Page 1

ARENA 30 C

WALL-HUNG, PRE-MIX

GAS-FIRED CONDENSING BOILER

INSTALLATION

AND

OPERATING INSTRUCTIONS

Appr. nr. B99.14 A - CE 0063 BL 3475

cod. 3543643/1 ediz. 04/2002

Page 2

ARENA 30 C

2

IMPORTANT

Your “benchmark” Installation, Commissioning and Service Record Log Book will be enclosed in

your customer information pack.

“This record must be completed and left with the end user”.

Ferroli is a member of the Benchmark initiative and fully supports the aims of the programme.

Benchmark has been introduced to improve the standards of installation and commissioning of central

heating systems in the UK and to encourage the regular servicing of all central heating systems to

ensure safety and efficiency.

Please see installation and servicing guidelines.

CE MARK

CE mark documents that the Ferroli gas appliances comply with the requirement contained in

European directives applicable to them.

In particular, the appliances comply with the following CEE directives and the technical specifications

provided from them:

• Gas appliances directive 90/396

• Efficiencies directive 92/42

• Low tension directive 73/23 (modified from the 93/68)

• Electromagnetic compatibility directive 89/396 (modified from the 93/68)

Year 2000 Compliance Declaration

We will guarantee that this products is altogether suitable for the data change in the Year 2000 (boiler

has no dependence from date change) and that no disruptions will occur which is caused by this

product.

• Read the warnings given in this manual thoroughly. They provide important information for safe

installation, use and maintenance

• Keep the manual carefully for future consultation.

• The instruction manual is an integral and essential

part of the product and must be kept by the user.

• If the appliance is sold or transferred to another

owner or if the owner moves, leaving the appliance behind, always ensure that the manual is

kept with the appliance for consultation by the

new owner and /or installer.

• Incorrect installation or poor maintenance absolves the manufacturer from all liability for damage to people or things.

• Installation and maintenance must be carried out

i conformity with current legislation, according to

the manufacturer’s instructions and by qualified

personnel.

• Before cleaning or maintenance, disconnect the

appliance from the mains via the switch on the

appliance or a suitable isolating device.

• In the event of malfunction or faulty operation,

deactivate the appliance. Do not attempt to repair or carry out any other operation on the

appliance directly. Contact qualified personnel

only.

• Repairs or the replacement of components must

be carried out exclusively by qualified personnel

using original spare parts only. Failure to respect

the above my compromise the safety of the appliance.

• To guarantee efficient operation, the appliance

must be serviced once a year by an authorised

service centre.

• The appliance may not be used for purposes

other than those for which it was explicitly designed. Any other use is considered improper and

therefore dangerous.

• Incorrect installation and use or failure to follow

the instructions provided by the manufacturer

absolve the manufacturer from all liability for

damage.

• After unpacking, check that the contents are

whole and undamaged.

• Keep packing out of reach of children as it is

potentially hazardous.

• To clean external parts, use a damp cloth moistened with soapy water if necessary. Avoid using

abrasive cleaning products and solvents.

Page 3

ARENA 30 C

3

INDEX

1. CHARACTERISTICS AND TECHNICAL DATA ................................................................ 4

1.1 Introduction ......................................................................................................................... 4

1.2 Structural charateristics ....................................................................................................... 5

1.3 Technical data table ............................................................................................................. 8

1.4 Diagrams.............................................................................................................................. 9

1.5 Functional flow chart ......................................................................................................... 10

2. INSTALLATION ............................................................................................................ 11

2.1 General Instructions .......................................................................................................... 11

2.2 Positioning and wall mounting .......................................................................................... 11

2.3 Connection to the hydraulic system.................................................................................. 12

2.4 Characteristics of the boiler water .................................................................................... 13

2.5 Connection to the gas system........................................................................................... 14

2.6 Condensation discharge connection ................................................................................. 14

2.7 Electrical connections ........................................................................................................ 15

2.8 Room thermostat, external unit and auxiliary controls..................................................... 15

2.9 Positioning the external probe.......................................................................................... 16

2.10 Flues................................................................................................................................. 17

2.11 Connection to concentric pipes ...................................................................................... 17

2.12 Connection to separate pipes ......................................................................................... 19

2.13 Table of losses for piping and accessories ...................................................................... 20

2.14 Terminal Position ............................................................................................................. 23

3. SERVICE AND MAINTENANCE .................................................................................. 24

3.1 Settings .............................................................................................................................. 24

3.2 Commissioning and testing ............................................................................................... 27

3.3 Maintenance ...................................................................................................................... 28

3.4 Replacement of parts ........................................................................................................32

3.5 Troubleshooting................................................................................................................. 36

4. OPERATING INSTRUCTIONS ...................................................................................... 39

4.1 Operation and controls ..................................................................................................... 39

4.2 Boiler control panel ........................................................................................................... 39

4.3 Ignition ............................................................................................................................... 40

4.4 Shut-down.......................................................................................................................... 40

4.5 Operating indications on the display ................................................................................ 40

4.6 Accessing the operating menu.......................................................................................... 40

4.7 Setting the heating system temperature .......................................................................... 41

4.8 Setting the domestic hot water temperature ................................................................... 41

4.9 Summer/Winter Selection ................................................................................................. 41

4.10 Aquafast device ............................................................................................................... 41

4.11 Outside temperature compensation ............................................................................... 42

4.12 Maintenance .................................................................................................................... 42

4.13 Anomalies ........................................................................................................................ 42

Page 4

ARENA 30 C

4

1.1 Introduction

Dear Customer,

Thank you for having chosen the Arena 30 C, the latest generation FERROLI wall-hung boiler, featuring

advanced design and cutting-edge technology.

The Arena 30 C is a pre-mix condensing thermal generator for heating and the production of domestic hot

water, with very high thermal efficiency and very low emissions, fired by natural gas or LPG.

The boiler body is made up of a prismatic mono-block heat exchanger, with a hexagonal base made from

aluminium alloy, inserted in a cylindrical steel jacket, with water cavity, and insulated externally with highdensity foam. The special design of the heat exchanger allows effective condensation of the water vapour

contained in the flue gases, making the Arena highly efficient. The heat exchanger has been designed to

maintain its characteristics of high thermal exchange over time.

Inside the aluminium mono-block heat exchanger, in a cooled combustion chamber, lies the pre-mix burner

assembly, with a radial shape and metallic surfaces, featuring electronic ignition with ionisation flame control,

which allows extremely low emission values, and at the same time guarantees high reliability and constant

operation over time.

The combustion circuit and the air intake are sealed from the installation environment.

The boiler is fitted with a variable speed fan and built-in modulating gas valve, connected directly to the

outside.

The boiler control and regulation system is microprocessor-based, with advanced self-diagnostics. The user

interface, made up of a keypad and display, is user-friendly, and shows the operating status of the appliance

at all times. The operating parameters and the data logs are saved internally and can be called up using the

Personal Computer interface to simplify Service operations.

The heat output is regulated continuously across the entire operating range, with temperature-scrolling

climate control, which automatically adapts the operating mode to the characteristics of the internal and

external environments, of the building and its location.

A special internal device allows ultra-fast production of domestic hot water: hot water is available at the boiler

outlet as soon as the hot water tap is opened.

Completing the fitted devices are a variable-speed heating pump and a fixed-speed domestic hot water

pump, a high-capacity expansion vessel, flowmeter, safety valve, drain cock, water pressure switch, flue gas

sensor, temperature sensors and safety thermostat.

