Page 1

OMNIA HYBRID C

REVERSIBLE HYBRID AIR-WATER HEAT PUMPS FOR SPLIT INSTALLATION

WITH INSTANTANEOUS DHW PRODUCTION

I

R

E

F

N

-

D

O

L

C

E

Y

S

A

G

R

E

F

R

I

T

G

N

E

A

R

EN

INSTALLATION, MAINTENANCE AND USER MANUAL

Cod. 3541T090 - Rev. 00 - 06/2019

EN

1

Page 2

• Read the warnings in this instruction booklet carefully since they provide important information on safe installation, use and maintenance.

• This instruction booklet is an integral and essential part of the product

and must be kept with care by the user for future reference.

• If the unit is sold or transferred to another owner or if it is to be moved,

always make sure the booklet stays with the appliance so that it can be

consulted by the new owner and/or installer.

• Installation and maintenance must be carried out by professionally qualified personnel, according to current regulations and the manufacturer's instructions.

• Incorrect installation or inadequate maintenance can result in damage

or injury. The manufacturer declines any liability for damage caused

by errors in installation and use or by failure to follow the instructions

provided.

• Before carrying out any cleaning or maintenance operation, disconnect

the unit from the power supply using the system switch and/or the special cut-off devices.

• In case of a fault and/or poor operation, deactivate the unit and do

not try to repair it or directly intervene. Contact professionally qualified

personnel. Any repair/replacement of the products must only be carried

out by qualified personnel using genuine parts. Failure to comply with

the above cancompromise the safety of the unit.

• Periodic maintenance performed by qualified personnel is essential in

order to ensure proper operation of the unit.

• This unit must only be used for its intended purpose. Any other use is

deemed improper and therefore hazardous.

• After unpacking, check the good condition of the contents. The packing

materials are potentially hazardous and must not be left within the

reach of children.

• The unit can be used by children aged at least 8 years and by persons with reduced physical, sensory or mental capabilities, or lacking

experience or the necessary knowledge, only if under supervision or

they have received instructions on its safe use and the related risks.

Children must not play with the unit. Cleaning and maintenance intended to be done by the user can be carried out by children aged at least

8 years only if under supervision.

• In case of doubt, do not use the unit. Contact the supplier.

• The unit and its accessories must be appropriately disposed of in compliance with current regulations.

• The images given in this manual are a simplified representation of the

product. In this representation there may be slight and insignificant differences with respect to the product supplied.

This symbol indicates "Caution" and is placed next to all safety warnings. Strictly follow these instructions in order to avoid danger

and damage to persons, animals and things.

☞

Allowed uses

This series of heat pumps is designed to produce cold or hot water for use in hydronic systems for conditioning/heating purposes and instantaneous production of

domestic hot water in an indirect way through a storage tank and a heat exchanger.

Any use differing from this proper use or beyond the operating limits indicated in this manual is forbidden unless previously agreed with the manufacturer.

This symbols calls attention to a note or important notice.

This symbol, which is used on the product, packaging or documents, means that at the end of its useful life, this product must Mnot be collected,

recycled or disposed of together with domestic waste.

Improper management of electric or electronic waste can lead to the leakage of hazardous substances contained in the product. For the purpose

of preventing damage to health or the environment, users are kindly asked to separate this equipment from other types of waste and to ask for it

to be dealt with by the municipal waste service or dealer under the conditions and according to the methods set down in national and international

laws transposing the Directive 2012/19/EU.

Separate waste collection and recycling of unused equipment helps to save natural resources and to guarantee that this waste is processed in a

manner that is safe for health and the environment. For more information about how to collect electric and electronic equipment and appliances,

please contact your local Council or Public Authority competent to issue the relevant permits.

The CE marking certifies that the products meet the essential requirements of the relevant directives in force.

The declaration of conformity may be requested from the manufacturer.

2

EN

Cod. 3541T090 - Rev. 00 - 06/2019

Page 3

SUMMARY

THIS MANUAL IS DIVIDED INTO SECTIONS. THEIR NAMES APPEAR IN THE HEADING OF EACH PAGE.

1. GENERAL FEATURES ................................................................................................5

1.1 Presentation of the system ............................................................................................. 5

1.2 Available system ............................................................................................................. 5

1.3 Components supplied with the indoor unit ..................................................................... 6

1.4 Components supplied with the outdoor unit ................................................................... 6

1.5 Remote control ............................................................................................................... 6

1.6 Accessories .................................................................................................................... 7

Plumbig kit .......................................................... 7

Cover plumbig kit ..................................................... 7

2. TECHNICAL DATA AN PERFORMANCE ...................................................................8

2.1 System technical data .................................................................................................... 8

2.2 Heat pump technical data ............................................................................................... 8

2.3 Boiler technical data ....................................................................................................... 9

2.4 Available static pressure ............................................................................................... 10

2.5 Operating limits heat pump .......................................................................................... 10

3. DIMENSIONAL AND PHYSICAL DATA ....................................................................11

3.1 Overall dimensions indoor unit ..................................................................................... 11

3.2 Overall dimensions outdoor unit ................................................................................... 12

4. GENERAL VIEW AND INTERNAL UNIT HYDRAULIC DIAGRAM ..........................13

4.1 General view ................................................................................................................ 13

4.2 Indoor unit hydraulic diagram ....................................................................................... 13

5. SYSTEM EXEMPLARY SCHEMES ...........................................................................14

6. INSTALLATION .........................................................................................................15

6.1 Inspections on arrival ................................................................................................... 15

6.2 Selecting the installation site and minimum operating area indoor unit ....................... 15

6.3 Selecting the installation site and minimum operating area outdoor unit ..................... 16

6.4 Installation diagrams .................................................................................................... 17

6.5 Limits to the length and heigth difference of refrigerant pipes ...................................... 18

6.6 Refrigerant connections indoor unit .............................................................................. 18

6.7 Refrigerant connections outdoor unit ........................................................................... 18

6.8 Refrigerant pipe insulation ............................................................................................ 19

6.9 Pipe ttings tightening .................................................................................................. 19

6.10 Tightness check (recommended operation) ............................................................... 19

6.11 Vacuum operation (obligatory) .................................................................................... 20

6.12 Indoor unit hydraulic connections ............................................................................... 20

Antifreeze system, antifreeze uids, additives and inhibitors ................... 21

System water characteristics ........................................... 21

Water lter .........................................................21

Tips for a successful installation......................................... 22

Filling with water .....................................................22

Piping insulation .....................................................22

6.13 Boiler gas connection ................................................................................................. 22

6.14 Boiler fume ducts ........................................................................................................ 23

Important .......................................................... 23

Installation type C10..................................................23

Connection with coaxial pipes .......................................... 23

Connection with separate pipes .........................................24

Use of Ø50 and Ø60 exible pipe (for ducting only).......................... 25

Connection to collective ues...........................................26

6.15 Condensate drain connection boiler ........................................................................... 28

6.16 Electrical connections indoor unit ............................................................................... 28

Remote alarm.......................................................30

2-way valve (SV2) ...................................................30

Room thermostat (ON/OFF - HEAT/COOL by digital input) ................... 30

External COOL/HEAT (thermostat)....................................... 31

Boiler (AHS) ........................................................ 31

Outside circulation pump (P_o) ......................................... 31

User interface ....................................................... 32

6.18 Electrical conections outdoor unit ............................................................................... 32

7. REMOTE CONTROLLER - USER MENU .................................................................32

7.1 Keyboard and display ................................................................................................... 33

7.2 Menu structure ............................................................................................................. 34

7.3 Home page ................................................................................................................... 37

7.4 Screen Unlock .............................................................................................................. 37

7.5 Turning ON/OFF controls .............................................................................................38

7.6 Change the water setpoint and the room setpoint ........................................................ 38

7.7 Adjusting space operation mode (HEAT/COOL/AUTO) ...............................................39

7.8 User menu .................................................................................................................... 39

7.9 Operation mode ............................................................................................................ 40

7.10 Preset temperature ..................................................................................................... 40

TEMP. PRE......................................................... 40

WEATHER TEMP.SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

ECO MODE ........................................................ 41

7.11 Schedule ..................................................................................................................... 42

TIMER ............................................................ 42

Weekly schedule.....................................................43

TIME (setting day and hour)............................................43

7.12 Options ....................................................................................................................... 44

SILENT MODE ...................................................... 44

Holiday Away ....................................................... 45

HOLIDAY HOME .................................................... 45

Backup Heater (ELECTRICAL BOOSTER) ................................45

7.13 Child lock .................................................................................................................... 46

7.14 Service information (change language) ...................................................................... 46

SERVCE CALL...................................................... 46

ERROR CODE ......................................................46

PARAMETER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

DISPLAY .......................................................... 47

7.15 Operation parameter .................................................................................................. 47

7.16 For Serviceman .......................................................................................................... 47

