Page 1

www.ferm.com 1007-30

Art. No. WEM1039

FWM-45/140

www.ferm.com

GB

D

NL

F

E

P

I

RUS

GR

USERS MANUAL 03

GEBRAUCHSANWEISUNG 15

GEBRUIKSAANWIJZING 27

MODE D’EMPLOI 39

MANUAL DE INSTRUCCIONES 51

MANUAL DE INSTRUÇÕES 64

MANUALE UTILIZZATI 77

РУКОВОДСТВО ПО ЭКСПЛУАТАЦИИ 89

O¢∏°π∂™ Ã∏™∂ø™ 102

GB Subject to change

D Änderungen vorbehalten

NL Wijzigingen voorbehouden

F Sous réserve de modifications

E Reservado el derecho de

modificaciones técnicas

P Reservado o direito a modificações

I Con riserva di modifiche

RUS Комлания Ferm постоянно

совершенству ет выпускаему ю

ею проедукцию. Позтому в

техничесие характеристики могут

вноситься без предварительного

уведомления.

GR HÚԇ̠ÙÔ ‰Èη›ˆÌ· ·ÏÏ·ÁÒÓ

Page 2

Ferm 119Ferm

02

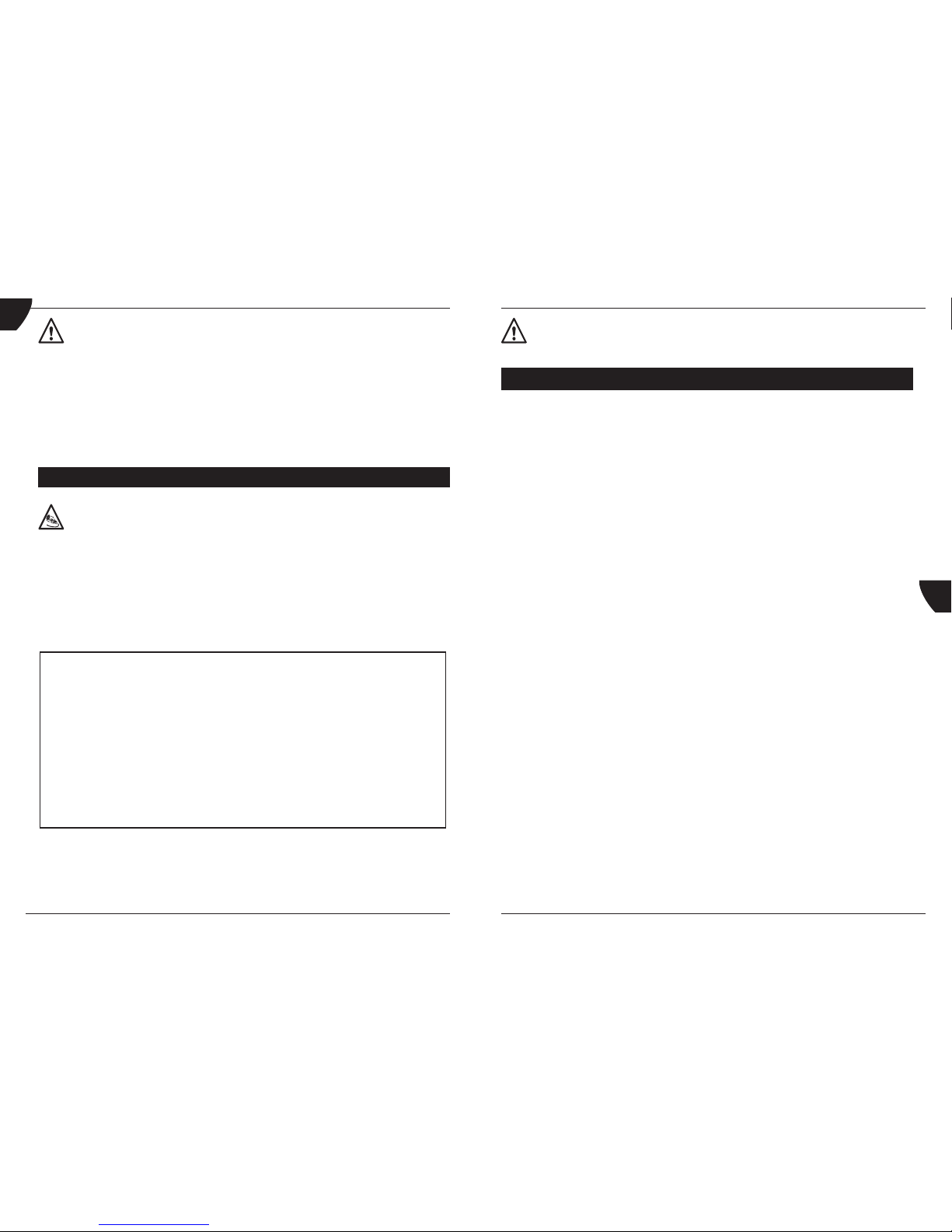

Fig. 1

Fig. 3

Fig. 2

32

33

9

8

7

35

5

4

1

21

31

37

19

3

2

28

6

18

20

29

30

25

16

10

17

13

36

14

34

12

15

11

26

2

4

2

7

2

3

22

38

39

40

E

E

AA

RR

TT

HH

II

NN

GG

E

A

R

T

H

I

N

G

Exploded view

1

3

2

4

6

5

10

60-70º

Page 3

Ferm 03

GB

D

NL

F

E

P

I

S

FIN

N

DK

WELDING APPLIANCE

The numbers in the following text refer to the picture on page 2

For your own safety and that of others, we recommend that you read this instruction

manual carefully before using this saw. Keep this instruction manual and the

documentation provided with the saw for future reference.

Introduction

The fusion welding process is used to melt the workpiece material under the influence of heat

supplied. With electrical arc welding use is also made of welding material (electrodes). The weld

originates after solidification.

The heat required is obtained by maintaining an electrical arc between the electrode and

workpiece. The welding process requires a strong current (45-140 A) with a relatively low

voltage (10–48 V). A transformer in the welding appliance ensures the lowering of the mains

voltage (230 V).

The device is not suitable for commercial use!

Contents

1. Machine information

2. Safety instructions

3. Mounting accessories

4. Operation

5. Service & maintenance

1. MACHINE INFORMATION

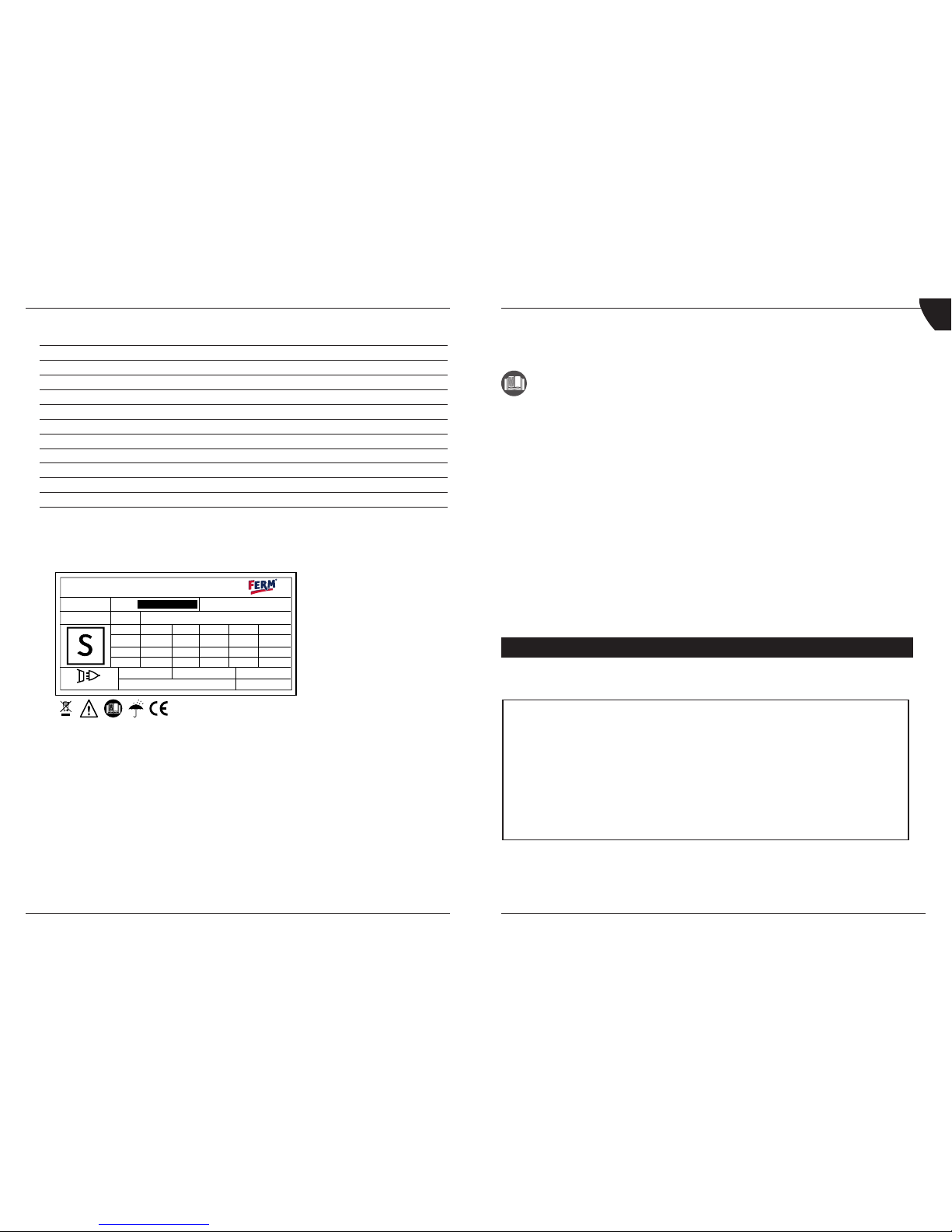

Technical specifications

Contents of packing

1 Welding appliance

1 Welding mask

1 Wire brush/scaling hammer

Voltage

Frequency

Welding power

Ignition voltage

Power factor

Electrode thickness

Weight

Dimensions

Thermal protection

Power cable

Welding cable

230 V ~

50 Hz

45-140 A

≤ 48 V

0.57

1.6 - 3.2 mm

16 kg

350 x 220 x 170 mm

75 ºC

H07RN-F3 x 1.5 mm

2

H01N2-D1 x 10 mm

2

Ferm

118

Spare parts list FWM-45/140

Ferm No. Description Position No.

100166 On/Off switch 2

100165 Indicator lamp 3

100177 thermic protection 16

100173 Fan 17

100175 handle 22

100163 earthclamp 38

100164 weldingclamp 39

100005 Wire brush /scaling hammer 100006 Welding lens 100007 Welding mask (excl. Weldinglens) -

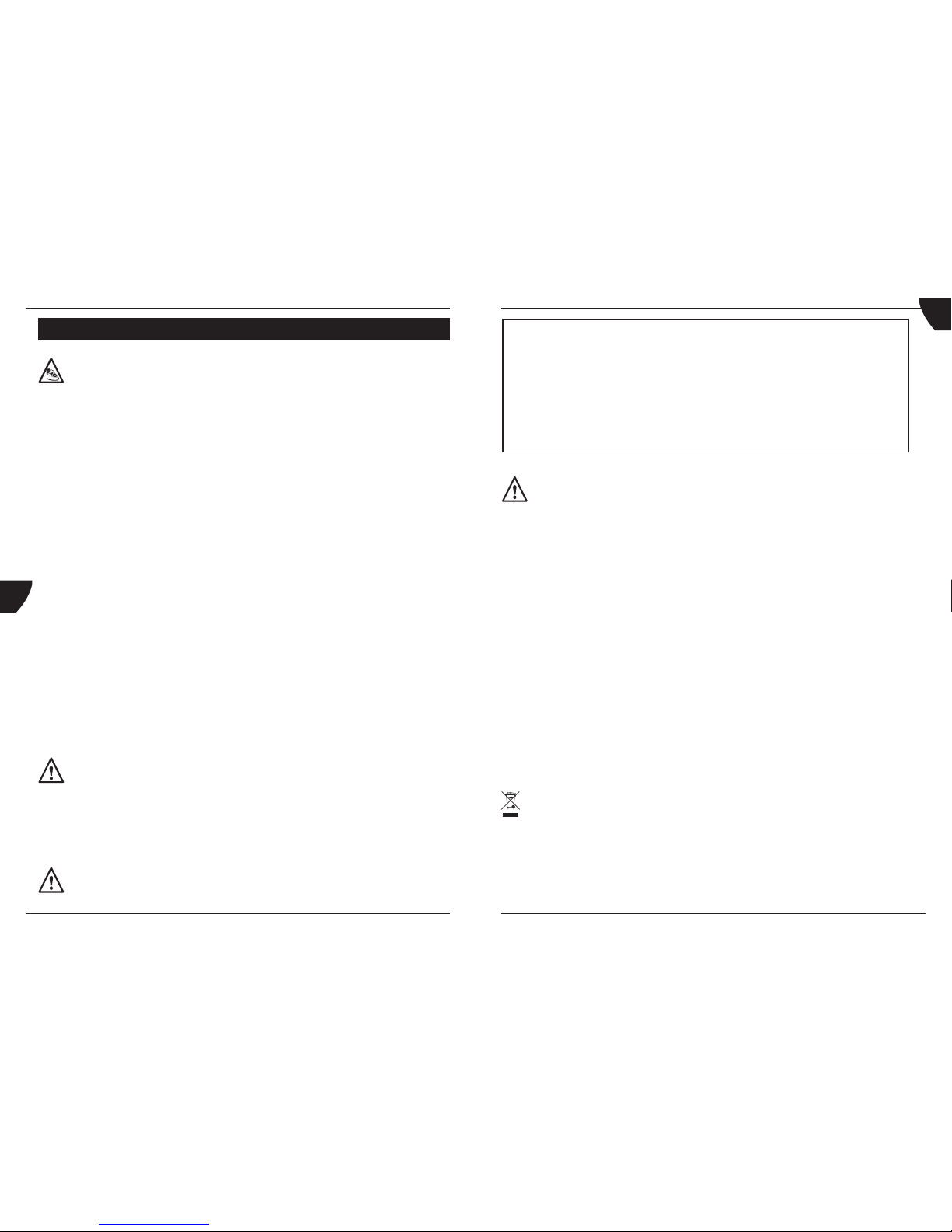

U1 = 230 V I1max = 31,6A

1 ~ 50Hz IP21S

1007-30

U0 = 48 V

45A/19.8V - 140A/23.6V

ĭmm 3.2 3.2 2.5 2.0 1.6

I

2

(A) 140 115 80 55 45

t

w

(S) 64 87 162 320 462

t

r

(S) 724 710 671 758 861

~ 50Hz

16 Kg

I

1eff

= 9.9 A

Art. no. WEM1039

EN 60974-6: 2003

FWM-45/140

,Ê°6°ÊUÊLINGENSTRAATÊÈÊUÊnäÓnÊ*Ê<7"Ê ÊUÊ777°,°"ÊUÊÊ Ê*,

S

erie no.

Page 4

Ferm 117

GB

D

NL

F

E

P

I

S

FIN

N

DK

1 User Manual

1 Safety instructions

1 Guarantee card

Check the machines, loose parts and accessories for transport damage.