1. CHARACTERISTICS AND TECHNICAL DATA

Page 5

ARENA 30 C

5

60

220

205

110120

460

760

368

739576,576,59544

108

50

68

12345

6

8

9

7

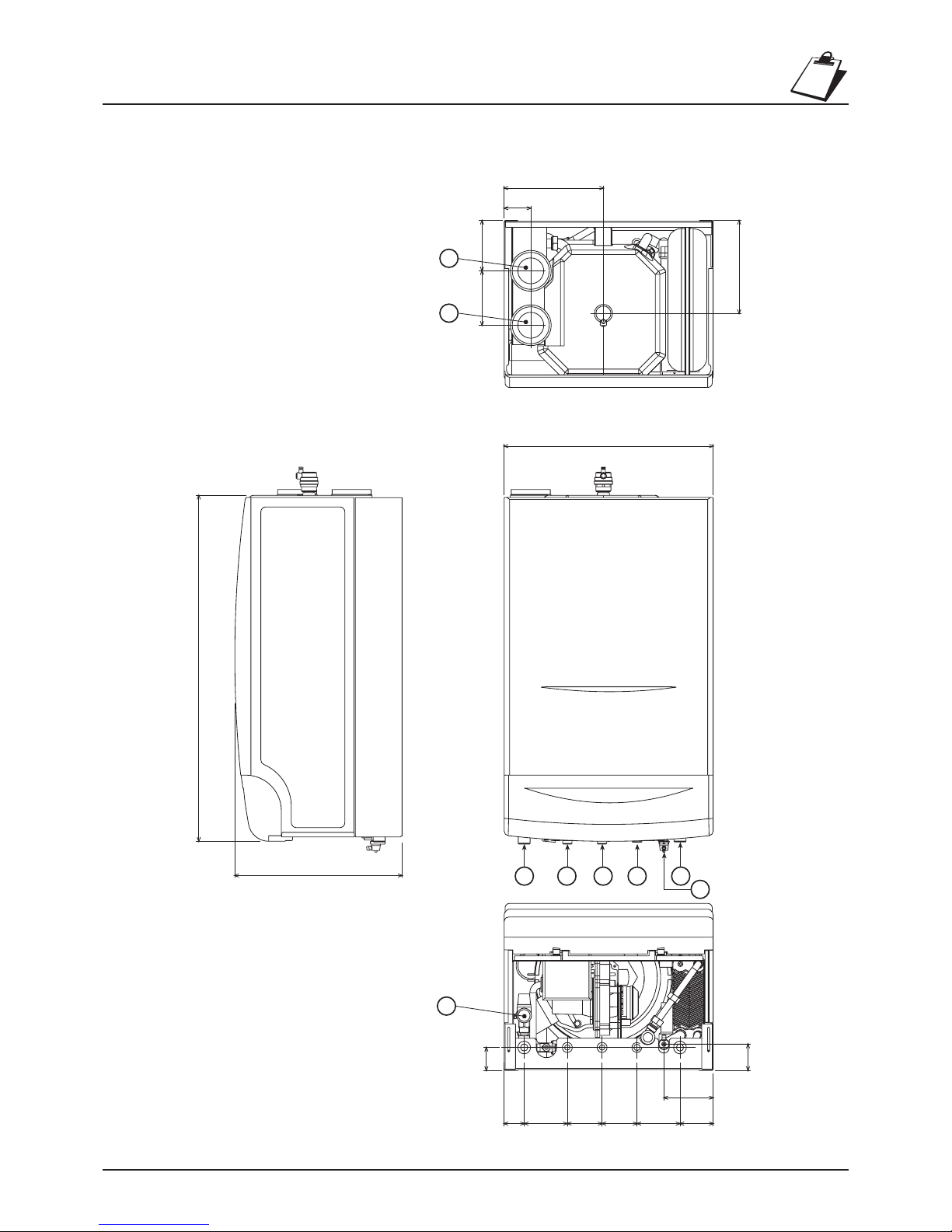

1.2 Structural charateristics

Dimensions and connections

Key

1 Heating outlet

2 Domestic hot water outlet

3 Gas inlet

4 Domestic hot water inlet

5 Heating return

6 Drain cock

7 Safety valve

8 Flue gas outlet

9 Air inlet

Fig. 1

Page 6

ARENA 30 C

6

114

213

14

220 16 136 151 194

32

216

56

44

69

70

215

214

179

161

217

191

186

49

34

35

Overall view and main components

Key

14 Safety valve

16 Fan

32 Heating pump

34 Heating temperature sensor

35 Auto air vent.

44 Gas valve

49 Safety thermostat

56 Expansion vessel

69 Flue gas outlet pipe

70 Air intake pipe

114 Water pressure switch

136 Flow-meter

151 System drain cock

161 Condensing heat exchanger

179 Non-return valve

186 Return sensor

191 Flue gas temperature sensor

194 Domestic hot water heat exchanger

213 Flexible inlet air pipe coupling

214 Flue gas outlet reducer

215 Air inlet reducer

216 Domestic hot water pump

217 Boiler body lagging

220 Ignition board

Fig. 2

Page 7

ARENA 30 C

7

Heating

outlet

Domestic

hot water

outlet

Gas

inlet

Domestic

hot water

inlet

Heating

inlet

Air

inlet

Flue gas

outlet

1644

56

49

191

136

32

34

186

22

82

188

216

114 14

Condensation

discharge

42

221

179

194

179

Key

14 Safety valve

16 Fan

22 Main burner assembly

32 Heating pump

34 Heating temperature sensor

42 Domestic hot water temperature sensor

44 Gas valve

49 Safety thermostat

56 Expansion vessel

82 Detection electrode

114 Water pressure switch

136 Flow-meter

179 Non-return valve

186 Return sensor

188 Ignition electrode

191 Flue gas temperature sensor

194 Domestic hot water heat exchanger

216 Domestic hot water pump

221 Bypass cock

Hydraulic diagram

Fig. 3

Page 8

ARENA 30 C

8

Heating

Maximum operating temperature, heating °C

Maximum operating pressure, heating bar

Minimum operating pressure, heating bar

Expansion vessel capacity litri

Expansion vessel pre-fill pressure bar

Boiler total water content litri

Domestic hot water

Domestic hot water supply ∆t 25°C l/min

Domestic hot water supply ∆t 30°C l/min

Domestic hot water supply ∆t 35°C l/min

Range of temperature regulation, domestic hot water °C

Maximum operating pressure, domestic hot water bar

Minimum operating pressure, domestic hot water bar

Dimensions, weights, conections

Height mm

Width mm

Depth mm

Empty weight kg

Gas system connections poll.

Heating system connections poll.

Domestic hot water circuit connections poll.

Condensation discharge (flexible pipe) mm

Maximum length separate flues D=80*

m

eq

(*Values expressed in equivalent air metres - refer to FERROLI calculation system)

Electrical power supply

Max Electrical Power Consumption W

Pump electrical power consumption (Speed I-II-III) W

Power supply voltage/frequency V/Hz

85

3

0,8

12

1

11,8

17,5

14,6

12,5

40 - 65

6

0,25

760

460

368

55

1/2”

3/4”

1/2”

15x20

100

150

48-67-93

230/50

Power

Heat rate Hi

Heat rate Hs

Natural Gas rate (G20)

Natural gas supply pressure (G20)

LPG Gas rate (G31)

LPG Gas supply pressure (G31)

Pmax Pmin

kW 31,5 8,2

kcal/h 27.090 7.052

nm

3

/h 3,27 0,80

mbar 20 20

kg/h 2,44 0,60

mbar 37 37

Useful heat output 80°C - 60°C

Useful heat output 50°C - 30°C

Combustion

CO2 (Natural Gas - G20) %

CO2 (LPG - G31) %

Flue gas temperature 80°C-60°C °C

Flue gas temperature 50°C-30°C °C

Flue gas flow rate kg/h

Quantity of condensation kg/h

pH of condensation water pH

Pmax

9,5

10,2

70

40

49

3,3

Pmin

9,0

9,5

65

32

13

1,4

4,1

kW 30,9 7,6

kcal/h 26.574 6.536

kW 34,3 8,4

kcal/h 29.498 7.224

kW 30,0 7,4

kcal/h 25.800 6.364

1.3 Technical data table

Page 9

ARENA 30 C

9

6,0

III

I

I

0,0

1,0

2,0

3,0

4,0

5,0

0 0,5 1 1,5 2 2,5 3

Q (m3/h)

3,5 4

H (m C.A.)

1.4 Diagrams

Heating pump head

Loss of boiler pressure

Fig. 4

Fig. 5

6,0

41,5 2 2,5 3 3,5

Q (m3/h)

1,0

2,0

3,0

4,0

5,0

1

0,0

0 0,5

H (m C.A.)