7.17 Weather temperature set for cool mode ..................................................................... 48

7.18 Weather temperature set for heat mode .................................................................... 48

8. REMOTE CONTROLLER - FOR SERVICEMAN MENU ...........................................49

8.1 How to go to FOR SERVICEMAN ................................................................................ 49

8.2 REMOTE CONTROLLER - SERVICE menù................................................................50

8.3 DHW mode setting ....................................................................................................... 54

8.4 COOL mode setting ...................................................................................................... 54

8.5 HEAT mode setting ....................................................................................................... 55

8.6 AUTO mode setting ..................................................................................................... 55

8.7 Temp. Type setting (to activate the internal temperature probe of the controller as room

Cod. 3541T090 - Rev. 00 - 06/2019

EN

3

Page 4

thermostat) ......................................................................................................................... 56

8.8 Room thermostat (ON/OFF - HEAT/COOL by digital input) ......................................... 56

8.9 Other heating source .................................................................................................... 57

8.10 AHS (bolier) ................................................................................................................ 57

8.11 Holiday away setting ................................................................................................... 57

8.12 Service call ................................................................................................................. 57

8.13 Restore factory settings .............................................................................................. 58

8.14 Special function .......................................................................................................... 58

8.15 Auto restart ................................................................................................................. 59

8.16 Test run ....................................................................................................................... 60

8.17 Check parameter list .................................................................................................. 62

Basic factory settings ................................................. 62

Settings to be changed for OMNIA HYBRID C.............................. 62

Tabella parametri .................................................... 63

9. BOILER CONTROLLER - USER MENU ...................................................................64

9.1 Control panel boiler ...................................................................................................... 64

Indication during operation ............................................. 64

9.2 Connection to the power supply, switching on and off.................................................. 65

Boiler not electrically powered .......................................... 65

Boiler electrically powered ............................................. 65

Spegnimento e accensione caldaia ...................................... 65

9.3 Adjustments .................................................................................................................. 66

Winter/summer switchover ............................................. 66

Heating temperature adjustment ........................................ 66

DHW temperature adjustment .......................................... 66

10. BOILER CONTROLLER - SERVICE MENU ...........................................................67

10.1 Adjustments ................................................................................................................ 67

Gas conversion...................................................... 67

Checking the combustion values ........................................ 68

100% calibration.....................................................68

Loading parameters with “BCC KEY”.....................................68

TEST mode activation ................................................ 68

Heating power adjustment ............................................. 69

Service menu ....................................................... 69

“Sc” - Combustion Control Parameters Menu .............................. 72

11. ALARMS ..................................................................................................................74

11.1 Heat pump alarms ......................................................................................................74

11.2 Boiler faults ................................................................................................................. 78

12. COMMISSIONING ....................................................................................................81

12.1 Heat pump commissioning ......................................................................................... 81

Preliminary heat pump checks ..........................................81

12.2 Boiler commissioning ................................................................................................. 81

Preliminary boiler checks .............................................. 81

First boiler ignition ................................................... 82

12.3 Final check before turning on the unit ........................................................................ 82

12.4 Turn on the unit ..........................................................................................................82

12.5 System water ow set point setting in heating mode ................................................. 82

12.6 Setting of system water delivery set point in cooling mode ........................................ 82

12.7 Domestic hot water production temperature setting ................................................... 82

13. MANAGEMENT PARAMETERS HEAT PUMP AND BOILER IN HEATING MODE 83

13.1 Boiler in integration to the heat pump (factory setting) ............................................... 83

13.2 Boiler in substitution of the heat pump ....................................................................... 84

14. WORKING MODES OF THE SYSTEM ....................................................................85

14.1 Plant operating modes ............................................................................................... 85

14.2 DHW operating mode ................................................................................................. 86

14.3 Plant operating modes + DHW ................................................................................... 86

15. MAINTENANCE .......................................................................................................87

15.1 General notes ............................................................................................................. 87

15.2 Apertura del pannello frontale ....................................................................................88

15.3 Access to internal components ...................................................................................89

15.4 Water load and system water pressure adjustment ...................................................89

15.5 System draining .......................................................................................................... 89

15.6 Heat pump routine maintenance ................................................................................ 89

15.7 Extraordinary maintenance and replacement of heat pump components .................. 91

Heat pump circulator ................................................. 91

15.8 Boiler periodical check ............................................................................................... 91

15.9 Boiler - Extraordinary maintenance and replacement of components ........................ 92

Boiler - Plate heat exchanger ........................................... 92

Boiler - Circulating pump .............................................. 93

Boiler - Replacing the main exchanger.................................... 93

Boiler - Disassembling the burner and cleaning the exchanger ................. 94

Boiler - Exchanger insulation replacement.................................95

Boiler - Fan.........................................................95

Boiler - Replacing the circuit board....................................... 96

Replacing the electrode and maintenance ................................. 96

Removing the diverter valve............................................96

Replacing the water pressure switch ..................................... 96

Cleaning or replacing the owmeter......................................97

Water inlet lter cleaning ..............................................98

15.10 Disconnection and disposal ...................................................................................... 98

16. ELECTRICAL DIAGRAM INDOOR UNIT ................................................................99

17. REFRIGERANT DIAGRAM ...................................................................................103

18. OUTDOOR UNIT ELECTRONIC BOARDS ...........................................................104

19. HEAT PUMP ELECTRONIC BOARD ....................................................................107

19.1 Electronic board’s DIP switch settings of the of the heat pump................................107

19.2 Parameters check in the electrical board ................................................................. 108

20. BOILER TERMINAL BLOCK .................................................................................109

20.1 Accessing to the electrical terminal board and to the fuse of the boiler electrical box 109

20.2 Variable output relay LC32 card (factory installed) ................................................... 109

20.3 ON/OFF (A g. 206) conguration ............................................................................ 110

21. GENERAL RECOMMENDATIONS ABOUT THE R410A REFRIGERANT USED 111

The manufacturer declines all responsibility for any inaccuracies in this manual due to printing or typing errors.

The manufacturer reserves the right to modify the products contents in this catalogue without previous notice.

4

EN

Cod. 3541T090 - Rev. 00 - 06/2019

Page 5

GENERAL FEATURES

1. GENERAL FEATURES

1.1 Presentation of the system

> GENERAL CHARACTERISTICS:

• The family of OMNIA HYBRID C hybrid heat pumps integrates the technology of the heat pump and the condensing boiler with instantaneous dhw production in

a single compact product.

• This represents the ideal solution for replacing old existing boilers, also on high temperature system with radiators.

• The compact dimensions, similar to those of a wall-hung boiler, make it easier to replace without losing significant space or requiring significant restructuring work.

• Internal electronics, by running the boiler or the heat pump as the climatic conditions vary, optimise the output of the system by always working in the most economic consumption-related modes possible.

• During heat pump operation in heating or conditioning mode, the boiler can produce dhw at the same time without interfering on heat pump operation, thereby

maximising the comfort of both services.

• If the heat pump is partially or fully blocked, the boiler can operate separately in heating and dhw production.

• it is composed of an external inverter unit available in 3 power sizes associated with an internal condensation unit with integrated hydronic module for cooling

circuit control.

• A highly versatile system that can operate in particularly cold climatic conditions (outdoor air down to -20°C).

• The split cooling circuit avoids the risk of freezing in particularly cold outdoor applications.

• The user interface is composed of a digital remote controller equipped with a large display and simple setting controls.

• Wall flue gas exhaust in cases pertaining to Lgs.D. 4 July 2014, No. 102.

> CHARACTERISTICS OF EXTERNAL UNIT:

• Approved for outdoor operation in completely exposed site.

• Breakaway starting current thanks to Inverter technology.

• Compressor with twin rotary DC INVERTER motor on vibration damping supports and wrapped in double layer of soundproofing material to reduce vibrations and

noise to a minimum.

• The compressor is also equipped with casing oil heating element.

• Two-flow electronic expansion valve, cycle inversion valve.

• Axial fans with brushless DC motor complete with protective grids.

• Outdoor air temperature probe already installed on the unit.

> CHARACTERISTICS OF INTERNAL UNIT:

• A particularly sturdy boiler, suitable for replacements even in particularly critical and resistant systems.

• Combustion module with high modulation range (1:10) with high thickness stainless steel primary exchanger, with larger passes maintaining high efficiency even

on old systems with oxidation and soiling

• M.G.R: Methane, LPG, Propane air Ready, with a simple configuration the internal unit can run on methane, lpg and propane-air without the use of any additional

conversion kits.

• MC2: Multi Combustion Control, combustion system with gas-adaptive patented technology for better adaptability of use to the varying gas network conditions

(ex. pressure fluctuations or drops)

• F.P.S: Flue gas Protection System. The standard flue gas check valve offers easy connection to pressurised collective flue systems

• Particularly suitable for operation in flues requiring “heavy duty” pipes thanks to approval for operation with flue gas exhaust with a diameter of 50mm.

• Can be combined with preheating systems for the domestic hot water.

