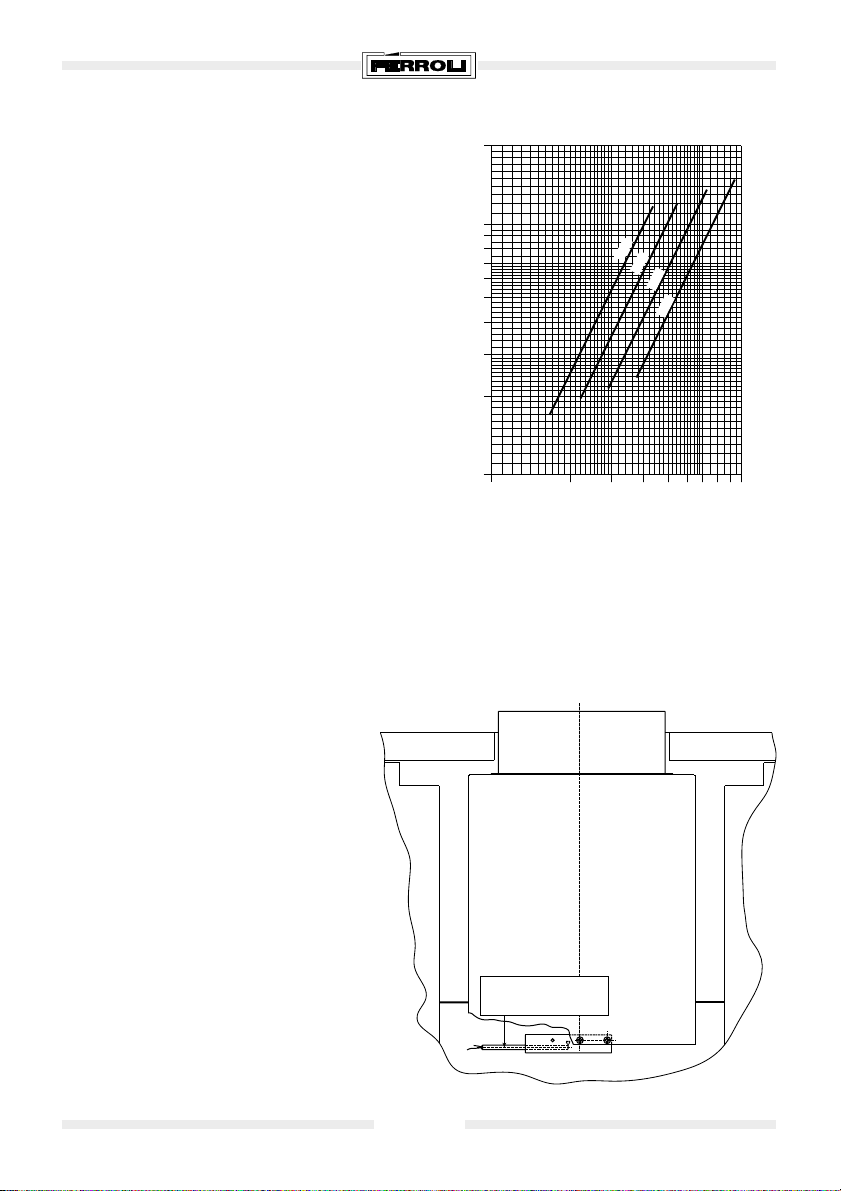

2.042.04

Characteristic pressure drop curveCharacteristic pressure drop curve

2.04

Characteristic pressure drop curve

2.042.04

Characteristic pressure drop curveCharacteristic pressure drop curve

Water pressure drop in all models is shown in fig.

3. The following diagram shows the pressure drop

in the boiler as a function of the water flow rate.

∆P mbar

200

100

90

80

70

60

50

40

30

20

4 EL.

5 EL.

6 EL.

7 EL.

Fig. 3

2.052.05

Safe discharge of combustion productsSafe discharge of combustion products

2.05

Safe discharge of combustion products

2.052.05

Safe discharge of combustion productsSafe discharge of combustion products

10

12345678910

Flow rate

The boiler comes with a FLUE GAS SAFETY THERMOSTAT, which provides a high level of safety and

control over the discharge of combustion products. This thermostat cuts off the supply of gas to the

burner in the event of a faulty flue draft.

If the FLUE GAS SAFETY THERMOSTAT has been activated, you should unscrew the protection cover

(part no. 5 in fig. 2a and 2b) and manually

“reset” the thermostat. After that, the boiler

will return to normal operation.