Page 10

ARENA 30 C

10

13

12

151412111087654

1245678101112

NL

321

24 V AC

24 V AC

X2

X1

131415

X5

X6

175

X10

X11

PC

3 2

X3

X4

123

6789101112

S4575B 1033

121110

87542

1

9

6

16

-

-

+

Output

-

-

DMF04

NL

L

N

NL

42

114

121110987654321

X7

----

191

72

32

98

216

186

188 82

34

136

139

138

49

4

5

NL

230 V

50 Hz

230 V

50 Hz

83

101

230V 50Hz Low voltage

Eco/Comfort

selection

12

1

DHW

disable switch

Key

16 Fan

32 Central heating pump

34 C.H. flow temperature sensor

42 D.H.W. temperature sensor

49 Overheat cut-off thermostat

72 Room thermostat (not fitted)

82 Ionisation electrode

83 Full sequence automatic control

98 Switch

101 Main P.C.B.

114 Water pressure switch

136 Flowmeter

138 Outside temperature sensor

139 Room unit (not fitted)

175 Transformer

186 Return temperature sensor

188 Hot surface igniter

191 Exhaust temperature sensor

216 Domestic hot water pump

1.5 Functional flow chart

Fig. 6

Page 11

ARENA 30 C

11

2. INSTALLATION

2.1 General Instructions

Gas Safety (Installation & Use) Regulations: 1996

In the interest of safety, it is the law that all gas appliances are installed by a competent person in accordance

with the above Regulations, Building Regulations/Building Standards Scotland, Codes of Practice, current

I.E.E. Regulations and the byelaws of the

Local Water Undertaking. Failure to comply

with the Regulations may lead to prosecution;

it is your responsibility to ensure that the law

is complied with.

N.B. For Northern Ireland the rules in force

apply.

IMPORTANT If the boiler is to be fitted in

a timber framed building it

should be fitted in

accordance with the

Institute of Gas Engineers

document IGE/UP/7. If in

doubt advice should be

sought from the Local

Supplier.

WARNING!! This appliance must be installed

in a room with sufficient ventilation, to avoid

dangerous conditions arising in the event of,

even minor, gas leaks. These safety standards

are imposed by the EEC Directive no. 09/396

for all gas appliances, including the so-called

sealed appliances.

2.2 Positioning and wall

mounting

The installation of the ARENA must be on a

suitable non-combustible load bearing wall

which will provide an adequate fixing for the

boiler mounting bracket assembly. The location should be in an area where the water

pipes will not be subjected to frost conditions.

In siting the combination boiler the following

limitations must be observed:

The combination boiler may be installed in any

room or internal space, although particular attention is drawn to the requirements of the current I.E.E. wiring

regulations and in Scotland the electrical provisions of the building regulations applicable in Scotland, with

respect to the installation of the combination boiler in a room or internal space containing a bath or shower.

Where a room sealed appliance is installed in a room containing a bath or shower any electrical switch or

appliance control utilising mains electricity must be situated so that it cannot be touched by a person using

the bath or shower.

The boiler is supplied ready for wall-hung installation. The rear frame of the appliance has a series of slots

> 50 cm

Minimum Recommended

A

B

D

3 cm

15 cm

1,5 cm

(from any openable panel)

15 cm

30 cm

C 10 cm 15 cm

A A

B

D

C

Fig. 7a

Page 12

ARENA 30 C

12

108

68

12345

6

Key

1 Heating outlet

2 Domestic hot water outlet

3 Gas inlet

4 Domestic hot water inlet

5 Heating return

6 Drain cock

Fig. 8

for fastening it to the wall, using screws with metal wall plugs.

The fastening to the wall must provide stable and effective

support of the appliance.

The boiler must be fastened to a closed part of wall, which is

free of apertures or holes behind the frame of the boiler that

may allow the internal components of the boiler to be reached.

If the appliance is enclosed in a cabinet or alongside another

appliance, space must be allowed for normal maintenance

operations. Fig. 7a shows the minimum and recommended

space to be left free around the appliance.

The boiler is supplied with a paper drilling template used to

trace the holes for fastening the appliance onto the wall.

Furthermore, upon request a metal version of the wall drilling

template is available, which can be reused for more than one

appliance.

Position the drilling template on the part of the wall chosen

for the installation of the boiler; using a spirit level, check that

the lower bracket is perfectly horizontal. Temporarily fasten

the drilling template to the wall using some adesive tape.

Trace the fastening points “A”. Drill two 10 mm holes 90 mm

deep to accept the wall plugs, fit wall plugs. Fit two special

wall plugs on the wall as described in the fig. 7c. Fasten the

wall bracket to the wall using an antitheft nut on the right side

and a standard nut (M8) on the left side. Mount the boiler on

the wall bracket and fix using an antitheft nut on the left side

and a standard nut (M8) on the right side.. The connection for

the water and gas pipes to the boiler are then

defined, from “B” lines (for vertical connections) or

from ”C” holes for horizontal connections (using

optional Ferroli kit).

Note If there is no drilling template for mounting

the appliance, simply fasten the boiler to

the wall using suitable support screws with

metal wall plugs, through the holes in the

boiler frame.

2.3 Connection to the hydraulic system

Make the connections to the corresponding couplings, according to the positions indicated in Fig. 3.

Arena

30 A

748

460

44 109,5 62 62 109,5 73

16 16

11

16

205

220

60

110120

8

9

7511061,561,511045

139

368

760

460

1 2 3 4 5

6

115

Ø 3/4” Ø 1/2” Ø 3/4”

Kit Ferroli

cod. 1KWMA78Y

A

A

B

C

Fig. 7b

Fig. 7c

Page 13

ARENA 30 C

13

In addition, shut-off valves should be installed between the boiler and the heating system to allow, if

necessary, the boiler to be isolated from the system. If a non-return valve is also installed in the domestic hot

water circuit, a safety valve must be fitted between the boiler and this circuit.

The discharge of the safety valve must be connected to a funnel or collection pipe, to avoid water leaking

onto the ground in the event of excessive pressure in the heating circuit.

Make the connections to the boiler so as its internal pipes are not subject to stress. For proper operation and

long-life of the boiler, the hydraulic system must be correctly proportioned and always complete with all the

accessories required to guarantee regular operation and conduction.

Upon request a connection kit can be supplied, simplifying connection to the system.

2.4 Characteristics of the boiler water

In the presence of water with hardness above 18 Clarke degrees, the water should be suitably treated, to avoid

any deposits in the boiler caused by hard water, or corrosion caused by aggressive water. It should also be

remembered that even minor deposits measuring just a few millimetres thick can cause, due to their low

thermal conductivity, significant overheating of the walls of the boiler, with consequent and serious problems.

The water must always be treated in the case of very large systems (with high water capacity) or systems with

the frequent inlet of recovered water. If, in these cases, the system needs to be partially or completely

emptied, it must be refilled with treated water.

Water System

Note The boiler is designed for sealed systems only and must NOT be used on open vented systems.

Central Heating

Detailed recommendations are given in BS6798, BS5449, BS6700 and CP342 Part 2. Pipework not forming

part of the useful heating surface should be insulated to prevent any heat losses or possible freezing (i.e. in

roof spaces or ventilated underfloor spaces). Drain taps should be positioned at the lowest point of the

system in accessible locations to permit the whole system to be drained down. The drain taps should be in

accordance with BS2879. Copper tubing to BS2871, Part 1 is recommended for water carrying pipework.

Pipework in horizontal runs should have a gradient where possible to facilitate the removal of air. Ensure that

the boiler heat exchanger is not a natural point for air collection.

Make Up Water

Provision must be made for replacing water lost from the sealed system. Reference should be made to

BS6798, for methods of filling and making up sealed systems. There must be no direct connection between

the boiler's central heating system and the mains water supply. The use of mains water to charge and

pressurise the system directly, is conditional upon the Local Water Byelaws. Again any such connection must

be disconnected after use.

Domestic Hot Water

Always fit a scale reducer in "hard water areas" (18 clarke degrees or over)". A 15mm copper connection

point on the boiler for attaching to the main supply is provided. The maximum domestic water pressure for

the inlet supply is 10 bar (145 P.S.I.). If the cold mains supply exceeds 5 bar (72 P.S.I.), a water governor

or pressure reducing valve must be fitted by the installer into the mains supply in an inconspicuous but

accessible position preferable between 3 and 5 metres (10-16ft) before the appliance. Such a valve must be

approved by the Water Research Council.