Product information

Fig. 1

1. Indicator lamp temperature

2. On/off switch

3. Rotary knob for setting current intensity

4. Welding cable with electrode holder

5. Earth cable with fixture

6. Rubber cap

7. Handle

8. Ventilation slots

9. Wire brush /scaling hammer

10. Welding mask

11. Electrodes

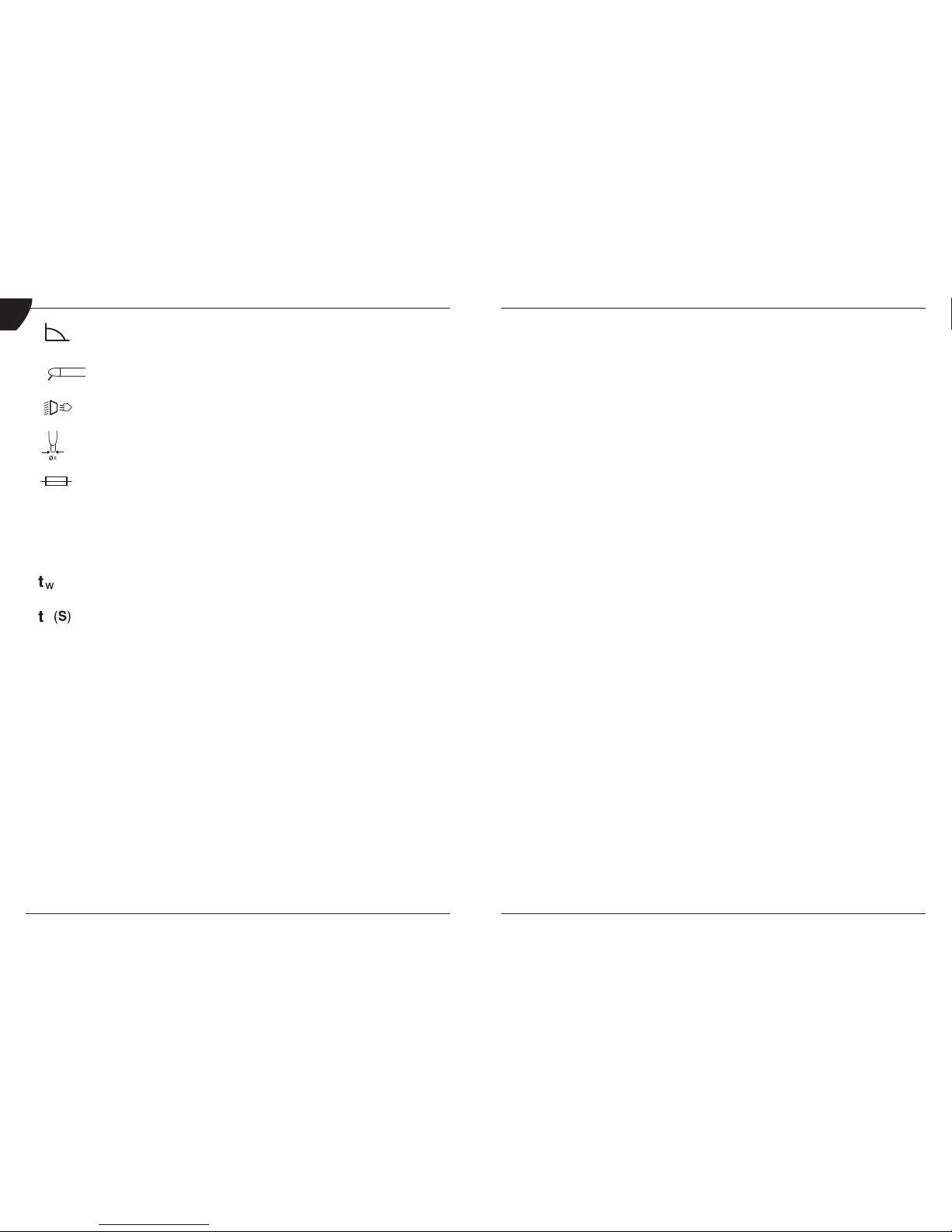

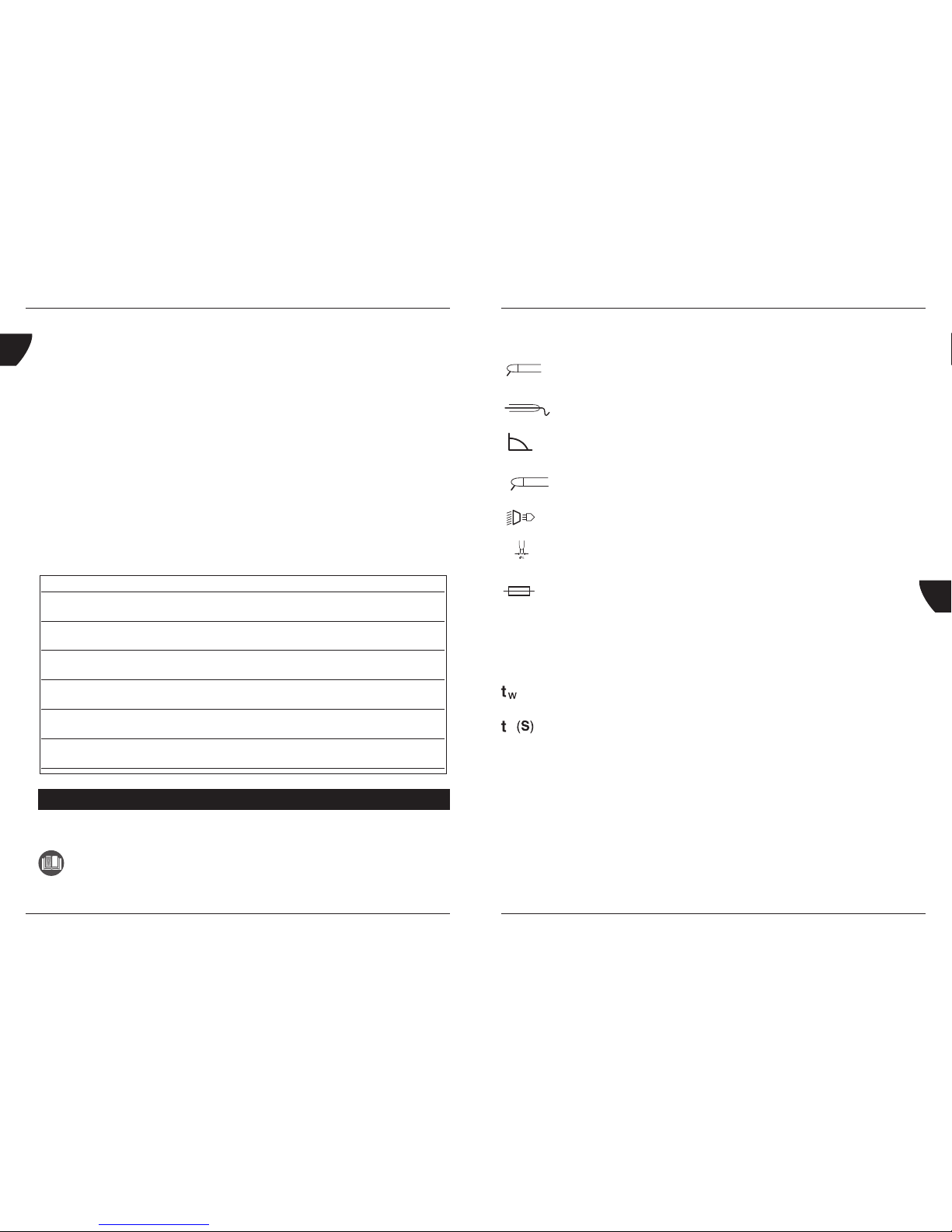

Table: setting and use

2. SAFETY INSTRUCTIONS

Explanation of the symbols

Read instructions carefully.

Ø Electrode (mm) Current intensity (A) Suitable for, among others:

1.6 45-55 Material thickness ≤ 2 mm

Repairing of moped/bicycle

2 50-75 Material thickness 2-3 mm

Repairing of wall stand

2.5 70-100 Material thickness 4-5 mm

Garden fence, garden toys

3.2 95-150 Material thickness 6-7 mm

Carport, garage

4 130-220 Material thickness 8-12 mm

Construction (heavy)

5 190-250 Material thickness ≥ 12 mm

Construction (very heavy)

Ferm

04

GB

D

NL

F

E

P

I

S

FIN

N

DK

Page 5

Ferm 05

GB

D

NL

F

E

P

I

S

FIN

N

DK

In accordance with essential applicable safety standards of European directives.

Denotes risk of personal injury, loss of life or damage to the tool in case of nonobservance of the instructions in this manual.

Indicates electrical shock hazard.

Immediately unplug the plug from the mains electricity in the case that the cord gets

damaged and during maintenance.

Keep bystanders away.

Do not expose in rain

Wear ear and eye protection.

Wear protective gloves.

Faulty and/or discarded electrical or electronic apparatus have to be collected at the

appropriate recycling locations.

Always use a welding mask during welding

Wear protecting clothes

Symbol for welding power sources which are suitable for supplying power to

welding operations carried out in an environment with increased hazard of electric

shock.

Standard for welding appliances for manual metal arc welding with limited duty.

Electrode holder

Earth terminal

EN60974-6

Ferm

116

GB

D

NL

F

E

P

I

S

GR

N

DK

Page 6

Ferm 115

GB

D

NL

F

E

P

I

S

GR

N

DK

Falling voltage

Single-phase transformer

Earthed mains plug

Electrode diameter

Fusing 16A

Maximum primary current intensity in Ampere

Secondary current intensity in Ampere

Load time, time between the reset (ON operation) and the set (OFF operation) of the

thermal cut out device.

Reset time, time between the set (OFF operation) and the reset (ON operation) of

the thermal cut out device.

Protection class. Sealed for objects up to 12 mm and against perpendicular falling

drip water. Stoppage with water control.

Insulation class

Open voltage in Volts

Mains voltage in Volts

General safety instructions for welding appliances

• The user of the machine must have been instructed how to use and operate the machine.

• Ensure a well-illuminated and tidy working environment.

• Always remove the plug from the plug socket before carrying out maintenance on the

machine.

• Remove the plug from the plug socket when you leave the machine.

• Do not use the machine before you have fully assembled and installed the machine as

described in the manual.

r

(S)

U

1

U

0

H

IP21S

I

2

I

1

Ferm

06

GB

D

NL

F

E

P

I

S

FIN

N

DK

Page 7

Ferm 07

GB

D

NL

F

E

P

I

S

FIN

N

DK

Specific safety instructions for welding appliance

• Welding causes sparks and hot metal. Remember that this is a fire hazard, and remove all

flammable objects from the working environment.

• Ensure good ventilation in the working environment. Gases are released when welding that

are a danger to your health.

• Do not weld containers or pipes that contain or have contained flammable liquids or gases

(danger of fire or explosion).

• Do not weld materials that have been cleaned with highly flammable liquids or that have

painted surfaces (likelihood of the release of dangerous gases).

• Do not work in a humid or wet environment and do not weld in the rain.

• Always protect your eyes with the welding mask supplied.

• Use gloves and protective clothing that are dry and not drenched in oil or dirt.

• The slag to be chipped off is sometimes glowing hot and can cause serious eye injuries

during removal. Always wear protective goggles and gloves.

• Ultraviolet radiation can burn your skin during welding. So always wear suitable protective

clothing.

• Your welding appliance is protected against overloading. The welding appliance therefore

automatically switches off if it overloads. The welding appliance automatically switches on

again after it has cooled sufficiently.

• During welding and cooling your workpiece can deform due to stresses. Always bear this in

mind.

• Only the welding cables included in the delivery kit may be used (Ø 10 mm

2

rubberized

welding cable).

• Special regulations apply to areas at risk of fire or explosions.

• Welded connections that are exposed to high stress and which must fulfill certain safety

requirements may only be carried out by specially trained and certified welders. Some

examples are: Pressure vessels, slide rails, tow couplings, etc.

• Important: Always connect the ground terminal as close as possible to the weld spot in such

a way that the welding current can take the shortest possible path from the electrode to the

ground terminal. Never connect the ground terminal to the housing of the welding device!

Never connect the ground terminal to grounded components that are located far away from

the workpiece, e.g., to a water pipe in another corner of the room. Otherwise, the protective

conductor system of the room in which you are welding could become damaged.

• The fusing of the supply lines to the power outlets must correspond to regulations (VDE

0100). Protective contact outlets may be fused with a max of 16A (types and technical data:

RT14-20, Ø 10 x 38, AC 400 V 16A. IEC 60269. slow blow. Manufacturer: Chint) (fuses or

line-protection switches). Higher amperage fuses can lead to burnt cables or fire damage

to the building.

Electrical safety

Switch off the machine at once if:

• There is a defect in the mains plug, power cable or there is damage to the cable.

• Defective switch.

• You see smoke or smell burnt insulation.

·ÚÔ˘ÛÈ¿˙ÔÓÙ·È Ù· ÂÍ·ÚÙ‹Ì·Ù· Ô˘ ÌÔÚ›Ù ӷ ·Ú·ÁÁ›ÏÂÙÂ.

¶ÂÚÈ‚·ÏÏÔÓ

°И· У· МЛУ ¿ıВИ ˙ЛМИ¿ ЩФ МЛ¯·У‹М· О·Щ¿ ЩЛ МВЩ·КФЪ¿, ·Ъ·‰›‰ВЩ·И М¤Ы· ЫВ ОПВИЫЩ‹

Ы˘ЫОВ˘·Ы›·. ∆· ВЪИЫЫfiЩВЪ· ·ЩЩfi Щ· ˘ПИО¿ Ы˘ЫОВ˘·Ы›·˜ МФЪФ‡У У· ·У·О˘ОПˆıФ‡У.

¶‹Б·›УВЩВ ·˘Щ¿ Щ· ˘ПИО· ЫЩ· О·Щ¿ППЛБ· ЫЛМВ›· ·УО‡ОПˆЫЛ˜.

∂П·ЩЩˆМ·ЩИО¿ О·И / ‹ ·ФЪЪИММ¤У· ЛПВОЩЪИО¿ ‹ ЛПВОЩЪФУИО¿ ·УЩИОВ›МВУ· Ъ¤ВИ

У· Ы˘ПП¤БФУЩ·И ЫЩИ˜ О·Щ¿ППЛПВ˜ ЩФФıВЫ›В˜ ·У·О˘ОПТЫВˆ˜.

∂ÁÁ˘ËÛË

√И fiЪФИ ВББ‡ЛФЛ˜ ·У·БЪ¿КФУЩ·И ЫЩЛУ ВЫˆОПВИМВУЛ О¿ЪЩ· ВББ‡ЛЫЛ˜ Ф˘ ‰И·Щ›ıВЩ·И

НВ¯ˆЪИЫЩ¿.

CE ¢∏§ø™∏ ™Àªª√ƒºø™∏™ (GR)

¢ЛПТУФ˘МВ МВ ·ФОПВИЫЩИО‹ М·˜ В˘ı‡УЛ, fiЩИ ·˘Щfi ЩФ ЪФ˚fiУ ПЛЪФ› Щ· ·Ъ·О¿Щˆ ЪfiЩ˘· ‹

Ù· ¤ÁÁÚ·Ê· ÚÔÙ‡ˆÓ:

EN60974-1, EN60974-6, EN60974-10

∫·Щ¿ ЩИ˙ ‰И·Щ¿НВИ˙ ЩˆУ ∫·УФУИЫМТУ ЩЛ˙ ∫ФИУ‹˙ ∞БФЪ¿˙:

2006/95/EC, 2004/108/EC

∞fi 01-05-2006

ZWOLLE NL

J.A. Bakker - van Ingen

CEO Ferm BV

¢В‰ФМ¤УФ˘ fiЩИ Л ‰И·ЪО‹˜ ‚ВПЩ›ˆЫЛ ЩˆУ ЪФ˚fiУЩˆУ М·˜ ·ФЩВПВ› ФПИЩИО‹ ЩЛ˜ ВЩ·ИЪВ›·˜ М·˜,

ВИК˘П·ЫЫfiМВı· ЩФ˘ ‰ИО·ИТМ·ЩФ˜ У· ЩЪФФФИФ‡МВ ЩИ˜ ЪФ‰И·БЪ·К¤˜ ЩФ˘ ЪФ˚fiУЩФ˜

¯ˆЪ›˜ ЪФЛБФ‡МВУЛ ВИ‰ФФ›ЛЫЛ.

Ferm BVñLingenstraat 6ñ8028 PMZwolleñ√ÏÏ·Ó‰›·

Ferm

114

GB

D

NL

F

E

P

I

S

GR

N

DK

Page 8

Ferm 113

GB

D

NL

F

E

P

I

S

GR

N

DK

AÓÙÈηٷÛÙ‹ÛÙ ÙËÓ ·ÎÔÓfiÂÙÚ· Ì ۂËṲ̂ÓË ÙË Ì˯·Ó‹ Î·È Ì ÙÔ Î·ÏÒ‰ÈÔ ¤Íˆ ·fi

ÙÔÓ ÚÂ˘Ì·ÙÔ‰fiÙË (Ú›˙·).

™˘ÓÙ‹ÚËÛË

с µВ‚·ИˆıВ›ЩВ fiЩИ Щ· ·УФ›БМ·Щ· ВН·ВЪИЫМФ‡ ‰ВУ ¤¯Ф˘У ОПВ›ЫВИ ·fi ЫОfiУЛ О·И ‚ЪФМИ¿. °И·

ЩЛУ ·К·›ЪВЫЛ В›МФУˆУ ПВО¤‰ˆУ ¯ЪЛЫИМФФИ‹ЫЩВ ¤У· М·П·Оfi ·У› ‚Ф˘ЩЛБМ¤УФ ЫВ

Ы·Ф˘УfiУВЪФ. ªЛУ ¯ЪЛЫИМФФИВ›ЩВ ‰И·П˘ЩИО¿ fiˆ˜ ВЩЪ¤П·ИФ, ФИУfiУВ˘М·, ·ММˆУ›·

О.П.

с ºЪФУЩ›ЫЩВ ТЫЩВ Л ‰·БО¿У· БИ· ЩФ ЛПВОЩЪfi‰ИФ О·И Л ‰·БО¿У· ЩЛ˜ БВ›ˆЫЛ˜ У·

·Ъ·М¤УФ˘У ·У¤·КВ˜ ·fi ЫОФ˘ЪИ¿ О·И ‰И·‚ЪТЫВИ˜, ЪФОВИМ¤УФ˘ У· ВН·ЫК·П›ЫВЩВ ЩЛУ

О·П‹ ЛПВОЩЪИО‹ В·К‹.

с ¡· ВП¤Б¯ВЩВ ·У¿ Щ·ОЩ¿ ¯ЪФУИО¿ ‰И·ЫЩ‹М·Щ· БИ· ЩЛ ЫКИ¯Щ‹ Ы‡У‰ВЫЛ ЩˆУ О·Пˆ‰›ˆУ ЩФ˘

ЛПВОЩЪФ‰›Ф˘ О·И ЩФ˘ ·УЩИОВИМ¤УФ˘.

§›·ÓÛË

∆o Ì˯·Ó‹Ì· ‰ÂÓ ¯ÚÂÈ¿˙ÂÙ·È ÚfiÛıÂÙË Ï›·ÓÛË.

µÏ¿‚˜

∂¿У ЪФО‡„ВИ О¿ФИ· ‚П¿‚Л .¯. ПfiБˆ ЩЛ˜ КıФЪ¿˜ О¿ФИФ˘ ВН·ЪЩ‹М·ЩФ˜, ·Ъ·О·ПФ‡МВ

ВИОФИУˆУ‹ЫЩВ МВ ЩФ ∫¤УЩЪФ ВИЫОВ˘ТУ Ф˘ ·У·БЪ¿КВЩ·И ЫЩЛУ О¿ЪЩ· ВББ‡ЛЫЛ˜. ™ЩФ ›Ыˆ

М¤ЪФ˜ ·˘ЩФ‡ ЩФ˘ ВБ¯ВИЪИ‰›Ф˘ ˘¿Ъ¯ВИ ¤У· ·У·Щ˘БМ¤УФ ‰И¿БЪ·ММ·, ЫЩФ ФФ›Ф

¶›Ó·Î·˜ ‚Ï·‚ÒÓ

ñ ∆Ф ЛПВОЩЪfi‰ИФ Ы˘УВ¯›˙ВИ У· ОФПП¿ВИ ЫЩФ

·УЩИОВ›МВУФ

ñ ∆Ф ЛПВОЩЪfi‰ИФ ·›ЪУВИ ОfiООИУФ-

ФЪЩФО·П› ¯ЪТМ·

ñ ∆Ф ЛПВОЩЪfi‰ИФ ПИТУВИ ·fiЩФМ·,

ВОЩИУ¿ЫЫФУЩ·˜

ñ ˘ÏÈÎfi Î·È ·Ú¿ÁÂÈ ˘ÂÚ‚ÔÏÈÎfi ıfiÚ˘‚Ô

О·Щ¿ ЩЛ Ы˘БОfiППЛЫЛ

ñ ∆Ô Ì˯¿ÓËÌ· ıÂÚÌ·›ÓÂÙ·È ˘ÂÚ‚ÔÏÈο

О·И ·У¿‚ВИ Л ВУ‰ВИОЩИО‹ П˘¯У›·

µÏ¿‚Ë ∞ÈÙ›·/·ÔηٿÛÙ·ÛË

ñ ГЪЛЫИМФФИ‹ЫЩВ ЩФ ЫˆЫЩfi Щ‡Ф

ЛПВОЩЪФ‰›Ф˘ (БВУИО‹˜ ¯Ъ‹ЫЛ˜)

ñ ∏ ¤ÓÙ·ÛË ÙÔ˘ Ú‡̷ÙÔ˜ Â›Ó·È Ôχ

¯·МЛП‹/ЫЩЪ¤„ЩВ ЩФУ ВЪИЫЩЪФКИОfi

ВИПФБ¤· 3 ЪФ˜ Щ· ‰ВНИ¿.

ñ ∏ ¤ÓÙ·ÛË ÙÔ˘ Ú‡̷ÙÔ˜ Â›Ó·È Ôχ ˘„ËÏ‹

БИ· ·˘ЩfiУ ЩФУ Щ‡Ф ЛПВОЩЪФ‰›Ф˘/ЫЩЪ¤„ЩВ

ЩФУ ВЪИЫЩЪФКИОfi ВИПФБ¤· 3 ЪФ˜ Щ·

·ЪИЫЩВЪ¿.

ñ ∏ ¤ÓÙ·ÛË ÙÔ˘ Ú‡̷ÙÔ˜ Â›Ó·È Ôχ

˘„ЛП‹/ЫЩЪ¤„ЩВ ЩФУ ВЪИЫЩЪФКИОfi

ВИПФБ¤· 3 ЪФ˜ Щ· ·ЪИЫЩВЪ¿.

ñ ∏ ¤ÓÙ·ÛË ÙÔ˘ Ú‡̷ÙÔ˜ Â›Ó·È Ôχ

˘„ЛП‹/ЫЩЪ¤„ЩВ ЩФУ ВЪИЫЩЪФКИОfi

ВИПФБ¤· 3 ЪФ˜ Щ· ·ЪИЫЩВЪ¿

ñ Œ¯Ô˘Ó ·ÔÊÚ·¯ı› Ù· ·ÓÔ›ÁÌ·Ù·

ВН·ВЪИЫМФ‡/О·ı·Ъ›ЫЩВ Щ· МВ ¤У· ЫЩВБУfi

·У› О·И ВЪИМ¤УВЩВ П›Б· ПВЩ¿ ¤ˆ˜ fiЩФ˘

Ы‚‹ЫВИ Л П˘¯У›·

Warning! Depending on the supply mains conditions at the point of connection, the

welding power source may cause interference to the supply to other electricity

users. If there is any doubt about this question advice should be sought from the

electricity supply authority.