Boiler rear viewBoiler rear view

Boiler rear view

Boiler rear viewBoiler rear view

If the FLUE GAS SAFETY THERMOSTAT

needs to be replaced, use original

manufacturer’s parts only and make sure

the electric connections and positioning of

the bulb (see fig. 4) are correct; NEVER

UNDER ANY CIRCUMSTANCES LEAVE

THE FLUE GAS SAFETY THERMOSTAT

DISCONNECTED FROM THE ELECTRIC

CIRCUIT.

In case of frequent tripping of the thermostatic switch, contact qualified personnel

only.

During cleaning of the draft diverter, be

careful not to damage the thermostat phial.

Flue gas safety

thermostat phial

Fig. 4

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

6

Page 7

3. BOILER INSTALLATION3. BOILER INSTALLATION

3. BOILER INSTALLATION

3. BOILER INSTALLATION3. BOILER INSTALLATION

(To be performed by qualified personnel only)

3.013.01

General warningsGeneral warnings

3.01

General warnings

3.013.01

General warningsGeneral warnings

The boiler should be installed according to current regulations (see para 1.02).

We suggest fitting isolating valves between the boiler and the heating system to isolate the boiler from

the system if necessary.

The rise in temperature of the heating water (the difference between the water flow and return

temperatures) should not exceed 20°C. This is so as to prevent possible damage caused by

condensation forming in the boiler.

Combustion products should be discharged through a flue with a cross section in accordance with

current standards and not less than the boiler flue outlet connection.

Connect the gas to the boiler in accordance with current regulations. The diameter of the boiler gas

inlet gas pipe does not dictate the choice of diameter for the pipe between the boiler and the gas meter

should be calculated based upon its length and pressure drop.

3.023.02

Boiler water characteristicsBoiler water characteristics

3.02

Boiler water characteristics

3.023.02

Boiler water characteristicsBoiler water characteristics

When the water supply has a hardness of more than 25 - 30 Fr., it should be treated before entering

the heating system to prevent both scaling (caused by hard water) and corrosion (caused by aggressive

water) in the boiler. Please remember that because of their low thermal conductivity, even small scales

just a few millimetres thick cause the boiler walls to overheat considerably with serious consequences.

You must treat the water used for the heating system in the following cases:You must treat the water used for the heating system in the following cases:

You must treat the water used for the heating system in the following cases:

You must treat the water used for the heating system in the following cases:You must treat the water used for the heating system in the following cases:

A) Very large systems (with large volumes of water).A) Very large systems (with large volumes of water).

A) Very large systems (with large volumes of water).

A) Very large systems (with large volumes of water).A) Very large systems (with large volumes of water).

B) Systems where partial or complete draining - and water refilling - are frequent.B) Systems where partial or complete draining - and water refilling - are frequent.

B) Systems where partial or complete draining - and water refilling - are frequent.

B) Systems where partial or complete draining - and water refilling - are frequent.B) Systems where partial or complete draining - and water refilling - are frequent.

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

7

Page 8

4. WIRING AND CONNECTION DIAGRAMS4. WIRING AND CONNECTION DIAGRAMS

4. WIRING AND CONNECTION DIAGRAMS

4. WIRING AND CONNECTION DIAGRAMS4. WIRING AND CONNECTION DIAGRAMS

4.014.01

Electrical connectionsElectrical connections

4.01

Electrical connections

4.014.01

Electrical connectionsElectrical connections

- Electrical connections should be performed according to the diagrams shown here.

- Connect the boiler to a single-phase, phase neutral, 230 V ~ 50 Hz power supply through a standard

terminal block or outlet with 2A max. fuses connected between the boiler and the power support.

Remember that the boiler should always be provided with good earthing.

IMPORTANT:IMPORTANT:

IMPORTANT: If on use a 230 V room thermostat, it must be in II class.

IMPORTANT:IMPORTANT:

The manufacturer disclaims any liability for damage to property or persons caused by

failure to earth the boiler correctly.