Attention - is drawn to the Model Water Byelaws.

Fittings manufactured from duplex (alpha-beta) brass are not acceptable for underground use and certain

water undertakings will not accept their use above ground.

Ensure all pipework is adequately supported.

Page 14

ARENA 30 C

14

2.5 Connection to the gas system

If necessary the local Gas supplier should be consulted, at the installation planning stage, in order to establish

the availability of an adequate supply of gas.

An existing service pipe must not be used without prior consultation with the Local Gas supplier.

A gas meter can only be connected by the Local Gas supplier, or by a Local Gas suppliers Contractor.

Installation pipes should be fitted in accordance with BS6891-1988.

Appliance inlet working pressure must be 20mbar MINIMUM, for NG and 37 mbar minimum for LPG.

Pipework from the meter to the combination boiler must be of an adequate size.

The boiler requires 2.73m3/h of natural gas, and 2,00 kg/h of LPG.

Do not use pipes of a smaller size than the combination boiler inlet gas connection.

The complete installation must be tested for gas soundness and purged as described in BS6981-1988. All

pipework must be adequately supported. An isolating gas valve is provided and should be fitted on the boiler

gas inlet. Please wait 10 minutes when lighting from cold before checking gas rate. Gas pressures should be

checked after the boiler has operated for 10 minutes to reach thermal equilibrium.

2.6 Condensation discharge connection

The boiler must be connected to the condensation discharge siphon, supplied as standard with the appliance.

1) Take out the flexible grey condensation discharge pipe A, already mounted in the boiler, from the proper

slot on the bottom;

2) Place the siphon on the wall, fix it to the wall with a screw + plug through the fixing point B;

3) Connect the grey pipe A to the hose connector E on the top of siphon, cutting it to the right length if

necessary;

4) Connect the corrugated pipe C to the bottom connector D;

5) Before definitively connecting the corrugated pipe C to the drainage system, fill the siphon with about 0,5

litres of water

Attenzione:

Riempire il sifone con

acqua prima di

collegarlo

A

Fig. 9

B

E

C

D

Attention:

Fill the siphon with

water before connecting

Page 15

ARENA 30 C

15

EDCBA

123456789101112

2.8 Room thermostat, external

unit and auxiliary controls

Below the electrical control box is a multipolar

terminal block, for connecting:

• Room thermostat (1-2)

WARNING: THE ROOM THERMOSTAT MUST

NOT HAVE LIVE CONTACTS. CONNECTING

230V TO THE ROOM THERMOSTAT TERMINALS WILL CAUSE IRREVERSIBLE DAMAGE

TO THE ELECTRONIC BOARD.

When connecting a room thermostat with daily

or weekly program, or a timer, avoid taking the

power supply to these devices from their switch

contacts. Their power supply must derive from

a direct connection to the mains or using batteries, depending on the type of device.

This appliance can also operate without a room

thermostat, yet the latter is recommended for

increased comfort and greater energy savings.

• Switch for economy/comfort remote selection (3-

4). With the switch turned off the boiler is maintained in “Comfort”, independently from the

setting on the menu or on the remote control.

• DHW exclusion switch (5-6) for remotely disable the DHW function. Open contact will exclude DHW.

• External temperature probe (7-8)

With the probe (optional) connected, the boiler

works in outside compensation temperature

mode, depending on the compensation curve

settled (ref. 4.11). If none probe is connected,

the boiler works in standard mode and setting

of a compensation curve (parameter 9 of menu)

is ignored by the control system.

• Remote control (9-10), for remote control and regulation of the boiler, with weekly chronothermostat

and climatic regulation functions.

To make these connections, unscrew the four

screws which fasten the lower protective plate

and connect the wires to the terminal block,

respecting the position of the terminals (refer to

the wiring diagrams, chap. 1.5)

Fig. 10 a

Fig. 10 b

Fig. 10 c

A Room thermostat

B Eco/Comfort selection switch

C Domestic hot water exclusion switch

D External temperature sensor

E Remote control

2.7 Electrical connections

Power supply

The boiler must be connected to a single-phase, 230 Volt-50 Hz power line, with max 3A fuses fitted between

boiler and the line, as well as a bipolar switch ON/OFF with contacts whose opening is at least 3 mm. The

boiler must always be properly earthed.

When electrically connecting the boiler to an electrical system with live and neutral, THE POLARITY MUST BE

RESPECTED (LIVE: brown wire / NEUTRAL: blue wire / EARTH: yellow-green). Note: If replacing the electrical

power cable, use only the “HAR H05 VV-F” cable, 3x0.75 mm2, with a maximum external diameter of 8 mm.

Page 16

ARENA 30 C

16

Fig. 12

Fig. 11

2.9 Positioning the external probe

The external probe is best installed on a wall facing north, north-west or which borders the majority of the

main living area. The probe must never be exposed to the early morning sun, and, in general and where

possible, must not receive direct sunlight; if necessary, it should be shielded.

The probe must not in any case be fitted near windows, doors, ventilation openings, flues, or sources of heat

which may alter the reading.

Note: The maximum length allowed for the electrical cable connecting the boiler to the external probe is

50 m. A common two-lead cable can also be used.

H

1/2H

1/2H

H

N

N W

Page 17

ARENA 30 C

17

2.10 Flues

Arena is a type-C boiler with forced draught, the air inlet and the flue gas outlet must be connected to one

of the exhaust–intake systems indicated as follows. Using the tables and the methods of calculation

described, first verify, before installation, that the flues do not exceed the maximum allowed length.

2.11 Connection to concentric pipes

An aluminium “60/100 concentric adapter” is available for connecting the boiler to 60/100 mm concentric

pipes. The extreme ease of mounting and the use of double-lip gaskets in the couplings makes this solution

extremely advantageous and safe. Furthermore, an aluminium and plastic concentric kit is available for

discharge using 80/125 concentric pipes.

The total length in linear metres of the concentric pipes must not exceed the maximum length indicated in

the first table below. The second table shows the reductions to be used for any bends in the pipes, excluding

the initial one.

For installation, connect the concentric kit directly to two diameter 80

bell-shaped reducers in the boilers, as indicated in Fig. 13. The

concentric kit can then be connected directly to a concentric bend

using a horizontal pipe or a concentric pipe in the vertical position.

Maximum allowable pipe length

Ø100/60 mm concentric

Arena 30 C 12 m

Vertical

11 m

Horizontal*

Reducers for concentric bends

90° concentric bend

45° concentric bend

1 m

0,5 m

Ø125/80 mm concentric

21 m

Vertical

20 m

Horizontal*

Fig. 13

1KWMA55Y

1KWMA57W

1KWMA35W

Ø 100

Ø 60

Øi 100

Øi 60

Page 18

ARENA 30 C

18

To locate the centre of the hole for the passage of the pipes in the wall, refer to Fig. 14:

Please consider that the horizontal concentric piping must have a slope towards the boiler of at least 3 mm/

m, to allow the condensation which forms in the flues to flow back to the boiler, and avoid external dripping.

The concentric pipes should be sealed with the relative pipe coupling seal at the points of coupling to the

wall. The external piping must protrude from the wall between 10 and 60 mm (Fig.15).

Fig. 14

Fig. 15

3°

60

110

142

Page 19

ARENA 30 C

19

Upon request, a wide range of pipes, bends and accessories can be supplied. For the various components,

refer to tables 1 – 2 – 3 or to the flue accessory catalogue.

A simple calculation can be performed to ensure that the maximum allowable pipe length is not exceeded:

1 For each component, table 1 – 2 – 3 lists the loss of pressure in “equivalent air-metres”, depending

on the position of installation of the component itself (air intake or flue gas exhaust, vertical or

horizontal).

The loss is called “equivalent air-metres” as it relates to the loss of a metre of air intake pipe (defined

as being equal to 1). For example, a 90° Ø80 bend in flue gas exhaust has a loss equivalent to 2.5

air-metres, that is equal to 2.5 linear metres of air intake pipe.

2 Once having completely defined the layout of the double flue system, add the losses in equivalent-

metres, according to the position of installation of all the components and accessories in the system

3 Check that the total loss calculated is less than or equal to 100 equivalent metres, that is the maximum

allowable for this model of boiler.