• Place of installation: also for outdoor use in a partially protected place that is up to -5°C, as standard

• Free methane/LPG/Propane-air conversion at the time of product testing and warranty activation, by the Authorised Assistance Centre

1.2 Available system

MOD. SYSTEM INDOOR UNIT OUTDOOR UNIT

04 OMNIA HY H 04E 28C OMNIA-UI HYBRID C 08 OMNIA-UE 04

06 OMNIA HY H 06E 28C OMNIA-UI HYBRID C 08 OMNIA-UE 06

08 OMNIA HY H 08E 28C OMNIA-UI HYBRID C 08 OMNIA-UE 08

Cod. 3541T090 - Rev. 00 - 06/2019

EN

5

Page 6

GENERAL FEATURES

1.3 Components supplied with the indoor unit

Description Shape

Installation, maintenance and user manual (this manual) 1

Square cock with filter (system return) 1

Square cock (system outlet) 1

Remote control 1

IJA

Y

IE IA

RVL-I PLUS 5

35°C

55°C

+

+A++

++

A

A

+

A

A

B

C

D

E

F

Energy label

* The unit is supplied with 3 energy labels (use only that one of the installed system).

1.4 Components supplied with the outdoor unit

Description Shape Q.ty

G

5

5

7

5

5

5

kW

kW

-

dB

63

dB

811/20132015

Q.ty

3*

Condensate water drain to be installed under the unit basement 1

1.5 Remote control

The user interface consists of a wired remote controller (up to 50 m from the unit)

which allows the management of:

- HEATING AND COOLING SYSTEM. The unit, if activated in heat or cool mode,

works by modulating the frequency of the compressor to maintain the temperature

of the produced water to the setpoint value set by the controller. Through parameter you can use the remote controller (eg. For single-zone systems) as a room

thermostat.

- HEATING WITH BOILER. As a function of the set parameters, can be activeted

in integration or substitution of the heat pump. The electronic board will activate

the boiler in case the heat pump does not work.

- SILENCED MODE: according to a programmed schedule, this reduces the maximum frequency of the compressor and the fan speed, to reduce the generated

noise and the power absorbed by the unit.

- ON / OFF using an external contact. The unit can be turned on and off (eg. thermostat / remote switch) via an external contact: in this case the unit will operate in

the mode set by the controller keyboard.

- HEAT / COOL via external contacts. The unit can be activated in heat or cool

mode via two external contacts (eg. thermostat that manages the heat and cool

demand / remote switch).

- ECO MODE: possibility of defining a time slot in hot mode where the heat pump

runs with a sliding setpoint defined by the chosen climatic curve. There are 8 climatic curves for low temperature systems (radiant floor) and 8 climatic curves for

fan coil or radiator systems).

- WEEKLY PROGRAMMING: this makes it possible to set a different schedule for

each day of the week defining the operating mode for each time slot (COLD/HOT)

and the work setpoint.

fig. 1 -

6

EN

Cod. 3541T090 - Rev. 00 - 06/2019

Page 7

GENERAL FEATURES

A

A

1.6 Accessories

Plumbig kit

The plumbig kit (cod.012050W0 consisting of a gas cock, water inlet cock and pipes and fittings) is available on request, which allows the hydraulic connection of the

unit to the wall.

A

fig. 2 - Hydraulic kit

A

fig. 3 - Hydraulic kit fitted

Hydraulic kit accessory

A

These two cocks are not part of the kit as they are supplied as standard with the indoor unit.

Cover plumbig kit

The plumbig cover kit (cod. 016008X0) is available on request, which allows the aesthetic covering of the wall hydraulic connections. The kit consists of a galvanized

sheet of the same color as the mantle, to be fixed with 4 screws under the indoor unit

fig. 4 - Cover hydraulic kit

Accessory cover kit accessory

fig. 5 - Cover hydraulic kit fitted

Cod. 3541T090 - Rev. 00 - 06/2019

EN

7

Page 8

TECHNICAL DATA AN PERFORMANCE

2. TECHNICAL DATA AN PERFORMANCE

2.1 System technical data

- Mod.

ERP class in heating / Seasonal efficiency

medium temperature (produced water 55°C)

ERP class in heating / Seasonal efficiency

low temperature (produced water 35°C)

(Class G - A++)

(Class G - A++)

04

++

A

++

A

127

183

Electric power supply V-ph-Hz 220-240V ~ 50 Hz

Type of compressor - Twin Rotary

No. of compressors / No. of cooling circuits

No.

Type of exchanger system side - piastre inox saldobrasate

Type of exchanger source side - batteria alettata

Type of fans - brushless DC

No. of fans

No.

Cooler fittings - liquid line ø 9,52

Cooler fittings - gas line ø 15,88

Internal unit expansion vessel volume l 8

SWL - External unit sound power level* dB(A) 62 66 69

SWL - Internal unit sound power level* dB(A) 43

External unit weight kg 60 60 76

Internal unit weight kg 43

NOTA: The values refer to units without any optional features or accessories.

Data declared according to EN 14511:

EER (Energy Efficiency Ratio) = ratio of cooling capacity in relation to absorbed power

COP (Coefficient Of Performance) = ratio of heat output in relation to absorbed power

A7W35 = source : air in 7°C b.s. 6°C b.u. / system : water in 30°C out 35°C

A7W45 = source : air in 7°C b.s. 6°C b.u. / system : water in 40°C out 45°C

A35W18 = source : air in 35°C b.s. / system : water in 23°C out 18°C

A35W7 = source : air in 35°C b.s. / system : water in 12°C out 7°C

NOTE: Efficiency class calculated according to European regulation 811/2013. The values refer to units

without any optional features or accessories.

06

++

A

++

A

133

187

++

A

++

A

1/1

1

08

126

171

2.2 Heat pump technical data

- Mod. 04 06 08

Heating capacity kW 4,1 6,1 8

Total power input kW 0,82 1,29 1,73

COP W/W 5 4,73 4,62

Water flow rate l/h 705 1049 1376

A7W35

Available pressure heat without cocks kPa 72 66 54

Available pressure heat with cocks kPa 68 57 39

Heating capacity kW 4,01 5,96 7,34

Total power input kW 1,13 1,68 2,13

COP W/W 3,55 3,55 3,45

Water flow rate l/h 690 1025 1262

A7W45

Available pressure heat without cocks kPa 72 67 58

Available pressure heat with cocks kPa 68 58 45

Cooling capacity kW 4,1 6,2 8

Total power input kW 0,84 1,43 1,93

EER W/W 4,88 4,34 4,15

Water flow rate l/h 705 1066 1376

A35W18

Prevalenza utile disponibile senza rubinetti kPa 72 66 54

Prevalenza utile disponibile con rubinetti kPa 68 57 39

Cooling capacity kW 4,12 6,15 6,44

Total power input kW 1,3 2,08 2,24

EER W/W 3,17 2,96 2,88

Water flow rate l/h 709 1058 1108

A35W7

Available pressure heat without cocks kPa 72 66 64

Available pressure heat with cocks kPa 68 57 54

IThe values refer to units without any optional features or accessories.

Data declared according to EN 14511:

EER (Energy Efficiency Ratio) = ratio of cooling capacity in relation to absorbed power

COP (Coefficient Of Performance) = ratio of heat output in relation to absorbed power

A7W35 = source : air in 7°C b.s. 6°C b.u. / system : water in 30°C out 35°C

A7W45 = source : air in 7°C b.s. 6°C b.u. / system : water in 40°C out 45°C

A35W18 = source : air in 35°C b.s. / system : water in 23°C out 18°C

A35W7 = source : air in 35°C b.s. / system : water in 12°C out 7°C

NOTE: Efficiency class calculated according to European regulation 811/2013. The values refer to units

without any optional features or accessories.

8

EN

Cod. 3541T090 - Rev. 00 - 06/2019

Page 9

2.3 Boiler technical data

Table. 1 - Boiler technical data

Data

GAS CATEGORY

Max. heating capacity

Min. heating capacity

Max. heat output in heating (80/60°C)

Min. heat output in heating (80/60°C)

Max. heat output in heating (50/30°C)

Min. heat output in heating (50/30°C)

Max. heating capacity in DHW

Min. heating capacity in DHW

Max. heat output in DHW

Min. heat output in DHW

Efficiency Pmax (80-60°C)

Efficiency Pmin (80-60°C)

Efficiency Pmax (50-30°C)

Efficiency Pmin (50-30°C)

Efficiency 30%

Gas supply pressure G20

Max. gas flow G20

Min. gas flow G20

CO2 - G20

Gas supply pressure G31

Max. gas flow G31

Min. gas flow G31

CO2 - G31

NOx emissions class

Max. working pressure in heating

Min. working pressure in heating

Max. heating adjustment temperature

Heating water content

Heating expansion vessel capacity

Heating expansion vessel precharge pressure

Max. working pressure in DHW

Min. working pressure in DHW

DHW flow rate Δt 25°C

DHW flow rate Δt 30°C

Protection rating

Power supply voltage

Electrical power input

Empty weight

Type of unit

PIN CE

Flue installation pressure C10-C11

TECHNICAL DATA AN PERFORMANCE

UM

II2HM3+ (IT) - II2H3+ (ES-GR) -

kW 24,5 Q

kW 2,9 Q

kW 24,0 P

kW 2,8 P

kW 26,0

kW 3,1

kW 28,5

kW 2,9

kW 28,0

kW 2,8

% 98,1

% 98,0

% 106,1

% 107,5

% 109,7

mbar 20

m3/h 3,02

m3/h 0,31

% 9 ±0,8

mbar 37

kg/h 2,21

kg/h 0,23

% 10 ±0,8

- 6 NOx

bar 3 PMS

bar 0.8

°C 95 tmax

litri 2,9

litri 8

bar 0.8

bar 9 PMW

bar 0,3

l/min 16,1

l/min 13,4 D

IP X5D

V/Hz 230V/50Hz

W 82

kg 28

C10-C11-C13-C23-C33-C43-C53

C63-C83-C93-B23-B33

Pa 80

-

II2H3B/P (RO)