General wiring diagram for mod. 51-68-85General wiring diagram for mod. 51-68-85

General wiring diagram for mod. 51-68-85

General wiring diagram for mod. 51-68-85General wiring diagram for mod. 51-68-85

230V

50Hz

L

1

4

5

2

N

3

31

1

42

2

169

3

4

16

32

6

18

17

98

L1

N1

7

129

3

4

1

2

253713

1

83

616

19

S 4561 B

HONEYWELL

118

117

21

8

114

9

10

11

12

13

2

14

20

116

160

72

C

63

1

14

49

15

92

24

X6

9

X5

X4

17

X3

22

82

25

Fig. 5a

KeyKey

Key

KeyKey

116116

116 Gas pressure switch

2424

24 Spark electrode

2424

2525

25 Pilot burner

2525

3232

32 Pump (not supplied)

3232

4949

49 Limit thermostat (manual reset)

4949

6363

63 Boiler control thermostat

6363

7272

72 Room thermostat

7272

Note:Note:

Note:

Note:Note:

8282

82 Ionization probe

8282

8383

83 Ignition PCB

8383

9292

92 Flue gas thermostat

9292

9898

98 Boiler on/off switch

9898

114114

114 Water flow pressure switch

114114

(not supplied)

116116

117117

117 Main gas valve

117117

118118

118 Pilot light gas valve

118118

129129

129 Ignition lockout re-set botton

129129

160160

160 Auxiliary contact

160160

169169

169 Suppression filter

169169

• Dotted lines indicate connections to be performed during installation.

• Terminals L1, N1, 6 are reserved for connecting an electronic compensator (not available in UK)

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

8

Page 9

Electrical connections diagram for mod. 51-68-85Electrical connections diagram for mod. 51-68-85

Electrical connections diagram for mod. 51-68-85

Electrical connections diagram for mod. 51-68-85Electrical connections diagram for mod. 51-68-85

X6

X5

X4

X3

39 171425671

1

3

S 4561 B

HONEYWELL

13 16

2

63

1

C

83

169

3

1

4

2

1

2

98

4

3

2

4

129

3514220191817161514131211 2221987610

N1

L1

N

L

160114

230V

50Hz

116

49

72

32

24

82

25

92

2423

L

N

N

L

118

117

Fig. 5b

KeyKey

Key

KeyKey

116116

116 Gas pressure switch

2424

24 Spark electrode

2424

2525

25 Pilot burner

2525

3232

32 Pump (not supplied)

3232

4949

49 Limit thermostat (manual reset)

4949

6363

63 Boiler control thermostat

6363

7272

72 Room thermostat

7272

Note:Note:

Note:

Note:Note:

8282

82 Ionization probe

8282

8383

83 Ignition PCB

8383

9292

92 Flue gas thermostat

9292

9898

98 Boiler on/off switch

9898

114114

114 Water flow pressure switch

114114

(not supplied)

116116

117117

117 Main gas valve

117117

118118

118 Pilot light gas valve

118118

129129

129 Ignition lockout re-set botton

129129

160160

160 Auxiliary contact

160160

169169

169 Suppression filter

169169

• Dotted lines indicate connections to be performed during installation.

• Terminals L1, N1, 6 are reserved for connecting an electronic compensator (not available in UK)

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

9

Page 10

General wiring diagram for mod. 102General wiring diagram for mod. 102

General wiring diagram for mod. 102

General wiring diagram for mod. 102General wiring diagram for mod. 102

L

230V

50Hz

1

L1

4

N1

5

2

N

3

98

42

3

1

2

1

169

3

4

6

7

1

16

32

18

17

83

22

8

129

3

4

1

2

253713

S 4561 B

HONEYWELL

61617

118

19

117

21

114

9

10

116

11

12

13

2

160

C

63

1

14

49

15

92

X6

9

X5

X4

14

X3

20

24

82

25

Fig. 5c

KeyKey

Key

KeyKey

2424

24 Spark electrode

2424

2525

25 Pilot burner

2525

3232

32 Pump (not supplied)

3232

4949

49 Limit thermostat (manual reset)

4949

6363

63 Boiler control thermostat

6363

8282

82 Ionization probe

8282

8383

83 Ignition PCB

8383

9292

92 Flue gas thermostat

9292

Note:Note:

Note: Dotted lines indicate connections to be performed during installation.