• Make sure that the welding appliance and electric wiring connections are properly made.

Any likelihood of electric shock can endanger life.

• Always ensure good connections, both of the electrode holder and the earth terminal.

• Do not allow electrical cables to be damaged by pulling. Disconnect cables before you

move the welding appliance.

• Avoid contact with the electrically conductive part of the welding appliance, the electrode

holder and the earth terminal.

• Always check that your mains voltage corresponds to the value on the type plate of the

machine.

• With the replacement of cables or plugs: Throw away old cables or plugs as soon as they

have been replaced by new ones. Inserting a loose cable plug in a plug socket is

dangerous.

• For all welding appliances working on 230 Volts use at least 16 Ampere fusing

• When use is made of extension leads: Use only an approved extension lead that is suitable

for the machine power. The cores must have a diameter of at least 1.5 mm

2

. Roll the cord

fully out if the extension cord is on a reel.

• Only allow qualified electricians to work on the supply voltage end, e.g., on cables, plug-in

connectors, outlets, etc.

3. FITTING ACCESSORIES

Make sure that the plug has been removed from the plug socket during the

assembly of accessories.

Installation of the machine

• Install the welding appliance in a dry and clean space (free of iron powder, dust and paint).

• Place the welding appliance on a firm and flat surface and at least 20 cm from the wall.

• Protect the welding appliance against rain and strong sunlight.

The welding mask

Fig. 2

• Slide the handle on the welding mask until it locks.

• Place the light glass (protective glass) in front of the dark welding glass. Slide both glasses

in front of the opening.

• Make sure that the glasses are positioned so that no (harmful) light can now penetrate the

opening.

• Replace the light protective glass when the view of the workpiece becomes insufficient

during welding. Replacing the dark welding glass is considerably more expensive than

replacing the light protective glass.

Ferm

08

GB

D

NL

F

E

P

I

S

FIN

N

DK

Page 9

Ferm 09

GB

D

NL

F

E

P

I

S

FIN

N

DK

Fitting new electrodes

The electrode consists of a metal core enclosed by a coating. At one end of the electrode the

core is not covered by the coating.

• Press the handle of the electrode holder against

the spring.

• Place an electrode with uncoated end (± 2 cm) in the electrode holder. Make sure that the

non-coated part makes good contact with the metal part of the electrode holder (electrode

not pushed too far in the electrode holder).

• Release the handle of the grip. The electrode is now fixed.

N.B! Do not allow the electrode to burn to lengths shorter than ± 5 cm because of

overheating and/or the deformation of the electrode holder. The burnt up electrode

will then be difficult to remove.

Removing used electrodes

Press the grip of the electrode holder against the spring so that the burnt up electrode can fall

from the holder.

N.B! Do not remove the electrode from the holder by hand. The electrode is very hot!

N.B! Watch where the waste electrode falls to prevent a fire hazard and possible

injury.

4. OPERATING

Before use:

a. General information about electric arc welding

b. The electrode

c. Protective clothing

d. Face protection

e. Working environment

a. General information about electric arc welding

The temperature of the arc amounts to approx. 7000° Celsius, so the end of the electrode and

the workpiece fuse. For as long as the arc is maintained, the electrode will melt and supply the

necessary welding material to the parts to be joined. The distance between the electrode and

the workpiece must be as short as possible (approx. 1.5 - 4 mm) depending on the diameter and

type of electrode. The current needed for welding is supplied by the welding appliance. The

power required by the welding appliance depends on the work to be done.

Make sure that the electrodes are completely dry, as moist electrodes cause problems. If the

electrode sticks to the workpiece during welding your current intensity is set too low.

Ы˘БОfiППЛЫЛ˜ (Ф ПВБfiМВУФ˜ ВБОПВИЫМfi˜ ·О·ı·ЪЫИТУ).

с ∫·ı·Ъ›ЫЩВ ЩЛ Ы˘БОfiППЛЫЛ ¯ЪЛЫИМФФИТУЩ·˜ МИ· Ы˘ЪМ¿ЩИУЛ ‚Ф‡ЪЩЫ·.

™ЛМВ›ˆЫЛ: ∏ ıВЪМФОЪ·Ы›· ЩФ˘ ·УЩИОВИМ¤УФ˘ Ф˘ Ы˘БОФПП‹ıЛОВ В›У·И ·ОfiМ· ФП‡

˘„ЛП‹. ªЛУ ·К‹УВЩВ ЩФ ·УЩИОВ›МВУФ Ф˘ Ы˘БОФПП‹Ы·ЩВ ¯ˆЪ›˜ В›‚ПВ„Л.

∂У‰ВИОЩИО‹ П˘¯У›· ıВЪМФОЪ·Ы›·˜

EÈÎ. 1

ŸЩ·У Л ıВЪМФОЪ·Ы›· ЩЛ˜ Ы˘ЫОВ˘‹˜ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ·˘НЛıВ› ˘ВЪ‚ФПИО¿, Ф

ВУЫˆМ·ЩˆМ¤УФ˜ ıВЪМФЫЩ¿ЩЛ˜ ı· ЩЛУ ·ВУВЪБФФИ‹ЫВИ (ı· ·У¿„ВИ Л ВУ‰ВИОЩИО‹ П˘¯У›·). √

ВУЫˆМ·ЩˆМ¤УФ˜ ·УВМИЫЩ‹Ъ·˜ ı· ·У·П¿‚ВИ ЩЛУ „‡НЛ ЩФ˘ МЛ¯·У‹М·ЩФ˜. ŸЩ·У ФПФОПЛЪˆıВ›

Л „‡НЛ ЩФ˘ МЛ¯·У‹М·ЩФ˜ П˘¯У›· ı· Ы‚‹ЫВИ.

∫·Щ¿ ЪФЩ›МЛЫЛ ·К‹ЫЩВ ЩФ МЛ¯¿УЛМ· У· ОЪ˘ТЫВИ БИ· ·ЪОВЩ‹ ТЪ·, ‰ИfiЩИ ˘fi Ы˘Уı‹ОВ˜

¤УЩФУЛ˜ ВЪБ·Ы›·˜ ·˘Н¿УВЩ·И Л Иı·УfiЩЛЩ· У· ВУВЪБФФИЛıВ› О·И ¿ПИ МВЩ¿ ·fi П›БФ ЩФ

ıВЪМИОfi Ы‡ЫЩЛМ· ‰И·ОФ‹˜ ПВИЩФ˘ЪБ›·˜ .

5. ™Œƒµπ™∫∞π ™À¡∆◊ƒ∏™∏

ºÚÔÓÙ›ÛÙ ӷ ÌËÓ Â›Ó·È ÙÔ Ì˯¿ÓËÌ· ÛÙËÓ Ú›˙·, fiÙ·Ó Î¿ÓÂÙ ÂÚÁ·Û›· Û˘ÓÙ‹ÚËÛ˘

ÛÙÔ ÌÔÙ¤Ú.

∆· ВЪБ·ПВ›· ЩЛ˜ ¤¯Ф˘У Ы¯В‰И·ЫЩВ› У· ПВИЩФ˘ЪБФ‡У БИ· МВБ¿ПВ˜ ¯ЪФУИО¤˜ ВЪИfi‰Ф˘˜ МВ

ВП¿¯ИЫЩЛ Ы˘УЩ‹ЪЛЫЛ. ∏ Ы˘УВ¯‹˜ ИО·УФФИЛЩИО‹ ПВИЩФ˘Ъ›· ВН·ЪЩ¿Щ·И ·fi ЩЛ ЫˆЫЩ‹

Ы˘УЩ‹ЪЛЫЛ ЩФ˘ МЛ¯·У‹М·ЩФ˜ О·И ЩФ Щ·ОЩИОfi О·ı¿ЪИЫМ·.

µÏ·‚Â

¶·Ъ·О¿Щˆ ·Ъ·Щ›ıВЩ·И ¤У·˜ ·ЪИıМfi˜ ·fi Иı·У¤˜ ·ИЩ›В˜ О·И О·Щ¿ППЛПВ˜ П‡ЫВИ˜, БИ· ЩИ˜

ВЪИЩТЫВИ˜ fiФ˘ ЩФ МЛ¯¿УЛМ· ‰ВУ ПВИЩФ˘ЪБВ› ЫˆЫЩ¿.

¶›Ó·Î·˜ ‚Ï·‚ÒÓ

ñ ∏ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ‰ВУ

ПВИЩФ˘ЪБВ›.

µÏ¿‚Ë ∞ÈÙ›·/·ÔηٿÛÙ·ÛË

ñ ∏ ‰·Áοӷ Ù˘ Á›ˆÛ˘ ‰ÂÓ Î¿ÓÂÈ Î·Ï‹

В·К‹ МВ ЩФ ·УЩИОВ›МВУФ.

ñ ∆Ф ЛПВОЩЪfi‰ИФ ‰ВУ ¤¯ВИ ЩФФıВЩЛıВ›

ÛˆÛÙ¿ ÛÙË ‰·Áοӷ.

ñ Œ¯ВИ ВУВЪБФФИЛıВ› ЩФ ıВЪМИОfi Ы‡ЫЩЛМ·

‰И·ОФ‹˜ ПВИЩФ˘ЪБ›·˜.

ñ ∂Ï·Ùو̷ÙÈ΋ ·ÛÊ¿ÏÂÈ· (ÛÙÔ ÎÔ˘Ù›

ЩФ˘МВЩЪЛЩ‹).

с Œ¯ÂÈ ÎÔ› ÙÔ Î·ÏÒ‰ÈÔ.

ñ √ ‰И·ОfiЩЛ˜ В›У·И ВП·ЩЩˆМ·ЩИОfi˜/ВИОФИУ

ˆÓ‹ÛÙ Ì ÙÔÓ ·ÓÙÈÚfiÛˆÔ Ù˘.

Ferm

112

GB

D

NL

F

E

P

I

S

GR

N

DK

Page 10

Ferm 111

GB

D

NL

F

E

P

I

S

GR

N

DK

·У·ЪМfi‰И· ¿ЩФМ· Ъ¤ВИ У· ·ФМ·ОЪ˘УıФ‡У ·fi ЩИ˜ Ы˘БОФППЛЩИО¤˜ ВЪБ·Ы›В˜.

ñ ™ÙËÓ ¿ÌÂÛË ÂÁÁ‡ÙËÙ· ÙˆÓ ÛÙ·ıÂÚÒÓ ¯ÒÚˆÓ ÂÚÁ·ÛÈÒÓ ‰ÂÓ ÂÈÙÚ¤ÂÙ·È Ó· ˘¿Ú¯Ô˘Ó

ЩФИ¯ТМ·Щ· ·УФИ¯ЩТУ ¯ЪˆМ¿ЩˆУ О·И Б˘·ПИЫЩВЪ¿. ∆· ·Ъ¿ı˘Ъ· Ъ¤ВИ У· ·ЫК·ПИЫЩФ‡У

ЩФ˘П¿¯ИЫЩФУ М¤¯ЪИ ЩФ ‡„Ф˜ ЩФ˘ ОВК·ПИФ‡ О·Щ¿ ЩЛ˜ ‰И·К˘Б‹˜ Л ·У·‰ЪФМИОfi О·ıЪ¤КЩИЫМ·

ЩˆУ ·ОЩИУФ‚ФПТУ, .¯. МВ О·Щ¿ППЛПЛ ‚·К‹.

¶ЪФВЩФИМ·Ы›· БИ· ¯Ъ‹ЫЛ

∂ÈÎ. 3

™˘М‚Ф˘П‹: ¶ЪФЩФ‡ ·Ъ¯›ЫВЩВ ЩЛ Ы˘БОfiППЛЫЛ ЫВ ¤У· ‰‡ЫОФПФ ·УЩИОВ›МВУФ, В›У·И О·П‡ЩВЪФ У·

О¿УВЩВ О¿ФИВ˜ ‰ФОИМ·ЫЩИО¤˜ Ы˘БОФПП‹ЫВИ˜ ЫВ ¤У· ‰ФО›МИФ.

с ºЪФУЩ›ЫЩВ ТЫЩВ ЩФ ·УЩИОВ›МВУФ У· В›У·И О·ı·Ъfi: О·ı·Ъ›ЫЩВ ЩФ ·fi ЩЛ ЫОФ˘ЪИ¿, ЩФ БЪ¿ЫФ

Î·È Ù· ˘ÔÏ›ÌÌ·Ù· ¯ÚˆÌ¿ÙˆÓ.

с ƒ˘ıМ›ЫЩВ О·Щ¿ППЛП· ЩЛУ ¤УЩ·ЫЛ ЩФ˘ ЪВ‡М·ЩФ˜, ¯ЪЛЫИМФФИТУЩ·˜ ЩФУ ВЪИЫЩЪФКИОfi

ВИПФБ¤· Ф˘ ‚Ъ›ЫОВЩ·И ЫЩФ ВМЪfi˜ М¤ЪФ˜ ЩЛ˜ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜.

∏ ВИПФБ‹ ЩЛ˜ ¤УЩ·ЫЛ˜ ЩФ˘ ЪВ‡М·ЩФ˜ ВН·ЪЩ¿Щ·И ·fi ЩФ ·УЩИОВ›МВУФ О·И ЩФУ Щ‡Ф ЩФ˘

ЛПВОЩЪФ‰›Ф˘ Ф˘ ı· ¯ЪЛЫИМФФИ‹ЫВЩВ.

с ∂ИЫ¿БВЩВ ЩФ ·О¿П˘ЩФ ¿ОЪФ ЩФ˘ ЛПВОЩЪФ‰›Ф˘ ЫЩЛ ‰·БО¿У· ЩФ˘ ЛПВОЩЪФ‰›Ф˘ О·И

Ы˘У‰¤ЫЩВ ЩЛ ‰·БО¿У· ЩЛ˜ БВ›ˆЫЛ˜ ЫЩФ ·УЩИОВ›МВУФ.

с £¤ЫЩВ ЫВ ПВИЩФ˘ЪБ›· ЩЛ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ МВ ЩФУ ОВУЩЪИОfi ‰И·ОfiЩЛ.

с ∫Ъ·Щ‹ЫЩВ ЩЛ М¿ЫО· Ы˘БОfiППЛЫЛ˜ ВМЪfi˜ ·fi ЩФ ЪfiЫˆfi Ы·˜ О·И МВЩ·ОИУ‹ЫЩВ ЩФ ¿ОЪФ

ЩФ˘ ЛПВОЩЪФ‰›Ф˘ В¿Уˆ ЫЩФ ·УЩИОВ›МВУФ, Ы·У У· ·У¿‚·ЩВ ¤У· Ы›ЪЩФ. ∞˘Щfi˜ В›У·И Ф

О·П‡ЩВЪФ˜ ЩЪfiФ˜ БИ· У· ‰ЛМИФ˘ЪБ‹ЫВЩВ ЩФ ЩfiНФ Ы˘БОfiППЛЫЛ˜. ªЛУ ¯Щ˘¿ЩВ ЩФ

·УЩИОВ›МВУФ МВ ЩФ ЛПВОЩЪfi‰ИФ. ªВ ·˘ЩfiУ ЩФУ ЩЪfiФ ı· ЪФО·П¤ЫВЩВ ˙ЛМИ¿ ЫЩФ

ЛПВОЩЪfi‰ИФ О·И ı· ‰˘ЫОФП¤„ВЩВ ЩФ ¿У·ММ· ЩФ˘ ЩfiНФ˘.

с ªfiПИ˜ ·У¿„ВЩВ ЩФ ЩfiНФ ЪФЫ·ı‹ЫЩВ У· ОЪ·Щ‹ЫВЩВ ЫЩ·ıВЪ‹ ·fiЫЩ·ЫЛ ·У¿МВЫ· ЫЩФ

•ЛПВОЩЪfi‰ИФ О·И ЩФ ·УЩИОВ›МВУФ. ∏ ·fiЫЩ·ЫЛ ·˘Щ‹ ı· Ъ¤ВИ У· В›У·И ›ЫЛ МВ ЩЛ ‰И¿МВЩЪФ

ЩФ˘ ЛПВОЩЪФ‰›Ф˘. ∫Ъ·Щ‹ЫЩВ ·˘Щ‹У ЩЛУ ·fiЫЩ·ЫЛ fiЫФ ЩФ ‰˘У·ЩfiУ ИФ ЫЩ·ıВЪ‹ О·Щ¿ ЩЛ

‰И¿ЪОВИ· ЩЛ˜ Ы˘БОfiППЛЫЛ˜.

с ªВЩ·ОИУ‹ЫЩВ ЩФ ЛПВОЩЪfi‰ИФ В¿Уˆ ЫЩФ ·УЩИОВ›МВУФ ЩЪ·‚ТУЩ·˜ ЩФ ‚‹М·-‚‹М·.

с ¶ЪФЫ·ı‹ЫЩВ У· ‰И·ЩЛЪ‹ЫВЩВ ЩЛ БˆУ›· ·У¿МВЫ· ЫЩФ ЛПВОЩЪfi‰ИФ О·И ЩФ ·УЩИОВ›МВУФ

МВЩ·Н‡ ЩˆУ 60Ж О·И ЩˆУ 70Ж ˆ˜ ЪФ˜ ЩЛУ О·ЩВ‡ı˘УЫЛ ЩЛ˜ О›УЛЫЛ˜.

с ŸЩ·У ФПФОПЛЪˆıВ› Л ОfiППЛЫЛ Ы‚‹ЫЩВ ЩФ ЩfiНФ, ·ФМ·ОЪ‡УФУЩ·˜ ЩФ ЛПВОЩЪfi‰ИФ ·fi ЩФ

·УЩИОВ›МВУФ.

с £¤ЫЩВ ЩЛ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ВОЩfi˜ ПВИЩФ˘ЪБ›·˜.

™∏ª∂πш™∏. ∂¿У ·К‹ЫВЩВ ЩЛ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ЫВ ПВИЩФ˘ЪБ›·,

˘¿Ъ¯ВИ МВБ¿ПЛ Иı·УfiЩЛЩ· ЩФ ЛПВОЩЪfi‰ИФ У· ¤ЪıВИ ЫВ В·К‹ (М¤Ыˆ ЩФ˘ ¿БОФ˘

ВЪБ·Ы›·˜) МВ ЩФ О·ПТ‰ИФ ЩЛ˜ БВ›ˆЫЛ˜ О·И У· ·Ъ¯›ЫВИ У· Ы˘БОФПП¿ ·УВН¤ПВБОЩ·.

с ∞К·ИЪ¤ЫЩВ ЩЛУ ОЪФ‡ЫЩ· ·fi ЩЛУ ОfiППЛЫЛ ¯ЪЛЫИМФФИТУЩ·˜ ЩФ М·ЩЫ·ОfiУИ.

¶ЪФЫ¤НЩВ Щ· Щ˘¯fiУ О·˘Щ¿ МВЩ·ППИО¿ ЪИУ›ЫМ·Щ· Ф˘ ВОЩИУ¿ЫЫФУЩ·И. ¡· КФЪ¿ЩВ

¿УЩФЩВ ЪФЫЩ·ЩВ˘ЩИО¿ Б˘·ПИ¿.

с ¶ФЩ¤ МЛУ Ы˘БОФПП¿ЩВ В¿Уˆ ЫЩ· О·Щ¿ПФИ· ЩЛ˜ ОЪФ‡ЫЩ·˜: Л ОЪФ‡ЫЩ· В›У·И ¤У· ЫЩЪТМ·

МФУˆЩИОТУ ·О·ı·ЪЫИТУ. ŸЩ·У Б›УВЩ·И Ы˘БОfiППЛЫЛ В¿Уˆ ЩЛ˜ МВИТУВЩ·И Л ·УЩФ¯‹ ЩЛ˜

b. The electrode

• The electrode consists of a metal core enclosed by a coating. The coating has the most

important purpose of protecting the welding pool and the transferring droplets against

oxygen and nitrogen in the surrounding air. The electrode melts during

welding. A part of the

coating vaporises so a protective gaseous shield originates.

part of the coating floats on the welding pool (it is lighter than steel) and also protects the

cooling weld. After cooling this coating becomes a solid but easily removable slag on the

welded joint.