Cod. 3541T090 - Rev. 00 - 06/2019

EN

9

Page 10

TECHNICAL DATA AN PERFORMANCE

HEATING MODE COOLING MODE

T4

T4

T1

20

46

-5

10

T4

02

2.4 Available static pressure

80

70

60

without cocks

50

with cocks

40

30

Available static pressure [kPa]

20

10

0

600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300 2400 2500

Watel flow rate [l/h]

2.5 Operating limits heat pump

HEATING MODE

35

30

With boiler

-2

46

20

10

Outside temperature °C

-20

T1

Leaving water temperature °C

-5

Outside temperature °C

COOLING MODE

51

Leaving water temperature °C

T1

5

10

EN

Cod. 3541T090 - Rev. 00 - 06/2019

Page 11

3. DIMENSIONAL AND PHYSICAL DATA

3.1 Overall dimensions indoor unit

440 320

700

DIMENSIONAL AND PHYSICAL DATA

29

110

220

7 Boiler Gas inlet - Ø 3/4”

8 DHW water outlet - Ø 1/2”

9 DHW water inlet - Ø 1/2”

10 Plant delivery - Ø 3/4”

11 Plant return - Ø 3/4”

Front view

Top view

220

202

160

115

44

fig. 6 - dimensional data and connections

14 Safety valve drain / drain taps

74 System filling cock

A6 Condensate discharge connection

L Liquid line

G Gas line

Side view

22950162

14 74

10

8

GL

7

11

9

A6

93

55 65 66 66 65 123

440

Bottom view

Cod. 3541T090 - Rev. 00 - 06/2019

EN

11

Page 12

3.2 Overall dimensions outdoor unit

860

333

350

355

895

960

590

DIMENSIONAL AND PHYSICAL DATA

Mod. 4 - 6

860

895

960

590

333

350

355

fig. 7 -

Mod. 4 6 UM

Weight net 60 60 kg

Mod. 8

12

EN

625

360

390

fig. 8 -

Mod. 8 UM

Weight net

Cod. 3541T090 - Rev. 00 - 06/2019

76

395

kg

Page 13

GENERAL VIEW AND INTERNAL UNIT HYDRAULIC DIAGRAM

56

TW_out

4. GENERAL VIEW AND INTERNAL UNIT HYDRAULIC DIAGRAM

4.1 General view

196

350

191

T2B

17

J5

4

4a

4.2 Indoor unit hydraulic diagram

7:BRXW

186

34

17

114

193

7:BLQ

56

194

36

241

1

81

186

SPHP

TW_in

T2

136

CHP

95

J6

J3

34

16

194

42

114

FL

14

32

145

44

T1B

fig. 9 - General view

LEGEND

1 Heat pump electric panel

4 Boiler electric box

4a Boiler controller

8 DHW water outlet

9 DHW water inlet

10 Plant delivery

11 Plant return

SPHP

7%7

CHP

32

14 Safety valve

16 Fan

17 Check valve

32 Heating circulating pump boiler

34 Heating temperature sensor boiler

36 Automatic air vent

42 DHW temperature probe

44 Gas valve

56 Expansion vessel

74 System filling tap

81 Ignition/Ionisation electrode

95 Diverter valve boiler

114 Water pressure switch

136 Flow meter

145 Water gauge

186 Return sensor boiler

191 Fume temperature sensor

193 Trap boiler

194

DHW exchanger

196 Condensate tray

241 Automatic bypass (inside the pump unit boiler)

350 Burner/Fan assembly

CHP Circolator heat pump

FL Flow heat pump

G Gas line

L Liquid line

SPHP Heat pump plate heat exchanger

T1 Heat pump outlet water temperature probe

T1B Indoor unit outlet water temperature probe

T2 Heat pump liquid refrigerant temperature probe

T2B heat pump gas temperature probe

TW_in Heat pump plate heat exchanger water inlet tem

perature probe

TW_out

Heat pump plate heat exchanger water outlet

temperature probe

-

7

7E

14

42

10

fig. 10 - Indoor unit hydraulic diagram

8

136

9

FL

11

L

G

Cod. 3541T090 - Rev. 00 - 06/2019

EN

13

95

74

Page 14

5. SYSTEM EXEMPLARY SCHEMES

18

OMNIA HYBRID C_01

SYSTEM EXEMPLARY SCHEMES

18

TWR

Mn

Tn_c

M1

T1_c

17

20b

M

FCUn

.......

FCU1

20a

Mn

Tn_h

FHLn

Mn

.......

T2_h

FHL1

M1

T1_h

M

11

9

L

UI

4

G

8

10

UE

14

EN

Cod. 3541T090 - Rev. 00 - 06/2019

> KEY IU Internal unit EU External unit 4 Wired remote control (provided as standard with the heat pump) 8 DHW outlet - Ø 1/2” 9 DHW inlet - Ø 1/2” 10 System delivery - Ø 3/4” 11 System return - Ø 3/4” 17 Check valve (not supplied) 18 Bypass valve (not sup-

plied) 20a Two-way valve (not supplied), controlled by SV2 20b Two-way valve (not supplied), controlled by SV2 in denied logic G Gas Line l Liquid Line T1_c - Tn_c Cold request room thermostat (not supplied) T1_h - Tn_h Hot request room thermostat (not supplied)

FCU 1...n Air terminal: it can only be used for cooling with radiant floor heating or for cooling and heating without radiant floor FHL 1...n Radiant floor / radiator only heating in zones TWR Integration of towel warmer in bathroom: if connected to the heating system it must

be integrated with an electrical resistor (R) actuated by the control (C) which closes the valve at the same time (M); if not connected to the system, heating is provided by the resistor only (R) actuated by the control (C) - - - - Electrical connections

Page 15

INSTALLATION

30

6. INSTALLATION

6.1 Inspections on arrival

Upon receipt of the unit it is essential to check that you have received all the material indicated on the accompanying document, and also that it has not been damaged

during transport. If so, have the dispatcher ascertain the extent of the damage suffered, alerting our customer management office in the meantime. Only by acting in

this way and in a timely manner will it be possible to have the missing material or compensation for damages.

Packing and storing

All machines are packed in cardboard boxes specific for each unit.

The indications required to correctly handle the appliance while storing and installing it are written on the packing.

The storage temperature must be between -25°C and 55°C.

☞

NOTA: Do not dispose of the packaging in the environment.

Do not dispose of, leave or leave within the reach of children the packaging material as it may be a potential source of danger.

Once the place in which the unit is to be installed has been chosen (see the relative sections) proceed as follows to unpack the two units.

fig. 11 -

6.2 Selecting the installation site and minimum operating area indoor unit

The place of installation must be free of powders, flammable objects or materials

or corrosive gases.

The unit is designed for wall hanging installation and is equipped as standard with

a hooking bracket. The fixing to the wall must guarantee a stable and effective

support.

600

☞

For the dismantling of the paneling and for normal maintenance activities the minimum operating spaces must be respected.

Select an installation location where the following conditions are met:

- Place that allows to respect the maximum lengths allowed for pipes, connections

to the unit of temperature probes, remote control etc ..

- Do not place objects or equipment on top of the unit.

- Make sure that all the precautions and prescriptions foreseen by local laws and

regulations regarding possible refrigerant leaks are correctly applied.

- It is advisable to place the boiler for domestic hot water production as close as

possible to the indoor unit.

fig. 12 -

0

300

500 500

fig. 13 -

Cod. 3541T090 - Rev. 00 - 06/2019

EN

15

Page 16

INSTALLATION

(Wall or obstacle)

Maintain

A

>600

>2000

>300

6.3 Selecting the installation site and minimum operating area outdoor unit

Select an installation site where the following conditions are satisfied and one that meets with your customer’s approval.

• Places that are well-ventilated.

• Places where the unit does not disturb next-door neighbors.

• Safe places which can bear the unit’s weight and vibration and where the unit can be installed at an even level.

• Places where there is no possibility of flammable gas or product leak.

• The equipment is not intended for use in a potentially explosive atmosphere.

• Places where servicing space can be well ensured.

• Places where the units’ piping and wiring lengths come within the allowable ranges.

• Places where water leaking from the unit cannot cause damage to the location (e.g. in case of a blocked drain pipe).

• Places where rain can be avoided as much as possible.