If the flue system chosen exceeds maximum allowable limit, some sections of the pipes should be

larger in diameter.

2.12 Connection to separate pipes

The separate Ø60 pipes for air intake and flue gas exhaust can be connected directly to the boiler, as shown

in Fig. 16a. Separate Ø80 pipes can be connected directly, once the two 80/60 (optional) reducers have been

fitted inside the boiler (Fig. 16b).

Ø60 Ø60

Flue Air

Ø80 Ø80

Ø80 Ø80

Flue Air

Fig. 16 a Fig. 16 b Fig. 16 c

Page 20

ARENA 30 C

20

2.13 Table of losses for piping and accessories

KWMA83U

KWMA86A

KWMA85A

KWMA86U

KWMA84U

Air Flue

Vertical

Horizontal

Vertical

Horizontal

KWMA01K

KWMA02K

KWMA05K

KWMA82A

KWMA38A • 0,50 m

KWMA83A • 1,00 m

KWMA06K • 2,00 m

KWMA07K • 4,00 m

Description

Tubo Ø 80

male-female

Female-female

bend 45° Ø 80 mm

Female-female

bend 90° Ø 80 mm

Male-female

bend 90° Ø 80 mm

Pipe fitting M/M/F Ø80

with inspecting

plug+trap for

condensate drainage

system

Description

Airwall terminal

products of

combustion Ø80 mm

Air terminal of inlet

protection Ø80 mm

Outlet flue air inlet

for concentric system

Ø80

Pipe fitting for

outlet flue Ø80 mm

Outlet flue air inlet

for connection with

split end Ø80 mm

0,5

1

2

4

0,5

1

2

4

0,8

1,6

3,2

6,4

1

2

4

8

1,2 1,8

2,0 2,5

1,5 2,0

7

Reduction

KWMA55U

5

2

4

3

Air Flue

Vertical

Horizontal

Vertical

Horizontal

Reduction

12

Condensate flue

outlet

KWMA03U

Spigot and socket

reduction Ø 80/100 mm

0

Accessories Ø 80 Accessories Ø 80

Tab. 2

The loss values listed refer to original FERROLI

pipes and accessories

Tab. 1

Page 21

ARENA 30 C

21

Air Flue

Vertical

Horizontal

Vertical

Horizontal

Description

3 3 4,0 4,5

3 4,5

4 5,2

Reduction

9

0

Accessories Ø 60

Air/flue wall terminal

Ø60 mm

KWMA90A

Male-female

bend 90° Ø 60 mm

KWMA88W

Male-female

bend 45° Ø 60 mm

KWMA39W

Male-female

flue Ø 60

KWMA89W • 1,00 m

5

KWMA02W

Spigot and socket

reduction

Ø 60/80 mm

Tab. 3

Page 22

ARENA 30 C

22

Fig. 17

For other accessories please refer to the manual: “Flue accessories and installation of forced air appliances”

Example of how to calculate the connection of two separate pipes, max flue length: 100 metres

The flue and air pipes must be sloped towards the boiler by at least 3%.

Ref.

1

2

3

N° Pieces

20

20

1

Vertical flue pipe

Vertical air pipe

Flue

Description

Length

o loss

32 m

20 m

12 m

64 mTotal

20 m

12

3

Page 23

ARENA 30 C

23

2.14 Terminal Position

Fig. 18

P

D, E

Q

Q

l

B

C

A

G

F

L

J

H

H

K

N

N

MM

Q

Directly below an opening, air brick, (0-7 kW)

opening windows, etc. (>7-14 kW)

(>14-32 kW)

(>32-70 kW)

Above an opening, air brick, (0-7 kW)

opening windows, etc. (>7-14 kW)

(>14-32 kW)

(>32-70 kW)

Horizontally to an opening, air brick, (0-7 kW)

opening windows, etc. (>7-14 kW)

(>14-32 kW)

(>32-70 kW)

Below gutters, soil pipes or drain pipes

Below eaves

Below balconies or car port roof

From a vertical drain pipe or soil pipe

From an internal or external corner

Above ground roof or balcony level

From a surface facing the terminal

(also see 6.1.2)

From a terminal facing the terminal

From an opening in the car port ( e.g. door,

window) into the dwelling

Vertically from a terminal on the same wall

Horizontally from a terminal on the same wall

From the wall on which the terminal is mounted

From a vertical structure on the roof

Above intersection with roof

Dimensions Terminal position

(kW input expressed in net)

Balanced flues room

sealed

Open flues

Natural

draught

Natural

draught

Fanned

draught

Fanned

draught

A

a

300 mm

600 mm

1500 mm

2000 mm

300 mm Not allowed 300 mm

B

a

300 mm

300 mm

300 mm

600 mm

300 mm Not allowed 300 mm

C

a

300 mm

400 mm

600 mm

600 mm

300 mm Not allowed 300 mm

D 300 mm 75 mm Not allowed 75 mm

E 300 mm 200 mm Not allowed 200 mm

F 600 mm 200 mm Not allowed 200 mm

G 300 mm 150 mmbNot allowed 150 mm

H 600 mm 300 mm Not allowed 200 mm

I 300 mm 300 mm Not allowed 300 mm

J 600 mm 600 mm N/A 600 mm

K 600 mm 1200 mm N/A 1200 mm

L 1200 mm 1200 mm N/A 1200 mm

M 1500 mm 1500 mm N/A 1500 mm

N 300 mm 300 mm N/A 300 mm

O N/A N/A N/A 50 mm

P N/A N/A See Table 2

and Fig. 6b

N/A

Q N/A N/A See Table 2

and Fig. 4

150 mm

NOTE N/A = Not applicable

a

I

n addition, the terminal should not be nearer than 150 mm (fanned draucht) or 300 mm (natural draught) to an opening in the building fabric formed for the purpose of accommodating

a built-in element such as a window frame, (see Figure C2). Separation distances are linked to the rated heat inputs as shown.

b

This dimension may be reduced to 75 mm for appliances of up to 5 kW heat input.

Minimum dimensions of flue terminal positions

Page 24

ARENA 30 C

24

Supply gas Restrictor

Methane (G20)

Propane (G31)

-

Ø 5,2 mm

Category

2H

3P

Nominal CO2 at maximum power

9,5 %

10,2 %

3.

SERVICE AND MAINTENANCE

3.1 Settings

Gas conversion

The adjustment and transformation operations must only be performed by Qualified Personnel.

FERROLI S.p.A. declines all liability for damage to persons and/or things deriving from tampering with the

appliance by non-authorised persons.

The appliance can operate with natural or LPG supply gas, and is factory configured for use with one of the

two gases, as is clearly marked on the packaging and on the rating plate on the appliance itself.

If the appliance has to be used with a gas other than the one it has been set for, it is necessary to insert (or

remove) the restrictor between the gas valve and the air inlet Venturi, and operate on the regulation screw

F (fig. 19) placed on the Venturi unit to regulate the CO2 content in the flue gas to the nominal value (within

+/- 0.1%) described in the following table::

To convert, proceed as follows:

1 Remove the lower protection plate and open the boiler casing

2 If necessary, insert or remove the restrictor following the instructions to points 3-11, otherwise go

to point 12

3 Disconnect the gas and the electrical power supply if the boiler is already installed

4 Remove the ignition device “A” from the valve body, removing the fastening screw ”B”

Fig. 19

C

D

B

A

F

Page 25

ARENA 30 C

25

5 Unscrew the union nut between the gas valve and the gas inlet pipe

6 Remove the flexible inlet air pipe from the Venturi mouthpiece on the fan

7 Unscrew the fastening screws “C” and remove the Venturi unit + gas valve

8 Unscrew the three fastening screws “D” and separate the gas valve and the Venturi

9 Replace the diaphragm “E”, making sure the new restrictor and the gasket are repositioned correctly

inside the housing in the valve body

10 Reassemble the gas valve, ignition device, connections, following the previous instructions in the

reverse order

11 Check the seal of the gas connections

12 Insert the probe of a combustion analyzer in the outlet flue gas of the boiler

13 Turn on the boiler and bring the burner to the maximum power: it is advised to open one or more

DHW taps and verify on the display that the parameter 8 (boiler power) arrives to 99.