• Handle the electrodes with care so the coating is not broken. Make sure that the electrodes

are thoroughly dry, so store them in a moisture-free place.

• It is of great importance to use the right electrode to make a good and strong welded joint. A

universal electrode will in many cases be suitable for your work.The electrode packaging

mentions in which positions welding can be done with the electrodes concerned (above the

head, downwards, etc. bearing in mind the speed of melting of the electrode). Separate

electrodes are commercially available for the welding of types of stainless steel and cast iron.

Consult your dealer about purchasing the right electrode.

c. Protective clothing

Wear thoroughly covering clothing so that the likelihood of the skin being burnt by ultraviolet

radiation or splashes of metal is minimised.

Preferably wear cotton overalls, welding gloves and safety shoes. Make sure that welding

spatter cannot end up in gloves or shoes.

A (leather) welding apron stops burning and sparks damaging overalls.

d. Face protection

Fig. 2

Use a good welding mask with (dark) welding glass and protective glass. Check that both

glasses are correctly fitted (well-fastened and not allowing any sunlight in).

The welding mask protects the welder against radiation, heat and weld spatter released during

the welding process. This also reduces the inhalation of welding fumes. The invisible ultraviolet

rays cause so-called “welder's flash”. This already originates after a few seconds of looking into

the electric arc.

Avoid the effects of this radiation and high temperatures on the face and other exposed body

parts such as the neck and arms.

Protect yourself against the dangerous effects of the electric arc and keep persons who are not

participating in the work at least 15 m from the arc.

Persons or assistants working in the vicinity of the electric arc must be advised of the hazards

and they must be equipped with the required protective gear. If required, set up protective walls.

e. Working environment

• Ensure a well ventilated working environment. Gases are released when welding that are a

danger to your health.

• Remove all flammable objects from the working environment. Welding causes sparks and

hot metal.

• Make sure that cooling water is present in the vicinity of workplace. Do not leave just welded

(hot) workpieces unattended in the workplace. Cool the workpiece before leaving the

workplace.

Ferm

10

GB

D

NL

F

E

P

I

S

FIN

N

DK

Page 11

Ferm 11

GB

D

NL

F

E

P

I

S

FIN

N

DK

Protection against radiation and burns

• At the work place, the hazard to the eyes must be indicated by a sign stating “Caution! Do

not look at the flames!” The workstations must be shielded as much as possible in such a

manner that personnel standing in the vicinity of the workstation are protected. Keep

unauthorized personnel away from the welding work.

• In the immediate vicinity of the stationary workstations, the walls should not be brightly

colored or glossy. Windows must be coated with suitable paint to at least eye-level to

prevent radiation reflecting or passing through.

Bringing into use

Fig. 3

Tip: Before you start welding difficult workpieces it is best to first try the welding out on a test

piece.

• Ensure a clean workpiece: remove any rust, grease and paint residues.

• Set the required current intensity using the knob on the front of the welding appliance.

The choice of current intensity depends on the workpiece and the type of electrode used.

• Place the part of the electrode without coating in the electrode holder and connect the earth

terminal to the workpiece.

• Switch the welding appliance on with the main switch.

• Keep the welding mask in front of your face and move the point of the electrode over the

workpiece as if you were striking a match. This is the best way to start the welding arc. Do

not strike the workpiece with the electrode. This will damage the electrode and impede the

creation of the welding arc.

• After creating the welding arc immediately try to keep the distance between point of the

electrode and the workpiece equal. Keep this distance equal to the diameter of the

electrode. Keep this distance as constant as possible during welding.

• Move the electrode in a gradual pulling movement over the workpiece.

• Keep the angle between electrode and workpiece between 60° and 70° in the direction of

movement.

• When the welded joint has been made, break the welding arc by removing the electrode

from the workpiece.

• Switch off the welding appliance.

N.B. If you leave the welding appliance on, the likelihood is great that the electrode

will make contact (through the work bench) with the earth cable and spontaneously

start to weld.

• Remove the slag from the welded joint with a scaling hammer.

Take care for hot flying metal particles. Always wear protective goggles.

• Never weld over slag residues: the slag forms an insulating and contaminated layer, and as

a result weakens the weld (so-called slag inclusion).

• Brush the weld clean using a wire brush.

ЛПВОЩЪФ‰›ˆУ, БИ· Ы˘БОfiППЛЫЛ ЩˆУ ‰И·КФЪВЩИОТУ Щ‡ˆУ ·УФНВ›‰ˆЩФ˘ ¯¿П˘‚· О·И

¯˘ЩФЫ›‰ЛЪФ˘. °И· ЩЛУ ·БФЪ¿ ЩФ˘ О·Щ¿ППЛПФ˘ ЛПВОЩЪФ‰›Ф˘ Ы˘М‚Ф˘ПВ˘ЩВ›ЩВ ЩФУ

ЪФМЛıВ˘Щ‹.

Á. ¶ÚÔÛٷ٢ÙÈÎfi˜ ÚÔ˘¯ÈÛÌfi˜

¡· КФЪ¿ЩВ ЪФ‡¯· Ф˘ У· О·П‡ЩФ˘У ФПfiОПЛЪФ ЩФ ЫТМ· Ы·˜, ¤ЩЫИ ТЫЩВ У·

ВП·¯ИЫЩФФИ‹ЫВЩВ ЩФУ О›У‰˘УФ ВБО·‡М·ЩФ˜ ·fi ЩЛУ ˘ВЪИТ‰Л ·ОЩИУФ‚ФП›· ‹ Щ·

ВОЩИУ·ЫЫfiМВУ· ЫЩ·БФУ›‰И· МВЩ¿ППФ˘.

∫·Щ¿ ЪФЩ›МЛЫЛ У· КФЪ¿ЩВ ФПfiЫˆМВ˜ КfiЪМВ˜ ВЪБ·Ы›·˜, Б¿УЩИ· БИ· Ы˘БОФППЛЩ¤˜ О·И

˘Ф‰‹М·Щ· ·ЫК·ПВ›·˜. ºЪФУЩ›ЫЩВ У· МЛУ ¤ЫВИ Щ‹БМ· Ы˘БОfiППЛЫЛ˜ ЫЩ· ·Ф‡ЩЫИ· ‹ Щ·

Б¿УЩИ· Ы·˜.

∏ (‰ВЪМ¿ЩИУЛ) Ф‰И¿ ·ФЩЪ¤ВИ Щ· ВБО·‡М·Щ· О·И ‰ВУ ВИЩЪ¤ВИ ЫЩФ˘˜ ЫИУı‹ЪВ˜ У·

‰И·ВЪ¿ЫФ˘У ЩЛ КfiЪМ·.

‰. ¶ÚÔÛÙ·Û›· ÚÔÛÒÔ˘

EÈÎ. 2

ГЪЛЫИМФФИ‹ЫЩВ МИ· О·П‹ М¿ЫО· Ы˘БОfiППЛЫЛ˜, МВ (ЫОФ‡ЪФ) Щ˙¿МИ Ы˘БОfiППЛЫЛ˜ О·И

ЪФЫЩ·ЩВ˘ЩИОfi Щ˙¿МИ.

µВ‚·ИˆıВ›ЩВ fiЩИ О·И Щ· ‰‡Ф Щ˙¿МИ· В›У·И ЩФФıВЩЛМ¤У· ЫˆЫЩ¿ (¤¯Ф˘У ЫЩВЪВˆıВ› О·П¿ О·И У·

‰ВУ ВИЩЪ¤Ф˘У ЩЛУ В›ЫФ‰Ф ЩФ˘ ЛПИ·ОФ‡ КˆЩfi˜).

∏ М¿ЫО· Ы˘БОfiППЛЫЛ˜ ЪФЫЩ·ЩВ‡ВИ ЩФ Ы˘БОФППЛЩ‹ ·fi ЩЛУ ·ОЩИУФ‚ФП›·, ЩЛ ıВЪМfiЩЛЩ· О·И

ЩЛУ ВОЩ›У·НЛ Щ‹БМ·ЩФ˜ О·Щ¿ ЩЛ ‰И¿ЪОВИ· ЩЛ˜ Ы˘БОfiППЛЫЛ˜. ∂›ЫЛ˜ ВЪИФЪ›˙ВИ ЩЛУ ВИЫУФ‹

ЩˆУ ·ВЪ›ˆУ ЩЛ˜ Ы˘БОfiППЛЫЛ˜.√И ·fiЪ·ЩВ˜ ˘ВЪИТ‰ВИ˜ ·ОЩ›УВ˜ ЪФО·ПФ‡У О·И ЩФ К·ИУfiМВУФ

ЩЛ˜ “ФКı·ПМ›·˜ ·fi ¤УЩФУФ КˆЩИЫМfi”. ∆Ф К·ИУfiМВУФ ·˘Щfi ВМК·У›˙ВЩ·И ЫВ П›Б· МfiПИ˜

‰В˘ЩВЪfiПВЩ·, fiЩ·У О¿ФИФ˜ ОФИЩ¿НВИ ЩФ ЛПВОЩЪИОfi ЩfiНФ.∞ФК‡БВЩВ ЩИ˜ Ы˘У¤ВИВ˜ ЩЛ˜

·ОЩИУФ‚ФП›·˜ О·И ЩˆУ ˘„ЛПТУ ıВЪМФОЪ·ЫИТУ Ф˘ ЪФЫ‚¿ПФ˘У ЩФ ЪfiЫˆФ О·И Щ· ˘fiПФИ·

ВОЩВıВИМ¤У· М¤ЪЛ ЩФ˘ ЫТМ·ЩФ˜, fiˆ˜ В›У·И Ф П·ИМfi˜ О·И Щ· ¯¤ЪИ·.

¶ЪФК˘П¿НЩВ ЩФУ В·˘Щfi Ы·˜ ·fi ЩИ˜ ВИО›У‰˘УВ˜ ВИ‰Ъ¿ЫВИ˜ ЩФ˘ КˆЩВИУФ‡ Ы˘БОФППЛЩИОФ‡

ЩfiНФ˘ О·И ·Ъ·МВЪ›ЫЩВ Щ· ¿ЩФМ·, Щ· ФФ›· ‰ВУ Ы˘ММВЩ¤¯Ф˘У ЫЩИ˜ ВЪБ·Ы›В˜, ЩФ˘П¿¯ИЫЩФУ

М¤¯ЪИ 15 М¤ЩЪ· ·г ЩФ Кˆ˜ ЩФ˘ Ы˘БОФППЛЩИОФ‡ ЩfiНФ˘.

∂›ЫЛ˜ ¿ЩФМ· Л ‚ФЛıФ›, ФИ ФФ›ФИ ‚Ъ›ЫОФУЩ·И ОФУЩ¿ ЫЩФ КˆЩВИУfi Ы˘БОФППЛЩИОfi ЩfiНФ Ъ¤ВИ

У· В›У·И ‰И‰·БМ¤УФИ БИ· ЩФ˘˜ ОИУ‰‡УФ˘˜ О·И У· В›У·И ВН·ЫК·ПИЫМ¤УФИ МВ ЪФК˘П·ОЩИО¿

‚ФЛı‹М·Щ·. ™В ВЪ›ЩˆЫЛ ·У¿БОЛ˜ ı· ЫЩЛıФ‡У ЪФК˘П·ОЩИО¿ ЩФИ¯ТМ·Щ·.

Â. ÃÒÚÔ˜ ÂÚÁ·Û›·˜

с ∂Н·ЫК·П›ЫЩВ ЩФУ О·Пfi ВН·ВЪИЫМfi ЩФ˘ ¯ТЪФ˘ ВЪБ·Ы›·˜. ∫·Щ¿ ЩЛ Ы˘БОfiППЛЫЛ ВОП‡ФУЩ·И

·¤ÚÈ·, Ù· ÔÔ›· Â›Ó·È ‚Ï·‚ÂÚ¿ ÁÈ· ÙËÓ ˘Á›· Û·˜.

с ∞ФМ·ОЪ‡УВЩВ fiП· Щ· В‡КПВОЩ· ˘ПИО¿ ·fi ЩФ ¯ТЪФ ВЪБ·Ы›·˜. ∏ Ы˘БОfiППЛЫЛ ЪФО·ПВ›

ÙËÓ ÂÎÙ›Ó·ÍË ÛÈÓı‹ÚˆÓ Î·È ÙËÁ̤ÓÔ˘ ÌÂÙ¿ÏÏÔ˘.

ñ ºÚÔÓÙ›ÛÙ ÒÛÙ ÛÙÔ ¯ÒÚÔ ÂÚÁ·Û›·˜ Ó· ˘¿Ú¯ÂÈ ¿ÌÂÛ· ‰È·ı¤ÛÈÌÔ ÓÂÚfi ÁÈ· „‡ÍË. ªËÓ

·К‹УВЩВ ¯ˆЪ›˜ В›‚ПВ„Л Щ· ·УЩИОВ›МВУ· Ф˘ МfiПИ˜ Ы˘БОФПП‹Ы·ЩВ (О·И О·›УВ ·ОfiМ·) ЫЩФ

¯ТЪФ ВЪБ·Ы›·˜. ¶ЪФЩФ‡ ·ФМ·ОЪ˘УıВ›ЩВ ·fi ЩФ ¯ТЪФ ВЪБ·Ы›·˜, ı· Ъ¤ВИ У· „‡НВЩВ

ЩФ ·УЩИОВ›МВУФ Ф˘ Ы˘БОФПП‹Ы·ЩВ.

¶ЪФК‡П·НЛ О·Щ¿ ЩЛУ ·ОЩИУФ‚ФП›· О·И ВБО·‡М·Щ·.

ñ ™ÙÔÓ ¯ÒÚÔ ÂÚÁ·Û›·˜ Ú¤ÂÈ Ó· Â›Ó·È ÙÔÔıÂÙË̤ÓÔÈ ›Ó·Î˜, ÔÈ ÔÔ›ÔÈ ÛËÌ·‰Â‡Ô˘Ó ÙÔÓ

О›У‰˘УФ ЩˆУ М·ЩИТУ “¶ЪФЫФ¯‹! ªЛУ ОФИЩ¿ЩВ ЫЩЛ КПfiБ·!” √ ¯ТЪФ˜ ВЪБ·Ы›·˜ Ъ¤ВИ У·

В›У·И ЫОИ·ЫМ¤УФ˜ ¤ЩЫИ, ТЫЩВ У· К˘П¿БФУЩ·И Щ· ¿ЩФМ· Ф˘ ‚Ъ›ЫОФУЩ·И ПЛЫ›ФУ. ∆·

Ferm

110

GB

D

NL

F

E

P

I

S

GR

N

DK

Page 12

Ferm 109

GB

D

NL

F

E

P

I

S

GR

N

DK

™∏ª∂πш™∏! ¶ЪФЫ¤НЩВ ЩФ ЫЛМВ›Ф fiФ˘ ı· ¤ЫВИ ЩФ ЛПВОЩЪfi‰ИФ, ТЫЩВ У·

·ФК‡БВЩВ ЩЛУ ЪfiОПЛЫЛ ˘ЪО·БИ¿˜ О·И ЩФУ ЩЪ·˘М·ЩИЫМfi.

4. §∂π∆√Àƒ°π∞

¶ÚÈÓ ·fi ÙË ¯Ú‹ÛË:

·. °ВУИО¤˜ ПЛЪФКФЪ›В˜ БИ· ЩЛ Ы˘БОfiППЛЫЛ МВ ЛПВОЩЪИОfi ЩfiНФ

‚. ∆Ф ЛПВОЩЪfi‰ИФ

Б. ¶ЪФЫЩ·ЩВ˘ЩИОfi˜ ЪФ˘¯ИЫМfi˜

‰. ¶ЪФЫЩ·Ы›· ЩФ˘ ЪФЫТФ˘

В. ГТЪФ˜ ВЪБ·Ы›·˜

·. °ВУИО¤˜ ПЛЪФКФЪ›В˜ БИ· ЩЛ Ы˘БОfiППЛЫЛ МВ ЛПВОЩЪИОfi ЩfiНФ

∏ ıВЪМФОЪ·Ы›· ЩФ˘ ЩfiНФ˘ КЩ¿УВИ ЩФ˘˜ 7000Ж C ВЪ›Ф˘, МВ ·ФЩ¤ПВЫМ· У· Щ‹ОВЩ·И ЩfiЫФ ЩФ

¿ОЪФ ЩФ˘ ЛПВОЩЪФ‰›Ф˘ fiЫФ О·И ЩФ ·УЩИОВ›МВУФ Ф˘ Ы˘БОФПП¿ЩВ.

°И· fiЫФ ‰И¿ЫЩЛМ· ‰И·ЪОВ› ЩФ ЩfiНФ, ЩФ ЛПВОЩЪfi‰ИФ ПИТУВИ О·И ·Ъ¤¯ВИ ЩФ ˘ПИОfi Ы˘БОfiППЛЫЛ˜

Ф˘ ··ИЩВ›Щ·И, ЪФОВИМ¤УФ˘ У· Ы˘БОФППЛıФ‡У Щ· ОФММ¿ЩИ·. ∏ ·fiЫЩ·ЫЛ ·У¿МВЫ· ЫЩФ

ЛПВОЩЪfi‰ИФ О·И ЩФ ·УЩИОВ›МВУФ ı· Ъ¤ВИ У· В›У·И Л МИОЪfiЩВЪЛ ‰˘У·Щ‹ (ВЪ›Ф˘ 1,5 - 4 mm),

·У¿ПФБ· МВ ЩЛ ‰И¿МВЩЪФ О·И ЩФУ Щ‡Ф ЩФ˘ ЛПВОЩЪfi‰›Ф˘. ∆Ф ЛПВОЩЪИОfi ЪВ‡М· Ф˘ ··ИЩВ›Щ·И

БИ· ЩЛ Ы˘БОfiППЛЫЛ ·Ъ¤¯ВЩ·И ·fi ЩЛ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜. ∏ ИЫ¯‡˜ Ф˘ ··ИЩВ›Щ·И

·fi ЩЛУ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ВН·ЪЩ¿Щ·И ·fi ЩЛУ ВЪБ·Ы›· Ф˘ Ъ¤ВИ У· Б›УВИ.

µВ‚·ИˆıВ›ЩВ fiЩИ Щ· ЛПВОЩЪfi‰И· В›У·И ЩВПВ›ˆ˜ ЫЩВБУ¿, О·ıТ˜ В›У·И Иı·УfiУ Щ· ˘БЪ¿

ЛПВОЩЪfi‰И· У· ‰ЛМИФ˘ЪБ‹ЫФ˘У ЪФ‚П‹М·Щ·. ∂¿У О·Щ¿ ЩЛ ‰И¿ЪОВИ· ЩЛ˜ Ы˘БОfiППЛЫЛ˜ ЩФ

ЛПВОЩЪfi‰ИФ ОФПП¿ВИ ЫЩФ ·УЩИОВ›МВУФ, ЩfiЩВ Л Ъ‡ıМИЫЛ ЩЛ˜ ¤УЩ·ЫЛ˜ ЩФ˘ ЪВ‡М·ЩФ˜ В›У·И ФП‡

¯·МЛП‹.