• Do not install the unit in places often used as a work space. In case of construction work (e.g. grinding etc.) where a lot of dust is created, the unit must be covered.

• Do not place any objects or equipment on top of the unit (top plate)

• Do not climb, sit or stand on top of the unit.

• Be sure that sufficient precautions are taken in case of refrigerant leakage according to relevant local laws and regulations.

Be sure to provide for adequate measures in order to prevent that the unit be used as a shelter by small animals. Small animals making contact with electrical parts can cause malfunctions, smoke or fire. Please instruct the

customer to keep the area around the unit clean.

Single installation

air inlet

>300

ir inlet

air inlet

Multiple installation in parallel between 2 or more units (lateral)

>300

>2000

Air inlet

>2000

>600

wall / obstacle

air outlet

Air outlet

fig. 14 -

fig. 16 -

>300

channel

>600

>600mm

fasten with

Fix with bolt

bolts

fig. 15 -

Multiple installation in parallel between 2 or more units (front / back)

>2000 >500 >3000 >3000 >300

fig. 17 -

condensation drain

Water Outlet

fig. 18 -

16

EN

Cod. 3541T090 - Rev. 00 - 06/2019

Page 17

INSTALLATION

■ Prepare a water drainage channel around the foundation, to drain waste water

from around the unit.

■ If water does not easily drain from the unit, mount the unit on a foundation of

concrete blocks, etc. (the height of the foundation should be about 100 mm.

■ If you install the unit on a frame, please install a waterproof plate (about 100

mm) on the underside of the unit to prevent water from coming in from the low side.

■ When installing the unit in a place frequently exposed to snow, pay special

attention to elevate the foundation as high as possible.

■ In heavy snowfall areas it is very important to select an installation site where

the snow will not affect the unit. If lateral snowfall is possible, make sure that the

heat exchanger coil is not affected by the snow (if necessary construct a lateral

canopy).

■ As the outdoor temperature is measured via the outdoor unit air thermistor,

make sure to install the outdoor unit in the shade, or a canopy should be constracted to avoid direct sunlight, so that it is not influenced by the sun’s heat,

otherwise protection may be possible to the unit.

■ Check the strength and level of the installation ground so that the unit will not

cause any operating vibration or noise after installation.

■ In accordance with the foundation drawing in the figure, fix the unit securely by

means of the foundation bolts. (Prepare four sets each of Ø10 Expansion bolts,

nuts and washers which are readily available on the market.)

■ It is best to screw in the foundation bolts until their length is 20 mm from the

foundation surface.

When installing the unit in a place exposed to strong wind, pay special attention

to the following.

Set the outlet side at a right angle to the direction of the wind.

Strong winds of >5 m/s or more blowing against the unit’s air outlet causes a short

circuit (suction of discharge air), and this may have the following consequences:

- Deterioration of the operational capacity.

- Frequent frost acceleration in heating operation.

- Disruption of operation due to rise of high pressure.

- When a strong wind blows continuously on the front of the unit, the fan can start

rotating very fast until it breaks.

fig. 19 -

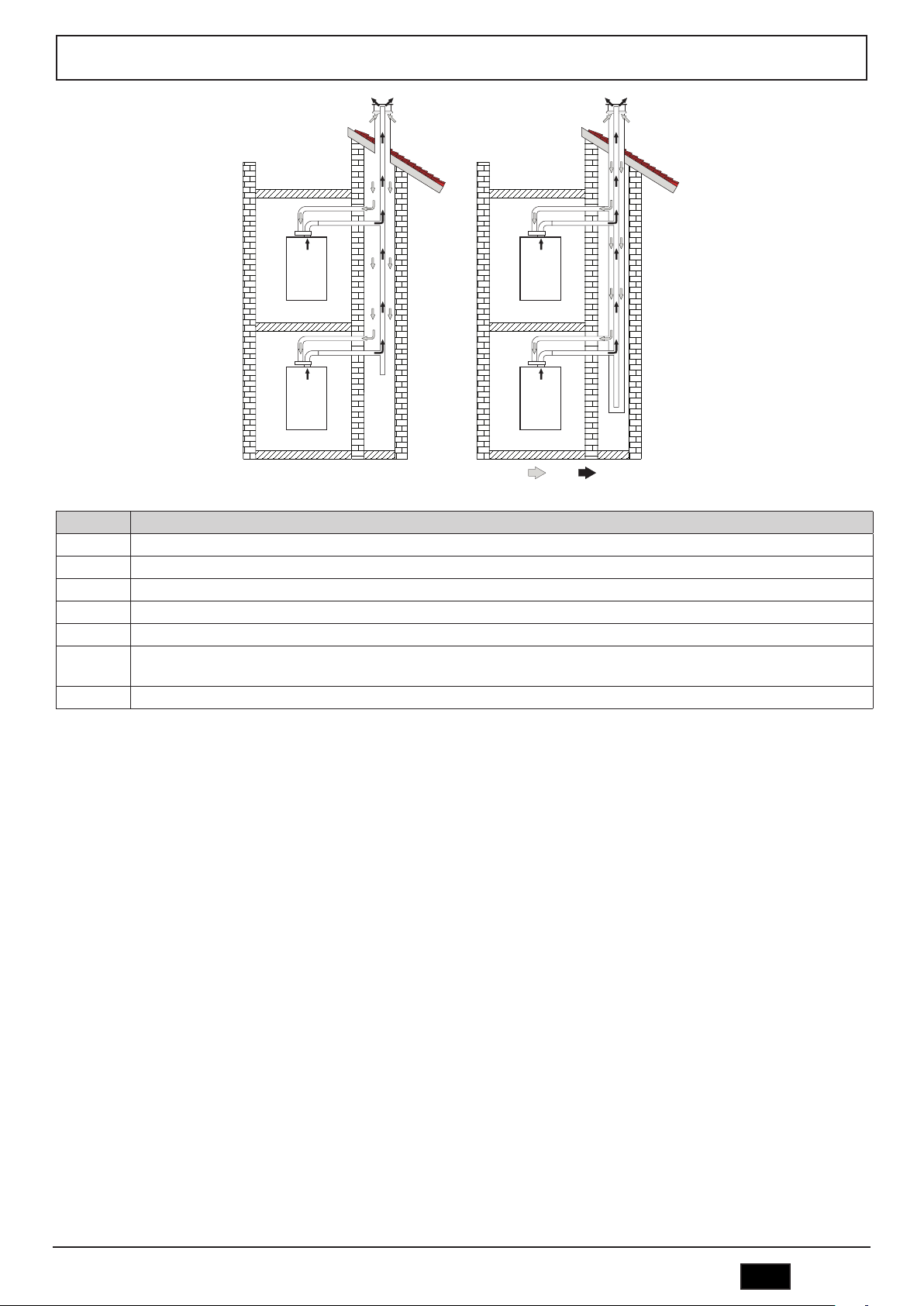

6.4 Installation diagrams

L’installazione può essere eseguita o con unità interna posta sopra l’unità esterna

o viceversa.

Outdoor unit positioned at the bottom and indoor unit at the top

In this case a trap (6) must be made on the intake piping (3) to halt the downflow of

refrigerant and to avoid liquid returning to the compressor. The relative connection

pipes

must be insulated.

Key:

1. Outdoor unit

2. Indoor unit

3. Piping on gas side (larger diameter)

4. Piping on liquid side

5. Trap

Outdoor unit positioned at the top and indoor unit at the bottom

In this case, traps (6) must be installed on the suction piping (3), every three meters of difference in level. These traps will allow the oil to return to the compressor.

The relative connection pipes must be insulated.

Key:

1. Outdoor unit

2. Indoor unit

3. Piping on gas side (larger diameter)

4. Piping on liquid side

5. Trap

fig. 20 -

☞

N.B.:The maximum difference in level between the indoor unit and outdoor

unit must not exceed the values given in the “LIMITS TO THE LENGTH AND

HEIGHT DIFFERENCE OF REFRIGERANT PIPES” section.

Cod. 3541T090 - Rev. 00 - 06/2019

fig. 21 -

EN

17

Page 18

INSTALLATION

6.5 Limits to the length and heigth difference of refrigerant pipes

The length of the refrigerant pipes between the indoor and outdoor units must be as short as possible and is in any case limited by compliance with the maximum

height difference values between the units.

Diminution of the difference in height between the units (H1,H2) and of the pipe lengths (L) will limit the load losses, consequently increasing the overall efficiency of

the machine.

Comply with the limits given in the following tables.

MOD. 4-6 8

Connections LIQUID line " 3/8

Connections GAS line " 5/8

Length with standard charge m 10

Cooling line maximum length m 20 30

Maximum diff.in height Outdoor unit low (H1) m 8 15

Maximum diff.in height Outdoor unit high (H2) m 10 20

Refrigerant charge Type R410A

Quantity of additional refrigerant per meter g/m 54

Contact our technical department for the required modifications if the units must operate beyond the specifications given above.

6.6 Refrigerant connections indoor unit

Comply with the following indications when connecting the cooling pipes:

• Match the ends of the previously flared pipe with those of the connections on the indoor units (see part. L e G “fig. 6 - dimensional data and connections” on page

11).