Note:Note:

9898

98 Boiler on/off switch

9898

114114

114 Water flow pressure switch (not supplied)

114114

116116

116 Gas pressure switch

116116

117117

117 Main gas valve

117117

118118

118 Pilot light gas valve

118118

129129

129 Ignition lockout re-set botton

129129

160160

160 Auxiliary contact

160160

169169

169 Suppression filter

169169

Terminals L1, N1, 6 are reserved for connecting an electronic compensator (not available in

UK)

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

10

Page 11

Electrical connections diagram for mod. 102Electrical connections diagram for mod. 102

Electrical connections diagram for mod. 102

Electrical connections diagram for mod. 102Electrical connections diagram for mod. 102

83

169

1

2

1

98

3

3

4

2

4

2

4

3925671

1

3

129

3514220191817161514131211 2221987610

N1L1

S 4561 B

HONEYWELL

63

X6

X5

X4

1714 1613

X3

2

1

C

24

82

25

92

N

L

230V

50Hz

114

116

160

49

32

LNNL

Fig. 5d

KeyKey

Key

KeyKey

2424

24 Spark electrode

2424

2525

25 Pilot burner

2525

3232

32 Pump (not supplied)

3232

4949

49 Limit thermostat (manual reset)

4949

6363

63 Boiler control thermostat

6363

8282

82 Ionization probe

8282

8383

83 Ignition PCB

8383

9292

92 Flue gas thermostat

9292

Note:Note:

Note: Dotted lines indicate connections to be performed during installation.

Note:Note:

9898

98 Boiler on/off switch

9898

114114

114 Water pressure switch (not supplied)

114114

116116

116 Gas pressure switch

116116

117117

117 Main gas valve

117117

118118

118 Pilot light gas valve

118118

129129

129 Ignition lockout reset botton

129129

160160

160 Auxiliary contact

160160

Terminals L1, N1, 6 are reserved for connecting an electronic compensator (not avbailable in

UK)

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

118

117

11

Page 12

4.02 Access to the control panel internal components4.02 Access to the control panel internal components

4.02 Access to the control panel internal components

4.02 Access to the control panel internal components4.02 Access to the control panel internal components

For access to the terminal block and the internal components of the control panel, proceed as follows:

a - Shut off the power supply to the boiler.

b - Lift off the boiler cover (held in place by slot pins).

c - Unscrew the two screws that hold the plastic panel against the side of the boiler .

d - Rotate the panel all the way round to its locked position.

e - Carry out the work and reassemble in reverse order.

Caution:Caution:

Caution: Handle the flame control electronic board (part 4 in fig. 6) and its connections with

Caution:Caution:

particular care.

4.034.03

Exploded view of the control panel (fig. 6)Exploded view of the control panel (fig. 6)

4.03

Exploded view of the control panel (fig. 6)

4.034.03

Exploded view of the control panel (fig. 6)Exploded view of the control panel (fig. 6)

55

5

55

77

7

77

44

4

44

33

3

33

1010

10

1010

11

1

11

88

8

88

KeyKey

Key

KeyKey

1.1.

1. Control panel

1.1.

2.2.

2. Wiring harness protection plate

2.2.

3.3.

3. Terminal block

3.3.

4.4.

4. Ignition PCB

4.4.

5.5.

5. Boiler control thermostat

5.5.

12

66

6

66

99

9

99

22

2

22

Fig. 6

6.6.

6. Limit thermostat (manual reset)

6.6.

7.7.

7. Flue gas thermostat

7.7.

8.8.

8. Boiler on/off switch

8.8.

9.9.

9. Ignition lockout reset

9.9.

10.10.

10. Combined temperature and pressure gauge

10.10.

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

Page 13

5. STARTUP AND SHUTDOWN5. STARTUP AND SHUTDOWN

5. STARTUP AND SHUTDOWN

5. STARTUP AND SHUTDOWN5. STARTUP AND SHUTDOWN

5.015.01

Checks to be carried out at first startupChecks to be carried out at first startup

5.01

Checks to be carried out at first startup

5.015.01

Checks to be carried out at first startupChecks to be carried out at first startup

It is good practice to check the following at first startup: that the cutoff valves between the boiler and

heating system are open; that all is well pressurized and vented; that there are no gas or water leaks

from the water system or boiler; that the electrical connections are correct and the earthing cable

connected to a good earthing system; that there are no inflammable liquids or materials in the

immediate vicinity of the boiler and that the flue is not blocked.

5.025.02

Startup procedureStartup procedure

5.02

Startup procedure

5.025.02

Startup procedureStartup procedure

- Set the boiler control thermostat knob to the desired temperature (not below 50°C).

- Open the gas cock upstream from the boiler.

- Vent gas supply pipework.

- Switch on boiler.

At this point the electronic control unit takes over and after a preset pause sends a command to the pilot

valve to open and triggers off the discharge to the spark electrodes, igniting the pilot burner.