‚. ∆Ф ЛПВОЩЪfi‰ИФ

с ∆Ф ЛПВОЩЪfi‰ИФ ·ФЩВПВ›Щ·И ·fi ¤У·У МВЩ·ППИОfi ˘Ъ‹У· Ф˘ ВЪИОПВ›ВЩ·И ·fi ЩЛУ

В¤У‰˘ЫЛ. ∏ В¤У‰˘ЫЛ ·›˙ВИ ЩФУ ФП‡ ЫЛМ·УЩИОfi ЪfiПФ ЩЛ˜ ЪФЫЩ·Ы›·˜ ЩФ˘ Щ‹БМ·ЩФ˜

ЩЛ˜ Ы˘БОfiППЛЫЛ˜ О·И ЩˆУ МВЩ·КВЪfiМВУˆУ ЫЩ·БФУИ‰›ˆУ ЩФ˘ МВЩ¿ППФ˘, ·fi ЩФ ФН˘БfiУФ

О·И ЩФ ¿˙ˆЩФ Ф˘ ˘¿Ъ¯Ф˘У ЫЩФУ ·¤Ъ· ЩФ˘ ВЪИ‚¿ППФУЩФ˜.

∆Ф ЛПВОЩЪfi‰ИФ ПИТУВИ О·Щ¿ ЩЛ Ы˘БОfiППЛЫЛ. ŒУ· М¤ЪФ˜ ЩЛ˜ В¤У‰˘ЫЛ˜ ·ВЪИФФИВ›Щ·И,

‰ЛМИФ˘ЪБТУЩ·˜ ¤У· ЪФЫЩ·ЩВ˘ЩИОfi ЫЩЪТМ· ·ВЪ›Ф˘.

ŒУ· М¤ЪФ˜ ЩЛ˜ В¤У‰˘ЫЛ˜ ПИТУВИ О·И ВИП¤ВИ ЫЩФ Щ‹БМ· ЩЛ˜ Ы˘БОfiППЛЫЛ˜ (Л В¤У‰˘ЫЛ

В›У·И ВП·КЪ‡ЩВЪЛ ·fi ЩФ ¯¿П˘‚·), МВ Ы˘У¤ВИ· У· ЪФЫЩ·ЩВ‡ВИ ЩФ Щ‹БМ· О·Щ¿ ЩЛУ „‡НЛ

ЩФ˘. ªfiПИ˜ ФПФОПЛЪˆıВ› Л „‡НЛ, Л В¤У‰˘ЫЛ ЫЩВЪВФФИВ›Щ·И ·ПП¿ ·ФМ·ОЪ‡УВЩ·И

В‡ОФП· ·fi ЩЛУ ВЪИФ¯‹ ЩЛ˜ ОfiППЛЫЛ˜.

с ºЪФУЩ›ЫЩВ У· МЛУ Ы¿ЫВИ Л В¤У‰˘ЫЛ ЩˆУ ЛПВОЩЪФ‰›ˆУ О·Щ¿ ЩЛ ¯Ъ‹ЫЛ ЩФ˘˜. ºЪФУЩ›ЫЩВ

ТЫЩВ Щ· ЛПВОЩЪfi‰И· У· В›У·И ВУЩВПТ˜ ЫЩВБУ¿, ·ФıЛОВ‡ФУЩ¿˜ Щ· ЫВ ¯ТЪФ ¯ˆЪ›˜ ˘БЪ·Ы›·.

с °И· ЩЛУ Ъ·БМ·ЩФФ›ЛЫЛ МИ·˜ ЫˆЫЩ‹˜ О·И ·УıВОЩИО‹˜ ОfiППЛЫЛ˜ В›У·И ФП‡ ЫЛМ·УЩИОfi У·

¯ЪЛЫИМФФИ‹ЫВЩВ ЩФ О·Щ¿ППЛПФ ЛПВОЩЪfi‰ИФ. ŒУ· ЛПВОЩЪfi‰ИФ БВУИО‹˜ ¯Ъ‹ЫЛ˜ В›У·И

О·Щ¿ППЛПФ БИ· ЩИ˜ ВЪИЫЫfiЩВЪВ˜ ВЪБ·Ы›В˜.

∏ Ы˘ЫОВ˘·Ы›· ЩˆУ ЛПВОЩЪФ‰›ˆУ ·У·К¤ЪВИ ЩЛ ı¤ЫЛ ЫЩЛУ ФФ›· МФЪВ› У· Б›УВИ

Ы˘БОfiППЛЫЛ МВ Щ· Ы˘БОВОЪИМ¤У· ЛПВОЩЪfi‰И· (ФЪФКИ·›·, О·Щ·ОfiЪ˘КЛ О.П. П·М‚¿УФУЩ·˜

˘fi„Л ЩЛУ Щ·¯‡ЩЛЩ· Щ‹НЛ˜ ЩФ˘ ЛПВОЩЪФ‰›Ф˘). ™ЩФ ВМfiЪИФ ‰И·Щ›ıВУЩ·И ‰И¿КФЪФИ Щ‡ФИ

N.B. The workpiece is still at a very high temperature.

Do not leave the hot workpiece unattended.

Indicator lamp temperature

Fig.1

When the temperature of the welding appliance becomes too high, the built-in thermostat will

switch off (indicator light comes on). The built-in ventilator cools the machine. After cooling the

lamp goes off again.

Preferably allow the machine a sufficient time to cool down; with intensive welding the likelihood

is great that the thermal cut-out will trigger again after a few minutes.

5. SERVICE & MAINTENANCE

Make sure that the machine is disconnected before carrying out any maintenance.

This machine has been designed to operate over a long period of time with a minimum of

maintenance. Continuous satisfactory operation depends upon proper machine care and

regular cleaning.

Malfunction

Should the machine fail to function correctly, a number of possible causes and the appropriate

solutions are given below:

Fault

• The welding appliance is not working.

• Electrode continues to 'stick' to the

workpiece.

Cause/solution

• Earth terminal does not have good

contact with the workpiece.

• Electrode is not properly positioned in its

holder.

• Thermal cut-out switched off.

• Fusing defective (in meter box).

• The cable is broken.

• The switch is defective/contact your

dealer.

• Use the right type of electrode (universal)

• Current intensity too low/turn button 3

clockwise

Ferm

12

GB

D

NL

F

E

P

I

S

FIN

N

DK

Page 13

Ferm 13

GB

D

NL

F

E

P

I

S

FIN

N

DK

Repairs and servicing should only be carried out by a qualified technician or service

firm.

Cleaning

• Make sure that the ventilation slots are free of dust and dirt. Use a soft cloth moistened with

soapy water for removing stubborn dirt. Do not use any solvents such as petrol, alcohol or

ammonia, etc.

• Make sure that the electrode holder and earth terminal remain corrosion-free so they can

continue making good electrical contact.

• Regularly check that welding and workpiece cables are firmly connected in their

connections

Lubrication

The machine requiers no additional lubrication.

Faults

Should a fault occur, e.g. after wear of a part, please contact the service address on the warranty

card. In the back of this manual you find an exploded view showing the parts that can be

ordered.

Environment

To prevent damage during transport, the appliance is delivered in a solid packaging which

consists largely of reusable material. Therefore please make use of options for recycling the

packaging.

Faulty and/or discarded electrical or electronic apparatus have to be collected at

the appropriate recycling locations.

Warranty

The guarantee conditions can be found on the separately enclosed guarantee card.

Fault

• Electrode is orange-red.

• Electrode spatters excessively and

makes a lot of noise during welding.

• The machine is too hot; indicator lamp is

on.

Cause/solution

• Current intensity too high for this type of

electrode/turn button 3 anti-clockwise

• Current intensity too high/turn button 3

anti-clockwise

• The ventilation slots are blocked/clean

them with a dry cloth; wait a few minutes

until the lamp goes off again.

3. ∆√¶√£∂∆∏™∏ ∂•∞ƒ∆∏ª∞∆ø¡

∫·Ù¿ ÙËÓ ÙÔÔı¤ÙËÛË ÚfiÛıÂÙˆÓ ÂÍ·ÚÙËÌ¿ÙˆÓ, ı· Ú¤ÂÈ Ó· ·ÔÛ˘Ó‰¤ÂÙ ÙÔ

ÚÂ˘Ì·ÙÔÏ‹ÙË (ÊȘ) ·fi ÙËÓ Ú›˙·.

∂ÁηٿÛÙ·ÛË ÙÔ˘ Ì˯·Ó‹Ì·ÙÔ˜

с ∆ФФıВЩ‹ЫЩВ ЩЛ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ЫВ НЛЪfi О·И О·ı·Ъfi ¯ТЪФ (¯ˆЪ›˜

ÚÈÓ›ÛÌ·Ù· Ûȉ‹ÚÔ˘, ÛÎfiÓË ‹ ¯ÚÒÌ·Ù·).

с ∆ФФıВЩ‹ЫЩВ ЩЛ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ЫВ В›В‰Л О·И ЫЩВЪВ‹ ВИК¿УВИ·, ЫВ

·fiЫЩ·ЫЛ ЩФ˘П¿¯ИЫЩФУ 20 cm ·fi ЩФУ ПЛЫИ¤ЫЩВЪФ ЩФ›¯Ф.

с ¶ЪФК˘П¿НЩВ ЩЛ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ·fi ЩЛ ‚ЪФ¯‹ О·И ЩФ ИЫ¯˘Ъfi ЛПИ·Оfi Кˆ˜.

∏ М¿ЫО· ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜

∂ÈÎ. 2

с ™‡ЪВЩВ ЩЛ П·‚‹ ЩЛ˜ М¿ЫО·˜ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ¤ˆ˜ fiЩФ˘ ·ЫК·П›ЫВИ.

с ∆ФФıВЩ‹ЫЩВ ЩФ ЪФЫЩ·ЩВ˘ЩИОfi Щ˙¿МИ ВМЪfi˜ ·fi ЩФ ЫОФ‡ЪФ Щ˙¿МИ

ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜. ™‡ЪВЩВ О·И Щ· ‰‡Ф Щ˙¿МИ· ВМЪfi˜ ·fi ЩФ ¿УФИБМ·.

ñ ºÚÔÓÙ›ÛÙ ӷ ÙÔÔıÂÙ‹ÛÂÙ ٷ Ù˙¿ÌÈ· Ì ٤ÙÔÈÔ ÙÚfiÔ, ÒÛÙ ӷ ÌËÓ ÌÔÚ› ÙÔ ‚Ï·‚ÂÚfi

Кˆ˜ У· ВИЫ¤ПıВИ ·fi ЩФ ¿УФИБМ·.

с ∂¿У О·Щ¿ ЩЛ Ы˘БОfiППЛЫЛ МВИˆıВ› Л ФЪ·ЩfiЩЛЩ· ЪФ˜ ЩФ ·УЩИОВ›МВУФ Ф˘ Ы˘БОФПП¿ЩВ,

·УЩИО·Щ·ЫЩ‹ЫЩВ ЩФ ЪФЫЩ·ЩВ˘ЩИОfi Щ˙¿МИ. ∏ ·УЩИО·Щ¿ЫЩ·ЫЛ ЩФ˘ ЫОФ‡ЪФ˘ Щ˙·МИФ‡

ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ОФЫЩ›˙ВИ ФП‡ ВЪИЫЫfiЩВЪФ ·fi ЩЛУ ·УЩИО·Щ¿ЫЩ·ЫЛ ЩФ˘

ЪФЫЩ·ЩВ˘ЩИОФ‡ Щ˙·МИФ‡.

∆ФФı¤ЩЛЫЛ У¤ˆУ ЛПВОЩЪФ‰›ˆУ

∆Ф ЛПВОЩЪfi‰ИФ ·ФЩВПВ›Щ·И ·fi ¤У·У МВЩ·ППИОfi ˘Ъ‹У· Ф˘ ВЪИОПВ›ВЩ·И ·fi ЩЛУ

В¤У‰˘ЫЛ. ™ЩФ ¤У· ¿ОЪФ ЩФ˘ ЛПВОЩЪФ‰›Ф˘, Ф ˘Ъ‹У·˜ ‰ВУ В›У·И О·П˘ММ¤УФ˜.

с ¶И¤ЫЩВ ЩЛ П·‚‹ ЩЛ˜ ‰·БО¿У·˜ БИ· ЩФ ЛПВОЩЪfi‰ИФ, ·ЫОТУЩ·˜ ›ВЫЛ ЫЩФ ВП·Щ‹ЪИФ.

с ™˘У‰¤ЫЩВ ЩФ ¿ОЪФ ЩФ˘ ЛПВОЩЪФ‰›Ф˘ МВ ЩФУ ·О¿П˘ЩФ ˘Ъ‹У· (± 2 cm) ЫЩЛ ‰·БО¿У· БИ·

ЩФ ЛПВОЩЪfi‰ИФ. ºЪФУЩ›ЫЩВ ТЫЩВ ЩФ ·О¿П˘ЩФ ¿ОЪФ ЩФ˘ ЛПВОЩЪФ‰›Ф˘ У· ВК·ЪМfi˙ВИ О·П¿

ЫЩФ МВЩ·ППИОfi ЩМ‹М· ЩЛ˜ ‰·БО¿У·˜ БИ· ЩФ ЛПВОЩЪfi‰ИФ (ЩФ ЛПВОЩЪfi‰ИФ ‰ВУ ı· Ъ¤ВИ У·

ВИЫ¤Ъ¯ВЩ·И ˘ВЪ‚ФПИО¿ М¤Ы· ЫЩЛ ‰·БО¿У·).

с ∂ПВ˘ıВЪТЫЩВ ЩЛ П·‚‹ ЩЛ˜ ‰·БО¿У·˜. ∆Ф ЛПВОЩЪfi‰ИФ ¤¯ВИ П¤ФУ ЩФФıВЩЛıВ›.

™∏ª∂πш™∏! ªЛУ ·К‹УВЩВ ЩФ М‹ОФ˜ ЩФ˘ ЛПВОЩЪФ‰›Ф˘ У· МВИˆıВ› ВЪИЫЫfiЩВЪФ

·fi ± 5 cm ‰ИfiЩИ Л ‰·БО¿У· БИ· ЩФ ЛПВОЩЪfi‰ИФ ˘ВЪıВЪМ·›УВЩ·И О·И/‹

·Ъ·МФЪКТУВЩ·И. ™В ·˘Щ‹У ЩЛУ ВЪ›ЩˆЫЛ, Л ·К·›ЪВЫЛ ЩФ˘ О·М¤УФ˘

ЛПВОЩЪФ‰›Ф˘ ı· В›У·И ‰‡ЫОФПЛ.

∞К·›ЪВЫЛ ¯ЪЛЫИМФФИЛМ¤УˆУ ЛПВОЩЪФ‰›ˆУ

¶И¤ЫЩВ ЩЛ П·‚‹ ЩЛ˜ ‰·БО¿У·˜ БИ· ЩФ ЛПВОЩЪfi‰ИФ ·ЫОТУЩ·˜ ›ВЫЛ ЫЩФ ВП·Щ‹ЪИФ, ¤ЩЫИ ТЫЩВ ЩФ

О·М¤УФ ЛПВОЩЪfi‰ИФ У· ¤ЫВИ ·fi ЩЛ ‰·БО¿У·.

™∏ª∂πш™∏! ªЛУ ·К·ИЪВ›ЩВ ЩФ ЛПВОЩЪfi‰ИФ ·fi ЩЛ ‰·БО¿У· МВ ЩФ ¯¤ЪИ. ∆Ф

ЛПВОЩЪfi‰ИФ О·›ВИ ¿Ъ· ФП‡.

Ferm

108

GB

D

NL

F

E

P

I

S

GR

N

DK

Page 14

Ferm 107

GB

D

NL

F

E

P

I

S

GR

N

DK

ЩФУ ·ОЪФ‰¤ОЩЛ БВ›ˆЫЛ˜ ЫВ БВИˆМ¤У· ЩМ‹М·Щ·, Щ· ФФ›· В›У·И ¿Ъ· ФП‡ М·ОЪИ¿ ·fi Щ·

ОФММ¿ЩИ, Ф˘ ВВНВЪБ¿˙ВЩ·И, .¯. ЫЩФУ ЫˆП‹У· ·ЪФ¯‹˜ УВЪФ‡ Л ЫВ ¿ППЛ БˆУ›· ЩФ˘

‰ˆМ·Щ›Ф˘. ¢И·КФЪВЩИО¿ ı· МФЪФ‡ЫВ У· ˙ЛМИˆıВ› ЩФ Ы‡ЫЩЛМ· ЩФ˘ ЪФК˘П·ОЩИОФ‡

·БˆБФ‡ ЫЩФ ‰ˆМ¿ЩИФ, ЫЩФ ФФ›Ф Ы˘БОФПП¿ЩВ.

ñ ∏ ÂÍ·ÛÊ¿ÏÈÛË ÙˆÓ ÚÔÛı¤ÛÂˆÓ ÚÔ˜ ÙËÓ Ú›˙· ÙÔ˘ ‰ÈÎÙ‡Ô˘ Ú¤ÂÈ Ó· ·ÓÙ·ÔÎÚ›ÓÂÙ·È

ÛÙȘ ÚԉȷÁڷʤ˜ (VDE 0100). √È ÚÔÊ˘Ï·ÎÙÈΤ˜ ·ʤ˜ ÙˆÓ ÚÈ˙ÒÓ ÌÔÚÔ‡Ó Ó·

·ЫК·П›˙ФУЩ·И (МВ ·ЫК¿ПВИВ˜ Л МВ ‰И·ОfiЩВ˜ ЩФ˘ ЪВ‡М·ЩФ˜) МВ max. 16A (∆‡ФИ О·И

ЩВ¯УИО¿ ЫЩФИ¯В›·: RT 14-20, O/ 10 x 38, AC 400 V 16A. IEC 60269. ∂П¿¯ИЫЩ· ВУВЪБЛЩИО¿.

¶·Ъ·БˆБfi˜: Chint).

∏ПВОЩЪИО‹ ·ЫК¿ПВИ·

∞ВУВЪБФФИ‹ЫЩВ ЩФ ВЪБ·ПВ›Ф ·М¤Ыˆ˜ В¿У:

с А¿Ъ¯ВИ О¿ФИФ ВП¿ЩЩˆМ· ЫЩФ ЪВ˘М·ЩФП‹ЩЛ (КИ˜) ‹ ЫЩФ О·ПТ‰ИФ

ЩЪФКФ‰ФЫ›·˜ ‹ ¤¯ВИ ЪФОПЛıВ› ‚П¿‚Л ЫЩ· ¿ПП· О·ПТ‰И·.

с √ ‰И·ОfiЩЛ˜ В›У·И ВП·ЩЩˆМ·ЩИОfi˜.

с ¶·Ъ·ЩЛЪ‹ЫВЩВ У· ‚Б·›УВИ О·Уfi˜ ‹ М˘Ъ›ЫВЩВ О·М¤УФ МФУˆЩИОfi ˘ПИОfi.

¶ЪФВИ‰ФФ›ЛЫЛ! ∞У¿ПФБ· МВ ЩИ˜ Ы˘Уı‹ОВ˜ ·ЪФ¯‹˜ ЪВ‡М·ЩФ˜ ЫЩФ ЫЛМВ›Ф ЩЛ˜

Ы‡У‰ВЫЛ˜, ВУ‰¤¯ВЩ·И Л ЛБ‹ ЩЪФКФ‰ФЫ›·˜ ЩЛ˜ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ У·

ВЛЪВ¿ЫВИ ЩЛУ ·ЪФ¯‹ ЪВ‡М·ЩФ˜ ЪФ˜ ЩФ˘˜ ¿ППФ˘˜ О·Щ·У·ПˆЩ¤˜. ∂¿У ¤¯ВЩВ

·ФЪ›В˜ ‹ ВИК˘П¿НВИ˜ Ы¯ВЩИО¿ МВ ·˘Щfi ЩФ ˙‹ЩЛМ· ı· Ъ¤ВИ У· Ы˘М‚Ф˘ПВ˘ЩВ›ЩВ

ЩЛУ ВЩ·ИЪВ›· ЛПВОЩЪФ‰fiЩЛЫЛ˜.