• Tighten the union by hand and then torque it with the aid of an adequate wrench.

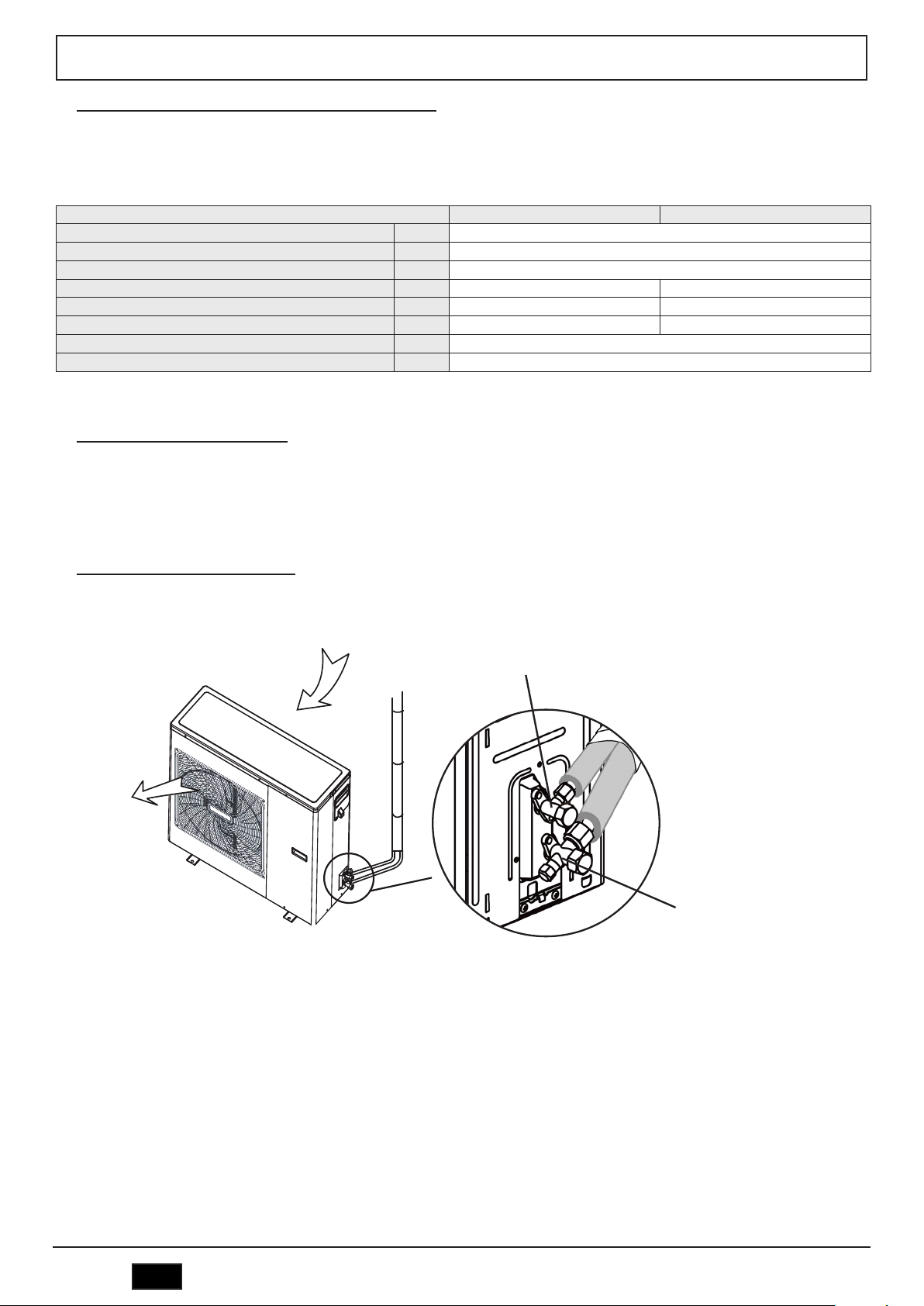

6.7 Refrigerant connections outdoor unit

• Match the ends of the pipe previously flared with those of the taps on the outdoor unit.

• Screw the fitting by hand and then tighten it with a suitable wrench.

LIQUID

CONNECTION

fig. 22 -

GAS

CONNECTION

18

EN

Cod. 3541T090 - Rev. 00 - 06/2019

Page 19

INSTALLATION

6.8 Refrigerant pipe insulation

To ensure system efficiency and its correct operation it is necessary to use preinsulated cooling connection lines easily available on the market. Pay also attention to the connection points according to what described.

Use thermal insulating tape to tie the hoses, from the area connecting the outdoor

unit cocks to the upper end of the hose in correspondence of the wall entry point.

(side figure) .

6.9 Pipe ttings tightening

Make sure that the connecting zone is free from dust and dirt.

• Make sure that the flare and connection are perfectly aligned.

• Tighten the union first by hand and then with an adequate torque wrench.

Leaks could occur if the parts are insufficiently tightened, while the flare could be damaged if it is tightened too strongly.

The table below lists the torques recommended for the various pipe diameters.

fig. 23 -

Nominal Diameter (“) External Diameter (mm) Ø

3/8 9.52 30-40

5/8 15.88 60-65

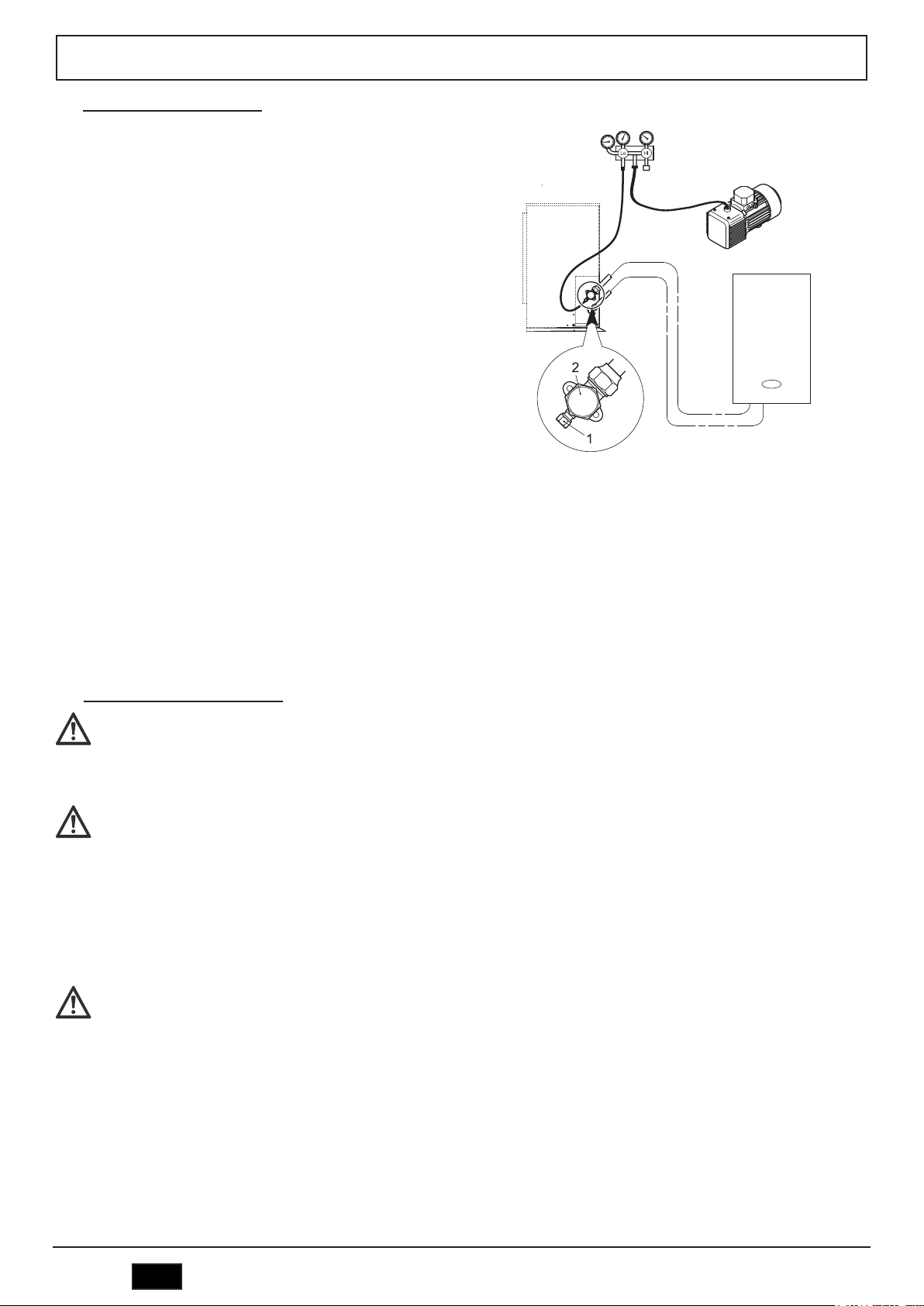

6.10 Tightness check (recommended operation)

Before setting the system in a vacuum, it is advisable to make sure that the cooling

circuit is tight, including the connecting joints between the pipes and the indoor

unit. Proceed in the following way:

• With the service valves of the outdoor unit completely shut, remove the cap

from the service tap (1- side figure) of the gas connection (the larger one)

• Connect the service valve to a monometric unit plus nitrogen bottle (N2).