The pilot burner flame, ionizing the detection electrode, sends a signal to the electronic control unit

which in turn sends a command to the main valve to open, igniting the main burner.

The boiler now functions automatically, controlled by the boiler control thermostat and/or by any other

command/control devices (room thermostat, electronic thermostat board, etc.).

Note:Note:

Note: If after having closely followed the startup procedure the burners fail to light and the reset button

Note:Note:

warning light on the electronic control unit is lit, it means that the board has locked out and you

should wait about 10 seconds before pressing the reset button.

After resetting, the board repeats the startup cycle.

If the burners still fail to light after the second attempt, read paragraph 9, “Fault finding”.

In the event of the electric power supply to the boiler being cut off, the burners shut down and

light up again automatically when the power returns.

5.035.03

Temporary shutdownTemporary shutdown

5.03

Temporary shutdown

5.035.03

Temporary shutdownTemporary shutdown

To turn the boiler off temporarily, simply switch off the power supply to the boiler. The electrical

components will be without power and the main and pilot burners will remain off.

5.045.04

Long-term boiler shutdownLong-term boiler shutdown

5.04

Long-term boiler shutdown

5.045.04

Long-term boiler shutdownLong-term boiler shutdown

Turn off inlet gas cock to the boiler and switch off the power supply.

Caution:Caution:

Caution: If the boiler remains unused for long periods during the winter, in order to avoid frost

Caution:Caution:

damages you should pour a suitable anti-freeze into the system or drain it completely.

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

13

Page 14

5.05 Inspections and controls after startup5.05 Inspections and controls after startup

5.05 Inspections and controls after startup

5.05 Inspections and controls after startup5.05 Inspections and controls after startup

At first startup:

- Make sure the gas supply is perfectly leakproof.

- Make sure the pilot light is adequate and well adjusted.

- Test boiler ignition by starting it and turning it off using the control thermostat.

- Check that no flue products escapes from the boiler draft diverter indicating that either the flue is

blocked or the draft is insufficient.

- Check the efficiency of the flue while the boiler is working.

- Check that there are no leaks from the points where the boiler/flue connects to the boiler and the

flue.

- Check that gas consumption, measured by the gas meter, matches the figure indicated in the

technical data table.

- Check that the water is circulating properly between the boiler and heating units.

- Make sure that when the pilot flame is extinguished, the safety devices are activated, shutting off

the main gas burners.

14

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

Page 15

6. REGULATING6. REGULATING

6. REGULATING

6. REGULATING6. REGULATING

As described above, the boiler is set up to operate on natural gas (G20); gas pressure has been tested

and calibrated by the manufacturer.

However, due to possible differences in pressure in the gas supply system, at first startup you should

check and if necessary adjust the pressure at the injectors to match the pressure level shown in table

3 (paragraph 2.02) of the technical data.

6.02 Gas pressure adjustment with the “Honeywell VR 4601 CB” valve in models 51-68-856.02 Gas pressure adjustment with the “Honeywell VR 4601 CB” valve in models 51-68-85

6.02 Gas pressure adjustment with the “Honeywell VR 4601 CB” valve in models 51-68-85

6.02 Gas pressure adjustment with the “Honeywell VR 4601 CB” valve in models 51-68-856.02 Gas pressure adjustment with the “Honeywell VR 4601 CB” valve in models 51-68-85

Adjust the supply pressure at the main burners by turning the stabilizer screw 7 (fig. 7).

To increase the pressure, turn the screw clockwise. To decrease the pressure, turn the screw

anticlockwise.

The pilot light requires no adjustment.

Caution:Caution:

Caution: Pressure measured at pressure test points 1 and 2 (fig. 7) is displayed 30 seconds or more

Caution:Caution:

after making the adjustment.

5

1

3

7

2

6

Key:Key:

Key:

Key:Key:

1.1.

1. Inlet pressure test point

1.1.

2.2.

2. Outlet pressure test point

2.2.

3.3.

3. Screw block stabilizer

3.3.

4.4.

4. Pilot coil electric connections

4.4.

5.5.

5. Main burner coil electric connections

5.5.

6.6.

6. Pilot burner supply

6.6.

7.7.

7. Main burner gas pressure adjustment screw

7.7.