с µВ‚·ИˆıВ›ЩВ fiЩИ Л Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ О·И ФИ ЛПВОЩЪИО¤˜ ВУТЫВИ˜ ¤¯Ф˘У

Ы˘У‰ВıВ› ЫˆЫЩ¿. ∏ ВУ‰В¯fiМВУЛ ЛПВОЩЪФПЛН›· МФЪВ› У· В›У·И ВИО›У‰˘УЛ БИ· ЩЛУ

·ÓıÚÒÈÓË ˙ˆ‹.

с ¡· ‚В‚·ИТУВЫЩВ ¿УЩФЩВ fiЩИ Л ‰·БО¿У· ЩФ˘ ЛПВОЩЪФ‰›Ф˘ О·И Ф ·ОЪФ‰¤ОЩЛ˜ БВ›ˆЫЛ˜

¤¯Ô˘Ó Û˘Ó‰Âı› Ì ·ÛÊ¿ÏÂÈ·.

с ªЛУ ЪФО·ПВ›ЩВ ‚П¿‚В˜ ЫЩ· ЛПВОЩЪФКfiЪ· О·ПТ‰И· ЩЪ·‚ТУЩ·˜ Щ·. ∞ФЫ˘У‰¤ЫЩВ Щ·

О·ПТ‰И· ЪФЩФ‡ ВИ¯ВИЪ‹ЫВЩВ У· МВЩ·ОИУ‹ЫВЩВ ЩЛ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜.

с ∞ФК‡БВЩВ У· ·ББ›˙ВЩВ Щ· ЛПВОЩЪИО¿ ·БТБИМ· ЩМ‹М·Щ· ЩЛ˜ Ы˘ЫОВ˘‹˜, О·ıТ˜ О·И ЩЛ

‰·БО¿У· ЩФ˘ ЛПВОЩЪФ‰›Ф˘ О·И ЩФУ ·ОЪФ‰¤ОЩЛ ЩЛ˜ БВ›ˆЫЛ˜.

с ¶¿УЩ· У· КЪФУЩ›˙ВЩВ ТЫЩВ Л Щ¿ЫЛ ЩФ˘ ‰ИОЩ‡Ф˘ У· В›У·И Л ›‰И· МВ ЩЛУ ·У·БЪ·КfiМВУЛ ЫЩЛУ

ИУ·О›‰· ¯·Ъ·ОЩЛЪИЫЩИОТУ ЩФ˘ МЛ¯·У‹М·ЩФ˜.

ñ ∫·Ù¿ ÙËÓ ·ÓÙÈηٿÛÙ·ÛË ÙˆÓ Î·Ïˆ‰›ˆÓ ‹ ÙˆÓ ÊȘ: ªÂÙ¿ ÙËÓ ·ÓÙÈηٿÛÙ·Û‹ ÙÔ˘˜ ÌÂ

ηÈÓÔ‡ÚÁÈ·, ·ÔÚÚ›„Ù ·Ì¤Ûˆ˜ Ù· ·ÏÈ¿ ηÏ҉ȷ Î·È Ù· ÊȘ. ∏ Û‡Ó‰ÂÛË ÛÙËÓ Ú›˙· ÂÓfi˜

¯·Ï·ÚÔ‡ ÊȘ Â›Ó·È ÂÈΛӉ˘ÓË.

с ŸПВ˜ ФИ Ы˘ЫОВ˘¤˜ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ Ф˘ ЩЪФКФ‰ФЩФ‡УЩ·И МВ Щ¿ЫЛ 230 Volt ı·

Ъ¤ВИ У· ¤¯Ф˘У ·ЫК¿ПВИ· ЩФ˘П¿¯ИЫЩФУ 16 amper

с ∫·Щ¿ ЩЛ ¯Ъ‹ЫЛ В¤ОЩ·ЫЛ˜ О·Пˆ‰›Ф˘ (М·П·УЩ¤˙·˜): ¡· ¯ЪЛЫИМФФИВ›ЩВ ·ФОПВИЫЩИО¿

ВБОВОЪИМ¤УФ О·ПТ‰ИФ В¤ОЩ·ЫЛ˜, О·Щ¿ППЛПФ БИ· ЩЛУ ИЫ¯‡ ЩФ˘ МЛ¯·У‹М·ЩФ˜. √И ·БˆБФ›

ı· Ъ¤ВИ У· ¤¯Ф˘У ‰И¿МВЩЪФ ЩФ˘П¿¯ИЫЩФУ 1,5 mm

2

. ∂¿Ó ÙÔ Î·ÏÒ‰ÈÔ Â›Ó·È Ù˘ÏÈÁ̤ÓÔ ÛÂ

М·П·УЩ¤˙· ı· Ъ¤ВИ У· ЩФ НВЩ˘П›НВЩВ ВУЩВПТ˜.

ñ ∂ÚÁ·Û›Â˜ ÛÙËÓ Ù¿ÛË ÙÔ˘ ‰ÈÎÙ‡Ô˘, .¯. ÛÙ· ηÏ҉ȷ, ÊȘ, Ú›˙˜ ÎÙÏ. ÌÔÚÔ‡Ó Ó·

‰ИВН¿БФ˘У МfiУФУ ВИ‰ИОВ˘М¤УФИ ЛПВОЩЪФПfiБФИ.

CE DECLARATION OF CONFORMITY (GB)

We declare under our sole responsibility that this product is in conformity

with the following standards or standardized documents:

EN60974-1, EN60974-6, EN60974-10

in accordance with the regulations:

2006/95/EC, 2004/108/EC

from 01-05-2006

ZWOLLE NL

J.A. Bakker - van Ingen

CEO Ferm BV

It is our policy to continuously improve our products and we therefore reserve the right to change

the product specification without prior notice.

Ferm BV • Lingenstraat 6 • 8028 PM Zwolle • The Netherlands

Ferm

14

GB

D

NL

F

E

P

I

S

FIN

N

DK

Page 15

Ferm 15

GB

D

NL

F

E

P

I

S

FIN

N

DK

SCHWEISSGERÄT FWM-45/140

Die Ziffern im nachstehenden Text verweisen auf die Abbildungen auf Seite 2

Um Ihre eigene Sicherheit und die Sicherheit Anderer zu gewährleisten, empfehlen

wir Ihnen, sich diese Bedienungsanleitung vor der ersten Inbetriebnahme gründlich

durchzulesen. Bewahren Sie diese Anleitung und die übrige Dokumentation

zusammen mit der Maschine auf.

Einführung

Beim Schmelzschweißen wird das Werkstückmaterial unter Einfluss zugeführter Wärme zum

Schmelzen gebracht. Beim Lichtbogenschweißen werden außerdem Schweißzusätze

(Elektroden) eingesetzt. Nach dem Erstarren ist die Schweißverbindung hergestellt.

Die erforderliche Wärme wird mittels eines elektrischen Bogens zwischen Elektrode und

Werkstück erzeugt. Für den Schweißvorgang ist eine hohe Stromstärke (45-140 A) mit relativ

niedriger Spannung (10–48 V) erforderlich. Ein Transformator im Schweißgerät bewirkt, dass

die Netzspannung (230 V) vermindert wird.

Das Gerät ist nicht für den gewerblichen Einsatz geeignet!

Inhalt

1. Technische Daten

2. Sicherheitsvorschriften

3. Montage des zubehörs

4. Bedienung

5. Wartung und Pflege

1. TECHNISCHE DATEN

Gerätedaten

Verpackungsinhalt

• Schweißgerät

• Schweißschild

Spannung

Frequenz

Schweißleistung

Zündspannung

Leistungsfaktor

Elektrodendurchmesser

Gewicht

Abmessungen

Thermoschutz

Netzkabel

Schweißkabel

230 V ~

50 Hz

45-140 A

≤ 48 V

0.57

1.6 - 3.2 mm

16.19 kg

350 x 220 x 170 mm

95 ºC (± 5 ºC)

H07RN-F3 x 1.5 mm

2

H01N2-D1 x 10 mm

2

°ВУИО¤˜ Ф‰ЛБ›В˜ ·ЫК·ПВ›·˜ БИ· Ы˘ЫОВ˘¤˜ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜

с √ ¯Ъ‹ЫЩЛ˜ ı· Ъ¤ВИ У· ¤¯ВИ ВО·И‰В˘ЩВ› ЫЩЛ ¯Ъ‹ЫЛ О·И ПВИЩФ˘ЪБ›· ЩФ˘ МЛ¯·У‹М·ЩФ˜.

с ºЪФУЩ›ЫЩВ ТЫЩВ Ф ¯ТЪФ˜ ВЪБ·Ы›·˜ У· В›У·И Щ·ОЩФФИЛМ¤УФ˜ О·И О·П¿ КˆЩИЫМ¤УФ˜.

с ¶ЪФЩФ‡ ВОЩВП¤ЫВЩВ ФФИ·‰‹ФЩВ ВЪБ·Ы›· Ы˘УЩ‹ЪЛЫЛ˜ ЫЩФ МЛ¯¿УЛМ· ı· Ъ¤ВИ У· ЩФ

·ФЫ˘У‰¤ВЩВ ·fi ЩЛУ Ъ›˙·.

с ¡· ·ФЫ˘У‰¤ВЩВ ЩФ МЛ¯¿УЛМ· ·fi ЩЛУ Ъ›˙· О¿ıВ КФЪ¿ Ф˘ ·ФМ·ОЪ‡УВЫЩВ ·fi ·˘Щfi.

с ªЛУ ¯ЪЛЫИМФФИВ›ЩВ ЩФ МЛ¯¿УЛМ· В¿У ‰ВУ ЩФ ¤¯ВЩВ ВБО·Щ·ЫЩ‹ЫВИ О·И Ы˘У·ЪМФПФБ‹ЫВИ

Û‡Ìʈӷ Ì ÙȘ Ô‰ËÁ›Â˜ ÙÔ˘ ÂÁ¯ÂÈÚȉ›Ô˘.

∂И‰ИО¤˜ Ф‰ЛБ›В˜ ·ЫК·ПВ›·˜ БИ· Ы˘ЫОВ˘¤˜ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜

с ∏ Ы˘БОfiППЛЫЛ ЪФО·ПВ› ЩЛУ ВОЩ›У·НЛ ЫИУı‹ЪˆУ О·И ЩЛБМ¤УФ˘ МВЩ¿ППФ˘. ¡· ¤¯ВЩВ

˘fi„Ë Û·˜ fiÙÈ ·˘Ùfi ÌÔÚ› Ó· ·ÔÙÂϤÛÂÈ ·ÈÙ›· ˘ÚηÁÈ¿˜, Û˘ÓÂÒ˜ ı· Ú¤ÂÈ Ó·

·ФМ·ОЪ‡УВЩВ fiП· Щ· В‡КПВОЩ· ˘ПИО¿ ·fi ЩФ ¯ТЪФ ВЪБ·Ы›·˜.

с ∂Н·ЫК·П›ЫЩВ ЩФУ О·Пfi ВН·ВЪИЫМfi ЩФ˘ ¯ТЪФ˘ ВЪБ·Ы›·˜. ∫·Щ¿ ЩЛ Ы˘БОfiППЛЫЛ ВОП‡ФУЩ·И

·¤ЪИ·, Щ· ФФ›· В›У·И ‚П·‚ВЪ¿ БИ· ЩЛУ ˘БВ›· Ы·˜.

с ªЛУ Ы˘БОФПП¿ЩВ ‰Ф¯В›· ‹ ЫˆП‹УВ˜ Ф˘ ВЪИ¤¯Ф˘У ‹ ВЪИВ›¯·У В‡КПВОЩ· ˘БЪ¿ ‹ ·¤ЪИ·

(О›У‰˘УФ˜ ˘ЪО·БИ¿˜ ‹ ¤ОЪЛНЛ˜).

с ªЛУ Ы˘БОФПП¿ЩВ ·УЩИОВ›МВУ· Ф˘ ¤¯Ф˘У О·ı·ЪИЫЩВ› МВ И‰И·›ЩВЪ· В‡КПВОЩ· ˘БЪ¿ ‹ ¤¯Ф˘У

‚·ММ¤УВ˜ ВИК¿УВИВ˜ (˘¿Ъ¯ВИ Иı·УfiЩЛЩ· ¤ОП˘ЫЛ˜ ВИО›У‰˘УˆУ ·ВЪ›ˆУ).

с ªЛУ ВОЩВПВ›ЩВ ЛПВОЩЪФЫ˘БОfiППЛЫЛ ЫВ ВЪИ‚¿ППФУ МВ ˘„ЛП‹ ˘БЪ·Ы›· ‹ ˘fi ‚ЪФ¯‹.

с £· Ъ¤ВИ У· ЪФЫЩ·ЩВ‡ВЩВ ¿УЩФЩВ Щ· М¿ЩИ· Ы·˜, ¯ЪЛЫИМФФИТУЩ·˜ ЩЛ М¿ЫО·

ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ Ф˘ Ы˘УФ‰В‡ВИ ЩФ МЛ¯¿УЛМ·.

с ¡· КФЪ¿ЩВ Б¿УЩИ· О·И ЫЩВБУfi ЪФЫЩ·ЩВ˘ЩИОfi ЪФ˘¯ИЫМfi, Ф ФФ›Ф˜ У· МЛУ ¤¯ВИ ˘БЪФ‡˜

ÏÂΤ‰Â˜ ·fi Ï¿‰È ‹ ¿ÏÏÔ˘˜ Ú‡Ô˘˜.

ñ ¶ÔÏϤ˜ ÊÔÚ¤˜, ÙÔ ÙËÁ̤ÓÔ ˘ÏÈÎfi Ô˘ ı· Ú¤ÂÈ Ó· ·Ê·ÈÚÂı› η›ÂÈ Î·È ÂÓ‰¤¯ÂÙ·È Ó·

ЪФО·П¤ЫВИ ЫФ‚·Ъfi ЩЪ·˘М·ЩИЫМfi ЩˆУ М·ЩИТУ О·Щ¿ ЩЛУ ·К·›ЪВЫ‹ ЩФ˘. ¡· КФЪ¿ЩВ

¿УЩФЩВ ЪФЫЩ·ЩВ˘ЩИО¿ Б˘·ПИ¿ О·И Б¿УЩИ·.

с ∏ ˘ВЪИТ‰Л˜ ·ОЩИУФ‚ФП›· Ф˘ ВО¤МВЩ·И О·Щ¿ ЩЛ Ы˘БОfiППЛЫЛ МФЪВ› У· ЪФО·П¤ЫВИ

ВБО·‡М·Щ· ЫЩФ ‰¤ЪМ· Ы·˜. ™˘УВТ˜, ı· Ъ¤ВИ У· КФЪ¿ЩВ ¿УЩФЩВ О·Щ¿ППЛПФ

ЪФЫЩ·ЩВ˘ЩИОfi ЪФ˘¯ИЫМfi.

с ∏ Ы˘БОВОЪИМ¤УЛ Ы˘ЫОВ˘‹ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ‰И·ı¤ЩВИ Ы‡ЫЩЛМ· ЪФЫЩ·Ы›·˜ ·fi ЩЛУ

˘ВЪКfiЪЩИЫЛ. ™˘УВТ˜, ЫВ ВЪ›ЩˆЫЛ ˘ВЪКfiЪЩИЫЛ˜, Л Ы˘ЫОВ˘‹

ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ Щ›ıВЩ·И ·˘ЩfiМ·Щ· ВОЩfi˜ ПВИЩФ˘ЪБ›·˜. ∏ Ы˘ЫОВ˘‹

ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ВУВЪБФФИВ›Щ·И О·И ¿ПИ ·˘ЩfiМ·Щ· fiЩ·У „˘¯ıВ› В·ЪОТ˜.

с ∫·Щ¿ ЩЛ ‰И¿ЪОВИ· ЩЛ˜ Ы˘БОfiППЛЫЛ˜ О·И ЩЛ˜ „‡НЛ˜ ˘¿Ъ¯ВИ Л Иı·УfiЩЛЩ· ЩФ ·УЩИОВ›МВУФ

У· ·Ъ·МФЪКˆıВ›, ПfiБˆ ЩˆУ Щ¿ЫВˆУ Ф˘ ·У·Щ‡ЫЫФУЩ·И. ∞˘Щfi ı· Ъ¤ВИ У· ЩФ ¤¯ВЩВ

Ы˘УВ¯Т˜ ˘fi„Л Ы·˜.

с ªФЪФ‡У У· ¯ЪЛЫИМФФИФ‡УЩ·И МfiУФУ Ы˘БОФППЛЩИОФ› ·БˆБФ›, ФИ ФФ›ФИ В›У·И

ÚÔÌËıÂ˘Ì¤ÓÔÈ (O/ 10 mm

2

МВ П¿ЫЩИ¯Ф ЪФК˘П·БМ¤УФИ Ы˘БОФППЛЩИОФ› ·БˆБФ›).

с ™ЩФ˘˜ ¯ТЪФ˘˜ МВ ·ВИП‹ ˘ЪО·БИ¿˜ Л ¤ОЪЛНЛ˜ ИЫ¯‡Ф˘У ВИ‰ИО¤˜ ‰И·Щ¿НВИ˜.

с √И Ы˘БОФППЛЩИО¤˜ Ы˘У‰¤ЫВИ˜, ФИ ФФ›В˜ ВОı¤ЩФУЩ·И ЫВ МВБ¿ПВ˜ ВУЩ¿ЫВИ˜ О·И Ъ¤ВИ У·

ВОПЛЪТУФ˘У ФЪИЫМ¤УВ˜ ·ЫК·ПИЫЩИО¤˜ ··ИЩ‹ЫВИ˜, МФЪФ‡У У· Ъ·БМ·ЩФФИФ‡УЩ·И

МfiУФУ ·fi ВИ‰ИО¿ ВО·И‰В˘М¤УФ˘˜ О·И ВНВЩ·ЫМ¤УФ˘˜ Ы˘БОФППЛЩ¤˜. ¶.¯: ИВЫЩИОФ›

П¤‚ЛЩВ˜, ЫИ‰ЛЪФЩЪФ¯И¤˜, ВН·ЪЩЛМ¤УВ˜ Ы˘ЫОВ˘¤˜ ЩˆУ ВИО·ıФ˘М¤УˆУ, ОЩП.

ñ ¶ÚÔÛÔ¯‹: ÚÔÛı¤ÛÙ ÙÔÓ ·ÎÚÔ‰¤ÎÙË Á›ˆÛ˘ ¿ÓÙ· ÙÔ ÔÈÔ ÎÔÓÙ¿ ÚÔ˜ ÙÔÓ ÙfiÔ

Ы˘БОfiППЛЫЛ˜, ТЫЩВ ЩФ ЪВ‡М· Ы˘БОfiППЛЫЛ˜ У· МФЪВ› У· ЪФ¯ˆЪВ› МВ ЩФУ ОФУЩИУfiЩВЪФ

‰˘У·Щfi ‰ЪfiМФ ·fi ЩФ ЛПВОЩЪfi‰ИФ ЪФ˜ ЩФУ ·ОЪФ‰¤ОЩЛ БВ›ˆЫЛ˜. ¶ФЩ¤ МЛУ Ы˘У‰¤ВЩВ

Ferm

106

GB

D

NL

F

E

P

I

S

GR

N

DK

Page 16

Ferm 105

GB

D

NL

F

E

P

I

S

GR

N

DK

¶ЪfiЩ˘Ф БИ· МЛ¯·У‹М·Щ· ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ¯ВИЪfi˜, МВВЪИФЪИЫМ¤УФ

Ы˘УЩВПВЫЩ‹ ПВИЩФ˘ЪБ›·˜.