14 By means of the analyzer, note the CO2 content in the flue gas with boiler to maximum power

15 If necessary, slowly operate on the regulation screw F (fig.19) placed on the Venturi to bring the CO

2

content to the nominal value (within +/- 0.1%) expected in the table for the correspondent gas type.

It is recommended to operate only on the screw F and not on the gas valve: this operation could

compromise the correct functioning of the appliance

16 Once the regulation has been made, apply the orange plate contained in the transformation kit next

to the data plate and reassemble the boiler casing and the lower protection plate.

Fig. 20

E

Page 26

ARENA 30 C

26

∆t setting

The thermal head ∆t, that is the difference in heating water

temperature between the central heating outlet and return, can be

set by varying the speed of the pump system (Fig. 21- A). Note that

an increase in speed corresponds to a reduction of the ∆t, and viceversa. The curve of flow rate/ head of the standard pump is shown

in Chapter 1.

To fully exploit the advantages of condensation, the central heating

return inlet should work at low temperatures, possibly below

45-50 °C. The boiler will also work correctly at higher return

temperatures, but in this case the temperature of the flue gas outlet

is near to or above the dew point, with consequent reductions in

condensation.

One specific feature of the ARENA boiler is the possibility to work

with high ∆t, up to 50°C. This feature can be exploited to maintain

a low central heating return inlet temperature even when the

required outlet temperature is high, and thus allow the appliance to

operate in full condensation mode.

Bypass setting

The boiler is fitted with a bypass between the outlet and return,

which guarantees minimum circulation inside the appliance even

with systems fitted with full-closing thermostatic zone valves. To

adjust the bypass, use a screwdriver on the adjustment cock,

operating from the bottom of the boiler

Adjusting the hydraulic system pressure

The fill pressure with the system cold, read on the boiler hydrometer “B”, must be around 1.5 bar. If the

system pressure falls during operation (caused by the evaporation of the gases dissolved in the water) to

values below the minimum described above, reset the initial value. For correct boiler operation, the pressure

inside, when hot, must be around 2 – 2.5 bar.

Fig. 21

Fig. 22

A

B

Page 27

ARENA 30 C

27

3.2 Commissioning and testing

The appliance must only be set-up for use by Qualified Personnel, such as personnel from Technical

organization.

Checks to be performed during the first ignition, and after all maintenance operations which may have

required the disconnection of the systems or intervention on the safety devices or parts of the boiler:

Before igniting the boiler:

• Open any shut-off valves between the boiler and the systems

• Check the seal of the gas system, proceeding with care and using a soapy water solution to find any leaks

from the connections.

• Fill the system as indicated earlier and ensure that the air contained in the boiler and the system has been

completely vented, by opening the air bleeding valve on the top of the appliance (Fig. 2) and any bleeding

valves in the system.

• Check that there are no water leaks in the heating system, in the domestic hot water circuits, in the

connections or in the boiler

• Check the correct connection of the electrical system

• Check that the appliance is properly earthed;.

• Check the correct connection of the appliance to the system for draining the condensation and the

functioning of the condensation drain system itself.

• Check that the pressure value and gas rate for the heating system are correct.

• Check that there are no flammable liquids or materials in the

immediate vicinity of the boiler

• Check that the non-return valve is operating (fig. A)

Igniting the boiler:

• Open the gas cock upstream from the boiler.

• Bleed the air in the pipe upstream from the gas valve.

• Close any switches or insert any plugs upstream of the boiler

• Place the main switch in the ON position.

• The boiler will switch on and perform a complete self-test cycle

lasting around one minute, to check the operation of the main parts. The display shows, in sequence:

Software version

Parameter version

Operation in test - ( )

• If the cycle is performed correctly:

- If domestic hot water or heating is not required, the display shows a small “o“ (standby mode) followed

by the temperature value of the outlet sensor. Then use the room thermostat or remote control to

activate the request for heating

- If there is a request, the display will pass from the standby phase “ o “ to the heating phase “ c “ and

the boiler will automatically begin operation, controlled by its regulation and safety devices.

- If anomalies arise during the self-test cycle or the successive ignition phase, the display will show the

corresponding error code and the boiler will shut-down. Wait around 15 seconds and then press the

reset button. The boiler will repeat the ignition cycle. If, after a second attempt, the boiler does not start,

refer to the paragraph on “Troubleshooting” 3.5.

Note In the case of power failures while the boiler is in operation, the burner assembly will switch off. On

the return of mains power, the boiler will again perform the self-test cycle, following which the burner

assembly will automatically restart (if there is still a request for heat).

operating

locked

fig. A

Page 28

ARENA 30 C

28

Checks during operation

• Ensure there are no gas or water leaks.

• Check the efficiency of the flues and air-flue gas pipes during the operation of the boiler.

• Check that the water circulation between the boiler and the systems is correct.

• Ensure that the gas valve modulates correctly both in the heating phase and the production of domestic

hot water.

• Check the correct ignition of the boiler, effecting a series of ignition and shut-down tests using the room

thermostat or the remote control.

• Ensure that the consumption of the fuel indicated by the counter corresponds to the values indicated in

table at pag. 8.

• Check that there is the correct flow rate of domestic hot water with the ∆t declared in the table: do not

rely on measurements effected using empirical systems. The measurements should be made using special

instruments at a point as close as possible to the boiler, considering the dispersion of heat from the piping.

• Ensure that without the request for heating the burner assembly turns on correctly on opening a domestic

hot water tap. Check that during operation in heating mode, on opening a domestic hot water tap, the

heating pump switches off, the domestic hot water pump starts and there is regular production of

domestic hot water.

• Check the correct setting of the parameters and effect any custom settings required (compensation curve,

heat rates, temperatures, etc.)

Shut-down

Close the gas cock upstream from the boiler and disconnect the electrical power supply to the appliance.

Warning - For long periods of inactivity during the winter months, in order to avoid damage due to freezing,

all the water should be drained from the boiler, both the domestic hot water and the heating system;

alternatively, drain only the domestic hot water and introduce the relative antifreeze into the heating system.

3.3 Maintenance

The following operations must only be performed by Qualified Personnel, such as personnel from our

Technical organization.

Seasonal checks on the boiler and the flue

The following checks should be made on the appliance at least once a year:

• The control and safety devices (gas valve, flow-meter, thermostats, etc.) must be working properly.

• The pipes and the air-flue gas terminals must be free of obstacles and not contain any leaks.

• The condensation draining system must be efficient and must not contain any leaks or blockages

• The gas and water systems must be perfectly sealed.

• The burner assembly and the heat exchanger must be clean. Follow the instructions in the next paragraph.

• The electrodes must be free of deposits and positioned correctly.

• The pressure of the water system when cold must be around 1 – 1.5 bar; if not, reset this value.

• The expansion vessel must be full.

• The circulation and domestic hot water pumps must not be blocked.

Page 29

ARENA 30 C

29

Cleaning the boiler body and the burner assembly

The burner assembly and the parts of the boiler

body in contact with condensation should be

cleaned once a year. To clean these parts, use

soft brushes or compressed air; do not use

chemical products or steel brushes.

To dismount the burner assembly and access

the boiler body, proceed as follows:

1. Close the gas supply cock and disconnect

the electrical power supply

2. Remove the lower protection plate and

the boiler casing

3. Disconnect cables “G” and “H” of the

electrodes from the ignition devices, Fig.

23a

4. Remove the ignition devices from the valve body, unscrewing screw “A”

5. Loosen the two fastening screws “B” and

slide the control panel support bracket

“C” and all the wiring forward. Fasten the

bracket in the position of maximum

extension

6. Disconnect the gas valve from the gas inlet

pipe, unscrewing the union nut behind the

valve, disconnect the flexible inlet air pipe

coupling “E” from the fan and the

compensation pipe “F” from the gas valve.

7. If there is less than 30 centimetres free

space below the fan, remove the fan-gas

valve unit by unscrewing the 4 fan fastening

nuts. If the space is greater, this is not

necessary, and the entire unit can be

removed together with the burner

assembly hexagonal support base (see

following points).