Fig. 7

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

4

15

Page 16

6.036.03

Gas pressure adjustment with the “DUNGS MBDLE 407 BO1” valve in model 102Gas pressure adjustment with the “DUNGS MBDLE 407 BO1” valve in model 102

6.03

Gas pressure adjustment with the “DUNGS MBDLE 407 BO1” valve in model 102

6.036.03

Gas pressure adjustment with the “DUNGS MBDLE 407 BO1” valve in model 102Gas pressure adjustment with the “DUNGS MBDLE 407 BO1” valve in model 102

4

3

1

5

6

Pa

Pe

9

8

7

2

Fig. 8

Key:Key:

Key:

Key:Key:

1.1.

1. Inlet gas pressure test point

1.1.

(Burner pressure is measured at test point on burner manifold)

2.2.

2. Pilot burner supply

2.2.

3.3.

3. Integral gas pressure switch

3.3.

4.4.

4. Gas pressure switch connector (grey)

4.4.

5.5.

5. V1-V2 gas valve power connector (black)

5.5.

6.6.

6. Gas governor

6.6.

7.7.

7. Gas flow rate regulator (valve V2)

7.7.

8.8.

8. Slow startup regulator (under the cover)

8.8.

9.9.

9. Cover protecting the incoming gas filter.

9.9.

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

16

Page 17

Gas pressure adjustment:Gas pressure adjustment:

Gas pressure adjustment:

Gas pressure adjustment:Gas pressure adjustment:

- Move the protective cover by turning it on its hinges.

- Using a small screwdriver (no. 3), turn the regulating screw to

set the required pressure.

Note:Note:

Note: The pilot light requires no adjustments.

Note:Note:

Fig. 8a

Main gas flow rate adjustmentMain gas flow rate adjustment

Main gas flow rate adjustment (valve V2)

Main gas flow rate adjustmentMain gas flow rate adjustment

- Loosen the securing screw using a screwdriver.

- Turn the knob to the required setting, then re-tighten the

securing screw.

Note:Note:

Note: Pressure measured at pressure test points is displayed 30

Note:Note:

seconds or more after performing the adjustment.

Fig. 8b

Slow startup adjustmentSlow startup adjustment

Slow startup adjustment

Slow startup adjustmentSlow startup adjustment

- Unscrew the black plastic cap

- Using the cap as a tool turn the pin under it to the desired

setting.

- Screw the plastic cap back.

Fig. 8c

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

17

Page 18

6.046.04

Pilot burner unit (fig. 9)Pilot burner unit (fig. 9)

6.04

Pilot burner unit (fig. 9)

6.046.04

Pilot burner unit (fig. 9)Pilot burner unit (fig. 9)

KeyKey

Key

KeyKey

11

1 Combustion chamber cover plate

11

22

2 Inspection window

22

33

3 Pilot burner

33

44

4 Ignition electrode

44

55

5 Flame rectification probe

55

66

6 Pilot injector

66

77

7 Ht lead

77

88

8 Pilot gas supply

88

3 ÷ 4 mm

3

4

5

Fig. 9

8

18

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

Page 19

7. FUEL CONVERSION (from natural to L.P.G. Gas)7. FUEL CONVERSION (from natural to L.P.G. Gas)

7. FUEL CONVERSION (from natural to L.P.G. Gas)

7. FUEL CONVERSION (from natural to L.P.G. Gas)7. FUEL CONVERSION (from natural to L.P.G. Gas)

In order to carry out such operation it must replace the main nozzles and that pilot, proceeding in the

following way:

- Turn off the gas and switch off the power supply to the boiler.

- Remove the main gas burners.

- Disassemble the pilot burner (fig. 8).

- Remove the main burners from manifold.

- Replace the main and pilot injectors taking care not to spoil the main injector sealing gaskets. If they

have been damaged, replace them.

- Re-assemble with care.

- Carefully screw in fully the pressure regulating screw 7 (fig. 7) on the “Honeywell VR 4601 CB” gas

valve in models 51-68-85 and the screws (fig. 8a and 8b) on the “DUNGS MBDLE 407 BO1” valve

in model 102.

- Check that the boiler functions correctly and that there are no gas leaks.

Moreover for the version with "Honeywell VR 4601 CB" gas valve (for models 51-68-85) should be

mounted on the body valve the appropriate calibrated adapter of slow ignition (supplied on request),

operating in the following way:

- remove from the body valve gas the plastic protection cover

“M”“M”

“M” (fig. 10)

“M”“M”

- screw the adapter N to the body gas valve

- replace the of protection cover

REMEMBER:REMEMBER:

REMEMBER: The L.P.G. injector kit may be obtained from our Commercial boiler sales department.