¢·БО¿У· ЛПВОЩЪФ‰›Ф˘

∞ÎÚÔ‰¤ÎÙ˘ Á›ˆÛ˘

¶ÙÒÛË Ù¿Û˘

ªÔÓÔÊ·ÛÈÎfi˜ ÌÂÙ·Û¯ËÌ·ÙÈÛÙ‹˜

°ÂȈ̤ÓÔ˜ ÚÂ˘Ì·ÙÔÏ‹Ù˘

¢И¿МВЩЪФ˜ ЛПВОЩЪФ‰›Ф˘

AÛÊ¿ÏÂÈ· 16A

ª¤БИЫЩЛ ¤УЩ·ЫЛ ЪˆЩВ‡ФУЩФ˜ ЪВ‡М·ЩФ˜ ЫВ ·М¤Ъ

ŒÓÙ·ÛË ‰Â˘ÙÂÚ‡ÔÓÙÔ˜ Ú‡̷ÙÔ˜ Û ·Ì¤Ú

ÃÚfiÓÔ˜ ÂÁÁÚ·Ê‹˜, ¯ÚfiÓÔ˜ ÌÂٷ͇ ÙÔ˘ reset (ÂÁ¯Â›ÚÈÛË Û‡Ó‰ÂÛ˘) Î·È Ú‡ıÌÈÛ˘

(ÂÁ¯Â›ÚÈÛË ·ÔÛ‡Ó‰ÂÛ˘) Ù˘ Û˘Û΢‹˜ Ù˘ ıÂÚÌ·ÓÙÈ΋˜ ·ÔÎÔ‹˜.

ÃÚfiÓÔ˜ ÙÔ˘ reset, ¯ÚfiÓÔ˜ ÌÂٷ͇ Ù˘ Ú‡ıÌÈÛ˘ (ÂÁ¯Â›ÚÈÛË ·ÔÛ‡Ó‰ÂÛ˘) ηÈ

ÙÔ˘ reset (ÂÁ¯Â›ÚÈÛË Û‡Ó‰ÂÛ˘) Ù˘ Û˘Û΢‹˜ Ù˘ ıÂÚÌ·ÓÙÈ΋˜ ·ÔÎÔ‹˜.

S∫·ЩЛБФЪ›· ЪФЫЩ·Ы›·˜. ™ЩВБ·Уfi БИ· ЫˆМ·Щ›‰И· МВ ‰И¿МВЩЪФ ¤ˆ˜ О·И 12 mm,

О·ıТ˜ О·И БИ· О·Щ·ОfiЪ˘КЛ ЩТЫЛ ЫЩ·БfiУˆУ УВЪФ‡. ¢И·ОФ‹ ПВИЩФ˘ЪБ›·˜ ЫВ

ВЪ›ЩˆЫЛ ·У›¯УВ˘ЫЛ˜ УВЪФ‡ .

∫·ЩЛБФЪ›· МfiУˆЫЛ˜

∆¿ЫЛ ПВИЩФ˘ЪБ›·˜ ЫВ ‚ФПЩ

∆¿ÛË ‰ÈÎÙ‡Ô˘ Û ‚ÔÏÙ

U

1

U

0

H

IP21S

r

(S)

I

2

I

1

EN60974-6

• Drahtbürste/Schlackenhammer

• Bedienungsanleitung

• Sicherheitsvorschriften

• Garantiekarte

Produktinformationen

Abb. 1

1. Temperaturanzeige

2. Ein-/Ausschalter

3. Drehschalter zur Einstellung der Stromstärke

4. Schweißkabel mit Elektrodenhalter (vormontiert)

5. Massekabel mit Werkstückklemme (vormontiert)

6. Gummifuß

7. Handgriff

8. Lüftungsschlitze

9. Drahtbürste/Schlackenhammer

10. Schweißschild

11. Elektroden

Tabel: Einstellung und Gebrauch

2. SICHERHEITSVORSCHRIFTEN

Erläuterung der Symbole

Anweisungen sorgfältig lesen.

Ø Elektrode (mm) Stromstärke (A) Geeignet u.a. für:

1,6 45 - 55 Materialdicke ≤ 2 mm

Reparatur eines Fahrrads (Mopeds)

2 50 - 75 Materialdicke 2 - 3 mm

Reparatur Wandregal

2,5 70 - 100 Materialdicke 4 - 5 mm

Gartentor, Spielgerät

3,2 95 - 150 Materialdicke 6 - 7 mm

Carport, Garage

4 130 - 220 Materialdicke 8 - 12 mm

Konstruktion (schwer)

5 190 - 250 Materialdicke ≥ 12 mm

Konstruktion (sehr schwer)

Ferm

16

GB

D

NL

F

E

P

I

S

FIN

N

DK

Page 17

Ferm 17

GB

D

NL

F

E

P

I

S

FIN

N

DK

Übereinstimmung mit den jeweils maßgeblichen EU-Sicherheitsrichtlinien.

Lebens- und Verletzungsgefahr und Gefahr von Beschädigungen am Gerät bei

Nichteinhaltung der Sicherheitsvorschriften in dieser Anleitung.

Deutet das Vorhandensein elektrischer Spannung an.

Ziehen Sie, falls das Kabel beschädigt wird und auch während Wartungsarbeiten,

sofort den Netzstecker.

Umstehende fernhalten.

Gegen Regen Schutzen

Schutzbrille und Gehörschutz tragen.

Schutzhandschuhe tragen.

Schadhafte und/oder entsorgte elektrische oder elektronische Geräte müssen an

den dafür vorge sehenen Recycling-Stellen abgegeben werden.

Beim Schweißen immer ein Schweißschild verwenden

Schutzkleidung tragen

Symbol für Schweißgeräte zu brauchen im Atmosphär mit Gefähr für elektrische

Spannung

Norm bezüglich Schweißstromquellen zum Lichtbogenhandschweißen für

begrenzten Betrieb

Elektrodenhalter

Masseklemmme

EN60974-6

2. √¢∏°ÿ∂™ °π∞ ∆∏¡ ∞™ºÕ§∂π∞

∂ÂÍ‹ÁËÛË ÙˆÓ Û˘Ì‚fiψÓ

¢И·‚¿ЫЩВ ЪФЫВОЩИО¿ ЩИ˜ Ф‰ЛБ›В˜.

CE ™˘ММfiЪКˆЫЛ МВ Щ· ВК·ЪМФЫЩ¤· ∂˘Ъˆ·˚О¿ ЪfiЩ˘· ·ЫК·ПВ›·˜.

∂ИЫЛМ·›УВИ ЩФУ О›У‰˘УФ ЪfiОПЛЫЛ˜ ЫˆМ·ЩИОТУ ‚П·‚ТУ, ı·У¿ЩФ˘ ‹ ‚П¿‚Л˜ ЫЩФ

МЛ¯¿УЛМ· ЫВ ВЪ›ЩˆЫЛ МЛ Щ‹ЪЛЫЛ˜ ЩˆУ Ф‰ЛБИТУ Ф˘ ·У·БЪ¿КФУЩ·И ЫВ ·˘Щfi ЩФ

ВБ¯ВИЪ›‰ИФ.

∂ИЫЛМ·›УВИ ЩФУ О›У‰˘УФ ЛПВОЩЪФПЛН›·˜.

µÁ¿ÏÙ ·Ì¤Ûˆ˜ ÙÔ ÊȘ ·fi ÙËÓ Ú›˙· Û ÂÚ›ÙˆÛË Ô˘ ˘ÔÛÙ› ‚Ï¿‚Ë ÙÔ

ηÏÒ‰ÈÔ Ú‡̷ÙÔ˜ Î·È Î·Ù¿ ÙË ‰È¿ÚÎÂÈ· ÂÚÁ·ÛÈÒÓ Û˘ÓÙ‹ÚËÛ˘.

∫Ъ·Щ‹ЫЩВ ЫВ ·fiЫЩ·ЫЛ ЩФ˘˜ ·ЪВ˘ЪИЫОФМ¤УФ˘˜.

¢ВУ ı· Ъ¤ВИ У· ¯ЪЛЫИМФФИВ›Щ·И ЫЩЛ ‚ЪФ¯‹.

ºÔÚ¿Ù Á˘·ÏÈ¿ ·ÛÊ·Ï›·˜ Î·È ˆÙÔ·Û›‰Â˜.

¡· ÊÔÚ¿Ù ÚÔÛٷ٢ÙÈο Á¿ÓÙÈ·.

∂П·ЩЩˆМ·ЩИО¿ О·И / ‹ ·ФЪЪИММ¤У· ЛПВОЩЪИО¿ ‹ ЛПВОЩЪФУИО¿ ·УЩИОВ›МВУ· Ъ¤ВИ

У· Ы˘ПП¤БФУЩ·И ЫЩИ˜ О·Щ¿ППЛПВ˜ ЩФФıВЫ›В˜ ·У·О˘ОПТЫВˆ˜.

∫·Щ¿ ЩЛ Ы˘БОfiППЛЫЛ, У· ¯ЪЛЫИМФФИВ›ЩВ ¿УЩФЩВ М¿ЫО·.

¡· ÊÔÚ¿Ù ÚÔÛٷ٢ÙÈÎfi ÚÔ˘¯ÈÛÌfi.

∆Ф Ы‡М‚ФПФ ·˘Щfi ¯ЪЛЫИМФФИВ›Щ·И БИ· У· ˘Ф‰В›НВИ ЛБ¤˜ ЩЪФКФ‰ФЫ›·˜

ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜, Ф˘ В›У·И О·Щ¿ППЛПВ˜ БИ· ЩЛУ ВОЩ¤ПВЫЛ ВЪБ·ЫИТУ

ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ ЫВ ВЪИ‚¿ППФУЩ· МВ ·˘НЛМ¤УФ О›У‰˘УФ ЛПВОЩЪФПЛН›·˜.

Ferm

104

GB

D

NL

F

E

P

I

S

GR

N

DK

Page 18

Ferm 103

GB

D

NL

F

E

P

I

S

GR

N

DK

¶ÂÚȯfiÌÂÓ· Û˘Û΢·Û›·˜

1 ™˘ЫОВ˘‹ Ы˘БОfiППЛЫЛ˜

1 ª¿ЫО· ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜

1 ™˘ЪМ¿ЩИУЛ ‚Ф‡ЪЩЫ·/М·ЩЫ·ОfiУИ

1 ∂Б¯ВИЪ›‰ИФ ¯Ъ‹ЫЛ˜

1 √‰ЛБ›В˜ БИ· ЩЛУ ·ЫК¿ПВИ·

1 ∫¿ЪЩ· ВББ‡ЛЫЛ˜

∂П¤НЩВ ЩФ МЛ¯¿УЛМ·, О·ıТ˜ О·И Щ· МВМФУˆМ¤У· М¤ЪЛ О·И ВН·ЪЩ‹М·Щ·, БИ· У· ‰В›ЩВ ·У ¤¯Ф˘У

¿ıВИ ˙ЛМИ¿ О·Щ¿ ЩЛ МВЩ·КФЪ¿.

¶ПЛЪФКФЪ›В˜ ЪФ˚fiУЩФ˜

∂ÈÎ. A

1. ∂У‰ВИОЩИО‹ П˘¯У›· ıВЪМФОЪ·Ы›·˜

2. ¢И·ОfiЩЛ˜ ПВИЩФ˘ЪБ›·˜ (On/Off)

3. ¶ВЪИЫЩЪФКИОfi˜ ВИПФБ¤·˜ БИ· ЩЛ Ъ‡ıМИЫЛ ЩЛ˜ ¤УЩ·ЫЛ˜ ЩФ˘ ЪВ‡М·ЩФ˜

4. ∫·ПТ‰ИФ ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜ МВ ‰·БО¿У· БИ· ЛПВОЩЪfi‰ИФ

5. ∫·ÏÒ‰ÈÔ Á›ˆÛ˘ Ì ‰·Áοӷ

6. ∂Ï·ÛÙÈ΋ Ù¿·

7. §·‚‹

8. ∞УФ›БМ·Щ· ВН·ВЪИЫМФ‡

9. ™˘ÚÌ¿ÙÈÓË ‚Ô‡ÚÙÛ·/Ì·ÙÛ·ÎfiÓÈ

10. ª¿ЫО· ЛПВОЩЪФЫ˘БОfiППЛЫЛ˜

11. ∏ПВОЩЪfi‰И·

T¯ÓÈΤ˜ ÚԉȷÁڷʤ˜

∏ПВОЩЪfi‰ИФ (mm) ŒУЩ·ЫЛ ЪВ‡М·ЩФ˜ (A) ∫·Щ¿ППЛПФ, МВЩ·Н‡ ¿ППˆУ, БИ·:

1,6 45-55 ¶¿¯Ô˜ ˘ÏÈÎÔ‡ ≤ 2 mm

∂ÈÛ΢¤˜

Ô‰ËÏ¿ÙˆÓ/ÌÔÙÔÔ‰ËÏ¿ÙˆÓ

2 50-75 ¶¿¯Ô˜ ˘ÏÈÎÔ‡ 2-3 mm

∂ИЫОВ˘‹ ‚¿ЫВˆУ -ЫЩЛЪИБМ¿ЩˆУ

2,5 70-100 ¶¿¯Ô˜ ˘ÏÈÎÔ‡ 4-5 mm

¶ВЪИКЪ¿НВИ˜, МИОЪ¤˜

ЫИ‰ЛЪФО·Щ·ЫОВ˘¤˜

3,2 95-150 ¶¿¯Ô˜ ˘ÏÈÎÔ‡ 6-7 mm

°Î·Ú¿˙, ÔÈÎȷΤ˜ ÛȉËÚÔηٷÛ΢¤˜

4 130-220 ¶¿¯Ô˜ ˘ÏÈÎÔ‡ 8-12 mm

µ·ÚȤ˜ ÛȉËÚÔηٷÛ΢¤˜

5 190-250 ¶¿¯Ô˜ ˘ÏÈÎÔ‡ ≥ 12 mm

¶Ôχ ‚·ÚȤ˜ ÛȉËÚÔηٷÛ΢¤˜

Abfallende Spannung

Einphasentransformator

Geerdeter Netzstecker

Elektrodendurchmesser

Sicherung 16 A

Maximale Primärstromstärke in Ampere

Sekundärstromstärke in Ampere

Ladezeit, Zeit zwischen dem Reset (ON-Betrieb) und dem Set (OFF-Betrieb) des

thermischen Abschaltmechanismus.

Reset-Zeit, Zeit zwischen dem Set (OFF-Betrieb) und dem Reset (ON-Betrieb) des

thermischen Abschaltmechanismus.

Schutzart. Schutz vor Berührung mit mittelgroßen Fremdkörpern (Ø >12 mm) und

senkrecht fallendem Tropfwasser.

Isolationsklasse

Leerlaufspannung in Volt

Netzspannung in Volt

Allgemeine Sicherheitsvorschriften für Schweißgeräte

• Der Gerätebediener muss über Gebrauch, Einstellung und Bedienung des Geräts

instruiert sein.

• Sorgen Sie für eine gut beleuchtete und saubere Arbeitsumgebung.

• Ziehen Sie immer den Stecker aus der Steckdose, ehe Sie Wartungsarbeiten am Gerät

ausführen.

• Ziehen Sie den Stecker aus der Steckdose, wenn Sie das Gerät zurücklassen.

r

(S)

U

1

U

0

H

IP21S

I

2

I

1

Ferm

18

GB

D

NL

F

E

P

I

S

FIN

N

DK

Page 19

Ferm 19

GB

D

NL

F

E

P

I

S

FIN

N

DK

• Verwenden Sie das Gerät nicht, ehe es den Anweisungen in der Anleitung gemäß völlig

montiert und installiert ist.

• Betätigen Sie Schweißgeräte nicht in explosionsgefähr-deten Atmosphären, zum Beispiel

in der Nähe von entzündbaren Flüssigkeiten, Gasen oder Staub. Scheißgeräte erzeugen

Funken, durch die Staub oder Dämpfe entzündet werden können.

Spezifische Sicherheitsvorschriften für Schweißgeräte

• Beim Schweißen werden Funken und heißes Metall frei. Dadurch entsteht Brandgefahr!

Entfernen Sie daher alles Brennbare aus dem Arbeitsbereich.

• Sorgen Sie für ausreichende Lüftung des Arbeitsbereichs. Beim Schweißen werden

gesundheitsgefährdende Gase frei.

• Führen Sie keine Schweißarbeiten an Behältern oder Leitungen aus, die brennbare

Flüssigkeiten oder Gase enthalten (Brand- oder Explosionsgefahr).

• Führen Sie keine Schweißarbeiten an Werkstücken aus, die mit leicht entflammbaren

Flüssigkeiten gereinigt wurden oder eine lackierte Oberfläche haben (dabei können

schädliche Gase frei werden).

• Arbeiten Sie nicht in feuchten oder nassen Umgebungen und schweißen Sie nicht im Regen.

• Die Augen müssen immer mit dem mitgelieferten Schweißschild geschützt werden.

• Tragen Sie trockene und nicht mit Öl oder Schmutz durchtränkte Handschuhe und

Schutzkleidung.

• Die abzuklopfende Schlacke kann glühend heiß sein. Das Entfernen der Schlacke kann

dann ernsthafte Augenverletzungen zur Folge haben. Tragen Sie immer eine Schutzbrille

und Handschuhe.

• Beim Schweißen können durch ultraviolette Strahlung Hautverbrennungen entstehen.

Tragen Sie daher angemessene Schutzkleidung.

• Das Schweißgerät ist mit einem Überlastungsschutz ausgestattet. Das bedeutet, dass es

bei Überlastung automatisch ausgeschaltet wird. Wenn es ausreichend abgekühlt ist, wird

das Gerät automatisch wieder eingeschaltet.

• Berücksichtigen Sie, dass das Werkstück sich während des Schweiß- und

Abkühlvorgangs durch Spannungen verformen kann.

• Es dürfen nur die im Lierumfang enthaltenen Schweißleitungen verwendet ( Ø 10 mm

2

Gummischweißleitung werden).

• In Feuer- und Explosionsgefährdeten Räumen gelten besondere Vorschriften.

• Schweißverbindungen, die großen Beanspruchungen ausgesetzt sind und bestimmte

Sicherheitsforderungen erfüllen müssen, dürfen nur von besonders ausgebildeten und

geprüften Schweißem ausgeführt werden. Beispiel sind: Druckkessel, Laufschienen,

Anhängerkupplungen usw.

• Achtung: Schliessen Sie die Masseklemme stets so nahe wie möglich an die

Schweißstelle an, so dass der Schweißstrom den kürzestmöglichen Weg von der

Elektrode zur Masseklemme nehmen kann.

Verbinden Sie die Masseklemme niemals mit dem Gehäuse des Schweißgerätes!

Schliessen Sie die Masseklemme niemals an geerdeten Teilen an, die weit vom Werkstück

entfernt liegen, z.B. einem Wasserrohr in einer anderen Ecke des Raumes. Andernfalls

könnte es dazu kommen, dass das Schutzleitersystem des Raumes, in dem Sie

schweißen, beschädigt wird.

• Die Absicherungen der Zuleitungen zu den Netzsteckdosen muss den Vorschriften

entsprechen (VDE 0100). Schutzkontaktsteckdosen dürfen mit max 16A (Typen und

technische Daten: RT14-20, Ø 10 x 38, AC 400 V 16A. IEC 60269. Traege ausloesen.