8. Progressively unscrew the 3 fastening nuts

“L”. Once removed, the unit “M” - burner

assembly, electrodes, hexagonal support

base - can be removed from the boiler

body as indicated in the series of images

23d - 23g. Intervene with care, avoiding

excessive force on the fins of the hexagonal

support base if the gasket “K” opposes

resistance due to deposits. Some drops of

water or residues may by released; avoid

where possible having these come into

contact with the electrical parts.

Fig. 23b

B

Fig. 23a

L

E

F

A

G

H

Page 30

ARENA 30 C

30

Fig. 23c

Fig. 23d

Fig. 23e

C

M

WARNING The hot wire spark electrode

is fragile! Both during and

after removal handle the

unit “M” with care to avoid

damaging the electrode.

9. The burner assembly can be cleaned in

place or removed by unscrewing the three

fastening screws on the hexagonal support

base.

10. The lower part of the boiler body – where

condensation takes place - can now be

accessed for cleaning. Carefully clean the

fins “N” and the condensation collection

and discharge area “O”.

The upper part where the burner assembly

is located does not require special

maintenance. If necessary, blow with

compressed air to eliminate small residues

of combustion.

11. Follow the previous instructions in the

reverse order and reassemble the boiler.

Always work with caution and pay special

care to all the sealing systems, especially

the gas seals and the gasket “K” between

the burner assembly hexagonal support

base and the condensation collector.

12. Once the boiler has been reassembled,

perform a complete operating test (as

specified in the previous chapter), checking

all the phases of ignition and operation,

and the correct functioning of the safety

and control devices, the sensors,

thermostats, gas valve, fan and pumps.

13. Check that there are no gas leaks, including

the parts inside the boiler (gas pipe, gas

valve connections, fan connections).

K

Page 31

ARENA 30 C

31

fig. 23g

fig. 23f

fig. 23h

N

O

Page 32

ARENA 30 C

32

Fig. 24

C

D

B

A

3.4 Replacement of parts

Initial procedure

a) The boiler is cold, electricity supply is isolated, and the gas supply is turned off at the inlet of the boiler

b) For replacement of parts where water connections are broken, it will be necessary to isolate and drain

either or both the central heating or domestic hot water circuits of the boiler only. The cold water mains

inlet is isolated at the inlet cock. The D.H.W. is drained by opening a hot tap.

The C.H. flow and return cocks are turned off at the isolation cocks. The C.H. is drained via the pressure

relief valve (twist about 1/2 of a turn) and the discharge tap on right . To ensure complete C.H. water

drainage, turn the screw of the non-return valve on “locked” position (fig. A - pag. 26)

c) Remove components following special notice below and replace in reverse order.

d) Ensure water and gas washers are in good condition.

Removing Boiler Jacket and sliding control panel

To remove the boiler jacket, unscrew the four screws on bottom of the boiler and the two screws on front

supporting the control panel. Gently pull up the jacket.

If necessary, to have more space for working, the control panel could be slid forward , loosing the two screws

“B” (fig. 23b) and pulling the support bracket “C” (fig. 23c)

Final procedure

• Re-open cocks and re-charge the system to about 1.5 bar, and vent boiler and radiators.

Re-charge to 1.5 bar if necessary.

• Upon completion of the work the following. Should be checked:

1) Gas soundness of all joints

2) Water soundness of all joints

3) The electricity supply.

4) The pressure of the sealed system and top up where necessary.

Gas valve

• Isolate gas and electricity supplies

• Remove the lower protection plate jacket

• Remove the ignition device “A” from the valve body, removing the fastening screw “B”

• Unscrew the union nut between the gas valve and the gas inlet pipe

• Remove the flexible inlet air pipe from the Venturi mouthpiece on the fan

• Unscrew the fastening screws “C” and remove the Venturi unit + gas valve

• Unscrew the three fastening screws “D” and separate the gas valve and Venturi

Page 33

ARENA 30 C

33

Fan

• Isolate gas and electricity supplies

• Remove the lower protection plate and jacket

• Remove the ignition device “A” (fig. 26) from the valve body, removing the fastening screw “B” (fig. 25)

• Unscrew the union nut between the gas valve and the gas inlet pipe

• Remove the flexible inlet air pipe from the Venturi mouthpiece on the fan

• Unscrew the four nut “A” fixing the fan (fig. 25)

• Unscrew the fastening screws “C” (fig. 24) and remove the Venturi unit + gas valve

Burner and electrodes

• Follow the “cleaning procedure” at page 29 from 1 to 8 to remove the burner assembly

• Carefully remove the hexagonal ceramic fibre

• To change the burner, remove the three fastening screw “A” (fig. 26)

• To change electrodes, unscrew the two screws to the supporting plate and remove it. Undo the brass nuts,

to electrodes “B” (fig. 27). Reassemble reverce order.

DHW Heat exchanger

• Isolate gas, electricity and water supplies

• Remove the lower protection plate and jacket. Slide forward the control panel.

• Drain water from DHW and CH circuits

• Unscrew the four A nuts connecting the heat exchanger and remove it

A

A

A

B

Fig. 25

Fig. 26

Page 34

ARENA 30 C

34

Replacement of pump head (fig. 27)

• Isolate electricity and flow and return pipes

• Remove casing

• Release pressure from boiler via pressure relief valve

• Unplug the pump lead “B” from the pump head

• Place a piece of cloth or other absorbent material over the rear

of the control panel to catch any drops of water that may fall

when the pump head is removed.

• Using a 4 mm allen wrench undo the two allen screws “C” in the

pump head, lift away pump head from the pump body

• Fit new head into pump body and secure with the allen screws

tightening evenly.

• Replace electrical connection.

Replacement of pump body (fig. 27)

• Proceed as for removal of pump head

• Disconnect the two nuts “D“ fixing the pump body

• Remove pump

• Reassemble in reverse order taking care to ensure the O-rings

are in place and undamaged.

Expansion Vessel (fig. 27)

Isolate electricity and water supplies

Remove outer case

Loosen the “E” connections to expansion vessel

Remove the expansion vessel

Re-assemble in reverse order

Re-pressure expansion vessel

(charge pressure 0,8-1 bar) through the air charging valve

Ensure pressure relief value is open

(twist about 1/2 of a turn) when repressurizing

D.H.W. temperature sensor (fig. 27)

• Isolate electricity

• Remove outer case

• Pull out sensor “F” from tube, with its spring

• Remove electrical connections from sensor

• Remove spring from sensor

• Replace in reverse order

C.H. temperature sensor, overheat cut off

thermostat and Aquafast Sensor

• Isolate electricity

• Remove outer case

• Identify the location of thermostat from fig.

28.

• Pull out thermostat or sensor from tube, with

its spring

• Remove electrical connections from sensor or

thermostat

• Remove spring from sensor or thermostat

Replace in reverse order

Fig. 27

A

F

C

D

D

E

A

B

C.H.

sensor

Fig. 28

Overheat

thermostat

Aquafast

sensor

Page 35

ARENA 30 C

35

D.H.W. flowmeter

• Isolate electricity and water supplies

• Open a hot water tap to release water pressure from the domestic side of the heat exchanger, close tap.

• Remove outer case

• Take off protective cover from main PCB and unplug flow meter lead from terminal

• Place a piece of cloth or some other absorbent material over rear of control panel to catch any drops of

water that may be released when removing the flow meter

• Using a 24mm open ended spanner, undo flow meter unions “A” and “B” (fig. 30) taking care not to twist

the copper tubing (access through base panel).

• Remove flow meter, check + clean filter + restrictor + fit to new flow meter.

• Reassemble in reverse order (fig. 30).

37 3938 38

Take care on correct position of components as reported in fig. 30

Key

37 Cold water inlet filter

38 Gasket

39 Cold water flow limiter

A

B

Fig. 29

Fig. 30

Page 36

ARENA 30 C

36

3.5 Troubleshooting

Diagnostics

The boiler features an advanced self-diagnostic system. In the case of an fault in operation, the display flashes

and the code identifying the fault appears. The faults marked with the letter “A” cause the permanent shutdown of the boiler. To reset operation the boiler must be restarted manually, pressing the “R” (reset) button.

The faults marked by the letter “F” cause temporary shut-down and are reset automatically as soon as the

value returns within the boiler’s normal operating range.