REMEMBER:REMEMBER:

“M”“M”

“M” on the adapter.

“M”“M”

Fig. 10

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

19

Page 20

8. MAINTENANCE AND CLEANING8. MAINTENANCE AND CLEANING

8. MAINTENANCE AND CLEANING

8. MAINTENANCE AND CLEANING8. MAINTENANCE AND CLEANING

The following operations are to be performed by qualified personnel only.

8.018.01

Seasonal inspection of the boiler and flueSeasonal inspection of the boiler and flue

8.01

Seasonal inspection of the boiler and flue

8.018.01

Seasonal inspection of the boiler and flueSeasonal inspection of the boiler and flue

Before the beginning of winter you should perform a general inspection of the boiler, heating system

and flue. The inspection should verify:

That the boiler flueways, burner and flue are clean.

That the water in the system is at the correct pressure – or correct level in the case of an open system.

That all control and safety devices operate properly.

That the probeand spark electrode are free of carbon deposits.

That the pilot flame correctly aligns with the probe.

That circulation pumps are free running.

That there are no gas leaks.

That the gas flow rate and pressure are correct.

That the pressure in the expansion vessel is as indicated in table 3 (paragraph 2.02).

8.028.02

Cleaning the boiler and the flueCleaning the boiler and the flue

8.02

Cleaning the boiler and the flue

8.028.02

Cleaning the boiler and the flueCleaning the boiler and the flue

To clean the boiler and the flue, remove the burner bars from the combustion chamber.

For access to the cast-iron exchanger, proceed as follows (fig. 11): Remove the cover of the casing

secured by slot pins; pull out the insulation covering the draft diverter, remove the smoke-box

inspection cover 2 and its insulation, secured with self-threading screws 1.

Now you may clean all the smoke passages in the boiler using a pipe brush 3. Remember you should

check and if necessary clean the flue and its connection to the boiler. Be careful not to damage the Flue

gas safety thermostat phial or capillary.

11

1

ImportantImportant

Important - Do not clean the burners with chemicals or a steel

ImportantImportant

brush, as these might change the air-gas mixture outlet holes.

When cleaning is complete, re-assemble carefully and in the

correct position. Then check the seal along the gas and smoke

11

22

2

22

44

4

44

33

3

33

circuits, functioning of the control and safety devices and gas

pressure and rate of flow.

KeyKey

Key

KeyKey

11

1 Securing screws

11

22

2 Inspection cover with insulation

22

33

3 Flue cleaning brush

33

44

4 Flue gas sampling point

44

20

Fig. 11

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

Page 21

9. FAULT FINDING9. FAULT FINDING

9. FAULT FINDING

9. FAULT FINDING9. FAULT FINDING

FaultFault

Fault

FaultFault

After a few startup attempts,After a few startup attempts,

After a few startup attempts,

After a few startup attempts,After a few startup attempts,

the electronic control unit fails tothe electronic control unit fails to

the electronic control unit fails to

the electronic control unit fails tothe electronic control unit fails to

ignite the boilerignite the boiler

ignite the boiler

ignite the boilerignite the boiler

At startup, there is no electricAt startup, there is no electric

At startup, there is no electric

At startup, there is no electricAt startup, there is no electric

discharge between the electrodesdischarge between the electrodes

discharge between the electrodes

discharge between the electrodesdischarge between the electrodes

No pilot ignitionNo pilot ignition

No pilot ignition

No pilot ignitionNo pilot ignition

Cause and Corrective ActionCause and Corrective Action

Cause and Corrective Action

Cause and Corrective ActionCause and Corrective Action

The pilot burner is clogged or dirty.

Check that the gas flow to the boiler is normal and that air

in the pipes has been removed.

Check that the electrodes are in their correct position and

free from scales (see fig. 9).

Make sure the boiler is connected to the power supply

and is well earthed.

Check that the pilot gas valve is powered up.

Check the connections to the detection and spark electrodes.

Check that the electrodes are in their right

position and free from scales.

Regulating thermostat is set too low.

Check the power supply.

Check the connections to the electronic control unit.

Make sure the NEUTRAL-PHASE connections have not

been reversed and the earth connection is effective.

Check incoming gas pressure and make sure the gas

pressure switch is open.

Reset the Flue gas safety thermostat.

Reset the safety thermostat.

No or little gas

Air is held in the pipes

.

Vent it as described in the chapter on startup.

Pilot injector is clogged or dirty.

Clean the injector with compressed air.