• Pressurize the system to a maximum 30 bar using the nitrogen in the bottle.

• Use liquid soap to check that the joints are tight.

Keep the bottle vertical during the pressurizing operation to prevent liquid nitrogen

from infiltrating into the system!

• Check all the connection joints on both the outdoor and indoor units to make

sure that they are tight. Bubbles will form if leaks are present. If bubbles

appear, make sure that the unions have been tightened and that the flares

are the right shape.

• Wipe off the liquid soap with a rag.

• Reduce the pressure of the nitrogen in the circuit by loosening the charge

pipe from the bottle.

• Having reduced the pressure, disconnect the nitrogen bottle.

U.E.

Tightening torque

Nxm

U.I.

CONNECTIONS

Cod. 3541T090 - Rev. 00 - 06/2019

GAS

fig. 24 -

EN

19

Page 20

INSTALLATION

6.11 Vacuum operation (obligatory)

ir and humidity in the cooling circuit impair the operation of the unit with effects

such as:

• Increased pressure.

• Reduced efficiency.

• Formation of ice on the capillary and subsequent blockage of the same.

• Corrosion in the circuit.

This is why a vacuum must be created in the connection pipes and indoor unit.

Proceed in the following way:

U.E.

• Connect the previously described charging pipe to the vacuum pump.

• Turn on the relative knob on the monometric unit to allow the pump to access

the cooling circuit.

• Wait until the pressure level measured by the pressure gauge is around 3 mm

Hg (400 Pa)

• As soon as the required vacuum value is reached, shut the connection cock and

stop the vacuum pump.

GAS

CONNECTIONS

fig. 25 -

☞

NOTA

■ To activate the system it is necessary to open both the liquid and gas shut-off valves of the outdoor unit: remove the caps from both valves, and then open the valves

with an Allen wrench.

■ It is advisable to open the valves when the installation of the system is complete from an electric and hydraulic point of view and it is therefore possible

to proceed with the first start-up.

6.12 Indoor unit hydraulic connections

U.I.

The safety valve outlet must be connected to a funnel or collection pipe to prevent water spurting onto the floor in case

of overpressure in the heating circuit. Otherwise, if the discharge valve cuts in and floods the room, the boiler manufacturer

cannot be held liable.

Before installation, flush all the pipes of the system thoroughly to remove any residuals or impurities that could affect

proper operation of the unit.

In case of replacement of generators in existing installations, the system must be completely emptied and cleaned of any

sludge and pollutants. For that purpose only use suitable guaranteed products for heating systems (see next section), that

do not harm metals, plastics or rubber.

The manufacturer declines any liability for damage caused to the generator by failure to properly clean the system.

Since the joints of the unit are made of brass and brass is an easily deformable material, using appropriate

tools for connecting the hydraulic circuit, inappropriate tools will cause damage to the pipes.

Make the connections to the respective points (see “fig. 6 - dimensional data and connections” on page 11) and to the symbols given on the unit.

20

EN

Cod. 3541T090 - Rev. 00 - 06/2019

Page 21

INSTALLATION

Antifreeze system, antifreeze fluids, additives and inhibitors

When necessary, antifreeze fluids, additives and inhibitors can be used only if the manufacturer of such fluids or additives guarantees that they are suitable and do not

cause damage to the exchanger or other components and/or materials of the boiler/heat pump and system. Do not use generic antifreeze fluids, additives or inhibitors

that are not specific for use in heating systems and compatible with the materials of the boiler/heat pump and system.

System water characteristics

The heat pumps are suitable for installation in heating systems with non-significant entry of oxygen (ref. systems “case

I” EN14868). A physical separator (e.g. plate heat exchanger) must be provided in systems with continuous entry of oxygen

(e.g. underfloor systems without antidiffusion pipes or open vessel), or intermittent (less than 20% of system water content).

The water within a heating system must have the characteristics required by UNI 8065, and comply with laws and regulations

in force and the provisions of EN14868 (protection of metallic materials against corrosion).

The filling water (first filling and subsequent replenishment) must be clear, with hardness below 15°F and treated with suitable

chemical conditioners against the initiation of corrosion, that are not aggressive on metals and plastics, do not develop gases

and, in low-temperature systems, do not cause proliferation of bacterial or microbial masses.

The water in the system must be periodically checked (at least twice a year during the season when the systems are used,

as required by UNI8065) and have: possibly a clear appearance, hardness below 15°F for new systems or 20°F for existing

systems, pH above 7 and below 8.5, iron content (Fe) below 0.5 mg/l, copper content (Cu) below 0.1 mg/l, chloride content

below 50mg/l, electrical conductivity below 200 µs/cm, and must contain chemical conditioners in a concentration sufficient

to protect the system for at least one year. Bacterial or microbial loads must not be present in low temperature systems.

Only use conditioners, additives, inhibitors and antifreeze liquids declared by the producer suitable for use in heating systems

and that do not cause damage to the heat exchanger or other components and/or materials of the boiler and system.

Chemical conditioners must ensure complete deoxygenation of the water, contain specific protection for yellow metals (copper and its alloys), anti-fouling agents for scale, neutral pH stabilizers and, in low-temperature systems, specific biocides for

use in heating systems.

Recommended chemical conditioners:

SENTINEL X100 and SENTINEL X200

FERNOX F1 and FERNOX F3

The unit is equipped with a frost protection system that activates the heat pump in heating mode when the system delivery

water temperature falls below 4°C. The device is not active if the power and/or gas supply to the unit is turned off. If necessary, for system protection use a suitable antifreeze liquid that meets the same requirements as set out above and provided

for by Standard UNI 8065.

In the presence of adequate chemical/physical system and feed water treatments and related high cyclicity controls able to

ensure the required parameters, for industrial process applications the product can be installed in open-vessel systems with

vessel hydrostatic height able to ensure compliance with the minimum operating pressure indicated in the product technical

specifications.

The presence of deposits on the indoor unit exchange surfaces due to non-compliance with the above requirements

will involve non-recognition of the warranty.

Water filter

A water filter must be installed at the entrance of the unit.

The unit is supplied as standard with two square taps. The tap with a blue handle is equipped with a filter (which can be disassembled by unscrewing the rear fitting)

and therefore acts as an interception tap and a water filter; this tap must be mounted on the system return connection (see part.10 “fig. 6 - dimensional data and

connections” on page 11). The tap with red handle must be mounted on the system delivery connection (see part 11 “fig. 6 - dimensional data and connections” on

page 11).

Cod. 3541T090 - Rev. 00 - 06/2019

EN

21

Page 22

INSTALLATION

Tips for a successful installation

For a correct design and installation of the hydraulic plant comply the local laws governing safety matters and sound.

The following information is suggestion for a correct installation of the unit.

• Before connecting the unit to the system wash adequately the pipes using clean water, filling and emptying and cleaning the filters.

• Only after that proceed connecting the unit to the system; this operation is crucial to ensure proper start-up without the need to have repeated stops to clean the

filter, with the possible risk of damage to heat exchangers and other components.

• Check by qualified personnel the quality of the water or of the mixture used; avoid the presence of inorganic salts, biological load (seaweeds, etc.) suspended

solids, dissolved oxygen and the pH. Water with inadequate characteristics can cause a pressure drop increase due to a rapid fouling of the filter, energy efficiency

decrease and corrosive symptom increase that can damage the unit.

• The pipes must have the least possible number of bends to minimize load losses and must be adequately supported in order to prevent the connections of the

unait from being excessively stressed.

• Install on-off valves near components that need to be serviced to isolate them when maintenance work needs to be done and to allow them to be replaced without

having to discharge the system.

• Before isolating the pipes and charging the system, carry out preliminary inspections to make sure that there are no leaks.

• Isolate all the chilled water pipes to prevent condensation from forming along the pipes themselves. Make sure that the material used is the steam barrier type,

failing this, cover the insulation with an appropriate protection. Also make sure that the air venting valves can be accessed through the insulation.

• The circuit can be maintained under pressure using an expansion vessel (present in the unit) and a pressure reducer. A system filling device can be used that

automatically, under a pressure value, provides for the loading and maintenance of the desired pressure.

• Check that all plant components are able to withstand the maximum static pressure (depending on the height of the building to be served).

☞

NOTE

• If there is no glycol in the system (antifreeze) or if the unit is not able to remain electrically powered for possible blackouts, in order to avoid possible icing problems,

empty the water during winter.

• The unit is only to be used in a closed water system. Application in an open water circuit can lead to excessive corrosion of the water piping.