The following table lists a number of indications for resolving the faults signalled by the boiler. Interventions

on the appliance must be effected only by Qualified Personnel, such as the personnel from the FERROLI

Customer Technical Service Centre. For any operations on the appliance or which require the opening of the

boiler, always request the assistance of the service centre.

Failed burner

assembly ignition

• No gas or low gas pressure

• Ignition or detection

electrode fault

• Defective gas valve

• Check that the gas pressure or the

gas flow to the boiler is correct and

that air has been eliminated from

the piping

• Check the wiring to the electrodes

and that these are positioned

correctly and free of deposits

• Check and replace the gas valve

Safety thermostat

activation

• Outlet sensor not active

• No system circulation

• Check the correct positioning and

operation of the outlet sensor

• Check the pump

Flue safety device

intervention

• Flue partially blocked

or insufficient

• Check the efficiency of the flue,

the flue gas exhaust pipes and

the outlet terminal

No flame following the

ignition phase

• Air/flue pipes blocked

• Air in gas supply

• Low gas pressure

• PCB

• Free the obstructions from the flue,

flue gas exhaust and air inlet pipes

and terminals

• Check and purge the gas line

• Check the pipe size and meter

governor

• Check the main board

Insufficient water system

pressure

• System empty • Fill the system

Fan fault • Fan not powered

• Defective fan

• Check the wiring to

the fan

• Replace the fan

Fault Possible cause Solution

Page 37

ARENA 30 C

37

Domestic hot water sensor

faulty

• Sensor damaged or

wiring cut

• Check wiring or replace the

sensor

Flue gas sensor faulty • Sensor damaged or

wiring cut

• Check wiring or replace the

sensor

External probe faulty • Sensor damaged or

wiring short-circuited

• Check wiring or replace the

sensor

No communication between

main board and ignition devices

• Wiring cut or incorrect

between main board and

ignition devices

• Check the wiring and the

connections between the

boards

Fault Possible cause Solution

Microprocessor faulty • Microprocessor operation

faulty

• Disconnect and restore the

electrical power supply. If the

problem persists check and/or

replace the main board

High flue gas temperature • Flue partially blocked

or insufficient

• Check the efficiency of the flue,

the flue gas exhaust pipes and

the outlet terminal

Excessive central heating

outlet temperature

• Pump blocked

• Pump faulty

• Free the pump by removing the

cap and rotating the shaft with a

screwdriver

• Check or replace the condenser

or the pump

Excessive central heating

return temperature

• No system circulation

• Domestic hot water heat

exchanger dirty or

blocked

• Check system and pump

• Clean domestic hot water heat

exchanger

Outlet sensor faulty • Sensor damaged or

wiring cut

• Check wiring or replace the

sensor

Return sensor faulty • Sensor damaged or

wiring cut

• Check wiring or replace the

sensor

Page 38

ARENA 30 C

38

Display and boiler off • Power failure • Check or await the return of the

electrical power supply

Radiators cold in winter • Room thermostat

adjusted too low or

defective

• Adjust the knob to a higher

temperature, replace if

necessary

Radiators hot in summer • Room thermostat

adjusted too high or

defective

• Adjust the knob to a lower

temperature, replace if

necessary

Large variations in

domestic hot water

temperature

• Water flow rate too low • Increase the water flow rate

(minimum three litres per minute)

Fault Possible cause Solution

Low domestic hot water

flow

• Insufficient mains water

pressure

• Heat exchanger with

passages partially blocked

• Install a pressure increase

device

• Request the cleaning of the

heat exchanger

No domestic hot water

flow

• Heat exchanger

blocked

• Defective flow-meter

• Request engineer for the cleaning

operations

• Request engineer for the

replacement of the flow-meter

No temperature increase

with boiler on

• Boiler dirty

• Boiler insufficient

• Check and clean the boiler body

• Check that the boiler is the right

capacity for the requirements of

the heating system

Loss of condensation from

the boiler

• Condensation discharge

blocked

• Check and clean the drain

trap

Page 39

ARENA 30 C

39

4. OPERATING INSTRUCTIONS

4.1 Operation and controls

The Arena 30C is a pre-mix condensing thermal generator for heating and the production of domestic hot

water, using natural gas or LPG (configured at the moment of installation) and managed by an advanced

microprocessor control system.

The operation of the appliance is mostly automatic. The heat rate for the heating function is regulated

automatically by the control system according to the characteristics of the internal and external environment

(with optional external probe installed), the characteristics of the building and its location. The heat rate for

the domestic hot water function is regulated automatically and continuously, to ensure rapid delivery and

comfort in all supply conditions.

The user simply has to set the required temperature from inside the living area (using the room thermostat

or the optional, yet recommended, remote control) or set the heating system temperature and the required

outlet temperature for the domestic hot water service. The regulation and control system will then provide

for optimal operation all year round.

The display provides continuous indication on the operating status of the appliance, and can display

additional information on the temperature of the sensors, the set-point, etc. or be used for the configuration

of such via the operating menu, using the keypad.

Any anomalies in operation involving the boiler or the heating system are signalled on the display and, where

possible, corrected automatically.

Display D1 Display D2

Ignition switch

0

1

L1 L2

fig. 31

4.2 Boiler control panel

MODE button - Use this button to scroll the parameters.

RESET button - Use this button to reset the operation of the boiler in the event of shut-

down.

MODIFY button - Use these buttons to modify the regulation values.

CONFIRM button - Use this button to enable the set regulation value.

MODE display - Indicates the operating mode of the boiler or the selected parameter.

DATA display - Indicates value of the parameters

Led L1 - Indicates:Economy Operation

Led L2 - Indicates:Comfort Operation

Function of the buttons

Display indications

Page 40

ARENA 30 C

40

4.3 Ignition

Check than any shut-off valves in the heating system and domestic hot water circuit outside of the boiler are

open. Open the gas cock upstream from boiler and press the main switch. The boiler will perform an selftest cycle lasting approximately one minute, at the end of which it is ready for operation. The ignition and

shut-down of the burner assembly are completely automatic operations, which depend on the requirements

of the heating system or domestic hot water circuit.

4.4 Shut-down

In the event of extended periods of inactivity close the gas cock upstream from the boiler and disconnect

the electrical power supply to the appliance. In this case, the boiler antifreeze protection function is also

disabled; this function switches on the burner assembly when the heating system temperature falls below

5°C. For extended periods of inactivity during the winter months, in order to avoid damage due to freezing,

all the water should be drained from the boiler, both the domestic hot water and the heating system;

alternatively, drain only the domestic hot water and introduce the special antifreeze into the heating system.

4.5 Operating indications on the display

During operation, without pressing any of the buttons the display shows the operating status of the

appliance:

Operating mode

Standby

Heating

Domestic hot water

Standby following domestic hot water op.

Standby following heating op.

Waiting for DHW production

Display “D1” Display “D2/D3”

Central heating outlet temperature

Central heating outlet temperature

Domestic hot water temperature

Domestic hot water temperature

Central heating outlet temperature

Domestic hot water temperature

Summer/Winter Selection (00=Summer • 11=Winter)

Economy/Comfort Selection

CH outlet temperature view and setting

Aquafast temperature view/DHW output setting

Domestic hot water temperature

External temperature

Flue gas temperature

Domestic hot water flow rate

Boiler power

Compensation curve setting

-

DISPLAY D1 DISPLAY D2/D3

4.6 Accessing the operating menu

Pressing the “ - mode” button once accesses the operating menu. Pressing the “ - mode” button again

displays the following parameters and information in sequence:

Page 41

ARENA 30 C

41

4.7 Setting the heating system temperature

Set, using the room thermostat or remote control, the desired temperature inside the rooms. When acting

on the room thermostat, the boiler is turned on and the heating system water is brought to the central heating

outlet set temperature or calculated temperature (with temperature scrolling active). On reaching the

required temperature inside the rooms, the generator will switch off.

If no room thermostat or remote control is installed, the boiler will maintain the heating system temperature

at the central heating outlet setpoint.

To set the central heating outlet temperature, access the operating menu, and using the button display

parameter 1 – central heating outlet temperature. On pressing one of the buttons the display will start