Poor pilot flamePoor pilot flame

Poor pilot flame

Poor pilot flamePoor pilot flame

Poor main burner flame:Poor main burner flame:

Poor main burner flame:

Poor main burner flame:Poor main burner flame:

too high, too low or too yellowtoo high, too low or too yellow

too high, too low or too yellow

too high, too low or too yellowtoo high, too low or too yellow

Smell of unburnt gasSmell of unburnt gas

Smell of unburnt gas

Smell of unburnt gasSmell of unburnt gas

No rise in temperatureNo rise in temperature

No rise in temperature

No rise in temperatureNo rise in temperature

while the boiler is workingwhile the boiler is working

while the boiler is working

while the boiler is workingwhile the boiler is working

Pilot injector is dirty

.

Gas valve filter is dirty.

Check that gas pressure at the burner is normal (see table

3 paragraph 2.02).

Injectors are dirty.

Check the boiler is clean.

Check that draft is sufficient.

Check that gas consumption is not excessive.

Make sure the regulating thermostat works.

Check that gas consumption is not below specifications.

Pegasus F2Pegasus F2

Pegasus F2

Pegasus F2Pegasus F2

21

Page 22

System water temperature isSystem water temperature is

System water temperature is

System water temperature isSystem water temperature is

too high or too lowtoo high or too low

too high or too low

too high or too lowtoo high or too low

Flare-ups at the burnerFlare-ups at the burner

Flare-ups at the burner

Flare-ups at the burnerFlare-ups at the burner

Delayed ignitionDelayed ignition

Delayed ignition

Delayed ignitionDelayed ignition

Regulating thermostat restartsRegulating thermostat restarts

Regulating thermostat restarts

Regulating thermostat restartsRegulating thermostat restarts

with too high a temperaturewith too high a temperature

with too high a temperature

with too high a temperaturewith too high a temperature

differencedifference

difference

differencedifference

Boiler forms condensateBoiler forms condensate

Boiler forms condensate

Boiler forms condensateBoiler forms condensate

Boiler becomes dirty quicklyBoiler becomes dirty quickly

Boiler becomes dirty quickly

Boiler becomes dirty quicklyBoiler becomes dirty quickly

Boiler shuts offBoiler shuts off

Boiler shuts off

Boiler shuts offBoiler shuts off

for no apparent reasonfor no apparent reason

for no apparent reason

for no apparent reasonfor no apparent reason

Check that the boiler is perfectly clean.

Check that the boiler rating is in proportion to the system.

Check the functioning of the regulating thermostat.

Check the pump is not blocked.

Make sure the pump characteristics are in proportion to

the size of the system.

Check that the gas pressure is sufficient

and that the boiler body is not dirty.

Check that the bulb is properly inserted.

Replace the thermostat

.

Check that the boiler is not running at too low a temperature.

Check that gas consumption is normal. Make sure the

burner flame is well adjusted.

Check that the burner flame is adjusted properly and that

gas consumption is in proportion to the boiler power.

Flue gas safety thermostat tripped.

Safety thermostat tripped after safe working temperature

has been exceeded.

Remember:Remember:

Remember: to avoid unnecessary expense, before contacting Service Department, make sure that any

Remember:Remember:

boiler failure is not due to the absence of electric power or gas supply.

Page 23

Page 24

ALL SPECIFICATIONS SUBJECT TO CHANGEALL SPECIFICATIONS SUBJECT TO CHANGE

ALL SPECIFICATIONS SUBJECT TO CHANGE

ALL SPECIFICATIONS SUBJECT TO CHANGEALL SPECIFICATIONS SUBJECT TO CHANGE

Lichfield Road, Branston Industrial Estate, Burton Upon Trent, Staffordshire DE14 3HDLichfield Road, Branston Industrial Estate, Burton Upon Trent, Staffordshire DE14 3HD

Lichfield Road, Branston Industrial Estate, Burton Upon Trent, Staffordshire DE14 3HD

Lichfield Road, Branston Industrial Estate, Burton Upon Trent, Staffordshire DE14 3HDLichfield Road, Branston Industrial Estate, Burton Upon Trent, Staffordshire DE14 3HD

Tel. 08707 282 885 - Fax 08707 282 886Tel. 08707 282 885 - Fax 08707 282 886

Tel. 08707 282 885 - Fax 08707 282 886

Tel. 08707 282 885 - Fax 08707 282 886Tel. 08707 282 885 - Fax 08707 282 886

Loading...

Loading...