• Water connections must be made in accordance with the outlook diagram delivered with the unit, with respect to the water intake and water outlet (refer to section

“DIMENSIONAL AND PHYSICAL DATA”).

• If air, moisture or dust gets in the water circuit, problems may occur. Therefore, always take into account the following when connecting the water circuit:

• Use clean pipes only.

• Hold the pipe end downwards when removing burrs

• Cover the pipe end when inserting it through a wall so that no dust and dirt enter.

• Use a good thread sealant for sealing the connections. The sealing must be able to withstand the pressures and temperatures of the system.

• When using non-brass metallic piping,make sure to insulate both materials from each other to prevent galvanic corrosion. Never use Zn-coated parts in the water

circuit. Excessive corrosion of these parts may occur as copper piping is used in the unit’s internal water circuit.

Filling with water

1. Connect the water supply to the relevant connection (see part 9 “fig. 6 - dimensional data and connections” on page 11) and open the valve.

2. Make sure the automatic air purge valve is open (at least 2 turns).

3. Fill with water until the manometer indicates a pressure of approximately 2.0 bar. Remove air in the circuit as much as possible using the air purge valves. Air present

in the water circuit might cause malfunctioning of the backup heater.

☞

NOTE

During filling, it might not be possible to remove all air in the system. Remaining air will be removed through the automatic air purge valves during the first

operating hours of the system. Topping up the water afterwards might be required.

The water pressure indicated on the manometer will vary depending on the water temperature (higher pressure at higher water temperature). However, at

all times water pressure should remain above 0.3 bar to avoid air entering the circuit.

Piping insulation

The complete hydraulic circuit that includes all the pipes must be insulated to avoid heat loss, condensation during operation, reduction of heating or cooling capacity,

as well as to prevent freezing of water pipes during winter.

6.13 Boiler gas connection

Before making the connection, ensure that the unit is arranged for operation with the type of fuel available.

The gas must be connected to the corresponding union (vedi fig. 6) in conformity with current regulations, with a rigid

metal pipe or with a continuous flexible s/steel tube, installing a gas cock between the system and boiler. Make sure

that all the gas connections are tight. Otherwise there may be a risk of fire, explosion or suffocation.

22

EN

Cod. 3541T090 - Rev. 00 - 06/2019

Page 23

INSTALLATION

6.14 Boiler fume ducts

THE BOILER MUST BE INSTALLED IN PLACES THAT MEET THE FUNDAMENTAL REQUIREMENTS FOR VEN-

TILATION. OTHERWISE THERE IS A DANGER OF SUFFOCATION OR INTOXICATION.

READ THE INSTALLATION AND MAINTENANCE INSTRUCTIONS BEFORE INSTALLING THE UNIT.

ALSO FOLLOW THE DESIGN INSTRUCTIONS.

IN CASE OF PRESSURES ABOVE 200 Pa INSIDE THE FUME EXHAUST PIPES, CLASS “H1” FLUES MUST BE USED.

Important

The unit is “type C” with sealed chamber and forced draught; the air inlet and fume outlet must be connected to one of the following extraction/suction systems. Before

installation, check and carefully observe the above prescriptions. Also, comply with the provisions concerning the positioning of wall and/or roof terminals and the

minimum distances from windows, walls, vents, etc.

Installation type C10

In case of flues under pressure in a collective flue, before installation and at subsequent maintenance operations, close the fume discharge duct coming from the flue.

OTHERWISE THERE IS DANGER OF SUFFOCATION DUE TO PRODUCTS OF COMBUSTION ESCAPING INTO THE BOILER ROOM.

Installation of the boiler according to type C10 must be carried out by specialist personnel doing the calculations required by current regulations in compliance with the

maximum positive pressure of the flue and the boiler.

Connection with coaxial pipes

For coaxial connection, fit the unit with one of the following starting accessories. For the wall hole dimensions, refer to the figure on the cover. Any horizontal sections of the fume exhaust must be kept

sloping slightly towards the boiler, to prevent possible condensate from flowing back towards the outside and causing dripping.

fig. 26 - Examples of connection with coaxial pipes ( = Air / = Fumes)

fig. 27 - Starting accessories for coaxial ducts

Cod. 3541T090 - Rev. 00 - 06/2019

EN

23

Page 24

INSTALLATION

Table. 2 - Max. length coaxial ducts

Coaxial 60/100 Coaxial 80/125

Max. permissible length (horizontal) 7 m 20 m

Max. permissible length (vertical) 8 m

Reduction factor 90° bend 1 m 0.5 m

Reduction factor 45° bend 0.5 m 0.25 m

Connection with separate pipes

fig. 28 - Examples of connection with separate pipes ( = Air / = Fumes)

Table. 3 - Typology

Type Description

C1X Wall horizontal exhaust and intake. The inlet/outlet terminals must be concentric or close enough to be undergo similar wind conditions (within 50 cm)

C3X Roof vertical exhaust and intake. Inlet/outlet terminals like for C12

C5X Wall or roof exhaust and intake separate or in any case in areas with different pressures. The exhaust and intake must not be positioned on opposite

walls.

C6X Intake and exhaust with separately certified pipes (EN 1856/1)

B2X Intake from installation room and wall or roof exhaust

B IMPORTANT - THE ROOM MUST BE PROVIDED WITH APPROPRIATE VENTILATION

For the connection of separate ducts, fit the unit with the following starting accessory:

Before installation, make sure the maximum permissible length has not been exceeded, by means of a simple calculation:

1. Establish the layout of the system of split flues, including accessories and outlet terminals.

2. Consult “Table. 5 - Accessories” on page 25 and identify the losses in meq (equivalent meters) of every component, according to the installation position.

3. Check that the sum total of losses is less than or equal to the maximum permissible length in “Table. 4 - Max. length separate ducts” on page 24.

Table. 4 - Max. length separate ducts

Max. permissible length 70 m

24

EN

fig. 29 - Starting accessory for separate ducts

eq

Cod. 3541T090 - Rev. 00 - 06/2019

Page 25

Table. 5 - Accessories

PIPE 1 m M/F 1KWMA83W 1,0 1,6 2,0

BEND

PIPE SECTION with test point 1KWMA70W 0,3 0,3

Ø 80

Ø 60

Ø 50

TERMINAL

FLUE

PIPE 1 m M/F 1KWMA89W 6.0

BEND 90° M/F 1KWMA88W 4.5

REDUCTION 80/60 041050X0 5.0

TERMINAL fumes, wall with antiwind 1KWMA90A 7.0

PIPE 1 m M/F 041086X0 12

BEND 90° M/F 041085X0 9

REDUCTION 80/50 041087X0 10

INSTALLATION

Losses in m

Air

intake

45° M/F 1KWMA65W 1,2 1,8

90° M/F 1KWMA01W 1,5 2,0

air, wall 1KWMA85A 2,0 fumes, wall with antiwind 1KWMA86A - 5,0

Split air/fumes 80/80 010027X0 - 12,0

Fume outlet only Ø80

ATTENTION: CONSIDER THE HIGH PRESSURE LOSSES OF Ø50 and Ø60 ACCESSORIES; USE THEM ONLY IF NECESSARY AND AT THE LAST FUME EXHAUST SECTION.

010026X0 +

1KWMA86U

eq

Fume exhaust

Vertical Horizontal

4,0

Use of Ø50 and Ø60 flexible pipe (for ducting only)

The chart includes the starting accessories code 041087X0 for Ø50 and code 041050X0 for Ø60.

Up to 4 m. of Ø80 mm flue can be used between the boiler and the passage with reduced width (Ø50 or Ø60), and up to 4 m. of Ø80 mm flue on the intake (with max.

length of Ø50 and Ø60 flues).

A =

Ø50 - 22 m MAX

Ø60 - 60 m MAX

fig. 30 -

Cod. 3541T090 - Rev. 00 - 06/2019

EN

25

Page 26

INSTALLATION

To use this width, follow the instructions below.

Access the SC menu (follow the instructions given in par. ““Sc” - Combustion Control Parameters Menu” on page 72) and bring the parameter SC04 to a value

corresponding to the length of the flue used.

Connection to collective flues

fig. 31 - Chart for flue parameter choice

fig. 32 - Examples of connection to collective flues ( = Air / = Fumes)

26

EN

Cod. 3541T090 - Rev. 00 - 06/2019

Page 27

INSTALLATION

fig. 33 - Connection examples - system C10 and C11 ( = Air / = Fumes)

Table. 6 - Typology

Type Description

C10 Unit connected through its ducts to a system of common flue pipes under pressure obtained in the structure

C11 Unit connected through its ducts to a system of common flue pipes under pressure

C2X Intake and exhaust in common flue (intake and exhaust in same flue)

C4X Intake and exhaust in common and separate flues, but undergoing similar wind conditions

C8X Exhaust in single or common flue and wall intake

B3X

Intake from installation room by means of concentric duct (that encloses the exhaust) and exhaust in common flue with natural draft.

B IMPORTANT- THE ROOM MUST BE PROVIDED WITH APPROPRIATE VENTILATION

C93 Exhaust to a vertical terminal and intake from existing flue.