™À™∫∂À∏ ∏§∂∫∆ƒ√™À°∫√§§∏™∏™ FWM-45/140

√È ·ÚÈıÌÔ› Ô˘ ÂÚȤ¯ÔÓÙ·È ÛÙÔ Î›ÌÂÓÔ ·Ó·Ê¤ÚÔÓÙ·È ÛÙ· ‰È·ÁÚ¿ÌÌ·Ù·, Ô˘ ˘¿Ú¯Ô˘Ó ÛÙȘ

ÛÂÏ›‰Â˜ 2

°И· ЩЛ ‰ИО‹ Ы·˜ ·ЫК¿ПВИ·, ·ПП¿ О·И БИ· ЩЛУ ·ЫК¿ПВИ· ЩˆУ ¿ППˆУ, ЪФЩВ›УФ˘МВ У·

‰И·‚¿ЫВЩВ ЪФЫВОЩИО¿ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ Ф‰ЛБИТУ ЪИУ ·fi ЩЛ ¯Ъ‹ЫЛ ·˘ЩФ‡ ЩФ˘

ЪИФУИФ‡. ¡· К˘П¿ЫЫВЩВ ·˘Щfi ЩФ ВБ¯ВИЪ›‰ИФ Ф‰ЛБИТУ, О·ıТ˜ О·И ЩФ ˘ПИОfi

ЩВОМЛЪ›ˆЫЛ˜ Ф˘ Ы˘УФ‰В‡ВИ ЩФ ЪИfiУИ БИ· МВППФУЩИО‹ ·У·КФЪ¿.

∂ÈÛ·ÁˆÁ‹

∏ ‰И·‰ИО·Ы›· Ы˘БОfiППЛЫЛ˜ МВ Щ‹НЛ ¯ЪЛЫИМФФИВ›Щ·И БИ· ЩЛУ Щ‹НЛ ЩФ˘ ˘ПИОФ‡ ЩФ˘ ·УЩИОВИМ¤УФ˘ Ф˘

ЪfiОВИЩ·И У· Ы˘БОФППЛıВ›, ˘fi ЩЛУ В›‰Ъ·ЫЛ ЩЛ˜ ‰ИФ¯ВЩВ˘fiМВУЛ˜ ıВЪМfiЩЛЩ·˜. ∂›ЫЛ˜, БИ· ЩЛ

Ы˘БОfiППЛЫЛ МВ ЛПВОЩЪИОfi ЩfiНФ (ЛПВОЩЪФЫ˘БОfiППЛЫЛ) ¯ЪЛЫИМФФИВ›Щ·И О·И ˘ПИОfi Ы˘БОfiППЛЫЛ˜

(ЛПВОЩЪfi‰И·). ∏ Ы˘БОfiППЛЫЛ Ъ·БМ·ЩФФИВ›Щ·И МВЩ¿ ЩЛ ЫЩВЪВФФ›ЛЫЛ ЩФ˘ ˘ПИОФ‡.

∏ ··ИЩФ‡МВУЛ ıВЪМfiЩЛЩ· ЪФ¤Ъ¯ВЩ·И ·fi ЩФ ЛПВОЩЪИОfi ЩfiНФ Ф˘ ‰ЛМИФ˘ЪБВ›Щ·И О·И

‰И·ЩЛЪВ›Щ·И МВЩ·Н‡ ЩФ˘ ЛПВОЩЪФ‰›Ф˘ О·И ЩФ˘ ·УЩИОВИМ¤УФ˘. ∏ ‰И·‰ИО·Ы›· Ы˘БОfiППЛЫЛ˜

··ИЩВ› ЪВ‡М· ˘„ЛП‹˜ ВУЩ¿ЫВˆ˜ (45-140 A) МВ Ы¯ВЩИО¿ ¯·МЛП‹ Щ¿ЫЛ (10–48 V). ŒУ·˜

МВЩ·Ы¯ЛМ·ЩИЫЩ‹˜ ЫЩФ ВЫˆЩВЪИОfi ЩЛ˜ Ы˘ЫОВ˘‹˜ ВН·ЫК·П›˙ВИ ЩФУ ˘Ф‚И‚·ЫМfi ЩЛ˜ Щ¿ЫЛ˜ ЩФ˘

‰ИОЩ‡Ф˘ (230 V).

∆Ф Ы˘БОЪfiЩЛМ· ‰ВУ В›У·И О·Щ¿ППЛПФ БИ· ВИ¯ВИЪЛМ·ЩИО‹ ¯Ъ‹ЫЛ!

¶ÂÚȯfiÌÂÓ·

1. ¶ПЛЪФКФЪ›В˜ БИ· ЩФ МЛ¯¿УЛМ·

2. √‰ËÁ›Â˜ ÁÈ· ÙËÓ ·ÛÊ¿ÏÂÈ·

3. ™˘Ó·ÚÌÔÏfiÁËÛË

4. ÃÚ‹ÛË

5. ™¤Ú‚Ș Î·È Û˘ÓÙ‹ÚËÛË

1. ¶§∏ƒ√º√ÿ∂™ °π∞ ∆√ ª∏ÃÕ¡∏ª∞

T¯ÓÈΤ˜ ÚԉȷÁڷʤ˜

∆¿ЫЛ

™˘¯УfiЩЛЩ·

πЫ¯‡˜ Ы˘БОfiППЛЫЛ˜

∆¿ЫЛ ¤У·ЪНЛ˜ ЩfiНФ˘

™˘УЩВПВЫЩ‹˜ ИЫ¯‡Ф˜

¶¿¯Ф˜ ЛПВОЩЪФ‰›Ф˘

µ¿ЪФ˜

¢И·ЫЩ¿ЫВИ˜

£ВЪМИО‹ ЪФЫЩ·Ы›·

О‡ЪИФs О·ПТ‰ИФ

™˘БОФППЛЩ‹˜ О·ПТ‰ИФ

230 V ~

50 Hz

45-140 A

≤ 48 V

0.57

1.6 - 3.2 mm

16.19 kg

350 x 220 x 170 mm

95 ºC (± 5 ºC)

H07RN-F3 x 1.5 mm

2

H01N2-D1 x 10 mm

2

Ferm

102

GB

D

NL

F

E

P

I

RUS

GR

N

DK

Page 20

Ferm 101

GB

D

NL

F

E

P

I

RUS

FIN

N

DK

Неисправный и/или бракованный электрический или электронный прибор

должен быть утилизирован должным образом.

Гарания

Услови я гарантии вы найдёте в отдельно прилагаемом гарантийном талоне.

CEДЕКЛАРАЦИЯ О СООТВЕТСТВИИ(RUS)

Под нашу исключительную ответственность удостоверяем, что данное изделие

удовлетворяет следующим стандартам и нормативным документам:

EN60974-1, EN60974-6, EN60974-10

согласно правилам:

2006/95/EC, 2004/108/EC

01-05-2006

НИДЕРЛАНДЫ

J.A. Bakker - van Ingen

CEO Ferm BV

Постоянное улучшение нашей продукции является нашей политикой и, поэтому, мы

оставляем за собой право на изменение технических характеристик продукции без

предварительного уведомления.

Ferm BV•Lingenstraat 6•8028 PMZwolle•Нидерланды

Hersteller: Chint) abgesichert werden (Sicherungen oder Leitungsschutzschalter). Höhere

Absicherungen können Leitungsbrand bzw. Gebäudebrandschäden zur Folge haben.

Elektrische Sicherheit

In folgenden Fällen muss das Gerät sofort ausgeschaltet werden:

• Fehler im Stecker/Netzkabel oder beschädigtes Kabel

• Defekter Schalter

• Qualm oder Gestank von verschmorter Isolierung

Abhängig von den Netzstrombedingungen am Anschlusspunkt kann die

Schweißstromquelle bei anderen Stromnutzern Störungen verursachen. Wenn Sie

diesbezüglich irgendwelche Zweifel haben, erkundigen Sie sich bitte bei Ihrem

Stromversorgungsunternehmen.

• Achten Sie darauf, dass die Verbindung zwischen Schweißgerät und Lichtnetz fehlerfrei

ist. Jede Elektroschockgefahr kann lebensbedrohlich sein.

• Sorgen Sie für einwandfreie Verbindungen, sowohl für den Elektrodenhalter als die

Masseklemme.

• Verhindern Sie, dass Stromkabel kaputt gezogen werden können. Ehe das Schweißgerät

versetzt wird, müssen die Kabel erst getrennt werden.

• Vermeiden Sie jeden Kontakt mit dem stromführenden Teil des Schweißgeräts, dem

Elektrodenhalter und der Masseklemme.

• Überprüfen Sie immer, ob die Netzspannung mit dem auf dem Typenschild des Geräts

angegebenen Wert übereinstimmt.

• Nach Ersetzen eines Kabels oder Steckers, muss das alte Kabel bzw. der alte Stecker

sofort weggeworfen werden. Das Einstecken eines losen Kabels in die Netzsteckdose ist

gefährlich.

• Verwenden Sie für alle Schweißgeräte mit 230 Volt Sicherungen von mindestens 16 Ampere.

• Verwenden Sie ausschließlich zugelassene Verlängerungskabel, die für die

Leistungsaufnahme des Geräts geeignet sind. Die Leiter müssen einen Querschnitt von

mindestens 1,5 mm

2

haben. Bei Verwendung einer Kabeltrommel muss das Kabel immer

ganz abgewickelt werden.

• Arbeiten auf der Netzspannungsseite, z.B. an Kabeln, Steckern, Steckdosen usw. nur von

einer Elektrofachkraft ausführen lassen.

3.MONTAGE DES ZUBEHÖR

Achten Sie beim Anbringen von Zubehör darauf, dass der Stecker aus der

Steckdose gezogen ist.

Aufstellen des Geräts

• Stellen Sie das Schweißgerät in einem trockenen, sauberen Raum (frei von Eisenstaub,

Staub und Lack) auf.

• Das Gerät muss auf einem stabilen, flachen Untergrund mit mindestens 20 cm Abstand zur

Wand stehen.

Ferm

20

GB

D

NL

F

E

P

I

S

FIN

N

DK

Page 21

Ferm 21

GB

D

NL

F

E

P

I

S

FIN

N

DK

• Vor Regen und greller Sonne schützen.

Schweißschild

Abb. 2

• Den Handgriff auf das Schweißschild schieben, bis er einrastet.

• Das helle Glas (Schutzglas) vor dem dunklen Schweißglas anbringen. Beide Gläser in die

dafür vorgesehene Öffnung schieben.

• Achten Sie darauf, dass die Gläser so angebracht sind, dass kein (schädliches) Licht mehr

durch die Öffnung eindringen kann.

• Wenn die Sicht auf das Werkstück beim Schweißen nicht mehr ausreicht, muss das helle

Schutzglas ausgewechselt werden. Das Ersetzen des dunklen Schweißglases ist

erheblich kostspieliger als das Ersetzen des hellen Schutzglases.

Einsetzen einer neuen Elektrode

Die Elektrode besteht aus einem Metallkern mit einer Ummantelung. An einem Ende ist die

Elektrode nicht von der Ummantelung umhüllt.

• Den Griff des Elektrodenhalters gegen den Federdruck zusammenkneifen.

• Eine Elektrode mit dem nicht ummantelten Ende (± 2 cm) in den Elektrodenhalter

einsetzen. Achten Sie darauf, dass der Kontakt zwischen dem nicht ummantelten Teil und

dem Metallteil des Elektrodenhalters richtig hergestellt wird (Elektrode nicht zu weit in den

Elektrodenhalter stecken).

• Den Hebel des Griffs entspannen. Die Elektrode sitzt jetzt fest.

Achtung! Um Überhitzung und/oder Verformung des Elektrodenhalters zu

vermeiden, darf die Elektrode nicht weiter als auf eine Länge von ± 5 cm in

abbrennen. Außerdem wird das Entfernen der abgebrannten Elektrode dadurch

erschwert.

Entfernen der abgebrannten Elektrode

Den Griff des Elektrodenhalters gegen den Federdruck zusammenkneifen, sodass die

abgebrannte Elektrode aus dem Halter fallen kann.

Achtung! Die Elektrode nicht mit der Hand aus dem Halter nehmen, sie ist sehr

heiß!

Achtung! Achten Sie darauf, wohin der Elektrodenabfall fällt, damit keine

Brandgefahr und Verletzungen verursacht werden können.

4. BEDIENUNG

Vor der Inbetriebnahme:

a. Allgemeine Informationen über Elektroschweißen

b. Die Elektrode

c. Schutzkleidung

d. Gesichtsschutz

Ремонт и обслуживание должен производить только квалифицированный

специалист или обслуживающая фирма.

Очистка

• Проверяйте вентиляционные отверстия на наличие пыли и грязи. Используйте

мягкую ткань увлажненную мыльной водой, чтобы удалить въевшуюся грязь. Не

используйте никаких растворителей, как например бензин, спирт или аммиак, и т.п.

• Проверяйте остается ли держатель электрода и зажим заземления без ржавчины,

для поддержания хорошей электрической проводимости.

• Регулярно проверяйте, жестко ли прикреплены кабели для сварки и заземления

к своим контактам.

Смазка

Машина не нуждаетс я в дополнительной смазке.

Hеисправноти

В случае неисправности, напр., после износа какой-либо части, обратитесь по адресу

пункта обслуживания, указанному в гарантийном талоне. Покомпонентное

представление изображения частей, которые можете заказать, вы найдете на последней

странице руководства.

Защита окружащей среды

Во избежание транспортных повреждений изделие поставляется в прочной упаковке.

Значительная часть материалов упаковки подлежит утилизации, поэтому просим

передать упаковку в соответствующую специализированную организацию.

Неисправность

• Электрод продолжает "прилипать" к

обрабатываемому материалу

• Электрод стал оранжево-красным

• Электрод сильно брызгает и создает

много шума во время сварки

• Машина сильно нагрелась; светится

лампа индикатора

Причина/решение

• Используйте правильный тип

электрода (универсальный)

• Сила тока слишком

маленькая/поверните колесо 3 по

часовой стрелке

• Слишком высокая сила тока для этого

типа электрода/поверните колесо 3

против часовой стрелки

• Сила тока слишком

высокая/поверните колесо 3 против

часовой стрелки

• Закупорены отверстия для

вентилляции/почистите их сухой

тканью; подождите несколько минут

пока лампа снова не выключится

Ferm

100

GB

D

NL

F

E

P

I

RUS

FIN

N

DK

Page 22

Ferm 99

GB

D

NL

F

E

P

I

RUS

FIN

N

DK

Лампа индикатора температуры

Pис. 1

Когда температура сварочного аппарата становится слишком высокой, вмонтированный

термостат отключится (включится лампа индикатора). Вмонтированный вентилятор

охлаждает машину. После охлаждения лампа опять выключится.

Предоставить машине достаточно времени для того, чтобы остыть; при интенсивной

сварке возрастает возможность, что через несколько минут температурный

предохранитель опять сработает.

5. СЕРВИС И ОБСЛУЖИВАНИЕ

При выполнении работ по техническому обслуживанию двигател я

убедитесь, что машина не находитс я под напр я жением.

Машины фирмы созданы дл я работы в течении продолжительного промежутка времени

при минимальном техническом обслуживании. Продолжительная удовлетворительна я

работа зависит от соответствующего ухода за машиной и регул я рной очистки.

Неисправности

На случай, если станок перестанет правильно работать, далее приводится несколько

причин и соответствующих решений:

Неисправность

• Не работает сварочный аппарат

Причина/решение

• Зажим заземления плохо

контактирует с обрабатываемым

материалом

• Электрод плохо установлен в

держателе

• Выключен температурный

предохранитель

• Дефект сплава (в измерительном

счетчике)

• Кабель испорчен

• Испорчен переключатель/свяжитесь

со своим поставщиком.

e. Arbeitsumgebung

a. Allgemeine Informationen über Elektroschweißen

Die Temperatur des Lichtbogens beträgt ca. 7000 Grad Celsius, wodurch die Spitze der

Elektrode und das Werkstück zum Schmelzen gebracht werden. Solange der Lichtbogen

instand gehalten wird, schmilzt die Elek trode ab und erzeugt so das erforderliche Schweiß gut

zur Verbindung der betreffenden Teile. Der Abstand zwischen Elektrode und Werkstück muss –

abhängig von Durchmesser und Art der Elektrode – so kurz wie möglich sein (ca. 1,5–4 mm).

Der für das Schweißen erforderliche Strom wird durch ein Schweißgerät geliefert. Wie hoch die

benötigte Leistung des Schweiß geräts ist, hängt von der auszuführenden Arbeit ab.

Sorgen Sie für trockene Elektroden, da feuchte Elektroden Probleme verursachen. Wenn die

Elektrode beim Schweißen am Werkstück klebt, ist die Stromstärke zu niedrig eingestellt.

b. Die Elektrode

• Die Elektrode besteht aus einem Eisenkern mit einer Ummantelung. Der Hauptzweck der

Ummantelung ist, das Schmelzbad und die übergehenden Tropfen vor dem in der

umgebenden Luft enthaltenen Sauerstoff und Stickstoff zu schützen. Während des

Schweißvorgangs schmilzt die Elektrode ab. Die Ummantelung verdampft teilweise,

wodurch ein schützender Gasmantel entsteht. Ein Teil der Ummantelung schwimmt auf

dem Schmelzbad (das Material ist leichter als Stahl) und schützt so auch die abkühlende

Schweißnaht. Nach dem Abkühlen bleibt das Ummantelungsmaterial als feste, aber

einfach entfernbare Schlacke auf der Schweißraupe zurück.

• Gehen Sie vorsichtig mit den Elektroden um, damit die Ummantelung nicht beschädigt

wird. Die Elektroden müssen immer ganz trocken sein und sind daher

feuchtigkeitsgeschützt zu lagern.

• Zur Herstellung einer guten, stabilen Schweißverbindung ist die Verwendung der richtigen

Elektrode besonders wichtig. In vielen Fällen ist für die erforderlichen Arbeiten eine

Universalelektrode ausreichend.Auf der Verpackung der Elektroden ist angegeben, in

welchen Positionen damit geschweißt werden kann (Überkopf-, Fall-, Wannenposition

usw.). Für das Schweißen von Edelstahlsorten und Gusseisen sind spezielle Elektroden im

Handel erhältlich. Ziehen Sie zum Erwerb der passenden Elektrode Ihren Händler zu Rate.

c. Schutzkleidung

Tragen Sie gut abschirmende Kleidung, um die Gefahr von Hautverbrennungen durch frei

werdende ultraviolette Strahlen und Metallspritzern zu minimieren.

Tragen Sie vorzugsweise einen Arbeitsoverall aus Baumwolle, Schweißhandschuhe und

Sicherheitsschuhe. Stellen Sie sicher, dass keine Schweißspritzer in die Handschuhe oder

Schuhe gelangen können.Eine Schweißerschürze (z. B. aus Leder) schützt vor Einbrennen

von Funken in den Overall.

d. Gesichtsschutz

Abb. 2

Verwenden Sie ein gutes Schweißschild mit (dunklem) Schweißglas und einem Schutzglas.

Überprüfen Sie beide Gläser auf vorschriftsgemäße Montage (fester Sitz und für Sonnenlicht

undurchlässig).

Das Schweißschild schütz den Schweißer vor Strahlen, Hitze und Schweißspritzern, die

während des Schweißvorgangs frei werden. Außerdem wird durch das Schild weniger

Schweißrauch eingeatmet.

Ferm

22

GB

D

NL

F

E

P

I

S

FIN

N

DK

Page 23

Ferm 23

GB

D

NL

F

E

P

I

S

FIN

N

DK